Experimental Study on Particle-Based Temporary Plugging Material Selection and Diversion Law of Shale Gas Reservoirs in WY Area, Sichuan, China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Material and Equipment

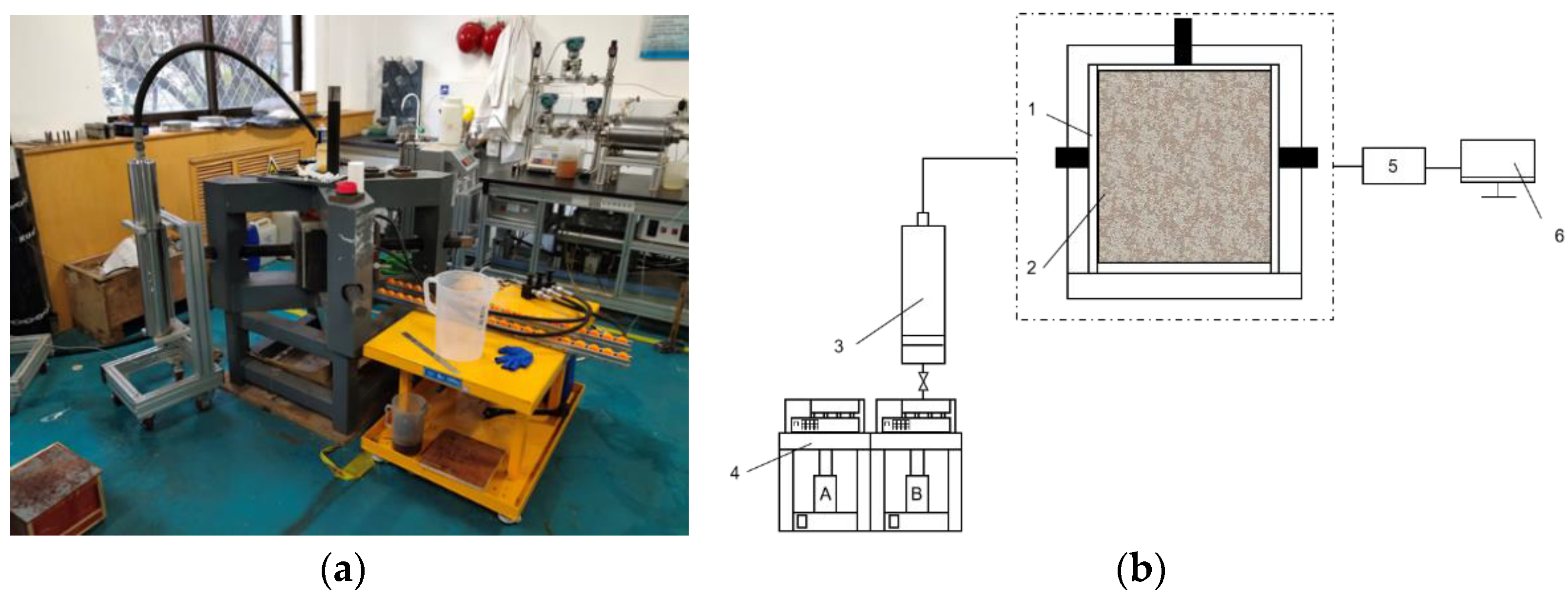

2.2. Experimental Setup and Procedure

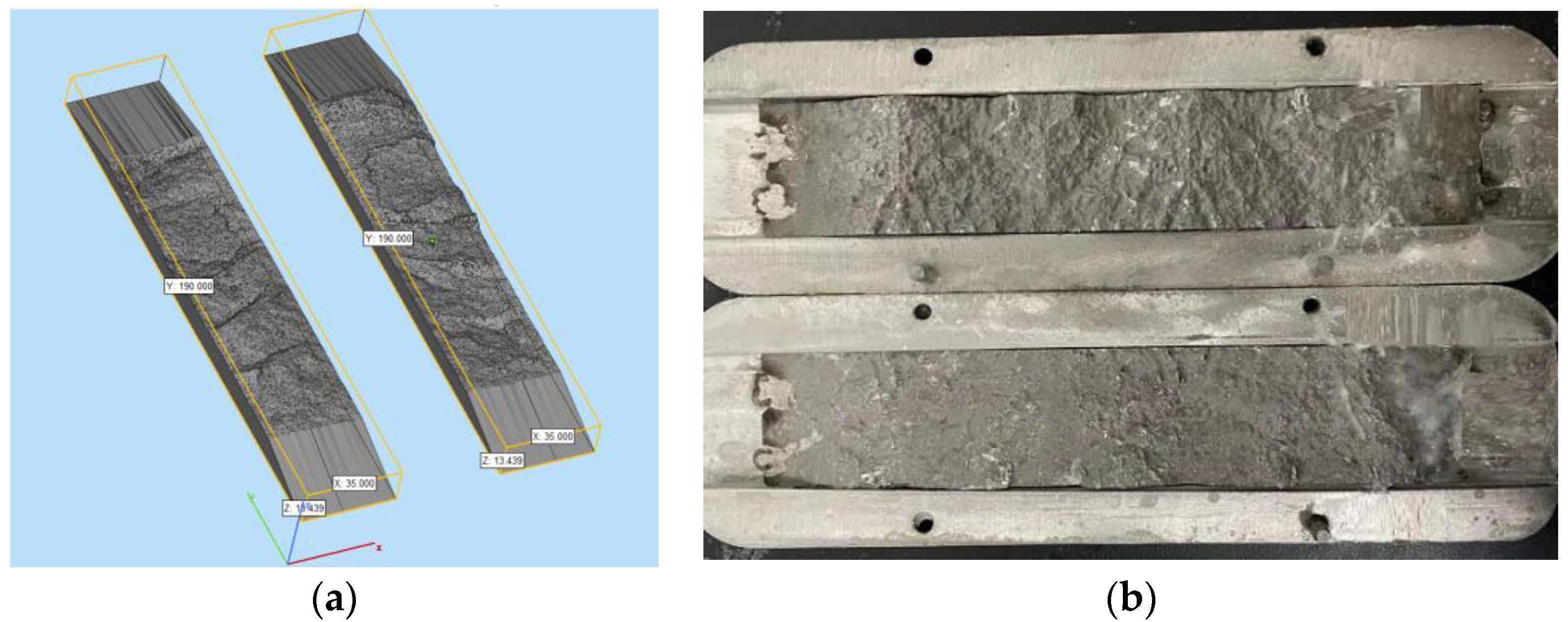

2.2.1. Fracture Temporary Plugging Experiment

2.2.2. Temporary Plugging Diversion Test of True Triaxial Large Scale Model

3. Results and Discussions

3.1. Fracture Temporary Plugging Experiment

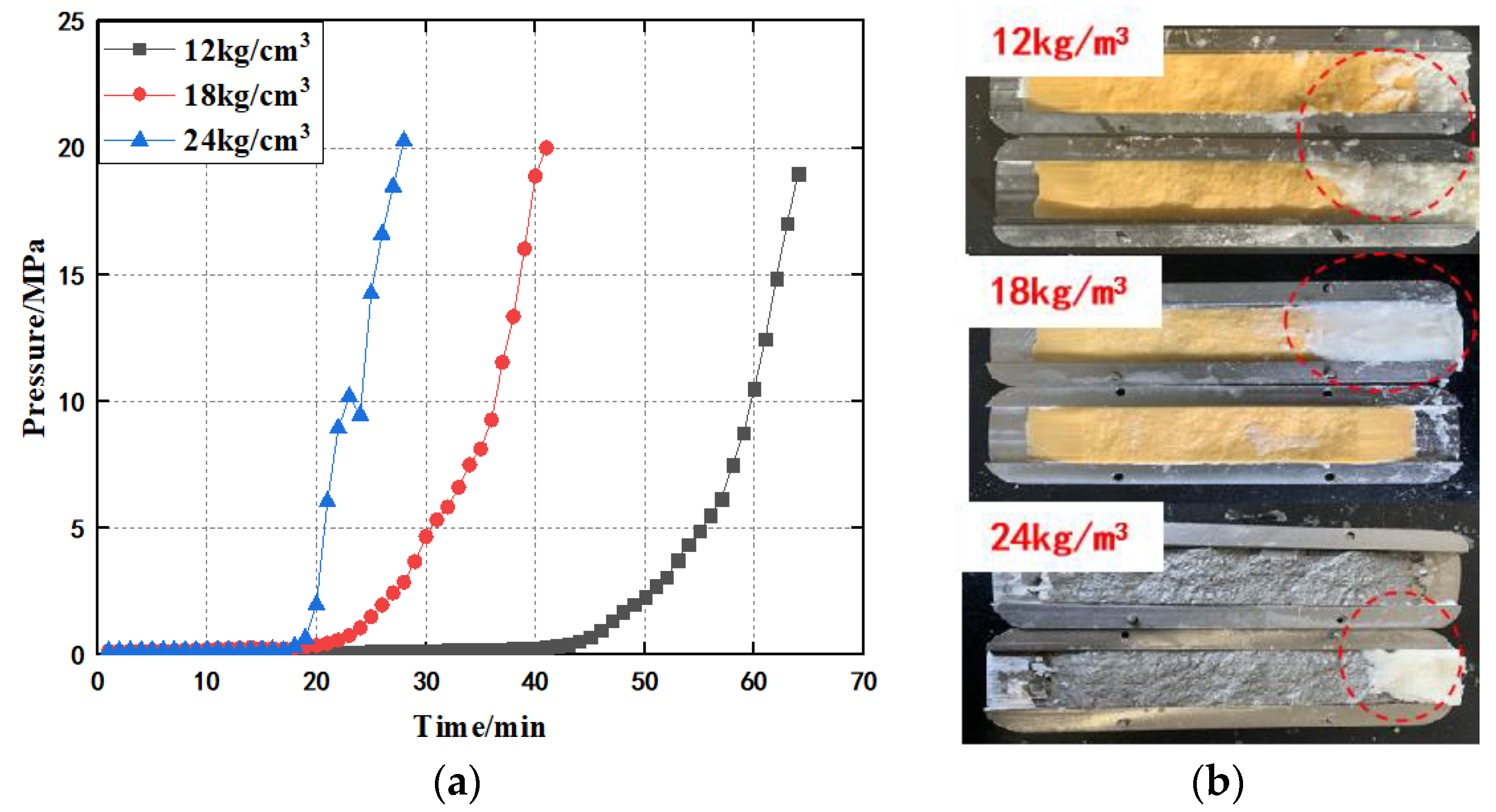

3.1.1. Same Ratio and Different Concentration

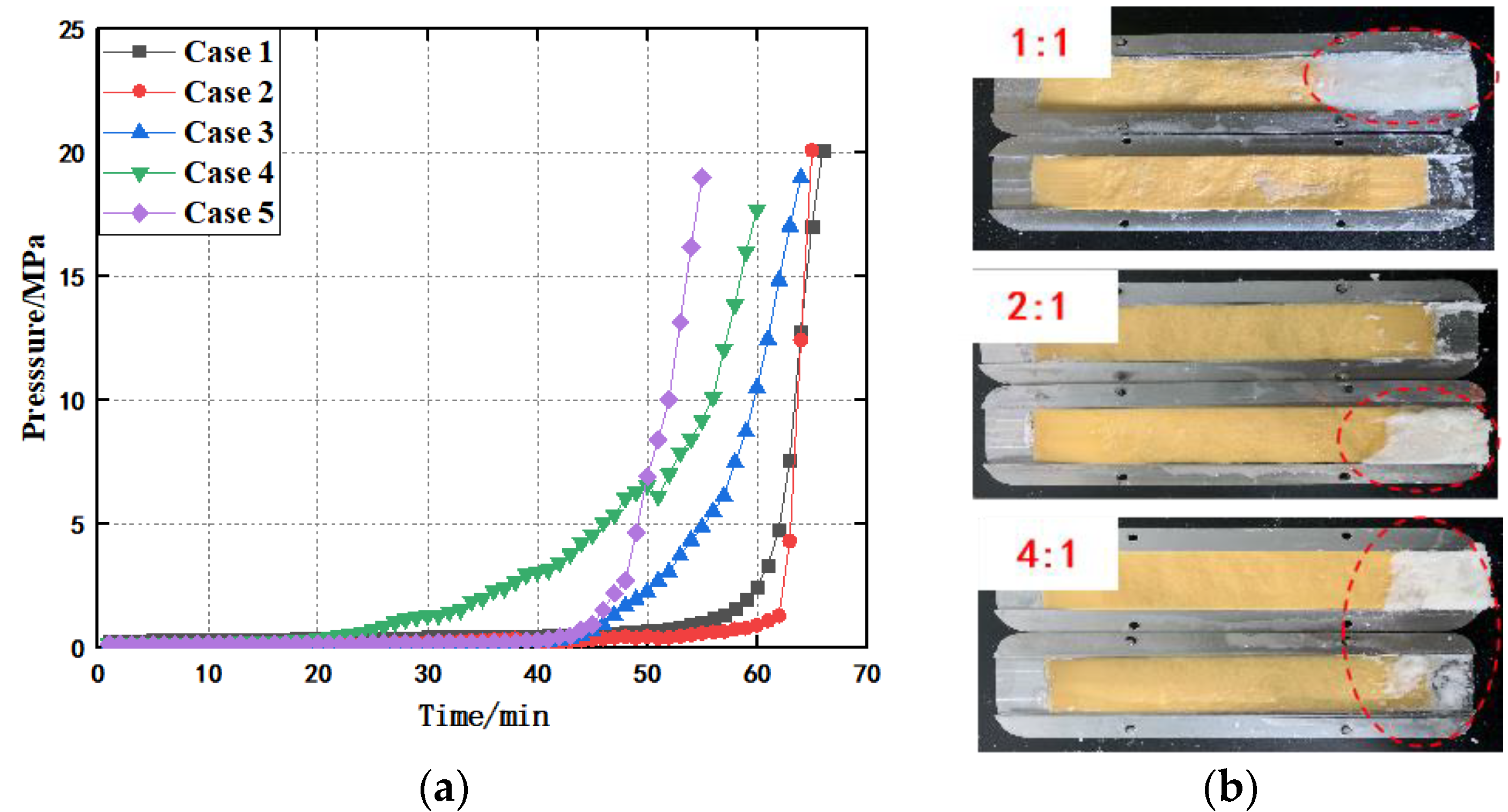

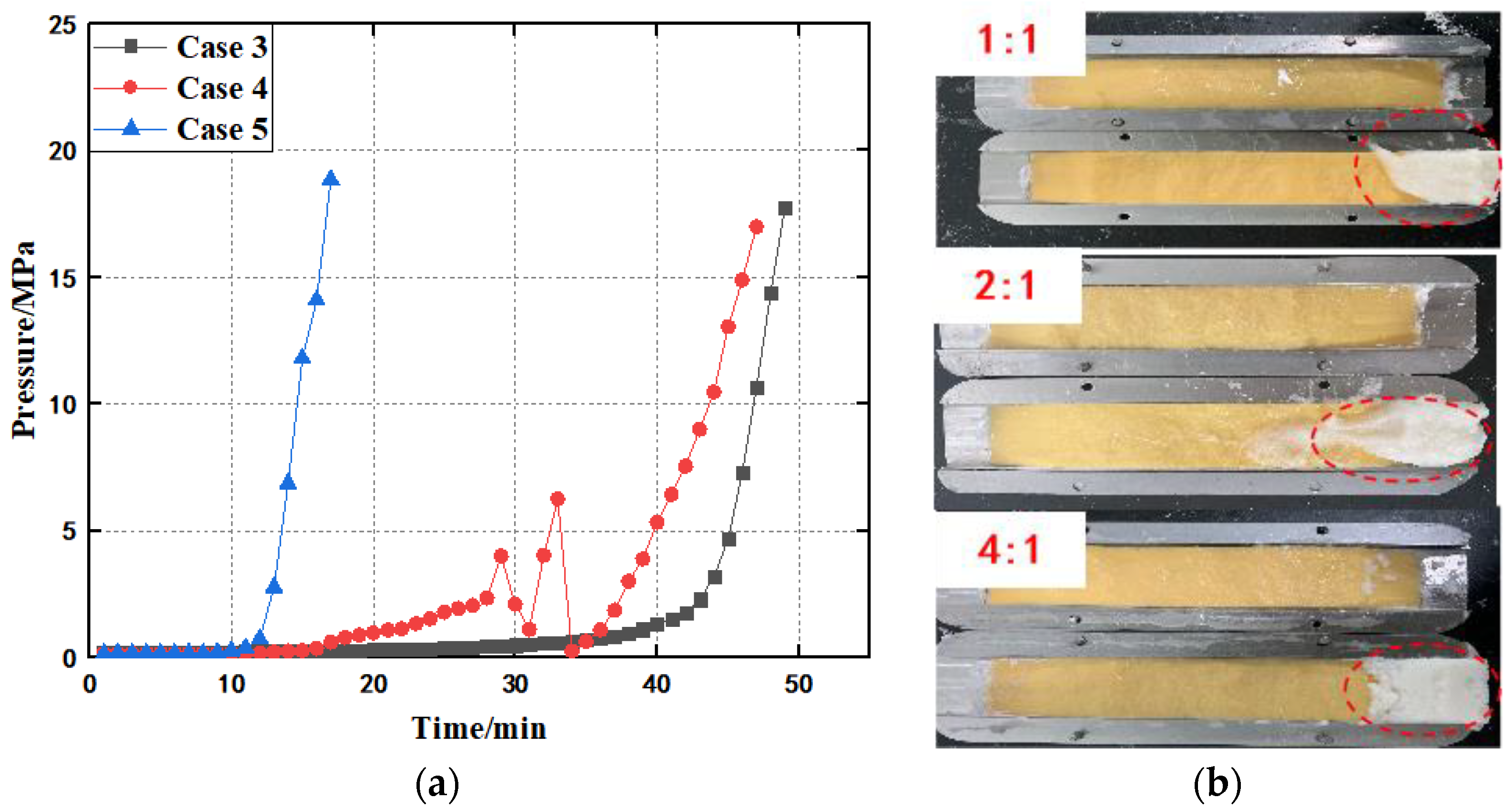

3.1.2. Different Proportions, Same Concentration

- 2.0 mm fracture width

- 4.0 mm fracture width

- 6.0 mm fracture width

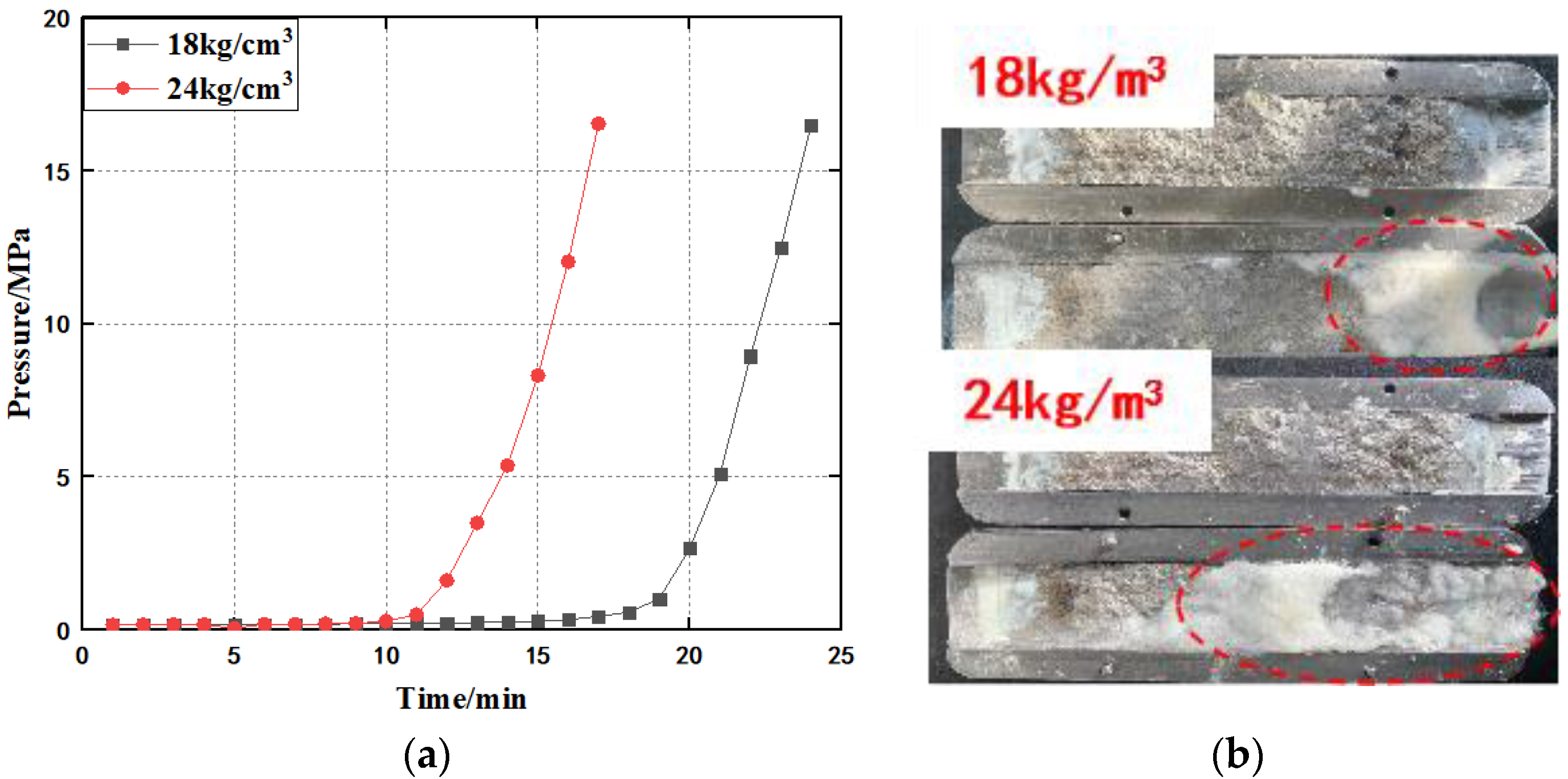

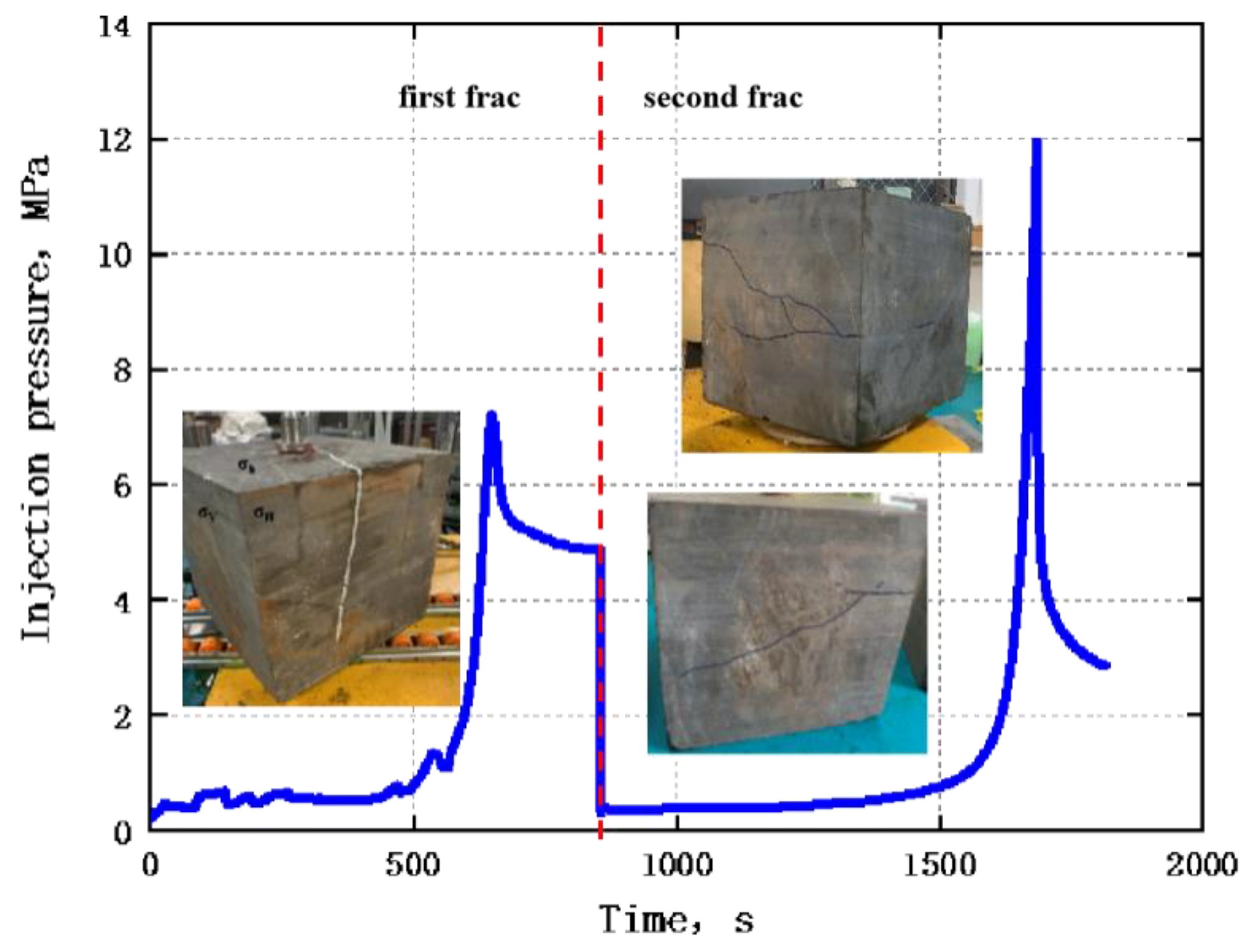

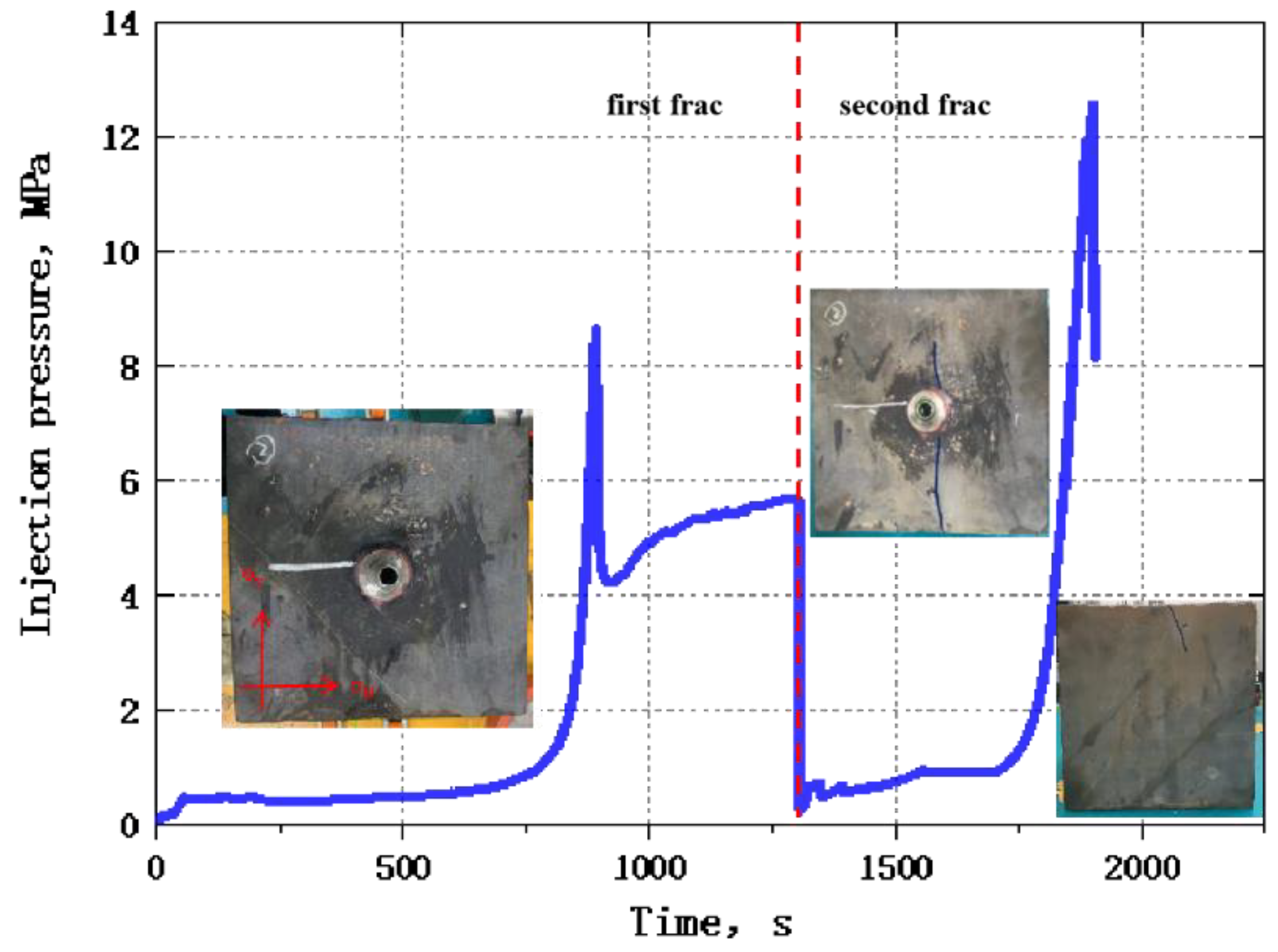

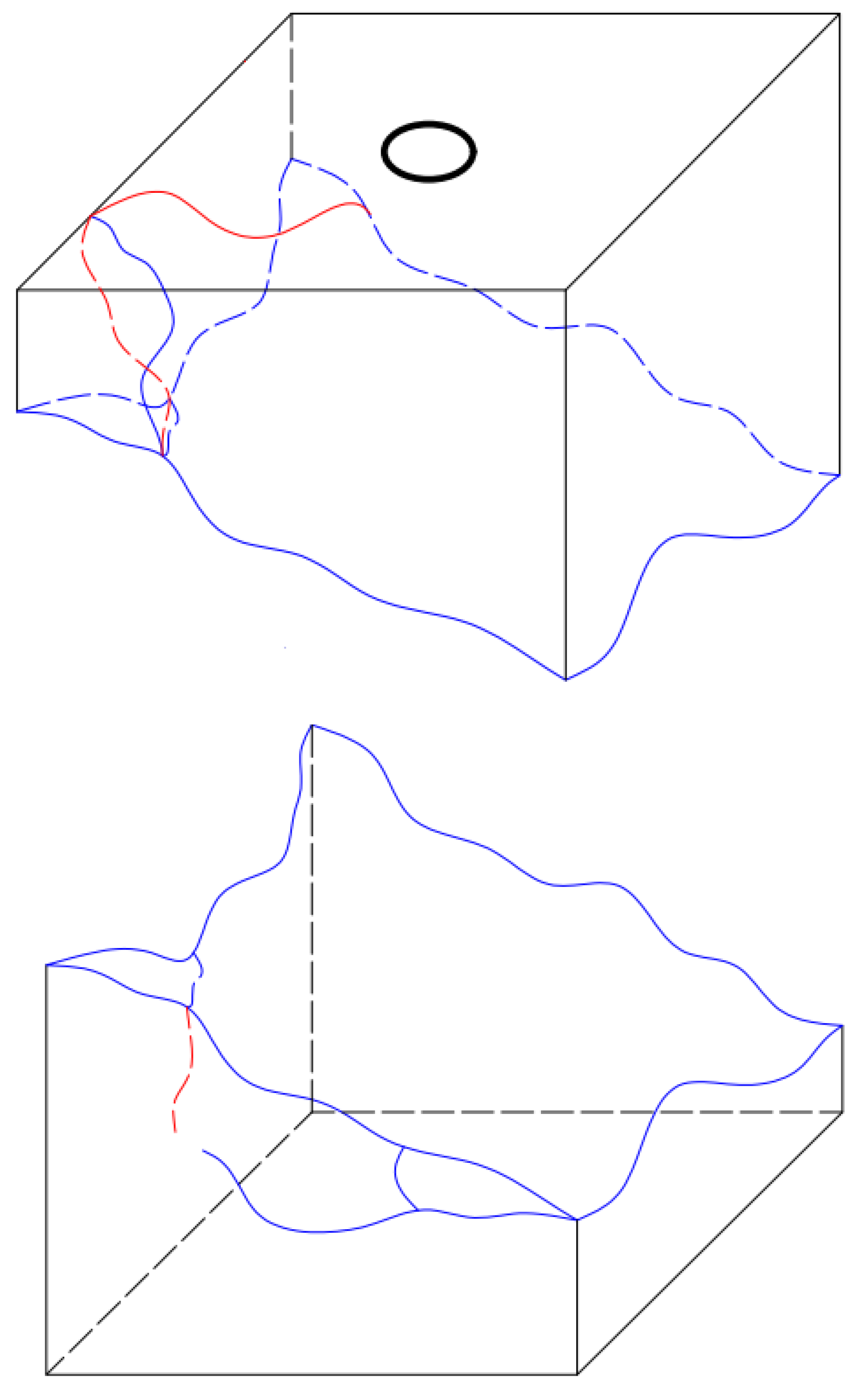

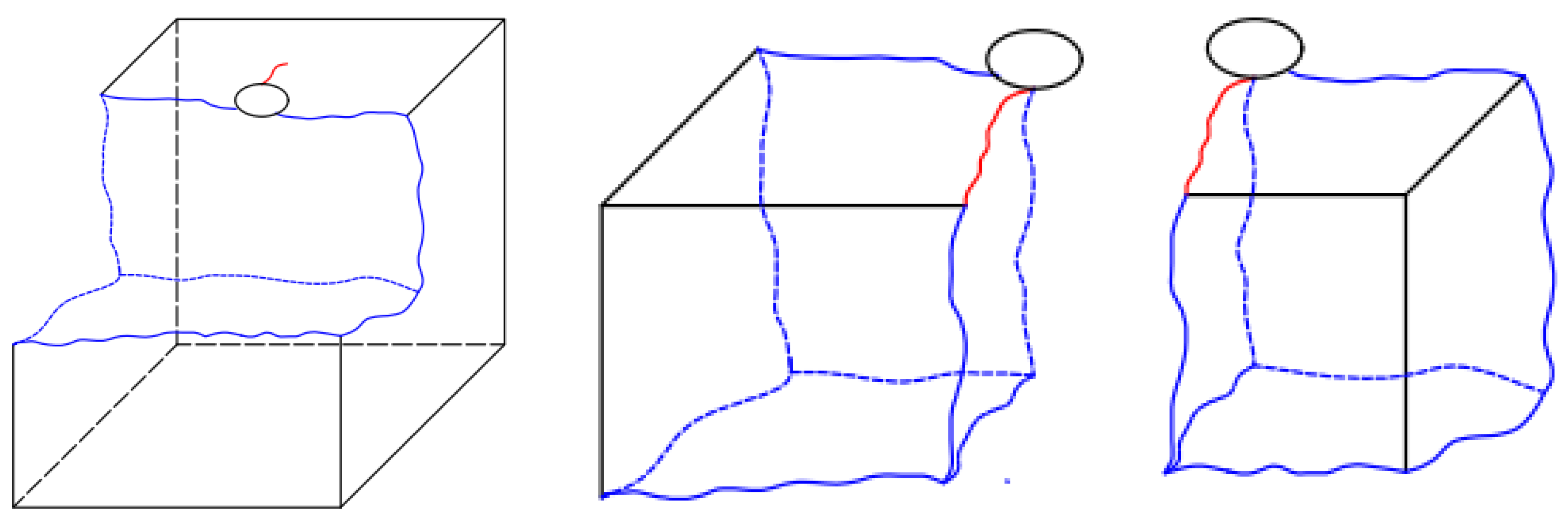

3.2. True Triaxial Large-Scale Model Temporary Plugging Diverting Test

3.2.1. Pumping Pressure Curve

- Calculation of equivalent width of fractured core

3.2.2. Overall Fracture Morphology

3.2.3. Influence of Triaxial Stress

4. Conclusions and Recommendations

- According to the fracture pressure response curve, the process of the temporary plugging experiment was divided into three stages. The formation period of the temporary plugging zone, where the initial pressure of temporary plugging increased from 0.0 MPa to 1.0 MPa, the temporary plugging agent began to accumulate in the fracture, and the pressure in the fracture gradually increased. The second stage was the temporary plugging growth period, where the pressure increased from 1.0 MPa to 5.0 MPa, at a slightly faster rate, and the temporary plugging agent gradually accumulated in the crack to form a plugging section, which gradually bore the pressure. The final stage was the late stage of temporary plugging, where the pressure increased from 5.0 MPa to beyond 10.0 MPa, and rose sharply, forming dense plugging sections.

- The plugging efficiency of the temporary plugging agent was determined by analyzing the time required for the pressure rise in the three major processes of temporary plugging. Because the constant flow mode was adopted in the experiments, the shorter the time required was, the higher the plugging efficiency and the smaller the liquid production were. The ratio of the temporary plugging agent was found to be the main factor affecting the temporary plugging efficiency. In addition, as the fracture width increases, the concentration should be increased appropriately.

- A comparison of the different proportions of sliding water and temporary plugging showed that the maximum sliding water system could temporarily plug 6.0 mm fracture widths. Under the same construction conditions, the volume of fracturing fluid with high concentration is larger than that with low concentration, and the corresponding construction cost is relatively high. Considering the economic efficiency of construction, when the fracture widths are 2.0, 4.0, or 6.0 mm, the corresponding optimal plugging scheme should be temporary plugging agent concentrations of 12.0, 18.0, and 18.0 kg/m3.

- In the true triaxial large-scale model experiment, the pressure increased first and then decreased multiple times, with an overall upward trend. This phenomenon occurred because after the fracturing fluid was injected into the wellbore, the liquid was filtrated along the formed fracture, and the temporary plugging agent gradually accumulated at the beginning of the fracture. Thus, aggregates were formed, and the fluid could not be filtrated into the fracture, forming a pressure rise. When the pressure increased to a certain extent, new fracture formation or old fracture extension made the liquid flow back into the rock, resulting in a rapid decline in the pressure. When the new filtration reached a certain degree, the temporary plugging agent formed a cluster again, resulting in a new round of pressure increase. Repeating this process until all filter points are blocked would continually increase the pressure.

- When the local stress difference is large, the old cracks can be temporarily blocked, while the new cracks can be opened along the direction of the maximum vertical principal stress. Hence, the fracturing fluid has good temporary plugging and diversion performance and can form a network structure with multiple fractures interwoven in the actual fracturing operation. Compared with the experimental results, it was found that the fracture pressure increased with an increase in axial stress. When the axial stress was constant, an increasing horizontal stress difference was accompanied by a correspondingly decreasing fracture pressure, while the crack deflection gradually decreased, and the crack width slightly decreased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Sheng, J.J.; Emadibaladehi, H.; Tu, J. Experimental study of the stimulating mechanism of shut-in after hydraulic fracturing in unconventional oil reservoirs. Fuel 2021, 300, 120982. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, J.; Liu, Y.; Yu, F. Evolution and management of thick-hard roof using goaf-based multistage hydraulic fracturing technology—A case study in western Chinese coal field. Arab. J. Geosci. 2021, 14, 876. [Google Scholar]

- Zhong, C.; Zolfaghari, A.; Hou, D.; Goss, G.G.; Lanoil, B.D.; Gehman, J.; Tsang, D.C.W.; He, Y.; Alessi, D.S. Comparison of the Hydraulic Fracturing Water Cycle in China and North America: A Critical Review. Environ. Sci. Technol. 2021, 55, 7167–7185. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.; Xu, Z.; Sun, R.; Fang, X.; Gao, D.; Jia, X.; Hu, J.; Weng, J. Laboratory evaluation on temporary plugging performance of degradable preformed particle gels (DPPGs). Fuel 2020, 289, 119743. [Google Scholar] [CrossRef]

- Jia, H.; Kang, Z.; Zhu, J.; Ren, L.; Cai, M.; Wang, T.; Li, Z. High density bromide-based nanocomposite gel for temporary plugging in fractured reservoirs with multi-pressure systems. J. Pet. Sci. Eng. 2021, 205, 108778. [Google Scholar] [CrossRef]

- Abrams, A. Mud design to minimize rock impairment due to particle invasion. J. Pet. Technol. 2013, 29, 586–592. [Google Scholar] [CrossRef]

- Loeppke, G.E.; Glowka, D.A.; Wright, E.K. Design and evaluation of lostcirculation materials for severe environments. J. Pet. Technol. 2013, 42, 328–337. [Google Scholar] [CrossRef]

- Carpenter, C. A Novel Completion Method for Sequenced Fracturing in the Eagle Ford Shale. J. Pet. Technol. 2014, 66, 122–125. [Google Scholar] [CrossRef]

- Xue, S.; Zhang, Z.; Wu, G.; Wang, Y.; Wu, J.; Xu, J. Application of a Novel Temporary Blocking Agent in Refracturing. In SPE Asia Pacific Unconventional Resources Conference and Exhibition; Society of Petroleum Engineers: Brisbane, Australia, 2015. [Google Scholar]

- Wang, D.; Zhou, F.; Ge, H.; Shi, Y.; Yi, X.; Xiong, C.; Liu, X.; Wu, Y.; Li, Y. An experimental study on the mechanism of degradable fiber-assisted diverting fracturing and its influencing factors. J. Nat. Gas Sci. Eng. 2015, 27, 260–273. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, F.; Ding, W.; Ge, H.; Jia, X.; Shi, Y.; Wang, X.; Yan, X. A numerical simulation study of fracture reorientation with a degradable fiber-diverting agent. J. Nat. Gas Sci. Eng. 2015, 25, 215–225. [Google Scholar] [CrossRef]

- Lichun, I.; Hongyin, X.; Qingming, T. Simulation experimental study on leakage stoppage under triaxial pressure. Drill. Prod. Technol. 2017, 40, 14–17. [Google Scholar]

- Gomaa, A.M.; Spurr, N.; Pirogov, A.; McCartney, E. Combining soluble particle diverter with specially engineered proppant to enhance fracture complexity and post-fracture conductivity. In SPE Annual Technical Conference and Exhibition; Society of Petroleum Engineers: Dubai, United Arab Emirates, 2016. [Google Scholar]

- Fu, H.; Yan, Y.; Xu, Y.; Liang, T.; Liu, Y.; Guan, B.; Wang, X.; Weng, D.; Feng, J. Experimental Study and Field Application of Fiber Dynamic Diversion in West China Ultra-Deep Fractured Gas Reservoir. In 52nd US Rock Mechanics/Geomechanics Symposium; American Rock Mechanics Association: Washington, DC, USA, 2018. [Google Scholar]

- Vidma, K.; Abivin, P.; Dunaeva, A.; Panga, M.; Nikolaev, M.; Usoltsev, D.; Mayo, J.T. Far-Field Diversion Technology to Prevent Fracture Hits in Tightly Spaced Horizontal Wells. In SPE Annual Technical Conference and Exhibition; Society of Petroleum Engineers: Dallas, TX, USA, 2018. [Google Scholar]

- Trumble, M.; Sinkey, M.; Meehleib, J. Got Diversion? Real Time Analysis to Identify Success or Failure. In SPE Hydraulic Fracturing Technology Conference and Exhibition; Society of Petroleum Engineers: The Woodlands, TX, USA, 2019. [Google Scholar]

- Staff, J. Perforating requirements for fracture stimulations. J. Pet. Technol. 1998, 50, 46. [Google Scholar] [CrossRef]

- Zhou, F.; Yi, X.; Yang, X.; Liu, X.; Wang, D. Dynamic fifiltration experiment of fifiber temporary pluggin artifificial fracture. Drill. Prod. Technol. 2014, 37, 83–86. [Google Scholar]

- Liu, Z.Y.; Chen, M.; Zhang, G.Q. Analysis of the influence of a natural fracture network on hydraulic fracture propagation in carbonate formations. Rock Mech. Rock Eng. 2014, 47, 575–587. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, S.; Duan, K. Study on the deformation and strength characteristics of hard rock under true triaxial stress state using bonded-particle model. Comput. Geotech. 2019, 112, 1–16. [Google Scholar] [CrossRef]

- Yang, S.; Fujian, Z.; Xianyou, Y.; Xiongfei, L.; Shengjiang, L.; Xiangdong, L. Laboratory study and field application of fiber-based fracture reorientation technology. In IPTC 2013 International Petroleum Technology Conference; OnePetro: Beijing, China, 2013. [Google Scholar]

- Yang, S.; Wei, J. Reservoir Physics; Schlumberger: Houston, TX, USA, 2015; pp. 152–155. [Google Scholar]

| Fracture Width (mm) | Temporary Plugging Agent Ratio, Mass Ratio 20–70 Mesh: 200–300 Mesh | Concentration (kg/m3) | Pump Rate (mL/min) |

|---|---|---|---|

| 2.0 | 1:4 | 12 | 60 |

| 1:2 | |||

| 1:1 | |||

| 2:1 | |||

| 4:1 | |||

| 1:4 | 18 | ||

| 1:2 | |||

| 1:1 | |||

| 2:1 | |||

| 4:1 | |||

| 1:4 | 24 | ||

| 1:2 | |||

| 1:1 | |||

| 2:1 | |||

| 4:1 |

| Text | σh (MPa) | σH (MPa) | σv (MPa) |

|---|---|---|---|

| 1 | 5.0 | 17.0 | 5.0 |

| 2 | 5.0 | 20.0 | 5.0 |

| 3 | 5.0 | 17.0 | 7.0 |

| 4 | 5.0 | 20.0 | 7.0 |

| 5 | 5.0 | 25.0 | 7.0 |

| Pressure | Test 1 | Test 2 | Test 3 | Test 4 | Test 5 |

|---|---|---|---|---|---|

| Horizontal stress difference (MPa) | 12.0 | 15.0 | 12.0 | 15.0 | 20.0 |

| Axial stress (MPa) | 5.0 | 5.0 | 7.0 | 7.0 | 7.0 |

| Burst pressure (MPa) | 7.22/11.9 | 8.6/12.5 | 13.8/20.0 | 8.9/15.9 | 4.9/13.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Ma, Y.; Jiang, H.; Wang, J.; Fan, L.; Guo, P. Experimental Study on Particle-Based Temporary Plugging Material Selection and Diversion Law of Shale Gas Reservoirs in WY Area, Sichuan, China. Processes 2022, 10, 1720. https://doi.org/10.3390/pr10091720

Xu H, Ma Y, Jiang H, Wang J, Fan L, Guo P. Experimental Study on Particle-Based Temporary Plugging Material Selection and Diversion Law of Shale Gas Reservoirs in WY Area, Sichuan, China. Processes. 2022; 10(9):1720. https://doi.org/10.3390/pr10091720

Chicago/Turabian StyleXu, Hualei, Yongle Ma, Houshun Jiang, Jie Wang, Longfei Fan, and Panyang Guo. 2022. "Experimental Study on Particle-Based Temporary Plugging Material Selection and Diversion Law of Shale Gas Reservoirs in WY Area, Sichuan, China" Processes 10, no. 9: 1720. https://doi.org/10.3390/pr10091720

APA StyleXu, H., Ma, Y., Jiang, H., Wang, J., Fan, L., & Guo, P. (2022). Experimental Study on Particle-Based Temporary Plugging Material Selection and Diversion Law of Shale Gas Reservoirs in WY Area, Sichuan, China. Processes, 10(9), 1720. https://doi.org/10.3390/pr10091720