New Optimization Framework for Improvement Sustainability of Wastewater Treatment Plants

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overview of the Framework

2.2. Basic Definition and Information Collection

2.2.1. Alternative Technologies Identification

2.2.2. Sustainability Objectives Determination

2.2.3. Information Collection and Treatment

2.3. Model Formulation and Solver Optimization

2.3.1. Weights Assignment

Subjective Weights–Interval SWARA II

Objective Weights–Interval CRITIC

Combined Weights–Minimize Deviation

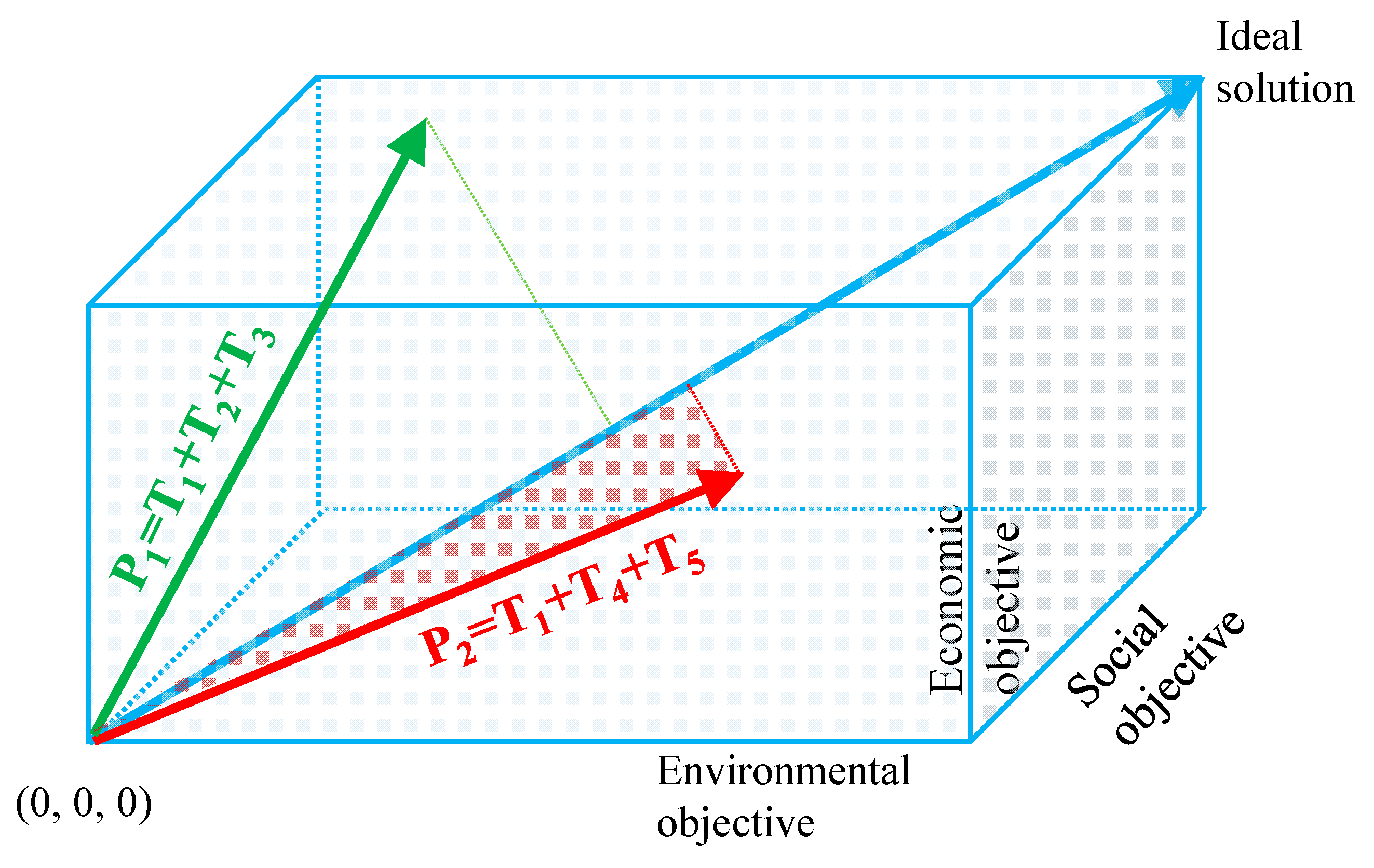

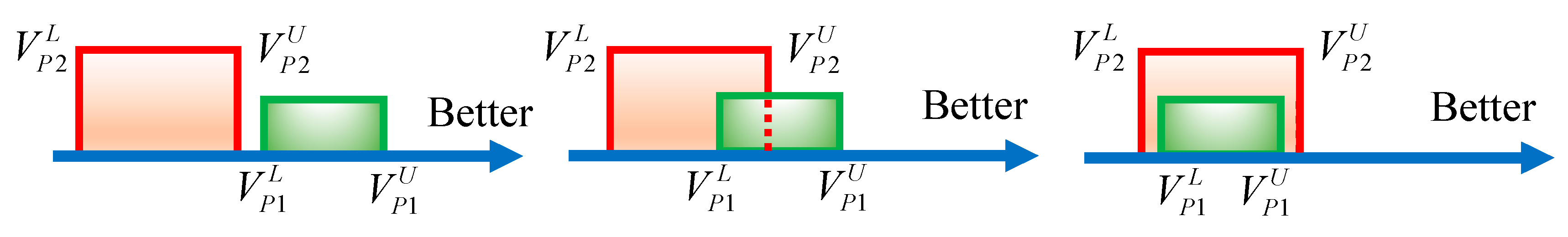

2.3.2. Multi-Objective Aggregation

2.3.3. Optimal Configuration Generation

3. Case Study and Results

3.1. Basic Definition and Information Collection in the Case Study

3.1.1. Ten Alternative Technologies

3.1.2. Three Sustainability Objectives

3.1.3. Information Collection and Treatment in the Case Study

3.2. Model Formulation and Solver Optimization in the Case Study

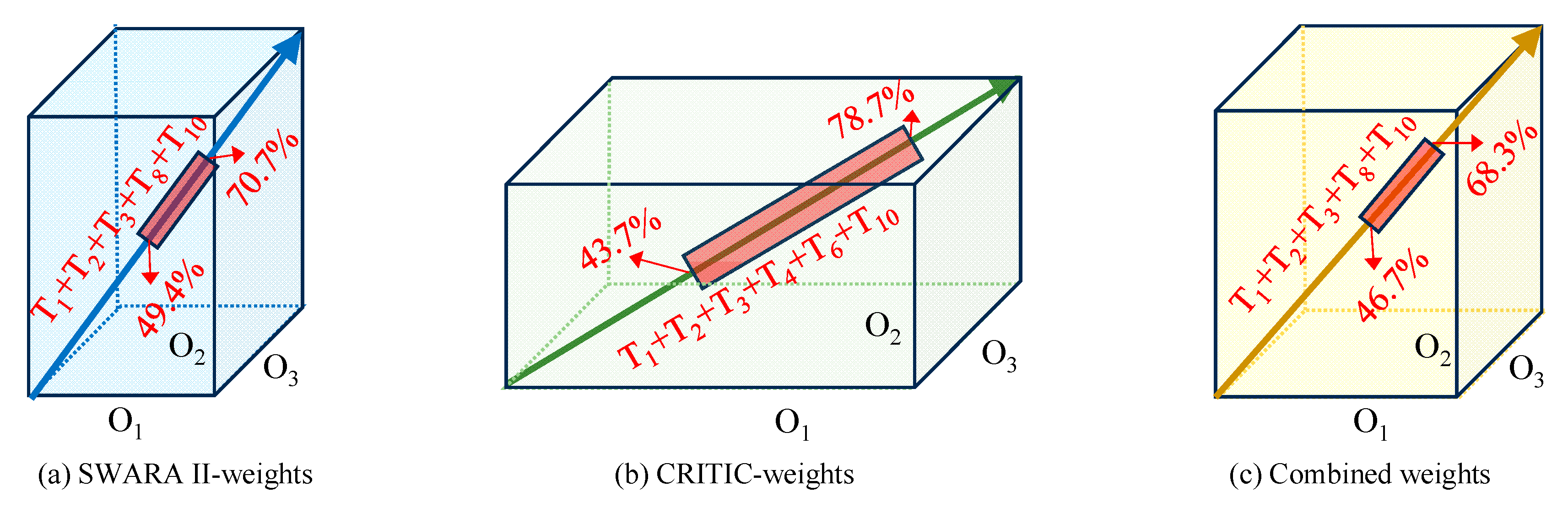

3.2.1. Weight Assignment in the Case Study

3.2.2. Multi-Objective Aggregation in the Case Study

3.2.3. Optimal Configuration Generation in the Case Study

4. Discussion

4.1. Effect of the Weighting Result

4.2. Weighted MOO Techniques Comparison

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kadam, R.; Khanthong, K.; Park, B.; Jun, H.; Park, J. Realizable wastewater treatment process for carbon neutrality and energy sustainability: A review. J. Environ. Manag. 2023, 328, 116927. [Google Scholar] [CrossRef] [PubMed]

- Kretschmer, F.; Hrdy, B.; Neugebauer, G.; Stoeglehner, G. Wastewater Treatment Plants as Local Thermal Power Stations-Modifying Internal Heat Supply for Covering External Heat Demand. Processes 2021, 9, 1981. [Google Scholar] [CrossRef]

- Kwon, S.; Zhang, C.L.; Oh, J.; Park, K. Sustainability assessment of retrofitting alternatives for large and old wastewater treatment plants in Seoul. Water Sci. Technol. 2023, 87, 969–986. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; He, Y.; Wang, X.; Chen, Z.Y.; Wei, X.; Lin, Y.Y.; Cao, C.J.; Huang, M.S.; Zheng, B.H. A comprehensive assessment of upgrading technologies of wastewater treatment plants in Taihu Lake Basin. Environ. Res. 2022, 212, 113398. [Google Scholar] [CrossRef]

- Shao, S.; Mu, H.L.; Keller, A.A.; Yang, Y.; Hou, H.C.; Yang, F.L.; Zhang, Y. Environmental tradeoffs in municipal wastewater treatment plant upgrade: A life cycle perspective. Environ. Sci. Pollut. Res. 2021, 28, 34913–34923. [Google Scholar] [CrossRef]

- Mayor, A.; Vinardell, S.; Ganesan, K.; Bacardí, C.; Cortina, J.L.; Valderrama, C. Life-cycle assessment and techno-economic evaluation of the value chain in nutrient recovery from wastewater treatment plants for agricultural application. Sci. Total Environ. 2023, 892, 164452. [Google Scholar] [CrossRef]

- Juznic-Zonta, Z.; Guisasola, A.; Baeza, J.A. Smart-Plant Decision Support System (SP-DSS): Defining a multi-criteria decision-making framework for the selection of WWTP configurations with resource recovery. J. Clean. Prod. 2022, 367, 132873. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Zhang, C.; Qiu, Y.; Li, B.; Pang, H.T.; Xue, Y.; Liu, Y.C.; Yuan, Z.G.; Huang, X. Wastewater treatment technology selection under various influent conditions and effluent standards based on life cycle assessment. Resour. Conserv. Recycl. 2019, 154, 104562. [Google Scholar] [CrossRef]

- Elawwad, A.; Matta, M.; Abo-Zaid, M.; Abdel-Halim, H. Plant-wide modeling and optimization of a large-scale WWTP using BioWin’s ASDM model. J. Water Process. Eng. 2019, 31, 100819. [Google Scholar] [CrossRef]

- Mohan, T.R.; Chanakya, H.N.; Kumar, M.S.M.; Rao, L. Achieving biological nutrient removal in an old sewage treatment plant through process modifications—A simulation and experimental study. J. Water Process. Eng. 2021, 45, 102461. [Google Scholar] [CrossRef]

- Baena-Moreno, F.M.; Malico, I.; Marques, I.P. Promoting Sustainability: Wastewater Treatment Plants as a Source of Biomethane in Regions Far from a High-Pressure Grid. A Real Portuguese Case Study. Sustainability 2021, 13, 8933. [Google Scholar] [CrossRef]

- Muñoz, I.; Portillo, F.; Rosiek, S.; Battles, F.J.; Martínez-Del-Río, J.; Acasuso, I.; Piergrossi, V.; De Sanctis, M.; Chimienti, S.; Di Iaconi, C. Prospective environmental and economic assessment of solar-assisted thermal energy recovery from wastewater through a sequencing batch biofilter granular reactor. J. Clean. Prod. 2019, 212, 1300–1309. [Google Scholar] [CrossRef]

- Hao, X.D.; Wang, X.Y.; Liu, R.B.; Li, S.; van Loosdrecht, M.C.M.; Jiang, H. Environmental impacts of resource recovery from wastewater treatment plants. Water Res. 2019, 160, 268–277. [Google Scholar] [CrossRef] [PubMed]

- Okan, B.; Erguder, T.H.; Aksoy, A. Plant-wide modeling of a metropolitan wastewater treatment plant to reduce energy consumption and carbon footprint. Environ. Sci. Pollut. Res. 2022, 30, 16068–16080. [Google Scholar] [CrossRef]

- Caligan, C.J.A.; Garcia, M.M.S.; Mitra, J.L.; San Juan, J.L.G. Multi-objective optimization for a wastewater treatment plant and sludge-to-energy network. J. Clean. Prod. 2022, 368, 133047. [Google Scholar] [CrossRef]

- Llácer-Iglesias, R.M.; López-Jiménez, P.A.; Pérez-Sánchez, M. Exploring options for energy recovery from wastewater: Evaluation of hydropower potential in a sustainability framework. Sustain. Cities Soc. 2023, 95, 104576. [Google Scholar] [CrossRef]

- Ullah, A.; Hussain, S.; Wasim, A.; Jahanzaib, M. Development of a decision support system for the selection of wastewater treatment technologies. Sci. Total Environ. 2020, 731, 139158. [Google Scholar] [CrossRef]

- Arroyo, P.; Molinos-Senante, M. Selecting appropriate wastewater treatment technologies using a choosing-by-advantages approach. Sci. Total Environ. 2018, 625, 819–827. [Google Scholar] [CrossRef]

- Attri, S.D.; Singh, S.; Dhar, A.; Powar, S. Multi-attribute sustainability assessment of wastewater treatment technologies using combined fuzzy multi-criteria decision-making techniques. J. Clean. Prod. 2022, 357, 131849. [Google Scholar] [CrossRef]

- Narayanamoorthy, S.; Brainy, J.V.; Sulaiman, R.; Ferrara, M.; Ahmadian, A.; Kang, D. An integrated decision making approach for selecting a sustainable waste water treatment technology. Chemosphere 2022, 301, 134568. [Google Scholar] [CrossRef]

- Priyanka; Kumar, S.; Kalia, S. MULTIMOORA-based MCDM model for sustainable ranking of wastewater treatment technologies under picture fuzzy environment. Expert. Syst. 2023, ahead of print. [Google Scholar] [CrossRef]

- Ordu, M.; Der, O. Polymeric Materials Selection for Flexible Pulsating Heat Pipe Manufacturing Using a Comparative Hybrid MCDM Approach. Polymers 2023, 15, 2933. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, M.R.N.; Singh, R.K.; Hasan, M.A. Decision support model to select crop pattern for sustainable agricultural practices using fuzzy MCDM. Environ. Dev. Sustain. 2018, 20, 641–659. [Google Scholar] [CrossRef]

- Fernández-Arévalo, T.; Lizarralde, I.; Fdz-Polanco, F.; Pérez-Elvira, S.I.; Garrido, J.M.; Puig, S.; Poch, M.; Grau, P.; Ayesa, E. Quantitative assessment of energy and resource recovery in wastewater treatment plants based on plant-wide simulations. Water Res. 2017, 118, 272–288. [Google Scholar] [CrossRef]

- Sucu, S.; van Schaik, M.O.; Esmeli, R.; Ouelhadj, D.; Holloway, T.; Williams, J.B.; Cruddas, P.; Martinson, D.B.; Chen, W.S.; Cappon, H.J. A conceptual framework for a multi-criteria decision support tool to select technologies for resource recovery from urban wastewater. J. Environ. Manag. 2021, 300, 113608. [Google Scholar] [CrossRef] [PubMed]

- Deepak, M.; Rustum, R. Review of Latest Advances in Nature-Inspired Algorithms for Optimization of Activated Sludge Processes. Processes 2022, 11, 77. [Google Scholar] [CrossRef]

- Xu, D.; Li, W.C.; Shen, W.F.; Dong, L.C. Decision-Making for Sustainability Enhancement of Chemical Systems under Uncertainties: Combining the Vector-Based Multiattribute Decision-Making Method with Weighted Multiobjective Optimization Technique. Ind. Eng. Chem. Res. 2019, 58, 12066–12079. [Google Scholar] [CrossRef]

- Wheeler, J.; Páez, M.A.; Guillén-Gosálbez, G.; Mele, F.D. Combining multi-attribute decision-making methods with multi-objective optimization in the design of biomass supply chains. Comput. Chem. Eng. 2018, 113, 11–31. [Google Scholar] [CrossRef]

- Leong, Y.T.; Lee, J.Y.; Tan, R.R.; Foo, J.J.; Chew, I.M.L. Multi-objective optimization for resource network synthesis in eco-industrial parks using an integrated analytic hierarchy process. J. Clean. Prod. 2017, 143, 1268–1283. [Google Scholar] [CrossRef]

- Manzardo, A.; Ren, J.Z.; Piantella, A.; Mazzi, A.; Fedele, A.; Scipioni, A. Integration of water footprint accounting and costs for optimal chemical pulp supply mix in paper industry. J. Clean. Prod. 2014, 72, 167–173. [Google Scholar] [CrossRef]

- Han, X.; Zhao, L.; Ye, Z.C. Multiobjective Economic-Environmental-Selectivity Optimization of the Dry Gas Based Ethylbenzene Production Process. Ind. Eng. Chem. Res. 2021, 60, 15679–15689. [Google Scholar] [CrossRef]

- Cossio, C.; Norrman, J.; McConville, J.; Mercado, A.; Rauch, S. Indicators for sustainability assessment of small-scale wastewater treatment plants in low and lower-middle income countries. Environ. Sustain. Ind. 2020, 6, 100028. [Google Scholar] [CrossRef]

- Gherghel, A.; Teodosiu, C.; Notarnicola, M.; De Gisi, S. Sustainable design of large wastewater treatment plants considering multi-criteria decision analysis and stakeholders’ involvement. J. Environ. Manag. 2020, 261, 110158. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.A.; Hou, H.X.; Fei, W.B.; Zhao, E.Y. Comparative Research to Surface Aeration and Blasting Aeration System Based on LCC Theory. Iop C Ser. Earth Env. 2017, 63, 012029. [Google Scholar] [CrossRef]

- Shahabadi, M.B.; Yerushalmi, L.; Haghighat, F. Estimation of greenhouse gas generation in wastewater treatment plants—Model development and application. Chemosphere 2010, 78, 1085–1092. [Google Scholar] [CrossRef]

- Kesireddy, A.; Carrillo, L.R.G.; Baca, J. Multi-Criteria Decision Making—Pareto Front Optimization Strategy for Solving Multi-Objective Problems. In Proceedings of the 2020 IEEE 16th International Conference on Control & Automation (ICCA), Singapore, 9–11 October 2020; pp. 53–58. [Google Scholar]

- Huang, Q.J. Selecting sustainable renewable energy-powered desalination: An MCDM framework under uncertain and incomplete information. Clean Technol. Environ. Policy 2022, 24, 1581–1598. [Google Scholar] [CrossRef]

- Wheeler, J.; Caballero, J.A.; Ruiz-Femenia, R.; Guillén-Gosálbez, G.; Mele, F.D. MINLP-based Analytic Hierarchy Process to simplify multi-objective problems: Application to the design of biofuels supply chains using on field surveys. Comput. Chem. Eng. 2017, 102, 64–80. [Google Scholar] [CrossRef]

- Keshavarz-Ghorabaee, M. Assessment of distribution center locations using a multi-expert subjective-objective decision-making approach. Sci. Rep. 2021, 11, 19461. [Google Scholar] [CrossRef]

- Yu, Y.; Wu, S.B.; Yu, J.X.; Xu, Y.; Song, L.; Xu, W.P. A hybrid multi-criteria decision-making framework for offshore wind turbine selection: A case study in China. Appl. Energ. 2022, 328, 120173. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Parhi, S.S.; Rangaiah, G.P.; Jana, A.K. Analysis of Weighting and Selection Methods for Pareto-Optimal Solutions of Multiobjective Optimization in Chemical Engineering Applications. Ind. Eng. Chem. Res. 2020, 59, 14850–14867. [Google Scholar] [CrossRef]

- Diakoulaki, D.; Mavrotas, G.; Papayannakis, L. Determining Objective Weights in Multiple Criteria Problems—The Critic Method. Comput. Oper. Res. 1995, 22, 763–770. [Google Scholar] [CrossRef]

- Xu, D.; Li, W.C.; Ren, X.S.; Shen, W.F.; Dong, L.C. Technology selection for sustainable hydrogen production: A multi-criteria assessment framework under uncertainties based on the combined weights and interval best-worst projection method. Int. J. Hydrog. Energy 2020, 45, 34396–34411. [Google Scholar] [CrossRef]

- Moradi-Aliabadi, M.; Huang, Y.L. Vector-Based Sustainability Analytics: A Methodological Study on System Transition toward Sustainability. Ind. Eng. Chem. Res. 2016, 55, 3239–3252. [Google Scholar] [CrossRef]

- Moradi-Aliabadi, M.; Huang, Y.L. Decision Support for Enhancement of Manufacturing Sustainability: A Hierarchical Control Approach. ACS Sustain. Chem. Eng. 2018, 6, 4809–4820. [Google Scholar] [CrossRef]

- Xu, Z.S.; Da, Q.L. The uncertain OWA operator. Int. J. Intell. Syst. 2002, 17, 569–575. [Google Scholar] [CrossRef]

- Tang, X.W.; Fu, J.L.; Ren, Y.Y. Application of precise aeration system on improving removal rate of TN in AAO + MBR process. Water Purif. Technol. 2020, 39, 133–137. (In Chinese) [Google Scholar]

- Hou, Y.L. Optimal Operation and Automatic Control of the Chemical Phosphorus Removal in Municipal WWTP. Master’s Thesis, Tsinghua University, Beijing, China, 2012. (In Chinese). [Google Scholar]

- Zhou, X. Online Monitoring and Control of Sludge Concentration in Sewage Treatment System. Master’s Thesis, North China Electric Power University, Beijing, China, 2012. (In Chinese). [Google Scholar]

- Li, H.; Dong, L.C.; Lv, L.P. Enhanced Biological Nitrogen Removal Performance of Low Carbon to Nitrogen Ratio Wastewater. China Water Wastewater 2022, 38, 80–85. (In Chinese) [Google Scholar]

- Wang, C.; Liu, Y.; Lv, W.Z.; Xia, S.Q.; Han, J.C.; Wang, Z.Y.; Yu, X.X.; Cai, L.H. Enhancement of nitrogen removal by supplementing fluidized-carriers into the aerobic tank in a full-scale A/O system. Sci. Total Environ. 2019, 660, 817–825. [Google Scholar] [CrossRef]

- Yang, P.; Zhou, J.Z.; Guan, Y.J.; Yang, X.M.; Liu, S.; Liu, Y.L.; Wu, D. Comparison of AAO and Bardenpho Processes Transformation Effect Based on MBBR. China Water Wastewater 2021, 37, 11–19. (In Chinese) [Google Scholar]

- Wang, W.; Lee, D.J. Valorization of anaerobic digestion digestate: A prospect review. Bioresour. Technol. 2021, 323, 124626. [Google Scholar] [CrossRef]

- Ali, I.; Abdelkader, L.; El Houssayne, B.; Mohamed, K.; El Khadir, L. Solar convective drying in thin layers and modeling of municipal waste at three temperatures. Appl. Therm. Eng. 2016, 108, 41–47. [Google Scholar] [CrossRef]

- Zhang, T.; Yan, Z.W.; Wang, L.Y.; Zheng, W.J.; Wu, Q.; Meng, Q.L. Theoretical analysis and experimental study on a low-temperature heat pump sludge drying system. Energy 2021, 214, 118985. [Google Scholar] [CrossRef]

- Llacer-Iglesias, R.M.; Lopez-Jimenez, P.A.; Perez-Sanchez, M. Hydropower Technology for Sustainable Energy Generation in Wastewater Systems: Learning from the Experience. Water 2021, 13, 3259. [Google Scholar] [CrossRef]

- Dong, H.J.; Zhang, L.; Geng, Y.; Li, P.; Yu, C.H. New insights from grey water footprint assessment: An industrial park level. J. Clean. Prod. 2021, 285, 124915. [Google Scholar] [CrossRef]

- Rodriguez-Garcia, G.; Molinos-Senante, M.; Hospido, A.; Hernández-Sancho, F.; Moreira, M.T.; Feijoo, G. Environmental and economic profile of six typologies of wastewater treatment plants. Water Res. 2011, 45, 5997–6010. [Google Scholar] [CrossRef]

- Pang, C.X.; Luo, X.; Rong, B.; Nie, X.B.A.; Jin, Z.Y.; Xia, X. Carbon Emission Accounting and the Carbon Neutralization Model for a Typical Wastewater Treatment Plant in China. Int. J. Environ. Res. Public Health 2023, 20, 140. [Google Scholar] [CrossRef]

| Linguistic Variables | Preference Values |

|---|---|

| Extreme low (EL) | 1 |

| Very low (VL) | 2 |

| Low (L) | 3 |

| Medium low (ML) | 4 |

| Medium (M) | 5 |

| Medium high (MH) | 6 |

| High (H) | 7 |

| Very high (VH) | 8 |

| Extreme high (EH) | 9 |

| Pollutant | Influent Concentration (mg/L) | Effluent Concentration (mg/L) | Removal Rate (%) |

|---|---|---|---|

| BOD5 | 220 | ≤10 | ≥95.45 |

| COD | 400 | ≤50 | ≥87.50 |

| SS | 280 | ≤10 | ≥96.43 |

| NH3-N | 34 | ≤8 | ≥76.47 |

| TN | 50 | ≤15 | ≥70 |

| TP | 5 | ≤1 | ≥80 |

| Technology | Brief Introduction |

|---|---|

| T1: Advanced aeration system (AAS) [47] | This is an effective wastewater aeration system with small air bubbles that improve biological degradation. The fine bubbles from APAS, having a larger surface area, enhance oxygen transfer. It allows accurate air flow control according to tank needs, ensuring optimal oxygen levels. This results in higher TN removal rates and lower energy usage. |

| T2: Precision dosing system (PDS) [48] | This refers to the precise delivery of treatment chemicals to the wastewater treatment process by controlling the design and operational parameters of the dosing system. By utilizing feed-forward control systems, PDS employs online analyzers in the inlet stream to provide real-time data to a dosing control system. This enables automatic adjustments of the dosing amount and timing to achieve optimal wastewater treatment results. |

| T3: Advanced automatic sludge control system (ASC) [49] | This utilizes advanced automation control systems to effectively monitor and regulate the sludge removal system in real-time. By incorporating parameters such as sludge flow, quality, and moisture content, the sludge removal equipment can be automatically adjusted, ensuring precise sludge discharge and treatment. Moreover, through sludge analysis and data management, the design and operation of the sludge removal system can be optimized, leading to enhanced sludge treatment efficiency and sustainability. |

| T4: External carbon source (ECS) [50] | ECS can enhance the treatment efficiency of the wastewater treatment process, especially in situations where the incoming wastewater has low organic matter concentrations or when nitrogen and phosphorus removal is necessary. This retrofitting technique involves careful control of the type and quantity of external carbon source added to prevent the overgrowth of microorganisms and the consequent production of excess sludge. |

| T5: Fluidized carriers supplementary (FCS) [51] | This system with fluidized carriers supplemented into the aerobic tank in the existing AAO system could improve nitrogen removal ability, primarily because of the higher relative abundance of nitrifying bacteria and denitrifying bacterial genera attached onto the biofilm formed on the carrier. |

| T6: Moving bed biofilm reactor (MBBR) [52] | Integrating an MBBR reactor into the existing wastewater treatment system can enhance treatment efficiency and improve water quality. MBBR offers several advantages, including high biomass concentrations, the ability to achieve high SRTs with relatively low HRTs, good resilience to shocks from organic loading, minimal sludge bulking issues, and low risks of carrier media clogging. |

| T7: Anaerobic digestion of sludge (AD) [53] | AD stabilizes sludge by converting volatile solids into biogas in the absence of air, requiring additional processing to recover and utilize the methane content of the biogas. AD offers advantages such as energy production, reduced sludge volume and disposal costs, and environmental benefits through reduced greenhouse gas emissions. It is a cost-effective and sustainable method for sludge management with resource utilization and minimal environmental impact. |

| T8: Solar convective drying (SCD) [54] | Sludge dewatering and drying are crucial processes in WWTPs for effective sludge management. While sludge treatment can be expensive, drying the sludge reduces its mass and volume, benefiting the environment, economy, and society. This innovative retrofit technology utilizes solar convective drying to replace conventional dewatering machines, resulting in significant energy savings and reduced volume of treated sludge. |

| T9: Heat pump drying (HPD) [55] | This is another energy-saving technology for drying sludge. This process involves a heat pump absorbing sensible and latent heat from the medium-temperature, high-humidity air leaving the drying chamber. As the air releases moisture, it is reheated and transferred to the sludge, causing internal moisture to migrate to the surface, evaporate into the drying medium, and effectively separate from the sludge, accomplishing the drying objective. |

| T10: Hydropower utilization (HPU) [56] | The case study presents an excellent opportunity for installing a mini hydropower system due to the significant 35 m drop in water discharge. Consequently, harnessing the energy generated by flowing water can power the investigated WWTP, reducing the dependence on external sources of electricity. |

| O1 | O2 | O3 | Budget Limit (BL, 106 CNY) | Construction Duration (CD, Day) | |

|---|---|---|---|---|---|

| T1 | [1.7%, 3.3%] | [2.2%, 4.3%] | [6.8%, 13.7%] | 1.2 | 20 |

| T2 | [6.7%, 13.3%] | [0.5%, 0.6%] | [3.6%, 3.6%] | 0.5 | 10 |

| T3 | [5.0%, 13.3%] | [2.0%, 3.4%] | [3.6%, 3.8%] | 1.0 | 15 |

| T4 | [10.0%, 20.0%] | [−6.1%, −5.6%] | [−1.8%, −1.8%] | 0.3 | 15 |

| T5 | [10.0%, 20.0%] | [−1.7%, −0.4%] | [−12.3%, −8.2%] | 4.4 | 30 |

| T6 | [13.3%, 16.7%] | [−0.4%, 0.2%] | [−4.1%, −2.1%] | 2.8 | 30 |

| T7 | [0.0%, 0.0%] | [13.2%, 14.3%] | [10.4%, 13.9%] | 5.2 | 20 |

| T8 | [0.0%, 0.0%] | [21.1%, 28.5%] | [0.0%, 0.0%] | 3.6 | 15 |

| T9 | [0.0%, 0.0%] | [15.1%, 15.1%] | [−9.7%, −9.7%] | 2.4 | 20 |

| T10 | [0.0%, 0.0%] | [2.6%, 2.6%] | [10.4%, 10.4%] | 2.0 | 10 |

| Objective | Order | Preference | Subjective Weight |

|---|---|---|---|

| O2 | 1 | [6, 7] | [0.458, 0.490] |

| O3 | 2 | [8, 9] | [0.323, 0.343] |

| O1 | 3 | - | [0.182, 0.205] |

| O1 | [0.241, 0.416] | [0.768, 1.347] | [0.311, 0.546] |

| O2 | [0.236, 0.277] | [0.623, 0.755] | [0.257, 0.307] |

| O3 | [0.283, 0.303] | [0.674, 0.747] | [0.274, 0.303] |

| Objective | Improvement Degree | Configuration | Cost | Construction Time |

|---|---|---|---|---|

| T1 + T2 + T3 + T4 + T5 | 7.4 | 90 | ||

| T1 + T7 + T8 | 10.0 | 55 | ||

| T1 + T2 + T3 + T7 + T10 | 9.9 | 75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Pang, F.; Xu, D.; Dong, L. New Optimization Framework for Improvement Sustainability of Wastewater Treatment Plants. Processes 2023, 11, 3156. https://doi.org/10.3390/pr11113156

Li H, Pang F, Xu D, Dong L. New Optimization Framework for Improvement Sustainability of Wastewater Treatment Plants. Processes. 2023; 11(11):3156. https://doi.org/10.3390/pr11113156

Chicago/Turabian StyleLi, Hang, Fei Pang, Di Xu, and Lichun Dong. 2023. "New Optimization Framework for Improvement Sustainability of Wastewater Treatment Plants" Processes 11, no. 11: 3156. https://doi.org/10.3390/pr11113156

APA StyleLi, H., Pang, F., Xu, D., & Dong, L. (2023). New Optimization Framework for Improvement Sustainability of Wastewater Treatment Plants. Processes, 11(11), 3156. https://doi.org/10.3390/pr11113156