Foam Systems for Enhancing Heavy Oil Recovery by Double Improving Mobility Ratio

Abstract

:1. Introduction

2. Experimental Section

2.1. Chemicals and Reagents

2.2. Preparation of Synthetic Brine

2.3. Foam Performance Evaluation

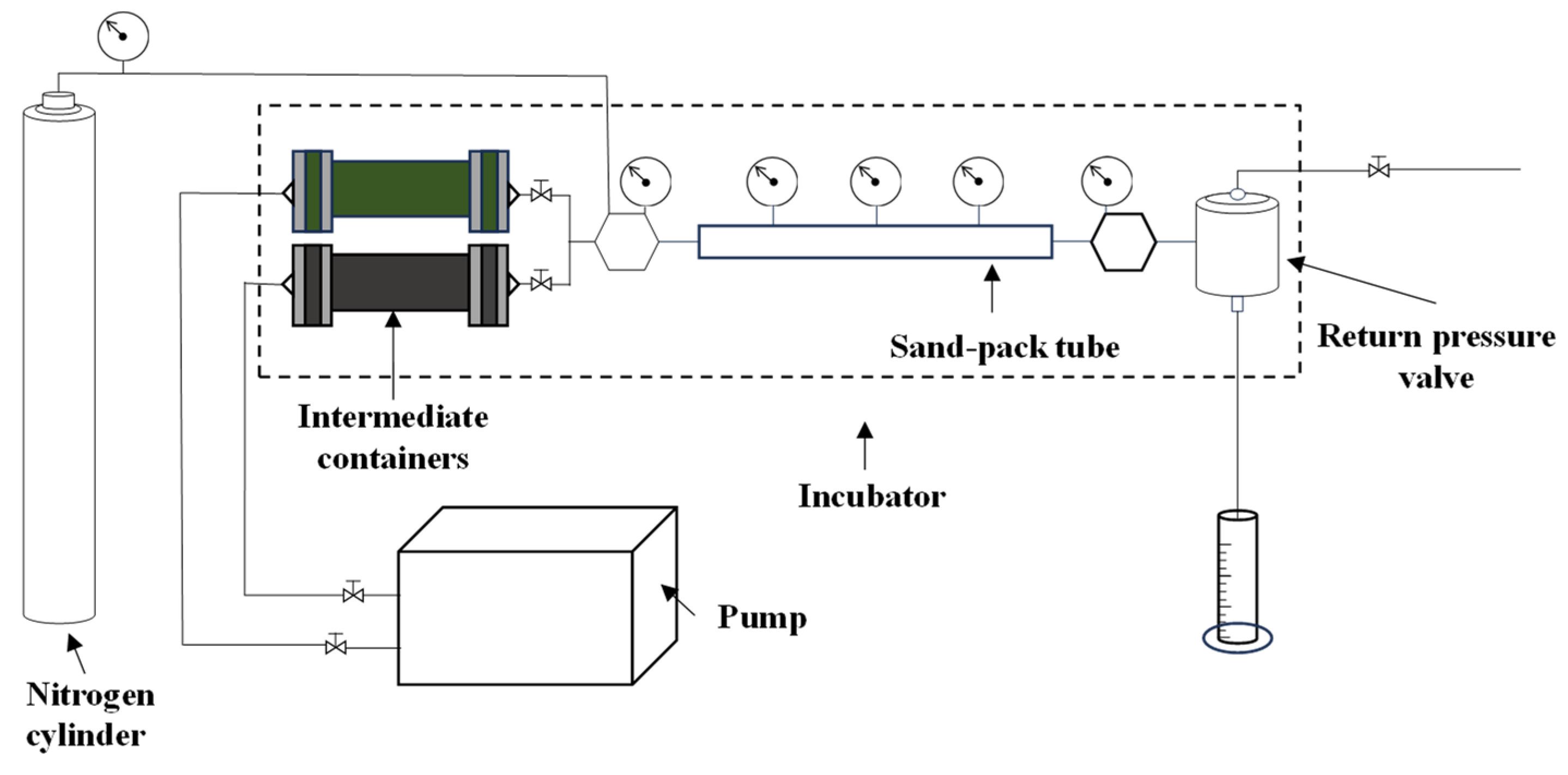

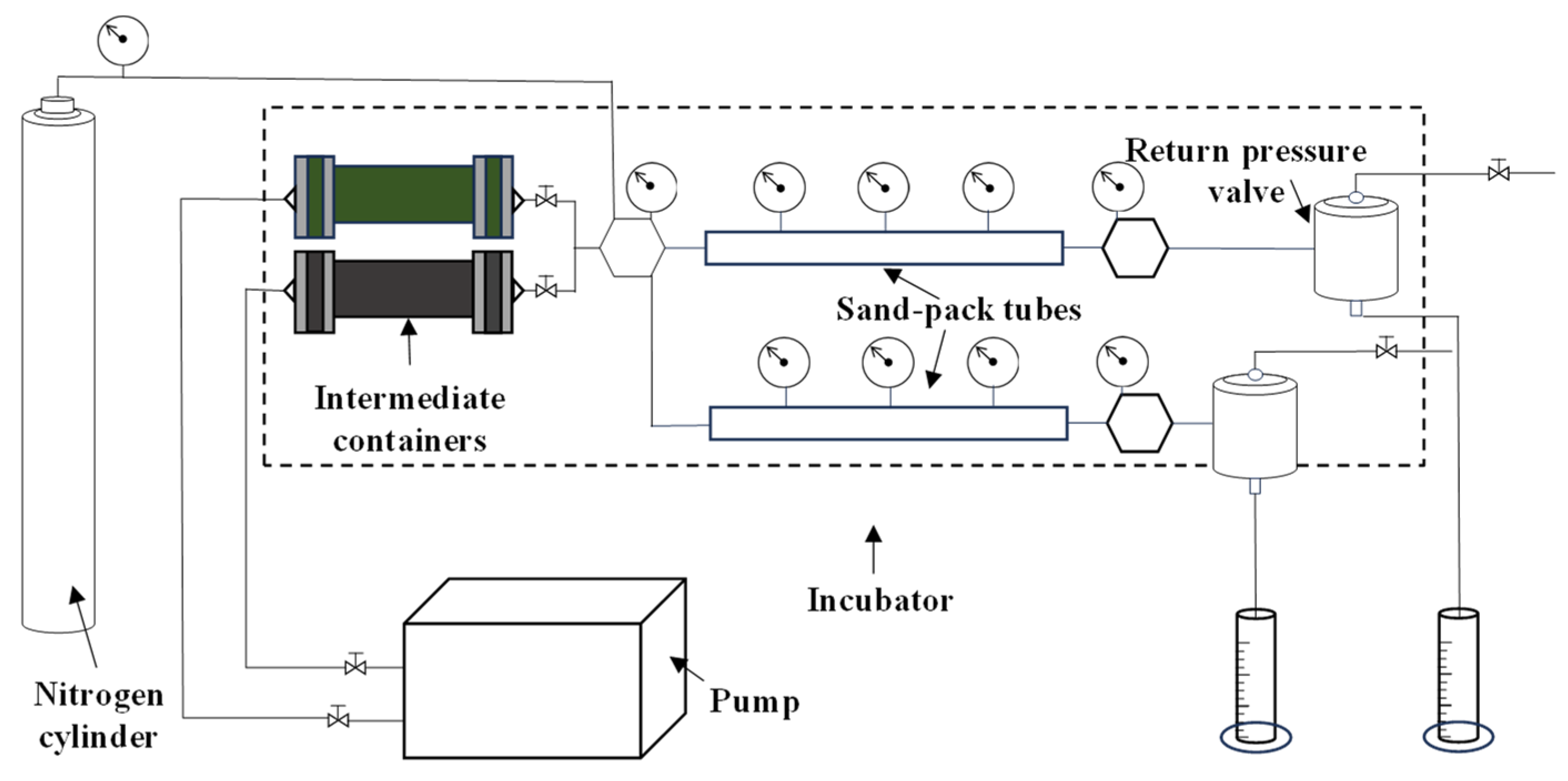

2.4. Flooding Experiments

3. Results and Discussion

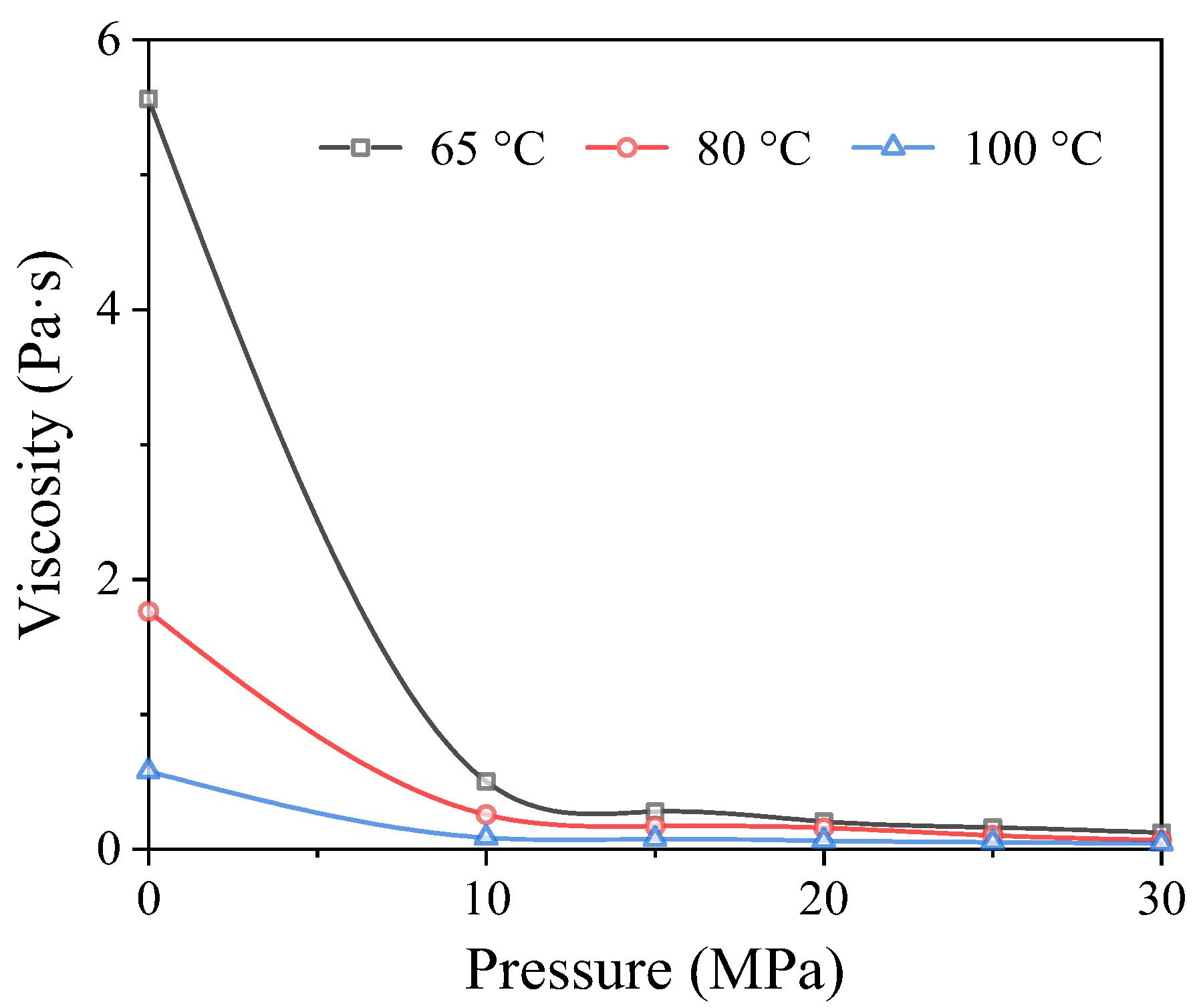

3.1. Viscosity Reduction Effect of Foam Systems

3.2. The Foam Performance of KX-048 Foam Systems

3.3. Mobility Ratio Control of Foam Systems

3.4. Enhanced Heavy Oil Recovery with Foam Systems (Heavy Oil Viscosity Reduction)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahmadi, M.; Chen, Z.X. Challenges and future of chemical assisted heavy oil recovery processes. Adv. Colloid Interface Sci. 2020, 275, 102081. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Hasanvand, M.Z.; Shokrolahzadeh, S. Technical and economic feasibility study of flue gas injection in an Iranian oil field. Petroleum 2015, 1, 217–222. [Google Scholar] [CrossRef]

- Al-Attas, T.A.; Ali, S.A.; Zahir, M.H.; Xiong, Q.G.; Al-Bogami, S.A.; Malaibari, Z.O.; Razzak, S.A.; Hossain, M.M. Recent Advances in Heavy Oil Upgrading Using Dispersed Catalysts. Energy Fuels 2019, 33, 7917–7949. [Google Scholar] [CrossRef]

- Al-sarkhi, A.; Salim, O.; Mohamed, N.M.; Sultan, A.; Saikia, T.; Al-Yami, J.; Alhems, L. Controlled In-Line Generation of Stable Oil-Water Emulsions for Enhanced Oil Recovery. Arab. J. Sci. Eng. 2022, 47, 12169–12182. [Google Scholar] [CrossRef]

- Aliev, F.A.; Mukhamatdinov, I.I.; Sitnov, S.A.; Ziganshina, M.R.; Onishchenko, Y.V.; Sharifullin, A.V.; Vakhin, A.V. In-Situ Heavy Oil Aquathermolysis in the Presence of Nanodispersed Catalysts Based on Transition Metals. Processes 2021, 9, 127. [Google Scholar] [CrossRef]

- Chen, X.Y.; Wang, N.; Xia, S.Q. Research progress and development trend of heavy oil emulsifying viscosity reducer: A review. Pet. Sci. Technol. 2021, 39, 550–563. [Google Scholar] [CrossRef]

- Cheng, K.Y.; Huang, Z.T.; Li, J.; Luo, T.T.; Li, H.B. Experimental Study on Enhancing Heavy Oil Recovery by Multimedia-Assisted Steam Flooding Process. Geofluids 2022, 2022, 1968032. [Google Scholar] [CrossRef]

- Cui, G.D.; Liu, T.; Xie, J.Y.; Rong, G.H.; Yang, L.H. A review of SAGD technology development and its possible application potential on thin-layer super-heavy oil reservoirs. Geosci. Front. 2022, 13, 101382. [Google Scholar] [CrossRef]

- Elkamel, L.S.; Sedaee, B. Optimization of Cyclic Steam Stimulation in Heavy Oil Naturally Fractured Reservoirs. Arab. J. Sci. Eng. 2022, 47, 11623–11633. [Google Scholar] [CrossRef]

- Gao, X.D.; Dong, P.C.; Cui, J.W.; Gao, Q.C. Prediction Model for the Viscosity of Heavy Oil Diluted with Light Oil Using Machine Learning Techniques. Energies 2022, 15, 2297. [Google Scholar] [CrossRef]

- Ghannam, M.T.; Selim, M.Y.E.; Zekri, A.Y.; Esmail, N. Viscoelastic Behavior of Crude Oil-Gum Emulsions in Enhanced Oil Recovery. Polymers 2022, 14, 1004. [Google Scholar] [CrossRef] [PubMed]

- Harding, T. Methods to Enhance Success of Field Application of In-Situ Combustion for Heavy Oil Recovery. SPE Reserv. Eval. Eng. 2023, 26, 190–197. [Google Scholar] [CrossRef]

- Hemmati-Sarapardeh, A.; Khishvand, M.; Naseri, A.; Mohammadi, A.H. Toward reservoir oil viscosity correlation. Chem. Eng. Sci. 2013, 90, 53–68. [Google Scholar] [CrossRef]

- Hua, D.D.; Liu, P.C.; Liu, P.; Xi, C.F.; Zhang, S.F.; Liu, P. Experimental study and numerical simulation of urea-assisted SAGD in developing exra-heavy oil reservoirs. J. Pet. Sci. Eng. 2021, 201, 108436. [Google Scholar] [CrossRef]

- Ilyushin, Y.V.; Kapostey, E.I. Developing a Comprehensive Mathematical Model for Aluminium Production in a Soderberg Electrolyser. Energies 2023, 16, 6313. [Google Scholar] [CrossRef]

- Jing, J.Q.; Yin, R.; Zhu, G.J.; Xue, J.; Wang, S.; Wang, S.H. Viscosity and contact angle prediction of low water-containing heavy crude oil diluted with light oil. J. Pet. Sci. Eng. 2019, 176, 1121–1134. [Google Scholar] [CrossRef]

- Khormali, A. Effect of water cut on the performance of an asphaltene inhibitor package: Experimental and modeling analysis. Pet. Sci. Technol. 2022, 40, 2890–2906. [Google Scholar] [CrossRef]

- Li, C.; Huang, W.C.; Zhou, C.G.; Chen, Y.L. Advances on the transition-metal based catalysts for aquathermolysis upgrading of heavy crude oil. Fuel 2019, 257, 115779. [Google Scholar] [CrossRef]

- Li, Y.; Liu, H.Q.; Jiao, P.; Wang, Q.; Liu, D.; Ma, L.Y.; Wang, Z.P.; Peng, H. Machine-Learning-Assisted Identification of Steam Channeling after Cyclic Steam Stimulation in Heavy-Oil Reservoirs. Geofluids 2023, 2023, 6593464. [Google Scholar] [CrossRef]

- Liu, W.; Du, L.; Zou, X.F.; Liu, T.; Wu, X.D.; Wang, Y.H.; Dong, J. Experimental study on the enhanced ultra-heavy oil recovery using an oil-soluble viscosity reducer and CO2 assisted steam flooding. Geoenergy Sci. Eng. 2023, 222, 211409. [Google Scholar] [CrossRef]

- Liu, Z.D.; Wang, H.J.; Blackbourn, G.; Ma, F.; He, Z.J.; Wen, Z.X.; Wang, Z.M.; Yang, Z.; Luan, T.S.; Wu, Z.Z. Heavy Oils and Oil Sands: Global Distribution and Resource Assessment. Acta Geol. Sin. Engl. Ed. 2019, 93, 199–212. [Google Scholar] [CrossRef]

- Lyadov, A.S.; Petrukhina, N.N. Extraction and Refining of Heavy Crude Oils: Problems and Prospects. Russ. J. Appl. Chem. 2018, 91, 1912–1921. [Google Scholar] [CrossRef]

- Marinina, O.; Nechitailo, A.; Stroykov, G.; Tsvetkova, A.; Reshneva, E.; Turovskaya, L. Technical and Economic Assessment of Energy Efficiency of Electrification of Hydrocarbon Production Facilities in Underdeveloped Areas. Sustainability 2023, 15, 9614. [Google Scholar] [CrossRef]

- Muraza, O.; Galadima, A. Aquathermolysis of heavy oil: A review and perspective on catalyst development. Fuel 2015, 157, 219–231. [Google Scholar] [CrossRef]

- Pershin, I.M.; Kukharova, T.V.; Tsapleva, V.V. Designing of distributed systems of hydrolithosphere processes parameters control for the efficient extraction of hydromineral raw materials. J. Phys. Conf. Ser. 2021, 1728, 012017. [Google Scholar] [CrossRef]

- Pratama, R.A.; Babadagli, T. A review of the mechanics of heavy-oil recovery by steam injection with chemical additives. J. Pet. Sci. Eng. 2022, 208, 109717. [Google Scholar] [CrossRef]

- Rad, M.J.; Alizadeh, O.; Takassi, M.A.; Mokhtary, M. Green surfactant in oil recovery: Synthesis of a biocompatible surfactant and feasibility study of its application in foam-based enhanced oil recovery. Fuel 2023, 341, 127646. [Google Scholar] [CrossRef]

- Sabeti, M.; Cheperli, A.; Rahimbakhsh, A.; Torabi, F. A new analytical model to predict heavy oil production rate in the SAGD process. Can. J. Chem. Eng. 2023, 101, 1648–1659. [Google Scholar] [CrossRef]

- Shafiei, M.; Kazemzadeh, Y.; Shirazy, G.M.; Riazi, M. Evaluating the role of salts on emulsion properties during water-based enhanced oil recovery: Ion type, concentration, and water content. J. Mol. Liq. 2022, 364, 120028. [Google Scholar] [CrossRef]

- Shi, H.; Mao, Z.Q.; Ran, L.C.; Ru, C.D.; Guo, S.W.; Dong, H. Heavy oil viscosity reduction through aquathermolysis catalyzed by Ni20(NiO)80 nanocatalyst. Fuel Process. Technol. 2023, 250, 107911. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, Y.Z.; Meng, Q.C.; Li, H.B.; Guo, F.J.; Guo, C.F.; Zhang, X.; Deng, J.P.; Dong, H. Effects of Porous Media on Foam Properties. Chemistryselect 2022, 7, e202201069. [Google Scholar] [CrossRef]

- Wang, Y.P.; Li, M.X.; Hou, J.; Zhang, L.L.; Jiang, C.Y. Design, synthesis and properties evaluation of emulsified viscosity reducers with temperature tolerance and salt resistance for heavy oil. J. Mol. Liq. 2022, 356, 118977. [Google Scholar] [CrossRef]

- Wu, R.N.; Yan, Y.H.; Li, X.X.; Tan, Y.B. Preparation and evaluation of double-hydrophilic diblock copolymer as viscosity reducers for heavy oil. J. Appl. Polym. Sci. 2023, 140, e53278. [Google Scholar] [CrossRef]

- Xing, L.M.; Quan, H.P.; Zhao, J.Y.; Huang, X.M. The viscosity reducers exhibit dispersing ability for resin in heavy oil. Can. J. Chem. 2023, 101, 6. [Google Scholar] [CrossRef]

- Yang, X.C.; Zhao, H.Y.; Zhang, B.; Zhao, Q.H.; Cheng, Y.L.; Zhang, Y.; Li, Y.Q. Displacement Characteristics and Produced Oil Properties in Steam Flood Heavy Oil Process. Energies 2022, 15, 6246. [Google Scholar] [CrossRef]

- Zhang, J.H.; Gao, H.; Xue, Q.H. Potential applications of microbial enhanced oil recovery to heavy oil. Crit. Rev. Biotechnol. 2020, 40, 459–474. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Q.W.; Fan, Z.Z.; Liu, Q.C. An in situ combustion process for recovering heavy oil using scaled physical model. J. Pet. Explor. Prod. Technol. 2019, 9, 2681–2688. [Google Scholar] [CrossRef]

- Zhang, X.H.; Wang, J.J.; Wang, L.; Li, Z.Q.; Hu, W.; Dai, Y.Q.; Kou, Y.Y.; Lei, S.J.; Li, Q.; Zhang, W.; et al. Catalytic capacity evolution of montmorillonite in in-situ combustion of heavy oil. Fuel 2023, 333, 126621. [Google Scholar] [CrossRef]

- Zhou, X.; Yuan, Q.W.; Peng, X.L.; Zeng, F.H.; Zhang, L.H. A critical review of the CO2 huff ‘n’ puff process for enhanced heavy oil recovery. Fuel 2018, 215, 813–824. [Google Scholar] [CrossRef]

| Na+ + K+ (mg·L−1) | Ca2+ (mg·L−1) | Mg2+ (mg·L−1) | Cl− (mg·L−1) | SO42− (mg·L−1) | HCO3− (mg·L−1) | Total Dissolved Salts (mg·L−1) |

|---|---|---|---|---|---|---|

| 53,090 | 7416 | 1204 | 97,400 | 1224 | 265 | 160,599 |

| Sand-Pack Model | Porosity (%) | Permeability (10−3 μm2) | Oil Saturation (%) | Foaming Agent |

|---|---|---|---|---|

| 1 | 36.28 | 229.7 | 86.44 | XHY-4 |

| 2 | 35.70 | 215.6 | 83.35 | KX-048 |

| 3 | 34.36 | 203.4 | 82.42 | - |

| Sand-Pack Model | Tube Permeability | Tube Volume (mL) | Pore Volume (mL) | Porosity (%) | Permeability (10−3 μm2) | Oil Saturation | Foaming Agent |

|---|---|---|---|---|---|---|---|

| 1 | Low | 501 | 176 | 35.15 | 87.1 | 81.25 | KX-048 |

| High | 500 | 180 | 36.74 | 484.8 | 87.78 | ||

| 2 | Low | 501 | 164 | 32.75 | 82.4 | 76.22 | XHY-4 |

| High | 500 | 176 | 35.93 | 540.2 | 80.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Xu, H.; Zhang, L.; Li, X.; Zhou, X.; Li, Q.; Wang, P.; Li, M.; Qiu, Y.; Zhang, X.; et al. Foam Systems for Enhancing Heavy Oil Recovery by Double Improving Mobility Ratio. Processes 2023, 11, 2961. https://doi.org/10.3390/pr11102961

Chen C, Xu H, Zhang L, Li X, Zhou X, Li Q, Wang P, Li M, Qiu Y, Zhang X, et al. Foam Systems for Enhancing Heavy Oil Recovery by Double Improving Mobility Ratio. Processes. 2023; 11(10):2961. https://doi.org/10.3390/pr11102961

Chicago/Turabian StyleChen, Chao, Hao Xu, Lidong Zhang, Xiaohui Li, Xiaosong Zhou, Qian Li, Peng Wang, Meng Li, Yuxing Qiu, Xiao Zhang, and et al. 2023. "Foam Systems for Enhancing Heavy Oil Recovery by Double Improving Mobility Ratio" Processes 11, no. 10: 2961. https://doi.org/10.3390/pr11102961

APA StyleChen, C., Xu, H., Zhang, L., Li, X., Zhou, X., Li, Q., Wang, P., Li, M., Qiu, Y., Zhang, X., Liu, S., He, G., & Li, H. (2023). Foam Systems for Enhancing Heavy Oil Recovery by Double Improving Mobility Ratio. Processes, 11(10), 2961. https://doi.org/10.3390/pr11102961