Enhanced UV/H2O2 System for the Oxidation of Organic Contaminants and Ammonia Transformation from Tannery Effluents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tannery Wastewater

2.2. Physicochemical Characterization of the Tannery Effluents

2.3. Experimental Analysis

2.4. Analytical Methods

3. Results and Discussions

3.1. Physicochemical Characterization of Tannery Wastewaters

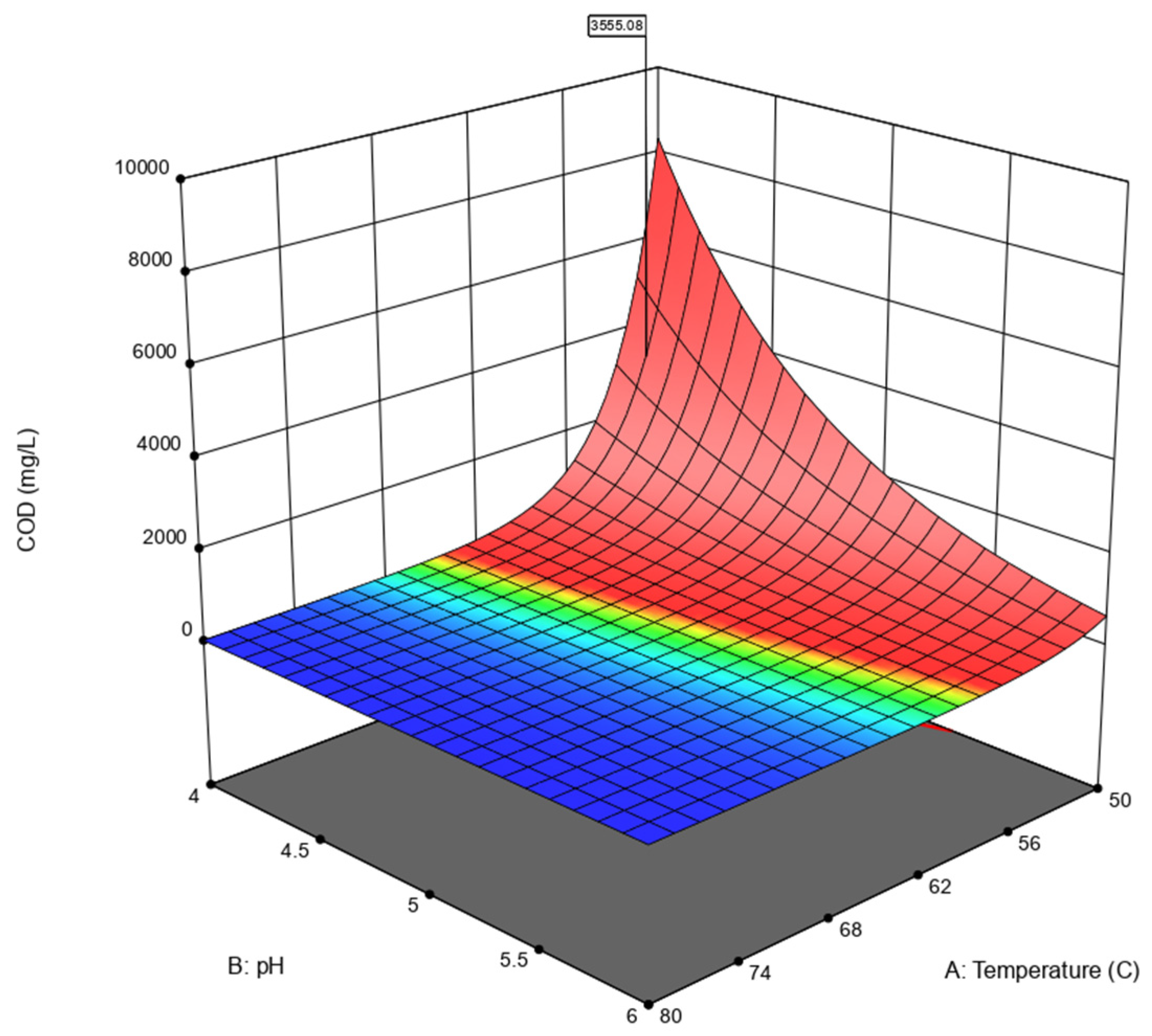

3.2. COD

3.3. Nitrification

3.4. Optimization and Validation of UV/H2O2 Operating Conditions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sivagami, K.; Sakthivel, K.P.; Nambi, I.M. Advanced Oxidation Processes for the Treatment of Tannery Wastewater. J. Environ. Chem. Eng. 2018, 6, 3656–3663. [Google Scholar] [CrossRef]

- Urbina-Suarez, N.A.; Machuca-Martínez, F.; Barajas-Solano, A.F. Advanced Oxidation Processes and Biotechnological Alternatives for the Treatment of Tannery Wastewater. Molecules 2021, 26, 3222. [Google Scholar] [CrossRef]

- Hansen, É.; de Aquim, P.M.; Hansen, A.W.; Cardoso, J.K.; Ziulkoski, A.L.; Gutterres, M. Impact of Post-Tanning Chemicals on the Pollution Load of Tannery Wastewater. J. Environ. Manag. 2020, 269, 110787. [Google Scholar] [CrossRef]

- Chhikara, S.; Hooda, A.; Rana, L.; Dhankhar, R. Chromium (VI) Biosorption by Immobilized Aspergillus Niger in Continuous Flow System with Special Reference to FTIR Analysis. J. Environ. Biol. 2010, 31, 561–566. [Google Scholar]

- Daneshvar, E.; Zarrinmehr, M.J.; Kousha, M.; Hashtjin, A.M.; Saratale, G.D.; Maiti, A.; Vithanage, M.; Bhatnagar, A. Hexavalent Chromium Removal from Water by Microalgal-Based Materials: Adsorption, Desorption and Recovery Studies. Bioresour. Technol. 2019, 293, 122064. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, Q.; Tang, Y.; Zhou, J.; Guo, H. Tannery Wastewater Treatment: Conventional and Promising Processes, an Updated 20-Year Review. J. Leather Sci. Eng. 2022, 4, 1–22. [Google Scholar] [CrossRef]

- Achouri, O.; Panico, A.; Bencheikh-Lehocine, M.; Derbal, K.; Pirozzi, F. Effect of Chemical Coagulation Pretreatment on Anaerobic Digestion of Tannery Wastewater. J. Environ. Eng. 2017, 143, 04017039. [Google Scholar] [CrossRef]

- Lofrano, G.; Meriç, S.; Zengin, G.E.; Orhon, D. Chemical and Biological Treatment Technologies for Leather Tannery Chemicals and Wastewaters: A Review. Sci. Total. Environ. 2013, 461–462, 265–281. [Google Scholar] [CrossRef]

- Urbina-Suarez, N.A.; Ayala-González, D.D.; Rivera-Amaya, J.D.; Barajas-Solano, A.F.; Machuca-Martínez, F. Evaluation of the Light/Dark Cycle and Concentration of Tannery Wastewater in the Production of Biomass and Metabolites of Industrial Interest from Microalgae and Cyanobacteria. Water 2022, 14, 346. [Google Scholar] [CrossRef]

- Haydar, S.; Aziz, J.; Saeed, M. Biological Treatment of Tannery Wastewater Using Activated Sludge Process. Pak. J. Eng. Appl. Sci. 2007, 1, 61–66. [Google Scholar]

- GracePavithra, K.; Jaikumar, V.; Kumar, P.S.; Sundar Rajan, P.S. A Review on Cleaner Strategies for Chromium Industrial Wastewater: Present Research and Future Perspective. J. Clean. Prod. 2019, 228, 580–593. [Google Scholar] [CrossRef]

- Urbina-Suarez, N.A.; Rivera-Caicedo, C.; González-Delgado, D.; Barajas-Solano, A.F.; Machuca-Martínez, F. Bicarbonate-Hydrogen Peroxide System for Treating Dyeing Wastewater: Degradation of Organic Pollutants and Color Removal. Toxics 2023, 11, 366. [Google Scholar] [CrossRef]

- Korpe, S.A.; Landge, V.; Hakke, V.S.; Rao, P.V.; Sonawane, S.H.; Sonawane, S.S. Advanced Oxidation Processes for Tannery Industry Wastewater Treatment. In Novel Approaches towards Wastewater Treatment and Resource Recovery Technologies; Elsevier: Amsterdam, The Netherlands, 2022; pp. 253–276. [Google Scholar] [CrossRef]

- Jessieleena, A.A.; Priyanka, M.; Saravanakumar, M.P. Comparative Study of Fenton, Fe2+/NaOCl and Fe2+/(NH4)2S2O8 on Tannery Sludge Dewaterability, Degradability of Organics and Leachability of Chromium. J. Hazard. Mater. 2021, 402, 123495. [Google Scholar] [CrossRef] [PubMed]

- Borba, F.H.; Pellenz, L.; Bueno, F.; Inticher, J.J.; Braun, L.; Espinoza-Quiñones, F.R.; Trigueros, D.E.G.; de Pauli, A.R.; Módenes, A.N. Pollutant Removal and Biodegradation Assessment of Tannery Effluent Treated by Conventional Fenton Oxidation Process. J. Environ. Chem. Eng. 2018, 6, 7070–7079. [Google Scholar] [CrossRef]

- Di Iaconi, C. Biological Treatment and Ozone Oxidation: Integration or Coupling? Bioresour. Technol. 2012, 106, 63–68. [Google Scholar] [CrossRef]

- Arslan-Alaton, I.; Gurses, F. Photo-Fenton-like and Photo-Fenton-like Oxidation of Procaine Penicillin G Formulation Effluent. J. Photochem. Photobiol. A Chem. 2004, 165, 165–175. [Google Scholar] [CrossRef]

- Vaiano, V.; Iervolino, G. Facile Method to Immobilize ZnO Particles on Glass Spheres for the Photocatalytic Treatment of Tannery Wastewater. J. Colloid Interface Sci. 2018, 518, 192–199. [Google Scholar] [CrossRef]

- Schrank, S.G.; José, H.J.; Moreira, R.F.P.M.; Schröder, H.F. Applicability of Fenton and H2O2/UV Reactions in the Treatment of Tannery Wastewaters. Chemosphere 2005, 60, 644–655. [Google Scholar] [CrossRef]

- Souza, E.A.; Cerqueira, U.M.; Silva, L.A. Comparative Study of Various Advanced Oxidation Processes for the Treatment of Tannery Wastewater. Desalination Water Treat. 2020, 181, 88–97. [Google Scholar] [CrossRef]

- Li, R.; Li, T.; Zhou, Q. Impact of Titanium Dioxide (TiO2) Modification on Its Application to Pollution Treatment—A Review. Catalysts 2020, 10, 804. [Google Scholar] [CrossRef]

- Assémian, A.S.; Kouassi, K.E.; Drogui, P.; Adouby, K.; Boa, D. Removal of a Persistent Dye in Aqueous Solutions by Electrocoagulation Process: Modeling and Optimization Through Response Surface Methodology. Water Air Soil Pollut. 2018, 229, 1–13. [Google Scholar] [CrossRef]

- Gomes, A.I.; Soares, T.F.; Silva, T.F.C.V.; Boaventura, R.A.R.; Vilar, V.J.P. Ozone-Driven Processes for mature Urban Landfill Leachate Treatment: Organic Matter Degradation, Biodegradability Enhancement and Treatment Costs for Different Reactors Configuration. Sci. Total. Environ. 2020, 724, 138083. [Google Scholar] [CrossRef]

- Rosales, A.G.; Rodríguez, C.D.; Ballen-Segura, M. Remoción de Contaminantes y Crecimiento Del Alga Scenedesmus Sp. En Aguas Residuales de Curtiembres, Comparación Entre Células Libres e Inmovilizadas. Ing. Y Cienc. 2018, 14, 11–34. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, W.; De Costa, Y.G.; Zhuang, W.-Q.; Yi, S. Assessing Inorganic Components of Cake Layer in A/O Membrane Bioreactor for Physical-Chemical Treated Tannery Effluent. Chemosphere 2020, 250, 126220. [Google Scholar] [CrossRef]

- Urbina-Suarez, N.A.; Barajas-Solano, A.F.; Zuorro, A.; Machuca, F. Advanced Oxidation Processes with Uv-H2O2 for Nitrification and Decolorization of Dyehouse Wastewater. Chem. Eng. Trans. 2022, 95, 235–240. [Google Scholar] [CrossRef]

- Tolkou, A.K.; Katsoyiannis, I.A.; Zouboulis, A.I. Removal of Arsenic, Chromium and Uranium from Water Sources by Novel Nanostructured Materials Including Graphene-Based Modified Adsorbents: A Mini Review of Recent Developments. Appl. Sci. 2020, 10, 3241. [Google Scholar] [CrossRef]

- Selvan, S.T.; Velramar, B.; Ramamurthy, D.; Balasundaram, S.; Sivamani, K. Pilot Scale Wastewater Treatment, CO2 Sequestration and Lipid Production Using Microalga, Neochloris aquatica RDS02. Int. J. Phytoremed. 2020, 22, 1462–1479. [Google Scholar] [CrossRef]

- Katsoyiannis, I.A.; Xanthopoulou, M.; Zouboulis, A.I. Cr(VI) Femoval from Ground Waters by Ferrous Iron Redox-Assisted Coagulation in a Continuous Treatment Unit Comprising a Plug Flow Pipe Reactor and Downflow Sand Filtration. Appl. Sci. 2020, 10, 802. [Google Scholar] [CrossRef]

- Korpe, S.; Rao, P.V. Application of Advanced Oxidation Processes and Cavitation Techniques for Treatment of Tannery Wastewater—A Review. J. Environ. Chem. Eng. 2021, 9, 105234. [Google Scholar] [CrossRef]

- Iqbal, M.; Muneer, M.; Hussain, S.; Parveen, B.; Javed, M.; Rehman, H.; Waqas, M.; Abid, M.A. Using Combined UV and H2O2 Treatments to Reduce Tannery Wastewater Pollution Load. Pol. J. Environ. Stud. 2019, 28, 3207–3213. [Google Scholar] [CrossRef]

- Guan, Y.-H.; Chen, J.; Chen, L.-J.; Jiang, X.-X.; Fu, Q. Comparison of UV/H2O2, UV/PMS, and UV/PDS in Destruction of Different Reactivity Compounds and Formation of Bromate and Chlorate. Front. Chem. 2020, 8, 581198. [Google Scholar] [CrossRef]

- Goutam, S.P.; Saxena, G.; Singh, V.; Yadav, A.K.; Bharagava, R.N.; Thapa, K.B. Green Synthesis of TiO2 Nanoparticles Using Leaf Extract of Jatropha curcas L. for Photocatalytic Degradation of Tannery Wastewater. Chem. Eng. J. 2018, 336, 386–396. [Google Scholar] [CrossRef]

- Wang, J.; Song, M.; Chen, B.; Wang, L.; Zhu, R. Effects of pH and H2O2 on Ammonia, Nitrite, and Nitrate Transformations during UV254nm Irradiation: Implications to Nitrogen Removal and Analysis. Chemosphere 2017, 184, 1003–1011. [Google Scholar] [CrossRef]

- Shu, H.-Y.; Chang, M.-C. Decolorization and Mineralization of a Phthalocyanine dye C.I. Direct Blue 199 Using UV/H2O2 Process. J. Hazard. Mater. 2005, 125, 96–101. [Google Scholar] [CrossRef] [PubMed]

- Rajagopal, S.; Paramasivam, B.; Muniyasamy, K. Photocatalytic Removal of Cationic and Anionic Dyes in the Textile Wastewater by H2O2 Assisted TiO2 and Micro-Cellulose Composites. Sep. Purif. Technol. 2020, 252, 117444. [Google Scholar] [CrossRef]

- Farzanehsa, M.; Vaughan, L.C.; Zamyadi, A.; Khan, S.J. Comparison of UV-Cl and UV-H2O2 Advanced Oxidation Processes in the Degradation of Contaminants from Water and Wastewater: A Review. Water Environ. J. 2023, 37, 1–11. [Google Scholar] [CrossRef]

- Nidheesh, P.V.; Couras, C.; Karim, A.V.; Nadais, H. A Review of Integrated Advanced Oxidation Processes and Biological Processes for Organic Pollutant Removal. Chem. Eng. Commun. 2021, 209, 390–432. [Google Scholar] [CrossRef]

- Saranya, D.; Shanthakumar, S. An Integrated Approach for Tannery Effluent Treatment with Ozonation and Phycoremediation: A Feasibility Study. Environ. Res. 2020, 183, 109163. [Google Scholar] [CrossRef]

- Hussain, Z.; Arslan, M.; Shabir, G.; Malik, M.H.; Mohsin, M.; Iqbal, S.; Afzal, M. Remediation of Textile Bleaching Effluent by Bacterial Augmented Horizontal Flow and Vertical Flow Constructed Wetlands: A Comparison at Pilot Scale. Sci. Total. Environ. 2019, 685, 370–379. [Google Scholar] [CrossRef] [PubMed]

- Sauer, T.P.; Casaril, L.; Oberziner, A.L.B.; José, H.J.; Moreira, R.d.F.P.M. Advanced Oxidation Processes Applied to Tannery Wastewater Containing Direct Black 38—Elimination and Degradation Kinetics. J. Hazard. Mater. 2006, 135, 274–279. [Google Scholar] [CrossRef] [PubMed]

- Mahamuni, N.N.; Adewuyi, Y.G. Advanced Oxidation Processes (AOPs) Involving Ultrasound for Waste Water Treatment: A Review with Emphasis on Cost Estimation. Ultrason. Sonochem. 2010, 17, 990–1003. [Google Scholar] [CrossRef]

- Saravanathamizhan, R.; Perarasu, V.R.; Dhandapani, B. Advanced Oxidation Process for Effluent Treatment in Textile, Pharmaceutical, and Tannery Industries. In Photocatalytic Degradation of Dyes: Current Trends and Future Perspectives; Elsevier: Amsterdam, The Netherlands, 2021; pp. 719–745. [Google Scholar] [CrossRef]

- Khuzwayo, Z.; Chirwa, E.M.N. Analysis of Catalyst Photo-Oxidation Selectivity in the Degradation of Polyorganochlorinated Pollutants in Batch Systems Using UV and UV/TiO2. S. Afr. J. Chem. Eng. 2017, 23, 17–25. [Google Scholar] [CrossRef]

- Josué, T.G.; Almeida, L.N.B.; Lopes, M.F.; Santos, O.A.A.; Lenzi, G.G. Cr (VI) Reduction by Photocatalyic Process: Nb2O5 an Alternative Catalyst. J. Environ. Manag. 2020, 268, 110711. [Google Scholar] [CrossRef]

| Parameter | Units | Standard Methods Number |

|---|---|---|

| COD | mg·L−1 | 5220C |

| BOD | 5210B-4500-OG | |

| Nitrates | 4500-NO3 B | |

| Nitrites | 4500-NO2 B | |

| Ammonia nitrogen | 4500-NH3 F | |

| Phosphates | 4500-P C | |

| Total Suspended Solids | 2540D | |

| Cr | 3111D | |

| Sulfides | 4500-S2 F | |

| Chlorides | 4500-ClB | |

| pH | pH units | 4500B |

| Conductivity | µS·cm−1 | 2510B |

| Parameter | Factor | ||

|---|---|---|---|

| Lower Lever (−1) | Medium Level (0) | Higher Level (+1) | |

| H2O2 (M) | 0.3 | 0.5 | 0.7 |

| Lamp power (W) | 30 | 45 | 60 |

| pH | 4 | 5 | 6 |

| Temperature (°C) | 50 | 65 | 80 |

| Parameter | Units | Average Value |

|---|---|---|

| COD | mg·L−1 | 6180.45 ± 3.24 |

| BOD | 2128.27 ± 2.86 | |

| Nitrates | 74.56 ± 0.67 | |

| Nitrites | 0.64 ± 0.08 | |

| Ammonia nitrogen | 18.32 ± 0.23 | |

| Phosphates | 21.8 ± 0.48 | |

| Total Suspended Solids | 1184.65 ± 1.46 | |

| Cr | 1.2 ± 0.04 | |

| Sulfides | 47.34 ± 0.54 | |

| Chlorides | 2100.38 ± 1.73 | |

| pH | pH units | 5.18 ± 0.03 |

| Conductivity | µS·cm−1 | 928.5 ± 1.12 |

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 188.50 | 14 | 13.46 | 2.78 | 0.0134 | significant |

| A-Temperature | 2.09 | 1 | 2.09 | 0.4321 | 0.5172 | |

| B-pH | 64.75 | 1 | 64.75 | 13.38 | 0.0012 | |

| C-Hydrogen Peroxide | 1.01 | 1 | 1.01 | 0.2091 | 0.6516 | |

| D-pW | 0.2136 | 2 | 0.1068 | 0.0221 | 0.9782 | |

| AB | 1.66 | 1 | 1.66 | 0.3427 | 0.5637 | |

| AC | 8.94 | 1 | 8.94 | 1.85 | 0.1867 | |

| AD | 76.36 | 2 | 38.18 | 7.89 | 0.0023 | |

| BC | 20.37 | 1 | 20.37 | 4.21 | 0.0513 | |

| BD | 50.94 | 2 | 25.47 | 5.26 | 0.0127 | |

| CD | 7.10 | 2 | 3.55 | 0.7338 | 0.4906 | |

| Residual | 116.16 | 24 | 4.84 | |||

| Lack of Fit | 9.54 | 7 | 1.36 | 0.2174 | 0.9762 | not significant |

| Pure Error | 106.62 | 17 | 6.27 | |||

| Cor Total | 304.66 | 38 | ||||

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 158.33 | 5 | 31.67 | 8.65 | <0.0001 | significant |

| A-Temperature | 1.77 | 1 | 1.77 | 0.4825 | 0.4921 | |

| B-pH | 119.48 | 1 | 119.48 | 32.63 | <0.0001 | |

| C-Hydrogen Peroxide | 6.22 | 1 | 6.22 | 1.70 | 0.2014 | |

| D-pW | 15.91 | 2 | 7.95 | 2.17 | 0.1300 | |

| Residual | 120.84 | 33 | 3.66 | |||

| Lack of Fit | 40.18 | 16 | 2.51 | 0.5293 | 0.8949 | not significant |

| Pure Error | 80.66 | 17 | 4.74 | |||

| Cor Total | 279.17 | 38 | ||||

| Factor | Parameter | Units | Minimum | Maximum |

|---|---|---|---|---|

| A | H2O2 | M | 0.2000 | 0.8000 |

| B | Lamp Power | W | 30.00 | 60.00 |

| C | pH | 4.50 | 7.50 | |

| D | Temperature | °C | 50.00 | 80.00 |

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 1428.27 | 14 | 102.02 | 19.12 | <0.0001 | significant |

| A-H2O2 | 98.85 | 1 | 98.85 | 18.52 | 0.0016 | |

| B-Lamp Power | 642.49 | 1 | 642.49 | 120.40 | <0.0001 | |

| C-pH | 62.48 | 1 | 62.48 | 11.71 | 0.0065 | |

| D-Temperature | 51.80 | 1 | 51.80 | 9.71 | 0.0110 | |

| AB | 10.53 | 1 | 10.53 | 1.97 | 0.1904 | |

| AC | 10.91 | 1 | 10.91 | 2.04 | 0.1832 | |

| AD | 0.2993 | 1 | 0.2993 | 0.0561 | 0.8176 | |

| BC | 14.75 | 1 | 14.75 | 2.76 | 0.1274 | |

| BD | 17.68 | 1 | 17.68 | 3.31 | 0.0988 | |

| CD | 5.26 | 1 | 5.26 | 0.9864 | 0.3441 | |

| A2 | 15.26 | 1 | 15.26 | 2.86 | 0.1218 | |

| B2 | 165.37 | 1 | 165.37 | 30.99 | 0.0002 | |

| C2 | 106.68 | 1 | 106.68 | 19.99 | 0.0012 | |

| D2 | 8.14 | 1 | 8.14 | 1.52 | 0.2451 | |

| Residual | 53.36 | 10 | 5.34 | |||

| Lack of Fit | 31.86 | 5 | 6.37 | 1.48 | 0.3383 | not significant |

| Pure Error | 21.50 | 5 | 4.30 | |||

| Cor Total | 1481.63 | 24 | ||||

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 5457.47 | 14 | 389.82 | 80.79 | <0.0001 | significant |

| A-H2O2 | 327.04 | 1 | 327.04 | 67.78 | <0.0001 | |

| B-Lamp Power | 2380.42 | 1 | 2380.42 | 493.36 | <0.0001 | |

| C-pH | 123.41 | 1 | 123.41 | 25.58 | 0.0005 | |

| D-Temperature | 298.50 | 1 | 298.50 | 61.87 | <0.0001 | |

| AB | 107.82 | 1 | 107.82 | 22.35 | 0.0008 | |

| AC | 12.03 | 1 | 12.03 | 2.49 | 0.1454 | |

| AD | 2.96 | 1 | 2.96 | 0.6126 | 0.4520 | |

| BC | 23.82 | 1 | 23.82 | 4.94 | 0.0505 | |

| BD | 32.10 | 1 | 32.10 | 6.65 | 0.0275 | |

| CD | 113.57 | 1 | 113.57 | 23.54 | 0.0007 | |

| A2 | 1.65 | 1 | 1.65 | 0.3418 | 0.5717 | |

| B2 | 706.58 | 1 | 706.58 | 146.44 | <0.0001 | |

| C2 | 172.05 | 1 | 172.05 | 35.66 | 0.0001 | |

| D2 | 88.53 | 1 | 88.53 | 18.35 | 0.0016 | |

| Residual | 48.25 | 10 | 4.82 | |||

| Lack of Fit | 38.85 | 5 | 7.77 | 4.13 | 0.0728 | not significant |

| Pure Error | 9.40 | 5 | 1.88 | |||

| Cor Total | 5505.72 | 24 | ||||

| Parameters (% Removal) | This Research (UV/H2O2) | [39] | [40] | [41] | [19] | ||

|---|---|---|---|---|---|---|---|

| UV/H2O2 | TiO2/ H2O2/UV | FENTON | UV/H2O2 | ||||

| COD | 43.34 ± 1.04 | 64.3 | 30.2 | 18.8 | 68.3 | 63.06 | 45.2 |

| TOC | 46.5 ± 0.67 | n.r | n.r | n.r | n.r | 60 | 57.7 |

| BOD | 68.65 ± 1.35 | n.r | 30.2 | n.r | n.r | 52.5 | 46.18 |

| Color | 43.4 ± 0.16 | 56 | n.r | 67.36 | 91.5 | n.r | |

| N-NH3 | 77.5 ± 0.28 | 16.45 | n.r | 78.8 | 90.7 | 12 | 0.5 |

| Cr | 85.23 ± 0.78 | 68.02 | 65.7 | n.r | n.r | n.r | n.r |

| TSS | 83.5 ± 1.55 | 9.21 | 49 | n.r | n.r | n.r | n.r |

| Chlorides | 62.5 ± 0.84 | n.r | 43 | n.r | n.r | n.r | n.r |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urbina-Suarez, N.A.; López-Barrera, G.L.; García-Martínez, J.B.; Barajas-Solano, A.F.; Machuca-Martínez, F.; Zuorro, A. Enhanced UV/H2O2 System for the Oxidation of Organic Contaminants and Ammonia Transformation from Tannery Effluents. Processes 2023, 11, 3091. https://doi.org/10.3390/pr11113091

Urbina-Suarez NA, López-Barrera GL, García-Martínez JB, Barajas-Solano AF, Machuca-Martínez F, Zuorro A. Enhanced UV/H2O2 System for the Oxidation of Organic Contaminants and Ammonia Transformation from Tannery Effluents. Processes. 2023; 11(11):3091. https://doi.org/10.3390/pr11113091

Chicago/Turabian StyleUrbina-Suarez, Néstor A., German L. López-Barrera, Janet B. García-Martínez, Andrés F. Barajas-Solano, Fiderman Machuca-Martínez, and Antonio Zuorro. 2023. "Enhanced UV/H2O2 System for the Oxidation of Organic Contaminants and Ammonia Transformation from Tannery Effluents" Processes 11, no. 11: 3091. https://doi.org/10.3390/pr11113091

APA StyleUrbina-Suarez, N. A., López-Barrera, G. L., García-Martínez, J. B., Barajas-Solano, A. F., Machuca-Martínez, F., & Zuorro, A. (2023). Enhanced UV/H2O2 System for the Oxidation of Organic Contaminants and Ammonia Transformation from Tannery Effluents. Processes, 11(11), 3091. https://doi.org/10.3390/pr11113091