The Synthesis and Application of Novel, Star-Shaped Surfactants for the Destabilization of Water in Arabian Heavy Crude Oil Emulsions

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Characterization

2.2. The Synthesis of Surfactants

- (a)

- The Synthesis of TNDT:

- (b)

- The Synthesis of ETNDT:

2.3. Preparation of W/O Emulsion

2.4. Emulsion-Separation Test

2.5. Photographic Study of the Demulsification Process

2.6. Relative Solubility Number (RSN)

3. Results

3.1. Characterization of ILs

3.2. The Solubility and Surface Activity of TNDT and ETNDT

3.3. The Effects of TNDT and ETND on the IFT of the W/O Interface

3.4. The Interactions of TNDT and ETND with Asphaltene

3.5. The Dehydration of W/O Emulsion Control Samples

3.6. The Dehydration of W/O Emulsions Using TNDT and ETND

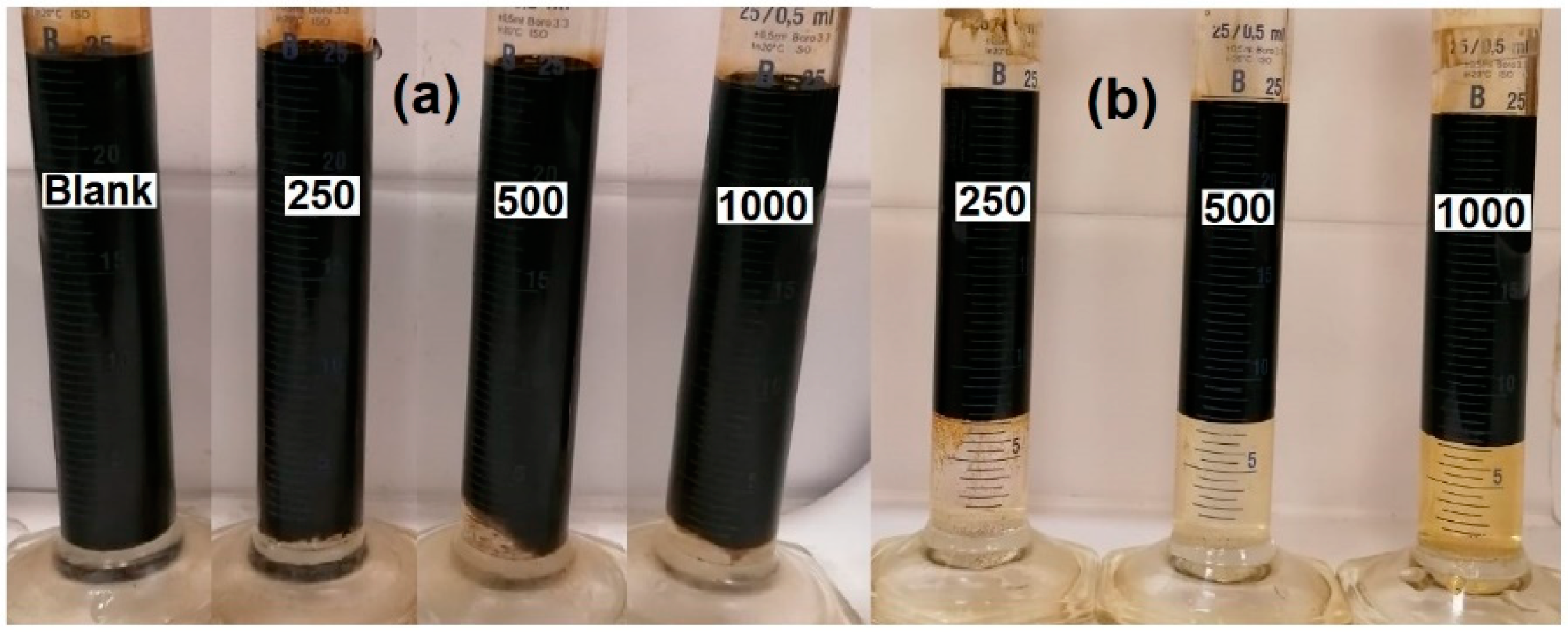

- (a)

- Relative Solubility Number (RSN)

- (b)

- Demulsifier dose effect

3.7. The Effect of Contact Time

- (c)

- The effect of demulsifier on the size of water droplets

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shuler, P.; Tang, Y.; Tang, H. Heavy oil production enhancement by viscosity reduction. In Proceedings of the SPE Western Regional Meeting, Anaheim, CA, USA, 27–29 May 2010. [Google Scholar]

- Ezzat, A.O.; Al-Lohedan, H.A. Dehydration of heavy crude oil emulsions using novel imidazolium-based poly ionic liquids. J. Mol. Liq. 2021, 326, 115284. [Google Scholar] [CrossRef]

- Ezzat, A.O.; Tawfeek, A.M.; Al-Lohedan, H.A. Synthesis and application of novel gemini pyridinium ionic liquids as demulsifiers for arabian heavy crude oil emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2022, 634, 127961. [Google Scholar] [CrossRef]

- Cendejas, G.; Arreguín, F.; Castro, L.V.; Flores, E.A.; Vazquez, F. Demulsifying super-heavy crude oil with bifunctionalized block copolymers. Fuel 2013, 103, 356–363. [Google Scholar] [CrossRef]

- Wong, S.; Lim, J.; Dol, S. Crude oil emulsion: A review on formation, classification and stability of water-in-oil emulsions. J. Pet. Sci. Eng. 2015, 135, 498–504. [Google Scholar] [CrossRef]

- Tian, Y.; Zhou, J.; He, C.; He, L.; Li, X.; Sui, H. The formation, stabilization and separation of oil–water emulsions: A review. Processes 2022, 10, 738. [Google Scholar] [CrossRef]

- Raya, S.A.; Mohd Saaid, I.; Abbas Ahmed, A.; Abubakar Umar, A. A critical review of development and demulsification mechanisms of crude oil emulsion in the petroleum industry. J. Pet. Explor. Prod. Technol. 2020, 10, 1711–1728. [Google Scholar] [CrossRef]

- Abdulredha, M.M.; Aslina, H.S.; Luqman, C.A. Overview on petroleum emulsions, formation, influence and demulsification treatment techniques. Arab. J. Chem. 2020, 13, 3403–3428. [Google Scholar] [CrossRef]

- Nadarajah, N.; Singh, A.; Ward, O.P. De-emulsification of petroleum oil emulsion by a mixed bacterial culture. Process Biochem. 2002, 37, 1135–1141. [Google Scholar] [CrossRef]

- Ali, M.; Alqam, M. The role of asphaltenes, resins and other solids in the stabilization of water in oil emulsions and its effects on oil production in Saudi oil fields. Fuel 2000, 79, 1309–1316. [Google Scholar] [CrossRef]

- Peng, Y.; Yu, B.; Zhang, X.; Gong, H.; Liu, Y. Numerical simulation on the effect of combining centrifugation, electric field and temperature on two-phase separation. Chem. Eng. Process.-Process Intensif. 2020, 148, 107803. [Google Scholar] [CrossRef]

- Yi, M.; Huang, J.; Wang, L. Research on crude oil demulsification using the combined method of ultrasound and chemical demulsifier. J. Chem. 2017, 2017, 9147926. [Google Scholar] [CrossRef]

- Alao, K.T.; Alara, O.R.; Abdurahman, N.H. Trending approaches on demulsification of crude oil in the petroleum industry. Appl. Petrochem. Res. 2021, 11, 281–293. [Google Scholar] [CrossRef]

- Tehrani-Bagha, A.R.; Holmberg, K. Cationic ester-containing gemini surfactants: Physical–chemical properties. Langmuir 2010, 26, 9276–9282. [Google Scholar] [CrossRef] [PubMed]

- Menger, F.M.; Littau, C. Gemini-surfactants: Synthesis and properties. J. Am. Chem. Soc. 1991, 113, 1451–1452. [Google Scholar] [CrossRef]

- Danino, D.; Talmon, Y.; Levy, H.; Beinert, G.; Zana, R. Branched threadlike micelles in an aqueous solution of a trimeric surfactant. Science 1995, 269, 1420–1421. [Google Scholar] [CrossRef]

- Liu, X.-G.; Xing, X.-J.; Gao, Z.-N. Synthesis and physicochemical properties of star-like cationic trimeric surfactants. Colloids Surf. A Physicochem. Eng. Asp. 2014, 457, 374–381. [Google Scholar] [CrossRef]

- Yoshimura, T.; Kusano, T.; Iwase, H.; Shibayama, M.; Ogawa, T.; Kurata, H. Star-shaped trimeric quaternary ammonium bromide surfactants: Adsorption and aggregation properties. Langmuir 2012, 28, 9322–9331. [Google Scholar] [CrossRef]

- Abdul-Raouf, M.E.-S.; Abdul-Raheim, A.-R.M.; Maysour, N.E.-S.; Mohamed, H. Synthesis, surface-active properties, and emulsification efficiency of trimeric-type nonionic surfactants derived from tris (2-aminoethyl) amine. J. Surfactants Deterg. 2011, 14, 185–193. [Google Scholar] [CrossRef]

- Bi, Y.; Li, W.; Liu, C.; Tan, Z.; Wang, Z.; Liu, X.; Wang, G.; Jia, X. Star-shaped quaternary ammonium compounds with terminal amino groups for rapidly breaking oil-in-water emulsions. Fuel 2021, 304, 121366. [Google Scholar] [CrossRef]

- El-Sharaky, E.S.A.; El-Tabey, A.E.; Mishrif, M.R. Novel star polymeric nonionic surfactants as crude oil emulsion breakers. J. Surfactants Deterg. 2019, 22, 779–793. [Google Scholar] [CrossRef]

- Ezzat, A.O.; Atta, A.M.; Al-Lohedan, H.A. One-step synthesis of amphiphilic nonylphenol polyethyleneimine for demulsification of water in heavy crude oil emulsions. ACS Omega 2020, 5, 9212–9223. [Google Scholar] [CrossRef] [PubMed]

- Ezzat, A.O.; Al-Lohedan, H.A.; Tawfeek, A.M.; Faqihi, N.A. One-Step Synthesis of New Amphiphilic Nonionic Surfactants Based on Alkylamine and Poly (ethylene glycol) Dimethacrylate for Demulsification of Arabian Heavy Crude Oil Emulsions. ACS Omega 2023, 8, 6030–6039. [Google Scholar] [CrossRef] [PubMed]

- Ezzat, A.O.; Atta, A.M.; Al-Lohedan, H.A.; Aldalbahi, A. New amphiphilic pyridinium ionic liquids for demulsification of water Arabic heavy crude oil emulsions. J. Mol. Liq. 2020, 312, 113407. [Google Scholar] [CrossRef]

- Ezzat, A.O.; Atta, A.M.; Al-Lohedan, H.A. Demulsification of stable seawater/Arabian heavy crude oil emulsions using star-like tricationic pyridinium ionic liquids. Fuel 2021, 304, 121436. [Google Scholar] [CrossRef]

- Schramm, L.L.; Stasiuk, E.N.; Marangoni, D.G. 2 Surfactants and their applications. Annu. Rep. Sect. “C” (Phys. Chem.) 2003, 99, 3–48. [Google Scholar] [CrossRef]

- Paria, S.; Khilar, K.C. A review on experimental studies of surfactant adsorption at the hydrophilic solid–water interface. Adv. Colloid Interface Sci. 2004, 110, 75–95. [Google Scholar] [CrossRef]

- Molina-Bolívar, J.; Aguiar, J.; Peula-García, J.; Ruiz, C.C. Surface activity, micelle formation, and growth of n-octyl-β-D-thioglucopyranoside in aqueous solutions at different temperatures. J. Phys. Chem. B 2004, 108, 12813–12820. [Google Scholar] [CrossRef]

- Qiao, W.; Peng, H.; Zhu, Y.; Cai, H. Synthesis and surface activity properties of symmetric double chains alkylbetaine surfactants derived from s-triazine. Colloids Surf. Physicochem. Eng. Asp. 2012, 405, 45–50. [Google Scholar] [CrossRef]

- Blesic, M.; Marques, M.H.; Plechkova, N.V.; Seddon, K.R.; Rebelo, L.P.N.; Lopes, A. Self-aggregation of ionic liquids: Micelle formation in aqueous solution. Green Chem. 2007, 9, 481–490. [Google Scholar] [CrossRef]

- Ueno, M.; Takasawa, Y.; Miyashige, H.; Tabata, Y.; Meguro, K. Effects of alkyl chain length on surface and micellar properties of octaethyleneglycol-n alkyl ethers. Colloid Polym. Sci. 1981, 259, 761–766. [Google Scholar] [CrossRef]

- Wu, J.; Xu, Y.; Dabros, T.; Hamza, H. Development of a method for measurement of relative solubility of nonionic surfactants. Colloids Surf. A Physicochem. Eng. Asp. 2004, 232, 229–237. [Google Scholar] [CrossRef]

- Sahiner, N.; Atta, A.M.; Yasar, A.O.; Al-Lohedan, H.A.; Ezzat, A.O. Surface activity of amphiphilic cationic pH-responsive poly (4-vinylpyridine) microgel at air/water interface. Colloids Surf. A Physicochem. Eng. Asp. 2015, 482, 647–655. [Google Scholar] [CrossRef]

- Liu, W.; Liu, W.; Wang, B.; Duan, H.; Peng, X.; Chen, X.; Zhao, Q. Novel hydroxy polyamine surfactant N-(2-hydroxyethyl)-N-dodecyl-ethanediamine: Its synthesis and flotation performance study to quartz. Miner. Eng. 2019, 142, 105894. [Google Scholar] [CrossRef]

- Wang, Z.-S.; Zhou, Z.-H.; Han, L.; Chen, X.; He, H.-J.; Zhang, Q.; Xu, Z.-C.; Gong, Q.-T.; Zhang, L.; Ma, G.-Y. The mechanism for lowering interfacial tension by extended surfactant containing ethylene oxide and propylene oxide groups. J. Mol. Liq. 2022, 359, 119364. [Google Scholar] [CrossRef]

- Huang, B.; Li, X.; Zhang, W.; Fu, C.; Wang, Y.; Fu, S. Study on Demulsification-Flocculation Mechanism of Oil-Water Emulsion in Produced Water from Alkali/Surfactant/Polymer Flooding. Polymers 2019, 11, 395. [Google Scholar] [CrossRef] [PubMed]

- Al-Sabagh, A.; Noor El-Din, M.; Abo-El Fotouh, S.; Nasser, N. Investigation of the demulsification efficiency of some ethoxylated polyalkylphenol formaldehydes based on locally obtained materials to resolve water-in-oil emulsions. J. Dispers. Sci. Technol. 2009, 30, 267–276. [Google Scholar] [CrossRef]

- Ahmadi, M.; Chen, Z. Molecular interactions between asphaltene and surfactants in a hydrocarbon solvent: Application to asphaltene dispersion. Symmetry 2020, 12, 1767. [Google Scholar] [CrossRef]

- Manek, M. Asphaltene dispersants as demulsification aids. In Proceedings of the SPE International Symposium on Oilfield Chemistry, San Antonio, TX, USA, 14–17 February 1995. [Google Scholar]

- Kovalenko, E.Y.; Sagachenko, T.A.; Cherednichenko, K.A.; Gerasimova, N.N.; Cheshkova, T.V.; Min, R.S. Structural Organization of Asphaltenes and Resins and Composition of Low Polar Components of Heavy Oils. Energy Fuels 2023, 37, 8976–8987. [Google Scholar] [CrossRef]

- Parra-Barraza, H.; Hernández-Montiel, D.; Lizardi, J.; Hernández, J.; Urbina, R.H.; Valdez, M.A. The zeta potential and surface properties of asphaltenes obtained with different crude oil/n-heptane proportions☆. Fuel 2003, 82, 869–874. [Google Scholar] [CrossRef]

- Vega, S.S.; Urbina, R.H.; Covarrubias, M.V.; Galeana, C.L. The zeta potential of solid asphaltene in aqueous solutions and in 50: 50 water+ ethylene glycol (v/v) mixtures containing ionic surfactants. J. Pet. Sci. Eng. 2009, 69, 174–180. [Google Scholar] [CrossRef]

- Hu, C.; Garcia, N.C.; Xu, R.; Cao, T.; Yen, A.; Garner, S.A.; Macias, J.M.; Joshi, N.; Hartman, R.L. Interfacial properties of asphaltenes at the heptol–brine interface. Energy Fuels 2016, 30, 80–87. [Google Scholar] [CrossRef]

- Goldszal, A.; Bourrel, M. Demulsification of crude oil emulsions: Correlation to microemulsion phase behavior. Ind. Eng. Chem. Res. 2000, 39, 2746–2751. [Google Scholar] [CrossRef]

- Bin Othman, A.A. Simulation and Design Study of the Topside of a Floating Production, Storage and Offloading Vessel (FPSO) (Crude Oil Stabilization Process). Bachelor’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2019. [Google Scholar]

- Sousa, A.M.; Matos, H.A.; Pereira, M.J. Properties of Crude Oil-in-Water and Water-in-Crude Oil Emulsions: A Critical Review. Ind. Eng. Chem. Res. 2021, 61, 1–20. [Google Scholar] [CrossRef]

- Atta, A.M.; Al-Lohedan, H.A.; Abdullah, M.M. Dipoles poly (ionic liquids) based on 2-acrylamido-2-methylpropane sulfonic acid-co-hydroxyethyl methacrylate for demulsification of crude oil water emulsions. J. Mol. Liq. 2016, 222, 680–690. [Google Scholar] [CrossRef]

- Poindexter, M.K.; Lindemuth, P.M. Applied statistics: Crude oil emulsions and demulsifiers. J. Dispers. Sci. Technol. 2004, 25, 311–320. [Google Scholar] [CrossRef]

- Al-Sabagh, A.M.; Kandile, N.G.; El-Ghazawy, R.A.; Noor El-Din, M. Synthesis and evaluation of new demulsifiers incorporating linear alkyl benzene moiety for treating water-in-oil emulsion. J. Dispers. Sci. Technol. 2013, 34, 996–1007. [Google Scholar] [CrossRef]

- Al-Sabagh, A.M.; Kandile, N.G.; Noor El-Din, M.R. Functions of demulsifiers in the petroleum industry. Sep. Sci. Technol. 2011, 46, 1144–1163. [Google Scholar] [CrossRef]

- Rondón, M.; Bouriat, P.; Lachaise, J.; Salager, J.-L. Breaking of water-in-crude oil emulsions. 1. Physicochemical phenomenology of demulsifier action. Energy Fuels 2006, 20, 1600–1604. [Google Scholar] [CrossRef]

- Rondón, M.; Pereira, J.C.; Bouriat, P.; Graciaa, A.; Lachaise, J.; Salager, J.-L. Breaking of water-in-crude-oil emulsions. 2. Influence of asphaltene concentration and diluent nature on demulsifier action. Energy Fuels 2007, 22, 702–707. [Google Scholar] [CrossRef]

| Test | Results |

|---|---|

| API gravity | 20.8 |

| Specific gravity 60/60 | 0.929 |

| Wax content (wt%) | 2.3 |

| Asphaltene content (wt%) | 8.3 |

| Heteroatoms (wt%) | 6.5 |

| Aromatic carbon (mol %) | 49.0 |

| Aromatic hydrogen (mol %) | 7.81 |

| Saturates (wt%) | 40.5 |

| Aromatics (wt%) | 30.8 |

| Resins (wt%) | 22.3 |

| Compound | cmc (mM) | (−∂γ/∂ ln c)T | γcmc (mN/m) | Δγ mN m−1 | Γmax × 10−6 (mol/m2) | Amin (nm2/Molecule) | RSN | Zeta Potential (mv) |

|---|---|---|---|---|---|---|---|---|

| ETNDT | 0.234 | 8.36 | 34 ± 0.5 | 38 ± 0.5 | 1.3 | 1.22 | 16.5 | 50 ± 0.9 |

| TNDT | 0.143 | 8.85 | 32 ± 0.5 | 40 ± 0.4 | 2.62 | 0.63 | 14 | 41 ± 0.1 |

| Demulsifier | Concentration (mg L−1) | IFT (mN/m) | Ω (mN m−1) |

|---|---|---|---|

| TNDT | 0 | 33.5 | 0 |

| 250 | 21 | 12.5 | |

| 500 | 12.5 | 21 | |

| 1000 | 11 | 22.5 | |

| ETNDT | 0 | 33.5 | 0 |

| 250 | 14 | 19.5 | |

| 500 | 6.5 | 27 | |

| 1000 | 5 | 28.5 |

| Compound | Conc. (ppm) | Zeta Potential (mv) | ||

|---|---|---|---|---|

| Surfactant | Asphaltene | Surfactant/Asph | ||

| TNDT | 250 500 1000 | 41 ± 0.1 | 24 ± 0.2 26 ± 0.1 30 ± 0.3 | |

| ETNDT | 250 500 1000 | 50 ± 0.9 | −40 ± 0.9 | 35 ± 0.5 35 ± 0.6 39 ± 0.4 |

| W/O Emulsion | |||||||

|---|---|---|---|---|---|---|---|

| 10/90 | 30/70 | 50/50 | |||||

| Compound | Dosage (ppm) | D% | t (min) | D% | t (min) | D% | t (min) |

| TNDT | 250 | 100 | 60 | 14 | 80 | 20 | 70 |

| 500 | 100 | 45 | 25 | 60 | 26 | 70 | |

| 1000 | 100 | 45 | 25 | 55 | 60 | 60 | |

| ETNDT | 250 | 100 | 40 | 94 | 50 | 86 | 30 |

| 500 | 100 | 30 | 100 | 45 | 100 | 30 | |

| 1000 | 100 | 30 | 98 | 45 | 100 | 25 | |

| ARBREAK 8846 | 250 | 30 | 420 | 100 | 375 | 100 | 310 |

| 500 | 42 | 360 | 100 | 330 | 100 | 255 | |

| 1000 | 65 | 360 | 100 | 280 | 100 | 180 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ezzat, A.O.; Al-Lohedan, H.A.; Albarqan, M.Y.; Toraba, M.A.; Faqihi, N.A. The Synthesis and Application of Novel, Star-Shaped Surfactants for the Destabilization of Water in Arabian Heavy Crude Oil Emulsions. Processes 2023, 11, 3162. https://doi.org/10.3390/pr11113162

Ezzat AO, Al-Lohedan HA, Albarqan MY, Toraba MA, Faqihi NA. The Synthesis and Application of Novel, Star-Shaped Surfactants for the Destabilization of Water in Arabian Heavy Crude Oil Emulsions. Processes. 2023; 11(11):3162. https://doi.org/10.3390/pr11113162

Chicago/Turabian StyleEzzat, Abdelrahman O., Hamad A. Al-Lohedan, Mohammed Yousef Albarqan, Meshary Abdullah Toraba, and Noorah A. Faqihi. 2023. "The Synthesis and Application of Novel, Star-Shaped Surfactants for the Destabilization of Water in Arabian Heavy Crude Oil Emulsions" Processes 11, no. 11: 3162. https://doi.org/10.3390/pr11113162

APA StyleEzzat, A. O., Al-Lohedan, H. A., Albarqan, M. Y., Toraba, M. A., & Faqihi, N. A. (2023). The Synthesis and Application of Novel, Star-Shaped Surfactants for the Destabilization of Water in Arabian Heavy Crude Oil Emulsions. Processes, 11(11), 3162. https://doi.org/10.3390/pr11113162