Effect of Tip Clearance on the Cavitation Performance of High-Speed Pump-Jet Propeller

Abstract

:1. Introduction

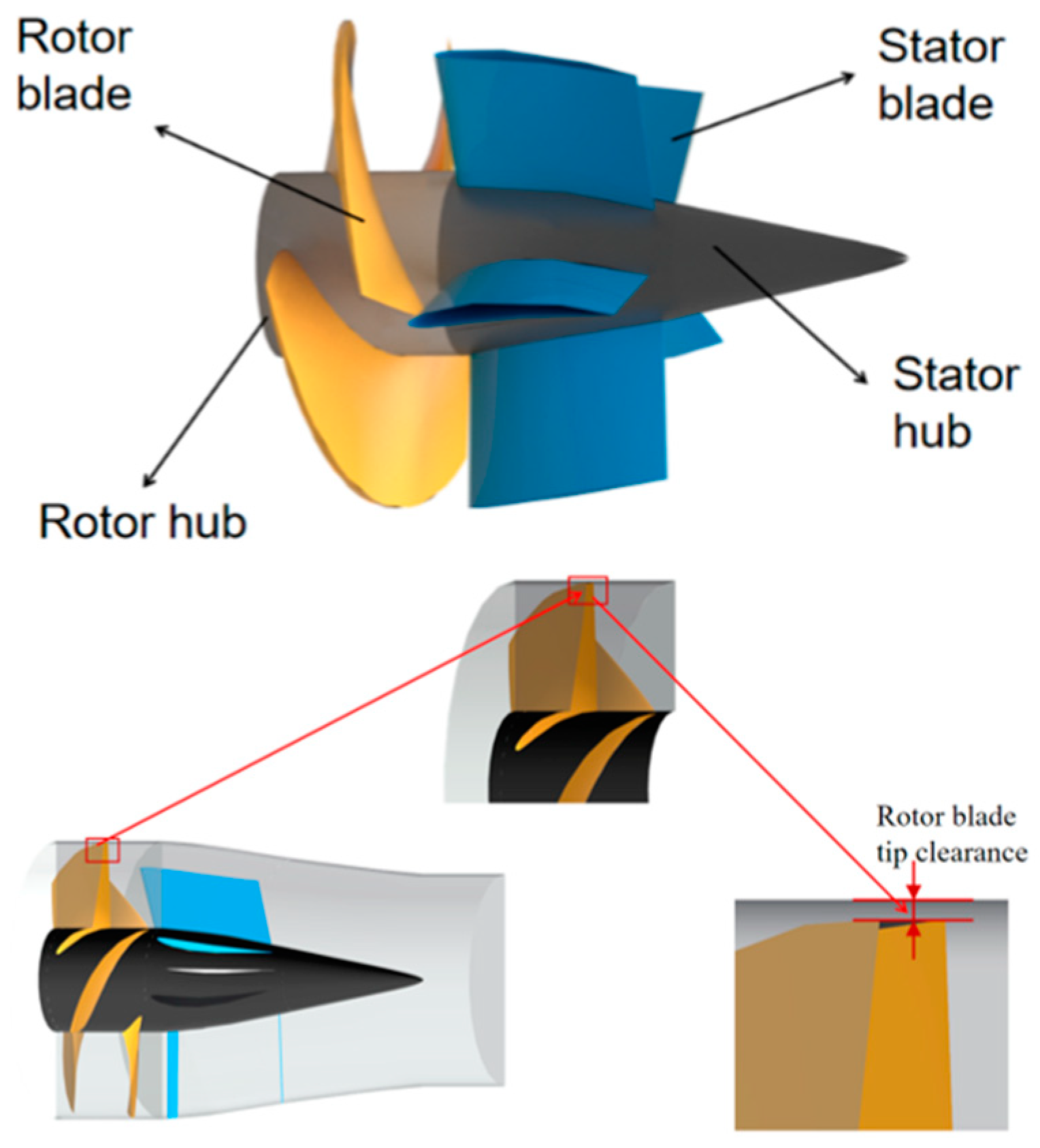

2. Research Principle and Physical Model of Pump-Jet Propulsion

3. Numerical Simulation

3.1. Turbulence Model

3.2. Cavitation Model

3.3. Computing Domains and Grids

4. Experiment and External Characteristics

4.1. Introduction to the Test Device

4.2. Comparison and Verification of External Features

5. Influence of Tip Clearance Coefficient on Cavitation Performance of Pump-Jet Propeller

5.1. Comparison of Cavitation Characteristics

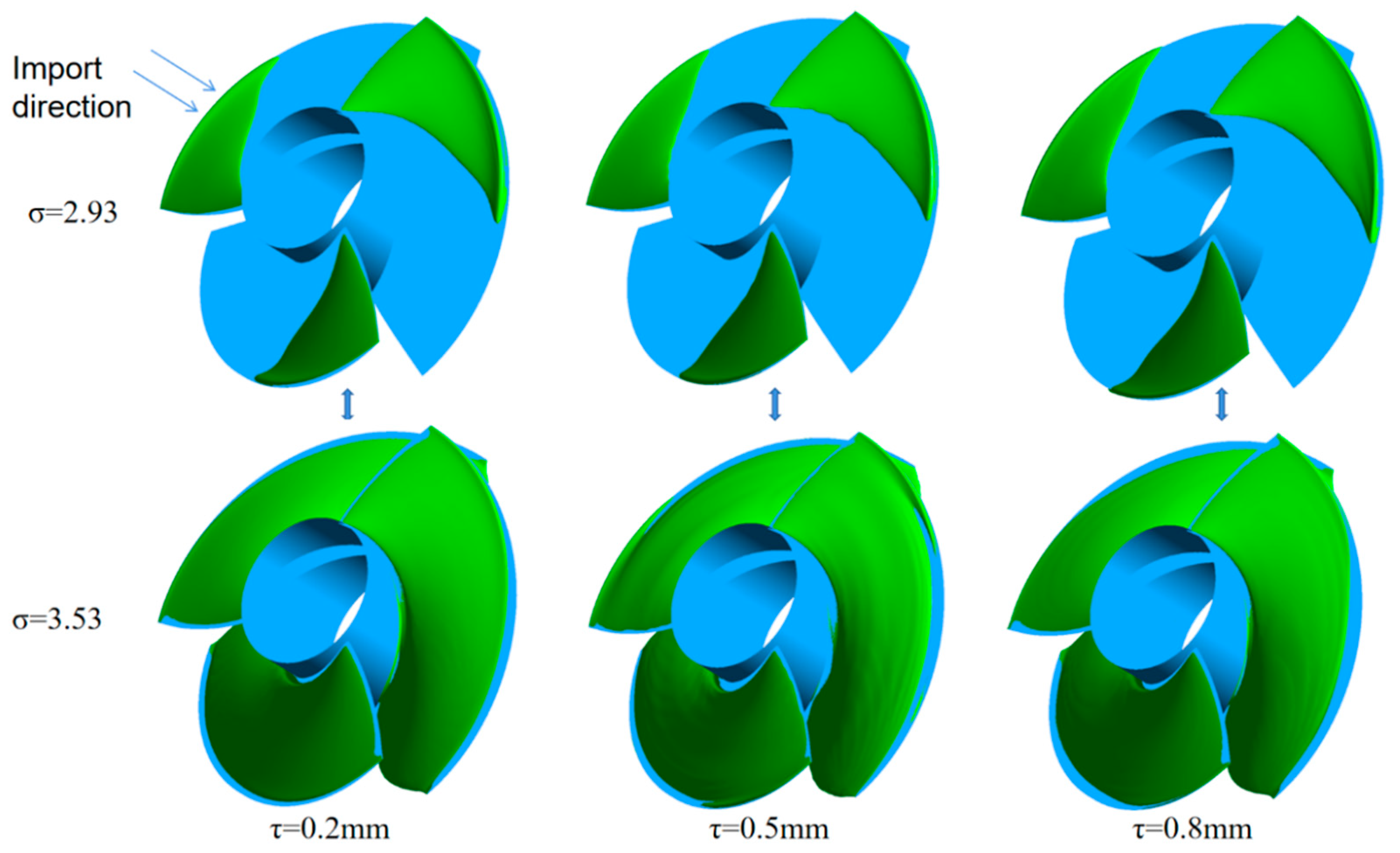

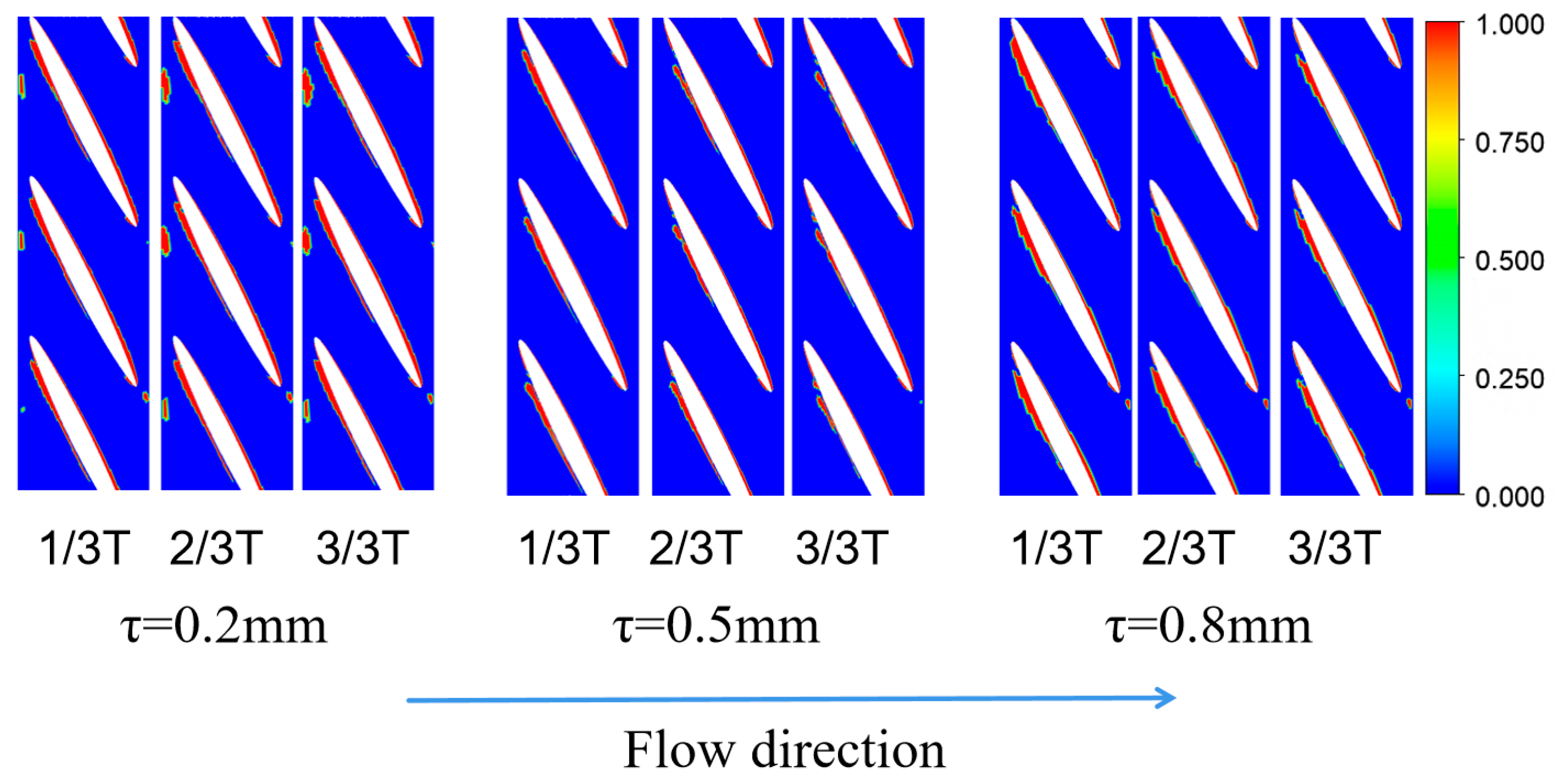

5.2. Distribution of Void Volume Fraction at Different Gaps

6. Transient Study on the Influence of Tip Clearance Coefficient on the Characteristics of Pump-Jet Propeller

6.1. Unsteady Analysis of Rotor Blade Radial Force with Different Tip Clearance Coefficients

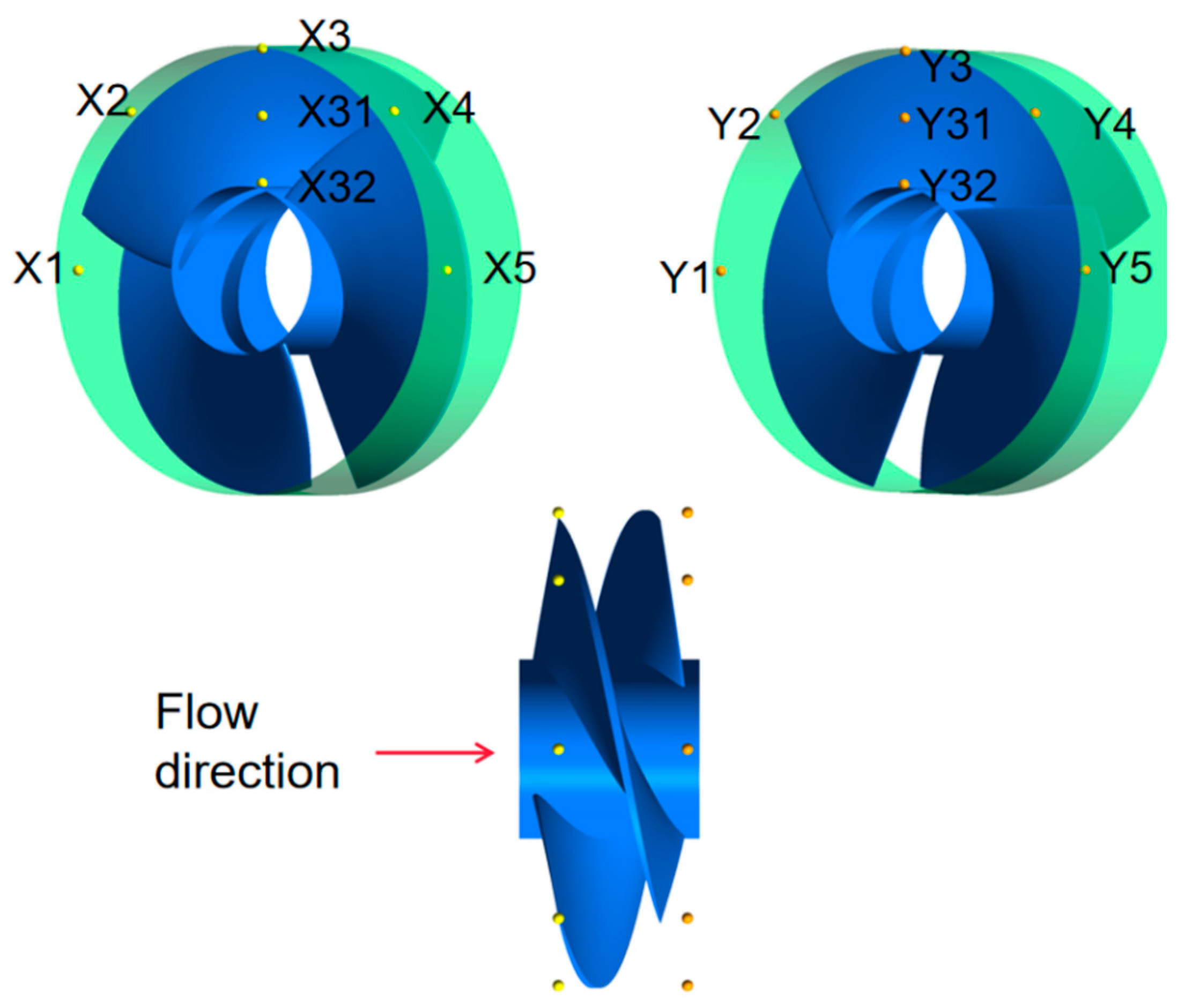

6.2. Pressure Pulsation Analysis under Different Tip Clearance

7. Conclusions

- (1)

- The head and efficiency of the pump-jet propeller decrease as the tip clearance at the rotor increases, when the clearance increases by 0.3 mm, the head decreases by about 15%, and the efficiency decreases by 15–25%.This can be attributed to stronger backflow caused by larger tip clearance compared to smaller tip clearance.

- (2)

- Cavitation initially occurs at the leading-edge end of the blade and then progresses towards the hub and trailing-edge of the rotor. In this process, it is observed larger clearances exhibit better anti-cavitation performance than smaller clearances. This can be attributed to the interference of clearance flow and leakage vortex at the rim, which affects the flow field structure, consumes energy, and reduces the pressure difference between the back surface and the working surface of adjacent blades.

- (3)

- The peak values of pressure pulsation in the hub with small gaps are lower compared to larger gaps. The reason is mostly the effect of the vortex. Because as the gap increases. More vortices are attached to the blade surface, resulting in increased vibration Therefore, when considering strength requirements, smaller gaps should be considered.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| CFD | Computational Fluid dynamics |

| FFT | Fast Fourier Transformation |

| u, v, ω | Velocity of fluid, m/s |

| Q | Flow rate, m3/s |

| T | Temperature, K |

| Fx, Fy, Fz | Forces on the element, Pa |

| ρ | Density, kg/m3 |

| μ | Viscosity, Pa∙s |

| Z | Number of blades |

| f | Frequency, Hz |

| σ | Cavitation number |

| P | Pressure, Pa |

| H | Head, m |

| Eff | Efficiency |

| Τ | Tip-clearance size, mm |

| Cp | The pressure fluctuation coefficient |

| αnuc | Volume fraction of gas nuclei in water |

| RB | Bubble radius |

| Fvap | Evaporation coefficient |

| Fcond | Condensation coefficient |

| μs | Viscosity of seawater, Pa∙s |

| U | Incoming velocity, m/s |

References

- McCormick, B.W.; Elsenhuth, J.J. Design and performance of propellers and pumpjets for underwater propulsion. AIAA J. 1963, 1, 2348–2354. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Satyanarayana, B.; Ramji, K.; Rao, M.N. Cavitation studies on axi-symmetric underwater body with pumpjet propulsor in cavitation tunnel. Int. J. Nav. Archit. Ocean Eng. 2010, 2, 185–194. [Google Scholar] [CrossRef]

- Gaggero, S.; Martinelli, M. Design and analysis of pumpjet propulsors using CFD-based optimization. Ocean Eng. 2023, 277, 114304. [Google Scholar] [CrossRef]

- Das, H.N.; Jayakumar, P.; Saji, V.F.; Yerram, R. CFD examination of interaction of flow on high-speed submerged body with pumpjet propulsor. In Proceedings of the 5th International Conference on High-Performance Marine Vehicles, Launceston, Australia, 8–10 November 2006. [Google Scholar] [CrossRef]

- Motallebi-Nejad, M.; Bakhtiari, M.; Ghassemi, H.; Fadavie, M. Numerical analysis of ducted propeller and pumpjet propulsion system using periodic computational domain. J. Mar. Sci. Technol. 2017, 22, 559–573. [Google Scholar] [CrossRef]

- Peng, H.; Guo, J.; Sun, Y.; Wang, G.; Qu, L. Numerical analysis of hydrodynamic force of front-and rear-stator pump-jet propulsion systems behind a submarine under oblique sailing. Ocean Eng. 2022, 266, 112565. [Google Scholar] [CrossRef]

- Zhu, Z.-F.; Fang, S.-L. Numerical investigation of cavitation performance of ship propellers. J. Hydrodyn. 2012, 24, 347–353. [Google Scholar] [CrossRef]

- Ji, B.; Luo, X.W.; Wu, Y.L.; Liu, S.H.; Xu, H.Y.; Oshima, A. Numerical investigation of unsteady cavitating turbulent flow around a full scale marine propeller. J. Hydrodyn. Ser. B 2010, 22, 747–752. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, W.; Van Esch, B.B.; Shi, L.; Dubuisson, M. Numerical and experimental investigation of tip leakage vortex trajectory and dynamics in an axial flow pump. Comput. Fluids 2015, 112, 61–71. [Google Scholar] [CrossRef]

- Shen, X.; Zhang, D.; Xu, B.; Shi, W.; van Esch, B. Experimental and numerical investigation on the effect of tip leakage vortex induced cavitating flow on pressure fluctuation in an axial flow pump. Renew. Energy 2021, 163, 1195–1209. [Google Scholar] [CrossRef]

- Shen, X.; Zhao, X.; Xu, B.; Zhang, D.; Yang, G.; Shi, W.; van Esch, B. Unsteady characteristics of tip leakage vortex structure and dynamics in an axial flow pump. Ocean Eng. 2022, 266, 112850. [Google Scholar] [CrossRef]

- Li, H.; Huang, Q.; Pan, G.; Dong, X. The scale effects on the open water performance of a pump-jet propulsor. J. Mar. Sci. Technol. 2021, 27, 348–367. [Google Scholar] [CrossRef]

- Donyavizadeh, N.; Ghadimi, P. Numerical investigation of the effect of tip clearance on hydrodynamic performance of the linear jet propulsion system and vortex generation behind the rotor. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 2395–2407. [Google Scholar] [CrossRef]

- Jiang, J.-W.; Wang, W.-Q.; Chen, K.; Huang, W.-X. Large-eddy simulation of three-dimensional aerofoil tip-gap flow. Ocean Eng. 2022, 243, 110315. [Google Scholar] [CrossRef]

- Lu, L.; Gao, Y.; Li, Q.; Du, L. Numerical investigations of tip clearance flow characteristics of a pumpjet propulsor. Int. J. Nav. Archit. Ocean Eng. 2018, 10, 307–317. [Google Scholar] [CrossRef]

- Lu, L.; Pan, G.; Wei, J.; Pan, Y. Numerical simulation of tip clearance impact on a pumpjet propulsor. Int. J. Nav. Archit. Ocean Eng. 2016, 8, 219–227. [Google Scholar] [CrossRef]

- Lu, L.; Pan, G.; Sahoo, P.K. Sahoo. CFD prediction and simulation of a pumpjet propulsor. Int. J. Nav. Archit. Ocean Eng. 2016, 8, 110–116. [Google Scholar] [CrossRef]

- Qin, D.; Pan, G.; Huang, Q.; Zhang, Z.; Ke, J. Numerical investigation of different tip clearances effect on the hydrodynamic performance of pumpjet propulsor. Int. J. Comput. Methods 2018, 15, 1850037. [Google Scholar] [CrossRef]

- Li, H.; Pan, G.; Huang, Q.; Shi, Y. Numerical prediction of the pumpjet propulsor tip clearance vortex cavitation in uniform flow. J. Shanghai Jiaotong Univ. (Sci.) 2020, 25, 352–364. [Google Scholar] [CrossRef]

- Qiu, C.; Pan, G.; Huang, Q.; Shi, Y. Numerical analysis of unsteady hydrodynamic performance of pump-jet propulsor in oblique flow. Int. J. Nav. Archit. Ocean Eng. 2020, 12, 102–115. [Google Scholar] [CrossRef]

- Ahn, S.J.; Kwon, O.J. Numerical investigation of a pump-jet with ring rotor using an unstructured mesh technique. J. Mech. Sci. Technol. 2015, 29, 2897–2904. [Google Scholar] [CrossRef]

- Yang, X.L.; Long, X.P. Numerical investigation on the jet pump performance based on different turbulence models. IOP Conf. Ser. Earth Environ. Sci. 2012, 15, 052019. [Google Scholar] [CrossRef]

- Zwart, P.J.; Gerber, A.G.; Belamri, T. A two-phase flow model for predicting cavitation dynamics. In Proceedings of the Fifth International Conference on Multiphase Flow, Yokohama, Japan, 30 May–3 June 2004; Volume 152. [Google Scholar]

- Kim, H.H.; Rakibuzzaman, M.; Kim, K.; Suh, S.H. Flow and fast fourier transform analyses for tip clearance effect in an operating Kaplan turbine. Energies 2019, 12, 264. [Google Scholar] [CrossRef]

| Item | Index |

|---|---|

| Rim diameter D1 | 170 mm |

| hub diameter D2 | 60 mm |

| Design mass flow | 531 kg/s |

| Number of rotor blades Z1 | 3 |

| Number of stator blades Z2 | 5 |

| Scheme | Grid Total | Head/m | Minimum Volume/m3 |

|---|---|---|---|

| 1 | 6,054,015 | 97.74 | 4.1179 × 10−15 |

| 2 | 8,831,030 | 99.32 | 3.5661 × 10−15 |

| 3 | 9,875,584 | 100.47 | 3.2632 × 10−15 |

| 4 | 11,001,471 | 101.15 | 2.9335 × 10−15 |

| 5 | 12,849,631 | 101.17 | 2.7423 × 10−15 |

| 6 | 13,426,552 | 101.18 | 2.5366 × 10−15 |

| 7 | 13,952,137 | 101.17 | 2.4520 × 10−15 |

| Instrument | Range | Precision |

|---|---|---|

| DN125 Electromagnetic flowmeter | 0–9999 m3/h | ±5% |

| Permanent magnet synchronous high-speed servo motor | 20,000 r/min; 110 kW; 52.5 N·m | ±5% |

| Vibration test bench and TPA | 0.1–10,000 Hz | ±3‰ |

| Tip-Clearances | Sum of Gas Phase | Sum of Water Phase | Percentage |

|---|---|---|---|

| 0.2 | 157,696 | 1.36245 × 106 | 11.57% |

| 0.5 | 193,593 | 1.72536 × 106 | 11.22% |

| 0.8 | 157,696 | 1.32126 × 106 | 9.37% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, G.; Duan, Y.; Yi, J.; Fu, Q.; Zhu, R.; Shi, W. Effect of Tip Clearance on the Cavitation Performance of High-Speed Pump-Jet Propeller. Processes 2023, 11, 3050. https://doi.org/10.3390/pr11113050

Gan G, Duan Y, Yi J, Fu Q, Zhu R, Shi W. Effect of Tip Clearance on the Cavitation Performance of High-Speed Pump-Jet Propeller. Processes. 2023; 11(11):3050. https://doi.org/10.3390/pr11113050

Chicago/Turabian StyleGan, Gongchang, Yuchen Duan, Jinbao Yi, Qiang Fu, Rongsheng Zhu, and Wenhao Shi. 2023. "Effect of Tip Clearance on the Cavitation Performance of High-Speed Pump-Jet Propeller" Processes 11, no. 11: 3050. https://doi.org/10.3390/pr11113050

APA StyleGan, G., Duan, Y., Yi, J., Fu, Q., Zhu, R., & Shi, W. (2023). Effect of Tip Clearance on the Cavitation Performance of High-Speed Pump-Jet Propeller. Processes, 11(11), 3050. https://doi.org/10.3390/pr11113050