Airflow Distributions in a Z Type Centripetal Radial Flow Reactor: Effects of Opening Strategy and Opening Rate

Abstract

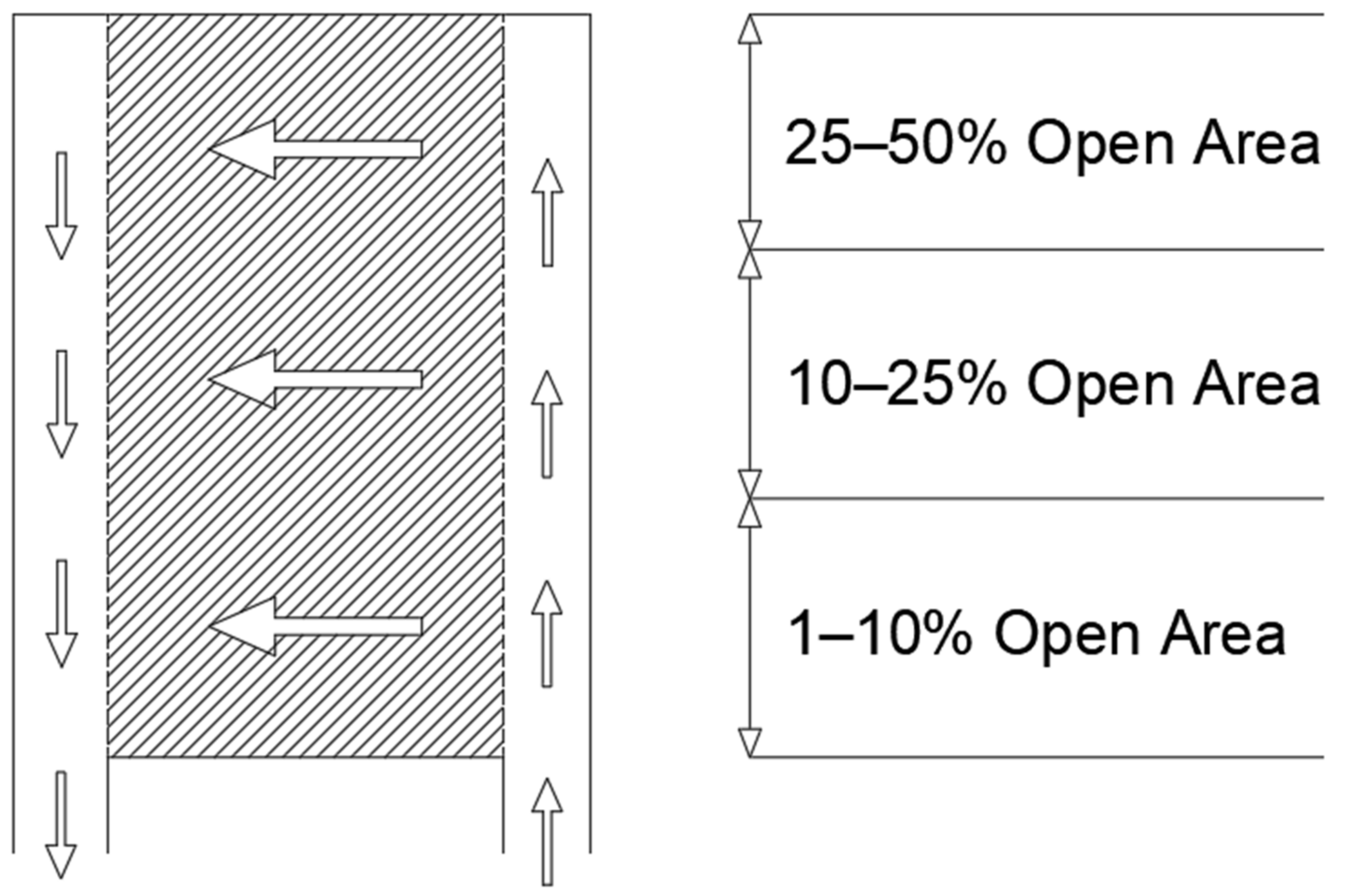

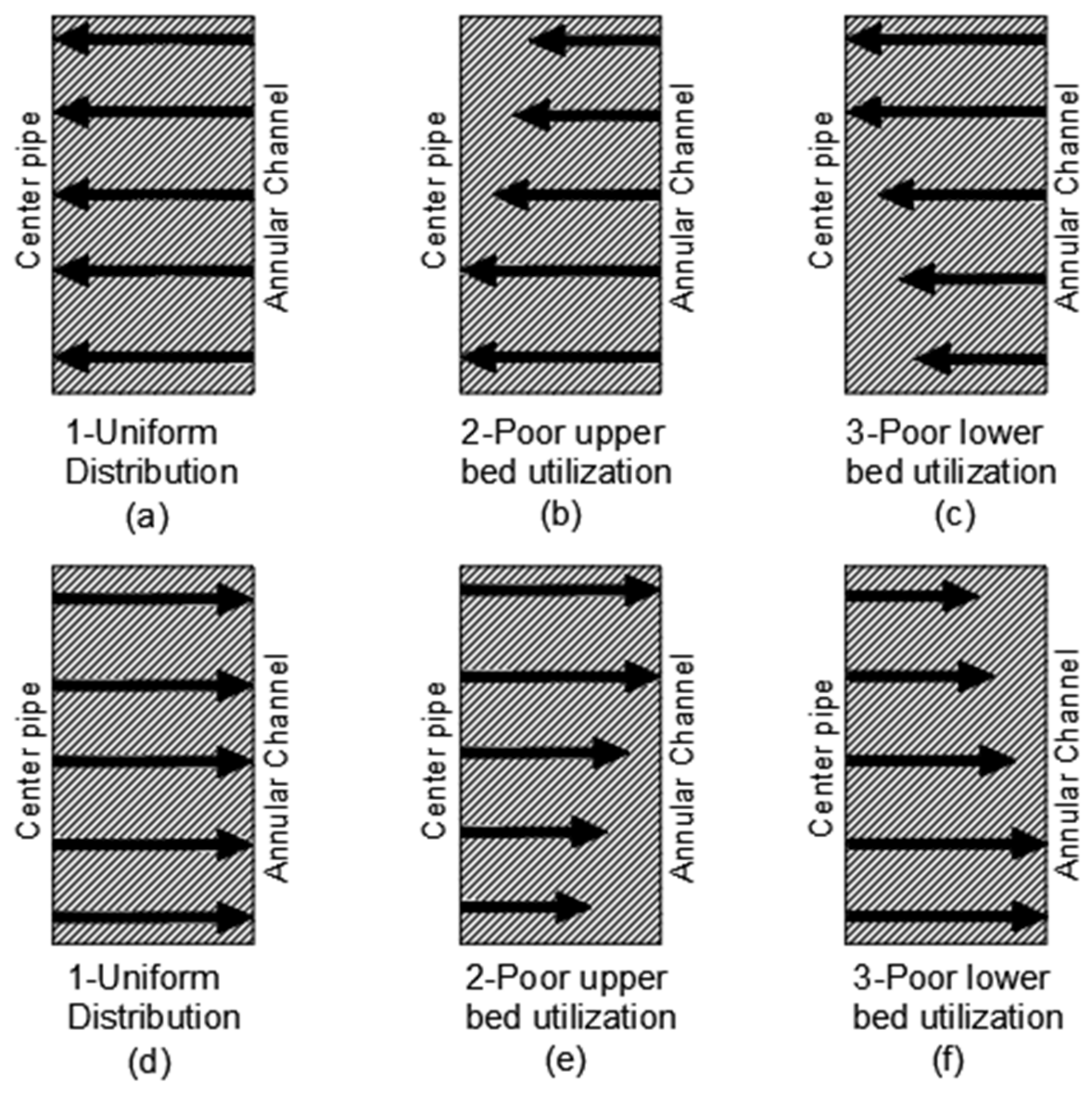

:1. Introduction

2. Simulation for a CP-Z-Type RFBR

2.1. Numerical Model

- (1)

- Continuity equation:

- (2)

- Momentum equation:From the equation above, S is the source term which in this study are using one other model that is porous media model. The porous media model is used for the catalyst bed.For the catalyst bed:In Equation (3), is the permeability and is the inertial resistance factor. Ergun equation, a semi-empirical correlation equation applicable over a wide range of Reynolds numbers has been used, and can be represented as:where the porosity of the catalyst bed is represented as and is the average diameter of the catalyst. In this simulation, the bed porosity and catalyst average diameter are assumed to be 0.38 and 4.6 mm, respectively.

- (3)

- k-ε equation:In the formula, represents the generation of turbulent kinetic energy due to the average velocity gradient; is the generation of turbulent kinetic energy due to the influence of buoyancy; , , , k and ε are all constants.

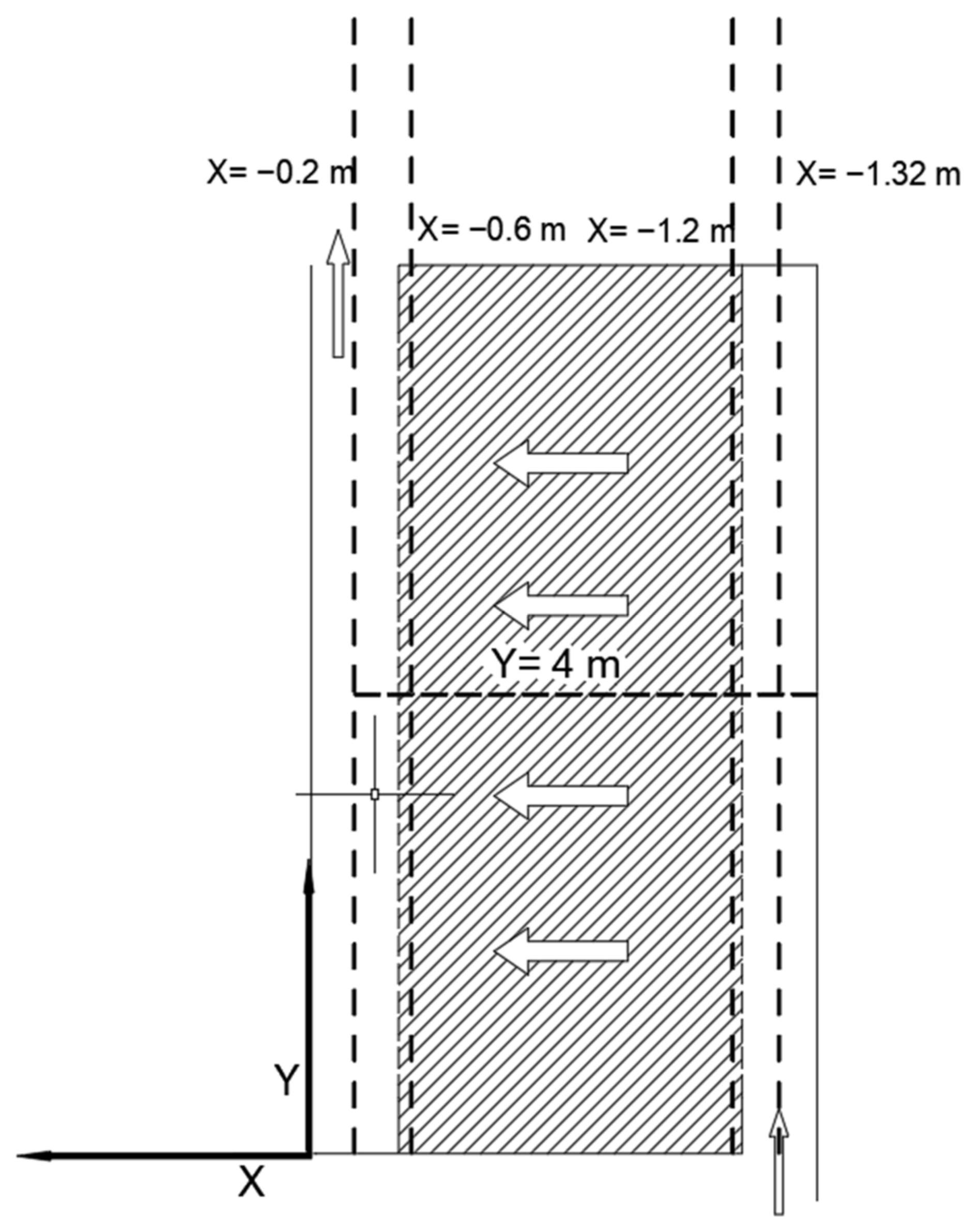

2.2. Geometrical Model

2.3. Assumptions and Boundary Conditions

- (1)

- The three-dimensional model will retain a 1/32 fan-shaped computing domain;

- (2)

- There is no temperature change during gas flow;

- (3)

- Feed gas is assumed to be an incompressible ideal gas;

- (4)

- The Y+ value is 30;

- (5)

- The viscous model was used as a standard k-epsilon with enhanced wall function.

3. Simulation Results and Discussion

3.1. Mesh Independence Test

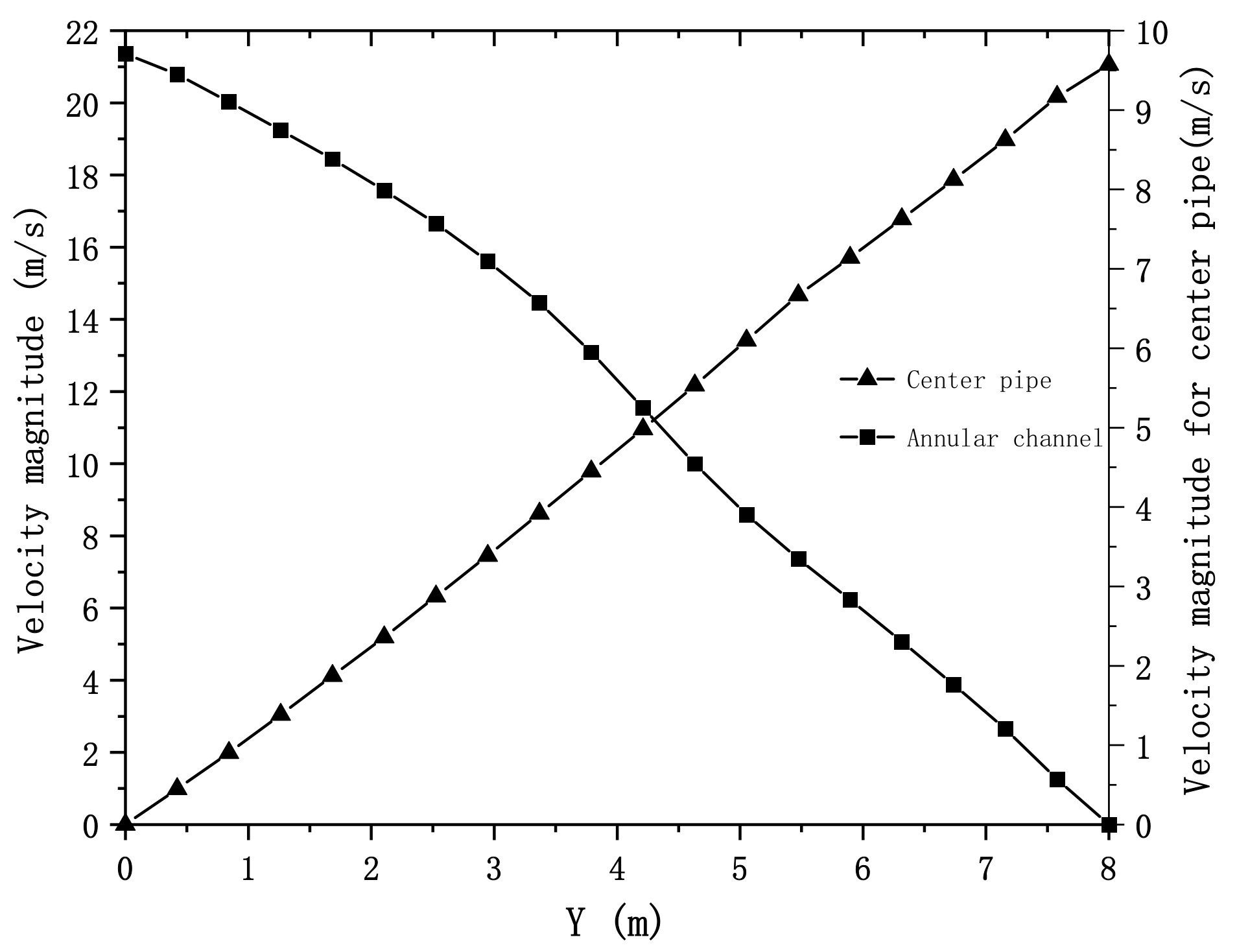

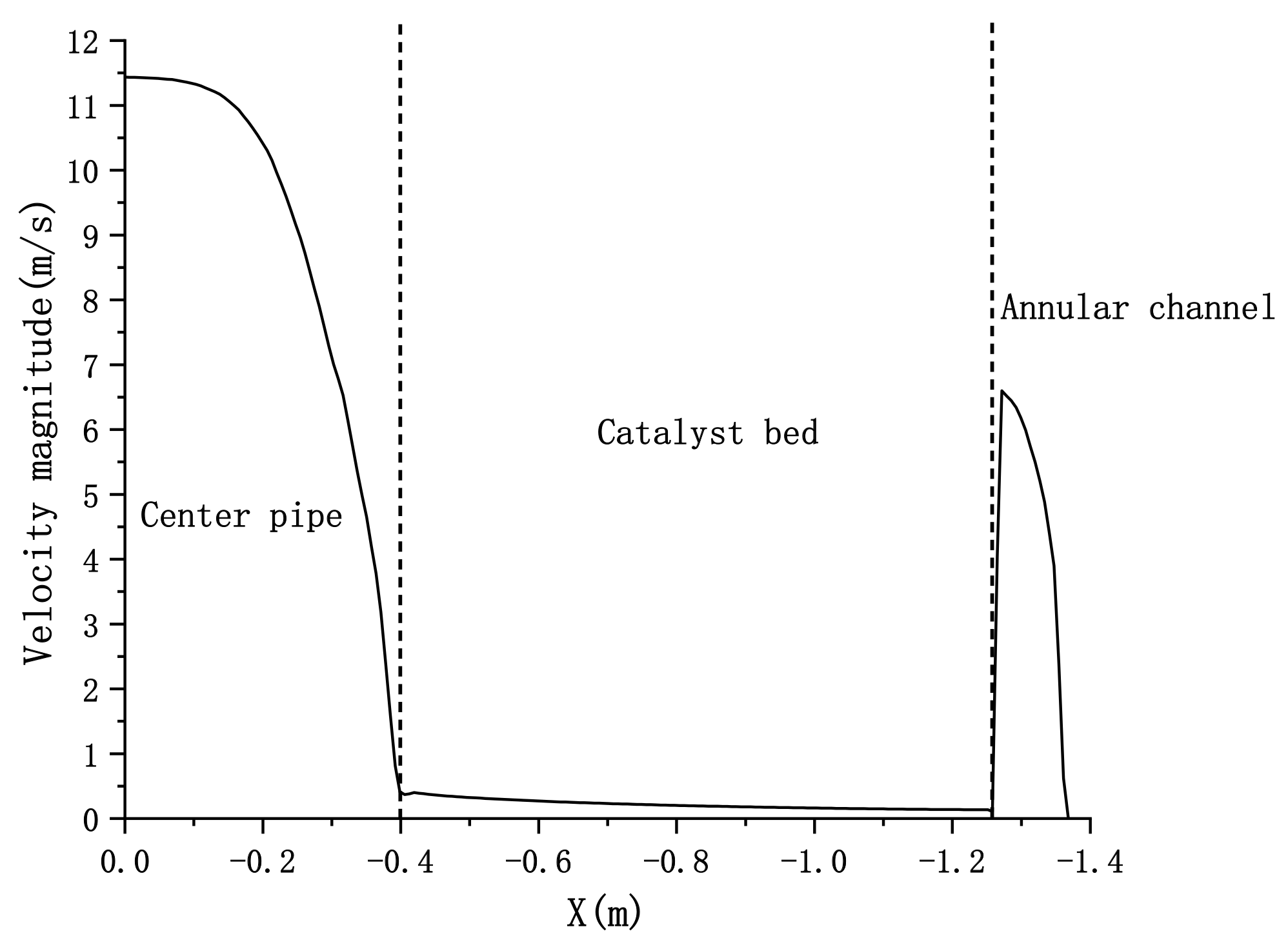

3.2. Radial Velocity Magnitude Result

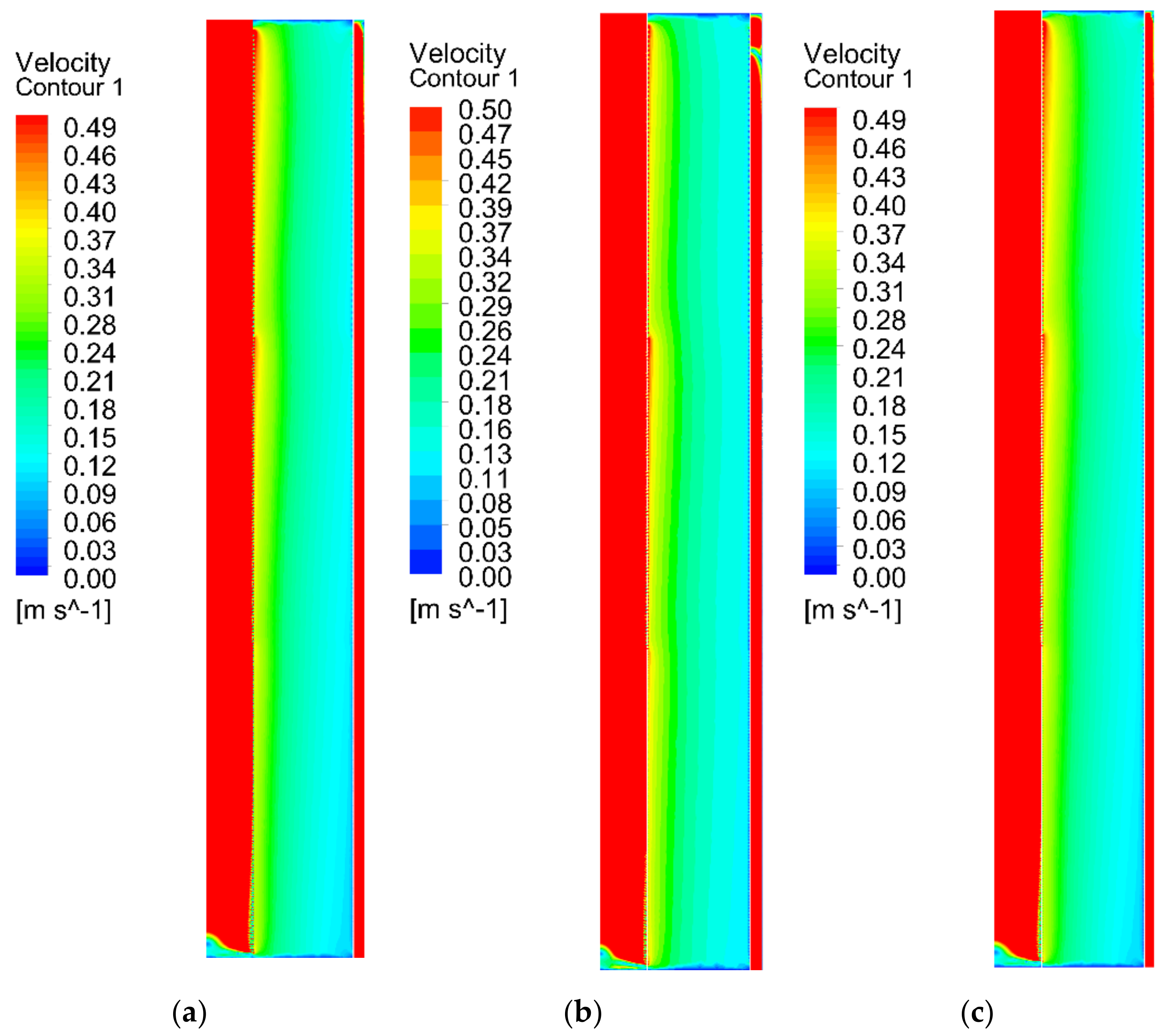

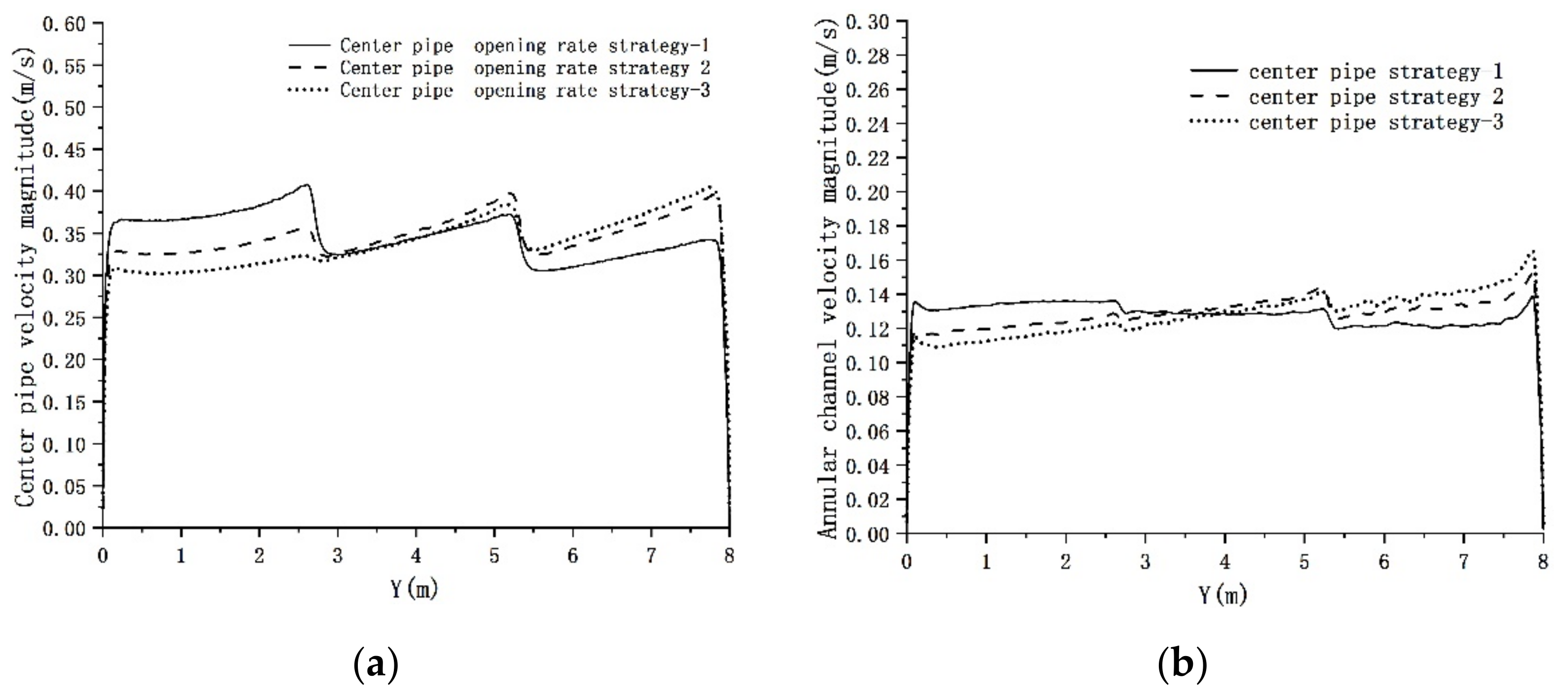

3.2.1. Flow Distribution Result

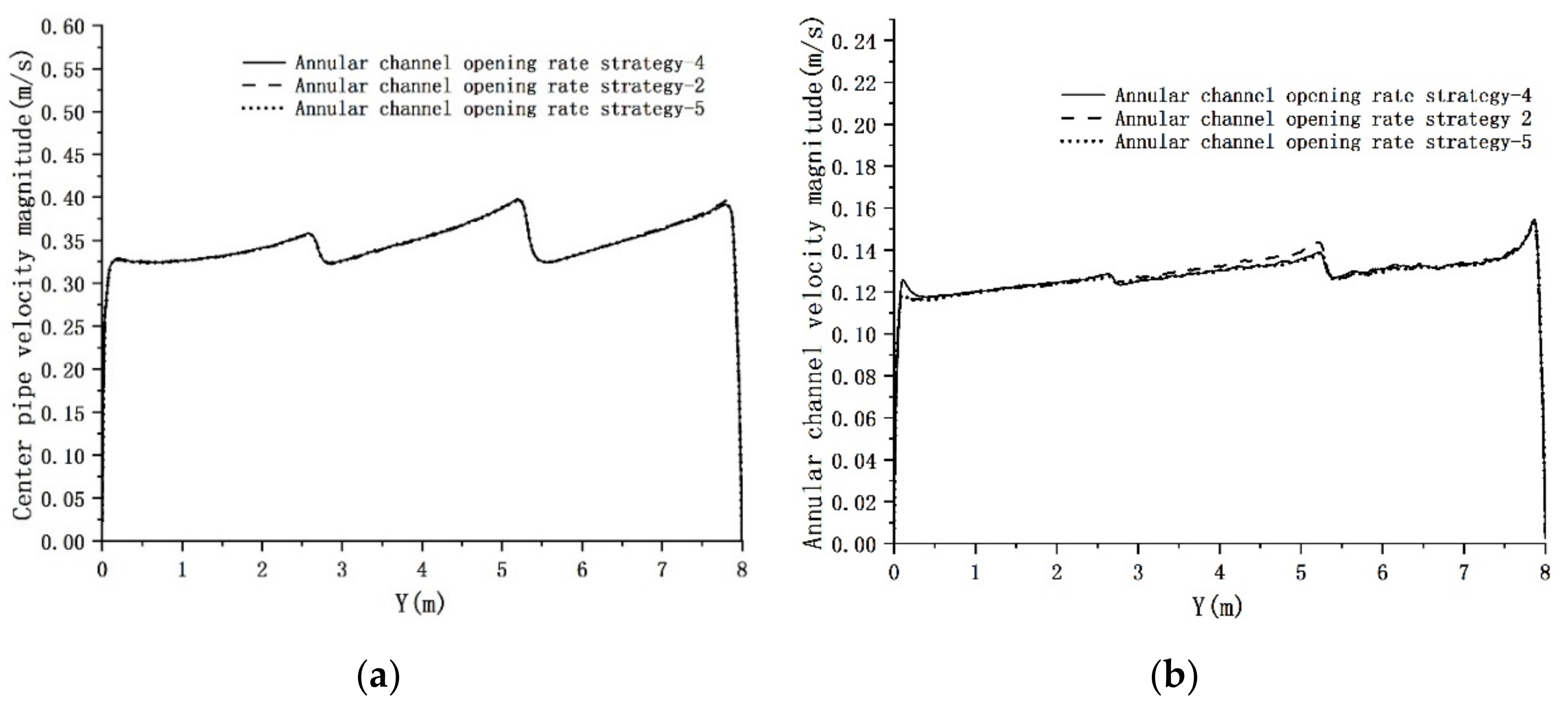

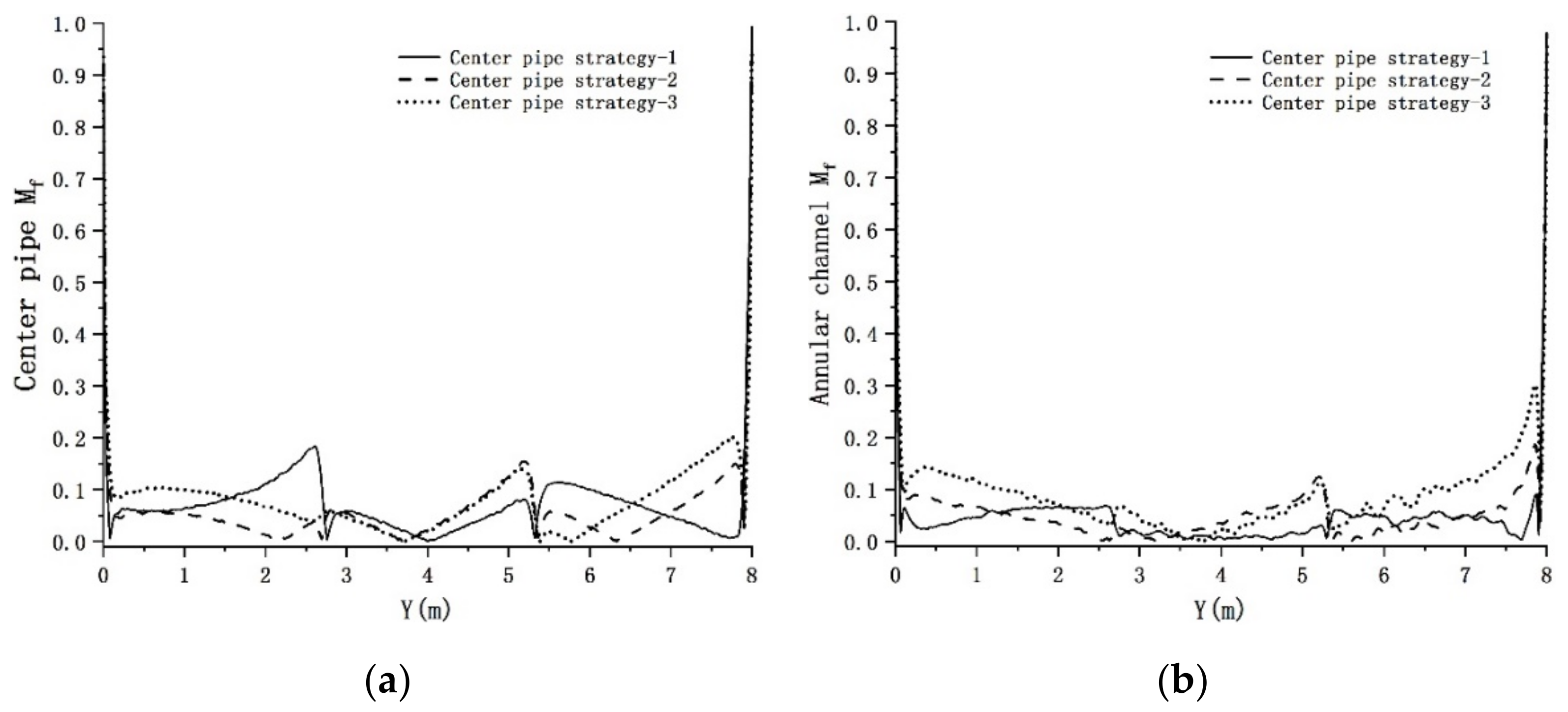

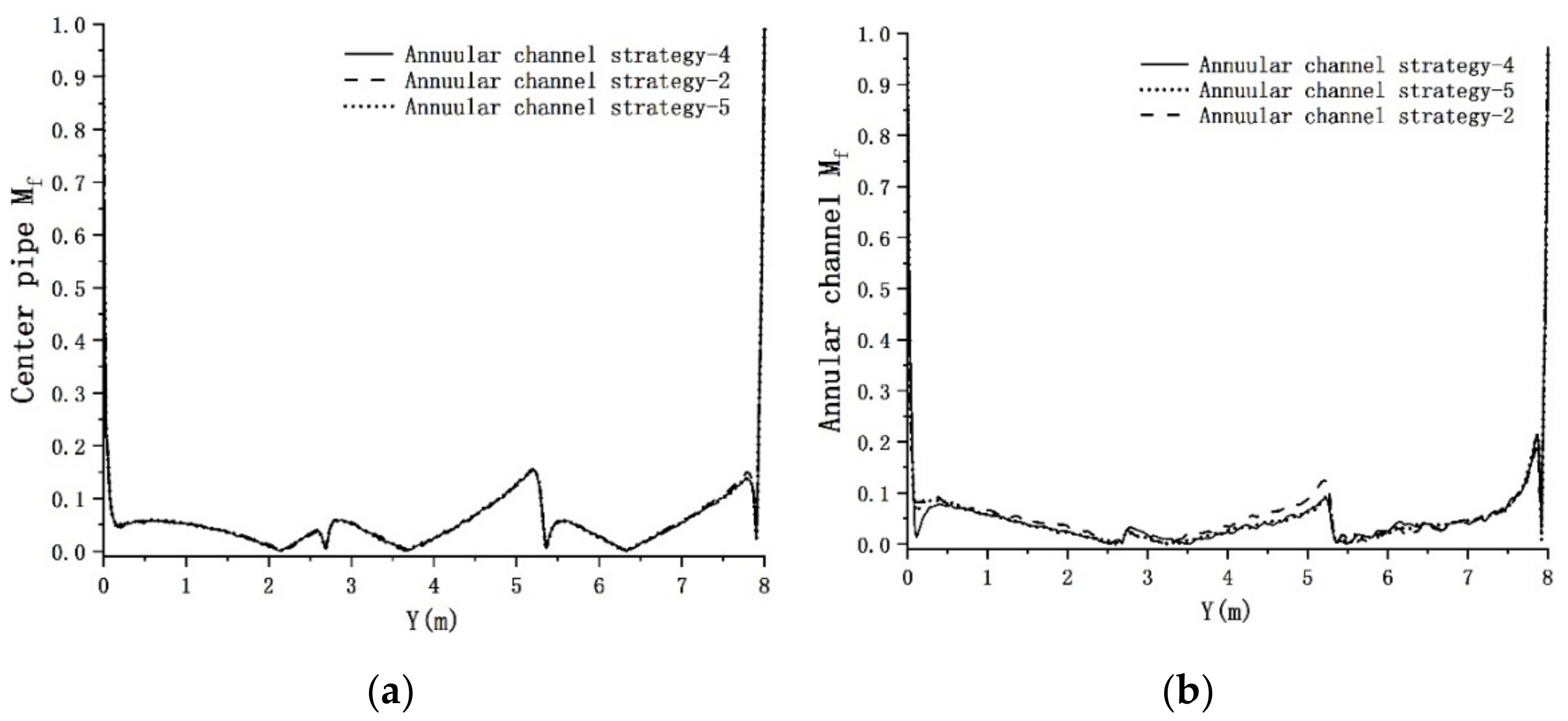

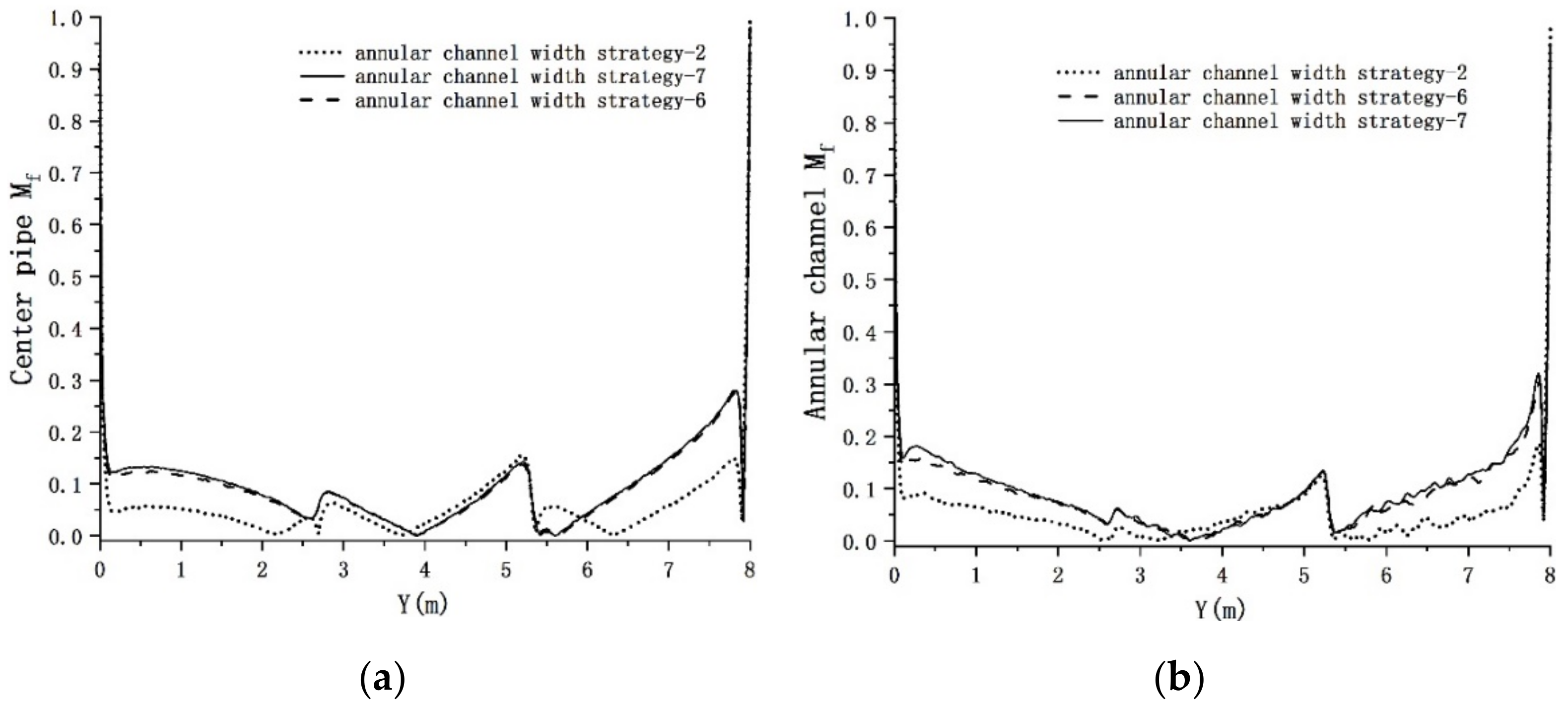

3.2.2. Flow Distribution Result

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, H.; Lin, X.; Xia, H. Development of vertical radial flow adsorbers for air separation plants. Hangyang Technol. 2015, 3, 13–19. [Google Scholar]

- Lu, J.L. Research on the Mechanism of Fluid Flow in a Radial Flow Adsorber. Ph.D. Thesis, Zhejiang University, Zhejiang, China, 2014. [Google Scholar]

- Epiepang, F.E.; Li, J.; Liu, Y.; Yang, R.T. Low-pressure performance evaluation of CO2, H2O and CH4 on Li-LSX as a superior adsorbent for air pre-purification. Chem. Eng. Sci. 2016, 147, 100–108. [Google Scholar] [CrossRef]

- Kapoor, A.; Yang, R.T. Roll-up in fixed-bed, multicomponent adsorption under pore-diffusion limitation. AIChE J. 1987, 33, 1215–1217. [Google Scholar] [CrossRef]

- Hlaváček, V.; Kubíček, M. Modeling of chemical reactors—XXV Cylindrical and spherical reaction with radial flow. Chem. Eng. Sci. 1972, 27, 177–186. [Google Scholar] [CrossRef]

- Calo, J.M. Cell model studies of radial flow, fixed bed reactors. In Chemical Reaction Engineering; American Chemical Society: Washington, DC, USA, 1978; pp. 550–561. [Google Scholar] [CrossRef]

- Balakotaiah, V.; Luss, D. Effect of flow direction on conversion in isothermal radial flow fixed-bed reactors. AIChE J. 1981, 27, 442–450. [Google Scholar] [CrossRef]

- Ponzi, P.R.; Kaye, L.A. Effect of flow maldistribution on conversion and selectivity in radial flow fixed-bed reactors. AIChE J. 1979, 25, 100–108. [Google Scholar] [CrossRef]

- Chu, L.; Wang, J.; Meng, Q.; Su, J. Analysis of Flow Filed of Radial Flow Molecular Sieve Adsorber Under Different Flow Rates. Low Temp. Spec. Gases 2014, 32, 17–20. [Google Scholar] [CrossRef]

- Miao, Z.; Pan, M. Application of Fluent software in the simulation of radial adsorber flow field. Chem. Manag. 2013, 10, 240–241. [Google Scholar]

- Li, J.; Zhou, H.; Lin, X. Numerical simulation of flow field in radial flow molecular sieve adsorber. Cryog. Technol. 2010, 2, 49–52. [Google Scholar]

- Lobanov, E.L.; Skipin, Y.A. Increasing the operating efficiency of radial reactors in reforming. Chem. Technol. Fuels Oils 1987, 22, 275–278. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Lu, J.; Qiu, L.; Zhang, X.; Sun, D. Fluid flow characteristics and structural parameter optimization of radial flow adsorber. CIESC J. 2014, 65, 3395–3402. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, Z.; Xu, M.; Zhu, B. Research on uniform fluid distribution design of radial reactor (I). Chem. Eng. 1980, 1, 98–112, 97. [Google Scholar]

- Zhang, C.; Zhu, Z.; Xu, M.; Zhu, B. Research on uniform fluid distribution design of radial reactor (II). Chem. Eng. 1980, 2, 82–89, 35. [Google Scholar]

- Zhu, Z.; Zhang, C.; Xu, M. Design parameters for uniform fluid distribution in momentum exchange radial reactors. Chem. Eng. 1983, 5, 48–58. [Google Scholar]

- Xu, M. Study on the hydrodynamic characteristics of radial flow reactor. CIESC J. 1990, 41, 181–186. [Google Scholar]

- Kareeri, A.A.; Zughbi, H.D.; Al-Ali, H.H. Simulation of Flow Distribution in Radial Flow Reactors. Ind. Eng. Chem. Res. 2006, 45, 2862–2874. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Meng, Y. The influence of the gas distribution system structure of the radial flow adsorber on the gas distribution effect. Chin. J. Eng. Sci. 2015, 37, 238–242. [Google Scholar] [CrossRef]

- Li, Y.; Si, H.; Wang, B.; Xue, L.; Wu, X. Optimization design research of air flow distribution in vertical radial flow adsorbers. Korean J. Chem. Eng. 2018, 35, 835–846. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.; Si, H.; Wang, B.; Wang, H.; Shen, Y.; Qin, Z. Numerical investigation into the distributor design in radial flow adsorber. Adv. Appl. Math. Mech. 2019, 11, 1436–1460. [Google Scholar]

- Celik, C.E.; Smolarek, J. Radial Bed Flow Distributor for Radial Pressure Adsorber Vessel. U.S. Patent 7,128,775, 31 October 2006. [Google Scholar]

| Dimensions | Dr | Da | Dcp | Lb | Ls1 | Ls2 | Lat | Lct | Dat | Dct |

| Values (mm) | 2736 | 2536 | 800 | 8000 | 100 | 50 | 8 | 10 | 10 | 8 |

| Operating Condition | ) | Catalyst Bed Porosity | Catalyst Average Diameter (mm) | Feed Gas Material |

| Values | 2.78 | 0.38 | 4.6 | Air |

| Changing Center Pipe Opening Rate | |||||||

| Central channel pore opening ratio | Annular channel pore opening ratio | Annular channel width (mm) | |||||

| up | middle | down | up | middle | down | ||

| Strategy 1 | 7% | 10% | 20% | 10% | 21% | 34% | 100 |

| Strategy 2 | 10% | 16% | 29% | 10% | 21% | 34% | 100 |

| Strategy 3 | 15% | 25% | 34% | 10% | 21% | 34% | 100 |

| Changing Annular Channel Opening Rate | |||||||

| Center pipe opening ratio | Annular channel opening ratio | Annular channel width (mm) | |||||

| up | middle | down | up | middle | down | ||

| Strategy 4 | 10% | 16% | 29% | 8% | 20% | 30% | 100 |

| Strategy 2 | 10% | 16% | 29% | 10% | 21% | 34% | 100 |

| Strategy 5 | 10% | 16% | 29% | 12% | 25% | 40% | 100 |

| Changing Annular Width | |||||||

| Center pipe opening ratio | Annular channel opening ratio | Annular channel width (mm) | |||||

| up | middle | down | up | middle | down | ||

| Strategy 2 | 10% | 16% | 29% | 10% | 21% | 34% | 100 |

| Strategy 6 | 10% | 16% | 29% | 10% | 21% | 34% | 90 |

| Strategy 7 | 10% | 16% | 29% | 10% | 21% | 34% | 80 |

| Non-Uniformity | Annular Channel | Center Pipe |

| Strategy 1 | 0.0114 | 0.0384 |

| Strategy 2 | 0.0124 | 0.035 |

| Strategy 3 | 0.0156 | 0.0385 |

| Strategy 4 | 0.012 | 0.0348 |

| Strategy 5 | 0.0118 | 0.0348 |

| Strategy 6 | 0.0154 | 0.0441 |

| Strategy 7 | 0.0165 | 0.0466 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Y.; Zhang, C.; Wang, H.; Li, Z.; Liu, Y. Airflow Distributions in a Z Type Centripetal Radial Flow Reactor: Effects of Opening Strategy and Opening Rate. Processes 2022, 10, 1250. https://doi.org/10.3390/pr10071250

Xing Y, Zhang C, Wang H, Li Z, Liu Y. Airflow Distributions in a Z Type Centripetal Radial Flow Reactor: Effects of Opening Strategy and Opening Rate. Processes. 2022; 10(7):1250. https://doi.org/10.3390/pr10071250

Chicago/Turabian StyleXing, Yuchen, Chuanzhao Zhang, Haoyu Wang, Ziyi Li, and Yingshu Liu. 2022. "Airflow Distributions in a Z Type Centripetal Radial Flow Reactor: Effects of Opening Strategy and Opening Rate" Processes 10, no. 7: 1250. https://doi.org/10.3390/pr10071250

APA StyleXing, Y., Zhang, C., Wang, H., Li, Z., & Liu, Y. (2022). Airflow Distributions in a Z Type Centripetal Radial Flow Reactor: Effects of Opening Strategy and Opening Rate. Processes, 10(7), 1250. https://doi.org/10.3390/pr10071250