Abstract

Global primary energy consumption has increased tenfold over the course of the 20th Century, the availability of non-renewable energy is becoming scarce, and the burning of fossil fuels is leading to global warming. Climate change has now become tangible. The will to act against fossil fuels has become apparent in the western world, and in Germany in particular. This poses a particular challenge for the chemical and pharmaceutical industry, since, in the future, not only will the energy input, but also the feedstock, have to come from non-fossil sources. They must be replaced by carbon capture and utilization, and the exploitation of a circular economy. Concepts for a climate-neutral chemical–pharmaceutical industry have been developed and evaluated. Due to a high predicted consumption of renewable energies and an insufficient expansion of these, Germany will remain an energy importer in the future. The largest consumer in a climate-neutral chemical–pharmaceutical industry will be electrolysis for hydrogen (up to 81%, 553 TWh/a). This can be circumvented by importing green ammonia and cracking. This will require investments of EUR 155 bn. An additional benefit will be increased independence from fossil resource imports, as green ammonia can be produced in a multitude of nations with strong potential for renewable energies and a diversified set of exporting nations.

1. Introduction

Global climate change caused by anthropogenic emissions is becoming a recognized problem for the entire world [1,2]. Following increasing public pressure, Germany has also passed several resolutions to reduce global warming potential (GWP). It was set in the coalition agreement of the current government to phase out coal-fired power generation by 2030 and to achieve climate neutrality by 2045 [3]. This poses several challenges for industry in Germany. To achieve these goals, 100% of the energy supply must come from renewable sources. This requires the expansion of the power grid with new lines, as well as the construction of short- and long-term storage technologies to bridge dark periods.

An unintended side-effect of the change to renewable energies (RE) is the increasing independence from individual energy suppliers. As currently apparent, this can affect the prosperity of the population in case of increasing international political conflicts. Case in point: the current price of fuel is rising to a record high last seen in the 1970s [4]. The trigger for this was the war in Ukraine and the sharp sanctions against a major supplier, Russia, which are also further spurring investment in RE. The German Finance Minister of Linder (Liberal Party) described investment in renewables as investment in “freedom energies” [5], signalling a shift in political consent towards the prioritization of RE in Germany. Following, this a EUR200 billion special fund towards climate neutrality has been announced [6].

A recent political desire is to transform Germany to climate neutrality in 2045, instead of 2050, as originally planned [7]. For the chemical–pharmaceutical industry, the general technical options based on rough mass and energy balances and cost estimates were already discussed in [8]. The economical fundamental basics for the green approach have been well known for a long time [9], and a scientific evaluation has been always available for politicians [10]. Even recently, many politically requested technologies, such as bioethanol, biodiesel or biogas, did not have eco-efficient inputs as politically desired, but this was well known in advance; sometimes, this is only related to engineering basics, such as the use of the wrong feedstock or too-small scales [11], biodiversity destruction and the socio-economic aspects of e.g., palm oil [12] or biogas [13]. Alternative fermentation pathways for bulk and basic chemical building blocks have been under evaluation for at least two decades [14].

For the chemical–pharmaceutical industry (ChPI), there is another challenge. Fossil fuels are not only used as energy sources for electricity and process heat generation, but also as a feedstock for many products. Replacing these is energetically expensive and requires investment in plant engineering and logistics. Alternatives could be biomass and coal from other industries. The ChPI is the third-largest industry in Germany and thus contributes significantly to the GDP and, therefore, the prosperity of the country. However, it also causes one-third of Germany’s carbon dioxide emissions [15].

Various studies and strategies have been developed to achieve this goal of climate neutrality for the ChPI. In this paper, selected studies are compared, and our own ones are developed. The focus is on the basic chemicals sector, as it is responsible for 90% of the GWP of the ChPI [15]. The goal is to develop a strategy to make the ChPI in Germany climate neutral. For this purpose, world-scale (WS)-sized plants are used for all scenarios in order to incorporate the economy of scale effect into the comparison between them. WS plants are, in most cases, the most efficient method of production in the ChPI [11,16]. This strategy must be in line with the existing and projected energy production and resources in order to prevent the ChPI from migrating. Furthermore, the decisive factors for transferability to other countries are determined.

2. Methodology for the Development of Climate Neutrality Concepts

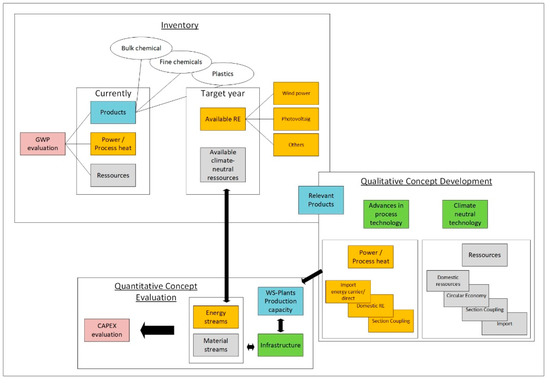

To develop a concept for the climate neutrality of the ChPI, the following steps are proposed: Inventory, Qualitative Concept Development and Quantitative Evaluation. These steps are displayed in Figure 1. As a basis for this, a target must be defined by how much the GWP of the industry must be reduced and in which target year this should be achieved. This is given in a top-down manner.

Figure 1.

Schematic representation of the procedure for the development of a climate-neutral concept for the ChPI.

In the first step (Inventory), the status of the ChPI is first recorded, taking into account the material and energy flows and the products produced. These are evaluated according to their emissions in order to identify the greatest impact on the GWP. The goal is to highlight the fossil energy and raw material sources. In the second step, predictions of climate-neutral domestic energy production are made in a bottom-up manner for the target year. Additionally, possible carbon-neutral feedstock sources, such as biomass or CCU, are surveyed for the target year.

In the Qualitative Concept Development, the future-relevant products and products with a high share in the GWP of the ChPI are firstly identified. Furthermore, climate-neutral technologies and advances in process engineering that lead to efficiency improvements or climate-neutral production are collected. Climate-neutral process engineering plant concepts are selected for the production of the relevant products. Since plants have an operating life of about 20 years, the plant concepts selected and built now are decisive for the carbon footprint in the target year. For these, supply concepts with electricity, process heat and raw materials from the climate-neutral technologies are determined. Initially, domestic supply, sectional coupling and circular economy will be used before import is considered.

The qualitative concept is now evaluated quantitatively. First, the plants for the relevant products are roughly designed. For these, the necessary supplies of electricity, process heat and raw materials are calculated. The required quantities are compared with the bottom-up analysis from the first step, and a decision is made as to whether the concept is viable. The necessary infrastructure is planned and designed for the calculated material and energy flows. Finally, the investment costs of the respective concepts are evaluated. On the basis of these figures, the concepts can be compared with each other, the aim being to bring about the transformation of ChPI with the lowest possible financial outlay.

Plant cost is split into capital expenditure (CAPEX) and operational expenditure (OPEX). The CAPEX for chemical plants can be approximated using various methods [17,18,19]. The accuracy of this estimate can be improved by increasing the level of detail and effort. With an accuracy of over +/− 30%, an order-of-magnitude approximation can estimate the CAPEX of a new plant based on the cost and capacity of an existing plant. An exponent n is used to scale the costs to the different capacities; this is usually correlated to 0.6. This is displayed in Equation (1) [17,18].

In order to estimate plant costs, this can also be conducted for individual pieces of equipment. The sum of the equipment costs then represents the CAPEX of the plant. The costs for instrumentation, assembly, secondary plant components and others are determined by multiplying the so-called Lang factor (L). As shown in Equation (2). This Lang factor is 3 for bulk chemicals [17,20].

Furthermore, it is assumed in this work that OPEX, as well as the reactants and required energy, scale linearly with the production rate.

Since the scenarios in this study were estimated with the same methodology and assumptions, the relative error was neglected. The reference plants used for this purpose were based on real data, so the absolute figures of this study were also close to reality within the limits of uncertainty introduced by the chosen well-established methods [17,18].

3. Overview of Existing Climate Neutrality Concepts

Various strategies have been developed to achieve greenhouse gas neutrality within the ChPI. The main greenhouse gas emissions of the ChPI can be summarized in three factors. Scope 1 includes the emissions that occur directly in the ChPI, i.e., during the in-house generation of electricity and process heat. Scope 2 includes indirect emissions from the ChPI, e.g., those that occur during the generation of electricity for the ChPI. Scope 3 includes emissions that are linked to products. This is a unique scope of GWP, which includes the GWP locked in the product and emitted during its life cycle or disposal. The resulting GWP is calculated with the amount of carbon required for production. For example, this is the case for products made from fossil raw materials, such as plastics. These emissions have a great impact on the carbon footprint of the ChPI [21]. Currently, the total greenhouse gas emissions are made up of 29% Scope 1, 21% Scope 2 and 50% Scope 3 emissions, as reported [15]. To reduce these emissions, the supply of electricity, process heat and feedstock to the ChPI must be climate-neutral [15].

In 2050, it is assumed for Scope 2 in all scenarios that at least 95% of electricity is generated from renewable energies. Furthermore, the use of fossil raw materials, such as crude oil and natural gas, is omitted. The largest differences in the denatured scenarios relate to the provision of process heat and the production paths within the German ChPI.

One pathway to climate neutrality is the electrification of the ChPI; thus, process heat is introduced into the chemical processes via electric heaters. Another advantage of this is the flexibility gained through faster start-up times. Thus, temporarily favourable energy prices can be used more effectively, and the ChPI can contribute to the management of RE [22]. This will be achieved by retrofitting the existing plants. The VCI (German ChPI branch association) calculated investment costs of EUR 68 billion for this in addition to the assumed baseline investment of EUR 7 bn per year. In this process, the electricity consumption of the ChPI will increase by 1160% to 684.6 TWh/a. In addition, other energy sources will be used, bringing the total energy demand to 840 TWh/a. The production of high-value chemicals (HVC) will continue to take place via the cracking of naphtha. This is produced in the FTS from hydrogen and carbon dioxide [15]. The Fraunhofer Institute’s “TN Strom” scenario is similar, but here, HVC are produced via methanol. This will result in energy consumption of 651 TWh/a in Germany, in which the hydrogen required has already been calculated as an energy input and the production of this has been disregarded [23].

Another strategy is the provision of process heat via synthetic energy sources, such as hydrogen, methanol or ammonia [8,22,23]. Therefore, in the scenarios “TN H2” and “TN PtG/PtL”, 359 TWh/a and 415 TWh/a, respectively, are used by chemically bound energies. The generation of this energy is attributed to the “conversion sector” and is not attributed to ChPI. This circumvents the issue of energy production [23]. Another option is to import chemically bound energy, such as “green naphtha”, for further processing in Germany [24].

The considered scenarios show an energy consumption of a climate-neutral ChPI from 651 TWh/a [23] to 840 TWh/a [15]. The DECHEMA has also considered the whole European ChPI, and found in their “maximum” scenario a total energy consumption of 4900 TWh/a, surpassing the available energy of 3400 TWh/a [22].

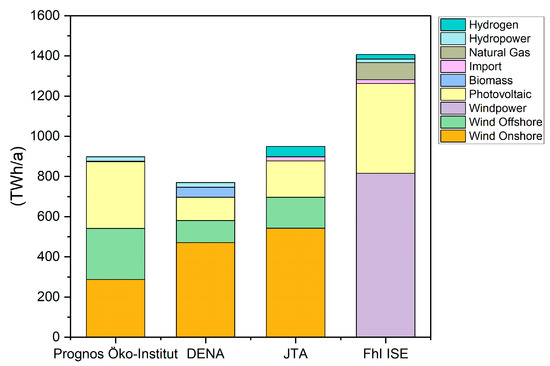

For a climate-neutral ChPI, the expansion of renewable energy generation will be indispensable. Various institutes and agencies have made projections for the energy available in 2050. The majority of the generated greenhouse-gas-neutral energy will come from wind power and photovoltaic sources. Other renewables, such as biomass, hydropower and geothermal energy, will play a minor role.

Figure 2 shows the projected available electric energy in 2050 from different studies. These include the prognosis from the consulting firm Prognos and collaborators [24], scenario EL95 from “Deutsche Energie-Agentur” (DENA) [25], “Szenario 95” from “Forschungszentrum Jürlich” [26] and scenario “Referenz” from the “Fraunhofer Institut ISE” [27]. These differ by the assumed expansion of the individual RE technologies. The most important factor seems to be not the technical potential, but the acceptance of the population and the political will. This is especially the case for onshore wind power plants. Distance regulations, such as the 10-H rule [28], and citizen initiatives driven by a “not in my backyard” mentality must be balanced by the expansion of PV plants. Due to the lower full load hours of PV compared with wind power, less energy is generated per unit power of the plants [26].

Figure 2.

Representation of the projected availability of RE in the year 2050 [24,25,26,27].

The composition of RE varies greatly across studies, but a trend towards expansion can still be seen. Currently, 251 TWh/a [29] is available, excluding biomass. In 2050, an availability of 1000 TWh/a is assumed as the average of the considered studies for the further course of the study. The predicted electrical energy consumption of ChPI is in the range of 400 to 700 TWh/a [8,15,23]; much more electricity will be proportionally consumed by ChPI in 2050 than in 2020. A mismatch between the generated energy and the consumed energy is created. Without overcoming this, industry will migrate, driven by rising electricity prices.

4. Alternative Climate Neutrality Concepts

In this study, the most energy-intensive and greenhouse-gas-emitting parts of the German ChPI have been considered. These make up about 90% of the greenhouse gas emissions of the German ChPI [15].

For the German ChPI in 2050 for constant production, 3130 kt/a ammonia, 520 kt/a urea, 1050 kt/a methanol and 4052 kt/a chlorine are required. Furthermore, high-value chemicals are produced traditionally via naphtha, of which 19,155 kt/a is required [15]. As a basis for climate-neutral production, the complete electrification of the ChPI is assumed here. This means that process heat is provided by electrical power and not by burning natural gas, as is currently the case. At the core of these products are the following plants summarized in Table 1.

Table 1.

Capacity, Power Usage and CAPEX of the most important plants for a climate-neutral ChPI.

Traditionally, the ChPI is based on crude oil and natural gas, which have a negative impact on the climate balance of the ChPI in the form of Scope 3 emissions. As an alternative, in a climate-neutral ChPI, naphtha will be obtained from biomass or from the circular economy. Naphtha makes up a large part of the feedstock of the ChPI [21]; this is produced in this study by Fischer-Tropsch via the synthesis of carbon dioxide and hydrogen [34]. In this study, hydrogen is obtained from electrolysis and carbon is obtained from section-coupling by means of carbon capture and utilization (CCU). Natural gas is traditionally used not only to generate electricity and heat, but also to produce hydrogen and, in turn, ammonia and other chemicals. Both of these utilizations have to be dispensed with for the ChPI to become climate-neutral.

Since no fossil carbon will be available for the ChPI in 2050, CCU is used in this study. CCU captures CO2 through gas washing and releases it back through heating; this makes CO2 accessible for other chemical processes. Energy consumption for this technology is between 2.6 and 6.5 GJ/tCO2, but is predicted to drop to 0.9 GJ/tCO2 by 2050 [23,36]. It is assumed that CO2 from other industries will be available due to section coupling. The sources for this are the cement industry, which produces 13.2 mt/a CO2 due to the process [37]. In addition, 17 mt/a is expected from waste incineration, 2 mt/a from lime burning and 7.4 mt/a from smaller industrial sources [23]. The remaining CO2 is provided by the circular economy of the ChPI.

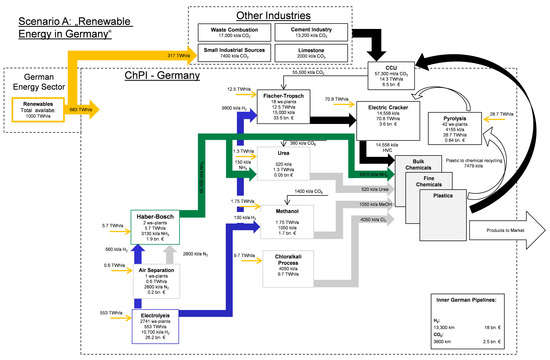

Scenario A, as shown in Figure 3, is based on the VCI study [15] and is considered the reference scenario for this comparison, since it represents a climate-neutral ChPI in Germany through the electrification of existing plants without change to production chains. The biggest difference to today’s ChPI is the use of CO2 from CCU and hydrogen from electrolysis as a feedstock for basic chemistry. For this, electrolysis plants have to be operated in Germany. Furthermore, CCU plants have to be built and operated in other sectors of industry to recycle carbon dioxide. In addition, the sources and sinks of hydrogen and CO2 will be connected by a pipeline network. For a pipeline network between the industrial sites concerned, an investment cost of EUR 2.5 bn was calculated for a length of 5600 km [23]. Additionally, a hydrogen pipeline network needs to be constructed. For this, FNB Gas proposed an expansion of the existing gas network for hydrogen and calculated costs of EUR 18 bn [38].

Figure 3.

Schematic display of the German ChPI for Scenario A “Renewable Energy in Germany”.

Energy is supplied solely by renewable energies from Germany. Of the 683 TWh required annually by the ChPI, 553 TWh/a are used for the electrolysis of water, which corresponds to 81%. A large part of the investment costs for the conversion of the current ChPI will be used for the construction of the electrolysis plants and for the FTS. These costs are closely related to the production of “green naphtha”. The conversion of the remaining ChPI for use is comparatively less expensive.

In scenario A, 68.3% of the available electricity in Germany will be required for the ChPI. In 2020, this share was 14% [39]. Other industries, such as the steel industry, will also have to dispense with fossil fuels in the future in order to become greenhouse-gas-neutral. Furthermore, electricity will continue to be needed in civil sectors. Therefore, the share of energy used in this scenario is unrealistic. In order to continue to pursue the goal of a climate-neutral ChPI, energy must be imported. This can be in the form of electrical energy over short distances from other European countries to avoid line losses. Another alternative is the import of chemically bound energy. Ammonia is a good substance for this because it has a high energy density, is chemically stable and does not contain carbon. In comparison with hydrogen, it can be transported at a higher temperature and at lower pressure, making it less costly [40].

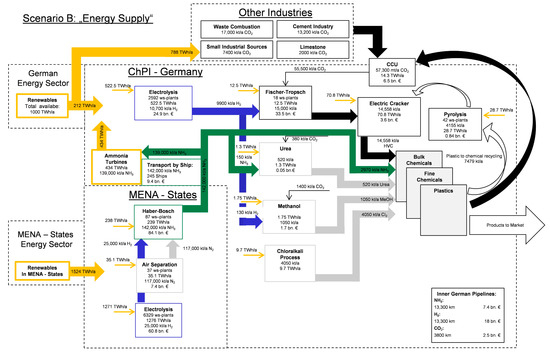

In scenario B, ammonia will be imported from states with more open space and higher solar intensity. Candidates for such locations are the MENA states (Middle East and Northern Africa); due to their proximity to Europe, the transport costs for the ammonia import can be minimized. For the transport tankers are used, which are also operated with ammonia [41]. Turbines with an efficiency of 60% are used to convert the ammonia back into electricity [40]. For the distribution of ammonia within Germany, a further pipeline network is assumed along the lines of the network for hydrogen, with investment costs of EUR 7.4 bn [42].

For the operation of a climate-neutral ChPI, it is assumed that 20% of the RE generated in Germany is available. The remaining energy is imported in the form of ammonia. This amounts to 142 mt/a, which has a CAPEX value of EUR 152.3 bn in the MENA states. To operate these, 1.524 TWh/a of renewable energy will be required there. For transport by ship, a fleet of 245 ships with investment costs of EUR 9.4 bn has been calculated.

Scenario B, as shown in Figure 4, also continues to use most of the available electricity to produce hydrogen for the production of “green naphtha”. More than all of the electricity generated by ammonia combustion is used for this purpose. A more effective way to supply hydrogen to the German ChPI is to crack the imported ammonia. Ammonia cracking has already been investigated as a process for providing hydrogen for fuel cells [43,44,45]. For the conversion of ammonia into hydrogen, a plant capacity of 55.4 ktH2/a with an input of 360 ktNH3/a is assumed. The parallel combustion of ammonia generates the heat for the cracking process [44]. The separation of the product mixture takes place via a Pressure Swing Adsorption [46,47,48]. CAPEX is assumed to be EUR 21.4 mio., with an electricity consumption of 0.19 TWh/a for such a plant.

Figure 4.

Schematic Display of German ChPI for Scenario B “Energy Supply”.

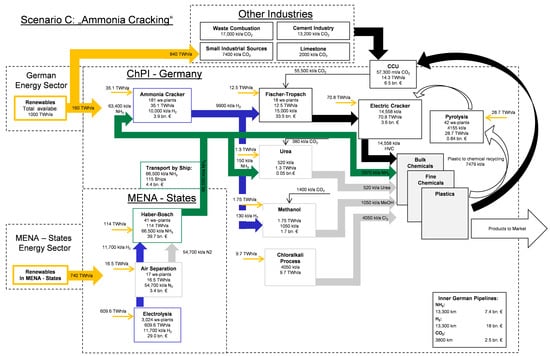

In scenario C, as shown in Figure 5, ammonia crackers were used instead of electrolysis plants to supply the ChPI with hydrogen. This requires less ammonia import from the MENA states than in scenario B. Thus, CAPEX abroad will also decrease to EUR 72.1 bn and the consumption of renewable energy to 740 TWh/a in MENA States. In addition, within the German ChPI, less needs to be invested in plants for the transformation to climate neutrality, since no hydrogen electrolysis plants are needed. Furthermore, this scenario achieves the lowest electricity consumption in Germany, with 160 TWh/a.

Figure 5.

Schematic display of German ChPI for Scenario C “Ammonia Cracking”.

As summarized in Table 2, the overall lowest cost is achieved by scenario A. However, the high energy consumption in Germany makes this scenario not feasible. An Alternative is provided by importing ammonia and using it to provide hydrogen through cracking for the German ChPI.

Table 2.

Summary of the calculated investment costs for each scenario.

5. Discussion

In this study, scenarios were considered to make the German ChPI climate-neutral, and energy and feedstock were identified as fundamental factors. Providing these for the ChPI in Germany will be an existential task for the next few decades. In Scenario A, the expansion of RE was considered as the basis for a climate-neutral ChPI. This transformation of the ChPI would incur investment costs of EUR 94.99 bn, exclusive of power-generation costs, as alternative pathways for hydrogen and carbon extraction, as well as additional infrastructure, would have to be developed. Included in the cost are the estimated CAPEX for CCU and distribution to chemical plants. This would require an energy consumption of 683 TWh per year for the production of an equal amount of end-products to today. In this work, different projections of the available RE in Germany were considered. An average of 1000 TWh/a can realistically be expected in 2045. The energy consumption of scenario A is thus disproportionately large compared with the current situation. An increase in energy costs could be expected in this case, which would make the production of chemical products in Germany unprofitable.

As an alternative, the possibility of importing energy in the form of ammonia from MENA countries was considered. This was presented in scenario B, and CAPEX of EUR 260.69 bn was calculated. The majority (58%) of this is accrued from plant construction for ammonia production in MENA countries. An annual import of 1420 kt of ammonia ensures an additional energy supply of 434 TWh/a, which can also be extended to other industries. This requires an expansion of 1524 TWh/a of RE in MENA countries. Infrastructure costs of EUR 37.3 bn for transport overseas and within Germany are invested in this scenario. From the presented scenarios A and B, it is obvious that a large part of the required electrical energy goes into the splitting of water into hydrogen.

Therefore, Scenario C was developed as a more cost-effective, but still realistic, alternative. Here, the technology of ammonia crackers is used to provide hydrogen for the German ChPI. For this, CAPEX of EUR 155.49 bn. was calculated, which was a reduction of 40% compared with scenario B. This is needed both for the production of ammonia, as in scenario B, and for the conversion into hydrogen. In doing so, 740 TWh/a of RE is required in the MENA countries for the production of ammonia, representing a 52% reduction compared with Scenario B. Scenario C requires less overall investment than Scenario B and is more realistic than Scenario A in terms of RE expansion in Germany; therefore, it is preferable.

The following points have to be made in the general discussion of human-made climate change, the possible solutions and the implications and the action directive to reduce GWP:

- To reduce GWP emissions in the German ChPI. energy demand has to be shifted towards renewable energies for both electrical power and process heat.

- Currently, half of the German ChPI-attributed GWP is based on fossil feedstock, such as oil and natural gas [15]. To replace these, alternative carbon sources have to be considered. As described, these are biomass, recycling and CCU, and all include section coupling within the industrial sector as a whole.

- CCU will have a primary role here, as some industries, such as the cement industry, will have process-related emissions, which will be impossible to eliminate. These can be bound within products of the ChPI and thus be valorized from harmful greenhouse gases to consumer goods. An estimated amount of 13.2 mt is annually available in Germany [37], as well as other sources. These include thermal waste disposal and other industrial processes. With section coupling, 39.2 mt of carbon capture can be made available to the ChPI with CCU [19,37].

- As well as feedstock towards non-fossil materials, such as carbon dioxide from CCU, CO2 will be required as a feedstock for ChPI and traded as such [23,24,49]. Section coupling will, therefore, become a major factor in running the economy. as trade with CO2 will develop naturally. Niche solutions for feedstock acquirement include the circular economy and will play a major role as a market for carbon dioxide from CCU and other sources evolves.

- An alternative to the usage of CO2 as feedstock is biomass. Several routes to the product can be found in the literature, and the first industrial applications are being prototyped and are already in industrial use [50,51]. This can be further expanded, as some biomass is potentially unused [52].

- Another GWP-reducing action is the expansion of the circular economy, as this saves energy, as well as material resources. This is supported by rising digitalization [53]. This is not only applicable to metals and carbon, but also to biologicals [54]. The development of urban mining projects, as shown by the University of Clausthal, is important to close gaps in resource procurement and increase the efficiency in which we use our environment [55].

- The pharmaceutical industry currently consumes 16 TWh of energy and emits 3 Mt CO2eq annually. The biggest factors are WFI consumption for CIP/SIP in the production of biologics. There is potential for GWP reduction through the introduction of continuous processes and the valorization of residual materials in the production of natural products [56,57,58]. Problem analyses and solutions such as these in the pharmaceutical industry are not always transferable to other industries. Companies and industries must, therefore, consider individual solutions for their specific GWP sources. This will lead to the easiest sources to eliminate being tackled first. This freedom of action will ensure that the most efficient GWP reduction is achieved.

- The problem becomes rewarding efforts to reduce GWP and penalizing emissions. Setting a political framework for this is feasible within a country with the help of CO2 certificates. In this way, climate protection can become a business decision. However, this will be difficult in international competition and trade without a superordinate body or international regulations. How this can be implemented on an international scale remains an open question.

The general discussion towards energy supply and renewable energy development is ongoing. Towards energy supply for the German ChPI and industry in general, additional points of conversation have to be made, and further research must be conducted and actions must be taken:

- Moving towards renewable electrical power generation requires consent within the populous to make the transition from traditional energy generation as efficient as possible. This includes the construction of power lines and wind turbines [26]. This is invoking a debate on land use, as RE production has proven to be more space-inefficient than traditional fossil energy generation. This predicament between preserving nature as is and developing more areas for RE is still subject to ongoing debates not only in Germany. Importing power via ammonia could be a solution to this problem.

- To guarantee a stable power supply, long- and short-term energy storage and supply is needed. The electrification of the ChPI can help net stability by buying power during high production [22].

- Even with the high aims of current policies, Germany will remain a net energy importer as it has been in the past. Germany recently intended to import LNG, and long-term contracts with places such as Qatar have been negotiated. German industry is investing at least EUR 1 bn in harbour terminal buildings for at least the next 5 years. Qatar is investing about USD 30 bn in upgrading the amounts of gas [59,60,61].

- A candidate for energy importation is ammonia, as its production is well understood by the ChPI. The substitution of hydrogen provided by natural gas with electrolysis is a minor one. Electrolysis has been subject to research and development for decades and is projected to become more cost-effective in the near future [31]. The transportation costs are lower than those of alternative green fuels [62]. Additionally, ammonia can be converted to electrical power as well as process heat [40,63,64,65]. This can also help to manage electrical power supply during fluctuations in wind and solar power.

- Producing ammonia in favourably located states from renewable sources can circumvent energy scarcity within Germany and keep the German ChPI supplied with hydrogen. Thus, the migration of oil and gas-based industry can be avoided.

- As the requirements of site factors are having access to renewable-energy-suitable areas, the list of possible countries is plentiful [66]. This can be used to diversify sources of green ammonia to avoid being affected by political conflict and other local factors. This would stabilize energy availability and grant a greater degree of independence. Recent efforts towards the importation of ammonia and hydrogen have been made by the German government, and they will have to continue to move towards a climate-neutral ChPI [67,68,69].

- As this technology develops and is being applied by other countries, the cost of ammonia plants will decrease and the efficiency of ammonia technology will increase. Ammonia-fired turbines, as well as co-fired ammonia methane, are currently under development and improvement by Mitsubishi and are projected to be commercial by 2025 [70]. The efficiency of power to ammonia to power was calculated to be between 31 and 39% [71]. This is of interest for further research.

- It has been found that ammonia can be cracked into hydrogen at a relatively low cost. To move towards a ChPI without Scope 3 emissions, CO2 and hydrogen have to be used as a feedstock for the traditional petrochemical industry. Furthermore, ammonia crackers are already commercially available [72,73] and under further study [74]. With further study, this technology can make a great impact towards climate neutrality.

- Nevertheless, to implement this strategy, steps have to be taken today: a framework for an ammonia-based ChPI needs to be developed. This includes ammonia infrastructure a national and international pipeline grid, as well as international shipping. Further development of ammonia-based technology and commercial availability is needed. In any case, the expansion of RE is not circumventable within Germany or internationally.

The approaches used and presented here can be summarized into basic steps:

- Inventory of current production and availability of future resources;

- Qualitative concept development with climate-neutral technologies;

- Quantitative concept evaluation of energy and material streams and, finally, costs.

The largest factors for these concepts are the following:

- The use of non-fossil energy sources (in this study, NH3 and H2) and renewable energies (photovoltaic or wind);

- Avoidance of fossil carbon as a feedstock for the synthesis of goods;

- Sector coupling and use of CCU;

- Application of the economy-of-scale principle where possible.

The critical success factors for a climate-neutral ChPI are the existence and availability of RE and carbon dioxide. These are indispensable for the climate-neutral production of an important raw material of the ChPI, naphtha. This is transferable to the ChPI of other nations as well as it is for Germany. If these are available in sufficient quantities, the respective ChPI can be made climate-neutral. Otherwise, energy and hydrogen can be imported via ammonia, as shown in this study. Carbon can be available through section coupling, as it is in Germany, or must be acquired from other renewable sources. This transformation requires investment in infrastructure and, in some cases, new plants.

If both energy production and resources are climate-neutral, the GWP will be reduced to zero. How such a climate-neutral ChPI can look was shown, and the path towards this outlined ChPI will be the content of businesses, politics and future research.

6. Conclusions

In this paper, different scenarios of a climate-neutral ChPI in 2045 are developed and presented. The climate-neutral ChPI in Germany will need up to 68% (680 TWh) of the total available green electricity in Germany in 2050 (1000 TWh). Therefore, Germany will remain an energy importer, as other industry branches will have an increased power requirement as well. Strategies for energy import in the form of ammonia have been developed and evaluated. Electrolysis for hydrogen production has been identified to be the main contributor to power usage in a climate-neutral ChPI (up to 81%). The cracking of ammonia as a feedstock for the Fischer–Tropsch synthesis of hydrocarbons is the most efficient way to make the German ChPI climate-neutral. In this scenario, only 160 TWh of green electricity is needed. The remaining energy need is supplied by H2 from NH3. Energy and hydrogen import through ammonia offers the additional benefit of a diversification of possible trade partners in the energy market and an independence from individual countries and organizations. This solution requires an investment of EUR 155 bn. As a feedstock input, CCU and the circular economy are gaining increasing importance. These reduce not only the GWP of the ChPI, but can also provide a solution to process the required GWP emissions from other industries through section coupling. The methods and concepts presented in this work, can be adopted by other nations to achieve the goal of climate neutrality within their respective ChPI. In order to prevent a migration of the ChPI, optimized political framework conditions must be created in order to make the restructuring of the industry feasible. This will ultimately come down to a business decision.

Author Contributions

Writing—original draft preparation, A.U., C.J., A.S., D.K. and J.S.; writing—review and editing, A.U., C.J., A.S., D.K. and J.S.; conceptualization, J.S.; resources, J.S.; supervision, J.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to acknowledge the fruitful discussions with their Clausthal University of Technology colleagues and especially the students Stefan Engbers, Michael Frank, Maximilian Mickler and Artur Nachtigall for their motivated efforts and contributing towards the idea in a group project work. The authors acknowledge financial support by the Open Access Publishing Fund of Clausthal University of Technology.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| CAPEX | Capital expenditure |

| CCU | Carbon capture and utilization |

| ChPI | Chemical–pharmaceutical industry |

| GWP | Global warming potential |

| MENA | Middle East and Northern Africa |

| OPEX | Operational expenditure |

| PAT | Process analytical technology |

| QbD | Quality by design |

| RE | Renewable energy |

| WFI | Water for injection |

| WS | World-scale |

References

- IPCC. Climate Change 2022: Impacts, Adaptation, and Vulnerability: Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change 2022; IPCC: Geneva, Switzerland, 2022. [Google Scholar]

- Cook, J.; Oreskes, N.; Doran, P.T.; Anderegg, W.R.L.; Verheggen, B.; Maibach, E.W.; Carlton, J.S.; Lewandowsky, S.; Skuce, A.G.; Green, S.A.; et al. Consensus on consensus: A synthesis of consensus estimates on human-caused global warming. Environ. Res. Lett. 2016, 11, 48002. [Google Scholar] [CrossRef]

- SPD; Bündnis 90/Die Grünen; FDP. Mehr Fortschritt Wagen: Bündnis für Freiheit, Gerechtigkeit und Nachhaltigkeit 2021; Koalitionsvertrag Zwischen SPD, Bündnis 90/Die Grünen und FDP: Berlin, Germany, 2021. [Google Scholar]

- Böcking, D. Massiver Preisanstieg: So Lange Müssen Verbraucher in Deutschland für Einen Liter Benzin Arbeiten. DER SPIEGEL [Online]. 16 March 2022. Available online: https://www.spiegel.de/wirtschaft/service/benzinpreis-verbraucher-arbeiten-zwei-minuten-laenger-pro-liter-a-e23bfc1b-6258-4673-bc86-a8d932bfed5f (accessed on 17 March 2022).

- Deutscher Bundestag. Stenographischer Bericht 19. Sitzung 2022; Deutscher Bundesta: Berlin, Germany, 2022. [Google Scholar]

- Nguyen, C. Klimaschutz: Bundesregierung Will 200 Milliarden Euro in Klimaschutz Investieren. Die Zeit [Online]. 6 March 2022. Available online: https://www.zeit.de/politik/deutschland/2022-03/klimaschutz-bundesregierung-erneuerbare-energie-lindner-habeck?page=8&utm_referrer=https%3A%2F%2Fwww.google.com%2F (accessed on 18 March 2022).

- Webseite der Bundesregierung|Startseite. Klimaschutzgesetz: Klimaneutralität bis 2045|Bundesregierung. Available online: https://www.bundesregierung.de/breg-de/themen/klimaschutz/klimaschutzgesetz-2021-1913672 (accessed on 21 March 2022).

- Schmidt, A.; Köster, D.; Strube, J. Climate Neutrality Concepts for the German Chemical–Pharmaceutical Industry. Processes 2022, 10, 467. [Google Scholar] [CrossRef]

- Sinn, H. Das grüne Pardoxon; Weltbuch Verlag Gmbh: Dresden, Germany, 2020; ISBN 9783906212616. [Google Scholar]

- Saling, P. The BASF Eco-Efficiency Analysis: A 20-Year Success Story, 1st ed.; BASF SE Sustainability Strategy: Ludwigshafen, Germany, 2016; ISBN 9783000542732. [Google Scholar]

- Reiber, S. Verpatzte Chance; Spiegel: Hamburg, Germany, 2022; pp. 44–45. [Google Scholar]

- Ayompe, L.M.; Schaafsma, M.; Egoh, B.N. Towards sustainable palm oil production: The positive and negative impacts on ecosystem services and human wellbeing. J. Clean. Prod. 2021, 278, 123914. [Google Scholar] [CrossRef]

- Albert, C.; Hermes, J.; Neuendorf, F.; Von Haaren, C.; Rode, M. Assessing and Governing Ecosystem Services Trade-Offs in Agrarian Landscapes: The Case of Biogas. Land 2016, 5, 1. [Google Scholar] [CrossRef] [Green Version]

- Peters, D.; Ulber, R.; Wagemann, K. Bioraffinerien: Die deutsche Roadmap. Chem. Unserer Zeit 2014, 48, 46–59. [Google Scholar] [CrossRef]

- Geres, R.; Kohn, A.; Lenz, S.C.; Ausfelder, F.; Bazzanella, A.; Möller, A. Roadmap Chemie 2050: Auf dem Weg zu einer Treibhausgasneutralen Chemischen Industrie in Deutschland: Eine Studie von DECHEMA und FutureCamp für den VCI; DECHEMA Gesellschaft für Chemische Technik und Biotechnologie e.V: Frankfurt am Main, Germany, 2019; ISBN 978-3-89746-223-6. [Google Scholar]

- Zhang, C.; Xu, Y. Economic analysis of large-scale farm biogas power generation system considering environmental benefits based on LCA: A case study in China. J. Clean. Prod. 2020, 258, 120985. [Google Scholar] [CrossRef]

- Peters, M.S.; Timmerhaus, K.D.; West, R.E. Plant Design and Economics for Chemical Engineers, 5th ed.; McGraw-Hill: Boston, MA, USA, 2004; ISBN 978-0071240444. [Google Scholar]

- Woods, D.R. Rules of Thumb in Engineering Practice; John Wiley Distributor; Wiley-VCH: Chichester, UK; Weinheim, Germany, 2007; ISBN 978-3-527-31220-7. [Google Scholar]

- Green, D.W.; Southard, M.Z. Perry’s Chemical Engineers’ Handbook, 8th ed.; McGraw-Hill: New York, NY, USA, 2008; ISBN 0071422943. [Google Scholar]

- Lang, H.J. Simplified Approach to Preliminary Cost Estimates. Chem. Eng. 1948, 55, 112–113. [Google Scholar]

- Levi, P.G.; Cullen, J.M. Mapping Global Flows of Chemicals: From Fossil Fuel Feedstocks to Chemical Products. Environ. Sci. Technol. 2018, 52, 1725–1734. [Google Scholar] [CrossRef]

- Bazzanella, A.M.; Ausfelder, F. Low Carbon Energy and Feedstock for the European Chemical Industry: Technology Study; DECHEMA Gesellschaft für Chemische Technik und Biotechnologie e.V: Frankfurt am Main, Germany, 2017. [Google Scholar]

- Fleiter, T.; Rehfeldt, M. Langfristszenarien für die Transformation des Energiesystems in Deutschland 3: Treibhausgasneutrale Hauptszenarien; Modul Industrie: Karlsruhe, Germany, 2021. [Google Scholar]

- Agora Energiewende and Wuppertal Institute. Climate-Neutral Industry (Executive Summary): Key Technologies and Policy Options for Steel; Chemicals and Cement: Berlin, Germany, 2019. [Google Scholar]

- Dena. Leitstudie Integrierte Energiewende. 2018. Available online: https://www.dena.de/themen-projekte/projekte/energiesysteme/dena-leitstudie-integrierte-energiewende/ (accessed on 12 March 2022).

- Brandes, J.; Haun, M.; Wrede, D.; Jürgens, P.; Kost, C.; Henning, H.-M. Wege zu Einem Klimaneutralen Energiesystem: Die deutsche Energiewende im Kontext Gesellschaftlicher Verhaltensweisen. Update November 2021: Klimaneutralität 2045, Freiburg, Germany. 2021. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/Fraunhofer-ISE-Studie-Wege-zu-einem-klimaneutralen-Energiesystem-Update-Klimaneutralitaet-2045.pdf (accessed on 1 March 2022).

- Robinius, M.; Markewitz, P.; Lopion, P. Kosteneffiziente und klimagerechte Transformationsstrategien für das deutsche Energiesystem bis zum Jahr 2050. Int. Nucl. Inf. Syst. 2020, 52, 161. [Google Scholar]

- Hehn, N.; Miosga, M. Die Zukunft der Windenergie in Bayern nach Einführung der 10 H-Regel. Inf. Zur Raumentwickl. 2015, 6, 97–109. [Google Scholar]

- Nieder, T. Auswertungstabellen zur Energiebilanz in Deutschland. 2021. Available online: https://ag-energiebilanzen.de/wp-content/uploads/2020/09/awt_2020_d.pdf (accessed on 1 March 2022).

- Chemie Technik. Linde Will Weltgrößte Wasserstoff-Elektrolyseanlage auf PEM-Basis in Leuna Bauen und Betreiben. Available online: https://www.chemietechnik.de/anlagenbau/linde-will-weltgroesste-wasserstoff-elektrolyseanlage-auf-pem-basis-in-leuna-bauen-und-betreiben-123.html (accessed on 30 December 2021).

- Smolinka, T.; Wiebke, N.; Sterchele, P.; Lehner, F.; Jansen, M. Studie: IndWEDe Industrialisierung der Wasser elektrolyse in Deutschland: Chancen und Herausforderungen für nachhaltigen Wasserstoff für Verkehr, Strom und Wärme; NOW GmbH: Berlin, Germany, 2018. [Google Scholar]

- Department of Forestry, Fisheries and the Environment. Minister Molewa Together with SASOL and Air Liquide. Inaugurate World’s First Largest Oxygen Production Plant in Secunda. Available online: https://www.dffe.gov.za/events/department_activities/molewa_sasolairliquide_oxygenplant_secunda#:~%7B%7D:text=Introduction%20and%20background%20Air%20Liquide%20recently%20started%20the,to%205%2C800%20tonnes%20per%20day%20at%20sea%20level%29 (accessed on 11 March 2022).

- Thyssenkrupp Industrial Solutions AG. Thyssenkrupp uhde Advanced Ammonia Processes dual Pressure. Available online: https://de.slideshare.net/tswittrig/thyssenkrupp-uhde-advanced-ammonia-processes-dual-pressure?from_action=save%20:Thyssenkrupp%20Uhde%20slides (accessed on 22 December 2021).

- de Klerk, A. Greener Fischer-Tropsch Processes for Fuels and Feedstocks; Klerk, A.D., Maitlis, P.M., Eds.; Wiley-VCH: Weinheim, Germany, 2013; ISBN 9783527329458. [Google Scholar]

- Riedewald, F.; Patel, Y.; Wilson, E.; Santos, S.; Sousa-Gallagher, M. Economic assessment of a 40,000 t/y mixed plastic waste pyrolysis plant using direct heat treatment with molten metal: A case study of a plant located in Belgium. Waste Manag. 2021, 120, 698–707. [Google Scholar] [CrossRef] [PubMed]

- Karpf, R.H.; Bergins, C. CO2 Abscheidung als Wertstoff-Rueckgewinnung: Eine Symbiose fuer die Umwelt? Müll Und Abfall 2016, 5, 05. [Google Scholar]

- Bellmann, E.; Zimmermann, P. Klimaschutz in der Beton- und Zementindustrie: Hintergrund und Hanglungsoptionen 2019; WWF: Berlin, Germany, 2019. [Google Scholar]

- Vereinigung der Fernleitungsnetzbetreiber Gas, e.V. Wasserstoffnetz 2050: Für ein klimaneutrales Deutschland. Available online: https://fnb-gas.de/wasserstoffnetz/h2-netz-2050/ (accessed on 7 January 2022).

- Statista. Chemisch-pharmazeutische Industrie: Energieverbrauch bis 2019|Statista. Available online: https://de.statista.com/statistik/daten/studie/203419/umfrage/energieverbrauch-in-der-chemisch-pharmazeutischen-industrie-in-deutschland/#:~:text=Die%20Statistik%20zeigt%20den%20Energieverbrauch%20in%20der%20chemisch-pharmazeutischen,Chemieindustrie%20Energie%20in%20H%C3%B6he%20von%20rund%20666.300%20Terajoule (accessed on 8 January 2022).

- Cesaro, Z.; Ives, M.; Nayak-Luke, R.; Mason, M.; Bañares-Alcántara, R. Ammonia to power: Forecasting the levelized cost of electricity from green ammonia in large-scale power plants. Appl. Energy 2021, 282, 116009. [Google Scholar] [CrossRef]

- Fahnestock, J.; Søgaard, K.; Lawson, E.; Kilemo, H. NoGAPS: Nordic Green Ammonia Powered Ships; Global Maritime Forum: New York, NY, USA, 2021. [Google Scholar]

- NuStar. Pipeline Transportation of Ammonia: Helping to Bridge the Gap to a Carbon Free Future. Available online: https://www.ammoniaenergy.org/wp-content/uploads/2021/11/AEA-Ammonia-Pipeline-Transportation-MEA-11-4-2021.pdf (accessed on 14 March 2022).

- Nigbur, F.E. Ammoniak-Cracker zur Brenngasversorgung von Brennstoffzellen. Ph.D. Dissertation, Universität Duisburg-Essen, Duisburg, Germany, 21 September 2021. [Google Scholar]

- Engbaek, J. Ammonia cracker for Hydrogen Generation for PEM Application, 2008. In Proceedings of the Annual NH3 Fuel Conference, Pittsburgh, PA, USA, 31 October 2018. [Google Scholar]

- Giddey, S.; Badwal, S.P.S.; Munnings, C.; Dolan, M. Ammonia as a Renewable Energy Transportation Media. ACS Sustain. Chem. Eng. 2017, 5, 10231–10239. [Google Scholar] [CrossRef]

- Myers, D.B.; Ariff, G.D.; James, B.D.; Lettow, J.S. Cost and Performance Comparison of Stationary Hydrogen Fueling Appliances. In Proceedings of the 2002 U.S. DOE Hydrogen Program Review, Golden, CO, USA, 6–10 May 2002. [Google Scholar]

- Asgari, M.; Snisi, H.; Mohammadi, H.; Sadighi, S. Designing a commercial scale pressure swing adsorber for hydrogen purification. Pet. Coal 2014, 56, 552–561. [Google Scholar]

- Kordesch, K.; Hacker, V.; Frankhauser, R.; Falschini, G. Ammonia Cracker for Production of Hydrogen. PCT/US01/41387, 25 July 2001. [Google Scholar]

- Rais, A. Is CCUS the Future of Decarbonizing the Industry? Process Worldwide [Online]. 7 March 2022. Available online: https://www.process-worldwide.com/is-ccus-the-future-of-decarbonizing-the-industry-a-1100698/ (accessed on 14 March 2022).

- Axens. Bio Olefins|Axens. Available online: https://www.axens.net/markets/renewable-fuels-bio-based-chemicals/bio-olefins#:~:text=Ethylene%20is%20one%20of%20the%20most%20important%20building,green%20route%20via%20catalytic%20dehydration%20of%20renewable%20ethanol (accessed on 5 January 2022).

- Koutinas, A.A.; Vlysidis, A.; Pleissner, D.; Kopsahelis, N.; Lopez Garcia, I.; Kookos, I.K.; Papanikolaou, S.; Kwan, T.H.; Lin, C.S.K. Valorization of industrial waste and by-product streams via fermentation for the production of chemicals and biopolymers. Chem. Soc. Rev. 2014, 43, 2587–2627. [Google Scholar] [CrossRef]

- Brosowski, A.; Adler, P.; Erdmann, G.; Stinner, W.; Thrän, D.; Mantau, U. Biomassepotenziale von Rest- und Abfallstoffen: Status Quo in Deutschland; Fachagentur Nachwachsende Rohstoffe e.V. (FNR): Gülzow-Prüzen, Germany, 2015; ISBN 978-3-942147-29-3. [Google Scholar]

- Kintscher, L.; Lawrenz, S.; Poschmann, H. A Life Cycle Oriented Data-Driven Architecture for an Advanced Circular Economy. Procedia CIRP 2021, 98, 318–323. [Google Scholar] [CrossRef]

- Kardung, M.; Cingiz, K.; Costenoble, O.; Delahaye, R.; Heijman, W.; Lovrić, M.; van Leeuwen, M.; M’Barek, R.; van Meijl, H.; Piotrowski, S.; et al. Development of the Circular Bioeconomy: Drivers and Indicators. Sustainability 2021, 13, 413. [Google Scholar] [CrossRef]

- Römer, F.; Goldmann, D. Reprocessing of a mining waste deposit in the Harz mountains—How contaminated sites might become raw material deposits in the future. Chemkon 2019, 26, 66–71. [Google Scholar] [CrossRef]

- Jensch, C.; Schmidt, A.; Strube, J. Versatile Green Processing for Recovery of Phenolic Compounds from Natural Product Extracts towards Bioeconomy and Cascade Utilization for Waste Valorization on the Example of Cocoa Bean Shell (CBS). Sustainability 2022, 14, 3126. [Google Scholar] [CrossRef]

- Jensch, C.; Strube, J. Proposal of a New Green Process for Waste Valorization and Cascade Utilization of Essential Oil Plants. Sustainability 2022, 14, 3227. [Google Scholar] [CrossRef]

- Schmidt, A.; Uhlenbrock, L.; Strube, J. Technical Potential for Energy and GWP Reduction in Chemical–Pharmaceutical Industry in Germany and EU—Focused on Biologics and Botanicals Manufacturing. Processes 2020, 8, 818. [Google Scholar] [CrossRef]

- Brauers, H.; Braunger, I.; Jewell, J. Liquefied natural gas expansion plans in Germany: The risk of gas lock-in under energy transitions. Energy Res. Soc. Sci. 2021, 76, 102059. [Google Scholar] [CrossRef]

- Kurmayer, N.J. Germany Signs Initial Contract to Build First LNG Terminal. EURACTIV [Online]. 7 March 2022. Available online: https://www.euractiv.com/section/energy/news/germany-signs-first-stage-contract-to-build-first-lng-terminal (accessed on 22 March 2022).

- Weiss, R. Germany Opens Door to Qatar Natural Gas in Pivot From Russia. Bloomberg [Online]. 20 March 2022. Available online: https://www.bloomberg.com/news/articles/2022-03-20/germany-reaches-deal-to-buy-qatari-gas-in-pivot-from-russia (accessed on 22 March 2022).

- Al-Breiki, M.; Bicer, Y. Comparative cost assessment of sustainable energy carriers produced from natural gas accounting for boil-off gas and social cost of carbon. Energy Rep. 2020, 6, 1897–1909. [Google Scholar] [CrossRef]

- Wang, Y. Energy Efficiency and Emissions Analysis of Ammonia, Hydrogen, and Hydrocarbon Fuels. J. Energy Nat. Resour. 2018, 7, 47. [Google Scholar] [CrossRef]

- Li, J.; Lai, S.; Chen, D.; Wu, R.; Kobayashi, N.; Deng, L.; Huang, H. A Review on Combustion Characteristics of Ammonia as a Carbon-Free Fuel. Front. Energy Res. 2021, 9, 822. [Google Scholar] [CrossRef]

- Kurata, O.; Iki, N.; Fan, Y.; Matsunuma, T. Pure Ammonia Combustion Micro Gas Turbine. In Proceedings of the 2019 AIChE Annual Meeting, Orlando, FL, USA, 10–15 November 2019. [Google Scholar]

- German National Academy of Sciences Leopoldina; Union of the German Academies of Sciences and Humanities e. V. Centralized and Decentralized Components in the Energy System: The Right Mix for Ensuring A Stable and Sustainable Supply; Laser Line GmbH: Berlin, Germany, 2020; ISBN 978-3-8047-4061-7. [Google Scholar]

- Uniper Plans to Make Wilhelmshaven a Hub for Climate friendly Hydrogen. Uniper [Online]. 14 April 2021. Available online: https://www.uniper.energy/news/uniper-plans-to-make-wilhelmshaven-a-hub-for-climate-friendly-hydrogen (accessed on 27 April 2022).

- GETEC unterzeichnet Abkommen für die Nutzung von Sauberem Wasserstoff aus den VAE|CHEManager. Available online: https://www.chemanager-online.com/news/getec-unterzeichnet-abkommen-fuer-die-nutzung-von-sauberem-wasserstoff-aus-den-vae (accessed on 27 April 2022).

- Göbelbecker, J. Getec Unterzeichnet Kooperationsabkommen für Grünen Wasserstoff. CHEMIE TECHNIK [Online]. 22 March 2022. Available online: https://www.chemietechnik.de/energie-utilities/getec-unterzeichnet-kooperationsabkommen-fuer-gruenen-wasserstoff-161.html (accessed on 22 March 2022).

- Mitsubishi Power. Mitsubishi Power|Mitsubishi Power Commences Development of World’s First Ammonia-fired 40 MW Class Gas Turbine System—Targets to Expand Lineup of Carbon-free Power Generation Options, with Commercialization around 2025. Available online: https://power.mhi.com/news/20210301.html (accessed on 18 March 2022).

- Institute for Sustainable Process Technology. Power to Ammonia: Feasibility Study for the Value Chains and Business Cases to Produce Co2-Free Ammonia Suitable for Various Market Applications. 2017. Available online: https://www.topsectorenergie.nl/sites/default/files/uploads/Energie%20en%20Industrie/Power%20to%20Ammonia%202017.pdf (accessed on 18 March 2022).

- Ammonia Cracker. Available online: https://samgasprojects.com/detail/ammonia-cracker.html (accessed on 18 March 2022).

- Luedicke, R. Ammonia Cracker, Hydrogen Generator. Available online: https://www.crystec.com/kllhyame.htm (accessed on 18 March 2022).

- Projekt NH3toH2. Available online: https://www.uni-due.de/energietechnik/de/pro_nh3toh2 (accessed on 18 March 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).