Research on Diesel Engine Speed Control Based on Improved Salp Algorithm

Abstract

:1. Introduction

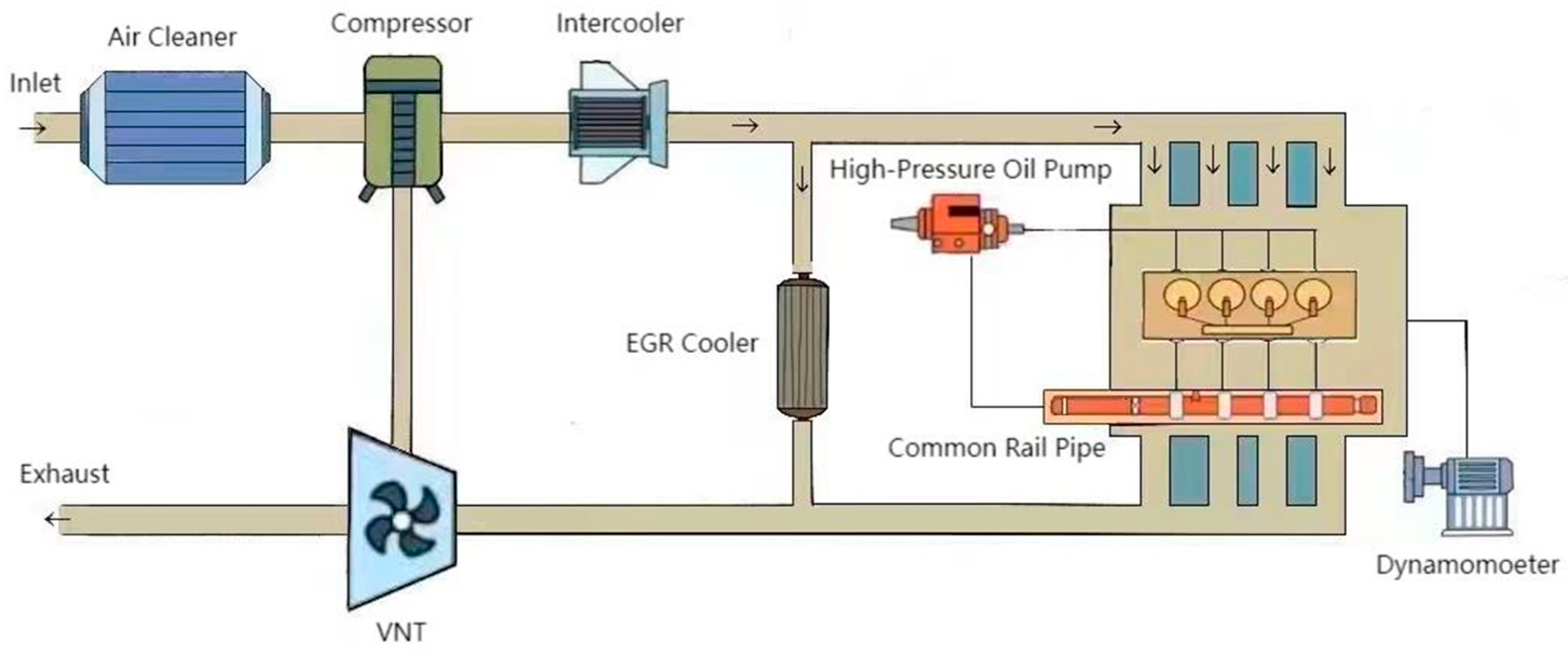

2. Diesel Engine System Model

2.1. Air Cleaner

2.1.1. Flow Exchange Model

2.1.2. Pressure Drop Model

- Laminar flow:

- Transition flow:

- Turbulent flow:

2.2. Turbocharger Model

2.3. Exhaust Gas Turbocharger Recirculation Model

2.4. High-Pressure Common Rail System Model

2.4.1. Common Rail Model

2.4.2. Fuel Injector Model

2.4.3. Pressure Pulsation Model

3. Control Algorithm Design

3.1. Leader Position

3.1.1. Salp Swarm Algorithm

3.1.2. Follower Position

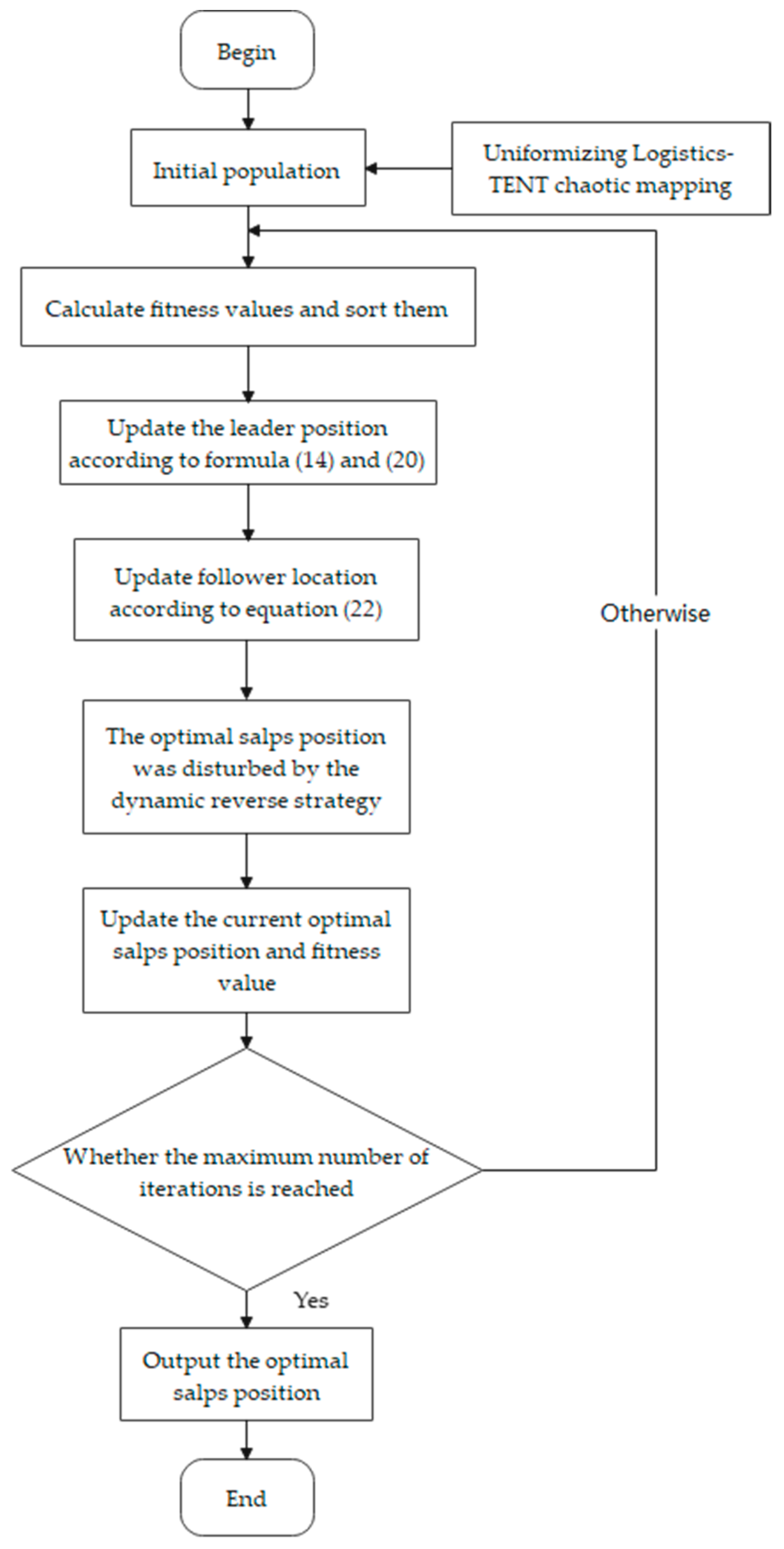

3.2. Improved Salp Swarm Algorithm

- Using logistic-tent chaotic mapping in place of random initialization of the salp swarm population, ensuring a more uniform distribution within the search space;

- Introducing adaptive parameters to balance the leader’s exploration and exploitation, enhancing the algorithm’s search scope in the early stages of iteration;

- Implementing an adaptive inertia weight factor for the followers’ positions to control the individual search scope and convergence speed while using an elite strategy to amplify the guiding effect of elite individuals;

- After updating the salps individual’s position, a dynamic reversal strategy is employed to perturb the salps with the updated optimal position, enhancing its search capability.

3.2.1. Logistic-Tent Chaotic Mapping

3.2.2. Adaptive Parameters

3.2.3. Adaptive Dynamic Inertia Weights and Elite Strategies

3.2.4. Dynamic Inversion Strategy

3.2.5. Algorithm Flowchart

4. Diesel Engine Speed Control Simulation Analysis

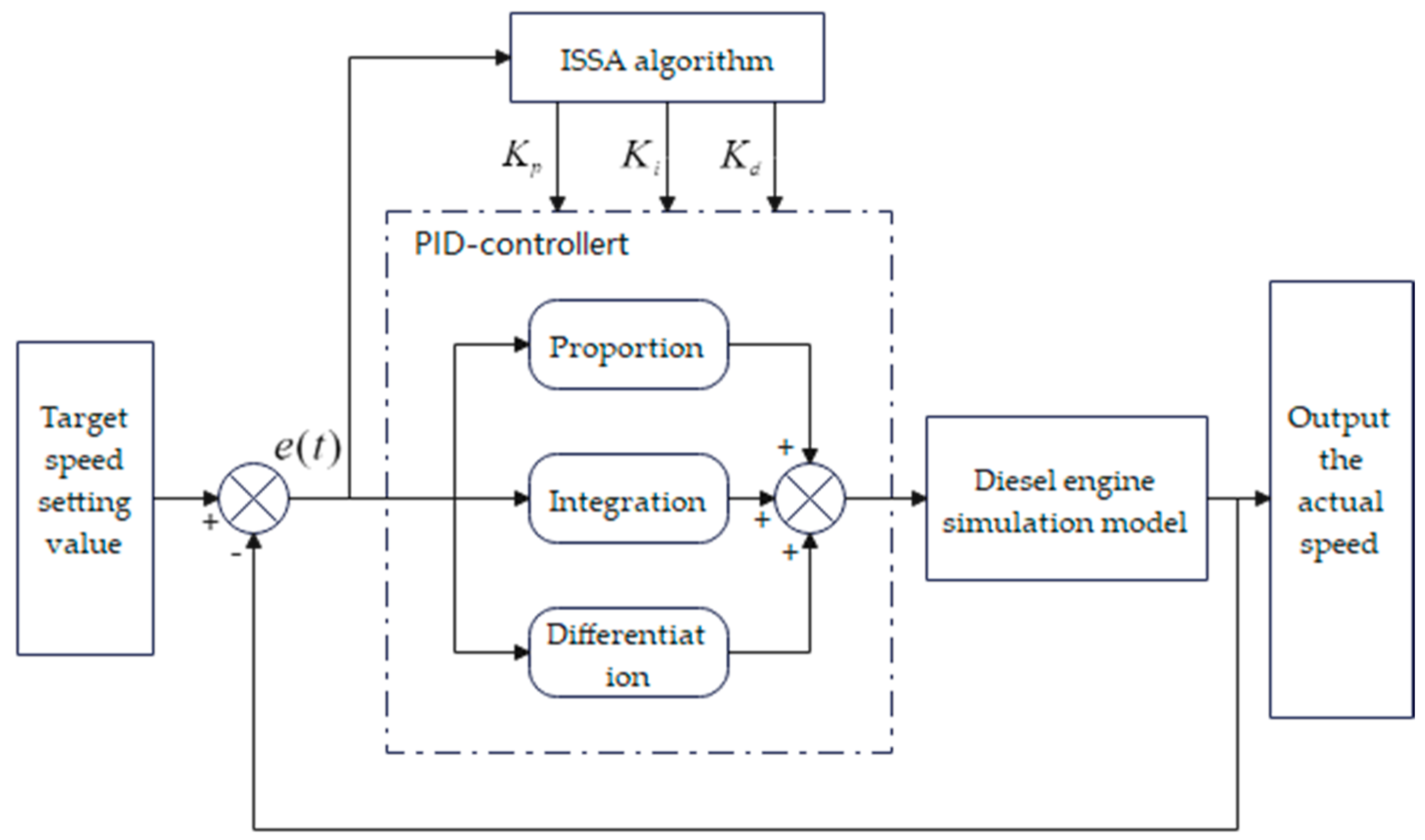

4.1. Principle of PID Control System Optimization Based on ISSA Algorithm

4.2. Model Simulation Accuracy Verification

4.3. Simulation Test of Speed Tracking Performance

4.3.1. Speed Step-Change Simulation Test

4.3.2. Load Surge Simulation Test

5. Conclusions

- To address the issues of reduced population diversity and the tendency to become trapped in local optima in the salp swarm algorithm, the algorithm was tested, both before and after improvements, using various benchmark functions. The test results on these benchmark functions showed that the improved salp swarm algorithm significantly enhances both global and local search capabilities. It effectively prevents the algorithm from becoming stuck in local optima, validating the feasibility and effectiveness of the improved approach;

- Utilizing the improved salp swarm algorithm for PID control parameter optimization led to reductions in speed overshoot and stabilization time. During sudden speed changes at 50% and 30% load, the ISSA, compared to the SSA, PSO, and engineering tuning methods, averaged reductions of 30.3% and 38.6% in overshoot and of 0.76 s and 0.84 s in stabilization time, respectively. When the load underwent abrupt changes, the ISSA, at speeds of 1200 r/min and 2400 r/min, reduced the overshoot by an average of 27.7% and 8.6%, respectively, and the stabilization time by an average of 1.52 s and 4.32 s. ISSA offers a more balanced control performance and, compared to the other three methods, excels in stable speed control and rapid response. Moreover, the system achieves faster stabilization times, proving its valuable significance in engineering applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ISSA | Improved salp swarm algorithm |

| PID | Proportional integral and differential |

| SSA | Salp swarm algorithm |

| MRAC | Model reference adaptive control |

| DTMCSI | Discrete-time minimum control synthesize integration |

| ECU | Electronic control unit |

| EGR | Exhaust gas recirculation |

| LTSSA | SSA integrated with the logistic-tent chaotic mapping |

| ASSA | Adaptive parameter salp swarm algorithm |

| WSSA | Inertia weight salp swarm algorithm |

| DSSA | Dynamic inverse strategy salp swarm algorithm |

| PSO | Particle swarm optimization |

| Mass flow rate | |

| Dynamic viscosity | |

| Orifice area | |

| Upstream pressure | |

| Upstream specific gas constant | |

| Upstream flow temperature | |

| Flow function | |

| Length of the component after the hole | |

| Diameter after the hole | |

| Density of the gas | |

| Wall friction coefficient | |

| Reynolds number | |

| Laminar friction coefficient | |

| Friction coefficient in turbulent flow | |

| Corrected rotational speed of the turbocharger | |

| Current rotational speed | |

| Reference temperature obtained from experiments | |

| Corrected mass flow rate of the turbocharger | |

| Current mass flow rate | |

| Pressure as measured in experiments | |

| Inlet pressure of the EGR | |

| Outlet pressure of the EGR | |

| Density of the mixed gas | |

| Cross-sectional area of the valve | |

| Flow coefficient | |

| Inlet temperature | |

| Outlet temperature | |

| Cooling efficiency | |

| Temperature of the cooling fluid | |

| Internal pressure of the common rail | |

| Time | |

| Volumetric modulus of the working fluid | |

| Volume of the rail | |

| Density of the fluid within the rail | |

| Mass flow rate through the pump | |

| Mass flow rate through the injector | |

| Fuel injection mass flow rate | |

| Nozzle orifice area | |

| Discharge coefficient | |

| Fuel density | |

| Pressure inside the pipe | |

| Pressure within the cylinder | |

| Type of stroke | |

| Injection mass per cycle | |

| Mass flow rate of injection per second | |

| Resonant frequency | |

| Volumetric modulus of the working fluid | |

| Length of the pipeline | |

| First salp in the j dimension | |

| Food source in the j dimension | |

| Upper limit of the j dimension | |

| Lower limit | |

| Random numbers between 0 and 1 | |

| Random numbers between 0 and 1 | |

| Current iteration count | |

| Maximum number of iterations | |

| Position of the i follower in the j dimension | |

| Initial velocity | |

| Acceleration | |

| System variable and the chaotic value of the system | |

| Control parameter | |

| Adaptive parameter | |

| Weight of individual i in iteration t | |

| Fitness value of individual i during iteration t | |

| Average fitness values of all salps in iteration t | |

| Minimum fitness values of all salps in iteration t | |

| Preset maximum inertia coefficients | |

| Preset minimum inertia coefficients | |

| Minimum values of dimension j for individual i in iteration t | |

| Maximum values of dimension j for individual i in iteration t | |

| Inversion coefficient | |

| Speed deviation | |

| Overshoot | |

| Settling time | |

| ,, | Weight values |

References

- Astrom, K.; Hagglund, T. The Future of PID Control. IFAC Proc. Vol. 2000, 33, 19–30. [Google Scholar] [CrossRef]

- Parada, M.; Sbarbaro, D.; Borges, R.; Peres, P. Robust PI and PID Design for First- and Second-Order Processes with Zeros, Time-Delay and Structured Uncertainties. Int. J. Syst. Sci. 2017, 48, 95–106. [Google Scholar] [CrossRef]

- Garpinger, O.; Hgglund, T.; Strm, K.J. Performance and robustness trade-offs in PID control. J. Process Control 2014, 24, 568–577. [Google Scholar] [CrossRef]

- Li, Y.; Xu, F.J.; Wang, B. Experimental Study on Loaded Suddenly and Unloaded Suddenly of 16 V Generator Diesel. Mod. Veh. Power 2015, 157, 27–29, 34. [Google Scholar]

- Astrom, K.J.; Hagglund, T. Automatic tuning of simple regulators with specifications on phase and amplitude margins. Automatica 1984, 20, 645–651. [Google Scholar] [CrossRef]

- Kiam, H.A.; Chong, G.; Li, Y. PID control system analysis, design, and technology. IEEE Trans. Control Syst. Technol. 2005, 13, 559–576. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Moore, K.L. Relay feedback tuning of robust PID controllers with iso-damping property. IEEE Trans. Syst. Man Cybern. Part B 2005, 35, 23–31. [Google Scholar] [CrossRef]

- Hernández-Alvarado, R.; García-Valdovinos, L.; Salgado-Jiménez, T.; Gómez-Espinosa, A.; Fonseca-Navarro, F. Neural Network-Based Self-Tuning PID Control for Underwater Vehicles. Sensors 2016, 16, 1429. [Google Scholar] [CrossRef] [PubMed]

- Meena, D.C.; Devanshu, A. Genetic algorithm tuned PID controller for process control. In Proceedings of the 2017 International Conference on Inventive Systems and Control (ICISC), Coimbatore, India, 19–20 January 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Abushawish, E.A.; Hamadeh, M.; Nassif, A. PID Controller Gains Tuning Using Metaheuristic Optimization Methods: A survey. Int. J. Comput. 2020, 14, 87–95. [Google Scholar] [CrossRef]

- Sun, W.F.; Liu, H.Y.; Wang, R.T.; Fu, T.P.; Lu, J.Q.; Wang, F.L. Design and Experiment of PID Control Variable Application System Based on Neural Network Tuning. Trans. Chin. Soc. Agric. Mach. 2020, 51, 55–64, 94. [Google Scholar]

- Feng, J.X.; Wang, Q.; Wang, Y.L.; Xu, B. Fuzzy PID control of ultrasonic motor based on improved quantum genetic algorithm. J. Jilin Univ. Eng. Technol. Ed. 2021, 51, 1990–1996. [Google Scholar]

- Zhai, M.D.; Zhang, B.; Li, X.L.; Long, Z.Q. Design and Implementation of Magnetic Suspension Vibration Isolation Platform with Quasi-Zero Stiffness Based on Fuzzy PID Control. J. Southwest Jiaotong Univ. 2023, 58, 886–895. [Google Scholar]

- Seyyed, M.H.; Ramin, F. Intelligent VIV control of 2DOF sprung cylinder in laminar shear-thinning and shear-thickening cross-flow based on self-tuning fuzzy PID algorithm. Mar. Struct. 2023, 89, 103377. [Google Scholar]

- Zhang, J.H.; Li, Y.M.; Qi, W.C.; Liu, C.L.; Yang, F.Z.; Li, Z.P. Synchronous Control System of Tractor Attitude in Hills and Mountains Based on Neural Network PID. Trans. Chin. Soc. Agric. Mach. 2020, 51, 356–366. [Google Scholar]

- Jiang, X.H.; Cheng, T.H. Design of a BP neural network PID controller for an air suspension system by considering the stiffness of rubber bellows. Alex. Eng. J. 2023, 74, 65–78. [Google Scholar] [CrossRef]

- Shi, J.Z.; Liu, Y. Simple Expert PID Speed Control of Ultrasonic Motors. Proc. CSEE 2013, 33, 120–126. [Google Scholar]

- Miao, R.L.; Dong, Z.P.; Wan, L.; Zeng, J.F. Heading Control System Design for a Micro-USV Based on an Adaptive Expert S-PID Algorithm. Pol. Marit. Res. 2018, 25, 13–16. [Google Scholar] [CrossRef]

- Matsumoto, H.; Morita, S.; Takiyama, T. Application of Fuzzy Control to Internal Combustion Engines. JSME Int. J. Ser. B-Fluids Therm. Eng. 1994, 37, 159–164. [Google Scholar] [CrossRef]

- Shao, C.; Song, K.; Cheng, T.; Xie, H. Active Disturbance Rejection Control of Diesel Engine Speed Based on Parameter Self-Learning. Trans. CSICE 2022, 40, 144–152. [Google Scholar]

- Song, E.Z.; Song, T.K.; Ma, C.; Yao, C.; Liu, Z.L. Research on Diesel Engine Speed Control Based on Model Reference Adaptive. Chin. Intern. Combust. Engine Eng. 2022, 43, 57–64. [Google Scholar]

- Liang, J.J.; Qin, A.K.; Suganthan, P.N.; Baskar, S. Comprehensive learning particle swarm optimizer for global optimization of multimodal functions. IEEE Trans. Evol. Comput. 2006, 10, 281–295. [Google Scholar] [CrossRef]

- Zamani, M.; Karimi-Ghartemani, M.; Sadati, N.; Mostafa, P. Design of a fractional order PID controller for an AVR using particle swarm optimization. Control. Eng. Pract. 2009, 17, 1380–1387. [Google Scholar] [CrossRef]

- Xiang, H.C.; Ma, Z.T.; Yang, Z.T.; Yang, M.Y.; Deng, K.Y.; Huang, M.; Liu, Y. Performance Response Characteristic of Turbocharged Diesel Engine Under Fluctuating HighBack Pressure Environment. Trans. CSICE 2023, 41, 404–411. [Google Scholar]

- Lei, L.; Yu, Y.H.; Shen, L.Z.; Wan, M.D.; Huang, F.L.; Wang, Z.J. Investigation on Transient Emissions of Diesel Engine at Different Altitudes. Trans. CSICE 2023, 41, 420–426. [Google Scholar]

- Shah, R.K.; Sekulic, D.P. Fundamentals of Heat Exchanger Design; John Wiley and Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Seyedali, M.; Amir, H.G.; Seyedeh, Z.M.; Shahrzad, S.; Hossam, F.; Seyed, M.M. Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar]

- Cheng, Y.X.; Zhang, T.; Liu, Y.G.; Chen, J. Lightweight Design Method of Girder Hoist Based on Improved Salp Swarm Algorithm. J. Northeast. Univ. Nat. Sci. 2023, 44, 223–232. [Google Scholar]

- Gao, Y. Pseudorandom Sequence IP Design Based on Logistic Chaos Algorithm; Heilongjiang University: Harbin, China, 2021. [Google Scholar]

- Qin, Q.X.; Liang, Z.Y.; Xu, Y. Image Encryption Algorithm Based on Logistic-Tent Chaotic Mapping and Bit Plane. J. Dalian Minzu Univ. 2022, 24, 245–252. [Google Scholar]

- Shi, Y.; Eberhart, R. A modified particle swarm optimizer. In Proceedings of the 1998 IEEE International Conference on Evolutionary Computation Proceedings, IEEE World Congress on Computational Intelligence (Cat. No.98TH8360), Anchorage, AK, USA, 4–9 May 1998; pp. 69–73. [Google Scholar]

- Lian, X.Q.; Liu, Y.; Chen, Y.M. Research on Multi-Peak Spectral Line Separation Method Based on Adaptive Particle Swarm Optimization. Spectrosc. Spectr. Anal. 2021, 41, 1452–1457. [Google Scholar]

- Feng, Z.X.; Li, J.L.; Ge, X.; Zhou, Y.J. Integrating multi strategy improved whale optimization algorithm and its application. Comput. Integr. Manuf. Syst. 2023, 1–23. [Google Scholar]

- Zeng, N.Y.; Song, D.D.; Li, H.; Yan, C.; You, Y.C. Improved Whale Optimization Algorithm and Turbine Disk Structure Optimization. J. Mech. Eng. 2021, 51, 254–265. [Google Scholar]

- Li, Y.L.; Wang, S.Q.; Chen, Q.R.; Wang, X.G. Comparative Study of Several New Swarm Intelligence Optimization Algorithms. Comput. Eng. Appl. 2020, 56, 1–12. [Google Scholar]

- Li, J.L.; Wang, G.Y.; Wang, Y.H.; Deng, D.R.; Zhao, Y.; He, S.C. Research on Diesel Engine Common Rail Pressure Control Based on Gaussian-Cauchy Mutation Seagull Optimization Algorithm. Chin. Intern. Combust. Engine Eng. 2022, 43, 16–25. [Google Scholar]

| Parameter | Numerical Value |

|---|---|

| Type | Supercharged Intercooled In-Line 4 Cylinders |

| Cylinder Bore | 95 mm |

| Stroke | 105 mm |

| Rated Power | 130/(3200 r/min)kW |

| Compression Ratio | 17.5 |

| Displacement | 2.977 L |

| Function Name | Function | Section | Starter |

|---|---|---|---|

| Sphere F | [−100, 100] | 0 | |

| Schwefel’s P2.22 | [−10, 10] | 0 | |

| Schwefel’s P1.2 | [−100, 100] | 0 | |

| Schwefel’s P2.21 | [−100, 100] | 0 | |

| Generalized Schwefel’s P2.26 | [−500, 500] | 0 | |

| Generalized Rastrigin’s F | [−5.12, 5.12] | 0 | |

| Ackley’s F | [−32, 32] | 0 | |

| Generalized Griewank’s F | [−600, 600] | 0 |

| Algorithm | SSA | LTSSA | ASSA | WSSA | DSSA | ISSA | |

|---|---|---|---|---|---|---|---|

| Function | |||||||

| F1 | 3.7 × 10−2 | 7.28 × 10−9 | 7.29 × 10−9 | 1.04 × 10−7 | 1.48 × 10−8 | 7.98 × 10−11 | |

| F2 | 1.37 | 2 × 10−2 | 1.9 × 10−2 | 4.81 × 10−5 | 9.5 × 10−2 | 3.18 × 10−6 | |

| F3 | 3.4 × 101 | 7.46 × 10−1 | 7.8 × 101 | 1.27 × 10−8 | 1 × 102 | 1.74 × 10−10 | |

| F4 | 1.07 × 101 | 1.86 × 10−2 | 2.75 × 101 | 3.7 × 10−5 | 2.98 × 101 | 2.46 × 10−6 | |

| F5 | −8.28 × 103 | −6.06 × 103 | −7.37 × 103 | −7.01 × 103 | −8.44 × 103 | −1.25 × 104 | |

| F6 | 5.07 × 101 | 4.97 × 10−9 | 6.37 × 101 | 6.39 × 10−9 | 4.28 × 101 | 4.03 × 10−11 | |

| F7 | 2.12 | 2.34 × 10−5 | 2.41 | 2.31 × 10−5 | 1.65 | 1.84 × 10−6 | |

| F8 | 3.47 × 10−8 | 1.23 × 10−2 | 4.65 × 10−2 | 4.97 × 10−8 | 1.15 | 2.86 × 10−10 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, B.; Shen, Q.; Wang, G.; Wang, Y.; Zhao, Y.; He, S.; Yu, X. Research on Diesel Engine Speed Control Based on Improved Salp Algorithm. Processes 2023, 11, 3092. https://doi.org/10.3390/pr11113092

Zeng B, Shen Q, Wang G, Wang Y, Zhao Y, He S, Yu X. Research on Diesel Engine Speed Control Based on Improved Salp Algorithm. Processes. 2023; 11(11):3092. https://doi.org/10.3390/pr11113092

Chicago/Turabian StyleZeng, Boshun, Qianqiao Shen, Guiyong Wang, Yuhua Wang, You Zhao, Shuchao He, and Xuan Yu. 2023. "Research on Diesel Engine Speed Control Based on Improved Salp Algorithm" Processes 11, no. 11: 3092. https://doi.org/10.3390/pr11113092

APA StyleZeng, B., Shen, Q., Wang, G., Wang, Y., Zhao, Y., He, S., & Yu, X. (2023). Research on Diesel Engine Speed Control Based on Improved Salp Algorithm. Processes, 11(11), 3092. https://doi.org/10.3390/pr11113092