An Automatic Welding Robot for the Roof of Spiral Steel Silo

Abstract

:1. Introduction

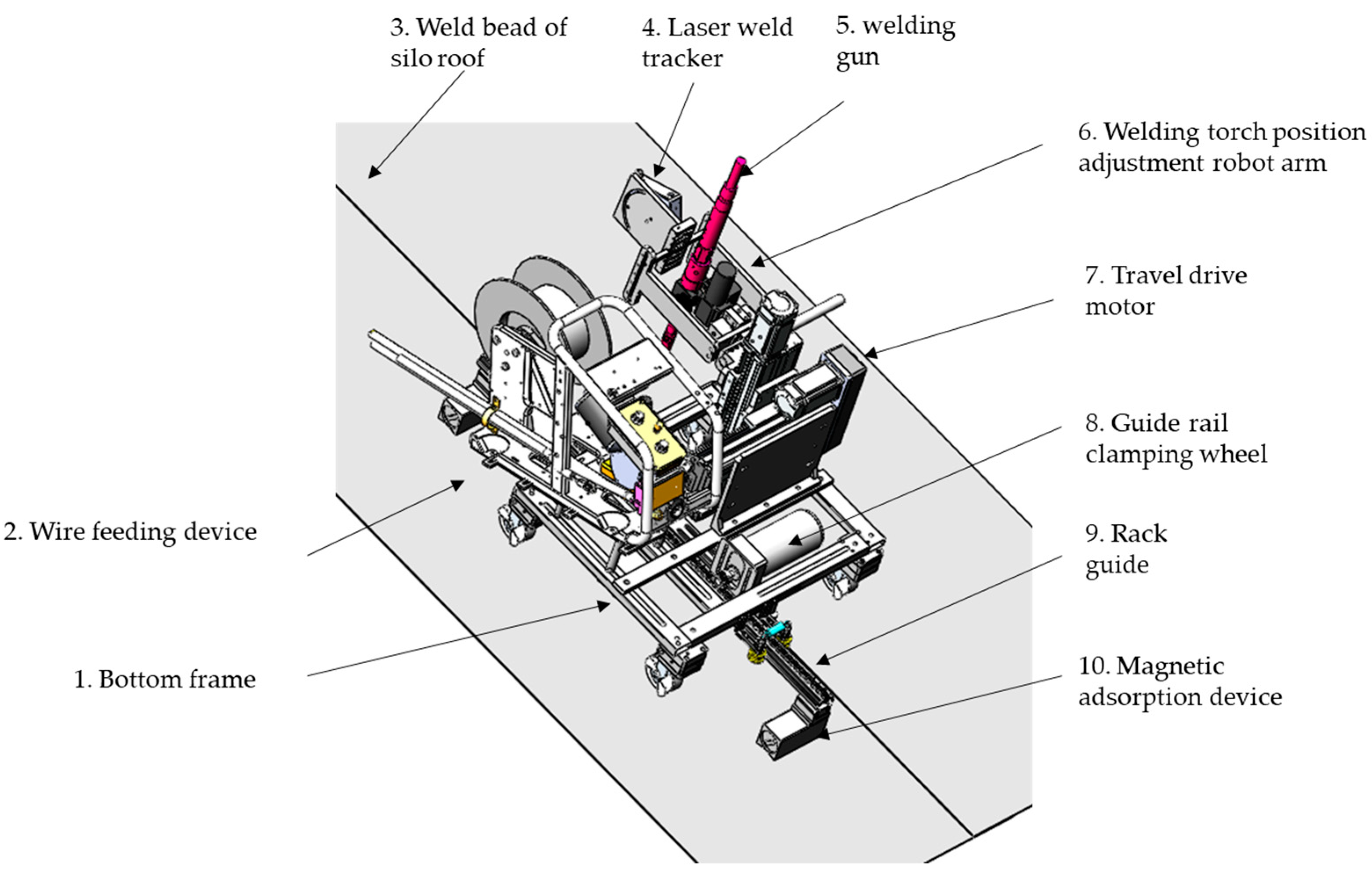

- The structural design of the prototype was carried out for the weld bead characteristics of the spiral steel silo and special welding conditions at the roof of the silo.

- In this paper, material properties and the weldability of the roof for a spiral steel silo were analyzed, the welding process experiment of a spiral steel silo was carried out, and appropriate welding process parameters were selected.

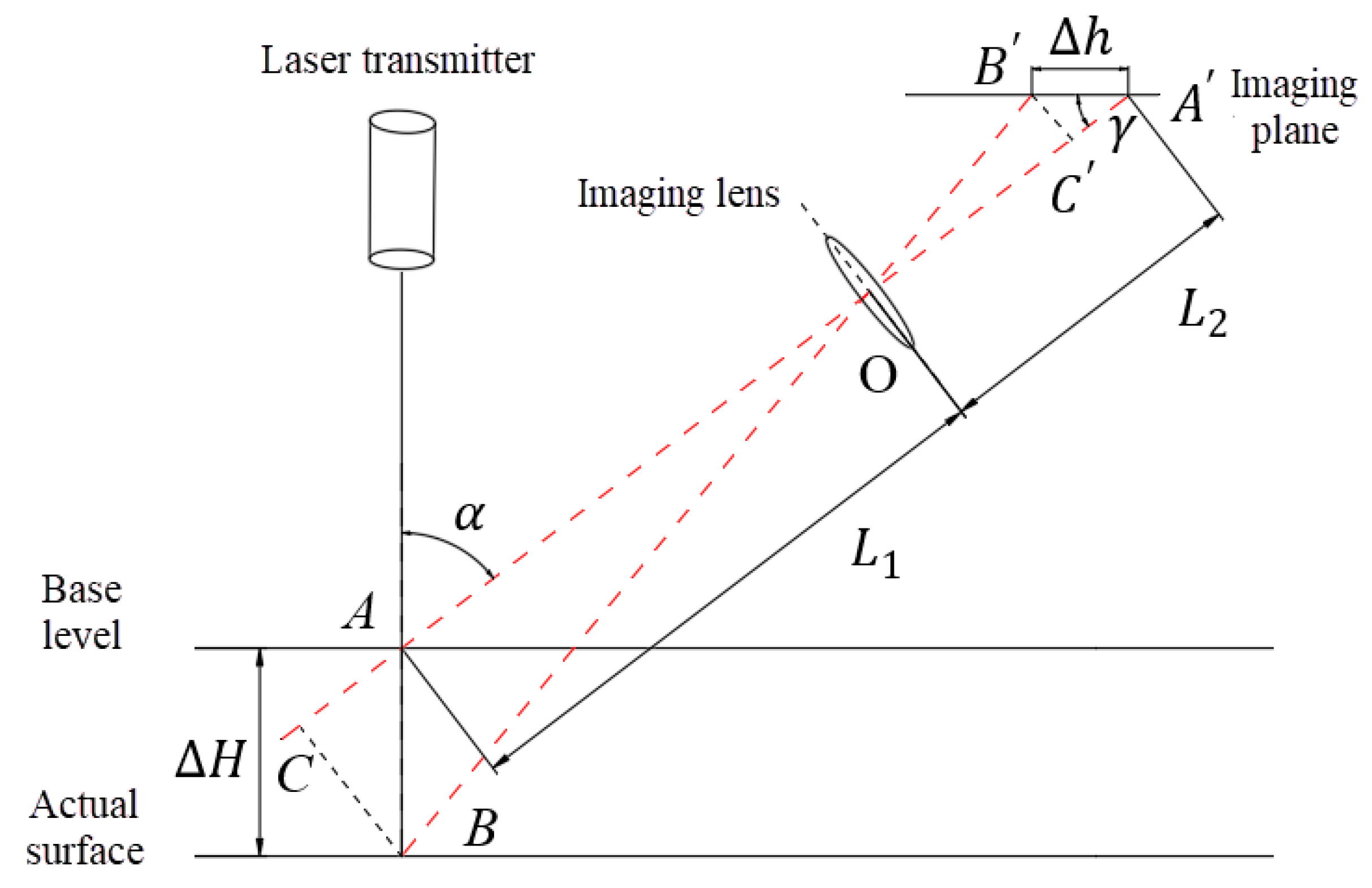

- Critical technologies for monitoring the weld bead on the roof of a spiral steel silo were investigated, and the structural light detection principle of the laser weld bead sensor was analyzed. The principles of related algorithms consisting of weld bead image enhancement, image filtering, binarization processing, and Harris corner detection processing based on Halcon were studied, and least squares polynomials were used to fit the weld bead trajectory.

- Finally, weld-tracking experiments and prototype-welding experiments were carried out, and the experimental results were analyzed. The results suggest that the prototype has a certain stability and accuracy in tracking the weld bead.

2. Materials and Methods

2.1. Weld Bead Characteristics and Welding Process at the Roof of Spiral Steel Silo

2.1.1. Characteristics of Roof of Steel Silo

2.1.2. Determination of Welding Process

- Welding current and voltage test

- Experimental process

The welding current and voltage test which includes 12 groups of welding tests, as shown in Table 1.- ii.

- Analysis of experimental results

After the completion of the welding test, an average of 12 points were selected for each weld path, and the height and width of each spot weld path were measured, respectively. The point-line diagrams were drawn according to data of the measurement points, and the comparisons of experimental data are shown in Figure 3.

- 2.

- Distance test between conductive nozzle and base metal

- i.

- The experimental process

Based on the previous experimental results, four sets of experiments were carried out by adjusting the welding current and voltage to optimum values, and the data obtained are shown in Table 2.- ii.

- Analysis of experimental results

Consistent with the analysis method of the current and voltage experimental results mentioned above, measurement points were selected, and point line diagrams were drawn. The curve of the height and width of the weld pass is shown in Figure 4.

2.2. Mechanical Structure

2.3. Key Technologies of Welding Seam Tracking at the Roof of Spiral Steel Silo

2.3.1. Principle of Structured Light Detection

2.3.2. Image Processing

- Image graying

- 2.

- Median filtering

- 3.

- Image binarization

- 4.

- Feature point detection

- 5.

- Trajectory fitting

3. Results

3.1. Weld Tracking Test

3.2. Welding Test

4. Discussion

5. Conclusions

- Considering the special working condition of the spiral steel plate silo roof, we developed a rail-type crawling robot, which is a good solution to this problem.

- Welding process parameter tests were implemented to determine the optimal parameters for welding: a current of 200 A, voltage of 20 V, and a distance of 12 mm between the conductive nozzle and the base material.

- The principal algorithms of image processing of weld beads were investigated, then the weld bead feature points were successfully identified and extracted using the principle of the Harris corner point detection algorithm, and finally, the trajectories were fitted using the least squares method.

- Finally, the weld tracking experiments and the prototype welding test were carried out. The weld tracking test showed that the tracking error of the weld bead was small. The mean absolute error in the horizontal positioning of the welding gun was 0.38 mm, and the maximum absolute error was 0.63 mm. The mean absolute error of the vertical positioning of the welding gun was 0.67 mm, and the maximum error was 1.18 mm. The results show that the tracking and positioning of the prototype for the weld bead are accurate. The welding test for the prototype shows that the welding process is stable and the welding effect is good.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Wang, H.; Yang, J.; Wang, F. A novel vertical waterproofing joint with trapezoidal steel plate connections for steel–concrete underground silos: Bending test and numerical simulation. Tunn. Undergr. Space Technol. 2023, 137, 105150. [Google Scholar] [CrossRef]

- Wójcik, M.; Sondej, M.; Rejowski, K.; Tejchman, J. Full-scale experiments on wheat flow in steel silo composed of corrugated walls and columns. Powder Technol. 2017, 311, 527–555. [Google Scholar] [CrossRef]

- Yan, R.; Chen, Z.; Wang, X. Structural Design and Stability Analysis of Large Welded Coal Storage Steel Plate Warehouse. Ind. Archit. 2014, 44, 158–165, 180. [Google Scholar] [CrossRef]

- Gao, B.; Wei, L. Discussion on the Construction Technology of Spiral Steel Plate Warehouse. Qinghai Sci. Technol. 2009, 16, 78–81. [Google Scholar]

- Zhou, X. Research on Roll Forming Technology and Unit Design of 50-Type Spiral Steel Silo. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2020. [Google Scholar]

- Sun, J. Analysis on development of welding automation technology. Sci. Consult. (Sci. Technol. Adm.) 2021, 68–69. [Google Scholar]

- Li, D.; Fu, T.; Yuan, Z.; Liu, Z.; Su, Y. Application status and development trend of domestic welding technology. Mod. Weld. 2008, 1, 5. [Google Scholar]

- Li, L.; Lin, B.; Zou, Y. Study on Seam Tracking System Based on Stripe Type Laser Sensor and Welding Robot. Chin. J. Lasers 2015, 42, 34–41. [Google Scholar]

- Rui, C.; Mcclamroch, N.H. Stabilization and Asymptotic Path Tracking of a Rolling Disk. In Proceedings of the IEEE Conference on Decision & Control, Kobe, Japan, 13 December 1996. [Google Scholar]

- Hong, J.; Zhao, H.; Zhang, K. Research on the welding process of tubular joints of pile legs of truss offshore platforms. China Water Transp. (Second. Half Mon.) 2014, 14, 340–341. [Google Scholar]

- Kam, B.O.; Jeon, Y.B.; Kim, S.B. Motion Control of Two-Wheeled Welding Mobile Robot with Seam Tracking Sensor. In Proceedings of the IEEE International Symposium on Industrial Electronics, Rio de Janeiro, Brazil, 9–11 June 2003. [Google Scholar]

- Park, J.-H.; Moon, H.-S. Advanced Automatic Welding System for Offshore Pipeline System with Seam Tracking Function. Appl. Sci. 2020, 101, 324. [Google Scholar] [CrossRef]

- Hascoet, J.Y.; Hamilton, K.; Carabin, G.; Rauch, M.; Alonso, M.; Ares, E. Shiphull Welding: Trajectory Generation Strategies Using a Retrofit Welding Robot. Mater. Sci. Forum 2012, 713, 115–120. [Google Scholar] [CrossRef]

- Guo, J.; Zhu, Z.; Sun, B.; Zhang, T. A novel field box girder welding robot and realization of all-position welding process based on visual servoing. J. Manuf. Process. 2021, 63, 70–79. [Google Scholar] [CrossRef]

- Li, A.M.; Zhang, C.H.; Li, H.L.; Xu, Z.Y.; Chen, X.H.; Qin, G.L.; Ye, S.W. Design of Automatic Welding Machine Based on PLC. In Proceedings of the International Conference on Intelligent Computation Technology & Automation, Shenzhen, China, 28–29 March 2011; IEEE: Piscataway, NY, USA, 2011. [Google Scholar] [CrossRef]

- Silva, M.F.; Barbosa, R.S.; Oliveira, A.L.C. Climbing Robot for Ferromagnetic Surfaces with Dynamic Adjustment of the Adhesion System. J. Robot. 2012, 2012, 906545. [Google Scholar] [CrossRef]

- Xu, Y.; Fu, W. Research on Coupling Adsorption Experiments for Wall–Climbing Robots in Coal Mine Shafts. Processes 2023, 11, 2016. [Google Scholar] [CrossRef]

- Lu, H.; Ma, M.; Liu, S.; Alghannam, E.; Zang, Y.; Li, S.; Zhang, W. Visual-Based Multi-Section Welding Path Generation Algorithm. Processes 2020, 8, 821. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.; Pyo, C. A Study on Fiber Laser Welding of High-Manganese Steel for Cryogenic Tanks. Processes 2020, 8, 1536. [Google Scholar] [CrossRef]

- Hu, S. Welding Automation Technology and Its Application; China Machine Press: Beijing, China, 2015. [Google Scholar]

- Chen, S. Welding Automation Technology; Science Press: Beijing, China, 2020. [Google Scholar]

- Qiu, Y.; Nie, Z.; Lei, Z. Practical Technical Manual for Welders; China Electric Power Press: Beijing, China, 2008. [Google Scholar]

- Yan, M.; Peng, X. Fundamentals of Magnetics and Magnetic Materials, 2nd ed.; Zhejiang University Press: Hangzhou, Chian, 2019. [Google Scholar]

- Shen, Q.; Zhang, J.; Gen, L.I. Optimized Design of Magnetic Adsorption Unit for Wall-Climbing Robots Based on Halbach Array. Light Ind. Mach. 2014, 32, 17–21. [Google Scholar]

- Zhang, X. Design of magnetic circuit (I)-static part of permanent magnet. Instrum. Mater. 1974, 55–71. [Google Scholar]

- Song, H.; Chen, P. Permanent Magnet Materials and Their Applications; Cambridge University Press: Cambridge, UK, 1984. [Google Scholar]

- Hao, W. Research on Automatic Weld Seam Tracking System Based on Machine Vision. Ph.D. Thesis, China University of Mining d Technology, Xuzhou, China, 2017. [Google Scholar]

- Yang, Q. Halcon Machine Vision Algorithms Principle and Programming Practice; Peking University Press: Beijing, China, 2019. [Google Scholar]

- Hao, L.; Xu, C.; Wang, D. Weld extraction based on least squares polynomial fitting method. Electron. Des. Eng. 2020, 28, 5. [Google Scholar]

| Test | Welding Voltage (V) | Welding Current (A) | Welding Speed (cm/min) | Wire Diameter (mm) | Distance (mm) | Gas Flow (L/min) |

|---|---|---|---|---|---|---|

| 1 | 16 | 150 | 40 | 1.2 | 12 | 12 |

| 2 | 160 | 40 | 1.2 | 12 | 12 | |

| 3 | 170 | 40 | 1.2 | 12 | 12 | |

| 4 | 18 | 170 | 40 | 1.2 | 12 | 12 |

| 5 | 180 | 40 | 1.2 | 12 | 12 | |

| 6 | 190 | 40 | 1.2 | 12 | 12 | |

| 7 | 20 | 190 | 40 | 1.2 | 12 | 12 |

| 8 | 200 | 40 | 1.2 | 12 | 12 | |

| 9 | 210 | 40 | 1.2 | 12 | 12 | |

| 10 | 22 | 210 | 40 | 1.2 | 12 | 12 |

| 11 | 220 | 40 | 1.2 | 12 | 12 | |

| 12 | 230 | 40 | 1.2 | 12 | 12 |

| Test | Distance (mm) | Welding Voltage (V) | Welding Current (A) | Welding Speed (cm/min) | Wire Diameter (mm) | Gas Flow (L/min) |

|---|---|---|---|---|---|---|

| 1 | 10 | 20 | 200 | 40 | 1.2 | 12 |

| 2 | 12 | |||||

| 3 | 14 | |||||

| 4 | 16 |

| NO. | X Actual Upper Computer | Y | Z Actual Upper Computer | ||

|---|---|---|---|---|---|

| 1 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 2 | 0.12 | 0.53 | 2.03 | 0.35 | 0.99 |

| 3 | 0.28 | 0.79 | 4.01 | 0.65 | 1.23 |

| 4 | 0.98 | 1.23 | 6.12 | 1.28 | 1.79 |

| 5 | 1.65 | 1.15 | 8.11 | 1.98 | 1.34 |

| 6 | 2.03 | 1.65 | 10.03 | 2.01 | 2.79 |

| 7 | 2.35 | 1.75 | 12.06 | 2.36 | 3.11 |

| 8 | 2.68 | 2.05 | 14.11 | 2.78 | 3.54 |

| 9 | 3.06 | 2.68 | 16.05 | 3.05 | 3.89 |

| 10 | 3.16 | 2.98 | 18.13 | 3.18 | 4.36 |

| Mean absolute error | 0.38 | 0.00 | 0.67 | ||

| Maximum absolute error | 0.63 | 0.00 | 1.18 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yuan, H.; Cao, W.; Zhang, D.; Peng, X.; Yang, Z. An Automatic Welding Robot for the Roof of Spiral Steel Silo. Processes 2023, 11, 3049. https://doi.org/10.3390/pr11113049

Zhang Y, Yuan H, Cao W, Zhang D, Peng X, Yang Z. An Automatic Welding Robot for the Roof of Spiral Steel Silo. Processes. 2023; 11(11):3049. https://doi.org/10.3390/pr11113049

Chicago/Turabian StyleZhang, Yuying, Hao Yuan, Wenwu Cao, Dong Zhang, Xudong Peng, and Zhixian Yang. 2023. "An Automatic Welding Robot for the Roof of Spiral Steel Silo" Processes 11, no. 11: 3049. https://doi.org/10.3390/pr11113049

APA StyleZhang, Y., Yuan, H., Cao, W., Zhang, D., Peng, X., & Yang, Z. (2023). An Automatic Welding Robot for the Roof of Spiral Steel Silo. Processes, 11(11), 3049. https://doi.org/10.3390/pr11113049