Molecular Simulation of Adsorption Separation of CO2 from Combustion Exhaust Mixture of Commercial Zeolites

Abstract

:1. Introduction

2. Computational Methods and Details

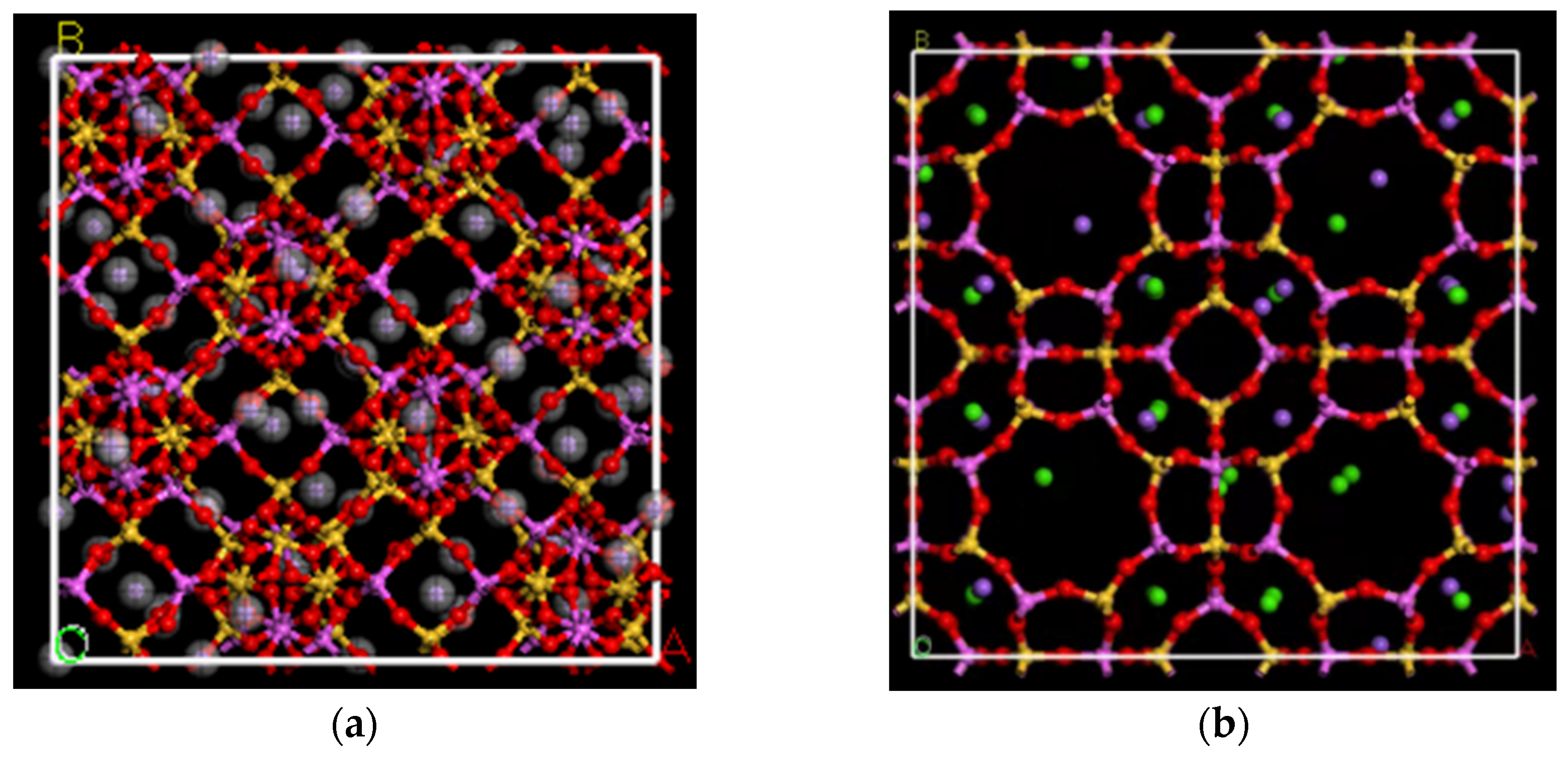

2.1. Models

2.2. Adsorbate–Adsorbent Interaction Potential

2.3. Molecular Simulation Methods

2.3.1. GCMC Simulations

2.3.2. EMD Simulations

3. Results

3.1. Validation of Model and Simulation

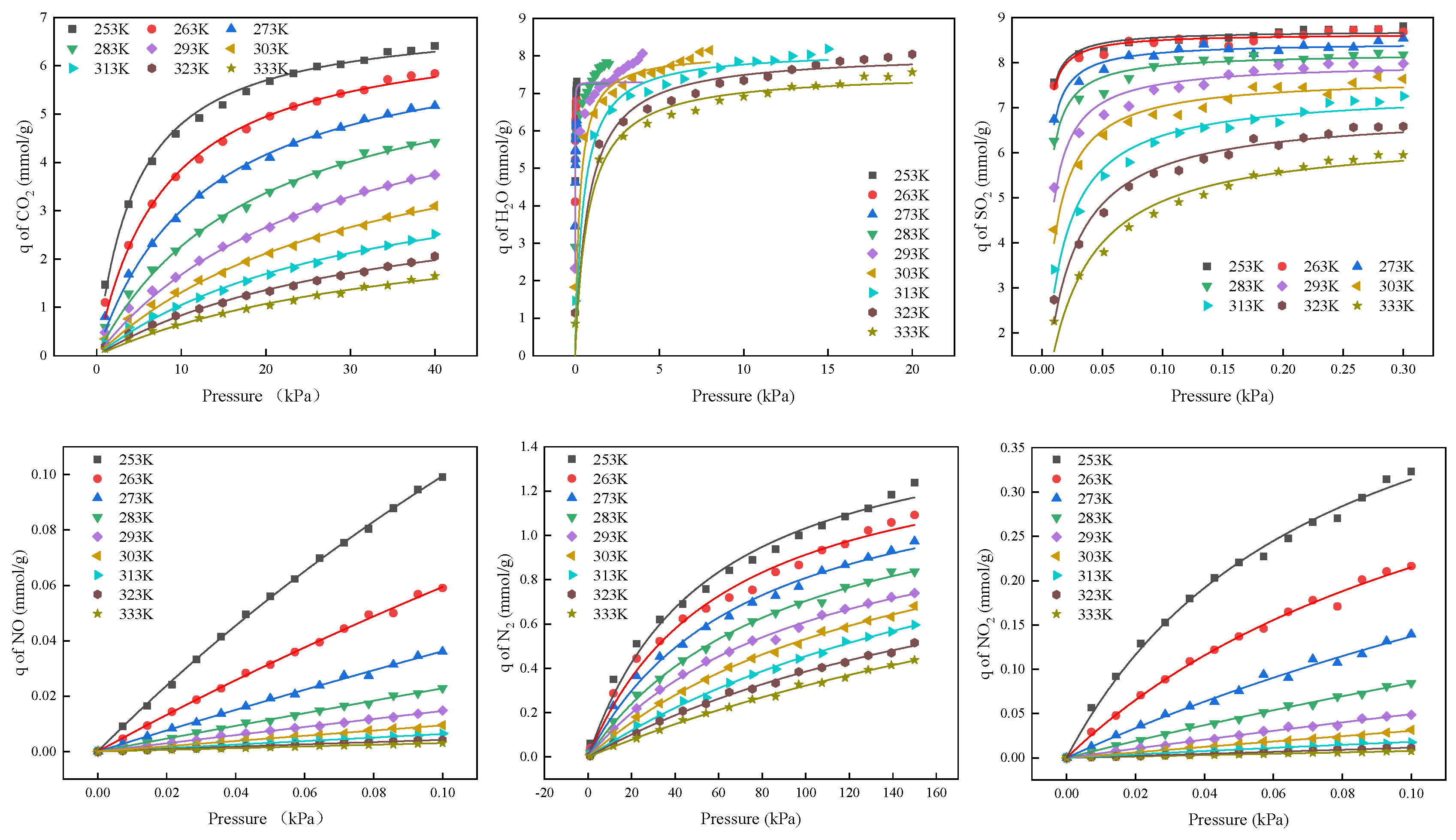

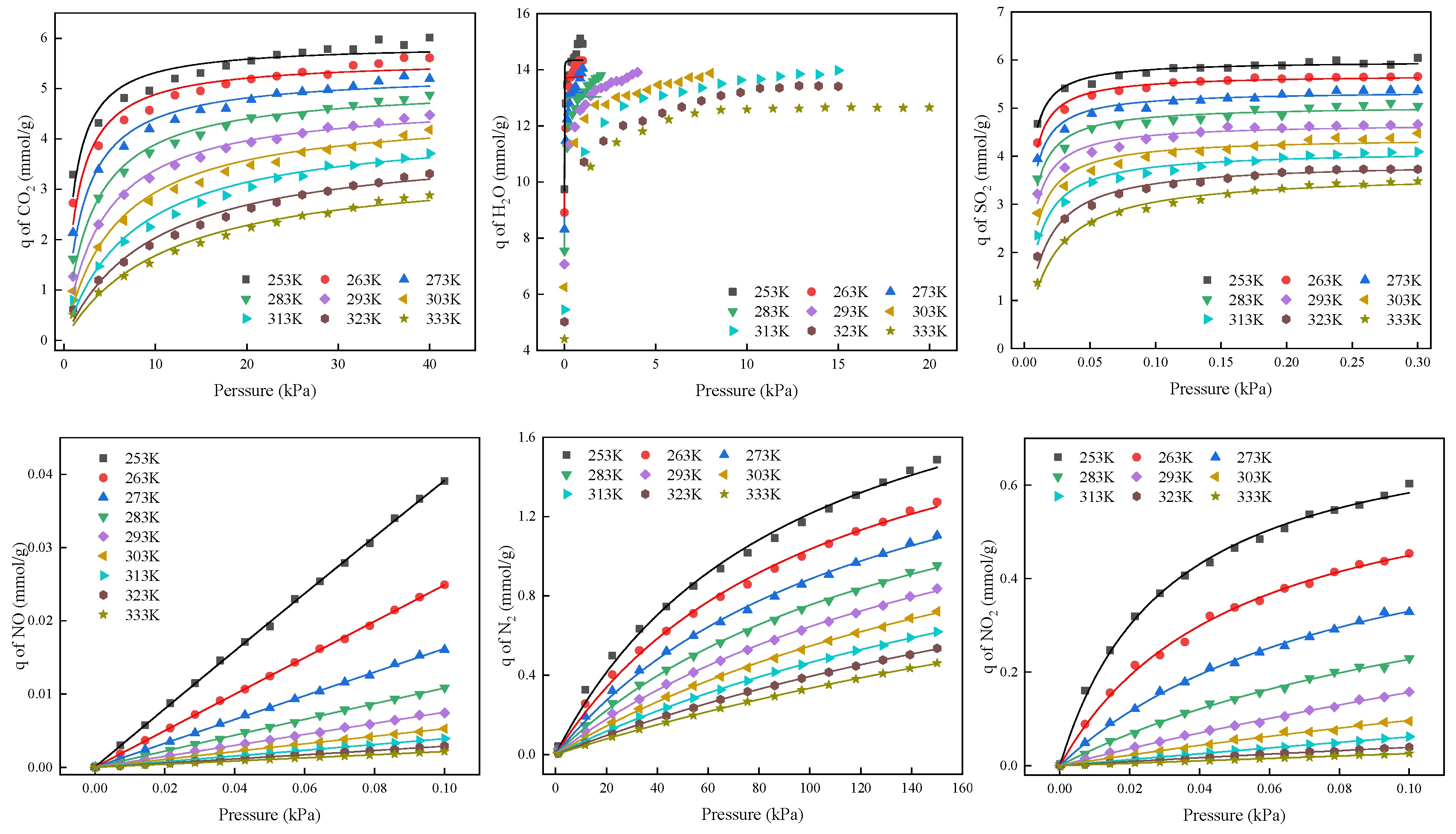

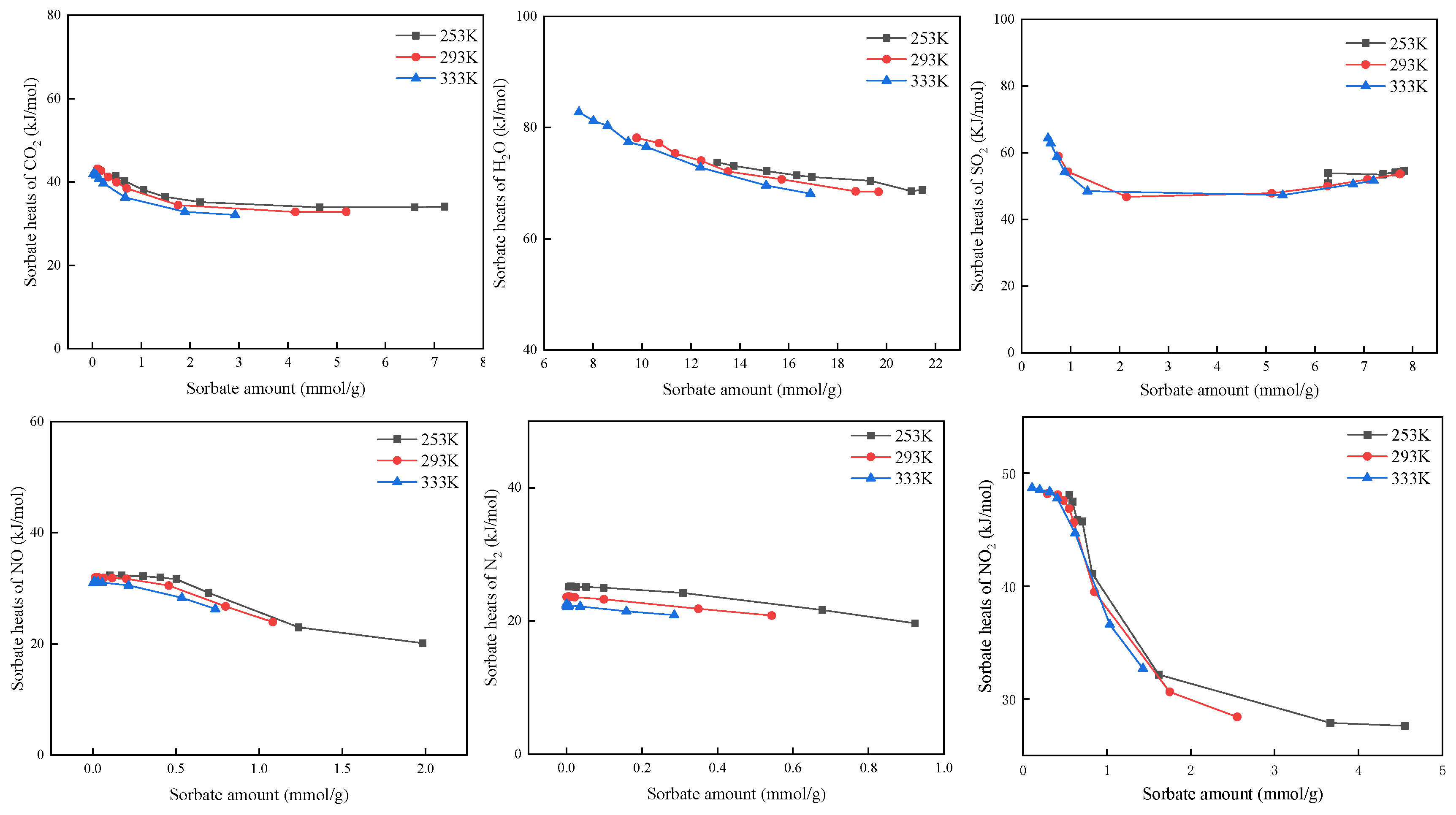

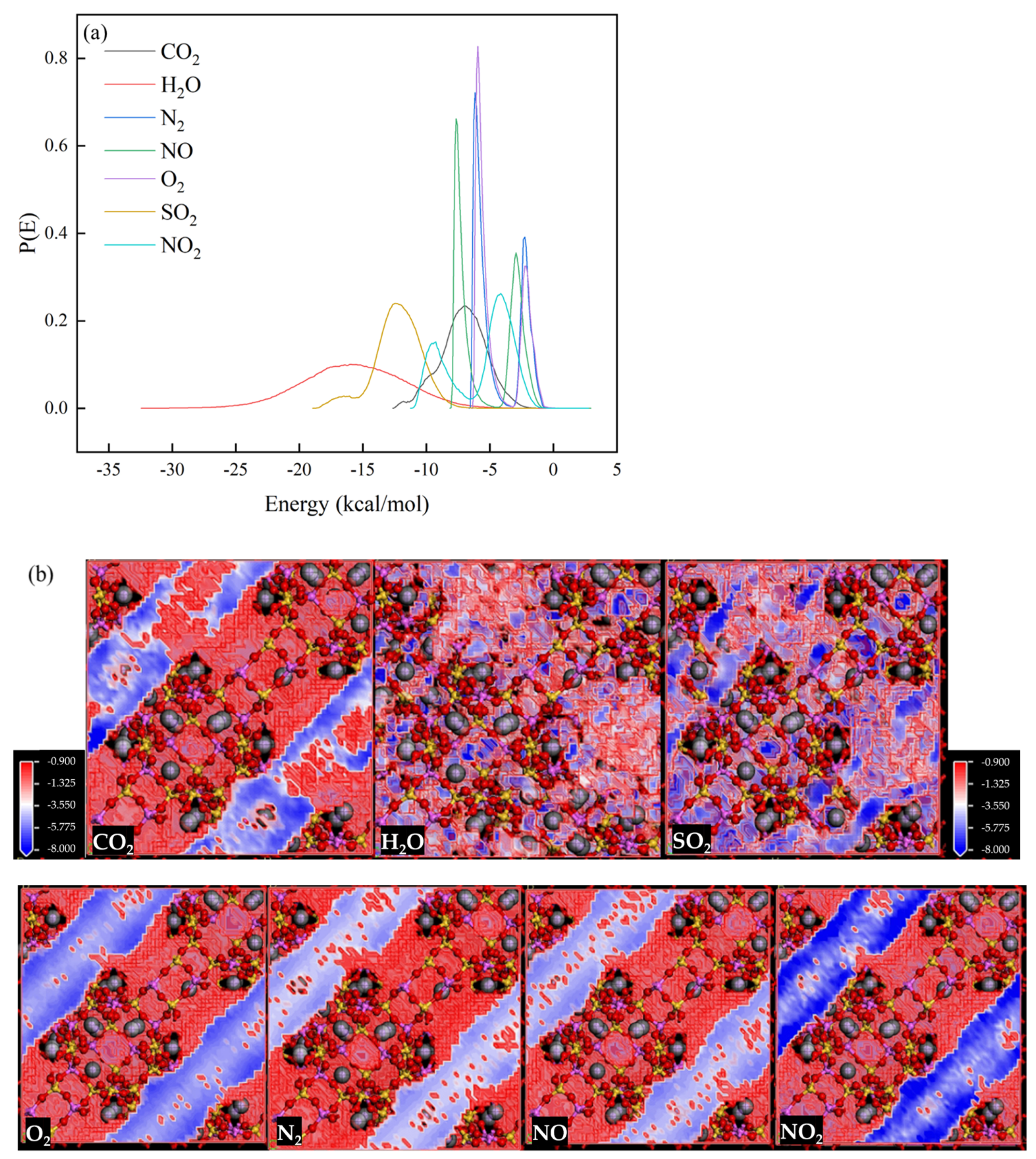

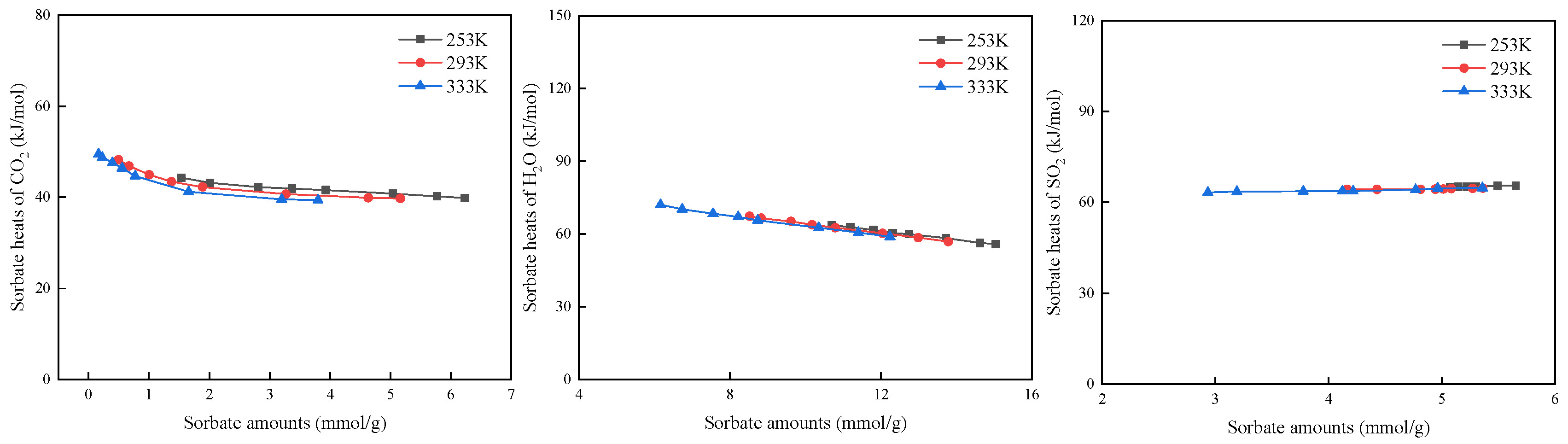

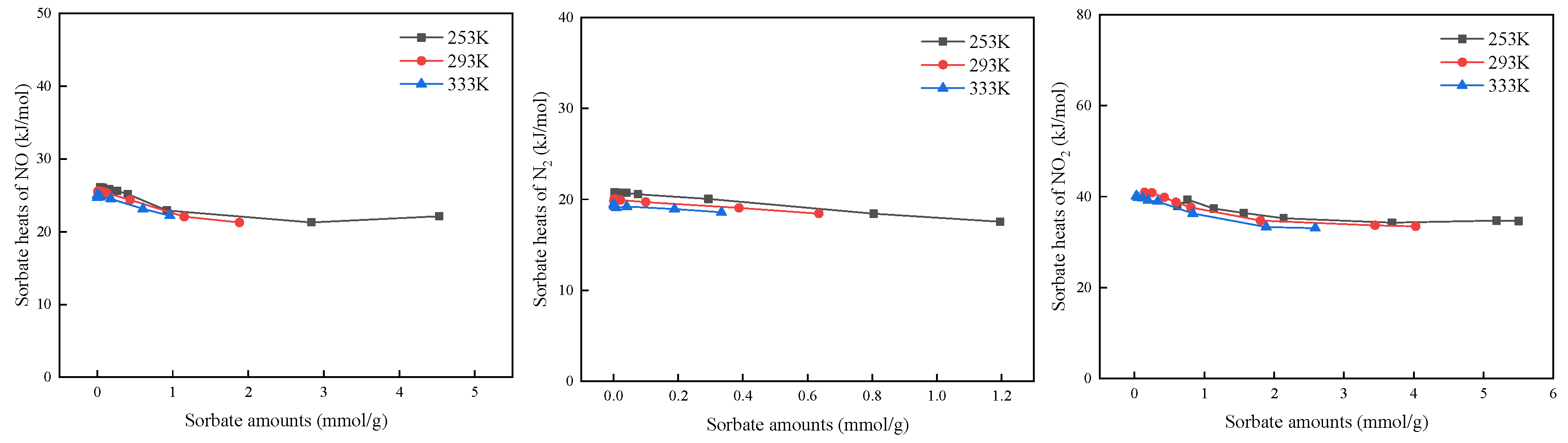

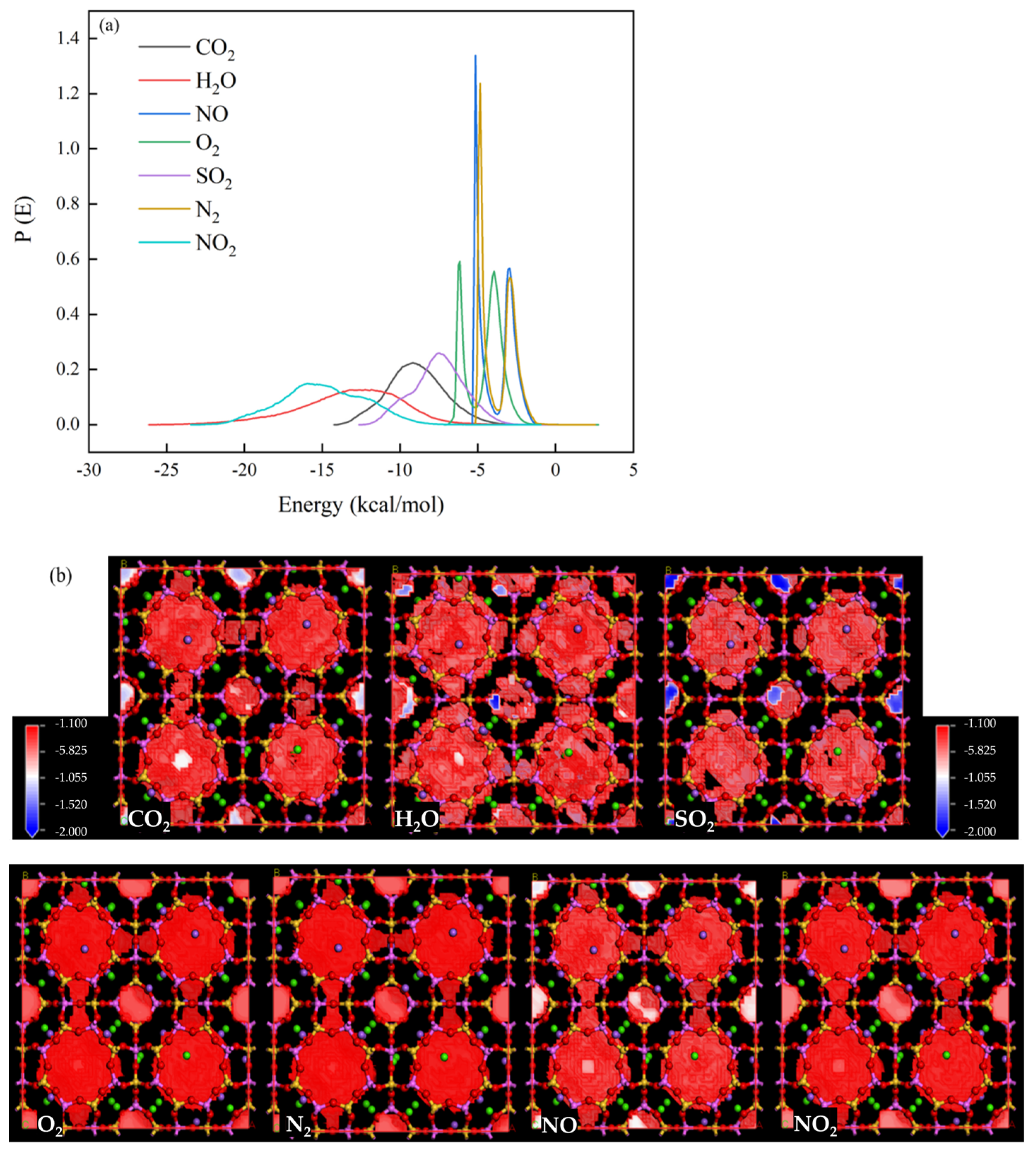

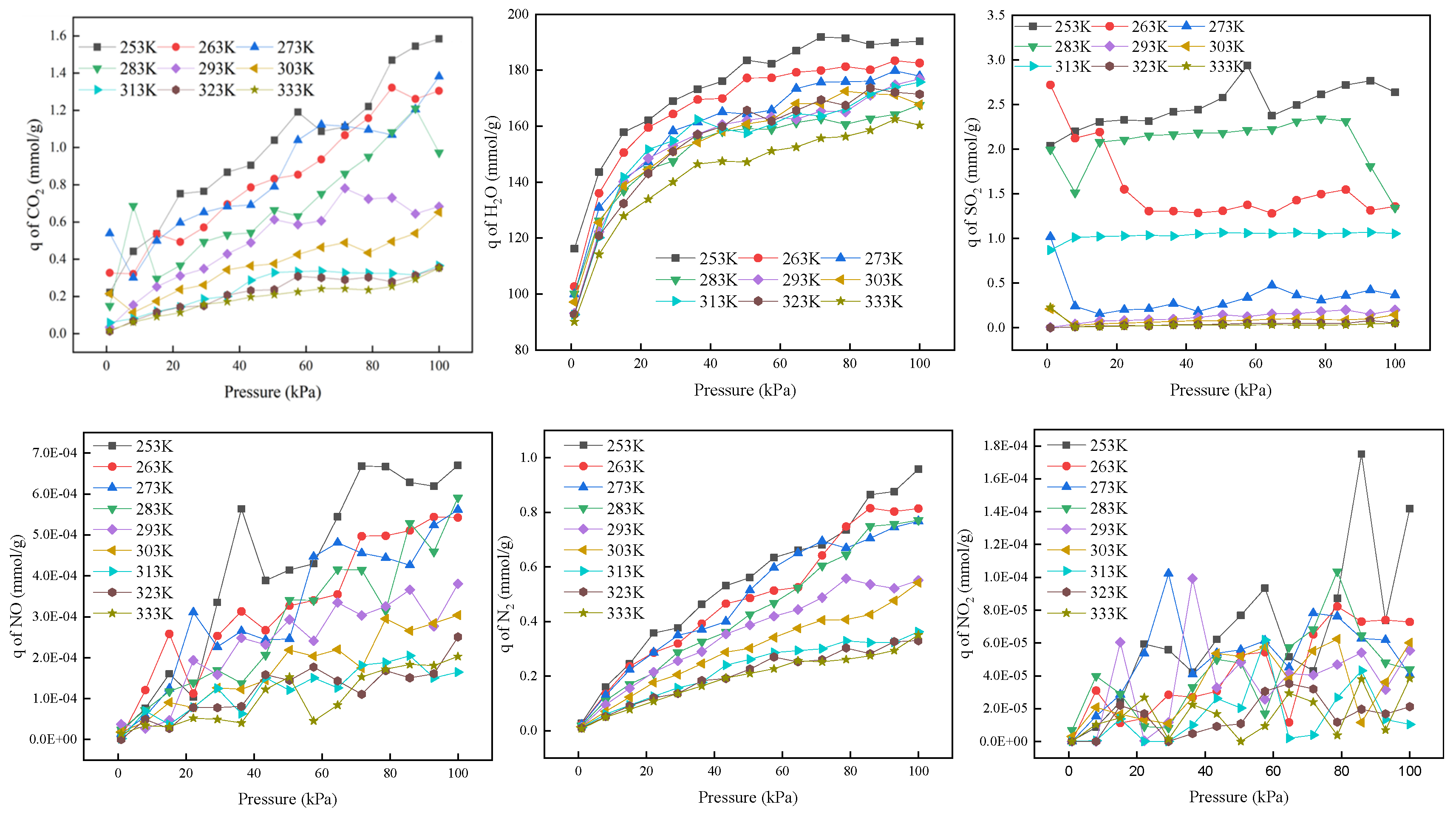

3.2. Adsorption Isotherms and Equilibrium Parameters of Pure Components

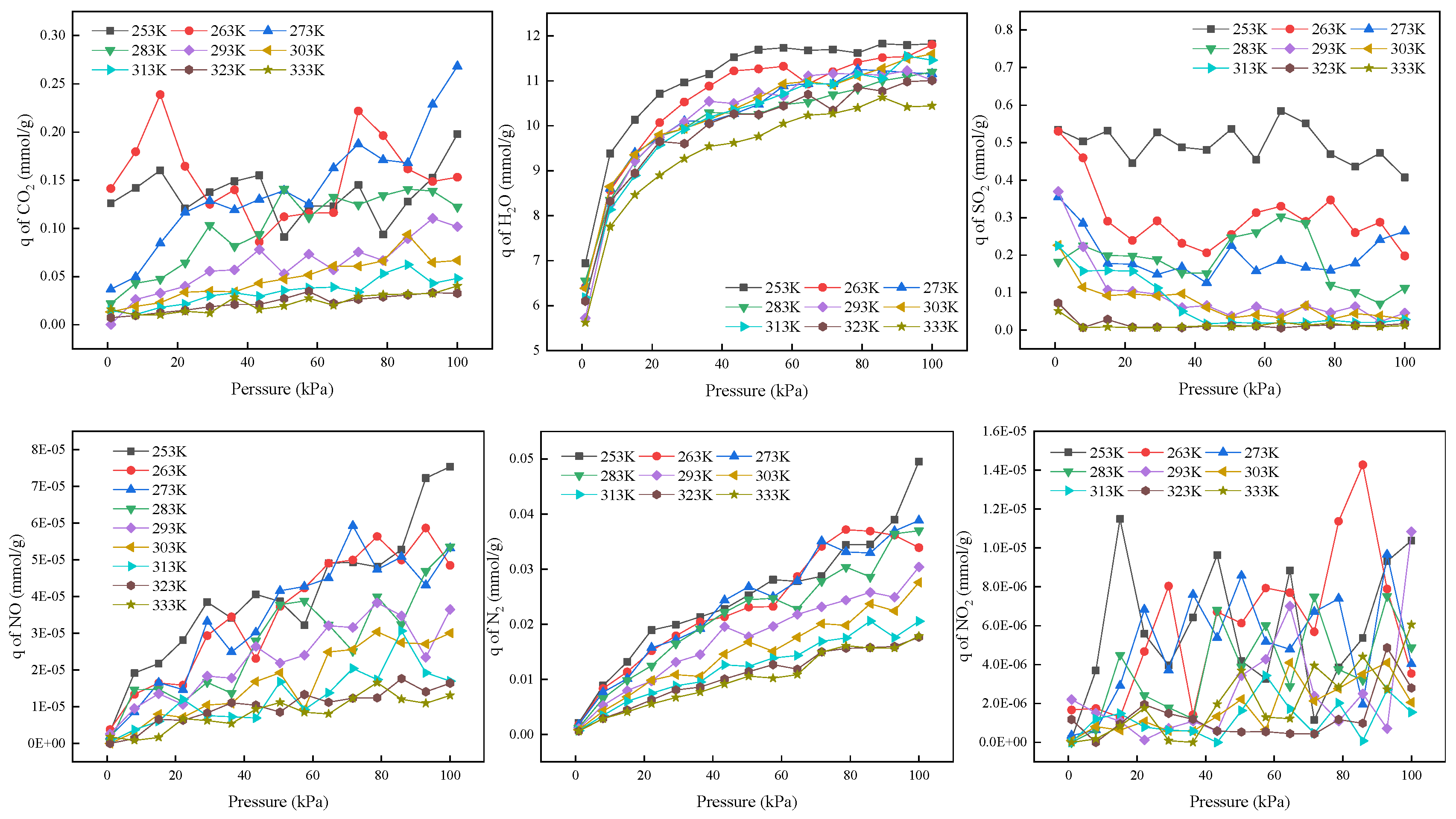

3.3. Adsorption Isotherms and Equilibrium Parameters in Mixture

3.4. Self-Diffusion from Mixture

3.5. Adsorption Selectivity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ritchie, H.; Roser, M.; Rosado, P. CO2 and Greenhouse Gas Emissions. Publishing Our World in Data. 2020. Available online: https://ourworldindata.org/co2-emissions?utm_source=tri-city%20news&utm_campaign=tricity%20news%3A%20outbound&utm_medium=referral (accessed on 1 August 2020).

- Satyapal, S.; Filburn, T.; Trela, J. Performance and properties of a solid amine sorbent for carbon dioxide removal in space life support applications. Energy Fuel 2001, 15, 250–255. [Google Scholar] [CrossRef]

- Kapdi, S.S.; Vijay, V.K.; Rajesh, S.K.; Prasad, R. Biogas scrubbing, compression and storage: Perspective and prospectus in Indian context. Renew. Energy 2001, 30, 1195–1202. [Google Scholar] [CrossRef]

- Chue, K.T.; Kim, J.N.; Yoo, Y.J.; Cho, S.H.; Yang, R.T. Comparison of activated carbon and zeolite 13X for CO2 recovery from flue gas by pressure swing adsorption. Ind. Eng. Chem. Res. 1995, 34, 591–598. [Google Scholar] [CrossRef]

- Mcewen, J.; Hayman, J.D.; Yazaydin, A.O. A comparative study of CO2, CH4 and N2 adsorption in ZIF-8, Zeolite-13X and BPL activated carbon. Chem. Phys. 2013, 412, 72–76. [Google Scholar] [CrossRef]

- Akhtar, F.; Liu, Q.L.; Hedin, N.; Bergström, L. Strong and binder free structured zeolite sorbents with very high CO2-over-N2. Energy Environ. Sci. 2012, 5, 7664–7673. [Google Scholar] [CrossRef]

- Raksajati, A.; Ho, M.T.; Wiley, D.E. Reducing the Cost of CO2 Capture From Flue Gases Using Phase-change Solvent Absorption. Energy Procedia 2014, 63, 2280–2288. [Google Scholar] [CrossRef]

- Liu, Z.; Li, X.; Shi, D.; Guo, F.Z.; Zhao, G.; Hei, Y.; Xiao, Y.; Zhang, X. Superior Selective CO2 Adsorption and Separation over N2 and CH4 of Porous Carbon Nitride Nanosheets: Insights from GCMC and DFT Simulations. Langmuir 2023, 39, 6613–6622. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Feng, Y.H.; Zhang, X.X. Molecular simulation of CO2/CH4 self- and transport diffusion coefficients in coal. Fuel 2014, 165, 19–27. [Google Scholar] [CrossRef]

- Wang, Y.; Levan, M.D. Adsorption Equilibrium of Carbon Dioxide and Water Vapor on Zeolites 5A and 13X and Silica Gel: Pure Components. J. Chem. Eng. Data 2009, 54, 2839–2844. [Google Scholar] [CrossRef]

- Hutson, N.D.; Zajic, S.C.; Yang, R.T. Influence of Residual Water on the Adsorption of Atmospheric Gases in Li−X Zeolite: Experiment and Simulation. Ind. Eng. Chem. Res. 2000, 39, 1775–1780. [Google Scholar] [CrossRef]

- Rege, S.U.; Yang, R.T.; Qian, K.Y.; Buzanowski, M.A. Air pre-purification by Pressure Swing Adsorption Using Single/Layered Beds. Chem. Eng. Sci. 2001, 56, 2745–2760. [Google Scholar] [CrossRef]

- Bai, J.L.; Huang, J.M.; Yu, Q.Y.; Demir, M.; Kilic, M.; Altay, B.N.; Hu, X.; Wang, L.L. N-doped porous carbon derived from macadamia nut shell for CO2 adsorption. Fuel Process. Technol. 2023, 249, 107854. [Google Scholar] [CrossRef]

- Bai, J.L.; Huang, J.M.; Jiang, Q.; Jiang, W.H.; Demir, M.; Kilic, M.; Altay, B.N.; Wang, L.L.; Hu, X. Synthesis and characterization of polyphenylene sulfide resin-derived S-doped porous carbons for efficient CO2 capture. Colloids Surf. A Physicochem. Eng. Asp. 2023, 674, 131916. [Google Scholar] [CrossRef]

- Harlick, P.; Tezel, F.H. An experimental adsorbent screening study for CO2 removal from N2. Microporous Mesoporous Mater. 2004, 76, 71–79. [Google Scholar] [CrossRef]

- Li, Y.; Yi, H.; Tang, X.; Li, F.; Yuan, Q. Adsorption separation of CO2/CH4 gas mixture on the commercial zeolites at atmospheric pressure. Chem. Eng. J. 2013, 229, 50–56. [Google Scholar] [CrossRef]

- Fu, D.L.; Davis, M.E. Carbon dioxide capture with zeotype materials. Chem. Soc. Rev. 2022, 51, 9340. [Google Scholar] [CrossRef]

- Li, Z.Y.; Liu, Y.S.; Zhang, C.Z.; Yang, X.; Ren, J.L.; Jiang, L.J. Methane recovery from coal bed gas using modified activated carbons: A combined method for assessing the role of functional groups. Energy Fuels 2015, 29, 6858–6865. [Google Scholar] [CrossRef]

- Bergh, J.V.; Shuai, B.; Vlugt, T.J.; Kapteijn, F. Diffusion in zeolites: Extension of the relevant site model to light gases and mixtures thereof in zeolites DDR, CHA, MFI and FAU. Sep. Purif. Technol. 2010, 73, 151–163. [Google Scholar] [CrossRef]

- Zhang, J.F.; Burke, N.; Zhang, S.C.; Liu, K.Y.; Pervukhina, M. Thermodynamic analysis of molecular simulations of CO2 and CH4 adsorption in FAU zeolites. Chem. Eng. Sci. 2014, 113, 54–61. [Google Scholar] [CrossRef]

- Akten, E.D.; Siriwardane, R.; Sholl, D.S. Monte Carlo simulation of single-and binary component adsorption of CO2, N2, and H2 in zeolite Na-4A. Energy Fuels 2003, 17, 977–983. [Google Scholar] [CrossRef]

- Golchoobi, A.; Pahlavanzadeh, H. Molecular simulation, experiments and modelling of single adsorption capacity of 4A molecular sieve for CO2–CH4 separation. Sep. Sci. Technol. 2016, 51, 2318–2325. [Google Scholar] [CrossRef]

- Prats, H.; Bahamon, D.; Alonso, G.; Giménez, X.; Gamallo, P.; Sayós, R. Optimal Faujasite structures for post combustion CO2 capture and separation in different wing adsorption processes. J. CO2 Util. 2017, 19, 100–111. [Google Scholar] [CrossRef]

- Flanigen, E.M. Chapter 2 Zeolite and molecular sieves. An historical perspective. In Studies in Surface Science & Catalysis; Elsevier: Amsterdam, The Netherlands, 2001; Volume 137, pp. 11–35. [Google Scholar]

- Fu, Y.G.; Liu, Y.S.; Li, Z.Y.; Zhang, Q.L.; Yang, R.T. Insights into adsorption separation of N2/O2 mixture on FAU zeolites under plateau special conditions: A molecular simulation study. Sep. Purif. Technol. 2020, 251, 117405. [Google Scholar] [CrossRef]

- Deng, H.; Yi, H.H.; Tang, X.L.; Yu, Q.F.; Ning, P.; Yong, L.P. Adsorption equilibrium for sulfur dioxide, nitric oxide, carbon dioxide, nitrogen on 13X and 5A zeolites. Chem. Eng. J. 2012, 188, 77–85. [Google Scholar] [CrossRef]

- Al-Naddaf, Q.; Rownaghi, A.A.; Rezaei, F. Multicomponent adsorptive separation of CO2, CO, CH4, N2, and H2 over core-shell zeolite-5A-MOF-74 composite adsorbents. Chem. Eng. J. 2019, 384, 123251. [Google Scholar] [CrossRef]

- Yang, R.T. Adsorbents Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

| Molecule | Temperature (K) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 253 | 263 | 273 | 283 | 293 | 303 | 313 | 323 | 333 | ||

| CO2 | q (mmol·g−1) | 7.02 | 6.91 | 6.76 | 6.56 | 6.36 | 5.49 | 4.38 | 3.63 | 3.07 |

| K (kPa−1) | 0.215 | 0.126 | 0.080 | 0.053 | 0.036 | 0.031 | 0.031 | 0.030 | 0.027 | |

| R2 | 0.994 | 0.991 | 0.992 | 0.992 | 0.991 | 0.992 | 0.992 | 0.993 | 0.991 | |

| H2O | q (mmol·g−1) | 15.28 | 14.10 | 13.12 | 13.31 | 13.11 | 13.33 | 13.35 | 12.95 | 12.13 |

| K (kPa−1) | 1310.6 | 1344.7 | 1260.5 | 1076.4 | 1043.8 | 832.1 | 764.5 | 665.5 | 657.9 | |

| R2 | 0.636 | 0.670 | 0.655 | 0.709 | 0.700 | 0.747 | 0.731 | 0.738 | 0.762 | |

| SO2 | q (mmol·g−1) | 8.70 | 8.64 | 8.44 | 8.21 | 8.00 | 7.68 | 7.36 | 6.91 | 6.40 |

| K (kPa−1) | 607.70 | 597.84 | 365.094 | 286.103 | 159.413 | 108.38 | 65.080 | 47.440 | 33.317 | |

| R2 | 0.911 | 0.882 | 0.944 | 0.927 | 0.936 | 0.959 | 0.959 | 0.968 | 0.957 | |

| O2 | q (mmol·g−1) | 0.69 | 0.73 | 0.78 | 1.19 | 0.73 | 0.37 | 0.76 | 0.55 | 0.45 |

| K (kPa−1) | 0.128 | 0.076 | 0.044 | 0.019 | 0.024 | 0.038 | 0.012 | 0.013 | 0.012 | |

| R2 | 0.997 | 0.998 | 0.996 | 0.992 | 0.997 | 0.991 | 0.998 | 1.000 | 0.999 | |

| NO | q (mmol·g−1) | 0.57 | 0.54 | 0.52 | 0.48 | 0.51 | 0.43 | 0.40 | 0.74 | 0.110 |

| K (kPa−1) | 77.457 | 41.615 | 20.934 | 11.777 | 5.768 | 3.963 | 2.439 | 0.759 | 0.163 | |

| R2 | 0.987 | 0.992 | 0.995 | 0.994 | 0.994 | 0.991 | 0.989 | 0.996 | 0.987 | |

| N2 | q (mmol·g−1) | 1.60 | 1.48 | 1.41 | 1.36 | 1.26 | 1.34 | 1.52 | 1.28 | 1.47 |

| K (kPa−1) | 0.018 | 0.016 | 0.014 | 0.011 | 0.009 | 0.007 | 0.004 | 0.004 | 0.003 | |

| R2 | 0.986 | 0.986 | 0.993 | 0.998 | 0.997 | 0.998 | 0.998 | 0.998 | 0.998 | |

| NO2 | q (mmol·g−1) | 0.55 | 0.50 | 0.60 | 0.59 | 0.66 | 1.12 | 0.17 | 0.14 | 0.15 |

| K (kPa−1) | 13.511 | 7.430 | 2.961 | 1.666 | 0.810 | 0.280 | 1.206 | 0.289 | 0.543 | |

| R2 | 0.995 | 0.995 | 0.992 | 0.997 | 0.993 | 0.997 | 0.990 | 0.992 | 0.995 | |

| Molecule | Temperature (K) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 253 | 263 | 273 | 283 | 293 | 303 | 313 | 323 | 333 | ||

| CO2 | q (mmol·g−1) | 5.88 | 5.57 | 5.31 | 5.06 | 4.79 | 4.57 | 4.29 | 3.95 | 3.55 |

| K (kPa−1) | 0.94 | 0.70 | 0.49 | 0.33 | 0.24 | 0.18 | 0.13 | 0.10 | 0.09 | |

| R2 | 0.89 | 0.93 | 0.96 | 0.97 | 0.98 | 0.97 | 0.97 | 0.98 | 0.98 | |

| H2O | q (mmol·g−1) | 14.35 | 13.75 | 13.21 | 13.04 | 13.15 | 13.12 | 13.15 | 12.69 | 12.29 |

| K (kPa−1) | 2073.6 | 1798.1 | 1659.9 | 1353.9 | 1154.5 | 906.91 | 704.88 | 651.66 | 556.85 | |

| R2 | 0.87 | 0.87 | 0.86 | 0.89 | 0.91 | 0.97 | 0.96 | 0.86 | 0.91 | |

| SO2 | q (mmol·g−1) | 7.76 | 7.68 | 7.50 | 7.36 | 7.26 | 7.23 | 7.01 | 6.89 | 6.82 |

| K (kPa−1) | 590.77 | 570.10 | 529.12 | 523.12 | 505.01 | 487.54 | 412.57 | 411.66 | 387.27 | |

| R2 | 0.98 | 0.99 | 0.99 | 0.98 | 0.94 | 0.98 | 0.97 | 0.97 | 0.98 | |

| O2 | q (mmol·g−1) | 1.73 | 1.54 | 1.47 | 1.36 | 1.25 | 1.20 | 1.15 | 1.07 | 1.05 |

| K (kPa−1) | 0.030 | 0.019 | 0.016 | 0.009 | 0.008 | 0.0043 | 0.004 | 0.0038 | 0.0025 | |

| R2 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | |

| NO | q (mmol·g−1) | 1.65 | 1.55 | 1.49 | 0.594 | 0.371 | 0.152 | 0.112 | 0.064 | 0.0360 |

| K (kPa−1) | 0.35 | 0.24 | 0.23 | 0.18 | 0.18 | 0.15 | 0.12 | 0.10 | 0.09 | |

| R2 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | |

| N2 | q (mmol·g−1) | 2.35 | 2.13 | 2.02 | 1.88 | 1.88 | 1.85 | 1.79 | 1.80 | 1.81 |

| K (kPa−1) | 0.01 | 0.0094 | 0.0077 | 0.0066 | 0.0052 | 0.0042 | 0.0035 | 0.0028 | 0.0022 | |

| R2 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | |

| NO2 | q (mmol·g−1) | 0.76 | 0.67 | 0.62 | 0.55 | 0.45 | 0.38 | 0.33 | 0.27 | 0.24 |

| K (kPa−1) | 32.38 | 19.85 | 11.48 | 7.07 | 4.02 | 2.84 | 1.49 | 0.71 | 0.48 | |

| R2 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | |

| Molecule | Temperature (K) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 253 | 263 | 273 | 283 | 293 | 303 | 313 | 323 | 333 | ||

| CO2 | Ds (×10−10 m2/s) | 1.25 | 1.18 | 0.91 | 1.50 | 2.61 | 3.27 | 2.38 | 1.01 | 2.13 |

| R2 | 0.98 | 0.95 | 0.99 | 0.99 | 0.99 | 0.96 | 0.99 | 0.99 | 0.99 | |

| H2O | Ds (×10−10 m2/s) | - | - | - | - | - | - | - | - | - |

| R2 | - | - | - | - | - | - | - | - | - | |

| SO2 | Ds (×10−10 m2/s) | 1.37 | 1.16 | 0.88 | 1.23 | 0.85 | 1.74 | 1.35 | 5.69 | 1.38 |

| R2 | 0.99 | 0.99 | 0.98 | 0.98 | 0.99 | 0.97 | 0.99 | 0.98 | 0.99 | |

| O2 | Ds (×10−10 m2/s) | 2.41 | 5.34 | 2.17 | 4.00 | 2.32 | 4.80 | 2.48 | 4.24 | 2.46 |

| R2 | 0.99 | 0.97 | 0.97 | 0.99 | 0.99 | 0.99 | 0.98 | 0.99 | 0.97 | |

| NO | Ds (×10−10 m2/s) | 2.85 | 7.33 | 4.16 | 2.08 | 1.25 | 6.77 | 2.60 | 2.60 | 5.11 |

| R2 | 0.98 | 0.99 | 0.97 | 0.91 | 0.93 | 0.98 | 0.99 | 0.99 | 0.98 | |

| N2 | Ds (×10−10 m2/s) | 6.25 | 5.23 | 3.04 | 4.37 | 2.49 | 4.25 | 7.07 | 3.53 | 10.07 |

| R2 | 0.99 | 0.99 | 0.94 | 0.99 | 0.89 | 0.98 | 0.99 | 0.97 | 0.99 | |

| NO2 | Ds (×10−10 m2/s) | 0.71 | 0.62 | 0.45 | 0.33 | 0.62 | 0.74 | 1.07 | 1.26 | 0.68 |

| R2 | 0.99 | 0.97 | 0.99 | 0.99 | 0.98 | 0.99 | 0.98 | 0.98 | 0.98 | |

| Molecule | Temperature (K) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 253 | 263 | 273 | 283 | 293 | 303 | 313 | 323 | 333 | ||

| CO2 | Ds (×10−10 m2/s) | 2.79 | 3.48 | 5.83 | 8.18 | 9.88 | 13.16 | 17.57 | 23.55 | 31.02 |

| R2 | 0.96 | 0.98 | 0.99 | 0.99 | 0.99 | 0.96 | 0.99 | 0.99 | 0.99 | |

| H2O | Ds (×10−10 m2/s) | - | - | - | - | - | - | - | - | - |

| R2 | - | - | - | - | - | - | - | - | - | |

| SO2 | Ds (×10−10 m2/s) | - | - | - | - | - | - | - | - | - |

| R2 | - | - | - | - | - | - | - | - | - | |

| O2 | Ds (×10−10 m2/s) | 16.30 | 25.10 | 37.53 | 46.42 | 62.83 | 70.38 | 84.43 | 113.82 | 141.02 |

| R2 | 0.98 | 0.98 | 0.99 | 0.98 | 0.99 | 0.99 | 0.99 | 0.99 | 0.97 | |

| NO | Ds (×10−10 m2/s) | 13.58 | 15.10 | 15.69 | 20.08 | 23.68 | 27.32 | 28.82 | 32.42 | 36.15 |

| R2 | 0.98 | 0.99 | 0.98 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | |

| N2 | Ds (×10−10 m2/s) | 8.49 | 9.87 | 12.63 | 15.26 | 18.90 | 23.85 | 28.08 | 32.50 | 36.02 |

| R2 | 0.98 | 0.99 | 0.98 | 0.98 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | |

| NO2 | Ds (×10−10 m2/s) | 8.49 | 9.87 | 12.63 | 15.26 | 18.90 | 23.85 | 28.08 | 32.50 | 36.02 |

| R2 | 0.98 | 0.99 | 0.98 | 0.98 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | |

| Temperature (K) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| S | 253 | 263 | 273 | 283 | 293 | 303 | 313 | 323 | 333 | |

| Pure | CO2/SO2 | 3506.1 | 5931.2 | 5708.1 | 6799.2 | 5608.6 | 4845.2 | 3475.7 | 3021.8 | 2590.7 |

| CO2/H2O | 13,281 | 21,772 | 30,636 | 41,471 | 60,181 | 64,566 | 74,059 | 79,445 | 96,961 | |

| CO2/O2 | 17.2 | 15.7 | 15.7 | 15.6 | 13.1 | 12.3 | 15.2 | 15.2 | 15.0 | |

| CO2/N2 | 51.9 | 36.7 | 28.4 | 23.7 | 19.3 | 19.5 | 21.2 | 19.7 | 19.9 | |

| CO2/NO | 29.3 | 25.8 | 20.2 | 16.4 | 12.9 | 9.9 | 7.1 | 5.2 | 4.3 | |

| CO2/NO2 | 4.9 | 4.3 | 3.3 | 2.8 | 2.4 | 1.8 | 1.5 | 0.4 | 1.0 | |

| Mixture | CO2/SO2 | 112.1 | 106.8 | 80.7 | 65.0 | 76.4 | 70.8 | 116.9 | 140.0 | 144.9 |

| CO2/H2O | 3403.9 | 3595.9 | 3282.0 | 2190.3 | 1828.9 | 865.9 | 964.0 | 622.0 | 608.7 | |

| CO2/O2 | 7.8 | 0.0 | 4.0 | 0.1 | 2.5 | 0.1 | 46.9 | 38.8 | 31.5 | |

| CO2/N2 | 108.1 | 98.7 | 78.3 | 55.2 | 45.8 | 42.4 | 31.8 | 28.7 | 23.5 | |

| CO2/NO | 14.7 | 16.5 | 16.7 | 10.2 | 7.5 | 7.5 | 5.6 | 6.4 | 4.9 | |

| CO2/NO2 | 9.2 | 1.4 | 10.0 | 4.7 | 2.5 | 3.0 | 3.3 | 2.6 | 3.0 | |

| Temperature (K) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| S | 253 | 263 | 273 | 283 | 293 | 303 | 313 | 323 | 333 | |

| Pure | CO2/SO2 | 360 | 403.9 | 506.2 | 613.5 | 739 | 757.7 | 777.4 | 699.5 | 586.9 |

| CO2/H2O | 5365 | 6297 | 8456 | 10,501 | 13,187 | 14,491 | 15,818 | 19,745 | 21,400 | |

| CO2/O2 | 96.8 | 128.1 | 106 | 131 | 107.1 | 157.5 | 126.8 | 102.7 | 121.1 | |

| CO2/N2 | 220.9 | 195.2 | 165 | 134 | 117.5 | 105.9 | 93.8 | 83.2 | 78.1 | |

| CO2/NO | 9.4 | 10.5 | 7.3 | 15.3 | 17.2 | 34.6 | 40.2 | 59 | 96.1 | |

| CO2/NO2 | 0.2 | 0.3 | 0.4 | 0.4 | 0.6 | 0.7 | 1.2 | 2.2 | 2.7 | |

| Mixture | CO2/SO2 | 593.1 | 558.4 | 534.2 | 542.3 | 480.5 | 549.8 | 494.5 | 483.0 | 376.3 |

| CO2/H2O | 1396.9 | 1337.4 | 1418.8 | 966.2 | 619.6 | 506.5 | 399 | 416.1 | 480.1 | |

| CO2/O2 | 266.6 | 238.7 | 234.3 | 200.4 | 180.5 | 162.5 | 140.2 | 122.2 | 108.4 | |

| CO2/N2 | 375.3 | 318.1 | 256.1 | 231.7 | 189.4 | 166.1 | 140.2 | 122.3 | 105.5 | |

| CO2/NO | 25.6 | 31.7 | 27.3 | 32.2 | 32.3 | 33.5 | 28.8 | 26.1 | 21.5 | |

| CO2/NO2 | 4.7 | 4.5 | 3.3 | 3.1 | 3.4 | 3.9 | 4.2 | 3.5 | 3.8 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Jiang, X.; Yang, X.; Wang, S.; Qiu, X.; Liu, L.; Gao, S.; Li, Z.; Zhang, C. Molecular Simulation of Adsorption Separation of CO2 from Combustion Exhaust Mixture of Commercial Zeolites. Processes 2023, 11, 2987. https://doi.org/10.3390/pr11102987

Wang Y, Jiang X, Yang X, Wang S, Qiu X, Liu L, Gao S, Li Z, Zhang C. Molecular Simulation of Adsorption Separation of CO2 from Combustion Exhaust Mixture of Commercial Zeolites. Processes. 2023; 11(10):2987. https://doi.org/10.3390/pr11102987

Chicago/Turabian StyleWang, Yutong, Xu Jiang, Xiong Yang, Shiqing Wang, Xiaolong Qiu, Lianbo Liu, Shiwang Gao, Ziyi Li, and Chuanzhao Zhang. 2023. "Molecular Simulation of Adsorption Separation of CO2 from Combustion Exhaust Mixture of Commercial Zeolites" Processes 11, no. 10: 2987. https://doi.org/10.3390/pr11102987

APA StyleWang, Y., Jiang, X., Yang, X., Wang, S., Qiu, X., Liu, L., Gao, S., Li, Z., & Zhang, C. (2023). Molecular Simulation of Adsorption Separation of CO2 from Combustion Exhaust Mixture of Commercial Zeolites. Processes, 11(10), 2987. https://doi.org/10.3390/pr11102987