Abstract

The high-ash tailings produced by flotation contains a large number of minerals that can be recycled. However, as the separation and purification technology for flotation tailings is not mature and separation efficiencies are low, it is generally treated as separation waste, resulting in the waste of mineral resources. In view of this phenomenon, the particle size composition and density composition of high-ash minerals in flotation tailings of coal slime as well as the type and content of mineral elements were measured. It was determined that the main mineral composition is quartz, and there is also a certain amount of chlorite (silicate mineral). A self-spinning hydrocyclone used for flotation tailings separation and purification was designed, and numerical simulation was carried out by fluent software. The internal flow field-, tangential velocity-, and axial velocity-distribution characteristics of the hydrocyclone at different rotational speeds were investigated. The physical model of the hydrocyclone was set up and the separation efficiency improvement test of fine particles was carried out. The results show that the overflow yield of −0.045 mm particles increased gradually with the increase in cylinder rotation speed. When the rotation speed increased to 900 r/min, the overflow yield of −0.045 mm particles can reach more than 90%, which can effectively realize the material classification according to 0.045 mm.

1. Introduction

The 2021 Annual report on the development of China’s coal industry shows that the coking coal output is about 500 million tons, of which about 30% of the output is recovered by the flotation method [1]. Flotation is the most widely used method in −0.5 mm (particle size less than 0.5 mm) coal slime separation, and the ash content of flotation tailings is usually above 65%. The main components of the tailings include kaolinite, montmorillonite, quartz, illite, etc., which are generally treated as separation waste at present. If flotation tailings are further separated and purified, it is expected that a large number of minerals would be recovered, saving mineral resources [2,3]. In recent years, a great deal of research has been carried out on mineral separation and purification from tailings.

Tan et al. [4] carried out an experimental study on scheelite recovery from copper, molybdenum, and bismuth flotation tailings of a tungsten polymetallic ore with high content of calcium carbonate. The process of scheelite recovery at room temperature used sodium hydroxide as a pH regulator, sodium silicate as an inhibitor, and 731 as a collector. Rough scheelite concentrate was heated, cleaned, and acid leached to improve the grade of scheelite concentrate, and a better recovery effect was achieved. Gao [5] conducted an experimental beneficiation study on the comprehensive recovery of rubidium and tin from fluorite flotation tailings. A large number of gangue minerals were removed in advance by a reverse flotation process to achieve the large enrichment of rubidium and tin in concentrate, and then, the rubidium and tin were recovered by iron removal. Finally, good experimental indexes were obtained. Deng et al. [6] proposed two separation techniques: carbon and iron mixed flotation with carbon particles as the carrier and iron suppression of floating kaolin. Combined with the washing process of a coal-preparation plant, kaolin was separated and recovered from flotation tailings, expanding the comprehensive use of flotation tailings and realizing the high value-added use of valuable minerals in flotation tailings. Yang et al. [7] reprocessed the fine waste coking coal (FWCC) generated in the separation process of raw coking coal, and recovered clean coal with an ash content of less than 12.5% using spiral separation, grinding, and flotation processes. A new process of regrinding, flotation, and separation has been developed, converting nearly 24% of FWCC into qualified clean coal and realizing the comprehensive utilization of this waste resource. Tang et al. [8] reported an efficient extraction method for recovering iron from flotation tailings via suspension, magnetization, roasting, and magnetic separation, which can reduce emissions. Zhang et al. [9] proposed a new combined extraction process for recovering rare earth, niobium and scandium from Bayan Obo tailings consisting of phase transformation of major minerals in a NaCl-Ca(OH)2-coal roasting and acid leaching process, which is conducive to comprehensive utilization of valuable elements in tailings. Mostajeran et al. [10] studied a series of ion exchange resins (chelating, solvent impregnated, and strongly acidic) in the recovery of Sc from synthetic and actual pregnant leach solutions obtained from acid-leaching of coal fly ash, and also attempted, for the first time, to selectively recover Sc in coal fly ash by ion exchange separation technique (from other rare earth elements as well as major Fe and Al contaminations), verifying a new method for recovering rare earth elements from secondary resources. Valeev et al. [11] developed a combined ash treatment process for recovering the useful value elements from the coal-fly ash waste from coal-fired power stations. A more comprehensive utilization of lignite fly ash was realized through the magnetic separation of an iron-containing fraction, carbon separation by flotation, and the extraction of aluminum by hydrochloric acid leaching in an autoclave.

As seen from the above literature review, most scholars have studied the purification and recovery of different tailings from a chemical and technological perspective, while the research on the separation and purification method of recovery of coal-slime tailings, especially research on improving the efficiency of such equipment, is still relatively lacking [12]. In this paper, the particle size composition and density composition of high-ash minerals in flotation tailings of coal slime were studied. The elemental types and contents of minerals were tested by XRF (X-ray Fluorescence) and XRD (X-ray Diffraction), and the mineral composition and particle size range were determined [13]. A self-spinning hydrocyclone was designed to improve the separation efficiency of high-ash minerals from flotation tailings and to provide technical ideas for enriching the separation of very fine materials.

2. Test Materials and Analysis

2.1. Source and Treatment of Coal Samples

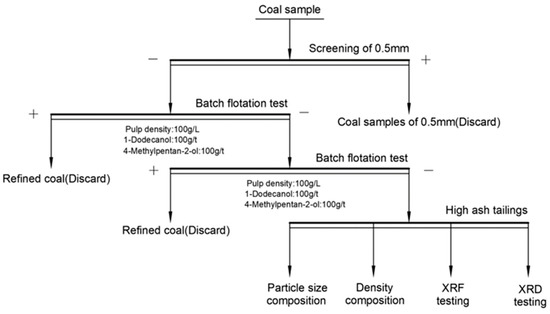

In this paper, the coal slime samples were collected from Liulin County, Shanxi Province, China. The total mass of the coal samples was 50 kg, and 3 kg of coal sample was taken according to the standard reduction. According to ISO 8858-1: Hard coal—Froth flotation testing—Part 1: Laboratory procedure [14], the low-ash cleaned coal was removed and the high-ash slime was obtained after two batch flotation tests. The coal sample treatment is shown in Figure 1.

Figure 1.

Coal sample processing treatment.

2.2. Material Analysis

The flotation high-ash tailings after treatment were analyzed and tested as follows:

- Particle size composition and density composition test.

The wet screening method and dry screening method were used to explore the main particle size range of high-ash minerals, using the sieve mesh sizes of 0.5 mm, 0.3 mm, 0.125 mm, 0.075 mm, and 0.045 mm. LXJ-11 high-speed centrifuge (Tai Da Electronic Equipment Factory, Dongguan, China) was used to carry out heavy-liquid analysis with different densities, and the density enrichment range of high-ash minerals was obtained.

- 2.

- Content and composition of mineral elements test.

An X-MET8000 X-ray fluorescence analyzer (Hitachi, Tokyo, Japan) was used to test the type and content of elements. The mineral composition was tested by a D/MAX-3B X-ray diffractometer (Shimadzu, Guangzhou, China). The diffraction conditions were as follows: Cu target, tube voltage of 36 kV, tube current of 40 mA, and diffraction angle of 5–65°.

3. Design of the Self-Spinning Hydrocyclone

3.1. Basic Structure

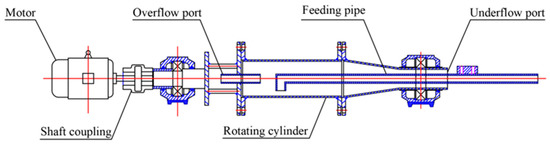

By conducting the above experimental study, the main particle size range of high-ash mineral enrichment in flotation tailings of coal slime can be obtained. If this part is separated effectively, the mineral separation and purification of flotation tailings are preliminarily realized. A centrifugal force field with high-speed rotation is an effective way to separate extremely fine materials [15]. Therefore, a self-spinning hydrocyclone with common characteristics of a static hydrocyclone and centrifuge is designed; its structural principle is shown in Figure 2. The working principle is as follows: under the motor-and-shaft coupling drive, the rotating cylinder rotates at a high speed, driving the suspension liquid inside the cylinder to enact high-speed centrifugal movement. Under the action of the centrifugal force field, the high-density particles move along the outer spiral near the hydrocyclone wall and are discharged from the underflow port; the low-density particles move along the inner spiral near the hydrocyclone center and are discharged from the overflow port.

Figure 2.

Schematic diagram of the self-spinning hydrocyclone.

3.2. Numerical Simulation

The rotational speed of the rotating cylinder is the core functional parameter of the self-spinning hydrocyclone. Different rotational speeds will form different velocity-field distributions in the hydrocyclone, thus producing different grading effects [16]. The Ansys Fluent 17.0 software (China Agent: Pera Corporation Ltd, Beijing, China) [17,18] was used to explore the internal-flow field distribution of the hydrocyclone at different rotational speeds, providing a theoretical basis for the selection of a self-rotational speed.

3.2.1. Selection of the Calculation Model

After consulting the applicable scope of each equation in ANSYS Help 17.0, the realizable K-ε model was selected for a turbulence model, and standard wall functions were selected for the near-wall treatment option; for the multiphase model, the volume of the fluid model was selected; the number of Eulerian Phases was set to 2; a high-precision second-order upwind format was adopted for the discretization of parameters such as the convection term; a ‘’SIMPLEC’’ mode was adopted for the coupling of velocity and pressure, and the convergence accuracy was set to 10−6.

A movable-region model selection followed: The hydrocyclone relies on the rotating cylinder to drive the internal liquid to rotate; thus, the entire calculation area should be divided into a movable region and a stationary region; the moving reference frame (MRF) model was selected for the simulation of the rotating cylinder.

3.2.2. Model Building and Mesh Division

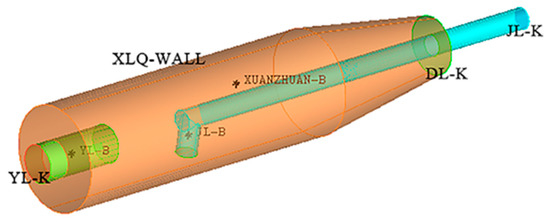

Solidworks software (Solidworks 2018, Waltham, MA, USA) was used to build a three-dimensional model of the self-spinning hydrocyclone, as shown in Figure 3. The entire flow-field calculation domain was divided into dynamic and static domains. The dynamic domain is XUANZHUAN-B, and the static domains are JL-B and YL-B. Ansys Gambit2.4.6 was used for the grid division of the model.

Figure 3.

Three-dimensional model of the self-spinning hydrocyclone.

3.2.3. Boundary Condition Setting

The velocity boundary condition was adopted for the feeding pipe, and the pressure boundary condition was adopted for the overflow port and underflow port. The relative pressure was set to 0 MPa. The wall surface was set at the rotational boundary condition, and the standard wall functions was selected for the near-wall area. The turbulence intensity and hydraulic diameter of the item in the Turbulence Specification Method were selected, and the turbulence intensity (%) was set to 1 and the hydraulic diameter was set according to model size.

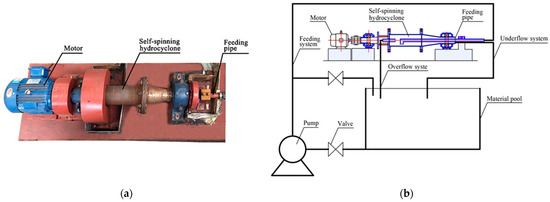

4. Mineral-Separation Test

A self-spinning hydrocyclone system was set up in the laboratory to carry out the mineral-separation test of flotation tailings from coal slime. The physical model and test system are shown in Figure 4. The rated frequency of the motor was 50 Hz and the rated speed was 2880 r/min. By using the frequency converter to change the frequency, the motor speed was adjusted to 300 r/min, 500 r/min, 700 r/min, and 900 r/min, and the pump flow was kept constant at 50 L/min. This test was used to verify the performance of the hydrocyclone, optimize the structure and working parameters of the device, and provide a new technical idea for improving the recovery efficiency of useful minerals in tailings.

Figure 4.

(a) Physical model of the self-spinning hydrocyclone; (b) the self-spinning hydrocyclone test system.

5. Results and Discussion

5.1. Material Analysis Results

5.1.1. Particle Size and Density Composition

The particle-size composition of flotation high-ash tailings is shown in Table 1. It shows that after batch flotation separation, the average ash content of high-ash tailings is 71.62%, among which the coal with −0.125 mm-sized particles accounts for 88.95% and the average ash content is 78.81%; the coal with −0.045 mm-sized particles accounts for 72.54% of the entire sample and the average ash content is 79.85%, comprising the main particle size range of minerals in tailings.

Table 1.

Particle size composition of flotation high-ash tailings.

The density composition of the mineral-enrichment area in −0.045 mm tailings is shown in Table 2. It can be calculated from the data in Table 2 that the average ash content of minerals at the density level of −1.80 g/cm3 is 25.49%, indicating that these minerals are mainly organic matter (coal). The yield of minerals with +1.80 g/cm3 density grade is 96.98% and the ash content is 81.42%. This density level indicates a high-ash mineral-enrichment area, from which a large number of useful minerals can be recovered. The above data indicates that as long as flotation tailings can be effectively separated into +0.045 mm and −0.045 mm according to the particle size of 0.045 mm, successful mineral separation and purification can be expected.

Table 2.

Density composition of mineral-enrichment area in −0.045 mm tailings.

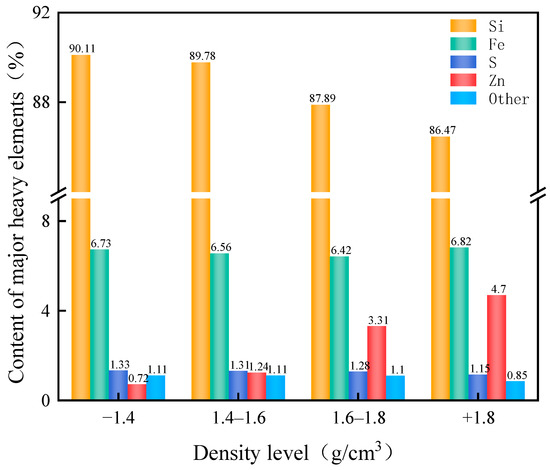

5.1.2. Results of the XRF and XRD Test

An XRF test was carried out in the mineral-rich area (−0.045 mm particle size) to determine the elemental types and content of minerals; then, an XRD test was used to determine the mineral composition. XRF can measure the types and contents of elements from element 11 (sodium) to element 92 (uranium) in the periodic table; the test results are shown in Table 3. According to Table 3, the content chart of main elements was made, as shown in Figure 5. It can be seen from Table 3 and Figure 5 that the main elements in the −0.045 mm mineral-enrichment area are Si and Fe. The preliminary speculation is that the mineral composition is mainly SiO2, but this requires confirmation by XRD.

Table 3.

Main element content of mineral-enrichment area in −0.045 mm tailings.

Figure 5.

Main elements content of mineral-enrichment area.

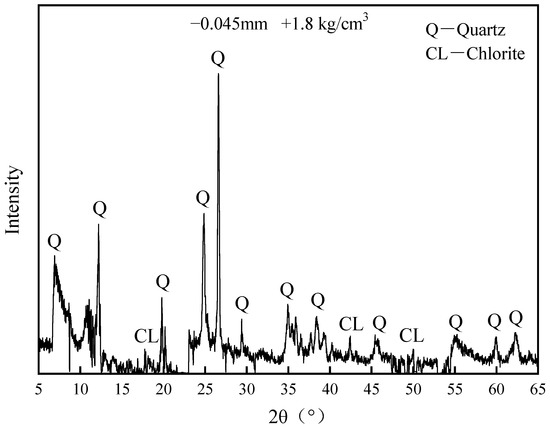

XRD test results are shown in Figure 6. It can be seen from the Figure that the mineral composition of −0.045 mm particle-size mineral-enrichment area is mainly quartz and also a certain amount of chlorite (silicate mineral). The determination of mineral-enrichment area and mineral species lays a foundation for the large-scale separation of useful minerals from flotation tailings.

Figure 6.

Major mineral composition of mineral-enrichment area.

5.2. Numerical Simulation Results

The feeding speed of the feeding pipe was set at 8 m/s. The model was numerically simulated when the rotational speed of the cylinder was set at 300 r/min, 500 r/min, 700 r/min, and 900 r/min, respectively, to analyze the pressure-, turbulence intensity-, and velocity-distribution characteristics in the device, and to explore the movement characteristics and laws of materials.

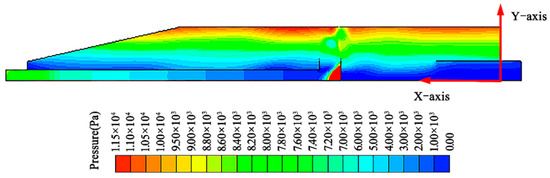

5.2.1. Distribution Characteristics of Pressure

The pressure distribution of the central section of the model is shown in Figure 7. It can be seen from Figure 7 that in the radial Y-axis direction, the pressure increases gradually with the increase in radius and the pressure is at its highest at the wall’s surface. When the material enters the hydrocyclone through the feeding pipe, the particles with coarse granularity or high density will move rapidly from the center to the wall surface. In the X-axis direction and on the same horizontal plane, the pressure values at each point are similar, which is conducive to the separation function of the cylinder and to increasing the processing capacity of the equipment. However, the pressure at the bottom of the cone section is small, which is not conducive to the discharge of high-concentration materials. At the axis (Y = 0), the pressure is small and air enters, forming an air column, and fine suspended materials are discharged from the overflow port.

Figure 7.

Pressure distribution of the central section (rotational speed is 900 r/min).

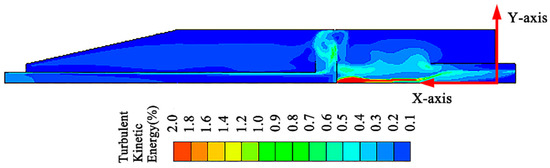

5.2.2. Distribution Characteristics of Turbulence Intensity

The turbulent intensity distribution of the central section is shown in Figure 8. It can be seen from the figure that the turbulence intensity of the flow field around the feed pipe is large, but the turbulence intensity of the other positions of the section is small. The low turbulence intensity is favorable to the separation process. The particles are evenly distributed and graded strictly according to the characteristics of the flow field so as to improve the separation accuracy.

Figure 8.

Turbulent intensity distribution of the central section (rotational speed is 900 r/min).

5.2.3. Distribution Characteristics of Velocity

The fluid velocity field in the self-spinning hydrocyclone can be divided into tangential velocity, axial velocity, and radial velocity. The flow characteristics and laws of each velocity field were explored using computational simulation conducive to the in-depth understanding of the movement trajectory of materials. Since the solid phase is not considered in this two-phase simulation, radial-velocity flow characteristics were not examined.

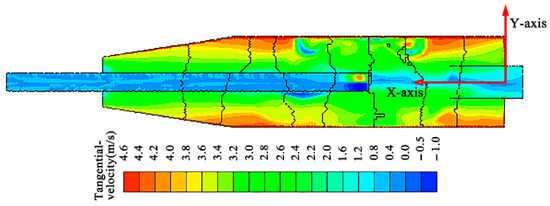

- Tangential velocity distribution characteristics

The tangential velocity was determined according to the centrifugal strength of the centrifugal force field in the hydrocyclone. The tangential velocity distribution is shown in Figure 9. Along the X-axis, tangential velocities at relative positions are basically the same. The tangential velocity changes as follows: starting from the wall surface, the tangential velocity points to the center line along the wall and the velocity value decreases gradually; the velocity drops to zero as it approaches the overflow pipe and the air column. The internal flow field of the hydrocyclone is similar to that of the centrifugal equipment. The tangential speed is determined by the cylinder speed and the grading granularity can be effectively changed by varying the cylinder’s rotation speed.

Figure 9.

Tangential velocity distribution at central section (rotational speed is 900 r/min).

- 2.

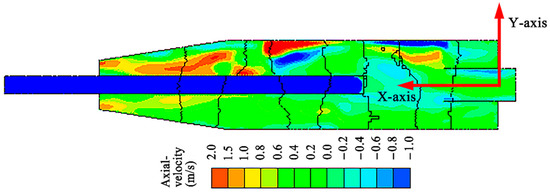

- Axial velocity distribution characteristics

The axial velocity distribution is shown in Figure 10. The size and direction of axial velocities determine the discharge velocity and quantity of the underflow port and overflow port. It can be seen from Figure 10 that in the X-axis direction, the distribution of axial velocity in relative positions is uneven and asymmetric. The axial velocity of the underflow port is larger than that of the overflow port, indicating that most of the material flows out of the underflow port. The axial velocity of the wall surface is zero, which further proves that the hydrocyclone operates similarly to centrifugal equipment. Under the action of a strong centrifugal force, coarse particles will be deposited on the inner wall of the cylinder. Discharing materials quickly is a problem that needs further study in the self-spinning hydrocyclone.

Figure 10.

Axial velocity distribution at central section (rotational speed is 900 r/min).

5.3. Mineral-Separation Test Results

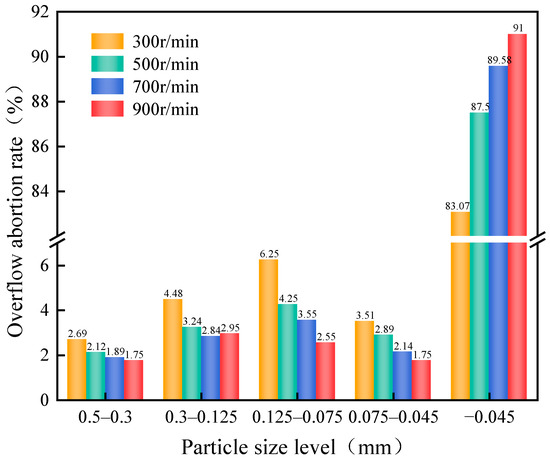

The separation results of materials at different cylinder rotation speeds are shown in Table 4. Figure 11 depicts the trend chart of material-overflow yield rate according to Table 4. It can be seen from the results that, with the increase in cylinder rotation speed, the proportion of +0.045 mm particles in overflow products gradually decreases, while −0.045 mm particles gradually increase, indicating that, with the increase in rotational speed, the centrifugal force on solid particles increases, +0.045 mm products become concentrated along the wall area, and −0.045 mm products become concentrated in the center area. When the rotational speed increased to 900 r/min, −0.045 mm particles account for more than 90% of the overflow yield. Hence, the material can be classified according to 0.045 mm particle size with high separation efficiency by using this self-spinning hydrocyclone.

Table 4.

Separation results of materials at different rotational speeds.

Figure 11.

Variation trend of material-overflow yield rate.

6. Conclusions

- The high-ash minerals in flotation tailings mainly concentrate in the range of −0.045 mm particle size and +1.80 g /cm3 density. Further, the main elements of the mineral-rich area are Si and Fe. An XRD test showed that the main component of the useful minerals was quartz, which has value in further separation and recovery. The determination of mineral-enrichment areas and mineral types lays a foundation for the large-scale separation and purification of useful minerals from flotation tailings.

- Using numerical simulation, the internal-flow field distribution of hydrocyclone at different rotational speeds was investigated. The pressure distribution characteristics show that the pressure increases gradually with an increase in radius and the highest pressure is at the wall surface. After the material enters the hydrocyclone, the solid particles will move rapidly from the center to the wall surface. In the same horizontal plane, the pressure value of each point is similar, which is beneficial for studying the separation function of the hydrocyclone cylinder and increasing the processing capacity of the equipment. The distribution characteristics of turbulence intensity show that the turbulence intensity at each position of the hydrocyclone is small, which is conducive to the separation process. The particles are evenly distributed according to the characteristics of the flow field, which can be adjusted with high precision.

- The distribution characteristics of tangential velocity and axial velocity were investigated by numerical simulation. First, the distribution characteristics of tangential velocity show that the tangential velocity at the relative position is basically the same along the X-axis direction. The tangential velocity points to the center line along the wall surface and gradually decreases. The maximum speed is near the wall surface. The tangential velocity is determined by the cylinder speed. Second, the axial velocity distribution characteristics show that, along the X axis, the axial velocity distribution is uneven and asymmetric and the particles are deposited on the inner wall of the cylinder, which is not conducive to the discharge of materials.

- The mineral-separation test showed that with an increase in cylinder rotation speed, the overflow yield of −0.045 mm particles increased gradually. When the rotation speed increased to 900 r/min, the overflow yield of −0.045 mm particles can reach more than 90%, which can effectively realize the material classification according to the 0.045 mm size. This provides a certain basis for the efficient separation and recovery of minerals from flotation tailings.

Author Contributions

Conceptualization, W.Z. and J.Z.; data curation, W.Z.; investigation, W.Z., S.W., C.C. and L.L.; methodology, W.Z.; project administration, J.Z.; resources, W.Z.; software, W.Z. and L.L.; writing—original draft, W.Z. and S.W.; writing—review and editing, S.W. and C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the University Scientific Research Project of The Education Department of Anhui Province (KJ2021A0429), the University Excellent Talents Training Funding Project of the Education Department of Anhui Province (gxyqZD2021109), the Natural Sciences Foundation of Anhui Province (2108085ME160), and the Open Foundation of State Key Laboratory of Mining Response and Disaster Prevention and Control in Deep Coal Mines (SKLMRDPC19KF11).

Institutional Review Board Statement

No applicable.

Informed Consent Statement

No applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

Special thanks to Zhu Jinbo of Anhui University of Science and Technology for his guidance of this study, and also to all those who participated in this study.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Gao, H. Coal industry development status and supply and demand situation analysis. China Coal Ind. 2022, 3, 75–77. [Google Scholar]

- Gui, X.; Xing, Y.; Cao, Y.; Liu, J. Recent advances and thinking in process intensification of low quality coal slime flotation. J. China Coal Soc. 2021, 46, 2715–2732. [Google Scholar]

- Yan, B. Analysis on consumption and saving situation of energy in coal. Coal Process. Compr. Util. 2022, 01, 43–46. [Google Scholar]

- Tan, X.; Wang, Z.; Xiao, Q.; Ling, S.; Liu, F. Study on recovery of scheelite from the flotation tailings of a high calcium carbonate-bearing tungsten polymetallic ore. Nonferrous Met. (Miner. Process. Sect.) 2021, 6, 161–167, 188. [Google Scholar]

- Gao, X. Beneficiation technique for comprehensive recovery of rubidium and tin from fluorite flotation tailings. Min. Metall. Eng. 2021, 41, 71–75. [Google Scholar]

- Deng, M.; Liu, H. Experimental study on recovery of kaolinite from flotation tailings through removal of iron using flotation process. Coal Prep. Technol. 2021, 4, 13–18. [Google Scholar]

- Yang, Z.; Xia, Y.; Wei, C.; Cao, Y.; Sun, W.; Liu, P.; Cheng, H.; Xing, Y.; Gui, X. New flotation flowsheet for recovering combustible matter from fine waste coking coal. J. Clean. Prod. 2019, 225, 209–219. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, Q.; Sun, Y.; Gao, P.; Han, Y. Pilot-scale extraction of iron from flotation tailings via suspension magnetization roasting in a mixture of CO and H2 followed by magnetic separation. Resour. Conserv. Recycl. 2021, 172, 105680. [Google Scholar] [CrossRef]

- Zhang, B.; Xue, X.; Yang, H. A novel process for recovery of scandium, rare earth and niobium from Bayan Obo tailings: NaCl-Ca(OH)2-coal roasting and acid leaching. Miner. Eng. 2022, 178, 107401. [Google Scholar]

- Mostajeran, M.; Bondy, J.-M.; Reynier, N.; Cameron, R. Mining value from waste: Scandium and rare earth elements selective recovery from coal fly ash leach solutions. Miner. Eng. 2021, 173, 107091. [Google Scholar] [CrossRef]

- Valeev, D.; Kunilova, I.; Alpatov, A.; Mikhailova, A.; Goldberg, M.; Kondratiev, A. Complex utilisation of ekibastuz brown coal fly ash: Iron & carbon separation and aluminum extraction. J. Clean. Prod. 2019, 218, 192–201. [Google Scholar]

- Li, W.; Zhang, G.; Wang, D. Technical research status and analysis of flotation tailings reselection. Clean Coal Technol. 2021, 27, 53–58. [Google Scholar]

- Fu, Y.; Zhang, X.; Dong, X.; Yao, S. Analysis of kaolinite distribution in flotation tailings based on XRD. Multipurp. Util. Miner. Resour. 2017, 2, 79–84. [Google Scholar]

- ISO 8858-1; Hard Coal—Froth Flotation Testing—Part 1: Laboratory Procedure. Technical Committee ISO/TC 27, Solid Mineral Fuels, Subcommittee SC 1, Coal Preparation: Terminology and Performance. ISO: Geneva, Switzerland, 2019.

- Song, M.; Zhao, L.; Xu, B.; Liu, L.; Zhang, S. Discussion on technology of improving separation efficiency of liquid-liquid hydrocyclone. Chem. Ind. Eng. Prog. 2021, 40, 6590–6603. [Google Scholar]

- Liu, Y.; Zhao, L.; Zhang, S.; Liu, L.; Xu, B. Research and application of filtering-swirl coupling technology in heterogeneous separation. J. Mech. Eng. 2022, 58, 120–154. [Google Scholar]

- Ao, X.; Liu, X.; Kang, D.; Luo, R.; Liu, Z.; Yao, X. Research on parallel common liquid bucket structure of hydrocyclone based on CFD. J. Qiqihar Univ. (Nat. Sci. Ed.) 2022, 38, 11–14. [Google Scholar]

- Li, H. Design of cyclone classification control system based on Fluent. Comput. Meas. Control. 2022, 30, 128–133, 154. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).