Abstract

The plastics business has grown rapidly in recent years, with annual growth rates ranging from 16% to 18% each year (second only to the telecommunications and textile industries). The plastic industry is regarded as a dynamic industry in the Vietnamese economy due to its rapid development rate. Its high growth stems from a big market with significant expansion potential, since Vietnam’s plastic sector is still in its early stages in comparison to the rest of the globe and plastic goods are pushed and utilized in many aspects of life. In order to ensure sustainable development and comply with the provisions of the Law on Environment Protection, plastic manufactures and importers must ensure to fulfill two responsibilities: (1) proper product and packaging recycling—applicable to products and packaging with recyclable value; and (2) the collection and treatment of waste—applicable to products and packaging containing hazardous substances, difficult to recycle, causing difficulties for waste collection and treatment. Therefore, raw materials supplier selection in the plastic industry is a complex decision, and decision makers must consider many qualitative factors, quantitative factors and environmental attributes during the decision making. As a result, the goal of this study is to present an integrated multicriteria decision making model (MCDM) strategy for sustainable supplier selection in the plastics sector under fuzzy environment circumstances. This paper makes a contribution by proposing a hybrid fuzzy analytic hierarchy process (AHP) and technique for order of preference by similarity to ideal solution (TOPSIS) approach model for raw material supplier selection in the plastics sector. This research also provided a useful guideline for supplier selection in other industries.

1. Introduction

Plastic is used to manufacture a wide range of things, providing an important contribution to human existence as well as the growth of many other eco-nomic sectors and fields such as power, electronics, telecommunications, transportation, fisheries, agriculture, etc. Plastic items are being applied and becoming alternatives for conventional seemingly irreplaceable materials such as wood, metal, silicate, and so on as science and technology advance. As a result, the plastic sector is becoming increasingly significant in countries’ lives and output [1]. Despite its rapid growth in recent years, Vietnam’s plastic industry is still primarily known as an economic and technical business in plastic processing, with little involvement in raw material procurement. Currently, the plastic industry requires an average of 3.5 million tons of input materials such as polyethylene (PE), polypropylene (PP), polystyrene (PS), and so on, not to mention hundreds of different auxiliary chemicals; however, domestic capacity can only meet about 900,000 tons of raw materials, chemicals, and additives for the needs of Vietnam’s plastic industry. As a result, the amount and value of plastic materials imported have steadily grown over the years [1]. Sample of plastic raw materials is shown in Figure 1.

Figure 1.

Plastics raw materials.

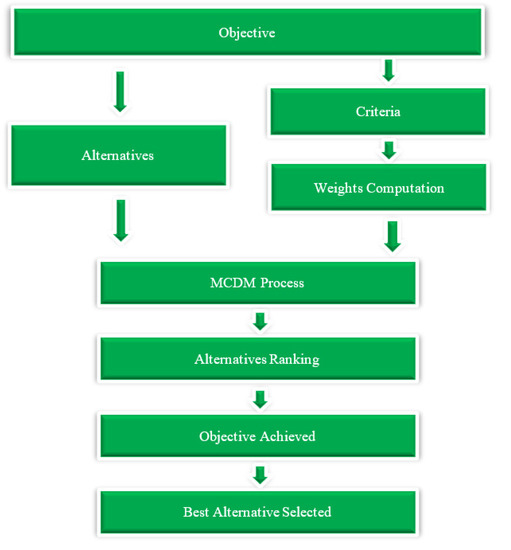

Currently, Vietnam has signed and implemented 11 free trade agreements (FTAs), in which several plastic resin products have been reduced to a 0–10% special preferential tax. This is an opportunity for domestic enterprises to take advantage of special preferential commitments in free trade agreements (FTAs) to reduce input production costs and increase competitiveness with regional partners. However, imported plastic materials must meet the provisions of the Law on Environmental Protection. Therefore, raw materials supplier selection in plastic industry is a multicriteria decision making, decision makers must consider many qualitative factors, quantitative factors, and environmental attributes during the decision-making process. The flowchart of the MCDM process is shown in Figure 2.

Figure 2.

Flowchart of MCDM process.

MCDM approaches such as the aggregated indices randomization method (AIRM), base-criteria method (BCM), best worst method (BWM), etc. can be used to help decision-making processes. The decision-maker must frequently take both qualitative and quantitative elements into account. In these situations, the MCDM technique is combined with fuzzy theory to develop a fuzzy MCDM strategy to support the decision-making processes. Although several MCDM models have been put forth to support supplier selection procedures in other industries, very few hybrid MCDM models have been created to address the supplier selection problem in the plastics industry, particularly in a fuzzy decision-making environment. In this research, the author proposed a fuzzy MCDM model for the plastics industry’s supplier selection. The fuzzy analytic hierarchical process (AHP) was used to determine the weights for each criterion in order to rank numerous suppliers. These weights were then entered into the technique for order of preference by similarity to ideal solution (TOPSIS) technique. The FAHP-TOPSIS model can aid in making the best decisions since it analyzes issues using a variety of criteria and enables decision-makers to examine the relationships between these criteria. It also accounts for the subjectivity, ambiguity, and diversity of the decision-makers. Therefore, the model in this study can assist businesses in the plastics industry in selecting the best supplier selection choices. The proposed model can be improved and used to support other sectors in various nations as a resource in solving MCDM challenges, even if the study is solely applicable to the plastics industry in Vietnam.

The remaining sections of this work are organized as follows. Section 2 discusses significant literature on the use of MCDM models in a variety of scientific domains. Section 3 explained the fundamental theory of two MCDM models. Section 4 applies the suggested methodology to a case study of a real-world plastics raw materials supplier evaluation to demonstrate its practicality. Section 5 presents the conclusions of our research.

2. Literature Review

Complex decision-making difficulties are frequent in many industries and economic sectors, and these challenges often entail several quantitative and qualitative criteria. The MCDM model has been used in a variety of domains in recent years, including facility placement selection difficulties [2,3], rating renewable energy sources [4,5], and the information technology business [6,7]. Among these, MCDM models are frequently applied in supplier evaluation and selection problems.

Zeljko Stevi et al. [8] used the measurement of alternatives and ranking according to compromise solution (MARCOS) for long-term supplier selection in the healthcare industry. In this work, the authors applied MCDM model for ranking of eight alternatives in healthcare industries regarding 21 criteria. Morteza Yazdani et al. [9] presented an MCDM model for green supplier selection that included quality function deployment (QFD), complex proportional assessment (COPRAS), and the decision-making trial and evaluation laboratory (DEMATEL). Goran Petrovi et al. [10] proposed a three-stage MCDM model, which included the fuzzy stepwise weight assessment ratio analysis model (fuzzy SWARA), the fuzzy technique for order preference by similarity to ideal solution (Fuzzy TOPSIS), and the fuzzy additive ratio assessment model (Fuzzy ARAS), for evaluating and selecting suppliers in the case of THK linear motion guide component procurement.

Based on the TOPSIS model, Yong Deng et al. [11] presented a novel MCDM model (containing fuzzy sets theory (FST) and Dempster–Shafer theory of evidence (DST)) for supplier selection challenges. Semih nüt et al. [12] created an MCDM methodology for supplier selection in a telecommunications firm based on the analytic network process (ANP) and the technique for order performance by similarity to ideal solution (TOPSIS). A real-world case study including six primary assessment criteria that the firm has developed to pick the best suited supplier is presented in this paper. Liu et al. [13] created a new MCDM model for sustainable supplier selection by merging best-worst method (BWM) and alternative queuing method (AQM) inside uncertain situations. As a result of our work, firms may support sustainable supply chain management.

Anupam Haldar et al. [14] presented a hybrid MCDM model for robust substitute selection. The TOPSIS and AHP methodologies were used by the authors in this study for general selection criteria. Ulutaş Alptekin et al. [15] created a new MCDM model that combines the benefits of three well-known and prominent multiple-criteria decision-making methods: multi-objective optimization based on simple ratio analysis (MOOSRA), multi-objective optimization based on ratio analysis (MOORA), and multi-objective optimization based on ratio analysis plus the full multiplicative form (MULTIMOORA) for supplier selection.

Wang Chen et al. [16] provided a comprehensive fuzzy multicriteria decision making (MCDM) strategy for green supplier selection and assessment in the luminance enhancement film (LEF) market that included the FAHP and TOPSIS models. Bojan Matic et al. [17] developed a fuzzy MCDM model for assessing and choosing suppliers in a construction company’s sustainable supply chain. The author determined the weight of all criteria using the complete consistency method (FUCOM) model, while rating some of the possible suppliers is done using a novel rough complex proportional assessment (COPRAS) approach. In the work of Mei-Yun Quan and colleagues [18], a hybrid MCDM strategy for large group green supplier selection with uncertain linguistic information was introduced. The purpose of this study is to offer a hybrid MCDM strategy for green supplier selection in a large group environment. Morteza Yazdani et al. [19] creative integrated a MCDM model of supplier selection problem. In this work, the author used a three MCDM model including stepwise weight assessment ratio analysis (SWARA) model, quality function deployment (QFD), and weighted aggregated sum product assessment (WASPAS) model. For supplier selection, Mazaher Ghorbani et al. [20] suggested a three-phase MCDM strategy based on the Kano model and fuzzy MCDM. The weights of all criteria are initially computed using a fuzzy Kano questionnaire and the FAHP model. In the second step, fuzzy TOPSIS ranks many possible providers.

Armin C. et al. [21] proposed a hybrid MCDM- mixed integer linear programming (MILP) approach for sustainable supplier selection. In decision making processes, the author considered two types of quantity discounts along with disruption risks. To find the sustainable supplier and optimal order allocation, they also applied the best worst method (BWM) model and revised multi-choice goal programming. Melih Yucesan et al. [22] proposed a MCDM model including best-worst method (BWM) and the interval type-2 fuzzy technique for order preference by similarity to ideal solution (IT2F TOPSIS) for green supplier selection in a plastic injection molding facility in Turkey.

According to this evaluation of the research, studies applying the MCDM approach to various fields of science and engineering have been increasing in number over the past few years. One of the fields where the MCDM model has been employed is in supplier selection problems. Especially in the plastics industry, decision makers have to evaluate both qualitative, quantitative factors and sustainable factors. Although some studies have reviewed applications of MCDM approaches in sustainable supplier selection in the plastics industry, very few works have focused on this problem in a fuzzy environment. This is a reason why in this work MCDM model including AHP with fuzzy logic, and TOPSIS is proposed for sustainable supplier selection in plastics industry.

3. Methodology

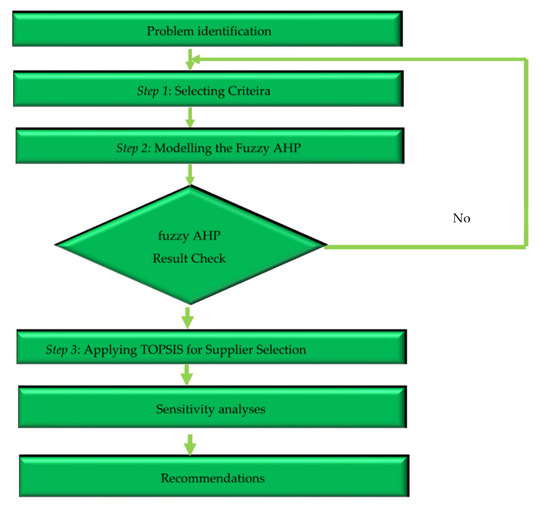

In this work, the authors proposed a MCDM model including fuzzy AHP and TOPSIS approach to select the sustainable supplier in plastics industry. There are three steps involved in this process, as shown in Figure 3:

Figure 3.

Research graph.

Step 1: Selecting evaluate criteria. In this step, the criteria for selecting the optimal supplier will be defined. All criteria have built through expert interviews and the results from others’ research.

Step 2: Applying the FAHP model. The FAHP model is the most effective tool for addressing complex problems of decision making with a connection to various qualitative criteria. The weight of criteria will be defined in this step.

Step 3: Utilizing the TOPSIS approach. The TOPSIS model is employed to rank some potential suppliers. The optimal alternative has the shortest geometric distance from the positive ideal solution (PIS) and the longest geometric distance from the negative ideal solution (NIS). The best sustainable supplier will be presented in this stage.

3.1. Process of Fuzzy Analytic Hierarchy

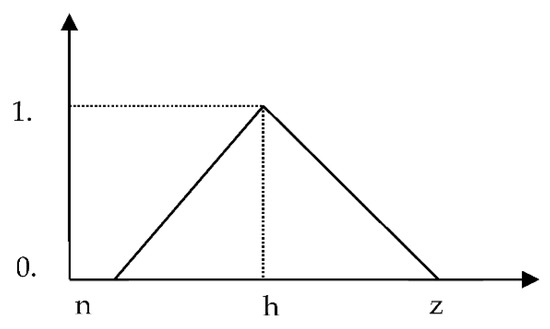

Zadeh (1965) [23] created fuzzy set theory. There are numerous types of fuzzy numbers available nowadays; triangular fuzzy numbers are used in this study due to their efficiency and convenience of usage [24,25,26,27,28]. Figure 4 depicts how it is defined.

Figure 4.

Fuzzy triangular number.

If k = h = z, becomes a real number [29]. According to Buckley, the FAHP technique should be used.

Step 1: The decision-maker weighs the criteria and alternatives.

Step 2: Make a pairwise comparison matrix

Fuzzy numbers are used to generate a pairwise comparison matrix. The matrix is expressed as follows:

If there are several decision makers, the preferences of each expert () are averaged and () is calculated as in Equation (3):

Step 3: The pairwise contribution matrix, as shown in Equation (4), will be updated based on the average preferences.

Step 4: Equation (5) is used to get the geometric mean of the fuzzified comparison results for each criteria, values are triangular values.

Step 5: Equation (5) [30] may be used to get the fuzzified weights for each criteria by merging the three minor stages:

Step 5a: Determine the vector summation of each .

Step 5b: Determine the inverse power of the summation vector. Sort into ascending order after replacing the fuzzified triangular.

Step 5c: Compute the fuzzified weight by multiplying each vector by its inverse vector.

Step 6: Because are still fuzzified triangular numbers, the defuzzification procedure must employ the Centre of Area approach [31], as illustrated in Equation (7).

Step 7: Even if is a normal integer, it must be normalized using Equation (8):

3.2. The Order of Preference by Similarity to Ideal Solution Model Technique

TOPSIS was created in 1981 [32] by Ching-Lai Hwang and Yoon, with additional advancements by Yoon [33], Hwang et al. [34]. The TOPSIS procedure is as follows:

Step 1: Make an assessment matrix with m choices and n criteria. With the intersection of each alternative and criteria provided as , we get the matrix .

Step 2: After that, the matrix is normalized to create the matrix:

Step 3: Make the following weighted normalized choice matrix:

where j = 1, 2,..., n so that and is the initial weight provided to the indicator , j = 1, 2,..., n.

Step 4: Determine the worst option () and the greatest option ():

Step 5: Determine the -distance between the desired alternative and the worst-case scenario :

In addition to the distance between the desired alternative and the worst case :

Step 6: Determine the degree of resemblance to the worst-case scenario:

Step 7: Sort the options according to (

4. Case Study

The plastics sector has grown at a 9 percent annual pace over the previous 50 years. Even during the economic downturn, the plastics industry rose by 3%. Following the crisis, this industry increased by 10% to 20% in Southeast Asian countries, China, and India. This shows that the potential of this industry is currently very large in Asia. Currently, the leading plastic production area belongs to Asia, with a share of 37% of total global plastic production. Despite strong growth, plastic raw materials to be unable to keep up with world demand. Currently, the world economy is in a period of prosperous development, leading to a huge demand for plastic packaging and components. This may lead to an increase in the price of plastic raw materials and plastic products in the near future.

Plastics cause environmental impact, particularly near the end of their life cycle, when they emit greenhouse gases and air pollutants when burnt or pollute water and soil in the form of microplastics. Therefore, the raw materials supplier selection in the plastic industry is a complex decision. Thus, the goal of this study is to present an integrated MCDM strategy that includes the FAHP and TOSIS models for sustainable supplier selection in the plastics sector while taking into account various environmental performance requirements. The author considers 15 criteria in decision making processes, and a list of criteria is shown in Table 1.

Table 1.

Criteria list.

The authors employed the fuzzy analytic hierarchy process to generate the weights for each criterion (AHP). Table 2 shows the weights of the 15 criteria.

Table 2.

Weight of criteria.

The topic of supplier selection is one of the most essential business activities connected to sustainable development since it has a substantial impact on product quality and quantity, as well as sustainability difficulties. The corporation must exercise caution when making judgments regarding plastics raw materials supplier selection since numerous aspects must be evaluated at the same time. The FAHP model defines the weight of criteria, and the TOPSIS model is then used to rank five possible providers. Normalized matrix and Normalized weighted matrix are shown in Table 3 and Table 4.

Table 3.

Normalized matrix.

Table 4.

Normalized weighted matrix.

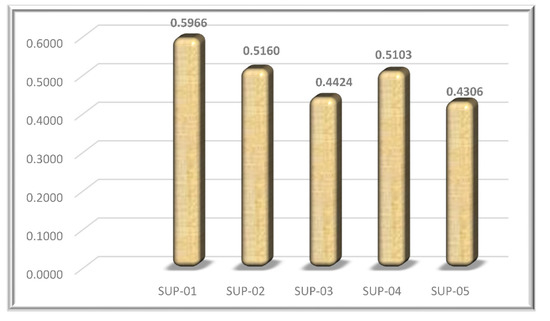

The authors suggested a fuzzy multicriteria decision making model, incorporating a fuzzy AHP and TOPSIS model, in this study to construct a decision support system in the selection of plastics raw material suppliers. In the initial step, a fuzzy AHP was used to establish the weight of all criteria, and the TOPSIS model was then utilized in the last stage to rank all probable plastics raw materials suppliers. The top three plastics raw material providers, as shown in Table 5 and Figure 5, were SUP-01, SUP-02, and SUP-04, with scores of 0.5966, 0.5160, and 0.5103, respectively. As a result, supplier 01 (SUP-01) is the best choice.

Table 5.

Ci value from TOPSIS.

Figure 5.

Ranking list of 05 potential plastics raw materials supplier.

A sensitivity analysis is performed to examine the outcome of the proposed model. In this case, the sensitivity analysis procedure will follow a method proposed by Ali Nezhad and Amini [35]. Each criterion’s weight is removed, respectively, then the individual weight of each criteria as well as the final ranking of the alternative is re-calculated. Criteria weights in all cases is shown in Table 6.

Table 6.

Criteria weights in all cases.

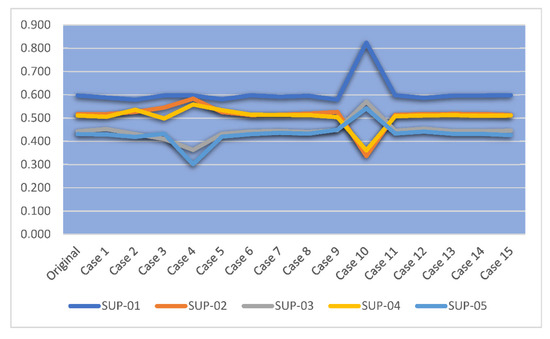

From Table 7 and Figure 6, the performance of Alternative 1 (SUP-01) is consistently the best. This suggests that, while there are some changes in the ranking of other alternatives, Alternative 1 performs well across all cases and the result of the proposed approach is robust.

Table 7.

Performance results in all cases.

Figure 6.

Ranking results in all cases.

5. Conclusions

Given that the global plastics sector has reached saturation, the growth rate of Vietnam’s plastics industry would likewise drop between 2019 and 2023. The Vietnamese plastics sector is significantly reliant on imported raw materials. However, the industry’s capacity for producing plastic materials will be significantly increased, and it is projected that by 2021, it will be able to supply 40% of local demand. The use of environmentally friendly plastic goods will be an unavoidable trend in the global plastics industry and the Vietnamese plastics industry in the future.

The authors of this paper developed an integrated MCDM strategy for sustainable supplier selection in the plastics sector. To rank multiple suppliers, the weights for each criterion were calculated using the fuzzy analytic hierarchy process (AHP) and then fed into the technique for order of preference by similarity to ideal solution (TOPSIS). The FAHP can be applied for ranking alternatives, but the number of suppliers selected is practically limited due to the number of pairwise comparisons that need to be made, and a disadvantage of the FAHP approach is that the input data, expressed in linguistic terms, depend on the experience of decision makers (and thus involves subjectivity). This is the reason why we proposed the TOPSIS model for ranking alternatives in the final stage. Also, TOPSIS is presented to reaffirm it as a systematic method and solve the disadvantages of the FAHP model as mentioned above. According to the results supplier 01 (SUP-01) is the best supplier. This study provides a significant contribution to the literature by proposing a fuzzy MCDM for plastics raw material suppliers. This study also gave a valuable guideline for selecting suppliers in other industries. The most significant contributions and successes in this study can be described as follows:

- ➢

- The proposed MCDM model is the first sustainable supplier evaluation and selection model in the plastics industry in Vietnam using expert interviews and literature reviews.

- ➢

- Second, this is the first study to provide a case study on evaluating sustainable suppliers for plastics industry in Vietnam under fuzzy environment conditions that utilizes a combination of fuzzy AHP and TOPSIS models.

- ➢

- The results of this study can be a valuable guide in assessing and selecting optimal suppliers, not only for the plastics industry but also for decision makers in other industries.

The methodology utilized in this study, while effective for prioritizing many alternatives and considerations, is not without significant drawbacks. The application of the AHP approach represents one such restriction. Even though a consistency check was carried out in the current study, the pairwise comparison matrix’s inconsistency should not be disregarded. This contradiction might actually show up in other issues. This disadvantage can be solved by the best-worst method (BWM), which eases the burden on decision-makers by necessitating fewer pairwise comparisons. To eliminate the interrelationships between components, the analytic network process (ANP) method may also be a preferable choice. Therefore, it is suggested that future investigations use these techniques.

Funding

The authors wish to express their gratitude to Van Lang University, Vietnam for supports for this research.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to express their gratitude to Van Lang University, Vietnam for financial support for this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hiệp Hội Nhựa Việt Nam. Tổng quan ngành nhựa Việt Nam. Available online: https://vpas.vn/gioi-thieu/tong-quan-nganh.html (accessed on 15 January 2022).

- Farahani, R.; Asgari, N. Combination Of MCDM and Covering Techniques in A Hierarchical Model for Facility Location: A Case Study. Eur. J. Oper. Res. 2007, 176, 1839–1858. [Google Scholar] [CrossRef]

- Ray, A.; De, A.; Dan, P. Facility Location Selection Using Complete and Partial Ranking MCDM Methods. Int. J. Ind. Syst. Eng. 2015, 19, 262. [Google Scholar] [CrossRef]

- Lee, H.; Chang, C. Comparative Analysis of MCDM Methods for Ranking Renewable Energy Sources in Taiwan. Renew. Sustain. Energy Rev. 2018, 92, 883–896. [Google Scholar] [CrossRef]

- Kumar, A.; Sah, B.; Singh, A.; Deng, Y.; He, X.; Kumar, P.; Bansal, R. A Review of Multi Criteria Decision Making (MCDM) Towards Sustainable Renewable Energy Development. Renew. Sustain. Energy Rev. 2017, 69, 596–609. [Google Scholar] [CrossRef]

- Eldrandaly, K.A.; Eldin, N.; Sui, D.Z.; Shouman, M.A.; Nawara, G. Integrating GIS and MCDM Using COM Technology. Int. Arab J. Inf. Technol. 2005, 2, 162–167. [Google Scholar]

- Peko, M.; Komatina, N.; Banduka, N.; Crnjac, M. The Assessment and Ranking of Failures in The Information Technology Industry Based on FMEA and MCDM. Ekon. Horiz. 2018, 20, 257–268. [Google Scholar] [CrossRef]

- Stević, Ž.; Pamučar, D.; Puška, A.; Chatterjee, P. Sustainable Supplier Selection in Healthcare Industries Using a New MCDM Method: Measurement of Alternatives and Ranking According to Compromise Solution (MARCOS). Comput. Ind. Eng. 2020, 140, 106231. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.; Hashemkhani Zolfani, S. Integrated QFD-MCDM Framework for Green Supplier Selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Petrović, G.; Mihajlović, J.; Ćojbašić, Ž.; Madić, M.; Marinković, D. Comparison of three fuzzy MCDM methods for solving the supplier selection problem. Facta Univ. Ser. Mech. Eng. 2019, 17, 455–469. [Google Scholar] [CrossRef]

- Deng, Y.; Chan, F.T. A new fuzzy dempster MCDM method and its application in supplier selection. Expert Syst. Appl. 2011, 38, 9854–9861. [Google Scholar] [CrossRef]

- Önüt, S.; Kara, S.; Işik, E. Long Term Supplier Selection Using a Combined Fuzzy MCDM Approach: A Case Study for a Telecommunication Company. Expert Syst. Appl. 2009, 36, 3887–3895. [Google Scholar] [CrossRef]

- Liu, H.; Quan, M.; Li, Z.; Wang, Z. A New Integrated MCDM Model for Sustainable Supplier Selection Under Interval-Valued Intuitionistic Uncertain Linguistic Environment. Inf. Sci. 2019, 486, 254–270. [Google Scholar] [CrossRef]

- Haldar, A.; Ray, A.; Banerjee, D.; Ghosh, S. A Hybrid MCDM Model For Resilient Supplier Selection. Int. J. Manag. Sci. Eng. Manag. 2012, 7, 284–292. [Google Scholar] [CrossRef]

- Ulutaş, A.; Stanujkic, D.; Karabasevic, D.; Popovic, G.; Zavadskas, E.; Smarandache, F.; Brauers, W. Developing of a Novel Integrated MCDM MULTIMOOSRAL Approach for Supplier Selection. Informatica 2021, 32, 145–161. [Google Scholar] [CrossRef]

- Wang Chen, H.; Chou, S.; Luu, Q.; Yu, T. A Fuzzy MCDM Approach for Green Supplier Selection from the Economic and Environmental Aspects. Math. Probl. Eng. 2016, 2016, 8097386. [Google Scholar] [CrossRef]

- Matić, B.; Jovanović, S.; Das, D.K.; Zavadskas, E.K.; Stević, Ž.; Sremac, S.; Marinković, M. A New Hybrid MCDM Model: Sustainable Supplier Selection in a Construction Company. Symmetry 2019, 11, 353. [Google Scholar] [CrossRef]

- Quan, M.; Wang, Z.; Liu, H.; Shi, H. A Hybrid MCDM Approach for Large Group Green Supplier Selection with Uncertain Linguistic Information. IEEE Access 2018, 6, 50372–50383. [Google Scholar] [CrossRef]

- Yazdani, M.; Hashemkhani Zolfani, S.; Zavadskas, E. New Integration of Mcdm Methods and Qfd in the Selection of Green Suppliers. J. Bus. Econ. Manag. 2016, 17, 1097–1113. [Google Scholar] [CrossRef]

- Ghorbani, M.; Mohammad Arabzad, S.; Shahin, A. A Novel Approach for Supplier Selection Based on the Kano Model and Fuzzy MCDM. Int. J. Prod. Res. 2013, 51, 5469–5484. [Google Scholar] [CrossRef]

- Cheraghalipour, A.; Farsad, S. A Bi-Objective Sustainable Supplier Selection and Order Allocation Considering Quantity Discounts Under Disruption Risks: A Case Study In Plastic Industry. Comput. Ind. Eng. 2018, 118, 237–250. [Google Scholar] [CrossRef]

- Yucesan, M.; Mete, S.; Serin, F.; Celik, E.; Gul, M. An Integrated Best-Worst and Interval Type-2 Fuzzy TOPSIS Methodology for Green Supplier Selection. Mathematics 2019, 7, 182. [Google Scholar] [CrossRef]

- Zadeh, L. Fuzzy sets. Inf. Control. 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Lee, A. A Fuzzy Supplier Selection Model with the Consideration of Benefits, Opportunities, Costs and Risks. Expert Syst. Appl. 2009, 36, 2879–2893. [Google Scholar] [CrossRef]

- Lee, A.; Kang, H.; Hsu, C.; Hung, H. A Green Supplier Selection Model for High-Tech Industry. Expert Syst. Appl. 2009, 36, 7917–7927. [Google Scholar] [CrossRef]

- Lee, A.; Kang, H.; Chang, C. Fuzzy Multiple Goal Programming Applied To TFT-LCD Supplier Selection by Downstream Manufacturers. Expert Syst. Appl. 2009, 36, 6318–6325. [Google Scholar] [CrossRef]

- Kang, H.; Lee, A. Priority Mix Planning for Semiconductor Fabrication by Fuzzy AHP Ranking. Expert Syst. Appl. 2007, 32, 560–570. [Google Scholar] [CrossRef]

- Cheng, C. Evaluating Weapon Systems Using Ranking Fuzzy Numbers. Fuzzy Sets Syst. 1999, 107, 25–35. [Google Scholar] [CrossRef]

- Dehghani, M.; Esmaeilian, M.; Tavakkoli-Moghaddam, R. Employing fuzzy ANP for green supplier selection and order allocations: A case Study, International Journal of Economy. Manag. Soc. Sci. 2013, 2, 565–575. [Google Scholar]

- Buckley, J. Fuzzy Hierarchical Analysis. Fuzzy Sets Syst. 1985, 17, 233–247. [Google Scholar] [CrossRef]

- Chou, S.; Chang, Y. The Implementation Factors That Influence the ERP (Enterprise Resource Planning) Benefits. Decis. Support Syst. 2008, 46, 149–157. [Google Scholar] [CrossRef]

- Hwang, C.; Yoon, K. Multiple Attribute Decision Making; Springer: New York, NY, USA, 1981. [Google Scholar]

- Yoon, K. A Reconciliation Among Discrete Compromise Solutions. J. Oper. Res. Soc. 1987, 38, 277. [Google Scholar] [CrossRef]

- Hwang, C.; Lai, Y.; Liu, T. A New Approach For Multiple Objective Decision Making. Comput. Oper. Res. 1993, 20, 889–899. [Google Scholar] [CrossRef]

- Abootalebi, S.; Hadi-Vencheh, A.; Jamshidi, A. Ranking The Alternatives With A Modified TOPSIS Method In Multiple Attribute Decision Making Problems. IEEE Trans. Eng. Manag. 2022, 69, 1800–1805. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).