Research and Performance Evaluation on Selective Absorption of H2S from Gas Mixtures by Using Secondary Alkanolamines

Abstract

:1. Introduction

2. Theoretical Basis

2.1. Characteristics of Molecular Structure

2.2. Reaction Mechanism

2.3. Absorption Performance Evaluation Calculation Method

3. Experimental Section

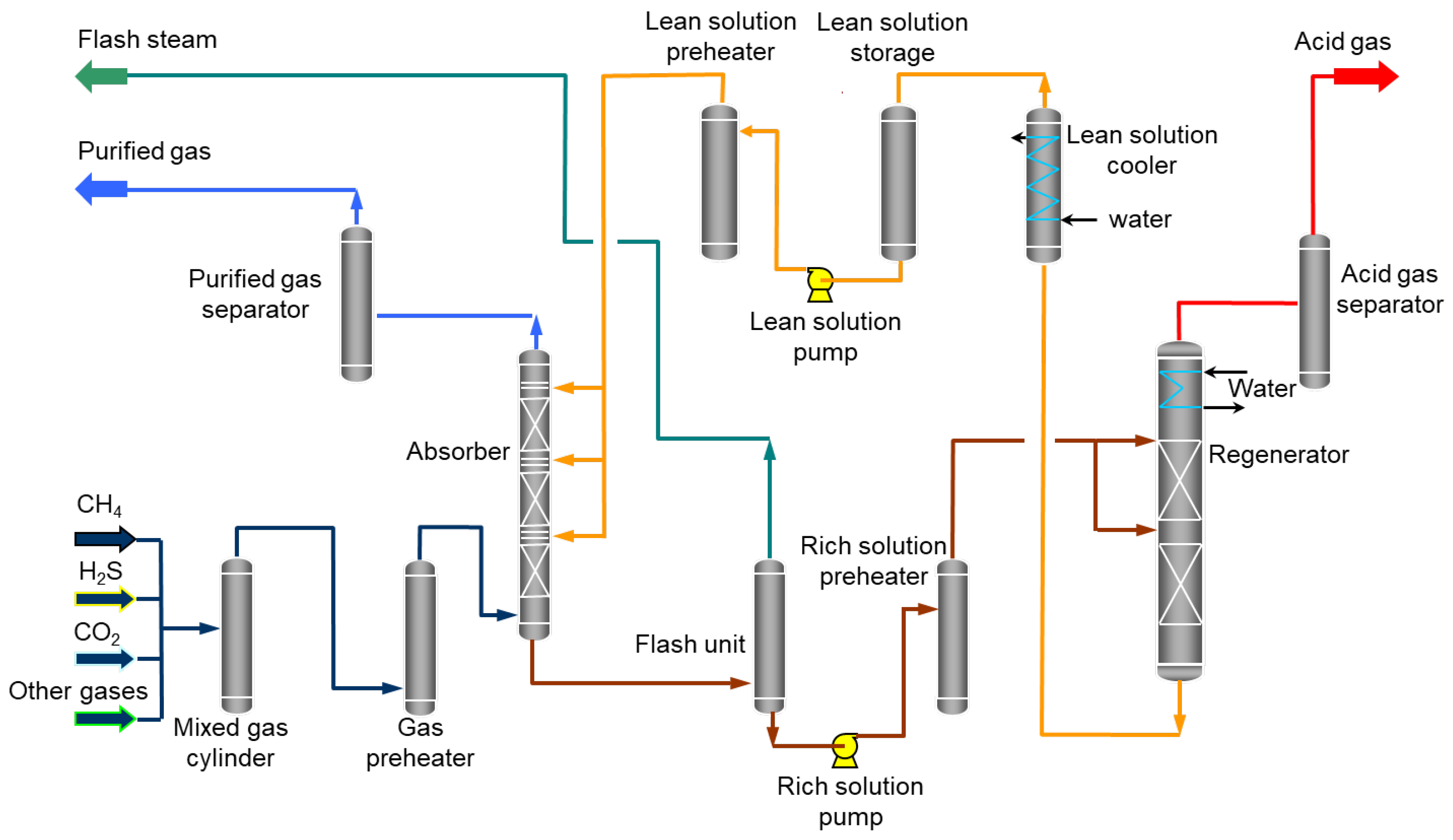

3.1. Experimental Apparatus and General Procedure

3.2. Materials and Analytical Methods

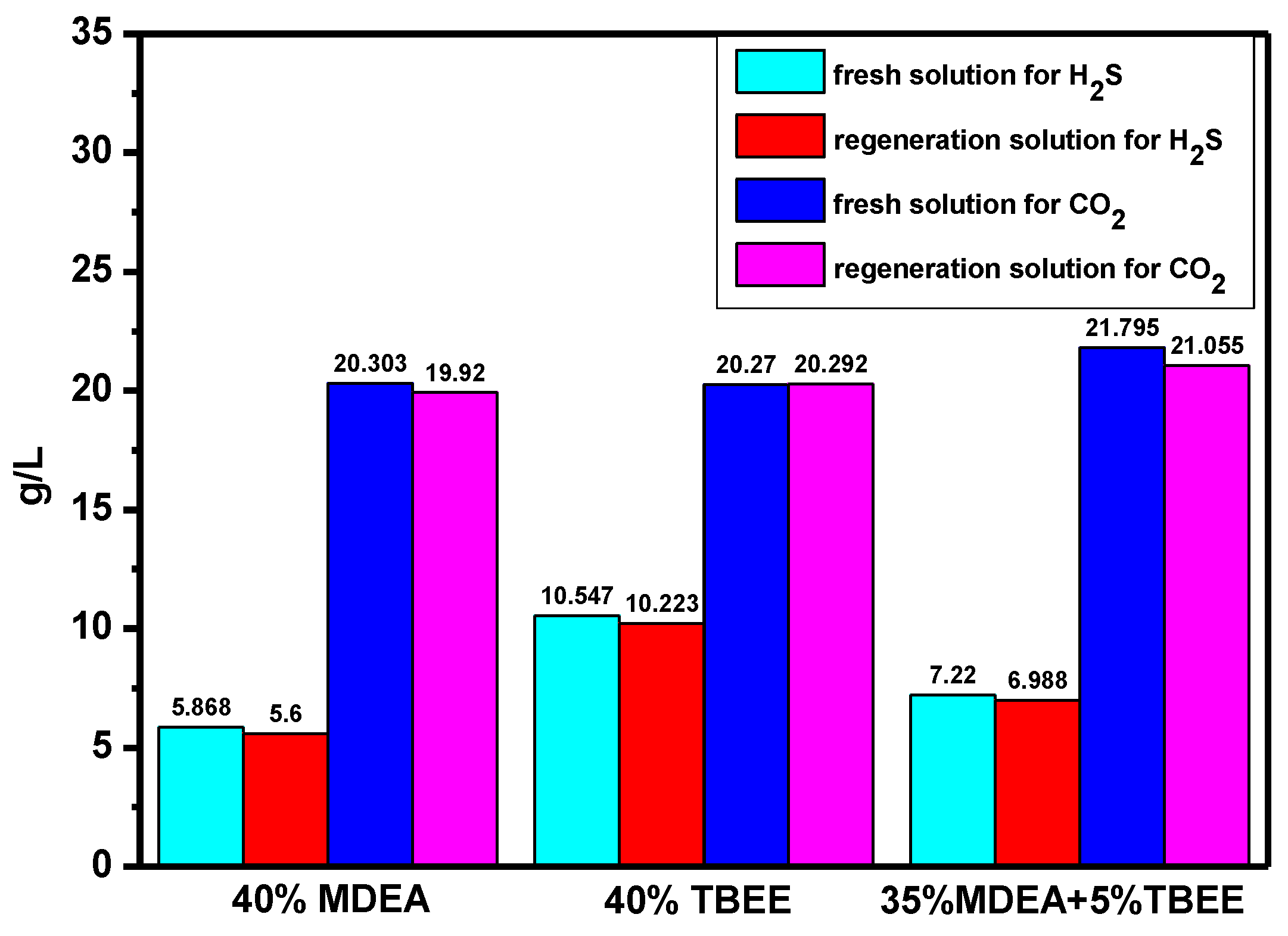

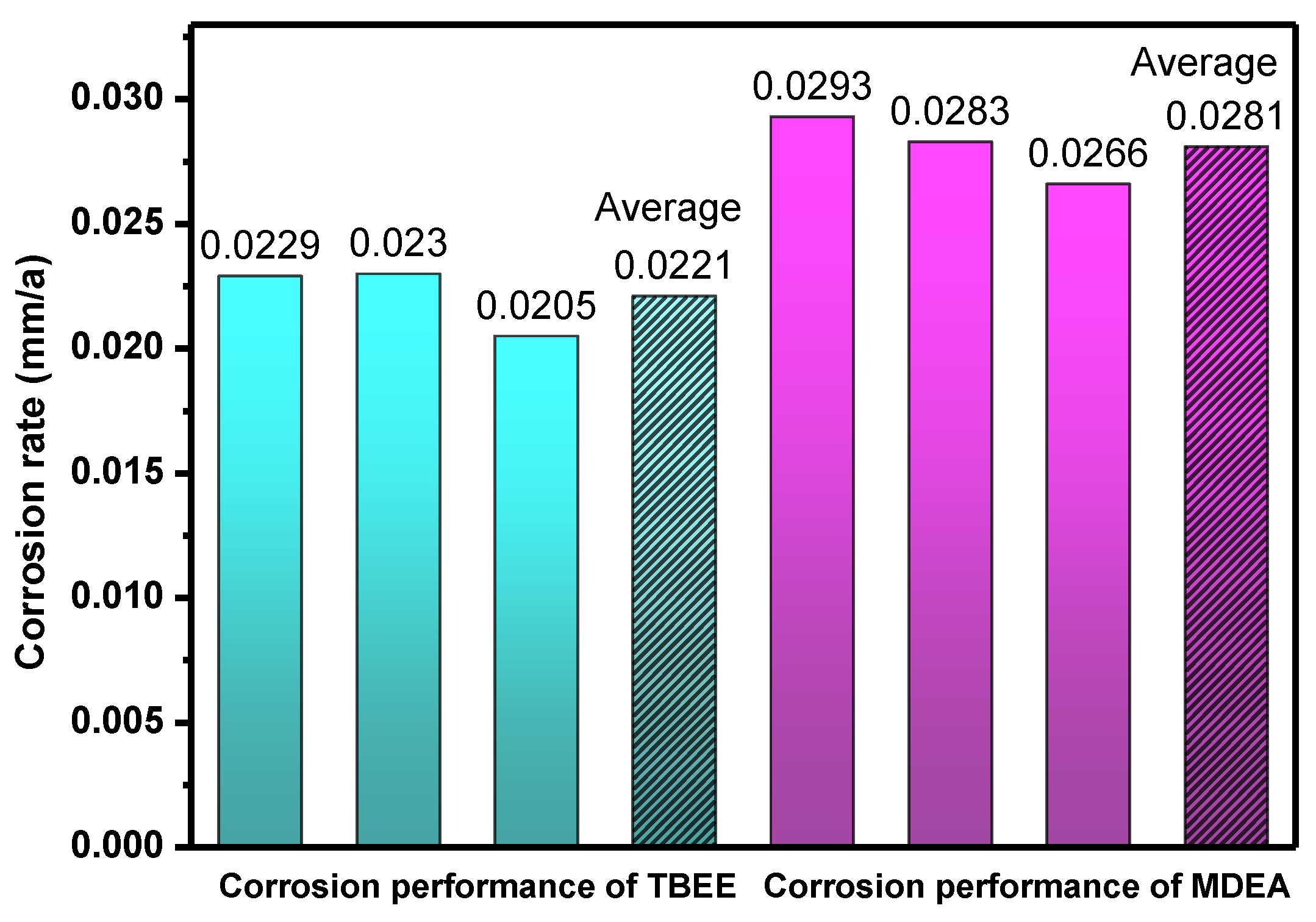

4. Results and Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, L.; Shen, B.; Sun, H.; Xu, S. Kinetics Study of CO2 Absorption into Solutions of UDS. Petrol. Sci. Technol. 2012, 30, 2563–2570. [Google Scholar] [CrossRef]

- Huttenhuis, P.J.G.; Agrawal, N.J.; Versteeg, G.F. The solubility of hydrogen sulfide in aqueous N-methyldiethanolamine solutions. Technology 2008, 1, 399–424. [Google Scholar] [CrossRef]

- Huttenhuis, P.J.G.; Agrawal, N.J.; Versteeg, G.F. Solubility of carbon dioxide and hydrogen sulfide in aqueous N-methyldiethanolamine solutions. Ind. Eng. Chem. Res. 2009, 48, 4051–4059. [Google Scholar] [CrossRef]

- Huttenhuis, P.J.G.; Agrawal, N.J.; Hogendoorn, J.A.; Versteeg, G.F. Gas solubility of H2S and CO2 in aqueous solutions of N-methyldiethanolamine. J. Petrol. Sci. Eng. 2007, 55, 122–134. [Google Scholar] [CrossRef]

- Liu, K.; Chang, H.; Xiong, G.; He, J.; Liu, Q.; Li, J. Modeling CO2, H2S, COS, and CH3SH Simultaneous Removal Using Aqueous Sulfolane–MDEA Solution. Processes 2021, 9, 1954. [Google Scholar] [CrossRef]

- Castrillon, M.C.; Moura, K.O.; Alves, C.A.; Bastos-Neto, M.; Azevedo, D.C.S.; Hofmann, J.; Möllmer, J.; Einicke, W.-D.; Gläser, R. CO2 and H2S removal from CH4-rich streams by adsorption on activated carbons modified with K2CO3, NaOH, or Fe2O3. Energy Fuel 2016, 30, 9596–9604. [Google Scholar] [CrossRef]

- Jin, P.; Huang, C.; Shen, Y.; Shen, Y.; Zhan, X.; Hu, X.; Wang, L.; Wang, L. Simultaneous separation of H2S and CO2 from biogas by gas–liquid membrane contactor using single and mixed absorbents. Energy Fuel 2017, 31, 11117–11126. [Google Scholar] [CrossRef]

- Ma, Y.; Guo, H.; Selyanchyn, R.; Wang, B.; Deng, L.; Dai, Z.; Jiang, X. Hydrogen sulfide removal from natural gas using membrane technology: A review. J. Mater. Chem. A 2021, 9, 20211–20240. [Google Scholar] [CrossRef]

- Wang, L.; Xu, Y.; Li, Z.; Wei, Y.; Wei, J. CO2/CH4 and H2S/CO2 selectivity by ionic liquids in natural gas sweetening. Energy Fuel 2018, 32, 10–23. [Google Scholar] [CrossRef]

- Li, F.; Laaksonen, A.; Zhang, X.; Ji, X. Rotten Eggs Revaluated: Ionic Liquids and Deep Eutectic Solvents for Removal and Utilization of Hydrogen Sulfide. Ind. Eng. Chem. Res. 2022, 61, 2643–2671. [Google Scholar] [CrossRef]

- Borhani, T.N.G.; Afkhamipour, M.; Azarpour, A.; Akbari, V.; Emadi, S.H.; Manan, Z.A. Modeling study on CO2 and H2S simultaneous removal using MDEA solution. J. Ind. Eng. Chem. 2016, 34, 344–355. [Google Scholar] [CrossRef]

- Mandal, B.P.; Guha, M.; Biswas, A.K.; Bandyopadhyay, S.S. Removal of carbon dioxide by absorption in mixed amines: Modelling of absorption in aqueous MDEA/MEA and AMP/MEA solutions. Chem. Eng. Sci. 2001, 56, 6217–6224. [Google Scholar] [CrossRef]

- Xia, J.; Kamps, A.P.S.; Maurer, G. Solubility of H2S in (H2O+ piperazine) and in (H2O+ MDEA+ piperazine). Fluid Phase Equilibria 2003, 207, 23–34. [Google Scholar] [CrossRef]

- Pacheco, M.A.; Kaganoi, S.; Rochelle, G.T. CO2 absorption into aqueous mixtures of diglycolamine® and methyldiethanolamine. Chem. Eng. Sci. 2000, 55, 5125–5140. [Google Scholar] [CrossRef]

- Aroonwilas, A.; Veawab, A. Characterization and comparison of the CO2 absorption performance into single and blended alkanolamines in a packed column. Ind. Eng. Chem. Res. 2004, 43, 2228–2237. [Google Scholar] [CrossRef]

- Sartori, G.; Ho, W.S.; Savage, D.W.; Chludzinski, G.R.; Wiechert, S. Sterically-hindered amines for acid-gas absorption. Sep. Purif. Methods 1987, 16, 171–200. [Google Scholar] [CrossRef]

- Sartori, G.; Savage, D.W. Sterically hindered amines for carbon dioxide removal from gases. Ind. Eng. Chem. Fund. 1983, 22, 239–249. [Google Scholar] [CrossRef]

- Weiland, R.H.; Chakravarty, T.; Mather, A.E. Solubility of carbon dioxide and hydrogen sulfide in aqueous alkanolamines. Ind. Eng. Chem. Res. 1993, 32, 1419–1430. [Google Scholar] [CrossRef]

- Li, M.H.; Chang, B.C. Solubilities of carbon dioxide in water+ monoethanolamine+ 2-amino-2-methyl-1-propanol. J. Chem. Eng. Data 1994, 39, 448–452. [Google Scholar] [CrossRef]

- Saha, A.K.; Bandyopadhyay, S.S.; Saju, P.; Biswas, A.K. Selective removal of hydrogen sulfide from gases containing hydrogen sulfide and carbon dioxide by absorption into aqueous solutions of 2-amino-2-methyl-1-propanol. Ind. Eng. Chem. Res. 1993, 32, 3051–3055. [Google Scholar] [CrossRef]

- Mandal, B.P.; Biswas, A.K.; Bandyopadhyay, S.S. Selective absorption of H2S from gas streams containing H2S and CO2 into aqueous solutions of N-methyldiethanolamine and 2-amino-2-methyl-1-propanol. Sep. Purif. Technol. 2004, 35, 191–202. [Google Scholar] [CrossRef]

- Mandal, B.P.; Bandyopadhyay, S.S. Simultaneous absorption of carbon dioxide and hydrogen sulfide into aqueous blends of 2-amino-2-methyl-1-propanol and diethanolamine. Chem. Eng. Sci. 2005, 60, 6438–6451. [Google Scholar] [CrossRef]

- Lu, J.G.; Zheng, Y.F.; He, D.L. Selective absorption of H2S from gas mixtures into aqueous solutions of blended amines of methyldiethanolamine and 2-tertiarybutylamino-2-ethoxyethanol in a packed column. Sep. Purif. Technol. 2006, 52, 209–217. [Google Scholar] [CrossRef]

- Sartori, G.; Savage, D.W.; Stogryn, E.L. Process for the Selective Removal of Hydrogen Sulfide from Gaseous Mixtures with Severely Sterically Hindered Secondary Amino Ether Alcohols. US4405585. Available online: http://www4.drugfuture.com/uspat/download/US4405585.pdf (accessed on 14 August 2022).

- Danckwerts, P.V. The reaction of CO2 with ethanolamines. Chem. Eng. Sci. 1979, 34, 443–446. [Google Scholar] [CrossRef]

- Blauwhoff, P.M.M.; Versteeg, G.F.; Van Swaaij, W.P.M. A study on the reaction between CO2 and alkanolamines in aqueous solutions. Chem. Eng. Sci. 1983, 38, 1411–1429. [Google Scholar] [CrossRef]

- Saha, A.K.; Bandyopadhyay, S.S.; Biswas, A.K. Kinetics of absorption of CO2 into aqueous solutions of 2-amino-2-methyl-1-propanol. Chem. Eng. Sci. 1995, 50, 3587–3598. [Google Scholar] [CrossRef]

- Alper, E. Reaction mechanism and kinetics of aqueous solutions of 2-amino-2-methyl-1-propanol and carbon dioxide. Ind. Eng. Chem. Res. 1990, 29, 1725–1728. [Google Scholar] [CrossRef]

- Ko, J.J.; Li, M.H. Kinetics of absorption of carbon dioxide into solutions of N-methyldiethanolamine+water. Chem. Eng. Sci. 2000, 55, 4139–4147. [Google Scholar] [CrossRef]

- Yu, W.C.; Astarita, G. Selective absorption of hydrogen sulphide in tertiary amine solutions. Chem. Eng. Sci. 1987, 42, 419–424. [Google Scholar] [CrossRef]

- Huang, K.; Zhang, X.; Xu, Y.; Wu, Y.; Hu, X. Protic ionic liquids for the selective absorption of H2S from CO2: Thermodynamic analysis. AIChE J. 2014, 60, 4232–4240. [Google Scholar] [CrossRef]

| R | Es Value | R′ | Es Value |

|---|---|---|---|

| -CH3 | 0.07 | -CH2CH2OH | 0.36 |

| -CH2CH3 | 0.36 | -(CH2CH2O)2H | 0.36 |

| -CH2CH2CH3 | 0.39 | -CH(CH3)CH2OCH2CH2OH | 0.93 |

| -CH(CH3)2 | 0.93 | -C(CH3)2CH2CH2OH | 1.74 |

| -CH2CH2CH2CH3 | 0.41 | -C(CH3)(CH2CH2OH)2 | 1.74 |

| -CH2CH(CH3)2 | 0.43 | -C(CH2CH2OH)3 | 1.74 |

| -CH(CH3)CH2CH3 | 0.96 | ||

| -C(CH3)3 | 1.74 |

| Temperature (°C) | MDEA Concentration (%) | (g/mL) | (g/mL) | S | ||

|---|---|---|---|---|---|---|

| 30 | 10 | 0.02605 | 0.06515 | 0.03105 | 0.07765 | 4.00 |

| 30 | 20 | 0.0466 | 0.1162 | 0.02775 | 0.06925 | 4.01 |

| 30 | 30 | 0.0647 | 0.162 | 0.0257 | 0.06435 | 3.99 |

| 30 | 40 | 0.08115 | 0.20675 | 0.02415 | 0.0616 | 3.93 |

| 30 | 50 | 0.10215 | 0.26115 | 0.02435 | 0.06225 | 3.91 |

| 40 | 10 | 0.0239 | 0.06 | 0.0285 | 0.0715 | 3.98 |

| 40 | 20 | 0.04495 | 0.11465 | 0.0268 | 0.0683 | 3.92 |

| 40 | 30 | 0.0616 | 0.16075 | 0.02445 | 0.06385 | 3.83 |

| 40 | 40 | 0.07785 | 0.20065 | 0.0232 | 0.0598 | 3.88 |

| 40 | 50 | 0.09075 | 0.23945 | 0.02165 | 0.05705 | 3.79 |

| 50 | 10 | 0.02055 | 0.0517 | 0.0245 | 0.0616 | 3.97 |

| 50 | 20 | 0.03895 | 0.10115 | 0.0232 | 0.06025 | 3.85 |

| 50 | 30 | 0.05975 | 0.1548 | 0.02375 | 0.0615 | 3.86 |

| 50 | 40 | 0.0693 | 0.17715 | 0.02065 | 0.0528 | 3.91 |

| 50 | 50 | 0.08185 | 0.21345 | 0.0195 | 0.05085 | 3.83 |

| 60 | 10 | 0.0193 | 0.0497 | 0.023 | 0.05925 | 3.88 |

| 60 | 20 | 0.03165 | 0.0828 | 0.01885 | 0.04935 | 3.82 |

| 60 | 30 | 0.04515 | 0.11735 | 0.01795 | 0.0466 | 3.85 |

| 60 | 40 | 0.05975 | 0.15835 | 0.0178 | 0.04715 | 3.77 |

| 60 | 50 | 0.07025 | 0.1897 | 0.01675 | 0.0452 | 3.70 |

| Temperature (°C) | TBEE Concentration (%) | (g/mL) | (g/mL) | S | ||

|---|---|---|---|---|---|---|

| 30 | 10 | 0.04165 | 0.0262808 | 0.073755 | 0.055776 | 15.85 |

| 30 | 20 | 0.08285 | 0.0521248 | 0.07337 | 0.055344 | 15.89 |

| 30 | 30 | 0.11625 | 0.0733824 | 0.06864 | 0.051936 | 15.84 |

| 30 | 40 | 0.15265 | 0.0976612 | 0.067595 | 0.05184 | 15.63 |

| 30 | 50 | 0.18995 | 0.121394 | 0.067265 | 0.051552 | 15.65 |

| 40 | 10 | 0.04045 | 0.0255164 | 0.07304 | 0.049056 | 15.85 |

| 40 | 20 | 0.0765 | 0.0482664 | 0.06842 | 0.046128 | 15.85 |

| 40 | 30 | 0.11095 | 0.0702156 | 0.070235 | 0.047232 | 15.80 |

| 40 | 40 | 0.1478 | 0.0934752 | 0.06798 | 0.046416 | 15.81 |

| 40 | 50 | 0.18435 | 0.1169532 | 0.068035 | 0.04656 | 15.76 |

| 50 | 10 | 0.03825 | 0.0242788 | 0.06908 | 0.04056 | 15.75 |

| 50 | 20 | 0.07065 | 0.0452452 | 0.066385 | 0.039264 | 15.61 |

| 50 | 30 | 0.10175 | 0.065338 | 0.06578 | 0.038928 | 15.57 |

| 50 | 40 | 0.13505 | 0.0869232 | 0.06391 | 0.038016 | 15.54 |

| 50 | 50 | 0.1716 | 0.1101464 | 0.061215 | 0.036384 | 15.58 |

| 60 | 10 | 0.03395 | 0.0217308 | 0.064075 | 0.03792 | 15.62 |

| 60 | 20 | 0.06365 | 0.0409136 | 0.06325 | 0.037536 | 15.56 |

| 60 | 30 | 0.09175 | 0.0592592 | 0.060225 | 0.035712 | 15.48 |

| 60 | 40 | 0.12225 | 0.0792064 | 0.058135 | 0.034752 | 15.43 |

| 60 | 50 | 0.15055 | 0.0978068 | 0.05742 | 0.034416 | 15.39 |

| 40% MDEA + 60% H2O | ||||||

|---|---|---|---|---|---|---|

| Entry | Raw Gas | Purified Gas | H2S Removal Rate% | CO2 Co-Absorption Rate% | ||

| H2S% | CO2% | H2S mg/m3 | CO2% | |||

| 1 | 2.01 | 30.45 | 366.86 | 25.66 | 98.37 | 23.41 |

| 2 | 1.97 | 30.43 | 359.74 | 25.19 | 98.34 | 25.17 |

| 3 | 2.00 | 30.50 | 374.23 | 25.60 | 98.33 | 23.82 |

| 4 | 2.05 | 30.46 | 398.27 | 25.96 | 98.29 | 22.28 |

| 5 | 2.04 | 30.50 | 378.24 | 25.85 | 98.36 | 22.87 |

| Average | 2.01 | 30.47 | 375.47 | 25.65 | 98.33 | 23.52 |

| 40% TBEE + 60% H2O | ||||||

|---|---|---|---|---|---|---|

| Entry | Raw Gas | Purified Gas | H2S Removal Rate% | CO2 Co-Absorption Rate% | ||

| H2S% | CO2% | H2S mg/m3 | CO2% | |||

| 1 | 2.08 | 30.29 | 27.04 | 25.17 | 99.88 | 24.90 |

| 2 | 2.01 | 29.21 | 32.49 | 25.23 | 99.86 | 20.54 |

| 3 | 2.03 | 29.55 | 37.06 | 26.00 | 99.84 | 18.65 |

| 4 | 2.11 | 30.17 | 25.72 | 26.70 | 99.90 | 18.24 |

| 5 | 2.10 | 30.41 | 28.71 | 26.67 | 99.88 | 19.28 |

| Average | 2.07 | 29.93 | 30.20 | 25.95 | 99.87 | 20.38 |

| 5% TBEE + 35% MDEA + 60% H2O | ||||||

|---|---|---|---|---|---|---|

| Entry | Raw Gas | Purified Gas | H2S Removal Rate% | CO2 Co-Absorption Rate% | ||

| H2S% | CO2% | H2S mg/m3 | CO2% | |||

| 1 | 1.96 | 30.98 | 47.18 | 26.35 | 99.79 | 22.55 |

| 2 | 2.02 | 30.5 | 44.19 | 25.71 | 99.80 | 23.43 |

| 3 | 1.92 | 30.42 | 47.53 | 25.86 | 99.78 | 22.42 |

| 4 | 2.02 | 30.6 | 46.79 | 26.01 | 99.80 | 22.59 |

| 5 | 2.02 | 30.59 | 45.3 | 26.05 | 99.80 | 22.39 |

| Average | 1.99 | 30.62 | 46.20 | 26.00 | 99.79 | 22.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, J.; Yang, C.; Fu, J.; He, J.; Li, J. Research and Performance Evaluation on Selective Absorption of H2S from Gas Mixtures by Using Secondary Alkanolamines. Processes 2022, 10, 1795. https://doi.org/10.3390/pr10091795

Xue J, Yang C, Fu J, He J, Li J. Research and Performance Evaluation on Selective Absorption of H2S from Gas Mixtures by Using Secondary Alkanolamines. Processes. 2022; 10(9):1795. https://doi.org/10.3390/pr10091795

Chicago/Turabian StyleXue, Jingwen, Chaoyue Yang, Jingqiang Fu, Jinlong He, and Jinjin Li. 2022. "Research and Performance Evaluation on Selective Absorption of H2S from Gas Mixtures by Using Secondary Alkanolamines" Processes 10, no. 9: 1795. https://doi.org/10.3390/pr10091795

APA StyleXue, J., Yang, C., Fu, J., He, J., & Li, J. (2022). Research and Performance Evaluation on Selective Absorption of H2S from Gas Mixtures by Using Secondary Alkanolamines. Processes, 10(9), 1795. https://doi.org/10.3390/pr10091795