Assessment of the Dimensionless Groups-Based Scale-Up of Gas–Solid Fluidized Beds

Abstract

1. Introduction

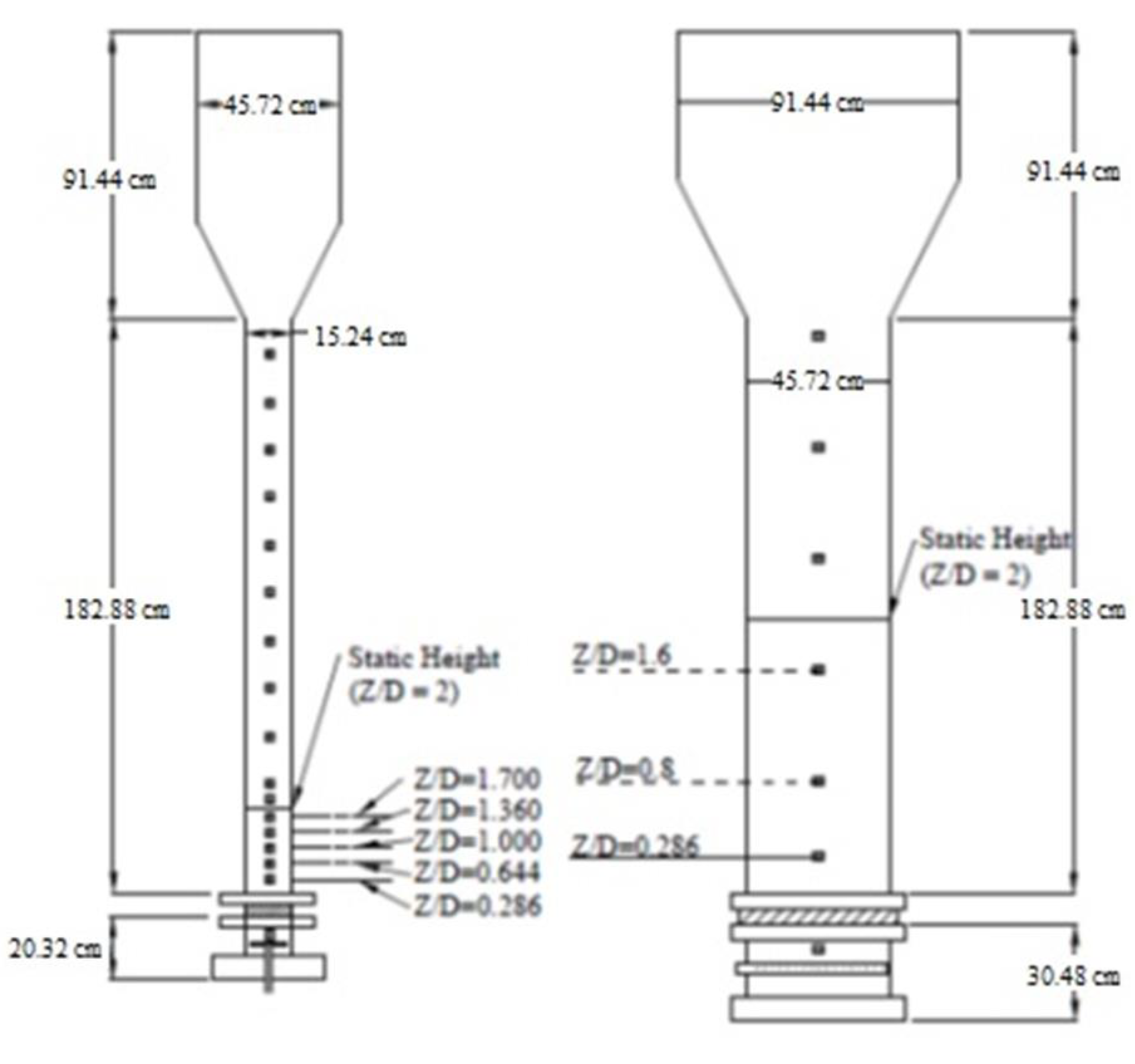

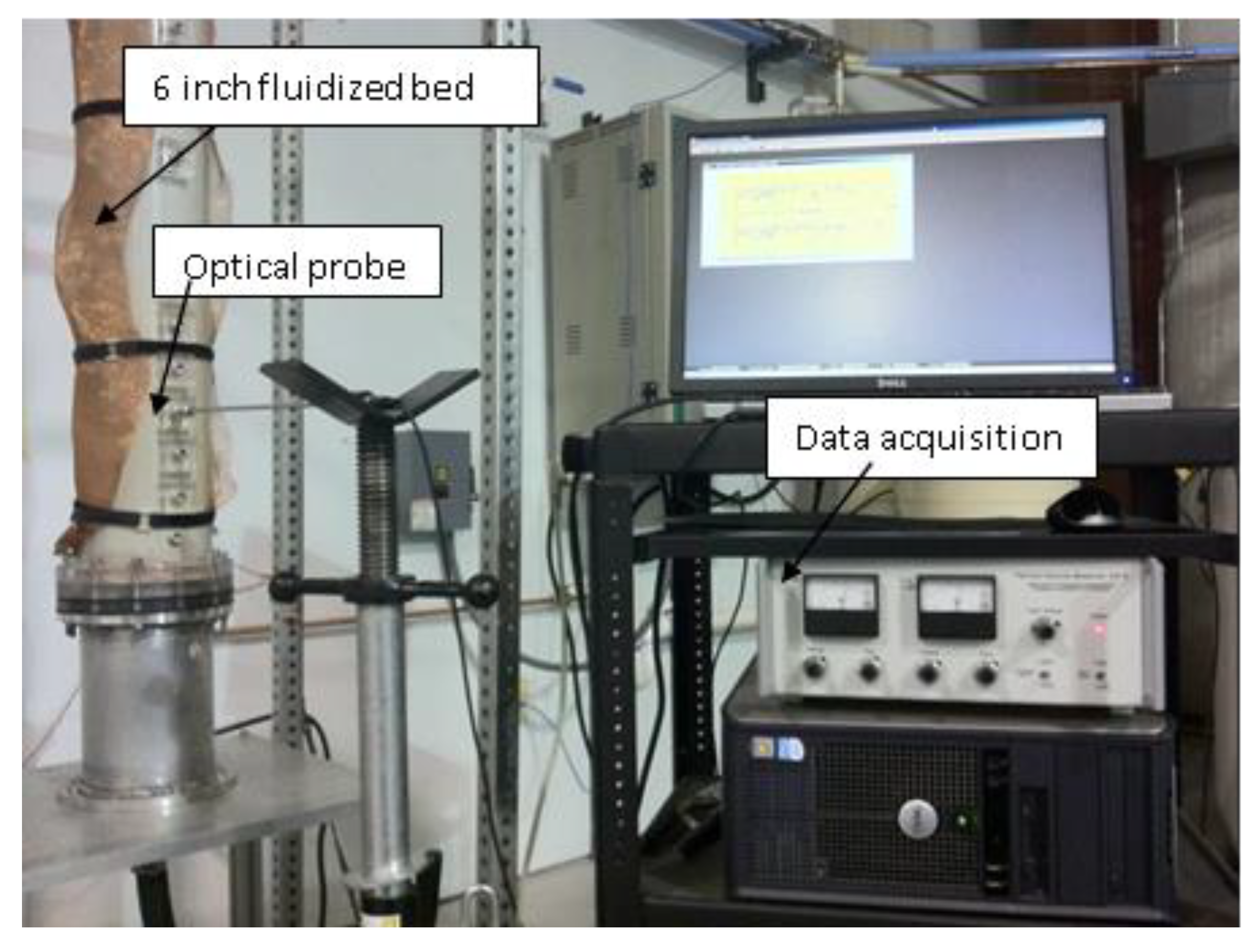

2. Experimental Set-Up and Measurement Techniques

2.1. Experimental Setup

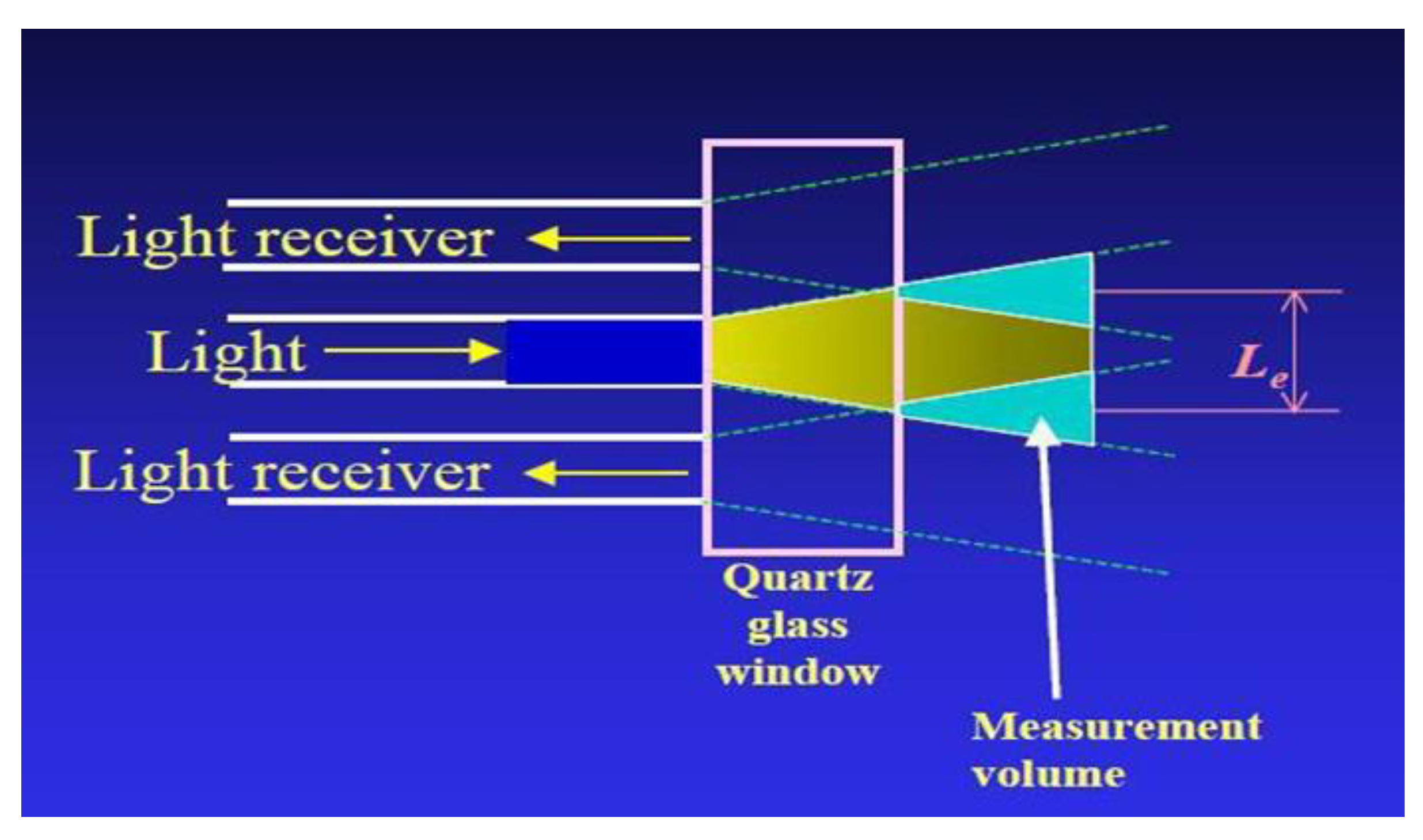

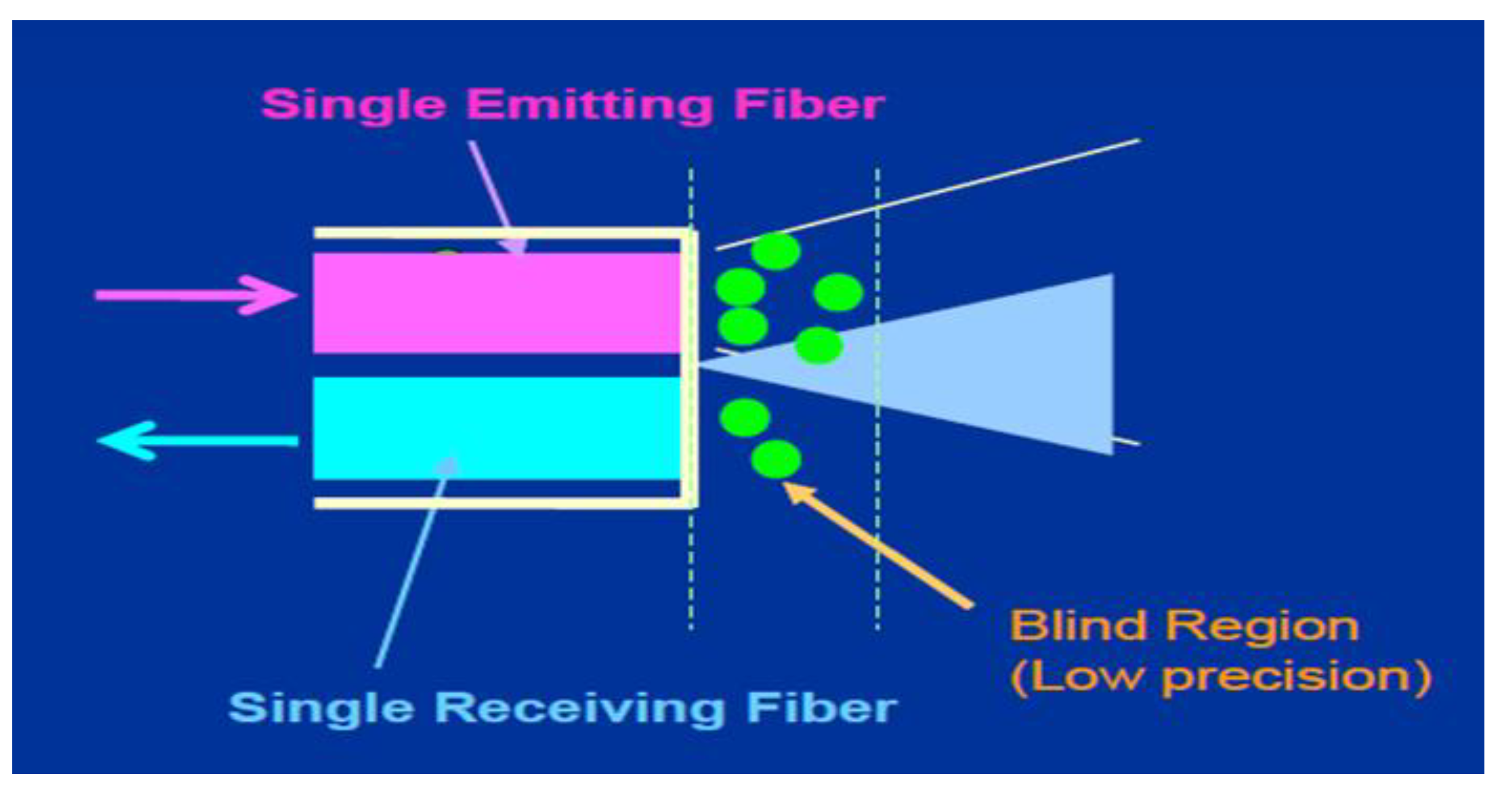

2.2. Measurement Techniques

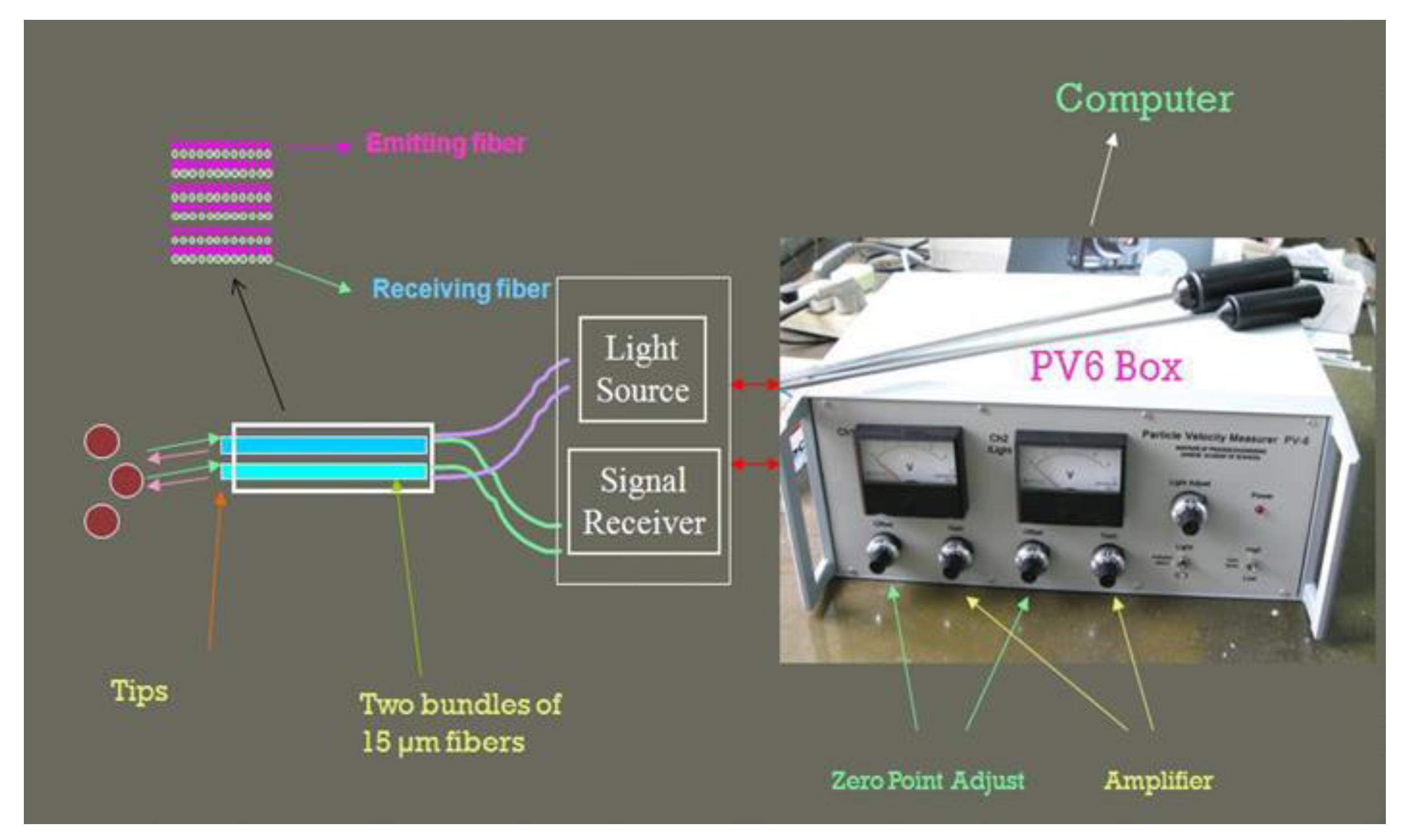

2.2.1. Optical Probe

2.2.2. Optical Probe Electronics

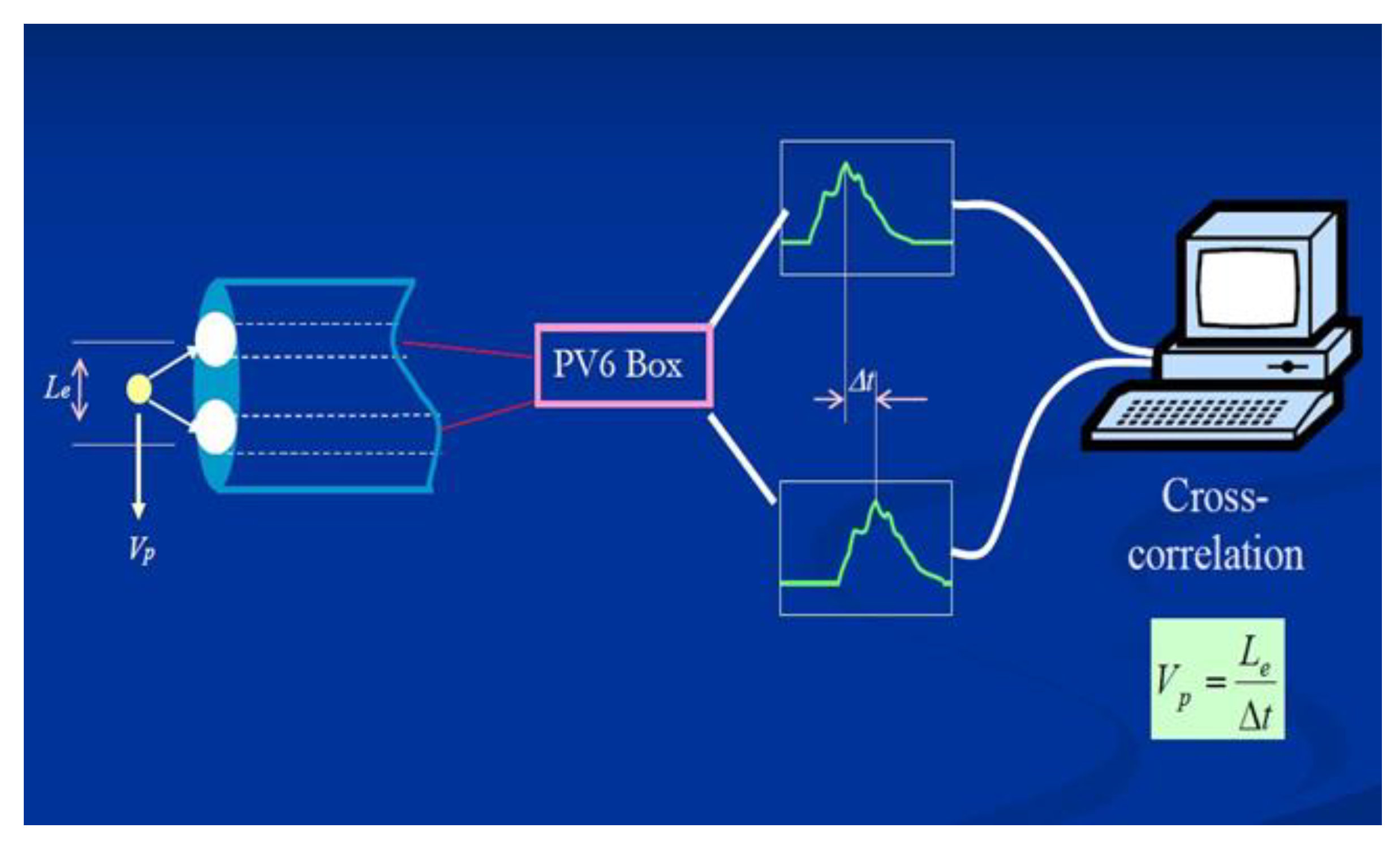

2.2.3. Solids Velocity Measurement

2.2.4. Solids Concentration Measurement

- The tips measure the number of particles in the measuring volume in front of the tips of the probe. The two tips produce signals related to voltage when there is movement and presence of particles. Any one of the signals can be taken to process the data.

- These recorded signals are then normalized as follows:where Vavg is average voltage, Vmax is maximum voltage, Vmin is minimum voltage.

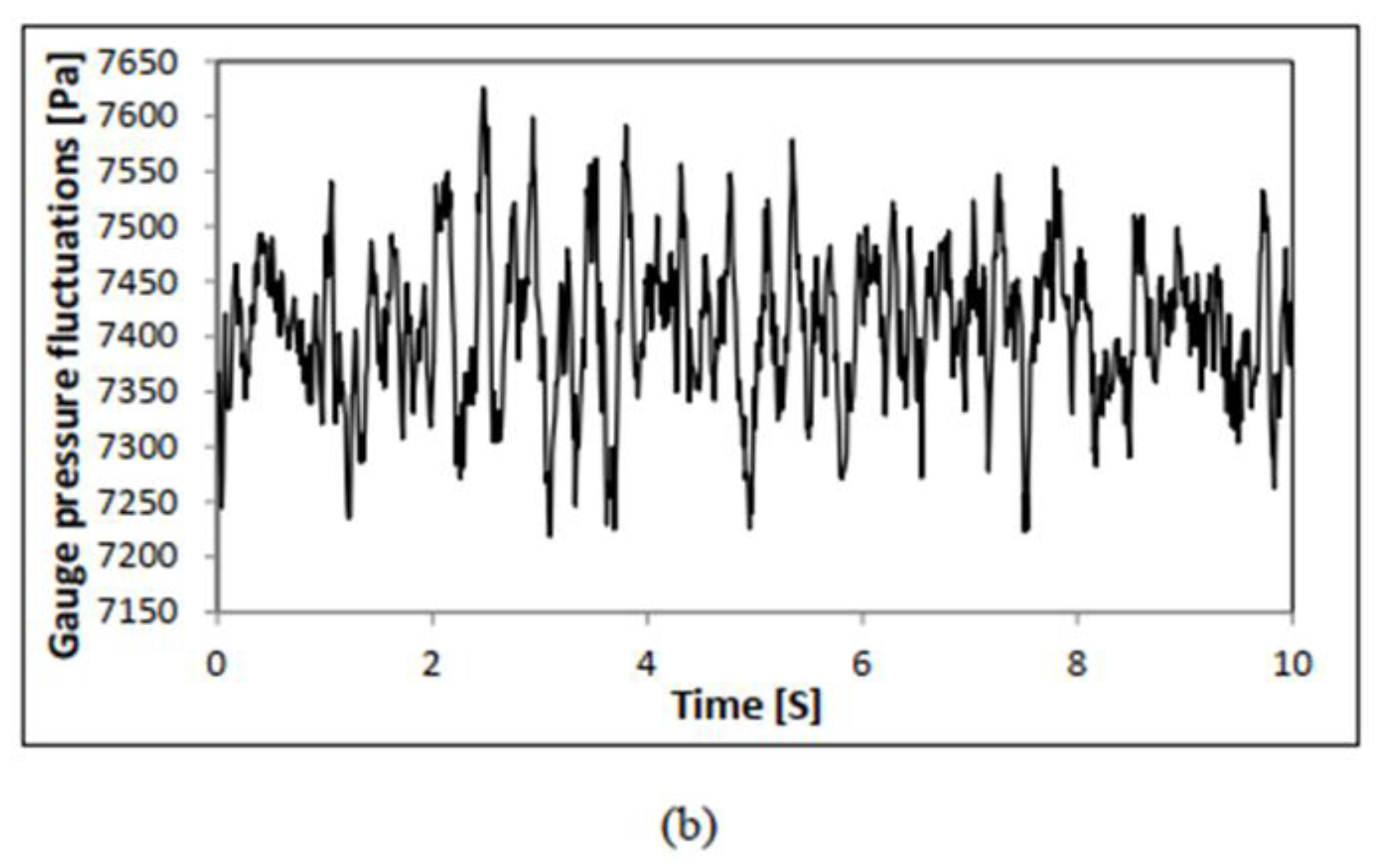

2.2.5. Pressure Transducer

2.2.6. Experimental Conditions

- Froude number (.

- The solids to gas density ratio ().

- The ratio of superficial gas velocity to minimum fluidization velocity ().

- Geometric ratios (), and ().

- Particle sphericity ().

- Particle size distribution.

3. Results and Discussion

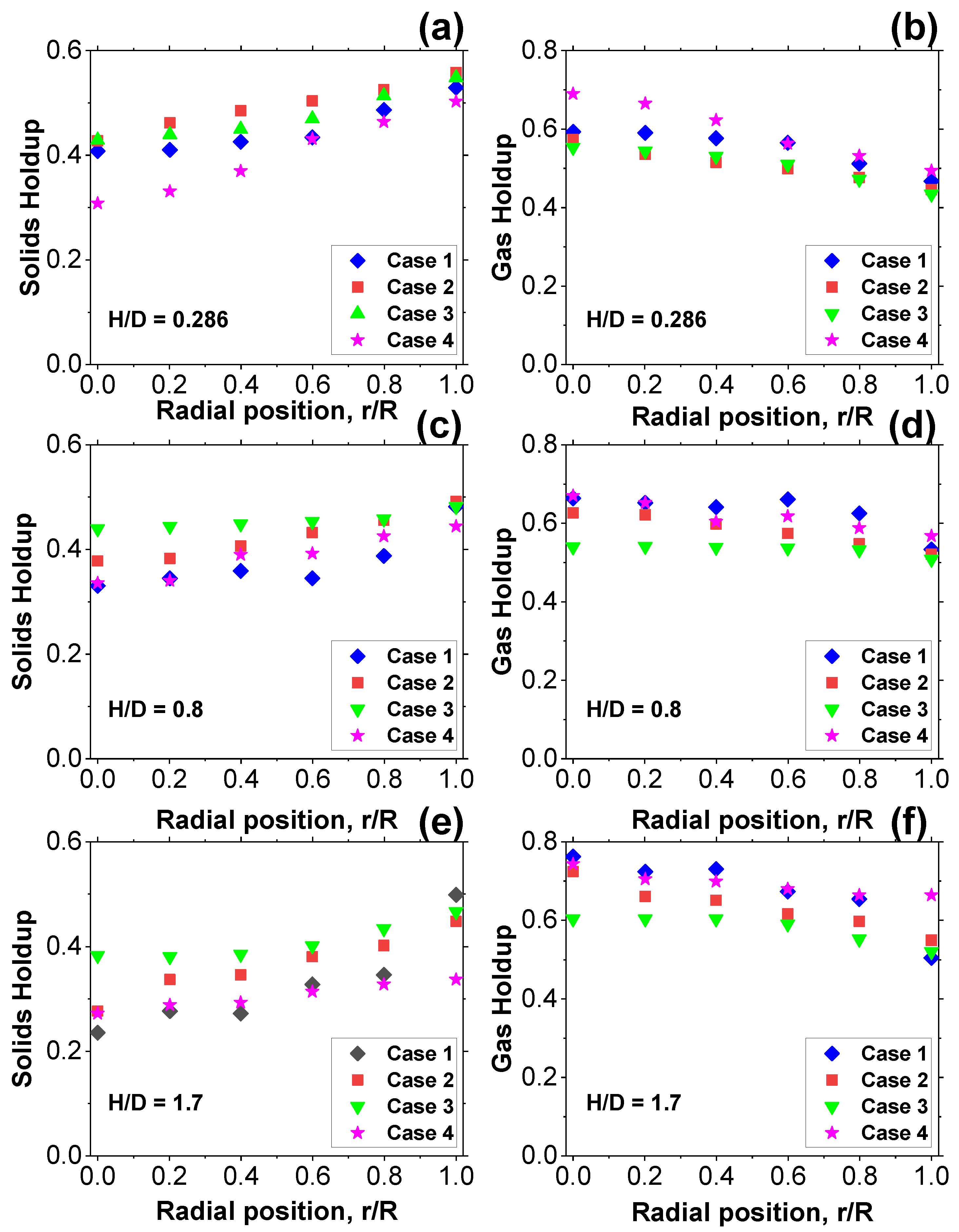

3.1. Solids and Gas Hold-Up

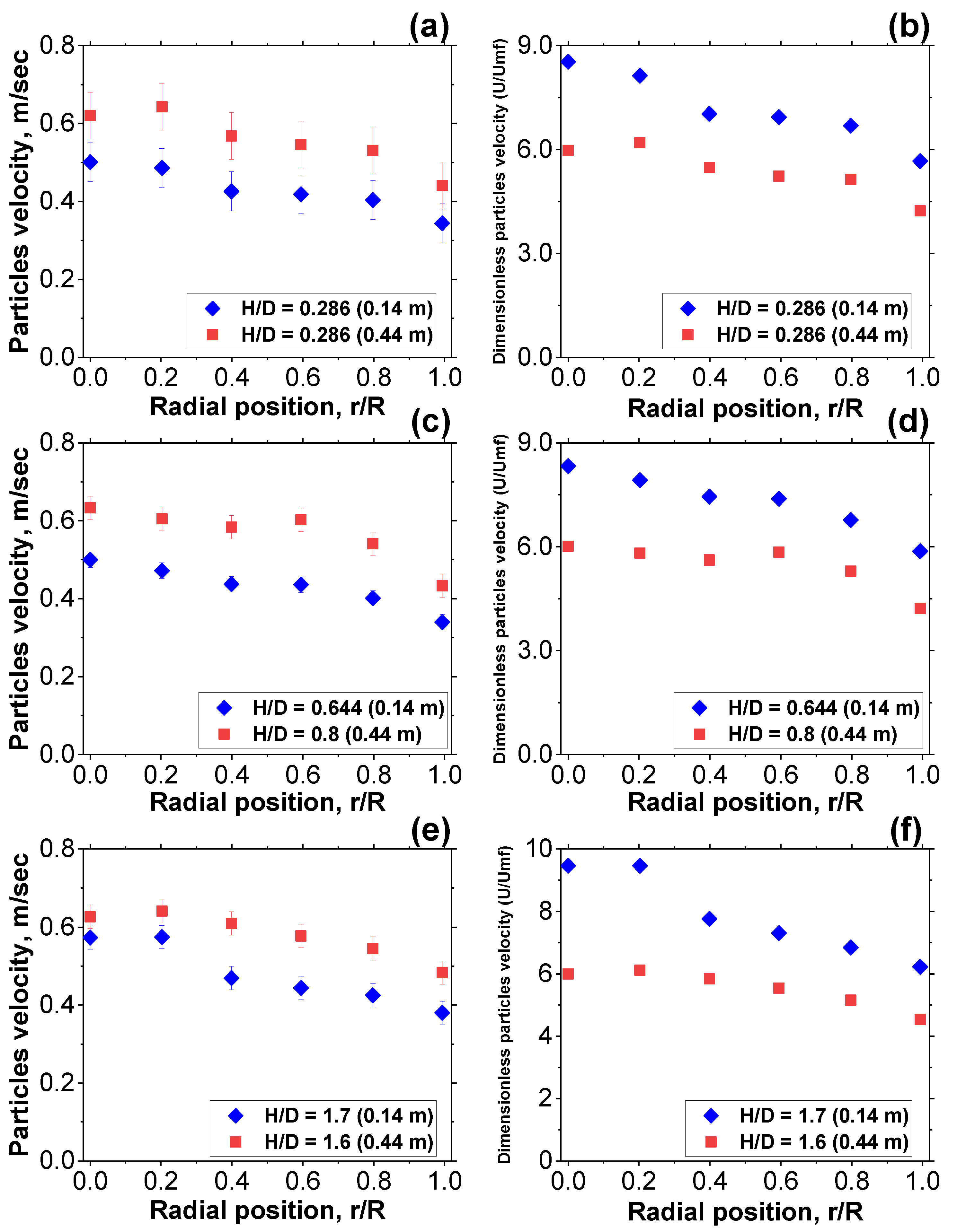

3.2. Particles Velocity

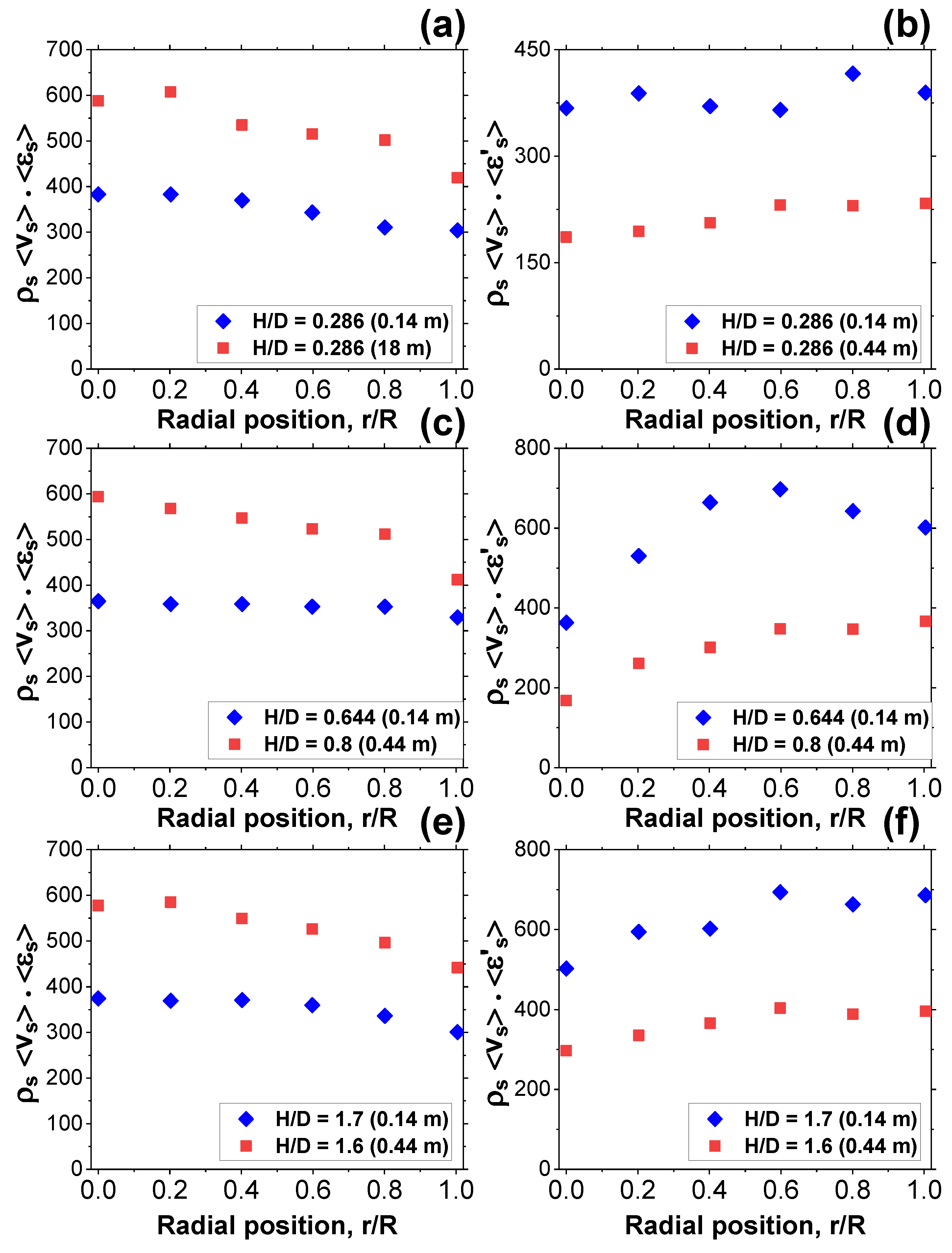

3.3. Mass Flux of up Flowing Particles

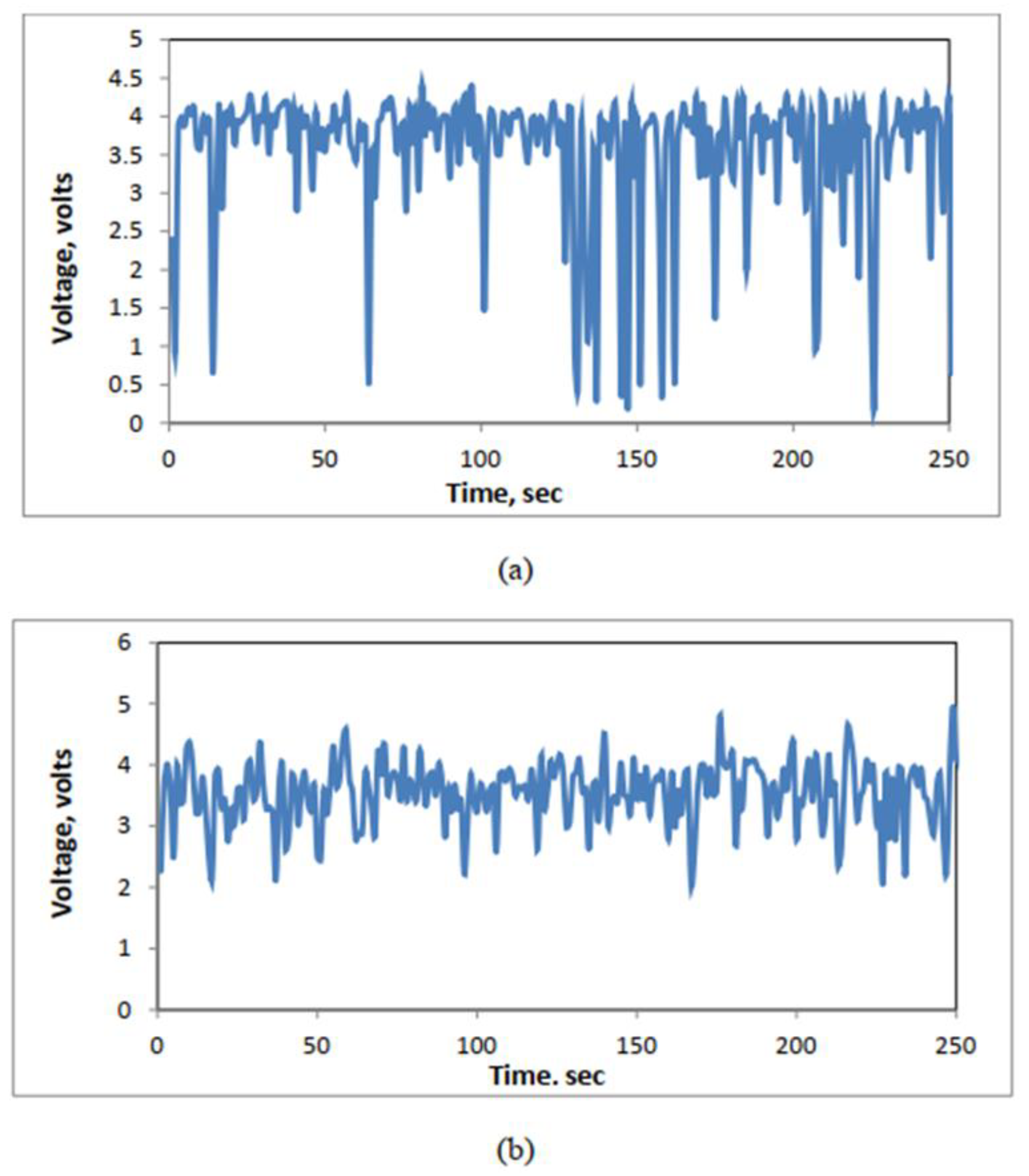

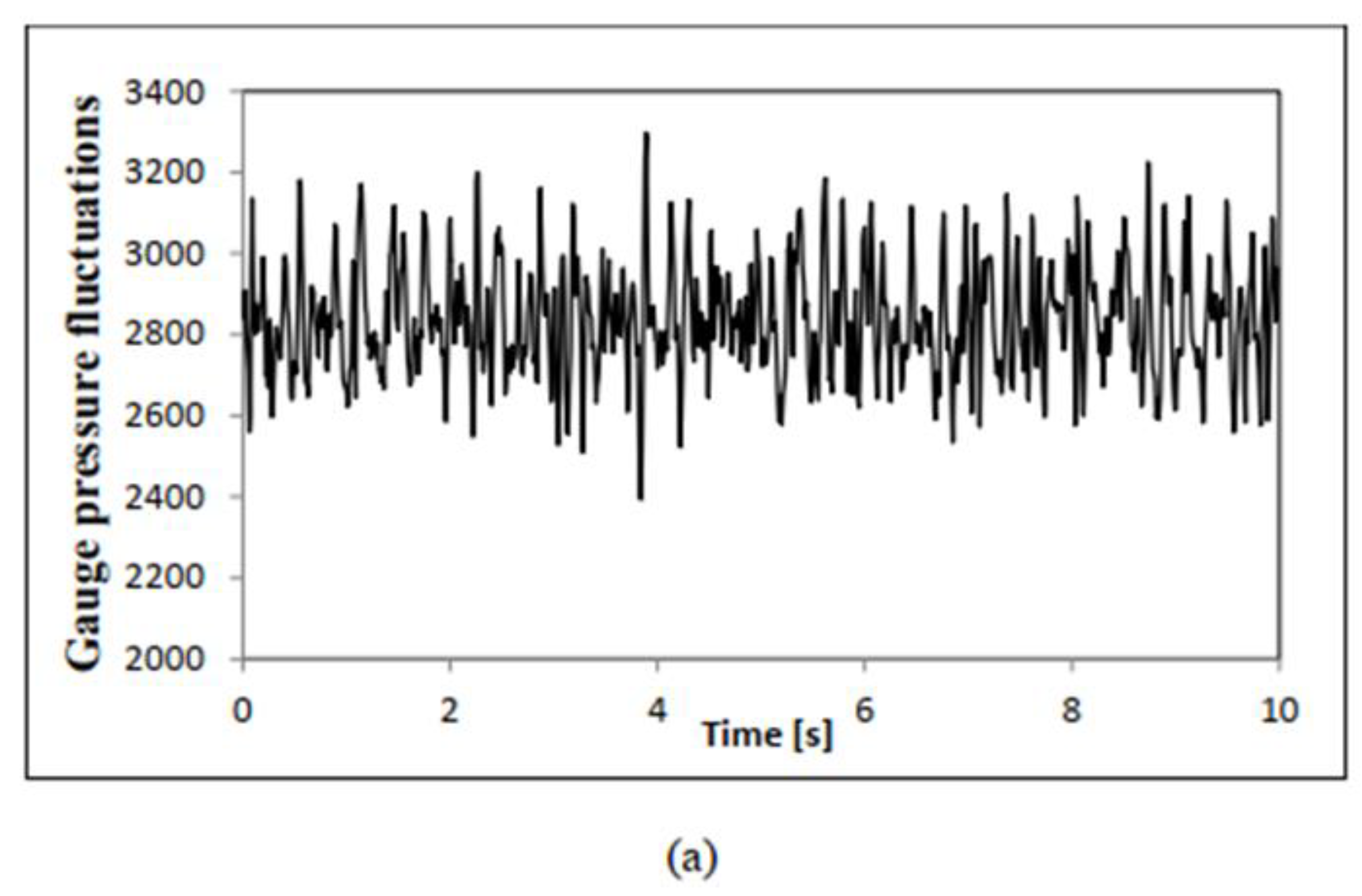

3.4. Time Series of the Optical Probe and Pressure Fluctuation Measurement

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| Column Diameter | |

| Particle Diameter | |

| FBR | Fluidized Bed Reactor |

| Froude Number | |

| g | Gravitational Constant |

| H | Bed Height |

| L | Column Height |

| P | Pressure |

| Gas Reynold No. | |

| Particle Reynold No. | |

| Drag Coefficient | |

| Coefficient of Particle Restitution | |

| Particle-Wall restitution coefficient | |

| Production of Turbulence Kinetic Energy | |

| Radial Distribution Function | |

| The Second Invariant of the Deviatoric Stress Tensor | |

| Unit Tensor | |

| Turbulence Quantities of Gas Phase | |

| P | Bed Pressure |

| Overall Pressure Drop | |

| T | Temperature |

| t | Time |

| U | Superficial Gas Velocity |

| Umf | Minimum Fluidization Velocity |

| Particle Velocity | |

| Terminal Velocity | |

| Greek letters | |

| Gas Volume Fraction | |

| Solid Volume Fraction | |

| Specularity Coefficient | |

| Diffusion Coefficient | |

| Energy Dissipation | |

| Stress Tensor | |

| Solid Bulk Viscosity | |

| Solid Shear Viscosity | |

| Solid Collisional Viscosity | |

| Solid Frictional Viscosity | |

| Solid Kinetic Viscosity | |

| Internal Friction Angle of Particle | |

| Transfer rate of Kinetic Energy | |

| Density | |

| Granular Temperature | |

| Dispersion Prandtl Number | |

References

- Sun, Y.; Sage, V.; Sun, Z. An enhanced process of using direct fluidized bed calcination of shrimp shell for biodiesel catalyst preparation. Chem. Eng. Res. Des. 2017, 126, 142–152. [Google Scholar] [CrossRef]

- Kim, S.W.; Kim, S.D. Void Properties in Dense Bed of Cold-Flow Fluid Catalytic Cracking Regenerator. Processes 2018, 6, 80. [Google Scholar] [CrossRef]

- Husin, H.; Faisal, M.; Gani, A.; Mamat, R. Combustion Efficiency in a Fluidized-Bed Combustor with a Modified Perforated Plate for Air Distribution. Processes 2021, 9, 1489. [Google Scholar]

- Git, P.; Hofmeister, M.; Singer, R.F.; Körner, C. Fluidization behavior of graphitized glassy particles in a fluidized carbon bed cooling process for investment casting. Particuology 2022, 65, 32–38. [Google Scholar] [CrossRef]

- Zhuang, H.; Chen, X.; Feng, T. Research on Technology of Medicinal Functional Food. Processes 2022, 10, 1509. [Google Scholar] [CrossRef]

- Coppola, A.; Scala, F.; Azadi, M. Direct Dry Carbonation of Mining and Industrial Wastes in a Fluidized Bed for Offsetting Carbon Emissions. Processes 2022, 10, 582. [Google Scholar] [CrossRef]

- Zhang, R.; Hoffmann, T.; Tsotsas, E. Novel Technique for Coating of Fine Particles Using Fluidized Bed and Aerosol Atomizer. Processes 2020, 8, 1525. [Google Scholar] [CrossRef]

- Ali, N.; Al-Juwaya, T.; Al-Dahhan, M. An advanced evaluation of spouted beds scale-up for coating TRISO nuclear fuel particles using Radioactive Particle Tracking (RPT). Exp. Therm. Fluid Sci. 2017, 80, 90–104. [Google Scholar] [CrossRef]

- Wang, S.; Shen, Y. Particle-scale modelling of the pyrolysis of end-of-life solar panel particles in fluidized bed reactors. Resour. Conserv. Recycl. 2022, 183, 106378. [Google Scholar] [CrossRef]

- Żukowski, W.; Jankowski, D.; Wrona, J.; Berkowicz-Płatek, G. Combustion behavior and pollutant emission characteristics of polymers and biomass in a bubbling fluidized bed reactor. Energy 2023, 263, 125953. [Google Scholar] [CrossRef]

- Wang, S.; Shen, Y. Coarse-grained CFD-DEM modelling of dense gas-solid reacting flow. Int. J. Heat Mass Transf. 2022, 184, 122302. [Google Scholar] [CrossRef]

- Abdelmotalib, H.M.; Youssef, M.A.M.; Hassan, A.A.; Youn, S.B.; Im, I.-T. Heat transfer process in gas–solid fluidized bed combustors: A review. Int. J. Heat Mass Transf. 2015, 89, 567–575. [Google Scholar] [CrossRef]

- Horio, M.; Nonaka, A.; Sawa, Y.; Muchi, I. A new similarity rule for fluidized bed scale-up. AIChE J. 1986, 32, 1466–1482. [Google Scholar] [CrossRef]

- Efhaima, A.; Al-Dahhan, M.H. Assessment of scale-up dimensionless groups methodology of gas-solid fluidized beds using advanced non-invasive measurement techniques (CT and RPT). Can. J. Chem. Eng. 2017, 95, 656–669. [Google Scholar] [CrossRef]

- Efhaima, A.; Al-Dahhan, M.H. Validation of the new mechanistic scale-up of gas-solid fluidized beds using advanced non-invasive measurement techniques. Can. J. Chem. Eng. 2021, 99, 1984–2002. [Google Scholar] [CrossRef]

- Glicksman, L.R. Scaling relationships for fluidized beds. Chem. Eng. Sci. 1984, 39, 1373–1379. [Google Scholar] [CrossRef]

- Nicastro, M.T.; Glicksman, L.R. Experimental verification of scaling relationships for fluidized bed. Chem. Eng. Sci. 1984, 39, 1381–1391. [Google Scholar] [CrossRef]

- Schouten, J.C.; Vander Stappen, M.L.M.; Van Den Bleek, C.M. Scale-up of chaotic fluidized bed hydrodynamics. Chem. Eng. Sci. 1996, 51, 1991–2000. [Google Scholar] [CrossRef]

- Mabrouk, R.; Radmanesh, R.; Chaouki, J.; Guy, C. Scale Effects on Fluidized Bed Hydrodynamics. Int. J. Chem. React. Eng. 2005, 3. [Google Scholar] [CrossRef]

- Glicksman, L.R.; Hyre, M.; Woloshun, K. Simplified scaling relationships for fluidized beds. Powder Technol. 1993, 77, 177–199. [Google Scholar] [CrossRef]

- Knowlton, T.M.; Karri, S.B.R.; Issangya, A. Scale-up of fluidized-bed hydrodynamics. Powder Technol. 2005, 150, 72–77. [Google Scholar] [CrossRef]

- Patience, G.S.; Chaouki, J.; Berruti, F.; Wong, R. Scaling considerations for circulating fluidized bed risers. Powder Technol. 1992, 72, 31–37. [Google Scholar] [CrossRef]

- Rüdisüli, M.; Schildhauer, T.J.; Biollaz, S.M.A.; van Ommen, J.R. Scale-up of bubbling fluidized bed reactors—A review. Powder Technol. 2012, 217, 21–38. [Google Scholar] [CrossRef]

- Frye, C.G.; Lake, W.C.; Eckstrom, H.C. Gas-solid contacting with ozone decomposition reaction. AIChE J. 1958, 4, 403–408. [Google Scholar] [CrossRef]

- Chen, W.; Hasegawa, T.; Tsutsumi, A.; Otawara, K. Scale-up effects on the time-averaged and dynamic behavior in bubble column reactors. Chem. Eng. Sci. 2001, 56, 6149–6155. [Google Scholar] [CrossRef]

- van Ommen, J.R.; Teuling, M.; Nijenhuis, J.; van Wachem, B.G.M. Computational validation of the scaling rules for fluidized beds. Powder Technol. 2006, 163, 32–40. [Google Scholar] [CrossRef]

- Romero, J.B. Factors Affecting Fluidized Bed Quality; University of Washington: Seattle, WA, USA, 1959. [Google Scholar]

- Broadhurst, T.; Becker, H. The Application of the Theory of Dimensions to Fluidized Beds. In Proceedings of the International Symposium, Fluidization and its Applications, Toulouse, France; 1973; pp. 10–27. [Google Scholar]

- Foscolo, P.U.; Di Felice, R.; Gibilaro, L.G.; Pistone, L.; Piccolo, V. Scaling relationships for fluidisation: The generalised particle bed model. Chem. Eng. Sci. 1990, 45, 1647–1651. [Google Scholar] [CrossRef]

- Glicksman, L.R. Scaling relationships for fluidized beds. Chem. Eng. Sci. 1988, 43, 1419–1421. [Google Scholar] [CrossRef]

- Clift, R.; Grace, J.R. The Mechanism of Bubble Break-Up in Fluidised Beds. Chem. Eng. Sci. 1972, 27, 2309–2310. [Google Scholar] [CrossRef]

- Stein, M.; Ding, Y.L.; Seville, J.P.K. Experimental verification of the scaling relationships for bubbling gas-fluidised beds using the PEPT technique. Chem. Eng. Sci. 2002, 57, 3649–3658. [Google Scholar] [CrossRef]

- Taofeeq, H.; Al-Dahhan, M. Comparison between the new mechanistic and the chaos scale-up methods for gas-solid fluidized beds. Chin. J. Chem. Eng. 2018, 26, 1401–1411. [Google Scholar] [CrossRef]

- Aradhya, S.; Taofeeq, H.; Al-Dahhan, M. Evaluation of the dimensionless groups based scale-up of gas–solid spouted beds. Int. J. Multiph. Flow 2017, 94, 209–218. [Google Scholar] [CrossRef]

- Zhang, H.; Johnston, P.M.; Zhu, J.X.; de Lasa, H.I.; Bergougnou, M.A. A novel calibration procedure for a fiber optic solids concentration probe. Powder Technol. 1998, 100, 260–272. [Google Scholar] [CrossRef]

- Wang, Z.; Bi, H.T.; Lim, C.J. Measurements of local flow structures of conical spouted beds by optical fibre probes. Can. J. Chem. Eng. 2009, 87, 264–273. [Google Scholar] [CrossRef]

- Wang, C.; Li, Z.; Wei, J.; Lan, X.; Ye, M.; Gao, J. Quantitative Measurement of Solids Holdup for Group A and B Particles Using Images and Its Application in Fluidized Bed Reactors. Processes 2022, 10, 610. [Google Scholar] [CrossRef]

- Hilal, N.; Gunn, D.J. Solid hold up in gas fluidised beds. Chem. Eng. Process. Process Intensif. 2002, 41, 373–379. [Google Scholar] [CrossRef]

- Fogler, H.S.; Brown, L.F. Predictions of Fluidized Bed Operation Under Two Limiting Conditions: Reaction Control and Transport Control. In Chemical Reactors; American Chemical Society: Washington, DC, USA, 1981; Volume 168, pp. 31–54. [Google Scholar]

| Condition/Cases | Case 1 | Case 2 | Case 3 | Case 4 | |||

|---|---|---|---|---|---|---|---|

| Dc (m) | 0.44 | 0.14 | 0.14 | 0.14 | |||

| L (m) | 4.877 | 4.775 | 4.775 | 4.775 | |||

| H (m) | 0.88 | 0.28 | 0.28 | 0.28 | |||

| T (K) | 298 | 298 | 298 | 298 | |||

| P (Kpa) | 101 | 101 | 101 | 101 | |||

| dp (µ m) | 210 | 70 | 210 | 200 | |||

| ρs (kg/(m3)) | 2500 | 2500 | 2500 | 5300 | |||

| ρf (kg/(m3)) | 1.21 | 1.21 | 1.21 | 1.21 | |||

| µ (kg·s m−2) | 1.81 × 10−5 | 1.81 × 10−5 | 1.81 × 10−5 | 1.81 × 10−5 | |||

| U (m/s) | 0.36 | 0.2 | 0.2 | 0.36 | Absolute Relative Difference % | ||

| Scaling groups/Particles | Glass beads | Copper | Cases 1 and 2 | Cases 1 and 3 | Cases 1 and 4 | ||

| φ | 0.95 | 0.95 | 0.95 | 0.85 | 0 | 0 | 10.5 |

| Dc/dp | 2095.24 | 2000 | 666.67 | 700 | 4.55 | 68.18 | 66.59 |

| H/Dc | 2 | 2 | 2 | 2 | 0 | 0 | 0 |

| ρs/ρf | 2066.12 | 2066.12 | 2066.12 | 4380.17 | 0 | 0 | 52.83 |

| U/Umf | 3.43 | 3.33 | 1.67 | 1.8 | 2.78 | 51.39 | 47.5 |

| Fr = (U2)/g × H | 0.015 | 0.0145 | 0.0145 | 0.047 | 3 | 3 | 68.18 |

| Additional scaling groups | |||||||

| Fr = (U2)/g × Dc | 0.03 | 0.029 | 0.029 | 0.094 | 3 | 3 | 68.18 |

| Um/((g × Dc)0.5) | 2.31 | 2.29 | 2.64 | 4.52 | 1.03 | 14.29 | 48.77 |

| Ref = ρf × dp × U/µ | 5.05 | 0.94 | 2.81 | 4.81 | 81.48 | 44.44 | 4.76 |

| Res = ρs × dp × U/µ(×10−3) | 10.44 | 1.93 | 5.8 | 21.08 | 81.48 | 44.44 | 50.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaid, F.M.; Al-Rubaye, H.; Aljuwaya, T.M.; Al-Dahhan, M.H. Assessment of the Dimensionless Groups-Based Scale-Up of Gas–Solid Fluidized Beds. Processes 2023, 11, 168. https://doi.org/10.3390/pr11010168

Zaid FM, Al-Rubaye H, Aljuwaya TM, Al-Dahhan MH. Assessment of the Dimensionless Groups-Based Scale-Up of Gas–Solid Fluidized Beds. Processes. 2023; 11(1):168. https://doi.org/10.3390/pr11010168

Chicago/Turabian StyleZaid, Faraj M., Haider Al-Rubaye, Thaar M. Aljuwaya, and Muthanna H. Al-Dahhan. 2023. "Assessment of the Dimensionless Groups-Based Scale-Up of Gas–Solid Fluidized Beds" Processes 11, no. 1: 168. https://doi.org/10.3390/pr11010168

APA StyleZaid, F. M., Al-Rubaye, H., Aljuwaya, T. M., & Al-Dahhan, M. H. (2023). Assessment of the Dimensionless Groups-Based Scale-Up of Gas–Solid Fluidized Beds. Processes, 11(1), 168. https://doi.org/10.3390/pr11010168