Modeling and Optimization of High-Capacity Experimental Reclaimers to Minimize the Seed and Lint Loss during Roller Ginning of Upland and Pima Cotton

Abstract

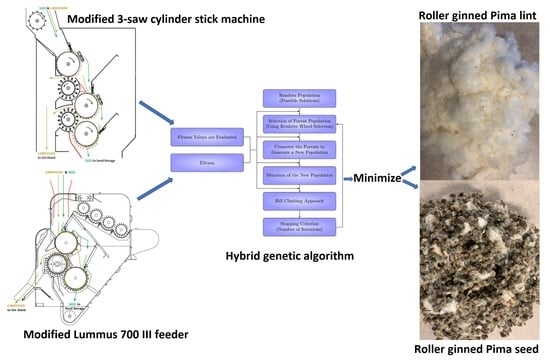

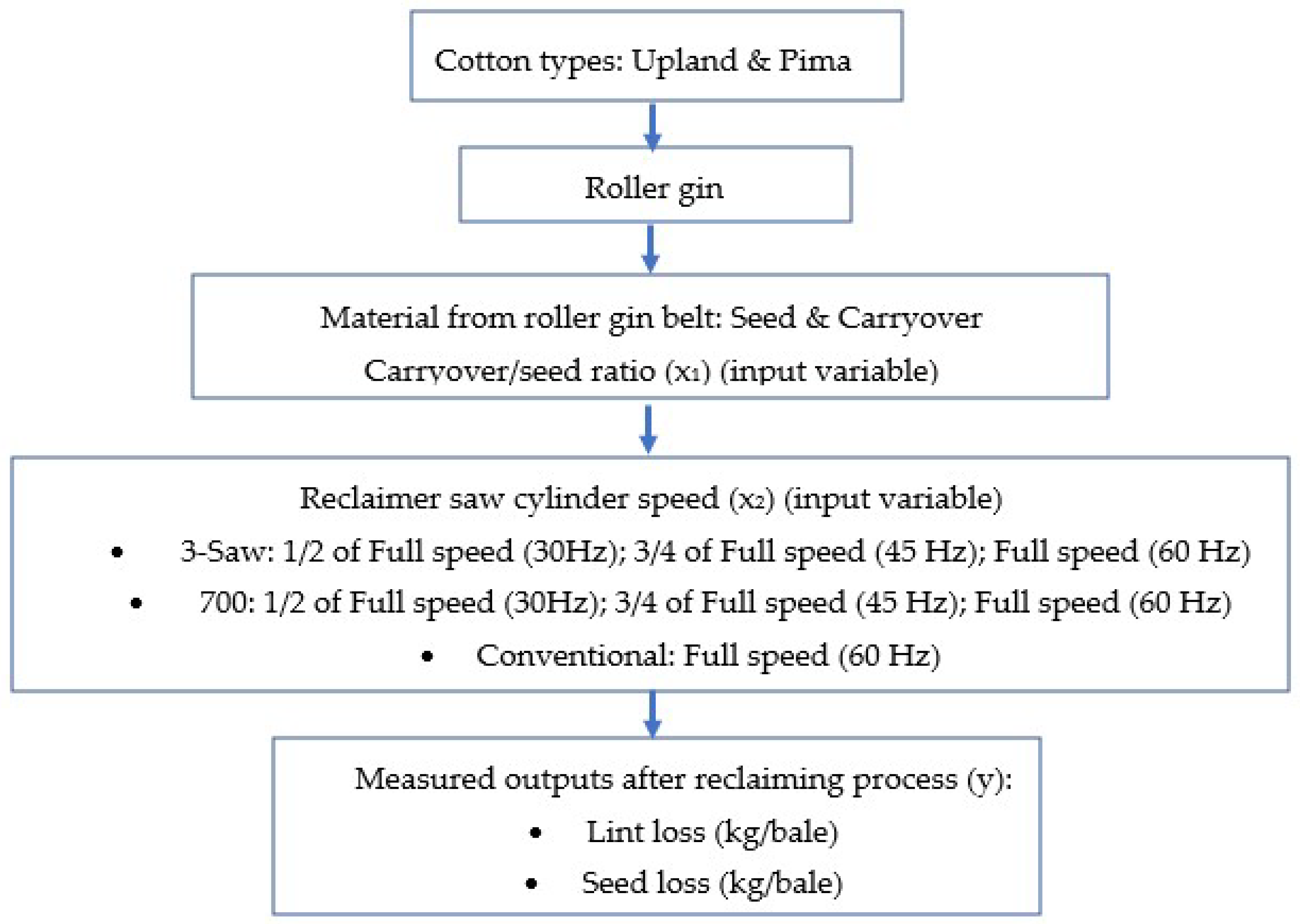

:1. Introduction

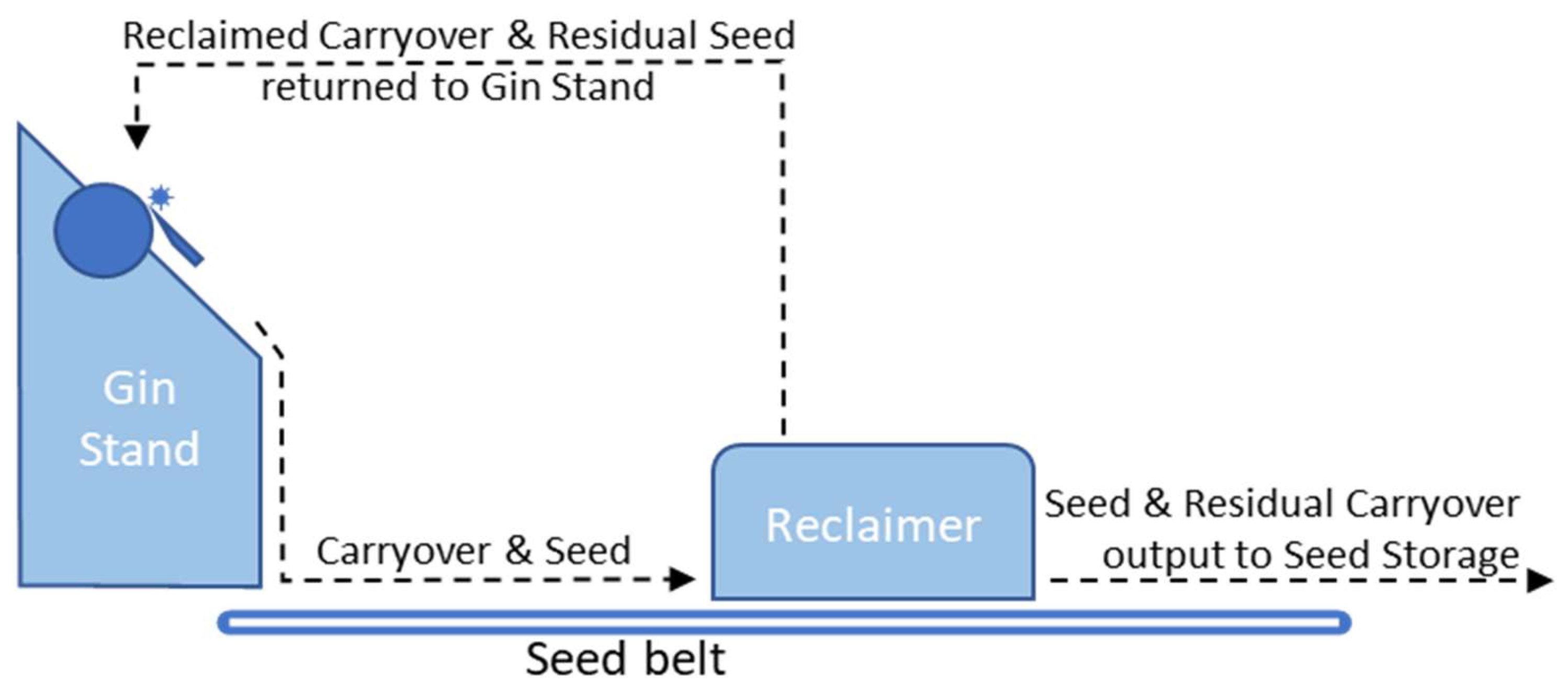

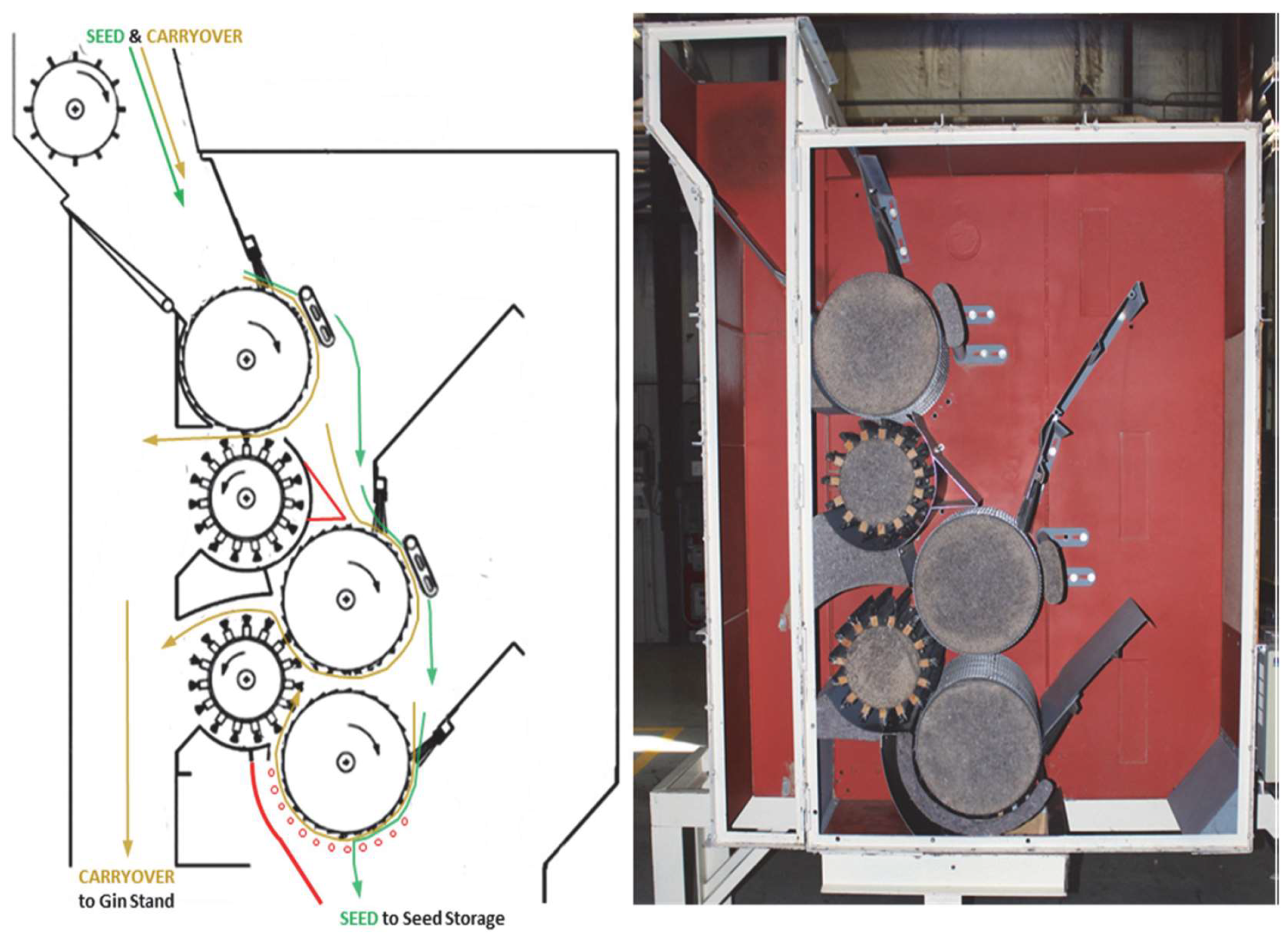

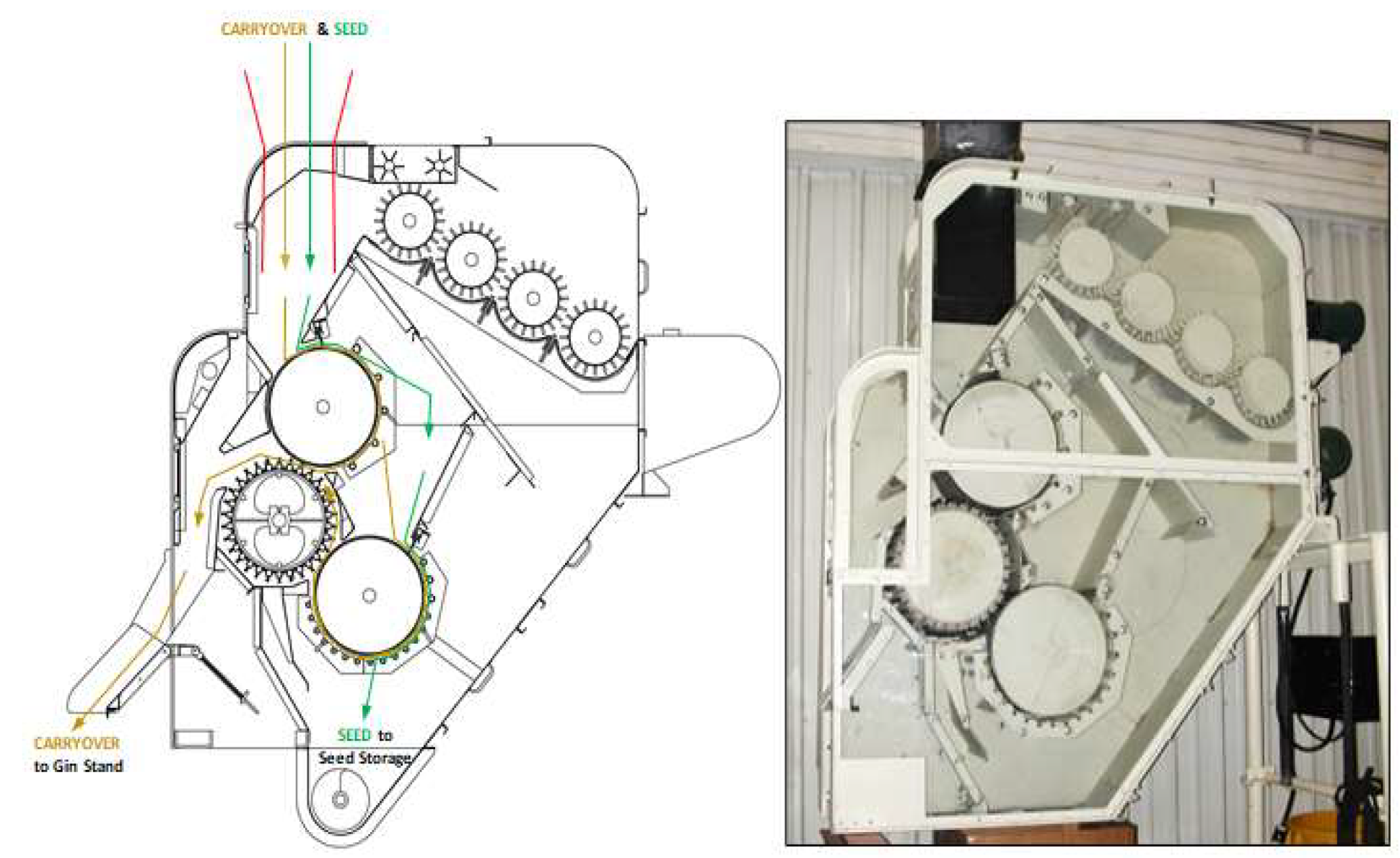

1.1. Background to Reclaimers

1.2. Objectives

- Develop response surface models and plots for the two experimental high-capacity reclaimers for process variables such as carryover/seed ratio and saw speed (full speed, ½ of full speed, and ¾ of full speed for seed and lint loss during the process).

- Optimize the process using a hybrid genetic algorithm (HGA) for the two high-capacity reclaimers independently and when placed in a parallel arrangement.

- Compare the lint and seed loss for the two experimental high-capacity reclaimers under optimized conditions with the conventional reclaimer and evaluate the economic loss.

2. Materials and Methods

2.1. Research Data

2.2. Response Surface Models

2.3. Optimization Scenarios Tested

- (a)

- 3-Saw reclaimer for minimization of seed and lint loss

- (b)

- 700 reclaimer for minimization of seed and lint loss

- (c)

- Both 3-saw and 700 recalimers in a parallel arrangement to minimize the seed and lint loss (Figure 8).

2.4. Process Model Optimization Methodology

2.5. Economic Analysis

3. Results

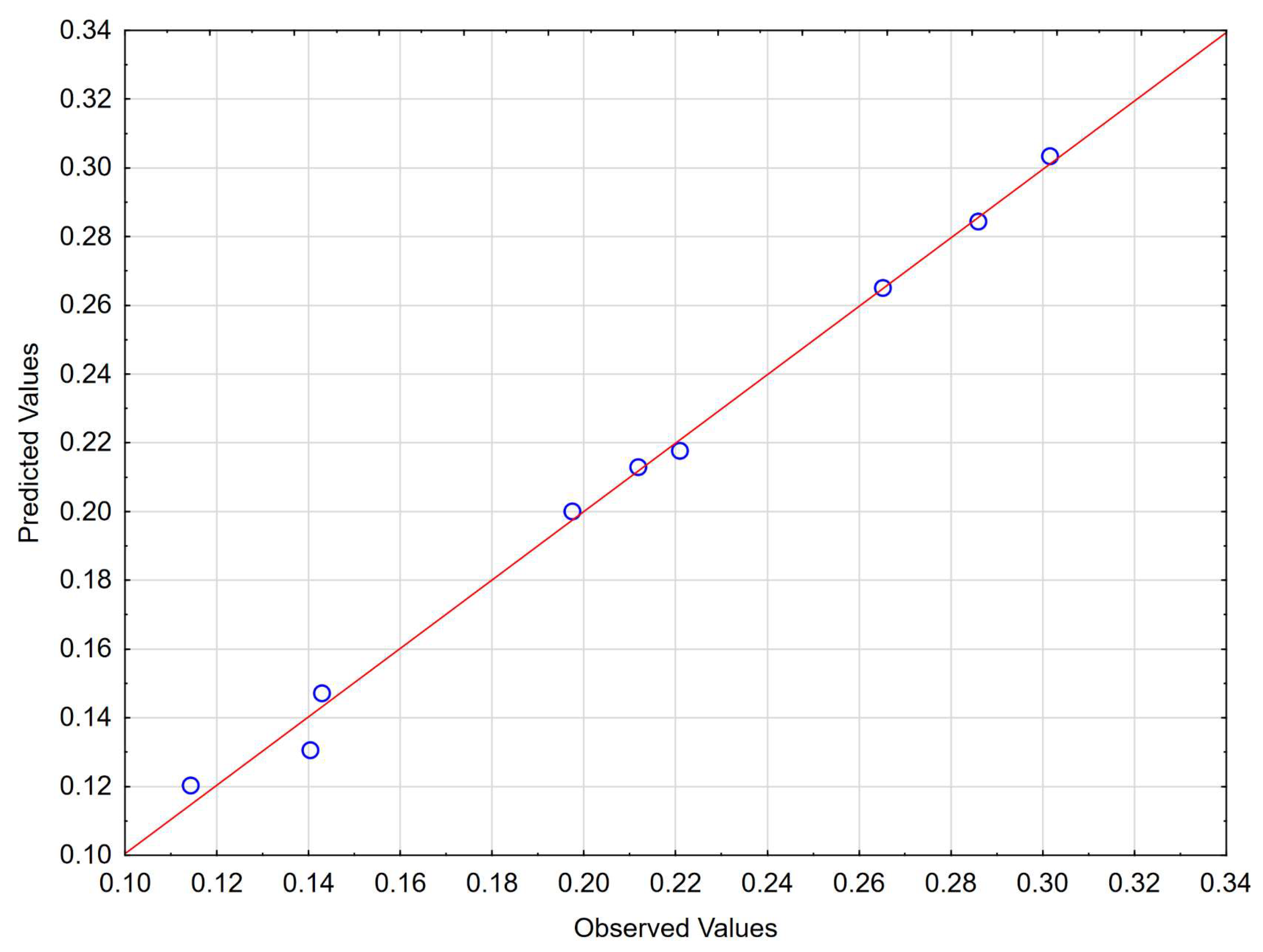

3.1. RSM Models and Surface Plots

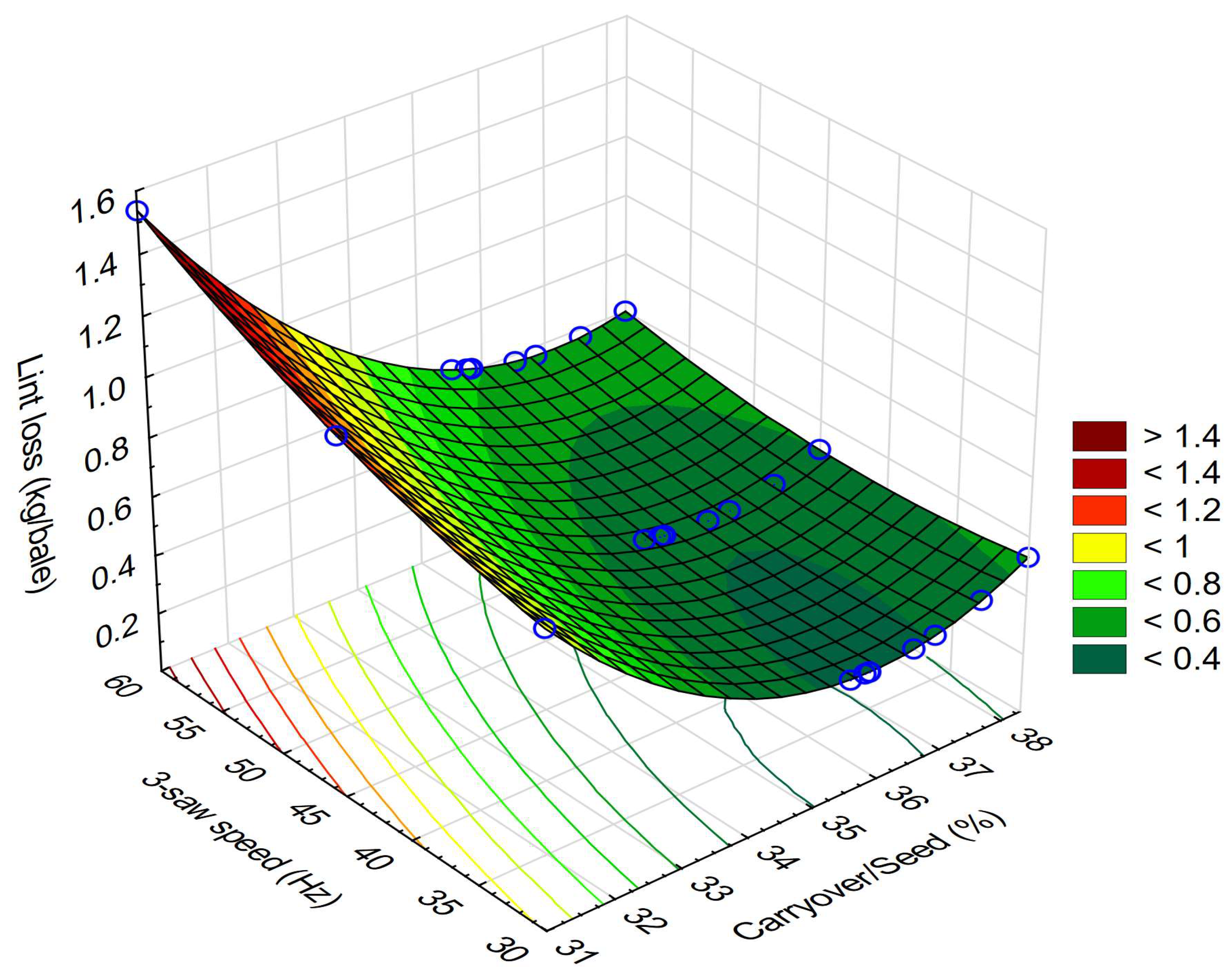

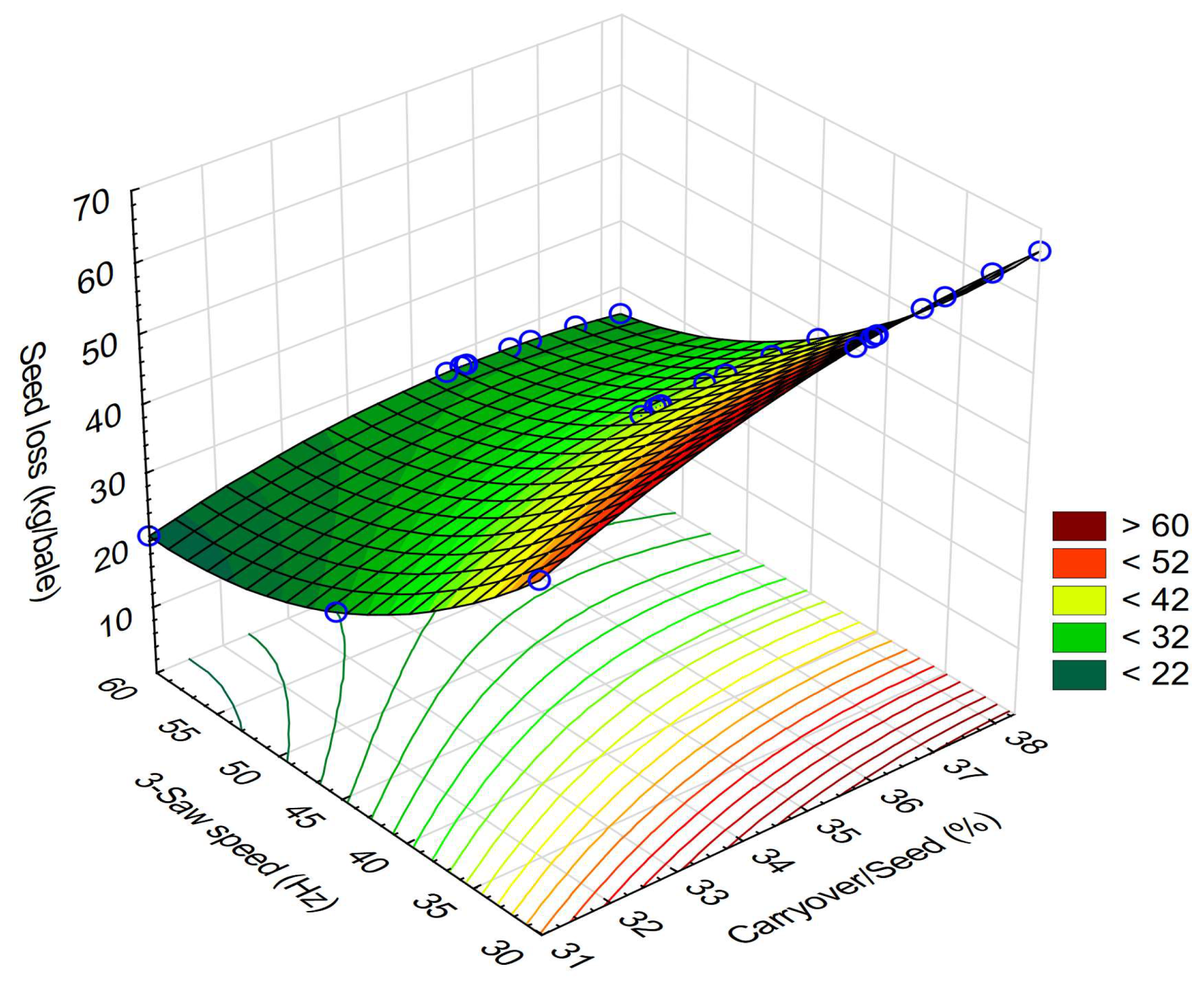

3.2. Upland Cotton—Surface Plots

3.2.1. 3-Saw Reclaimer

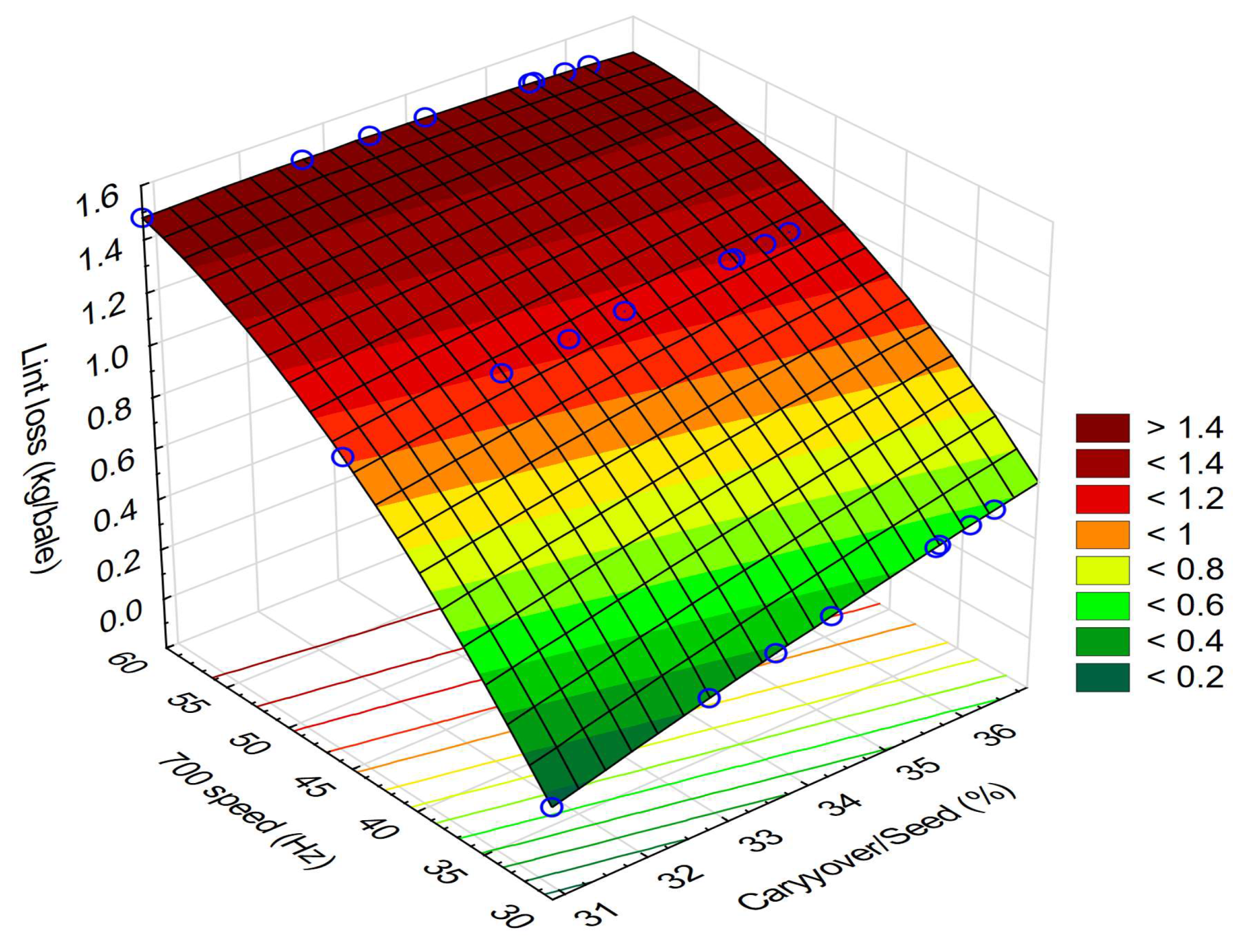

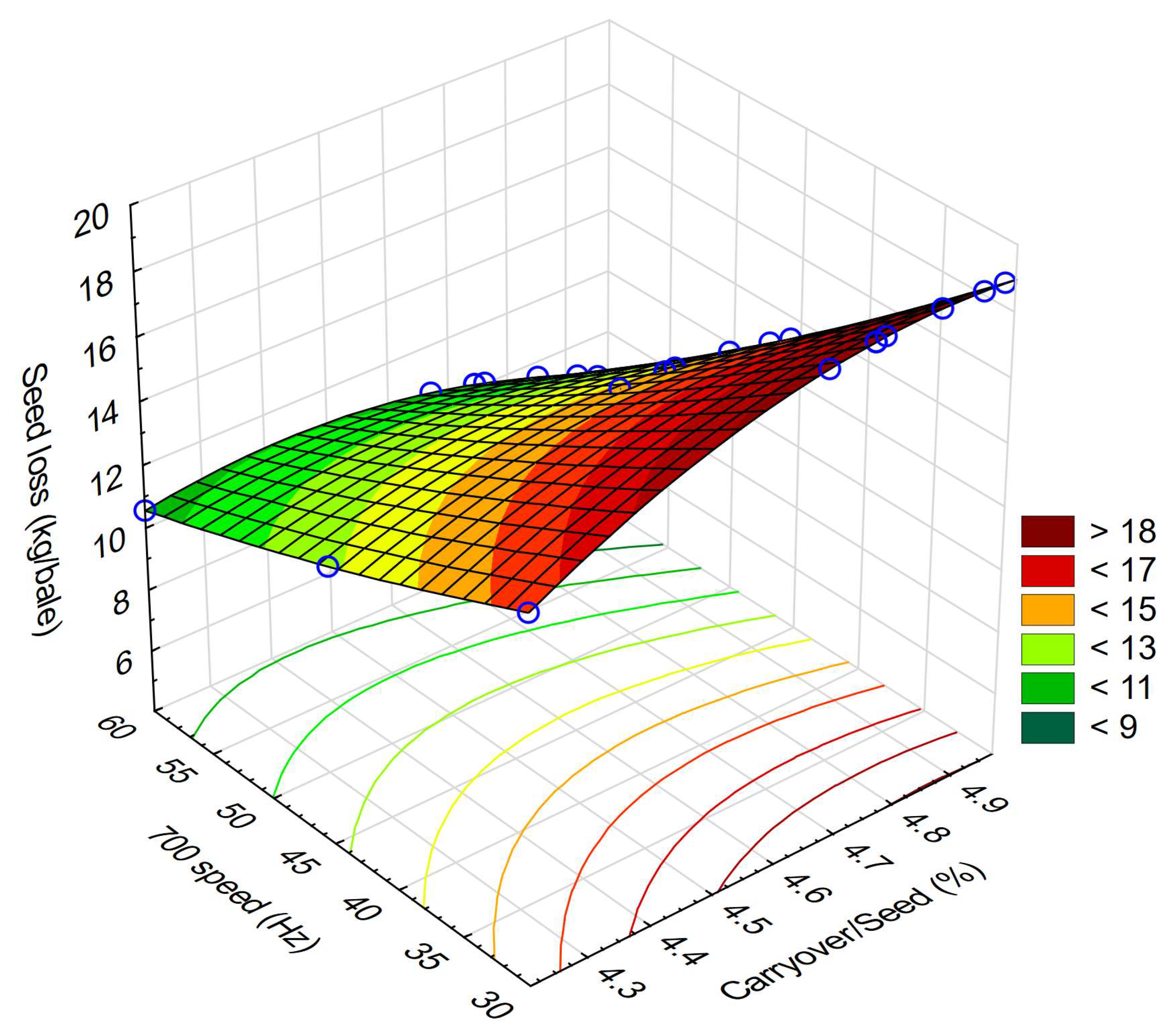

3.2.2. 700 Reclaimer

3.3. Pima Cotton-Surface Plots

3.3.1. 3-Saw Reclaimer

3.3.2. 700 Reclaimer

3.3.3. General Reclaimer Settings to Minimize the Seed and Lint Loss Based on Surface Plots

3.4. Process Conditions Identified by HGA to Minimize the Seed and Lint Loss

3.5. Process Conditions to Minimize Seed and Lint Loss in a Parallel Arrangement

3.6. Economic Analysis

4. Discussion

5. Conclusions

- Response surface models developed adequately described the reclaiming process based on the coefficient of determination values of >0.84, and all the models were found to be statistically significant except the lint loss model for the 3-saw reclaimer.

- The surface plots indicated that reclaimer speed had a more prominent effect on the lint and seed loss than the carryover/seed ratio. Even though the carryover/seed ratio tested was narrow, it still impacted the lint loss for both 3-saw and 700 reclaimers.

- For 3-saw, higher carryover/seed ratios and lower reclaimer speeds, and for 700, lower carryover/seed ratio and lower reclaimer speeds are necessary to minimize the lint loss, whereas for seed loss, carryover/seed ratio did not have much impact, but higher reclaimer speeds reduced the seed loss.

- For Pima cotton, both 3-saw and 700 reclaimers need to be operated at lower reclaimer speeds to minimize the lint loss; in the case of seed loss, the carryover/seed ratio had a marginal effect, whereas higher reclaimer speeds reduced the seed loss.

- Under the optimized process conditions, 700 reclaimer is the best for Upland and Pima cotton compared to the 3-saw reclaimer. Compared to the conventional reclaimer used by the industry, the 700 minimized the seed and lint loss for Upland cotton, whereas the conventional performed better for Pima cotton.

- The economic loss based on the lint and seed loss while reclaiming Upland carryover indicated that the 700 reclaimer resulted in 40% as much loss (6.44 versus 15.97 $/bale) than the conventional reclaimer. In the case of Pima cotton, the conventional reclaimer performed better than the 700 reclaimer by lowering the seed loss and further reducing the economic loss (3.44 vs. 3.59 $/bale).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

USDA Disclaimer

References

- Meyer, L.; Dew, T.; Grace, M.; Lanclos, K.; MacDonald, S.; Soley, G. The World and United Stated Cotton Outlook. In Proceedings of the USDA’s 99th Annual Agricultural Outlook Forum, U.S. Agriculture: Seeds of Growth through Innovation, Hybrid Event, 23–24 February 2023; Available online: https://www.usda.gov/sites/default/files/documents/2023AOF-cotton-outlook.pdf (accessed on 6 September 2023).

- USDA. Economic Research Service. Available online: https://www.ers.usda.gov/topics/crops/cotton-and-wool/cotton-sector-at-a-glance/ (accessed on 6 September 2023).

- Cotton Incorporated. Available online: https://www.cottoninc.com/cotton-production/quality/us-cotton-fiber-chart/properties-of-the-growing-regions/ (accessed on 6 September 2023).

- NASS. Running Bales Produced and Equivalent 480-Pound Bales Ginned by Crop—States and United States (2023): 2021 and 2022 Crop. In Cotton Ginnings 2022 Summary; USDA, National Agricultural Statistics Service: Washington, DC, USA, 2023. [Google Scholar]

- Armijo, C.B.; Foulk, J.A.; Whitelock, D.P.; Hughs, S.E.; Holt, G.A.; Gillum, M.N. Fiber and yarn properties from high-speed roller ginning of upland cotton. Appl. Eng. Agric. 2013, 29, 461–471. [Google Scholar]

- Bennett, C.A. Saw and Toothed Cotton Ginning Developments; Texas Cotton Ginners Association: Dallas, TX, USA, 1960. [Google Scholar]

- Armijo, C.B.; Whitelock, D.P.; Funk, P.A.; Thomas, J.W. Evaluating alternative seed-cotton reclaimers for high-speed roller ginning. Appl. Eng. Agric. 2020, 36, 245–256. [Google Scholar] [CrossRef]

- Gillum, M.N. USDA Southwestern Cotton Ginning Research Laboratory Annual Report: Crop Years 1978–1979; USDA: Washington, DC, USA, 1979; pp. 220–239. [Google Scholar]

- Whitelock, D.P.; Armijo, C.B.; Gamble, G.R.; Hughs, S.E. Survey of seed-cotton and lint cleaning equipment in U.S. roller gins. J. Cotton Sci. 2007, 11, 128–140. [Google Scholar]

- Khuri, A.; Cornell, J. Response Surfaces: Designs and Analysis; Dekker: New York, NY, USA, 1987. [Google Scholar]

- Myers, R.H. Response Surface Methodology; Allyn and Bacon: Boston, MA, USA, 1971; p. 246. [Google Scholar]

- Tirado-Kulieva, V.A.; Sánchez-Chero, M.; Yarlequé, M.V.; Aguilar, G.F.V.; Carrión-Barco, G.; Cruz, A.G.Y.S.; Sánchez-Chero, J. An Overview on the Use of Response Surface Methodology to Model and Optimize Extraction Processes in the Food Industry. Curr. Res. Nutr. Food Sci. 2021, 9, 745–754. [Google Scholar] [CrossRef]

- Mahmoud, Y.; Seid, J. Applications of Response Surface Methodology in the Food Industry Processes. Food Bioproc. Tech. 2017, 10, 413–433. [Google Scholar]

- Joudi-Sarighayeh, F.; Abbaspour-Gilandeh, Y.; Kaveh, M.; Szymanek, M.; Kulig, R. Response surface methodology approach for predicting convective/infrared drying, quality, bioactive and vitamin C characteristics of pumpkin slices. Foods 2023, 12, 1114. [Google Scholar] [CrossRef] [PubMed]

- Rheem, S. Optimizing Food Processing through a New Approach to Response Surface Methodology. Food Sci. Anim. Resour. 2023, 43, 374–381. [Google Scholar] [CrossRef] [PubMed]

- Carpena, M.; Caleja, C.; Pereira, E.; Pereira, C.; Ćirić, A.; Soković, M.; Soria-Lopez, A.; Fraga-Corral, M.; Simal-Gandara, J.; Ferreira, I.C.F.R.; et al. Red Seaweeds as a Source of Nutrients and Bioactive Compounds: Optimization of the Extraction. Chemosensors 2021, 9, 132. [Google Scholar] [CrossRef]

- Madureira, J.; Melgar, B.; Santos-Buelga, C.; Margaça, F.M.A.; Ferreira, I.C.F.R.; Barros, L.; Cabo Verde, S. Phenolic compounds from irradiated olive wastes: Optimization of the heat-assisted extraction using response surface methodology. Chemosensors 2021, 9, 231. [Google Scholar] [CrossRef]

- Danbaba, N.; Nkama, I.; Badau, M.H. Application of response surface methodology (RSM) and central composite design (CCD) to optimize minerals composition of rice-cowpea composite blends during extrusion cooking. Int. J. Food Sci. Nutr. Eng. 2015, 5, 40–52. [Google Scholar]

- Alaya, I.B.; Pereira, E.; Dias, M.I.; Pinela, J.; Calhelha, R.C.; Soković, M.; Kostić, M.; Prieto, M.A.; Essid, F.; Caleja, C.; et al. Development of a natural preservative from chestnut flowers: Ultrasound-assisted extraction optimization and functionality assessment. Chemosensors 2021, 9, 141. [Google Scholar] [CrossRef]

- Zhang, Y. Application of Response Surface Methodology in Dance Health and Training Safety. Math. Probl. Eng. 2022, 2022, 9818664. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef] [PubMed]

- Goldberg, D. Genetic algorithm in search. In Optimization and Machine Learning; Addison-Wesley: Reading, MA, USA, 1989. [Google Scholar]

- Liang, J.; Lim, K.; Niu, F.; Xia, T.; Jiang, Y. Genetic algorithm predicts blended oil formulations with improved nutrition, prolonged frying life, and low cost. ACS Food Sci. Technol. 2022, 2, 1517–1524. [Google Scholar] [CrossRef]

- Wang, B.; Wei, J.; Lv, B.; Song, Y. An improved genetic algorithm for the multi-temperature food distribution with multi-station. Int. J. Adv. Comput. Sci. Appl. 2022, 13, 24–29. [Google Scholar] [CrossRef]

- Lapczynska-Kordon, B.; Fraczek, J.; Slipek, Z.; Ivanowa, T. Genetic algorithms in optimization of dried fruits and vegetables quality. In Proceedings of the 12th International Scientific Conference, Engineering for Rural Development, Latvia University of Agriculture Faculty of Engineering, Jelgava, Lativia, 23–24 May 2013; Volume 12. [Google Scholar]

- Lee, C.K.H. A review of applications of genetic algorithms in operations management. Eng. Appl. Artif. Intell. 2018, 76, 1–12. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; McCulloch, R. Application of hybrid genetic algorithm routine in optimizing food and bioengineering processes. Foods 2016, 5, 76. [Google Scholar] [CrossRef] [PubMed]

- Beg, A.H.; Islam, M.Z. Advantages and limitations of genetic algorithms for clustering records. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), Hefei, China, 5–7 June 2016; pp. 2478–2483. [Google Scholar] [CrossRef]

- Data Science Workbench, version 14; Statistica, 14.1.0.8; Cloud Software Group, Inc.: Fort Lauderdale, LA, USA, 2023. Available online: http://tibco.com(accessed on 5 September 2023).

- Maghawry, A.; Kholief, M.; Omar, Y.; Hodhod, R. An approach for evolving transformation sequences using hybrid genetic algorithms. Int. J. Comput. Intell. Syst. 2020, 13, 223–233. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Heikkila, D.J. Biomass Grinding Process Optimization Using Response Surface Methodology and a Hybrid Genetic Algorithm. Bioengineering 2019, 6, 12. [Google Scholar] [CrossRef] [PubMed]

- Tumuluru, J.S. Pelleting of Pine and Switchgrass Blends: Effect of Process Variables and Blend Ratio on the Pellet Quality and Energy Consumption. Energies 2019, 12, 1198. [Google Scholar] [CrossRef]

| Cotton Types | Percentage of U.S. Production | HVI Properties | End Uses |

|---|---|---|---|

| Upland (Gossypium hirsutum) | 97% | UI (%): 80.3 UHML (mm): 28.194–28.702 Micronaire: 3.94 Strength: 30.5 | Apparel, home use (curtains, upholstery, etc.), hospital/medical use |

| Pima (Gossypium barbadense) | 3% | UI (%): 81.2 UHML (mm): 29.972–30.48 Micronaire: 4.29 Strength (g/tex): 32.2 | Expensive/high end apparel, sewing thread |

| Treatment | First or Top Saw Speed (rpm) | Second or Middle Saw Speed (rpm) | Bottom Saw Speed (rpm) |

|---|---|---|---|

| Conventional (Full) (60 Hz) | 205 | 205 | -na- |

| 3-Saw-1/2 (30 Hz) | 196 | 149 | 92 |

| 3-Saw-3/4 (45 Hz) | 296 | 224 | 139 |

| 3-Saw-Full (60 Hz) | 395 | 299 | 186 |

| 700-1/2 (30 Hz) | 231 | -na- | 231 |

| 700-3/4 (45 Hz) | 347 | -na- | 347 |

| 700-Full (30 Hz) | 464 | -na- | 464 |

| Modified 3-Saw Cylinder Stick Machine (3-Saw) | Modified 2-Saw Cylinder Gin-Stand Feeder (700) | Conventional Reclaimer | |||

|---|---|---|---|---|---|

| CO/seed a (%) (x1) | Reclaimer speed b (Hz) (x2) | CO/seed (%) (x1) a | Reclaimer speed (Hz) (x2) b | CO/seed (%) (x1) a | Reclaimer speed b (Hz) (x2) |

| Upland | |||||

| 30.99–37.59 | 30–60 | 30.85–36.87 | 30–60 | 35.7 | 60 |

| Pima | |||||

| 4.218–6.071 | 30–60 | 4.211–4.973 | 30–60 | 4.70 | 60 |

| Cotton Types | Optimization Scenarios |

|---|---|

| Pima Upland |

|

| |

|

| Upland | |||

|---|---|---|---|

| 3-Saw | Models | Coefficient of Determination (R2) | Statistical Significance |

| Lint loss (kg/bale) | 0.99 | p < 0.01 | |

| Seed loss (kg/bale) | 0.99 | p < 0.01 | |

| 700 | |||

| Lint loss (kg/bale) | 0.92 | p < 0.1 | |

| Seed loss (kg/bale) | 0.99 | p < 0.001 | |

| Pima | |||

| 3-Saw | Models | Coefficient of Determination | Statistical Significance |

| Lint loss (kg/bale) | 0.84 | NS | |

| Seed loss (kg/bale) | 0.99 | p < 0.01 | |

| 700 | |||

| Lint loss (kg/bale) | 0.99 | p < 0.01 | |

| Seed loss (kg/bale) | 0.99 | p < 0.0001 | |

| Model Terms | Upland Cotton | Pima Cotton | ||||||

|---|---|---|---|---|---|---|---|---|

| 3-Saw | 700 | 3-Saw | 700 | |||||

| Lint Loss | Seed Loss | Lint Loss | Seed Loss | Lint Loss | Seed Loss | Lint Loss | Seed Loss | |

| Intercept | ns | ns | ns | ns | ns | ns | * | * |

| Linear | ||||||||

| x1 | * | ns | ns | ns | ns | ns | * | ** |

| x2 | ns | ns | ns | ns | ** | ns | ** | * |

| Quadratic | ||||||||

| x12 | * | ns | ns | ns | ns | ns | * | ** |

| x22 | ns | ** | ns | ** | ** | ns | * | * |

| Interactive | ||||||||

| x1x2 | ns | ns | ns | ns | ns | ns | ** | ** |

| Upland | Minimum | Minimum | |

|---|---|---|---|

| x1 (Carryover/Seed Ratio) | x2 (Reclaimer Speed, Rpm) | Lint Loss (kg/bale) | Seed Loss (kg/bale) |

| 3-saw | |||

| 35.97 | 32.43 | 0.38 | |

| 31.21 | 59.99 | 21.29 | |

| 700 | |||

| 31.24 | 30.08 | 0.19 | |

| 33.83 | 59.86 | 13.90 | |

| Pima | Minimum | Minimum | |

| 3-saw | |||

| 4.292 | 46.41 | 0.094 | |

| 5.904 | 59.80 | 13.22 | |

| 700 | |||

| 4.866 | 30.16 | 0.13 | |

| 4.965 | 59.99 | 8.58 | |

| Cotton Variety | Carryover/Seed Ratio (%) | Reclaimer Speed (Hz) | Minimum Seed Loss (kg/bale) | Minimum Lint Loss (kg/bale) |

|---|---|---|---|---|

| Upland | ||||

| 3-saw | 31.05 | 59.56 | 20.84 | 1.51 |

| 700 | 33.54 | 59.68 | 13.95 | 1.48 |

| Pima | ||||

| 3-saw | 5.988 | 59.75 | 13.01 | 0.15 |

| 700 | 4.926 | 59.99 | 8.91 | 0.34 |

| Upland | Lint Loss (kg/bale) | Seed Loss (kg/bale) | Economic Loss ($/bale) |

|---|---|---|---|

| Conventional-Industry standard | 5.63 | 24.37 | 15.97 |

| 3-Saw (minimum lint loss) (Table 7) | 0.38 (minimum) | 59.40 | 18.38 |

| 3-Saw (minimum seed loss) (Table 7) | 1.46 | 21.29 (minimum) | 8.63 |

| 700 (minimum lint loss) (Table 7) | 0.19 (minimum) | 37.68 | 11.58 |

| 700 (minimum seed loss) (Table 7) | 1.48 | 13.90 (minimum) | 6.44 |

| 3-Saw and 700-parallel arrangement (seed and lint loss) (Table 8) | 2.99 | 34.79 | 15.03 |

| Pima | |||

| Conventional-Industry standard | 0.69 | 4.32 | 3.44 |

| 3-Saw (minimum lint loss) (Table 7) | 0.094 (minimum) | 15.99 | 4.93 |

| 3-Saw (minimum seed loss) (Table 7) | 0.15 | 13.22 (minimum) | 4.30 |

| 700 (minimum lint loss) (Table 7) | 0.13 (minimum) | 18.99 | 5.92 |

| 700 (minimum seed loss) (Table 7) | 0.35 | 8.58 (minimum) | 3.59 |

| 3-Saw and 700-parallel arrangement (minimum seed and lint loss) (Table 8) | 0.49 | 21.92 | 7.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tumuluru, J.S.; Armijo, C.B.; Whitelock, D.P.; Funk, P.A. Modeling and Optimization of High-Capacity Experimental Reclaimers to Minimize the Seed and Lint Loss during Roller Ginning of Upland and Pima Cotton. Processes 2023, 11, 2868. https://doi.org/10.3390/pr11102868

Tumuluru JS, Armijo CB, Whitelock DP, Funk PA. Modeling and Optimization of High-Capacity Experimental Reclaimers to Minimize the Seed and Lint Loss during Roller Ginning of Upland and Pima Cotton. Processes. 2023; 11(10):2868. https://doi.org/10.3390/pr11102868

Chicago/Turabian StyleTumuluru, Jaya Shankar, Carlos B. Armijo, Derek P. Whitelock, and Paul A. Funk. 2023. "Modeling and Optimization of High-Capacity Experimental Reclaimers to Minimize the Seed and Lint Loss during Roller Ginning of Upland and Pima Cotton" Processes 11, no. 10: 2868. https://doi.org/10.3390/pr11102868

APA StyleTumuluru, J. S., Armijo, C. B., Whitelock, D. P., & Funk, P. A. (2023). Modeling and Optimization of High-Capacity Experimental Reclaimers to Minimize the Seed and Lint Loss during Roller Ginning of Upland and Pima Cotton. Processes, 11(10), 2868. https://doi.org/10.3390/pr11102868