Study on Health Indicator Construction and Health Status Evaluation of Hydraulic Pumps Based on LSTM–VAE

Abstract

1. Introduction

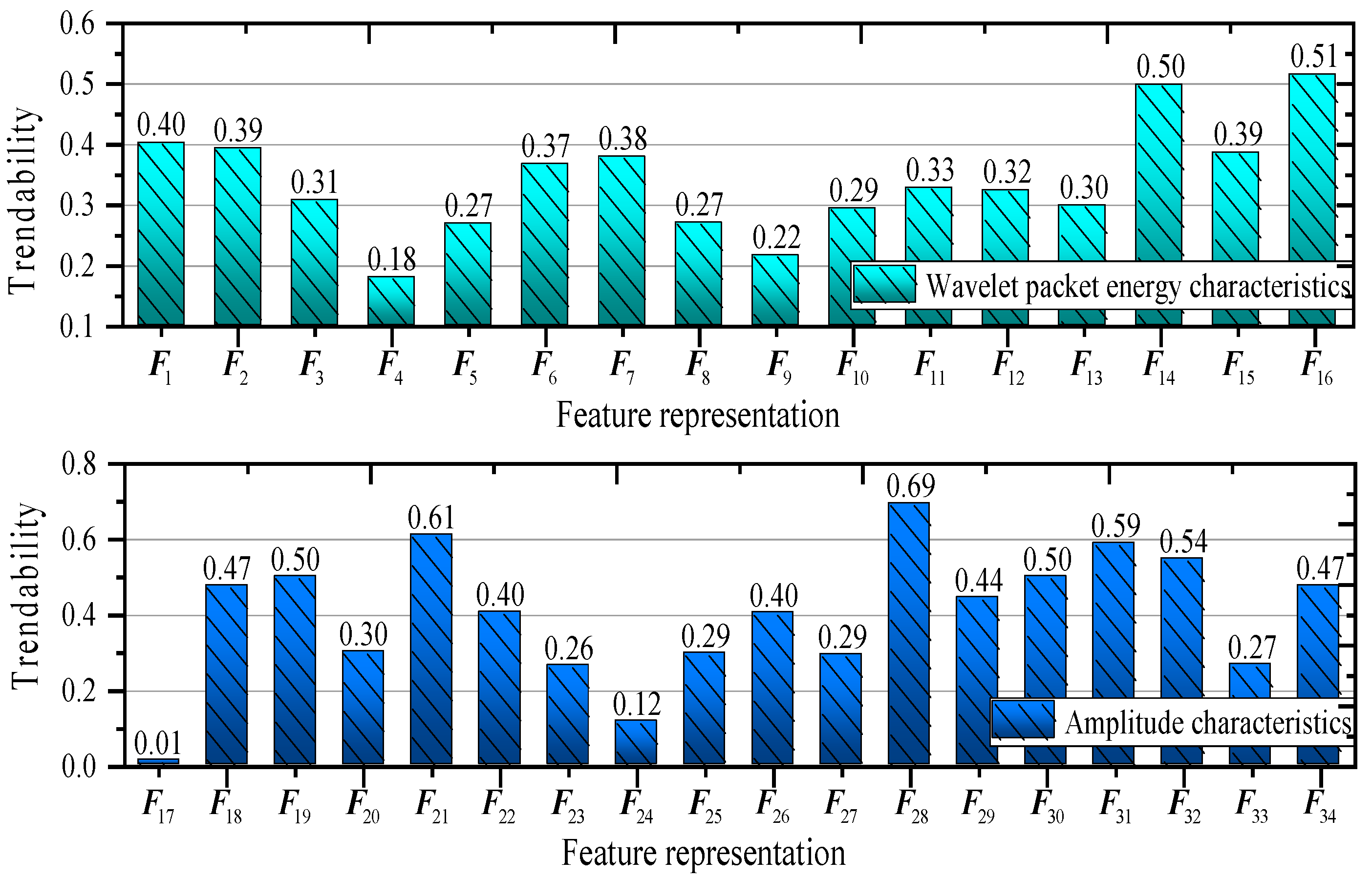

2. Feature Extraction and Feature Selection

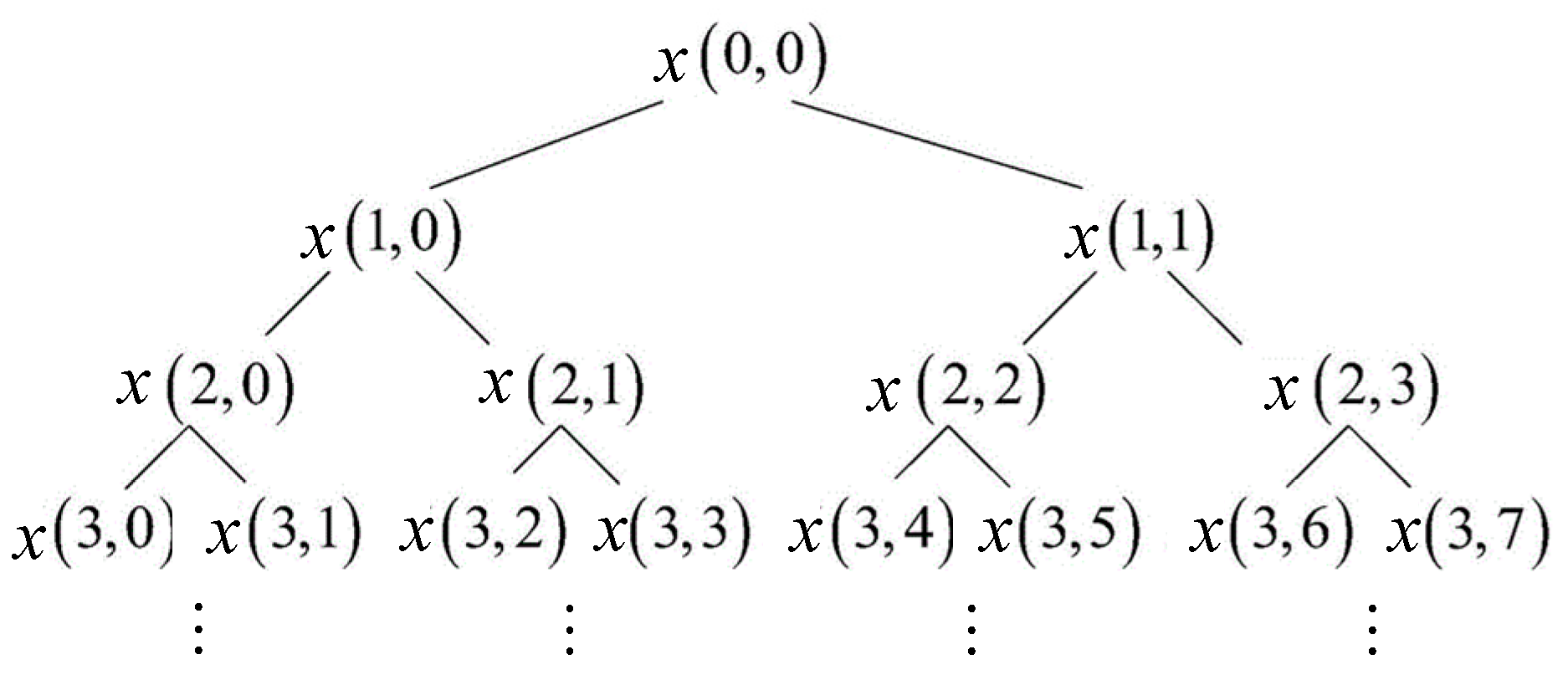

2.1. Wavelet Packet Energy Feature Extraction

2.2. Time–Frequency Domain Feature Extraction

2.3. Health Indicator Evaluation Index

- (1)

- Monotonicity

- (2)

- Robustness

- (3)

- Trendability

3. Variational Auto-Encoder (VAE) and LSTM Neural Network

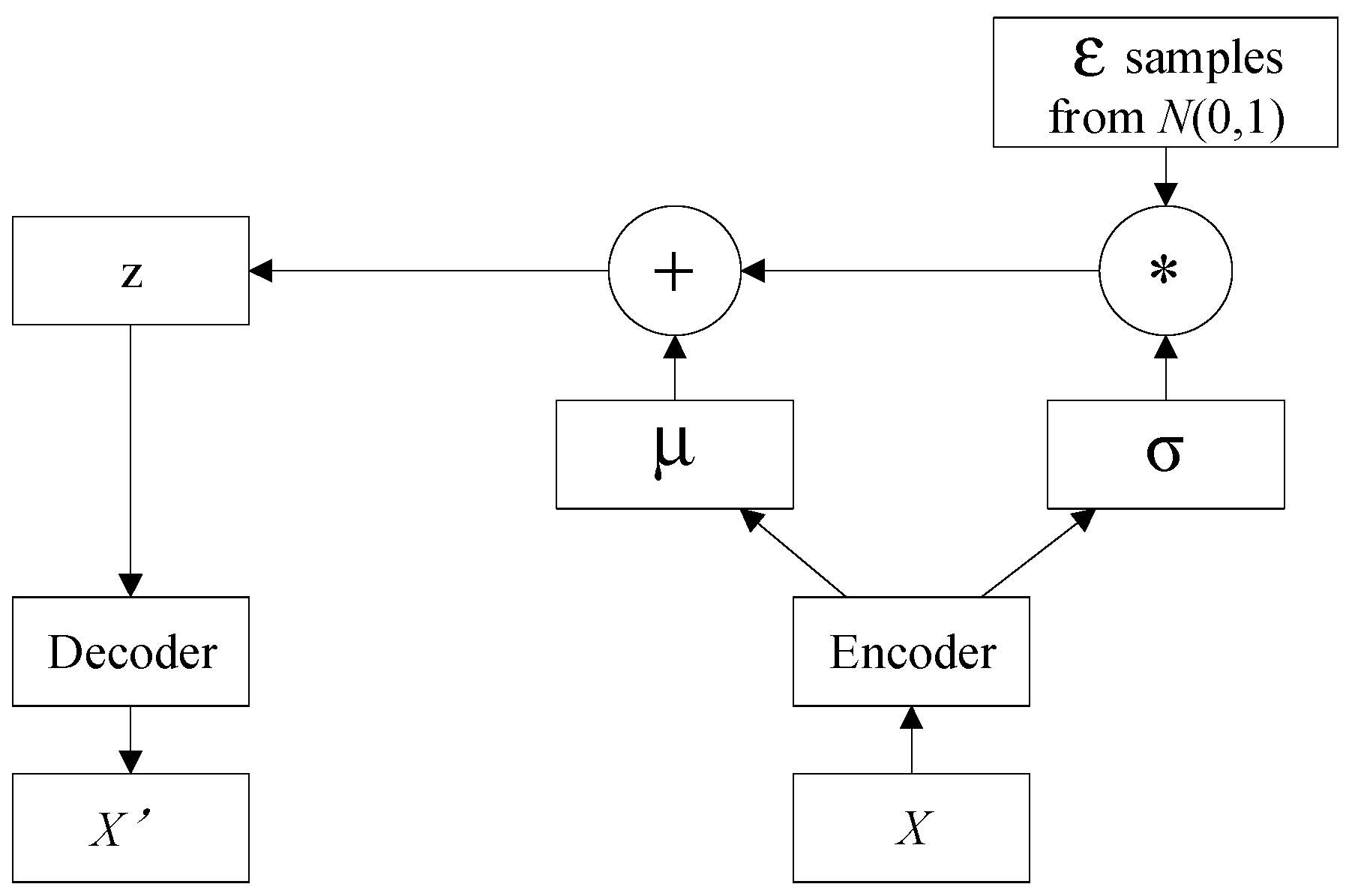

3.1. Variational Auto-Encoder (VAE)

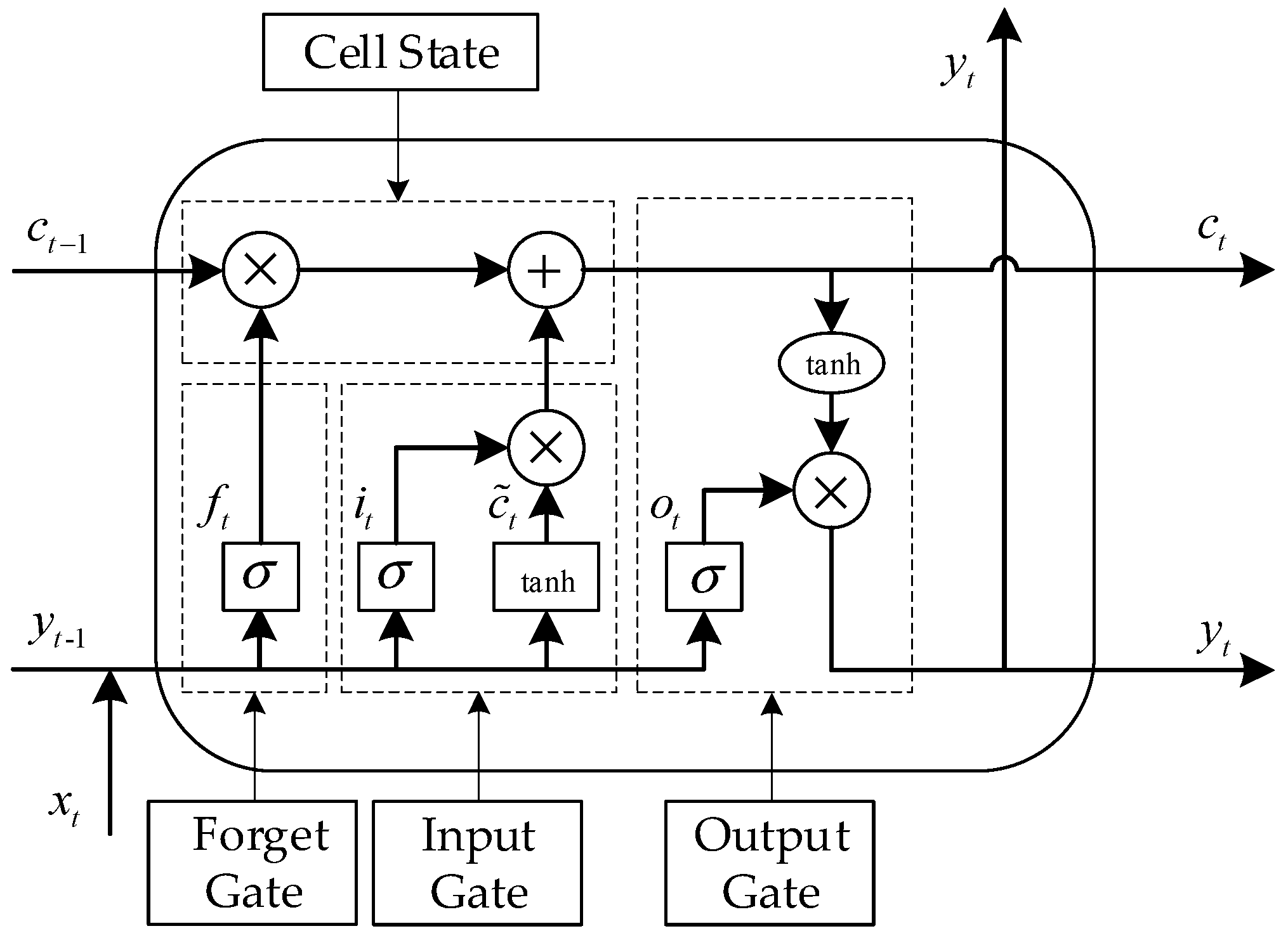

3.2. LSTM Neural Network

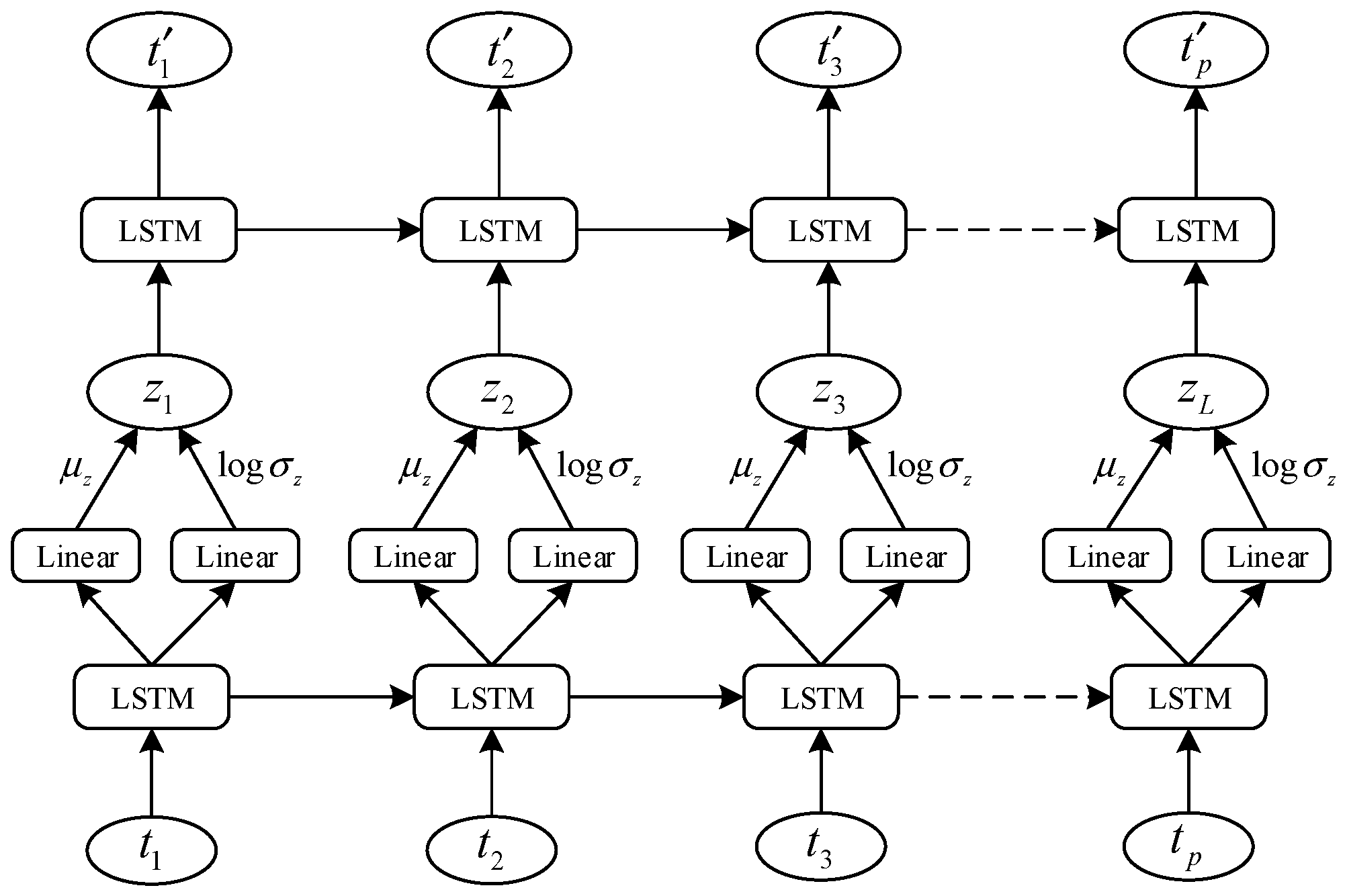

4. Health Assessment Model Based on LSTM–VAE

4.1. Structure of LSTM–VAE Health Assessment Model

4.2. Health Assessment Process of Gear Pump based on LSTM–VAE

- (1)

- Obtaining the whole-life acceleration test data of the gear pump.

- (2)

- Feature extraction of data.

- (3)

- Feature selection.

- (4)

- LSTM–VAE model training.

- (5)

- The health status assessment of the gear pump.

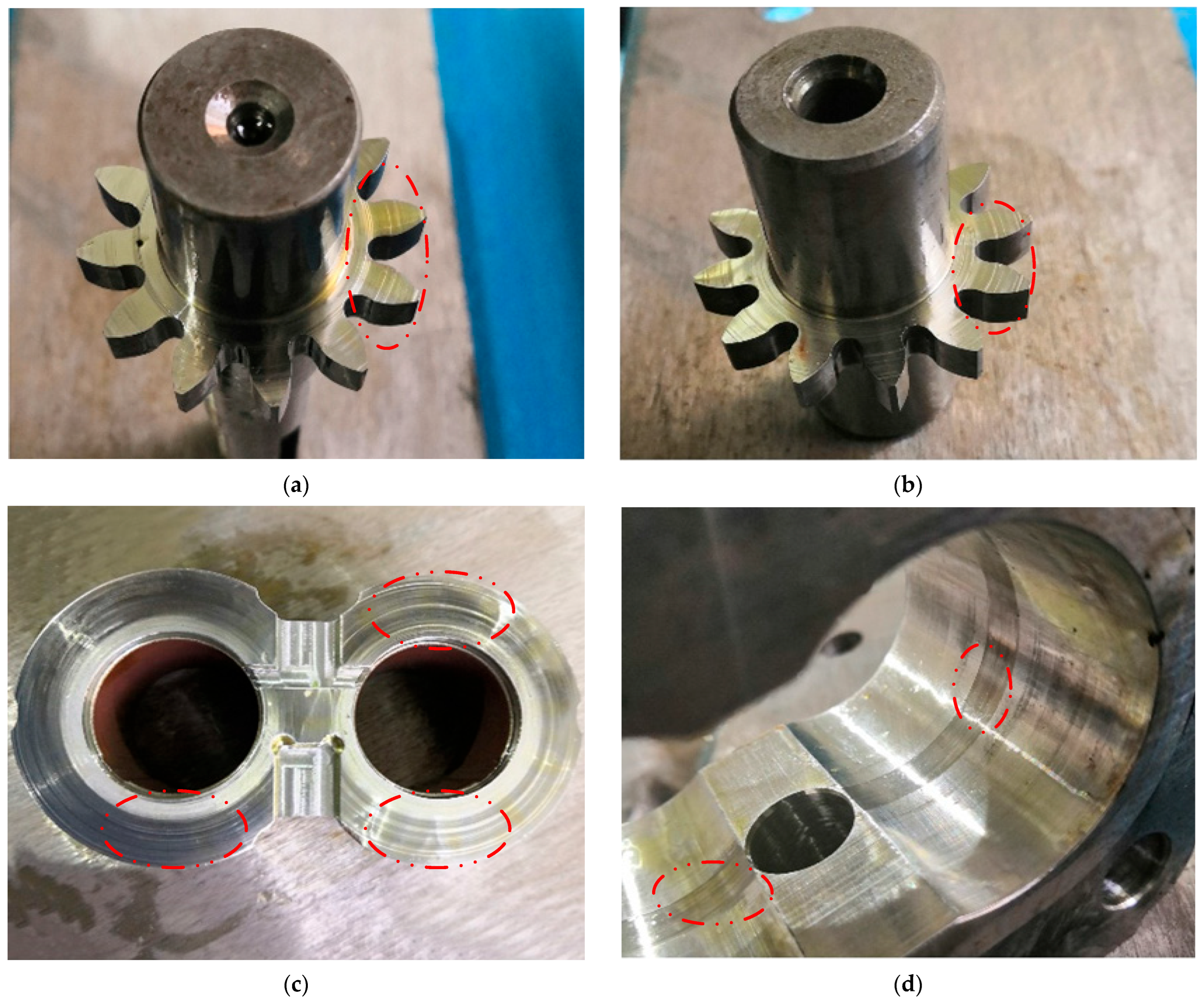

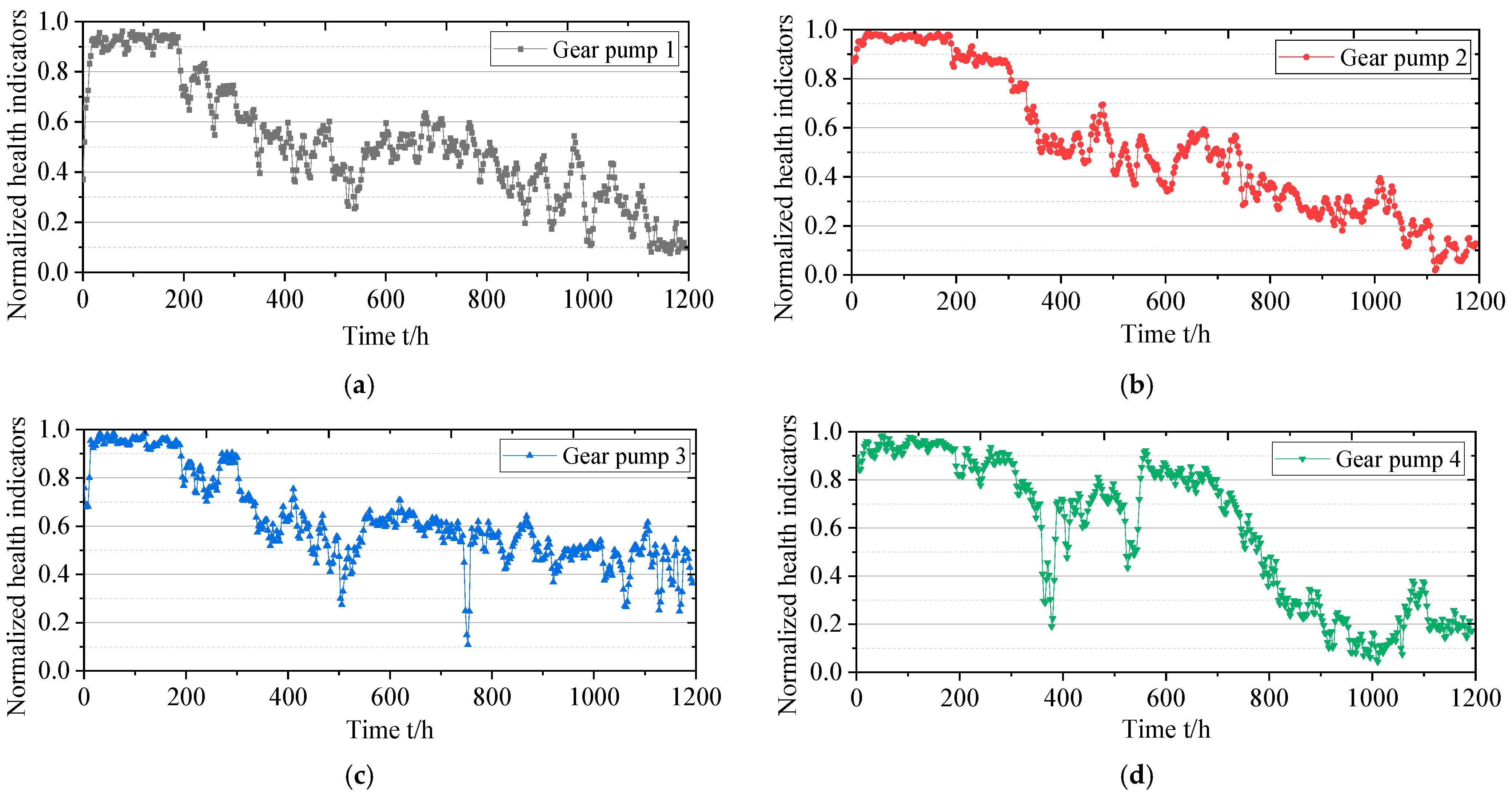

5. Construction of the Gear Pump Health Indicator Based on LSTM–VAE

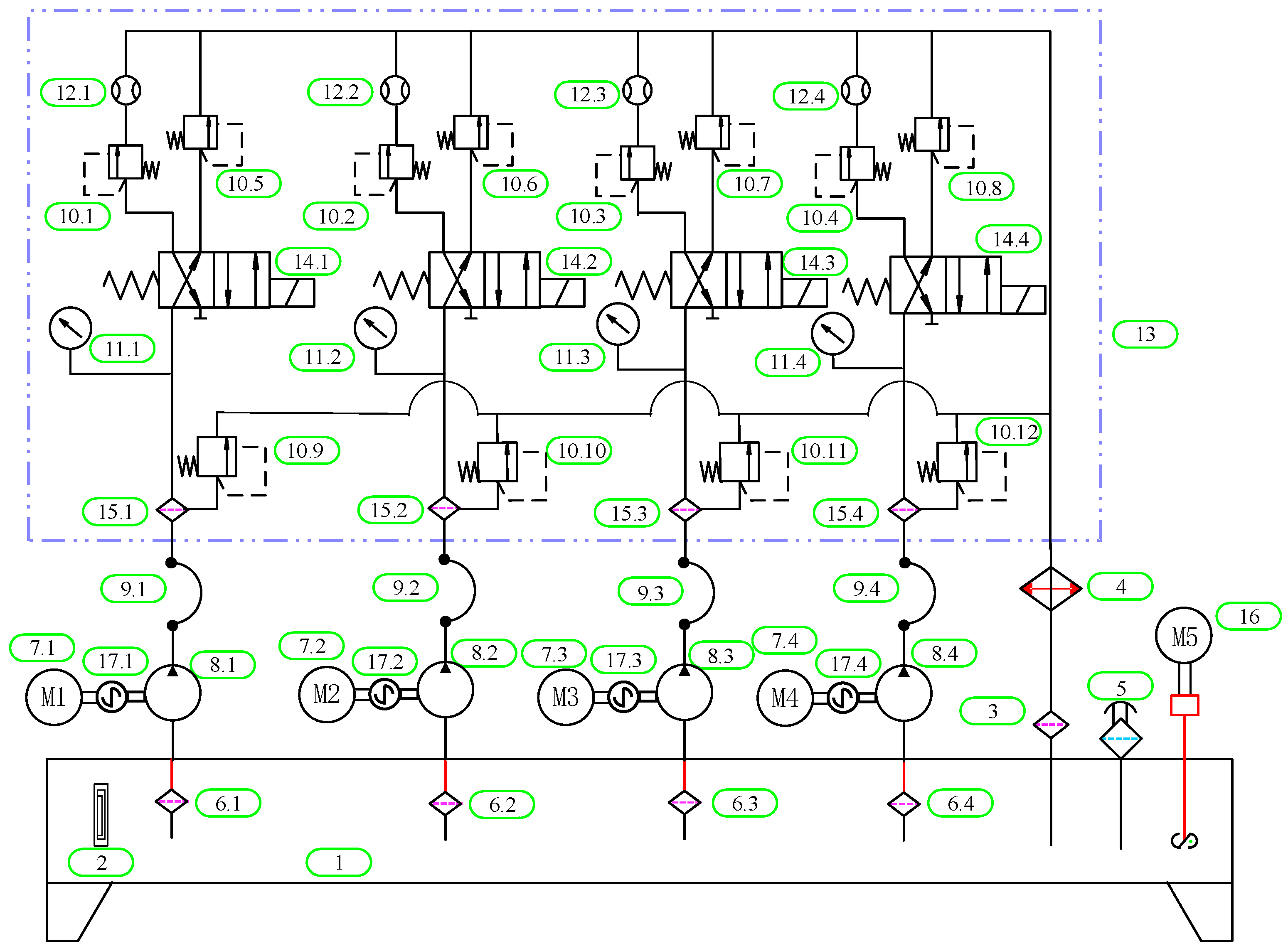

Composition of the Test System

6. Conclusions

- (1)

- In terms of energy feature extraction from the wavelet packet decomposition of the gear pump, there were two frequency ranges that were highly correlated with the performance degradation characteristics, the and frequency bands. With the decline in the health status of the gear pump, the energy ratio of these two frequency bands showed obvious changes. In the time-domain and frequency-domain feature extraction, with the operation of the gear pump, the time-domain characteristics of the vibration signal, such as the impulse factor, peak value, root mean square value, clearance factor, and variance, showed significant changes with the change in the gear pump health status. The frequency-domain characteristics of the vibration signal, such as gravity frequency, mean square frequency, and average power, showed obvious changes with the change in the health status of the gear pump.

- (2)

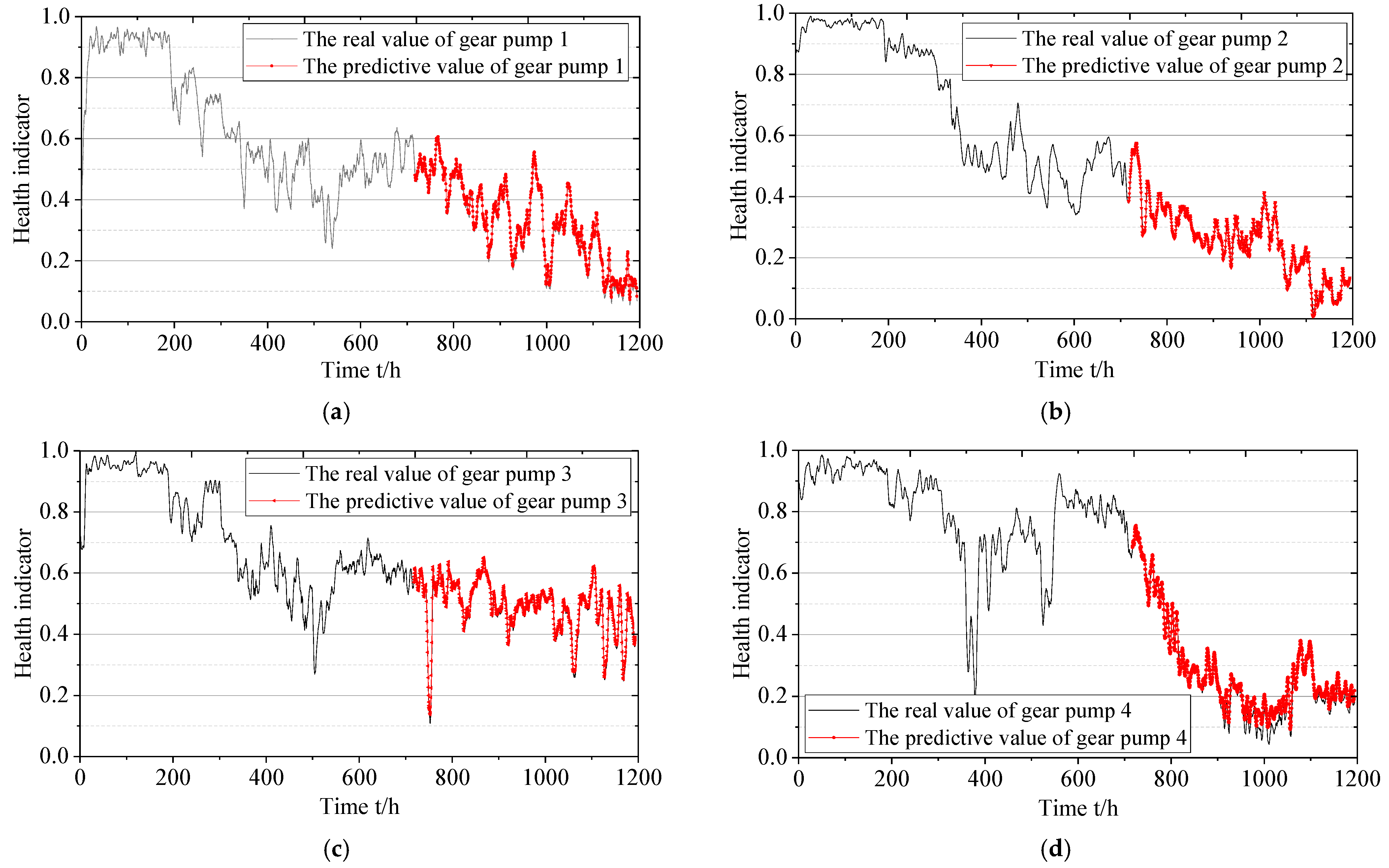

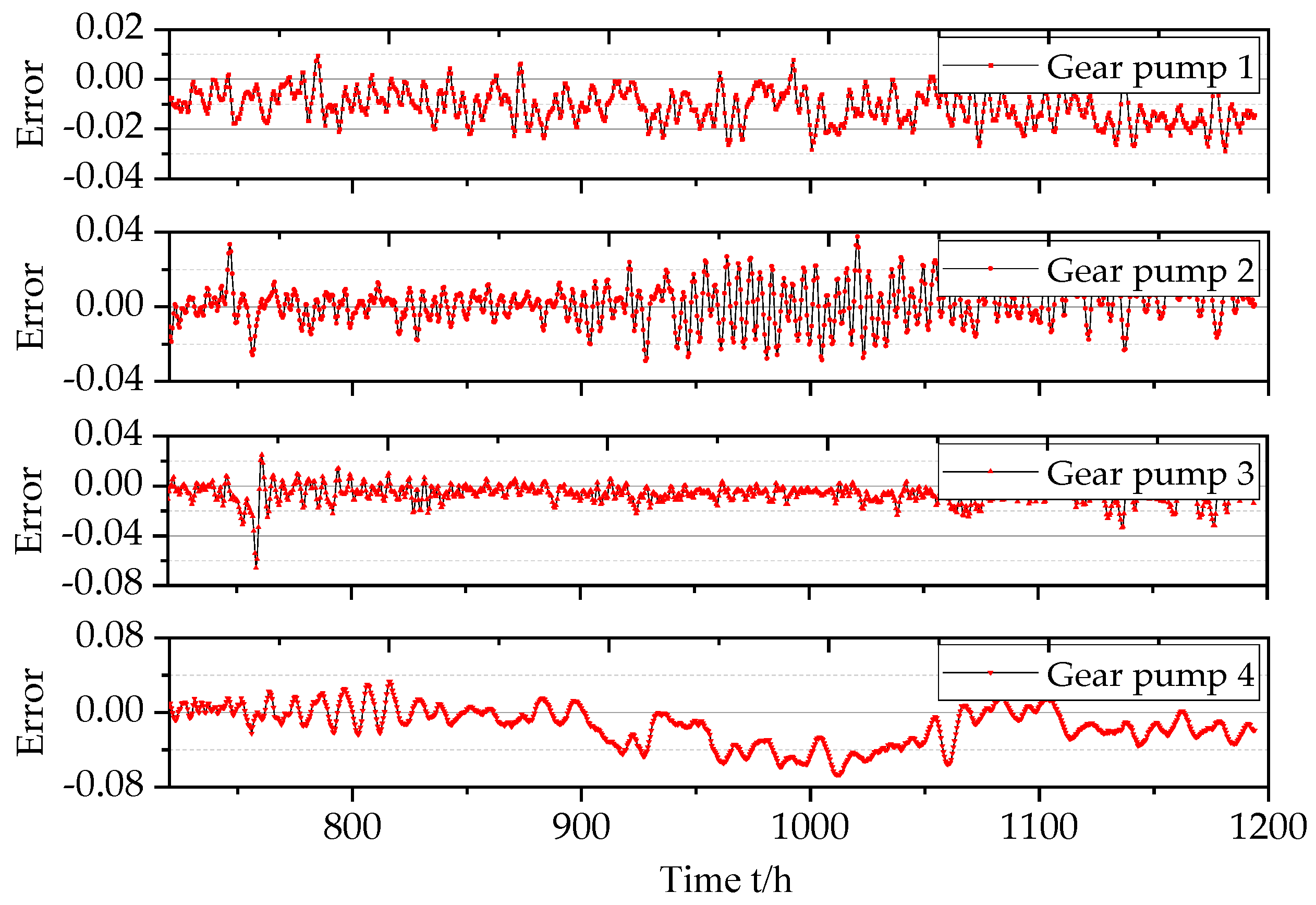

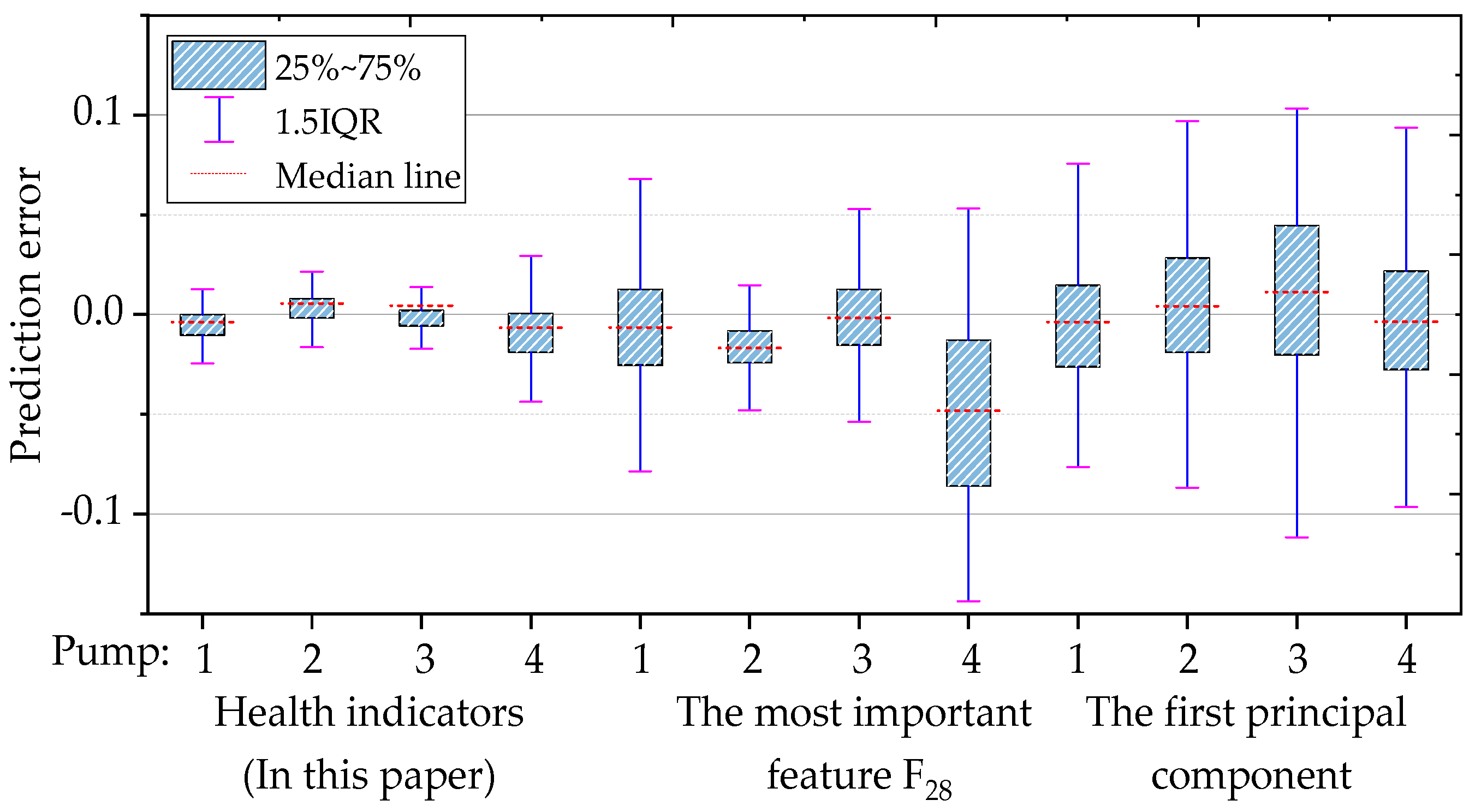

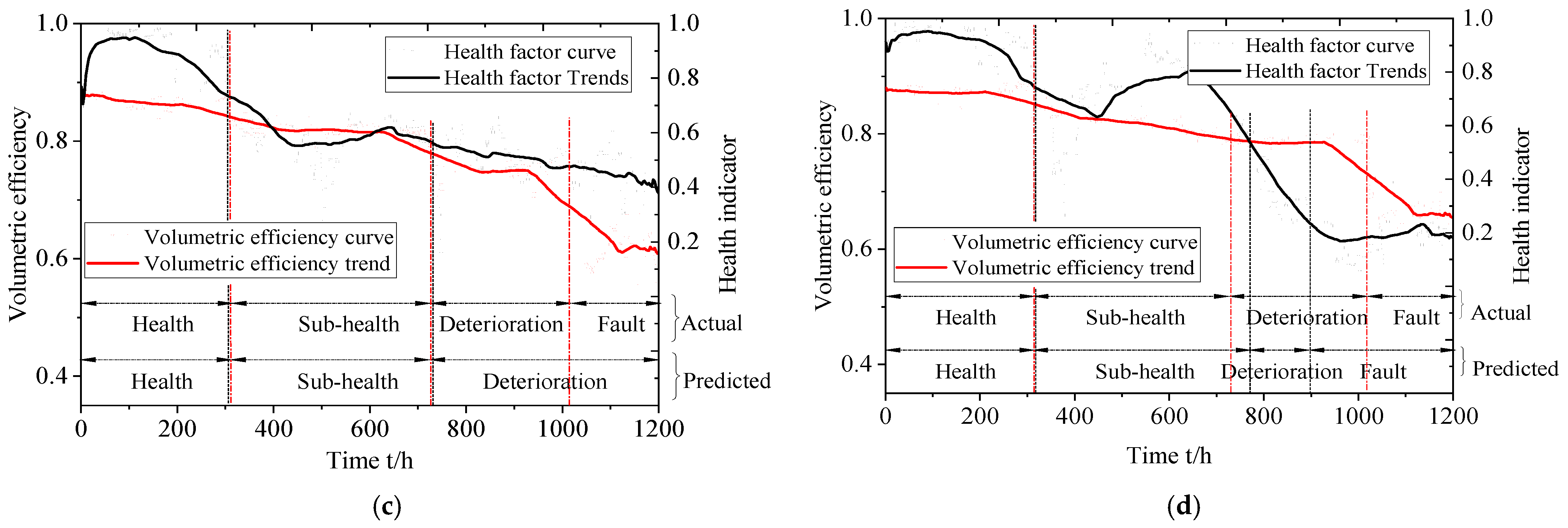

- The LSTM–VAE-based health indicator construction method of the gear pump proposed in this paper effectively constructed the one-dimensional HI curve of the whole-life operation data of the gear pump under the condition that only the health status operation data of the gear pump were needed. In addition, the proposed gear pump health indicator was superior to the traditional feature selection and PCA dimension reduction health indicator construction method in terms of trendability, robustness, and monotonicity.

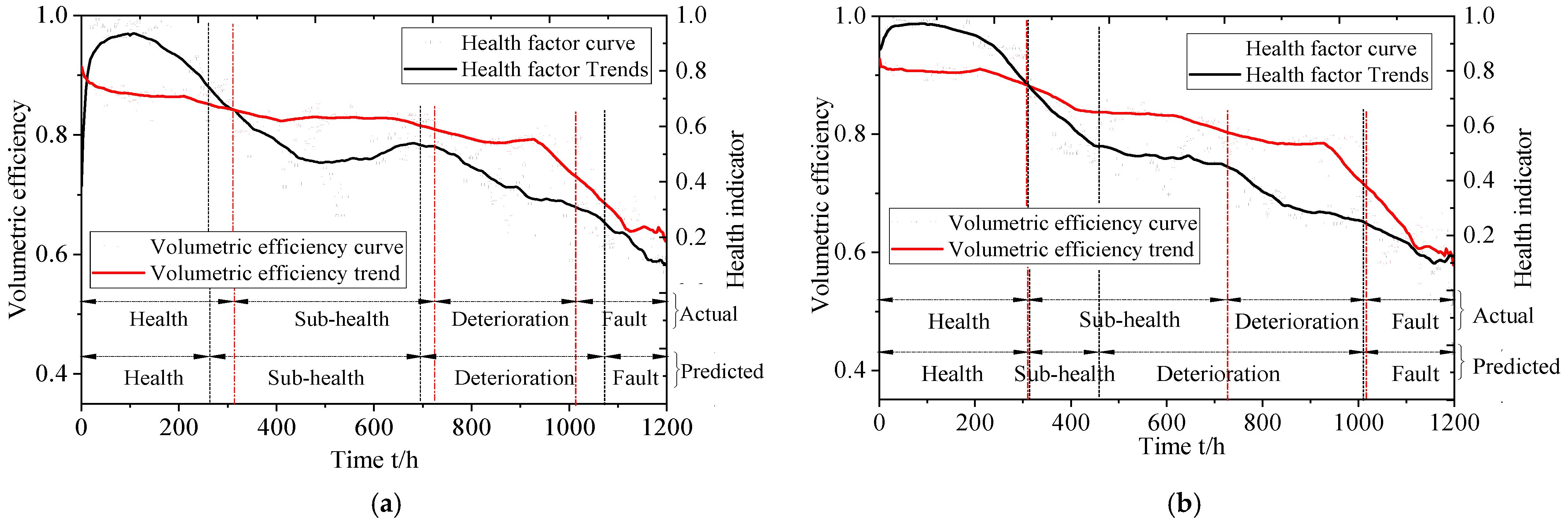

- (3)

- The health indicator of the gear pump constructed by the method proposed in this paper had an obvious correlation with the volumetric efficiency. According to the one-dimensional HI curve of the gear pump’s life cycle operating data, the health status of the gear pump can be accurately assessed, which is of great significance for the intelligent operation, maintenance, and health management of gear pumps.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, S.; Zhu, Y.; Yuan, S. Intelligent Fault Identification of Hydraulic Pump Using Deep Adaptive Normalized CNN and Synchrosqueezed Wavelet Transform. Reliab. Eng. Syst. Saf. 2022, 224, 108560. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, H.; Liu, J.; Wang, C.; Ge, J.; Zhu, Y.; Chen, X.; Hu, B. Flow characteristics of oblique submerged impinging jet at various impinging heights. J. Mar. Sci. Eng. 2022, 10, 399. [Google Scholar] [CrossRef]

- Jiang, W.; Li, Z.; Li, J.; Zhu, Y.; Zhang, P. Study on a fault identification method of the hydraulic pump based on a combination of voiceprint characteristics and extreme learning machine. Processes 2019, 7, 894. [Google Scholar] [CrossRef]

- Jiang, W.; Li, Z.; Lei, Y.; Zhang, S.; Tong, X. Deep learning based rolling bearing fault diagnosis and performance degradation degree recognition method. J. Yanshan Univ. 2020, 44, 526–536. [Google Scholar]

- Keller, N.; Sciancalepore, A.; Vacca, A. Demonstrating a Condition Monitoring Process for Axial Piston Pumps with Damaged Valve Plates. Int. J. Fluid Power 2022, 23, 205–236. [Google Scholar] [CrossRef]

- Sun, X.; Zhou, G.; Yu, Y.; Li, F. Overview of prognostics and health management of mechanical equipment. Ordnance Ind. Autom. 2016, 35, 30–33. [Google Scholar]

- Xi, B.; Wang, C.; Xi, W.; Liu, Y.; Wang, H.; Yang, Y. Experimental investigation on the water hammer characteristic of stalling fluid in eccentric casing-tubing annulus. Energy 2022, 253, 124113. [Google Scholar] [CrossRef]

- Liao, G. Data-Driven Methods of Equipment Health Assessment and Maintenance Decision-Making. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2016. [Google Scholar]

- Zhang, H.; Xia, S.; Cheng, Z.; Li, X. A health assessment method of compressor based on improved Mahalanobis distance. Electr. Meas. Instrum. 2018, 55, 32–36+93. [Google Scholar]

- Bedotti, A.; Pastori, M.; Casoli, P.; Lettini, A. Condition Monitoring Based on Thermodynamic Efficiency Method for an Axial Piston Pump. In Proceedings of the BATH/ASME 2018 Symposium on Fluid Power and Motion Control, Bath, UK, 12 September 2018. [Google Scholar]

- Tang, S.; Zhu, Y.; Yuan, S. An adaptive deep learning model towards fault diagnosis of hydraulic piston pump using pressure signal. Eng. Fail. Anal. 2022, 138, 106300. [Google Scholar] [CrossRef]

- Li, N.; Lei, Y.; Lin, J.; Ding, S.X. An Improved exponential model for predicting remaining useful life of rolling element bearings. IEEE Trans. Ind. Electron. 2015, 62, 7762–7773. [Google Scholar] [CrossRef]

- Lei, Y.; Li, N.; Jing, L. A new method based on stochastic process models for machine remaining useful life prediction. IEEE Trans. Instrum. Meas. 2016, 65, 2671–2684. [Google Scholar] [CrossRef]

- Gaperin, M.; Jurii, D.; Bokoski, P.; Viintin, J. Model-based prognostics of gear health using stochastic dynamical models. Mech. Syst. Signal Process. 2011, 25, 537–548. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Bing, W.; Jian, S.; Li, Y. The application of a general mathematical morphological particle as a novel indicator for the performance degradation assessment of a bearing. Mech. Syst. Signal Process. 2017, 82, 490–502. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.S. Application of relevance vector machine and survival probability to machine degradation assessment. Expert Syst. Appl. 2011, 38, 2592–2599. [Google Scholar] [CrossRef]

- Hai, Q.; Lee, J.; Jing, L.; Gang, Y. Robust performance degradation assessment methods for enhanced rolling element bearing prognostics. Adv. Eng. Inform. 2003, 17, 127–140. [Google Scholar]

- Vasko, R.; Eljaroudi, A.; Boston, J.R.; Rudy, T.E. Hidden Markov model topology estimation to characterize the dynamic structure of repetitive lifting data. In Proceedings of the International Conference of the IEEE Engineering in Medicine & Biology Society, Chicago, IL, USA, 30 October–2 November 1997. [Google Scholar]

- Tang, S.; Zhu, Y.; Yuan, S. Intelligent Fault Diagnosis of Hydraulic Piston Pump Based on Deep Learning and Bayesian Optimization. ISA Trans. 2022, 1, 1–16. [Google Scholar] [CrossRef]

- Hu, B.; Wang, H.; Liu, J.; Zhu, Y.; Wang, C.; Ge, J.; Zhang, Y. A numerical study of a submerged water jet impinging on a stationary wall. J. Mar. Sci. Eng. 2022, 10, 228. [Google Scholar] [CrossRef]

- Chao, Q.; Zhang, J.; Xu, B.; Wang, Q.; Lyu, F.; Li, K. Integrated slipper retainer mechanism to eliminate slipper wear in high-speed axial piston pumps. Front. Mech. Eng. 2022, 17, 13. [Google Scholar] [CrossRef]

- Tang, S.; Zhu, Y.; Yuan, S. A Novel Adaptive Convolutional Neural Network for Fault Diagnosis of Hydraulic Piston Pump with Acoustic Images. Adv. Eng. Inform. 2022, 52, 101554. [Google Scholar] [CrossRef]

- Chao, Q.; Gao, H.; Tao, J.; Wang, Y.; Zhou, J.; Liu, C. Adaptive decision-level fusion strategy for the fault diagnosis of axial piston pumps using multiple channels of vibration signals. Sci. China Technol. Sci. 2022, 65, 470–480. [Google Scholar] [CrossRef]

- Tamilselvan, P.; Wang, P. Failure diagnosis using deep belief learning based health state classification. Reliab. Eng. Syst. Saf. 2013, 115, 124–135. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, X.; Jiang, Z.; Hu, C. Unsupervised health indicator of bearing based on deep learning. Chin. J. Sci. Instrum. 2018, 39, 7. [Google Scholar]

- Zhu, Y.; Li, G.; Tang, S.; Wang, R.; Su, H.; Wang, C. Acoustic Signal-based Fault Detection of Hydraulic Piston Pump using a Particle Swarm Optimization Enhancement CNN. Appl. Acoust. 2022, 192, 108718. [Google Scholar] [CrossRef]

- Tang, S.; Zhu, Y.; Yuan, S. An Improved Convolutional Neural Network with an Adaptable Learning Rate towards Multi-signal Fault Diagnosis of Hydraulic Piston Pump. Adv. Eng. Inform. 2021, 50, 101406. [Google Scholar] [CrossRef]

- Javed, K.; Gouriveau, R.; Zerhouni, N.; Nectoux, P. Enabling health monitoring approach based on vibration data for accurate prognostics. IEEE Trans. Ind. Electron. 2014, 62, 647–656.2. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, L.; Xu, J. Degradation feature selection for remaining useful life prediction of rolling element bearings. Qual. Reliab. Eng. Int. 2016, 32, 547–554. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, W.; Zhang, S.; Xue, D.; Zhang, S. Research on prediction method of hydraulic pump remaining useful life based on KPCA and JITL. Appl. Sci. 2021, 11, 9389. [Google Scholar] [CrossRef]

- Liao, L. Discovering prognostic features using genetic programming in remaining useful life prediction. IEEE Trans. Ind. Electron. 2013, 61, 2464–2472. [Google Scholar] [CrossRef]

- Li, N.; Lei, Y.; Liu, Z.; Lin, J. A particle filtering-based approach for remaining useful life predication of rolling element bearings. In Proceedings of the 2014 International Conference on Prognostics and Health Management, Cheney, WA, USA, 22–25 June 2014. [Google Scholar]

| Time-Domain Feature | Calculation Method | Feature Representation |

|---|---|---|

| Mean value | ||

| Variance | ||

| Root mean square value | ||

| Kurtosis | ||

| Peak value | ||

| Root amplitude | ||

| Peak-to-peak value | ||

| Absolute mean value | ||

| Standard deviation | ||

| Shape factor | ||

| Crest factor | ||

| Impulse factor | ||

| Kurtosis index | ||

| Clearance factor |

| Frequency-Domain Feature | Calculation Method | Feature Representation |

|---|---|---|

| Gravity frequency | ||

| Mean square frequency | ||

| Frequency variance | ||

| Average power |

| Serial Number | Component Name | Component Model | Performance Parameters of Component |

|---|---|---|---|

| 1 | Gear pump | CBWF-304 | Preset pressure: 20 MPa, rated speed: 2500 r/min, nominal displacement: 4 mL/r |

| 2 | Flowmeter | MG015 | Range of flow variation: 1~40 L/min |

| 3 | Acceleration sensor | YD-36D | Frequency range: 1 Hz~12 kHz |

| 4 | Pressure sensor | PU5400 | Measuring range: 0~400 bar |

| 5 | Torque and rotational speed sensor | CYT-302 | Torque range: 0~2 Nm, rotational speed range: 0–3000 r/min |

| 6 | Temperature sensor | CWDZ11 | Measuring range: −50~100 °C |

| 7 | Data acquisition card | NI PXIe-6363 | 16-bit, 2 MS/s |

| Feature Representation | Characteristics Interpretation | Trendability |

|---|---|---|

| Impulse factor | 0.691164 | |

| Peak value | 0.607977 | |

| Gravity frequency | 0.585184 | |

| Wavelet packet energy characteristic | 0.544904 | |

| Wavelet packet energy characteristic | 0.514463 | |

| Mean square frequency | 0.497961 | |

| Root mean square value | 0.497791 | |

| Clearance factor | 0.497791 | |

| Variance | 0.473714 | |

| Average power | 0.473714 |

| Gear Pump | Evaluation Indexes | Health Indicator Based on PCA Method | Health Indicators (Present Study) | |

|---|---|---|---|---|

| Pump 1 | Monotonicity | 0.0083 | 0.0133 | 0.0259 |

| Robustness | 0.8254 | 0.4796 | 0.9927 | |

| Trendability | 0.6426 | 0.2212 | 0.8909 | |

| Pump 2 | Monotonicity | 0.0242 | 0.0317 | 0.0442 |

| Robustness | 0.8575 | 0.4856 | 0.9971 | |

| Trendability | 0.8093 | 0.1774 | 0.9525 | |

| Pump 3 | Monotonicity | 0.0217 | 0.0225 | 0.0117 |

| Robustness | 0.8198 | 0.4887 | 0.9945 | |

| Trendability | 0.5231 | 0.1890 | 0.8272 | |

| Pump 4 | Monotonicity | 0.0167 | 0.0100 | 0.0375 |

| Robustness | 0.8119 | 0.4847 | 0.9925 | |

| Trendability | 0.7882 | 0.2042 | 0.8703 |

| Running Time | t = 310 | t = 733 | t = 1028 | |

|---|---|---|---|---|

| Health indicator | Pump 1 | 0.66 | 0.52 | 0.30 |

| Pump 2 | 0.75 | 0.45 | 0.23 | |

| Pump 3 | 0.73 | 0.56 | 0.48 | |

| Pump 4 | 0.75 | 0.64 | 0.19 | |

| Mean value | 0.74 | 0.54 | 0.24 | |

| Health Indicator | Operating Status |

|---|---|

| 0.74 < HI ≤ 1 | Health |

| 0.54 < HI ≤ 0.74 | Sub-health |

| 0.24 < HI ≤ 0.54 | Deterioration |

| HI ≤ 0.24 | Fault |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Jiang, W.; Wu, X.; Zhang, S.; Chen, D. Study on Health Indicator Construction and Health Status Evaluation of Hydraulic Pumps Based on LSTM–VAE. Processes 2022, 10, 1869. https://doi.org/10.3390/pr10091869

Li Z, Jiang W, Wu X, Zhang S, Chen D. Study on Health Indicator Construction and Health Status Evaluation of Hydraulic Pumps Based on LSTM–VAE. Processes. 2022; 10(9):1869. https://doi.org/10.3390/pr10091869

Chicago/Turabian StyleLi, Zhenbao, Wanlu Jiang, Xiang Wu, Shuqing Zhang, and Dongning Chen. 2022. "Study on Health Indicator Construction and Health Status Evaluation of Hydraulic Pumps Based on LSTM–VAE" Processes 10, no. 9: 1869. https://doi.org/10.3390/pr10091869

APA StyleLi, Z., Jiang, W., Wu, X., Zhang, S., & Chen, D. (2022). Study on Health Indicator Construction and Health Status Evaluation of Hydraulic Pumps Based on LSTM–VAE. Processes, 10(9), 1869. https://doi.org/10.3390/pr10091869