Abstract

Countries all over the world are making their contribution to the common goal of energy saving and emission reduction. Solar energy is gaining more attention as a renewable energy source. Polysilicon is an important raw material for solar panels and the production of polysilicon is a vital part of the photovoltaic industry. Polysilicon production is a typical process industry enterprise, and its production process is continuous and highly energy intensive. Therefore, it is necessary to forecast and analyze the consumption of polysilicon production plants. To address the problem that it is difficult to predict future consumption based on historical data alone due to the time-series, massive, nonlinear, and complex nature of data in polysilicon workshops. This study proposes a combined workshop energy consumption prediction model based on Bayesian estimation of time-series decomposition and convolutional neural network (TSD-CNN). The method uses a time-series decomposition method to model the periodic and long-term trend components of the raw consumption data and uses a Bayesian estimation algorithm to optimally estimate the model parameters for each component. With the real-time collection of energy consumption data for equipment, the application of that method described above has successfully improved the accuracy of prediction, production management efficiency and safety warning capabilities in enterprises. Furthermore, it helps to provide decision support for energy conservation and consumption reduction studies. To verify the practicality and reliability of the algorithm in practical applications, experiments were conducted with the energy consumption data of the reduction furnace in the polysilicon production plant, and by comparing it with the commonly used regression methods SVM, LSTM and TSD, the results show that the combined prediction method has a greater improvement in the accuracy of energy consumption prediction.

1. Introduction

At present, population, energy, and environmental issues are major problems facing all of humanity. Among them, energy is an important material basis for the world’s economic development and a central driving force for improving people’s living standards [1]. The BP World Energy Statistics Yearbook 2021 stated that carbon emissions from world energy used remain high in 2020 during the impact of the epidemic on the world, with the largest increase in energy consumption demand in China, up 2.1% from 2019 [2]. The 2020 IEA World Energy Outlook 2021 report showed that global carbon emissions from the electricity sectors were 12.3 billion tons in 2020 (36% of total energy-related emissions), higher than any other sectors [3]. Coal is the world’s largest single source of electricity, providing more than one third of the world’s electricity supply. [4].

Despite the negative impact of the epidemic on the world’s energy sector, the share of renewable energy types as solar and wind, continues to grow [5]. As one of the key strategic emerging industries in the energy revolution, the photovoltaic industry has seen the overall cost of power generation fall by 82% to 88% over the past decade through process and technological improvements [6]. Today, 90% of polysilicon producers use the modified Siemens method of silicon production, and the process of making polysilicon alone accounts for about 35% of the total energy consumption of the enterprise [7]. The reduction furnace equipment accounts for about 60% of the total energy expenditure for polysilicon production, so there is a great potential for energy savings. This means that polysilicon producers need to further “strengthen technological innovation, control production cycles and reduce production costs”, and that only with more real-time energy monitoring and more accurate energy forecasts for the entire process industry will they achieve greater profitability.

The preparation of polysilicon in the process industry is characterized by high risk, complex processes and high energy consumption, and the monitoring of the main operating parameters of the workshop equipment alone is no longer sufficient to meet the requirements of current polysilicon production enterprises [8,9]. Many studies have been carried out by national and international scholars on the production processes of process industry companies. Nastasi et al. [10] used a Genetic Algorithm (GA) to optimize the parameters of a neural network model for a steelmaking plant to improve the prediction model for the shop floor energy consumption of the plant and compared the prediction results with the traditional Autoregressive Integrated Moving Average (ARIMA) algorithm to analyze the results, showing that the optimized neural network model had better predictive power and less data redundancy. Shang Z et al. [11] proposed a whale optimization algorithm-based power forecasting model with high prediction accuracy for complex and non-linear power load forecasting. Jin N Y et al. [12] predicted the future short-term energy consumption of building air conditioning based on a Long Short-Term Memory Neural Network (LSTM), and the experiments showed that the former predicted the future short-term energy consumption more accurately compared with the prediction of the Multilayer Perceptron Prediction (MLP) algorithm. Lin et al. [13] proposed a method for improving the accuracy and sensitivity of HVAC power consumption forecasting that involved the use of clustering techniques to locate clusters with similar information in hourly data. Their method had many similarities to the time-series decomposition in this study. Scarabaggio et al. [14] proposed a distributed demand-side management (DSM) approach which considered objective factors such as weather conditions and user demand when modelling; we drew on this operation in this study. Lu Y et al. [15] had explored the use of Time Series Decomposition (TSD) and Convolutional Neural Network (CNN) forecasting methods for predicting energy consumption in automotive paint shops. Furthermore, we will continue to build on her research and eventually arrive at an optimized model with a much smaller historical data requirement. The results indicated that all the above models have relatively strong predictive capability in energy consumption prediction, but some are very data dependent and require a large amount of data for model training. To solve the problem of high stand-alone energy consumption prediction in the polysilicon reduction furnace plant, with continuous real-time data, but a small number of devices and data. Those research results inspired us to continue our exploration in combined prediction model. In summary, in view of the strong data dependence of the neural network model and the characteristics of continuity, dynamism, nonlinear and small amount of data for energy consumption data of reduction furnace equipment [16], this study proposes a prediction model and prediction method based on temporal decomposition and convolutional neural network (TSD-CNN), aiming to solve the following problems: 1. using that model to improve the accuracy of energy consumption prediction in the production process of an enterprise 2. using that method which uses less data and less computation to obtain more accurate prediction results 3. improve the enterprise production management efficiency and safety warning capability. Finally, conducted crucial experiment in the polysilicon production plant to verify the validity of the model.

The sections of this study are as follows: with Section 2 describes the architecture of the polysilicon reduction plant energy capture and designs the overall structure of the reduction furnace energy model prediction. Section 3 analyses the historical energy consumption data of the reduction furnace and presents the basis for the construction of the cyclic component model, the trend component model, the time-series decomposition model, and the Convolutional Neural Network model for the consumption of the reduction furnace. Section 4 demonstrates the processing of the reduction furnace energy consumption dataset. Section 5 evaluates the performance of the model through experimental analysis and compares and analyses the prediction effectiveness of several energy consumption prediction methods. Section 6 draws conclusions.

2. Energy Consumption Data Collection Architecture and Energy Consumption Prediction Model

2.1. General Structure of the Energy Consumption Collection and Analysis System

At present, polysilicon is mainly produced using the modified Siemens method [17], and the core production equipment is the polysilicon reduction furnace. In the reduction furnace chassis arranged with a heat carrier silicon core, 50 Hz alternating current heat the core at the core temperature of 1200–1400 K. TCS and H2 in the silicon rod surface reaction [18], polysilicon is “born and raised”.

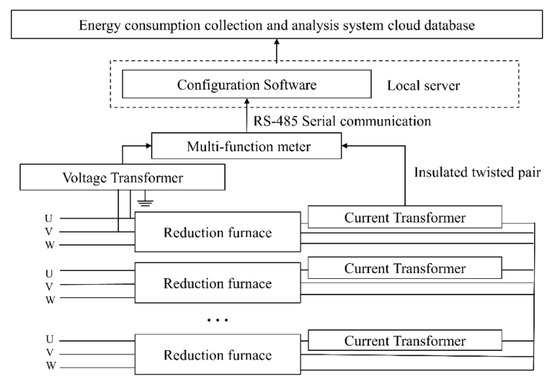

Taking the energy consumption data of the polysilicon reduction furnace as the collection object. The energy consumption collection and analysis system collect and monitors in real-time a total of four types of energy consumption data, namely current, voltage, power, and collection frequency of the equipment. The overall scheme of energy consumption data collection is shown in Figure 1.

Figure 1.

Overall scheme of data collection.

- (1)

- Current (voltage) transformers. According to the rated power of the polysilicon plant equipment and the input current and voltage values, a transformer with the appropriate CT ratio to connect to the circuit is selected. The current transformer in series with the reduction furnace and the voltage transformer is in parallel with the reduction furnace.

- (2)

- Multifunctional meters: The DTS-606 multifunctional meter is used for monitoring and management of high energy consumption equipment to measure current, voltage, power, sampling frequency, collection time and other electricity consumption parameters of the secondary circuit. The RS-485 communication interface and standard Modbus protocol is configured to transfer power consumption parameters to the data monitoring centre.

- (3)

- Servers: The local server is a DELL R740 server with Windows Server 2019 operating system installed as the enterprise local server. Enterprise drives use disk array technology to support uninterrupted data writes and real-time backups with robust performance and high security.

- (4)

- Serial communication: The serial server model USR-TCP232-304, with RS-485 terminals and TCP-Server mode of operation, is suitable for real-time data transmission and communication in the reduction furnace workshop.

- (5)

- Based on the Modbus protocol data link, the serial server establishes network communication with the server via Ethernet and sends a signal query request to check the IP address and checksum of the returned data. Identifying the identifier in the packet, reading the corresponding data, and storing the data for identification. The multifunction converts the serial server data which is collected by meter into network data. Completing the signal conversion between the Device Layer and the Data Link Layer.

- (6)

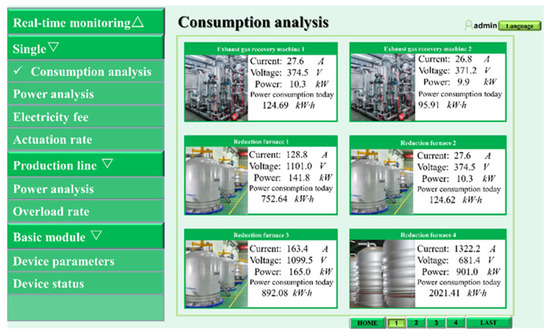

- Energy consumption collection system integration. The energy collection and analysis system is a software platform based on a B/S architecture, i.e., the back-end is connected to a database to store and process the data, and the front-end uses a web-enabled interface to display the operation of the equipment and energy consumption data in the polysilicon production plant. It has four main functional modules: real-time monitoring of individual machines, real-time monitoring of the whole line, analysis of individual machines and setting of basic modules. The functional web interface of the energy consumption collection system is shown in Figure 2.

Figure 2. Web function interface of energy consumption acquisition system.

Figure 2. Web function interface of energy consumption acquisition system.

Data acquisition solution: The current (voltage) transformer in series is connected in the three-phase circuit of the reduction furnace. Insulated twisted-pair cable connects three-phase meters for secondary value conversion of electrical signals. The communication interface of the meter communicates with the industrial Ethernet switch through the RS-485 to Ethernet serial port, converts the serial data into network data, and transmits the data to local and cloud database through the source interface.

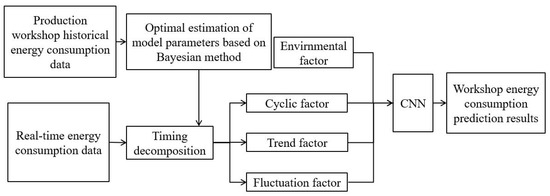

2.2. Reduction Furnace Energy Model Prediction Structure

The predictive structure of the reduction furnace energy model is shown in Figure 3. Firstly, the Fourier transform basis function and segmentation function are used with periodic characteristics to fit the periodic and trend components of the real-time energy consumption data to build a time-series decomposition model. Then based on Bayesian theory [19], historical data on energy consumption is used as a priori information [20] and Markov chain Monte Carlo (MCMC) simulation methods to estimate the parameters of the cyclic factor model, trend factor model, fluctuation factor model [21]. Finally, the resulting period and trend feature data and stochastic factors such as environmental variables are provided to the Convolutional Neural Network as input, performing a convolution operation to obtain the predicted energy consumption of the reduction furnace.

Figure 3.

Structure of workshop energy consumption prediction model.

3. Reduction Furnace Energy Prediction Model

3.1. Periodic Component Model

Owing to the cyclical nature of the reduction furnace energy consumption data, this is mainly due to factors such as low and high season variations in order demand and holidays. In this study, we considered the problem of periodicity of energy consumption data due to the difference between weekdays and weekends, and choose the most widely used Fourier transform analysis method to fit the periodicities of data [22]. Using the Fourier Transform in signal processing to filter the frequency is the greatest method to fit the data according to the spectrum of the data with different periods. If the historical energy consumption data are also considered as a signal, the spectrum of the energy consumption data can be obtained by Fourier Transform. The Fourier Formula can be expressed [23] as:

In this study, when processing energy consumption data from reduction furnaces, we added the period parameter T to the Fourier Transform function. By adjusting the value of T to fit the energy consumption data to reduce the variance of the data, the final periodic component of the energy consumption data are obtained.

Its expression is as follows:

where is the Fourier coefficient and the periodic component of the shop floor energy consumption data can be expressed as:

where

3.2. Trend Component Model

Consider that reduction furnace energy consumption data are affected by orders, production tasks and other factors, showing different trend changes. If one uses a single trend fit, it will swamp these features. This study adopted a segmentation function to fit the trend components of the workshop energy consumption data, to reveal the characteristic information of energy consumption at different times and improve the accuracy of the trend fitting. A linear model representation of the energy consumption data divided into N segments:

where, (X iL, XiR) is the linear model for segment i. X iL, XiR are the start and end values of segment i. N means the number of segments of the overall energy consumption data.

We set N-1 trend turning points SN, and when t is greater than the trend segmentation points SK, the trend function is modified, and its expression is:

where, k is the slope; a(t) is the indicator function set in this study, a(t) takes 1 when ti is greater than the trend segment point Si, otherwise it takes 0; indicates the rate of change coefficient of the slope of the ith segment; is the offset coefficient; b is the offset parameter.

3.3. Bayesian Inference-Based Solution of the Time-Series Decomposition Model

Reading the historical data shows that the energy consumption data are non-linear, time-series and dynamic [24]. Bayesian state estimation methods can measure the uncertainty of a time-series and to update the parameters based on updated data. With the help of Bayesian methods, the time-series model is solved based on a priori information to estimate the model parameters and improve the accuracy of the fit.

Parameter estimates for the period and trend functions. If the unknown parameters of the periodic function are regarded as random variables. According to the prior information on energy consumption, we can determine the prior distribution of the unknown parameters as . We also consider the probability density function as a sequence of random samples, then the joint distribution of the energy consumption data set sequence D and parameter ω is:

Our task is to obtain the parameters of the periodic model and to determine the exact model. That is, to determine the distribution of the parameter ω conditional on the energy consumption data set:

where, m (x) is the edge density of the energy consumption data and is generally a constant c. The posterior distribution of the unknown parameter ω in Equation (7), which includes the energy consumption data and a priori information about the parameter ω. In this study, we provide the parameter ω by taking the estimate of the posterior mean:

In practice, the posterior distribution of Equation (8) is difficult to obtain by solving for it, and we commonly use sampling methods to estimate the parameter values. The Markov Chain Monte Carlo (MCMC) [24] method is an effective way to calculate the Bayesian posterior distribution. Using the MCMC algorithm, we simulate the model parameters a posteriori and take the posterior mean as an estimate of the model parameters. Gibbs sampling [25] is an important MCMC sampling algorithm and the calculation can be expressed as follows:

- (1)

- Randomly generated initial samples of the period function parameter ω:

- (2)

- Gibbs sampling for i iterations:where, “~” denotes one Gibbs iteration process of completing the to transfer by drawing from the parameter probability density function on the right. Then we obtain the sample value of the parameter by noting the s iterations of the parameter , j = 1, 2, …, n.

- (3)

- When the Markov chain converges in i (i < s) iterations of the loop. We obtain the a posteriori mean value of each parameter from the Monte Carlo integration formula. The unknown parameter estimate of the periodic function , where denotes any of the unknown parameters in {α ,T}.

3.4. Convolutional Neural Networks

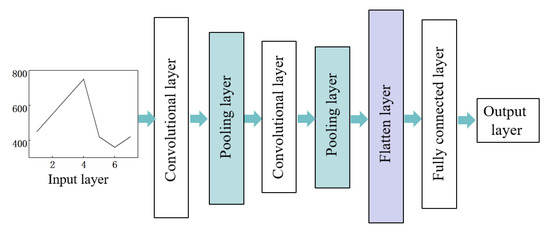

Convolutional Neural Networks (CNNs) [26,27] are deep neural network for processing visual images, which consist of an input layer, an output layer, and multiple hidden layers. The hidden layer consists of several convolutional layers, pooling layers, and fully connected layers. In this study, we used CNN for energy consumption prediction, because CNN has a strong local feature capturing ability and can handle the coupling relationship of energy consumption data in multiple dimensions. Sharing weights between neurons in the same layer not only reduces the complexity of the network and improves prediction efficiency, but also provides a better fit [28]. Therefore, by decomposing the time series of energy consumption data to obtain multidimensional factors [29].

The convolutional neural network model used in this study refers to the Alex Net model, which consists of two convolutional layers and two pooling layers. To prevent gradient disappearance or gradient explosion [30], we added a ReLU activation function [31] to each convolutional layer. Providing a Flatten function [32] to turn two-dimensional arrays into one-dimensional data. And we introduce a Dropout layer to attenuate overfitting. The structure of the Convolutional Neural Network is shown in Figure 4.

Figure 4.

Convolutional Neural Network Model.

In the convolutional layer, extract the local node combination information from the energy consumption data sequence. Repeating slide over all data by each convolution kernel yields multiple sets of output data, and when the input signal is , the convolution layer is calculated as:

where, is the m times convolutional mapping of the kth layer, the output of the convolution layer; n is the number of convolutions; is the weight of the kth convolution kernel of layer m doing the ith operation; is the offset of the kth level relative to the mth level; * represents the convolution operation; and represents the ReLU activation function.

Pooling layers [33] are mainly for retaining key features, reducing dimensionality and over-fitting. In this study, we apply a one-dimensional convolutional neural network to time series data, assuming that its mth layer is a convolutional layer, then it is calculated as:

where, h (·) is the averaging function; is the pooling layer weights; and is the bias matrix.

Obtaining a series of features after the pooling layer, the fully connected layer connects each neuron with all the inputs out of the pooling layer by means of full connectivity, pooling all the features together. Flatten function to turn two-dimensional arrays into one-dimensional data and finally outputting the energy consumption prediction.

4. Example Analysis

4.1. Data Sets and Data Pre-Processing

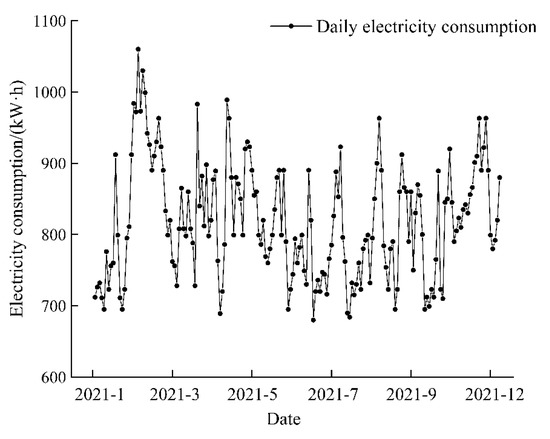

This study used polysilicon reduction furnace energy consumption data as a research to verify the prediction effectiveness of a combined Bayesian estimation-based Time-Series decomposition and convolutional neural network prediction method (TSD-CNN). The step size of the data were 1 day and there were 354 samples. Figure 5 showed the variation in energy consumption values for a polysilicon plant’s reduction furnace over the course of a year, where factors such as holidays had a significance impact on the progress of production operations as well as energy consumption.

Figure 5.

Daily energy consumption data of workshop.

There were many outliers and missing values in the raw data due to meter reading errors and unexpected conditions such as power outages. To reduce the error in the training of the model caused by outliers and missing values, we used proximity averaging to fill in missing values and replace outliers.

4.2. Time Series Decomposition Based on Bayesian Estimation

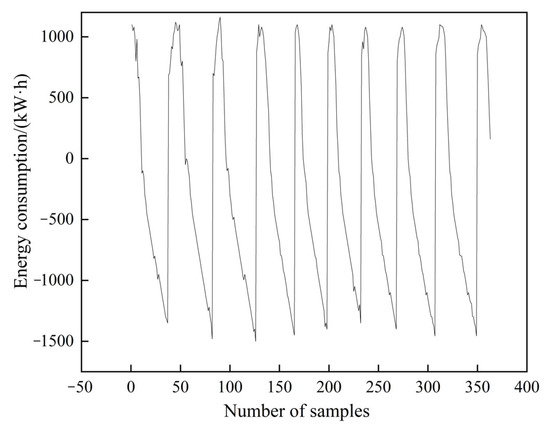

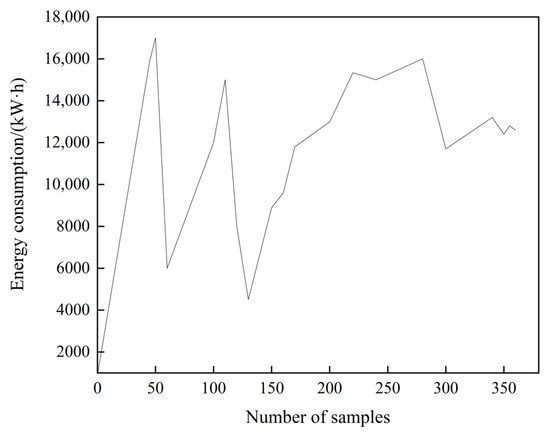

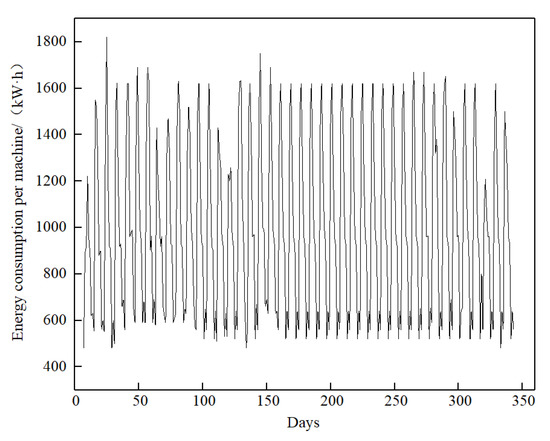

We decomposed the 354 samples of workshop energy consumption data in time series by Bayesian parameter estimation methods. In Gibbs sampling, setting the number of iterations to 5000 and removing the first 800 unstable data, the results of the main parameters of the simulation experiment are shown in Table 1, plotting the periodic and trend components of the data by the resulting parameters. The timing decomposition cyclic factor, trend factor, fluctuation factor results are shown in Figure 6, Figure 7 and Figure 8.

Table 1.

Estimation results of model parameters.

Figure 6.

Cyclic factor.

Figure 7.

Trend factor.

Figure 8.

Fluctuation factor.

The analysis showed that:

- (1)

- The regularity of the cycle of the energy consumption data were strong, which facilitates the analysis and prediction of the neural network;

- (2)

- The trend component of energy consumption was highly volatile. It was necessary to analyze data on environmental factors in relation to them for prediction.

5. Structural Parameter Setting and Evaluation of the Model

5.1. Model Structure Parameter Setting

We learned through repeated experiments that the prediction effect is better when the step size is 49, the convolutional kernel size is 3 × 3, and the pooling layer scale is 2 × 1.

5.2. Evaluation Model Settings

- (1)

- Contrast settings. To verify the effectiveness of the method in this paper, we selected Long Short-Term Memory Neural Network (LSTM), Support Vector Machine (SVM), and Time Series Decomposition (TSD) algorithm as comparisons.

- (2)

- Model evaluation. In this study, we assessed the predictive effect of the model using (Accuracy) ACC [33], (R Squared) and (mean square error) MSE [5,15].where, TP is a positive sample predicted to be True by the model, FP is a negative sample predicted to be False by the model, FN is a positive sample predicted to be False by the model and TN is a negative sample predicted to be True by the model; yi is the ith true value of energy consumption in the test set; y is the ith predicted value of energy consumption; and is the average value of energy consumption in the test set.

5.3. Results and Discussion

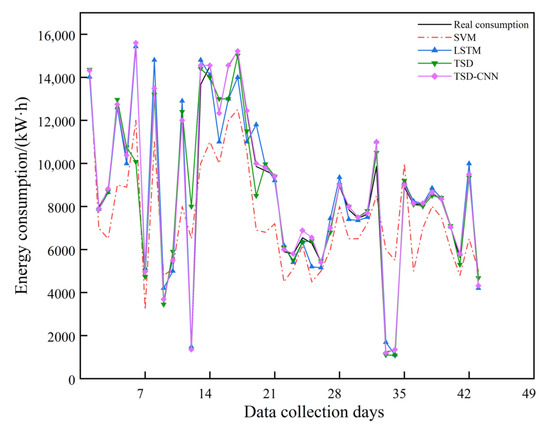

According to the schedule of enterprises, we adopted SVM, LSTM, TSD, and the method of this study to collect and compare the energy consumption data of polysilicon reduction furnace for 43 days from 9 April 2022 to 21 May 2022 with the prediction results of several methods.

Due to space limitation, the actual energy consumption for one consecutive week from 9 May 2022 to 15 May 2022 is selected for comparison with the predicted energy consumption results under various prediction methods, as shown in Table 2 and Table 3 and Figure 9.

Table 2.

Comparison of the prediction results of other models and the TSD-CNN model.

Table 3.

Evaluation of other models and TSD-CNN.

Figure 9.

Energy consumption prediction results.

Energy consumption data were time- series, complex, and nonlinear. According to the data statistics and experimental results, the above four energy consumption prediction methods were basically correct in determining future energy consumption trends. However, SVM was the worst prediction method because it was better at solving linear problems, so the prediction results deviated significantly from the actual energy consumption.

Compared with the prediction effect of SVM, LSTM, TSD and TSD-CNN have higher prediction accuracy for future energy consumption. The LSTM had a long-term memory function for sequence modelling problems and was simple to build. However, each LSTM cell had four fully connected layers inside. Using LSTM to build models with large time horizons was computationally intensive and poor at predicting short-term changes in data.

TSD and TSD-CNN were better at predicting energy consumption in situations where the data set was small and there were large differences in energy consumption between two adjacent days. CNN further provides TSD with a multi-dimensional coupling of the data, such as historical production schedules and the impact of machine start-up power on energy consumption. As can be seen from Table 3, that method in this paper, the Accuracy was 17.1% and 4.3% better than LSTM and TSD respectively. And the highest agreement () between predicted and actual values using this study’s method was 0.196 better than TSD, which meaning that the predicted values match the actual situation by 19.6%, and the MSE is reduced by 9.5%. Meaning that applying that method to describe the experimental data had better accuracy.

6. Conclusions

This study predicted the energy consumption of a polysilicon reduction furnace by using TSD-CNN. We applied a time-series decomposition method to decompose the historical energy consumption data into periodic and trend factors. A Bayesian estimation method with local feature extraction was used to explain well the inner pattern of the energy consumption prediction problem. In this paper, the Accuracy was 17.1% and 4.3% better than LSTM and TSD respectively. And the agreement of the prediction results increased by 0.196 or 19.6% over the TSD, and the MSE decreased by 9.5%, indicating that the model using this method described the experimental data with better accuracy and achieved a quasi-absolute result with a smaller data set. In summary, the combined TSD-CNN energy prediction method can provide data to further optimize the polysilicon production process. It is of great positive significance to provide a certain reference basis for the modernization and upgrading of high energy consumption equipment, the study of energy saving and consumption reduction decisions and the diagnosis of energy consumption anomalies.

However, as the method in this study mainly targets the reality of small data sets. The next step for our team members to continue is to improve the algorithm and optimize the decomposition strategy in the process of temporal decomposition based on Bayesian estimation to further improve the prediction accuracy and solve intermediate data redundancy problems caused by decomposing the source data. In addition, our team will also extract energy consumption data from other devices. We will perform predictive analysis on larger data sets to improve the robustness and portability of the method.

Author Contributions

This study was conceptualized by R.M. and L.Z. The software was designed by R.M. and validated by X.C. and S.Z. S.Z. provided resources and B.X. curated data. The original draft of the manuscript was prepared by R.M. B.X. and Y.Z. reviewed and edited the manuscript. L.Z. assisted with project administration and X.C. managed funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Major science and technology projects in the field of high technology in Xinjiang Production and Construction Corps, grant number 2021AA006.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Heffron, R.J.; Koerner, M.-F.; Schoepf, M.; Wagner, J.; Weibelzahl, M. The role of flexibility in the light of the COVID-19 pandemic and beyond: Contributing to a sustainable and resilient energy future in Europe. Renew. Sustain. Energy Rev. 2021, 140, 110743. [Google Scholar]

- Wang, S.X.; Zhao, X.; Wang, H.; Li, M. Small-world Neural Network and Its Performance for Wind Power Forecasting. CSEE J. Power Energy Syst. 2020, 6, 362–373. [Google Scholar]

- Zhang, W.L. Iop. Influencing Factors and Projections of Coal Price. In Proceedings of the 2020 Asia Conference on Geological Research and Environmental Technology, Kamakura, Japan, 21–22 August 2021. [Google Scholar]

- Xiang, X.W.; Ma, X.; Ma, Z.L.; Ma, M. Operational Carbon Change in Commercial Buildings under the Carbon Neutral Goal: A LASSO-WOA Approach. Buildings 2022, 12, 54. [Google Scholar]

- Swain, R.B.; Karimu, A.; Grad, E. Sustainable development, renewable energy transformation and employment impact in the EU. Int. J. Sustain. Dev. World Ecol. 2022, 5, 1–14. [Google Scholar]

- Xu, Q.F.; Gao, P.; Chao, T. Research on Network Loss of Distributed Energy Integration into Power System. In Proceedings of the International Symposium on Energy Environment and Green Development (EEGD), Chongqing, China, 20–22 November 2020. [Google Scholar]

- Zou, Z.; Yu, M.; Wang, Z.; Liu, X.; Guo, Y.; Zhang, F.; Guo, N. Nonlinear Model Algorithmic Control of a pH Neutralization Process. Chin. J. Chem. Eng. 2013, 21, 395–400. [Google Scholar]

- Andersen, R.; Andersen, A.-L.; Larsen, M.S.S.; Brunoe, T.D.; Nielsen, K. Potential Benefits and Challenges of Changeable Manufacturing in the Process Industry. In Proceedings of the 52nd CIRP Conference on Manufacturing Systems (CMS), Ljubljana, Slovenia, 12–14 June 2019. [Google Scholar]

- Szczepaniak, M.; Trojanowska, J. Methodology of Manufacturing Process Analysis. In Proceedings of the 6th International Scientific-Technical Conference on Advances in Manufacturing II (MANUFACTURING), Pozan, Poland, 19–22 May 2019; pp. 281–294. [Google Scholar]

- Nastasi, G.; Colla, V.; Cateni, S.; Campigli, S. Implementation and comparison of algorithms for multi-objective optimization based on genetic algorithms applied to the management of an automated warehouse. J. Intell. Manuf. 2018, 29, 1545–1557. [Google Scholar]

- Shang, Z.; He, Z.; Song, Y.; Yang, Y.; Li, L.; Chen, Y. A Novel Combined Model for Short-Term Electric Load Forecasting Based on Whale Optimization Algorithm. Neural Process. Lett. 2020, 52, 1207–1232. [Google Scholar]

- Jin, N.Y.; Jo, H.-H. Prediction of Weekly Load using Stacked Bidirectional LSTM and Stacked Unidirectional LSTM. J. Korean Inst. Inf. Technol. 2020, 18, 9–17. [Google Scholar]

- Lin, C.M.; Lin, S.F.; Liu, H.Y.; Tseng, K.Y. Applying the naive Bayes classifier to HVAC energy prediction using hourly data. Microsyst. Technol. Micro-Nanosyst. Inf. Storage Process. Syst. 2022, 28, 121–135. [Google Scholar]

- Scarabaggio, P.; Grammatico, S.; Carli, R.; Dotoli, M. Distributed Demand Side Management with Stochastic Wind Power Forecasting. IEEE Trans. Control. Syst. Technol. 2022, 30, 97–112. [Google Scholar]

- Lu, Y.; Sheng, B.; Zhang, Z.; Zhang, Y. A shop floor energy consumption prediction method based on time series decomposition and CNN. Comput. Appl. Softw. 2021, 38, 339–344. [Google Scholar]

- Liu, A.; Yan, D.; Wong-Leung, J.; Li, L.; Phang, S.P.; Cuevas, A.; Macdonald, D. Impurity Gettering by Diffusion-doped Polysilicon Passivating Contacts for Silicon Solar Cells. In Proceedings of the 7th IEEE World Conference on Photovoltaic Energy Conversion (WCPEC)/A Joint Conference of 45th IEEE PVSC/28th PVSEC/34th EU PVSEC, Milan, Italy, 10–15 June 2018; pp. 1667–1671. [Google Scholar]

- Qu, W.; Hong, H.; Li, Q.; Xuan, Y. Co-producing electricity and solar syngas by transmitting photovoltaics and solar thermochemical process. Appl. Energy 2018, 217, 303–313. [Google Scholar]

- Pica, C.; Munteanu, R.; Pavel, S.; Beleiu, H. Modeling of Photovoltaic Panels. In Proceedings of the 10th International Conference and Expositions on Electrical and Power Engineering (EPE), Iasi, Romania, 18–19 October 2018; pp. 769–773. [Google Scholar]

- Ding, J.; Zhang, Z. Bayesian statistical models with uncertainty variables. J. Intell. Fuzzy Syst. 2020, 39, 1109–1117. [Google Scholar]

- Jiang, Z.; Skorupski, W. A Bayesian approach to estimating variance components within a multivariate generalizability theory framework. Behav. Res. Methods 2018, 50, 2193–2214. [Google Scholar]

- Van Ravenzwaaij, D.; Cassey, P.; Brown, S.D. A simple introduction to Markov Chain Monte-Carlo sampling. Psychon. Bull. Rev. 2018, 25, 143–154. [Google Scholar]

- Singh, P. Novel Fourier quadrature transforms and analytic signal representations for nonlinear and non-stationary time-series analysis. R. Soc. Open Sci. 2018, 5, 181131. [Google Scholar]

- Nelson, J.D.B. On the coefficient quantization of the Fourier basis. IEEE Trans. Signal Process. 2003, 51, 1838–1845. [Google Scholar]

- Fong, F.J.; Chen, W.Y.; Tsao, S.; Hsiao, T.C.; Huang, C.F. The Study of the Geometry and Growth Trend of Silicon Carbide Crystals. In Proceedings of the 9th European Conference on Silicon Carbide and Related Materials (ECSCRM 2012), Saint-Petersburg, Russia, 2–6 September 2012; pp. 56–59. [Google Scholar]

- Norton, R.A.; Christen, J.A.; Fox, C. Sampling hyperparameters in hierarchical models: Improving on Gibbs for high-dimensional latent fields and large datasets. Commun. Stat. Simul. Comput. 2018, 47, 2639–2655. [Google Scholar]

- Koprinska, I.; Wu, D.; Wang, Z. Convolutional Neural Networks for Energy Time Series Forecasting. In Proceedings of the International Joint Conference on Neural Networks (IJCNN), Rio de Janeiro, Brazil, 18–23 June 2018. [Google Scholar]

- Zhou, D.-X. Deep distributed convolutional neural networks: Universality. Anal. Appl. 2018, 16, 895–919. [Google Scholar]

- Zhang, Q.; Wu, Y.N.; Zhu, S.-C. Interpretable Convolutional Neural Networks. In Proceedings of the 31st IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Salt Lake City, UT, USA, 18–22 June 2018; pp. 8827–8836. [Google Scholar]

- Zhang, Z.; Kuang, Z.; Luo, P.; Feng, L.; Zhang, W. Temporal Sequence Distillation: Towards Few-Frame Action Recognition in Videos. In Proceedings of the 26th ACM Multimedia Conference (MM), Seoul, Korea, 22–26 October 2018; pp. 257–264. [Google Scholar]

- Shima, Y.; Nakashima, Y.; Yasuda, M. Classifying for a Mixture of Object Images and Character Patterns by Using CNN Pre-trained for Large-scale Object Image Dataset. In Proceedings of the 13th IEEE Conference on Industrial Electronics and Applications (ICIEA), Wuhan, China, 31 May–2 June 2018; pp. 2360–2365. [Google Scholar]

- Martino, L.; Elvira, V.; Luengo, D.; Corander, J.; Louzada, F. Orthogonal parallel MCMC methods for sampling and optimization. Digit. Signal Process. 2016, 58, 64–84. [Google Scholar]

- Fujimura, S.; Kojima, T.; Okanoue, Y.; Shoji, K.; Inoue, M.; Omori, K.; Hori, R. Classification of Voice Disorders Using a One-Dimensional Convolutional Neural Network. J. Voice 2022, 36, 15–20. [Google Scholar]

- Oh, B.K.; Glisic, B.; Kim, Y.; Park, H.S. Convolutional neural network-based data recovery method for structural health monitoring. Struct. Health Monit. Int. J. 2020, 19, 1821–1838. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).