1. Introduction

China, the world’s largest emitter of carbon, emitted about 10.2 billion tons of carbon in 2020, accounting for about one-third of global carbon emissions [

1]. To respond to the severe need for carbon emission reduction, China, in 2020, formally proposed the strategic goals of carbon peaking by 2030 and carbon neutrality by 2060. As a pillar industry of China’s national economy, the manufacturing industry occupies an important position in the nation’s socio-economic development [

2], but it is worth noting that the development strategies of many manufacturing enterprises in China are energy-intensive and highly polluting, and the rapid economic growth they bring is often at the cost of serious environmental pollution and ecological damage [

3]. Constantly promoting green and low-carbon innovation in manufacturing [

4] and low-carbon manufacturing [

5] has become the mainstream trend of the future development of manufacturing.

The sharing economy, which originates from non-ownership and more efficient use of resources, profoundly changing traditional ways of conducting business and production and consumption systems around the world [

6,

7], provides a new direction for the transformation and development of traditional manufacturing industries [

8], which has been named shared manufacturing. Shared manufacturing socializes the reuse of idle manufacturing resources that become sunk costs and can reduce the environmental load by inhibiting new production and efficient use of products [

9]. Shared manufacturing has received much attention and discussion due to its “positive side effects” [

10] in terms of reducing the environmental footprint [

11], reducing carbon emissions [

12], promoting environmental sustainability, and driving new trends in green practices [

13], and is seen as the answer to sustainability challenges [

14].

Shared manufacturing not only brings new opportunities to manufacturing companies but also brings many operational and management challenges [

15]. As a new manufacturing model, shared manufacturing has not yet truly formed a development model that takes into account the quality and efficiency of development and focuses on the efficient use of resources and comprehensive environmental protection [

16]. As “economic actors” pursuing their own interests [

17], enterprises are always faced with the dilemma of “economic development and environmental protection”. Shared manufacturing still has challenges such as insufficient supply quality, uncertain product quality [

6], unpredictable service quality [

18], and poor service quality control [

19]. The poor sustainability of a quality input mode and low level of quality impede its role in supporting the transformation and development of the manufacturing industry.

Scholars have conducted extensive research on how to improve manufacturing quality levels based on game theory. Liu et al. constructed a three-party evolutionary game model of shared manufacturing for manufacturing enterprises under the government regulation mechanism and studied the impact of government regulation on the quality of shared manufacturing supply [

8]; Wang et al. built an evolutionary game model from the perspective of a group to observe different manufacturing service allocation trends, finding that manufacturing service allocation plays an important role in promoting high-quality service management [

20]; and Ehsan et al. developed a fair service combination model in cloud manufacturing based on game theory and studied the strategy to improve the service quality level [

21]. Other scholars have also explored quality improvement paths in manufacturing from multiple perspectives, including quality cost sharing [

22], responsibility cost sharing [

23], profit allocation [

24], and supply–demand balance [

25]. The aforementioned studies provide a certain theoretical basis for the present research, but they are all based on external means such as resource allocation and government supervision, and do not fundamentally solve the problems of low quality and poor sustainability of quality investment.

Studies have confirmed that human information processing, decision making, and behavior are largely influenced and guided by emotions and sentiments [

26], and the emotional attitudes of shared manufacturing participants toward quality improvement can profoundly affect shared practices. This paper combined the rank-dependent expected utility (RDEU) theory with evolutionary games to establish an evolutionary game model that considers participants’ emotions, and studied the impact of the heterogeneous emotions of each participant on the improvement of shared manufacturing quality.

Compared with previous studies, the main contributions and innovations of this paper are as follows.

- (1)

In terms of content, compared with traditional research perspectives such as factor input and external regulation, this paper innovatively explored the impact of participant emotions on the improvement of shared manufacturing quality from the perspective of participants’ heterogeneous emotions. The research content of this paper may help to broaden the path of quality improvement.

- (2)

In terms of method, due to the differences in the values and interests of decision makers, there are different psychological preferences, emotions, and risk attitudes of decision makers, which profoundly affect their behavioral decisions. Traditional game analysis methods cannot effectively explain the different psychological preferences and emotions of decision makers due to their limitations. This paper combined the rank-dependent expected utility (RDEU) theory with evolutionary games, which enriches evolutionary game theory and its applications to a certain extent.

The rest of this article is organized as follows.

Section 1 introduces the research background and research question.

Section 2 reviews the relevant literature and briefly introduces the innovative points of this paper.

Section 3 presents the theoretical assumptions.

Section 4 introduces the main models from three aspects: main research questions, parameter assumptions, and model construction. In

Section 5, the strategy stability and strategy combination stability of the game model are analyzed. The main content of

Section 6 is the simulation analysis.

Section 7 includes research conclusions and managerial implications.

3. Theoretical Assumptions

The RDEU theory, first proposed by Quiggin [

53], is a utility theory that considers the psychological preferences and emotions of decision makers. Under the conditions of decision uncertainty as well as high randomness [

54], a real-valued function defined by a utility function and a decision weight function are used to characterize the degree of decision makers’ preferences for different decisions [

55].

The function expression is:

For the set of strategies , . Assuming that the strategies are ranked according to the magnitude of the utility function and specifying , the utility rank of the strategy is defined as , and then the probability distribution function of the strategy is . The greater the utility of the strategy, the greater its cumulative probability, and accordingly, the greater the weight of the strategy utility in the decision.

At this point, the decision weight function , where is the sentiment function, which is a monotonically increasing function satisfying .

The function is used for the possibility of to be enlarged or reduced.

There are three cases as follows.

- (1)

When , is a concave function, for any , narrows the possibility of , indicating the pessimism of the participants.

- (2)

When, is a convex function, for any , widens the possibility of , indicating the optimism of the participants.

- (3)

When , the possibility is unchanged, indicating a rational mood among participants.

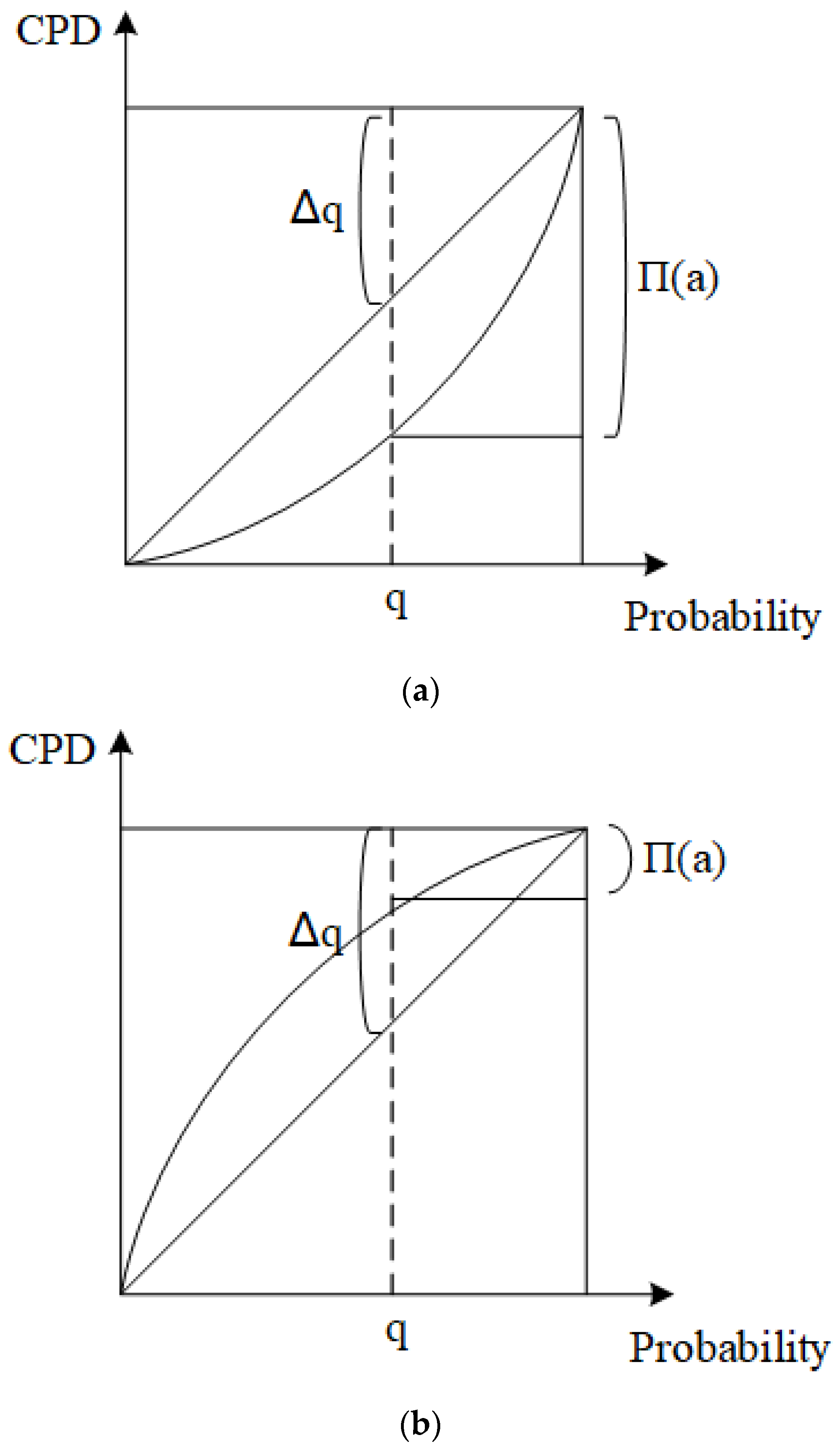

As shown in

Figure 1, CPD denotes the cumulative probability distribution,

Figure 1a represents the utility function diagram of the decision maker under pessimism, and

Figure 1b displays the utility function diagram of the decision maker under optimism.

The RDEU theory treats decision weights in a nonlinear way by extending the utility theory (EU) in traditional game theory in a nonlinear way. This approach can positively portray the emotion of game participants under the uncertainty condition both theoretically and practically, and therefore, the RDEU theory can overcome the shortage of traditional game theory in the attitude dimension to a certain extent, and the evolutionary game analysis integrating this theory can also more objectively and accurately portray the emotional state of each participant in shared manufacturing and the influence of their emotional intensity on behavioral decisions.

6. Simulation Analysis

To reveal the evolution of a shared manufacturing supply chain and shared platform more intuitively, MATLAB

™ was used for simulation and analysis. Herein, the typical benchmark enterprise of shared manufacturing in China, the Mold Lao crowd space, was taken as an example, with the parameters were set with reference to the literature [

20,

25], and specific parameter settings are listed in

Table 9.

Section 5 analyzes the stability of strategy combinations of shared manufacturing supply chains and shared platforms in four contexts, (rational, rational), (emotional, emotional), (rational, emotional), and (emotional, rational), based on the different emotional states of shared manufacturing supply chains and shared platforms. More specifically, when the game subject is in an emotional state, its emotional state can be further subdivided into optimistic and pessimistic, and different emotional states have different effects on strategy choice. Based on the above parameter settings, this section further analyzes the evolutionary stability of the system under nine specific scenarios of (rational, rational), (optimistic, optimistic), (pessimistic, pessimistic), (optimistic, pessimistic), (pessimistic, optimistic), (optimistic, rational), (pessimistic, rational), (rational, optimistic), (rational, optimistic), and (rational, pessimistic) on the basis of the above four scenarios.

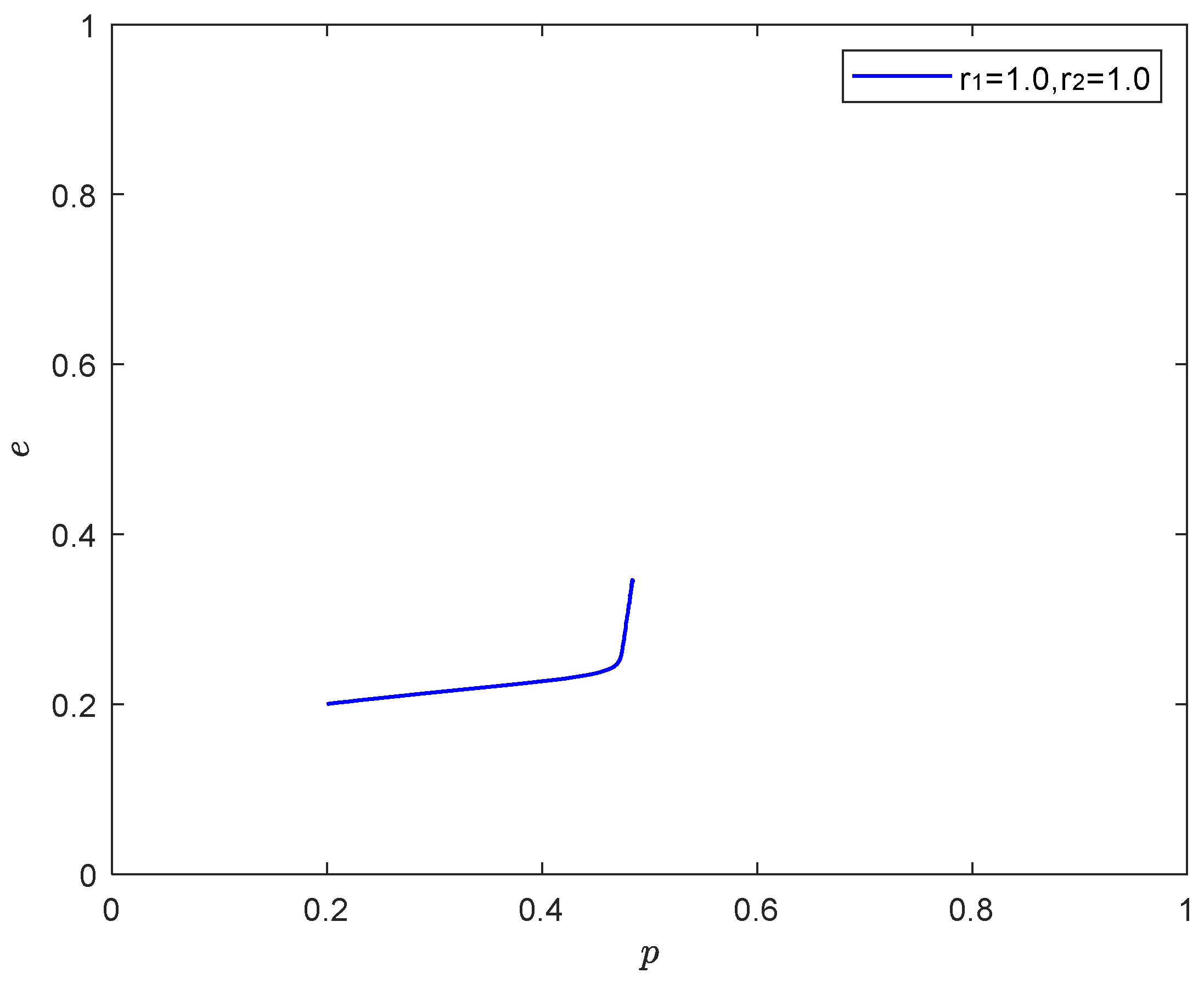

6.1. (Rational, Rational) State Analysis

Figure 3 reflects the equilibrium strategy when the shared manufacturing supply chain is rational and the shared platform is rational. When

, the game has a mixed strategy Nash equilibrium. This is consistent with the results presented in

Section 4.2. In terms of the action probabilities of the shared manufacturing supply chain and the shared platform, the probabilities of the shared manufacturing supply chain quality innovation synergy and the shared platform regulation were both low, where the shared manufacturing supply chain quality innovation synergy was between 0.2 and 0.4, while the shared platform was slightly higher than the probability of the shared manufacturing supply chain choosing the positive action because the shared platform needs to take some regulatory responsibility, and its probability was between 0.4 and 0.6. This result is more akin to the actual situation in shared manufacturing.

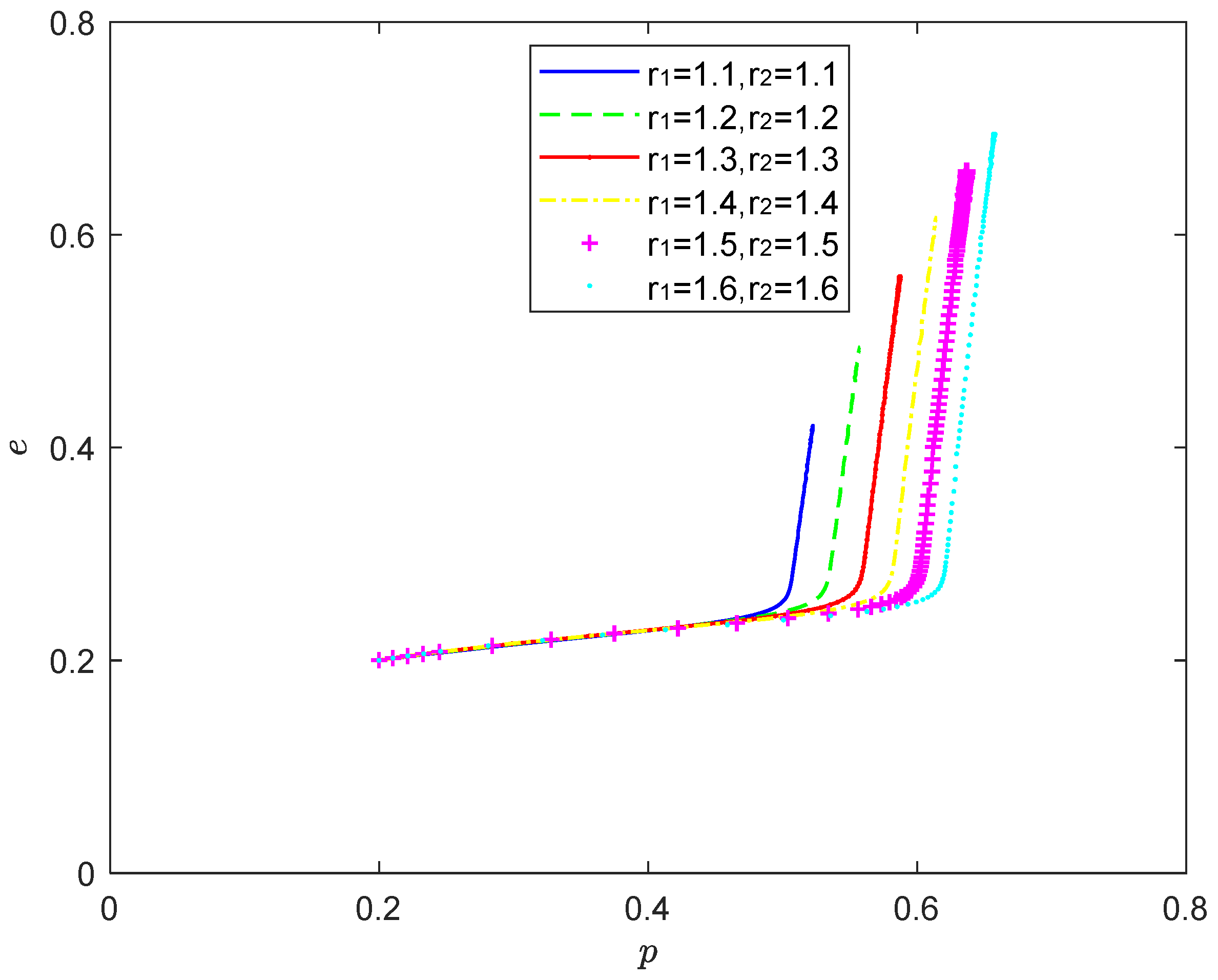

6.2. (Optimistic, Optimistic) State Analysis

Figure 4 illustrates the equilibrium strategy when the shared manufacturing supply chain is optimistic and the shared platform is optimistic, i.e., when

. Moderate optimism could still facilitate the strategy evolution of the shared manufacturing supply chain and the shared platform toward their Pareto optimum, but as the optimism of the game players deepened, the probability of both the shared manufacturing supply chain choosing quality innovation synergy and the shared platform choosing regulation decreased, and the mixed strategy Nash equilibrium point kept moving from the upper-right corner of the chart to the lower-left. These findings indicate that when the shared manufacturing supply chain and the attitude toward quality innovation synergy are too optimistic and the shared platform is too optimistic about regulation, the shared manufacturing supply chain and the shared platform choose inaction more often than not. In shared manufacturing practices, over-optimism should be avoided.

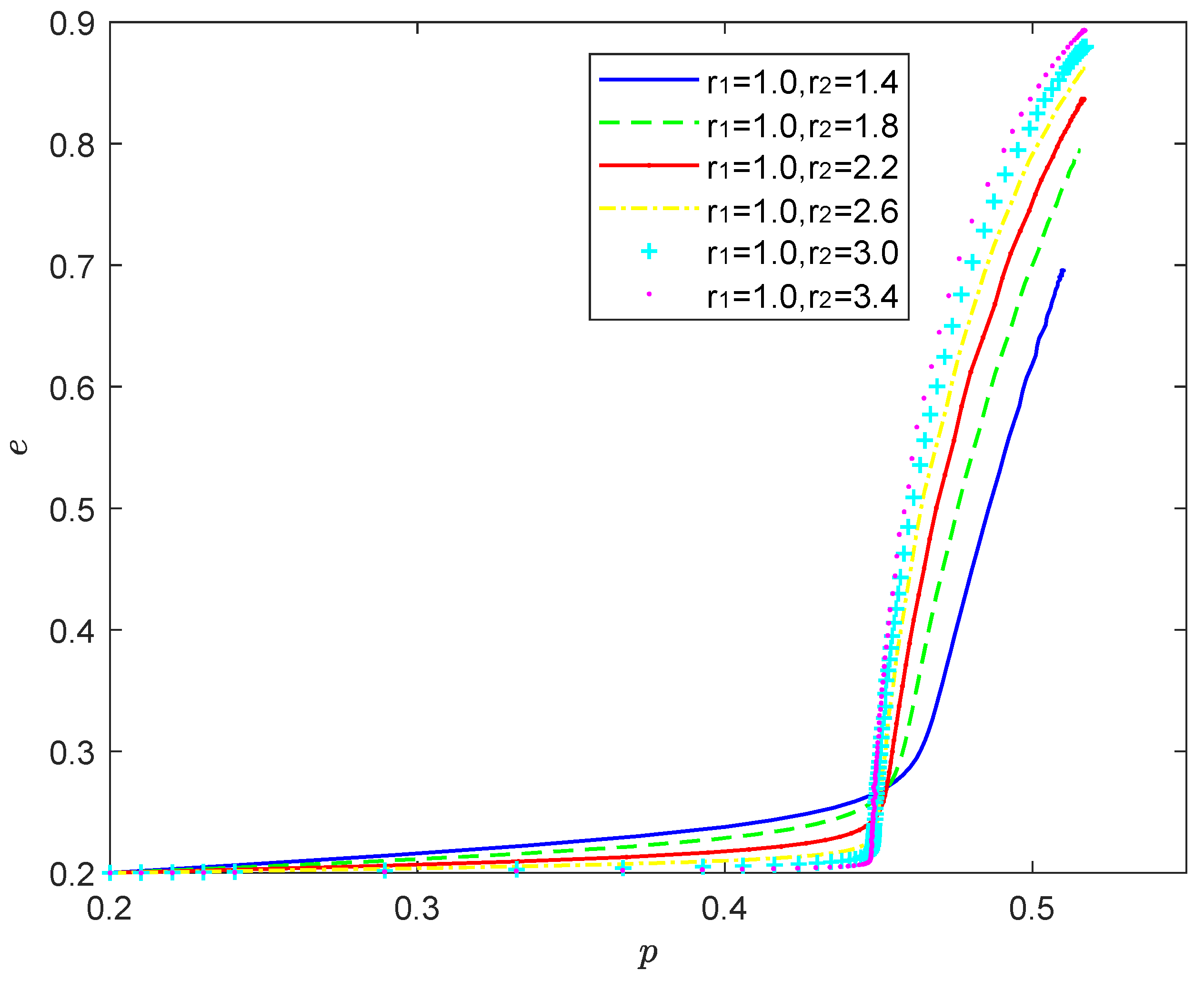

6.3. (Pessimistic, Pessimistic) State Analysis

Figure 5 reflects the equilibrium strategy when the shared manufacturing supply chain is pessimistic and the shared platform is pessimistic, i.e., when

. As the optimism of the game players deepened, the probability of both the shared manufacturing supply chain choosing quality innovation synergy and the shared platform choosing regulation increased, and the mixed strategy Nash equilibrium point kept moving up to the upper-right corner of the chart. This is consistent with the conclusion in the existing literature that “pessimism will prompt individuals to take positive actions” [

48]. These findings suggest that an appropriate pessimism increases the willingness to collaborate on quality innovation in shared manufacturing supply chains and increases the willingness to regulate by shared platforms. This is more consistent with reality, where the pressure of manufacturing transformation and development leads to high pessimism, and the probability of the shared manufacturing supply chain choosing quality innovation synergy increases and the probability of the shared platform choosing regulation increases under the continuous demands of the state, society, and industry.

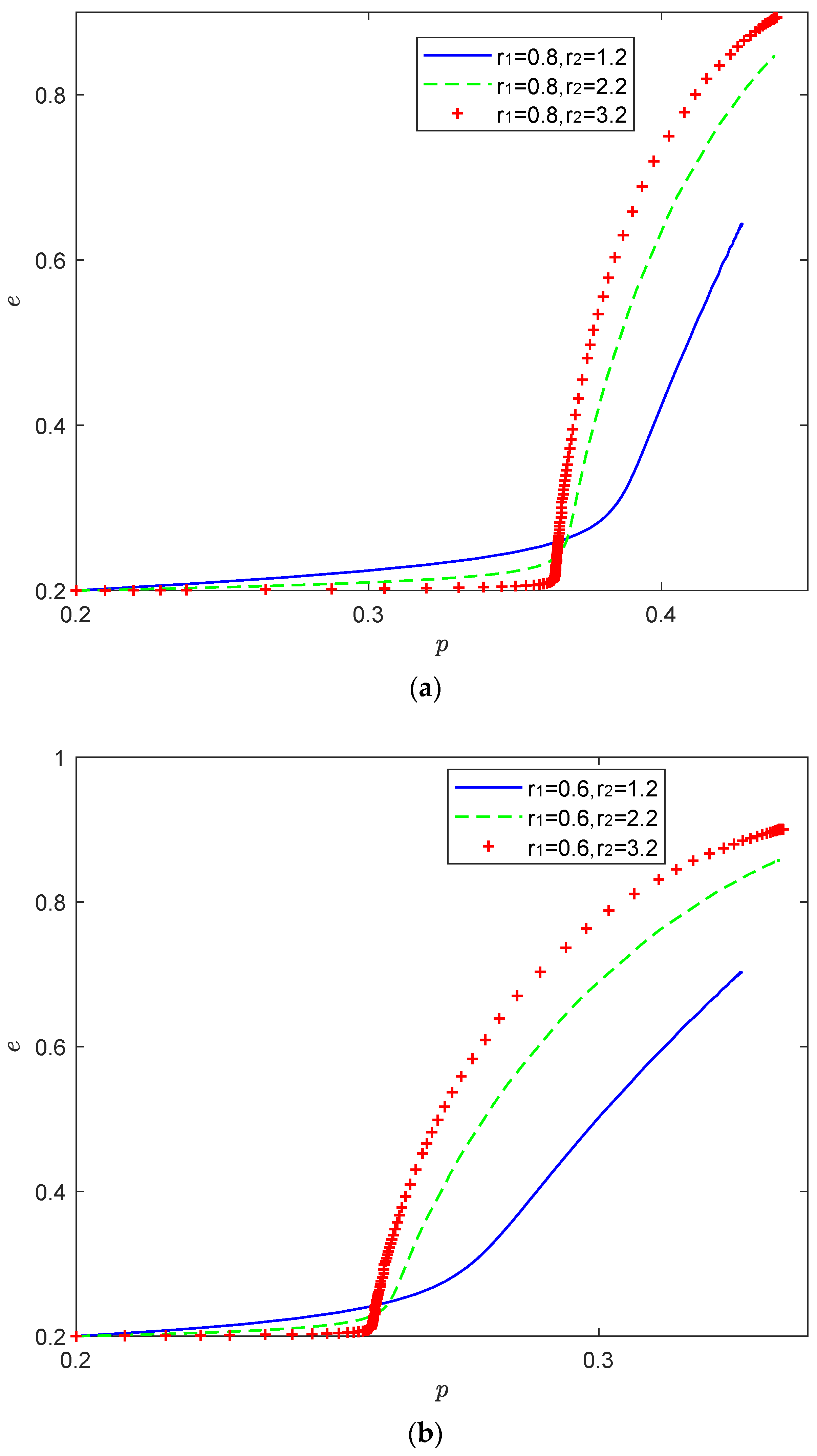

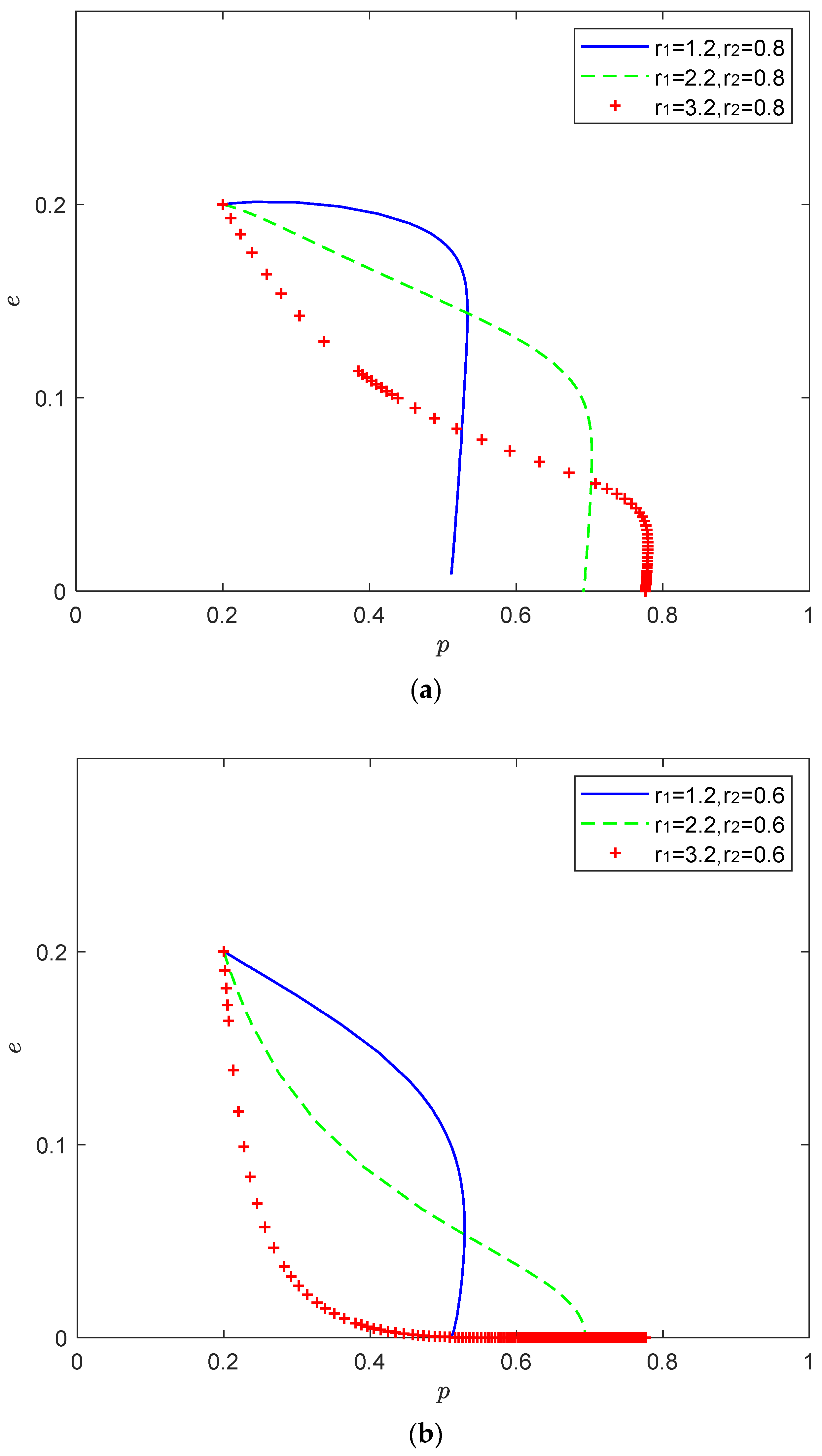

6.4. (Optimistic, Pessimistic) State Analysis

Figure 6 illustrates the equilibrium strategy when the shared manufacturing supply chain is optimistic and the shared platform is pessimistic, i.e., when

.

Figure 6 demonstrates that when the optimism of the shared manufacturing supply chain was certain, as the pessimism of shared platform deepened, the probability of both the shared manufacturing supply chain choosing quality innovation synergy and the shared platform choosing regulation increased, and the mixed strategy Nash equilibrium point also kept moving toward the upper-right corner of the chart, which shows that when the shared manufacturing supply chain maintains moderate optimism, the deepening pessimism of the shared platform enhances the probability of quality innovation synergy in shared manufacturing supply chains. Comparing

Figure 6a–c, with the deepening optimism of the shared manufacturing supply chain, the trajectory of the strategy evolution of the shared manufacturing supply chain and the shared platform was found to change significantly, and when the optimism of the shared manufacturing supply chain was deeper, the strategy evolution trajectory of each game subject had the tendency to evolve to the lower-left corner of the chart, and the system evolved for a longer period of time (negative quality innovation synergy, no regulation). The strategy combination state of the shared manufacturing supply chain was such that, when the shared manufacturing supply chain was over-optimistic, the shared manufacturing supply chain and the shared platform were in a state of inaction in the short term, which is not conducive to the Pareto improvement of the system. The above conclusions show that the impact of “optimism” on quality decision making is not as simple as “optimism will reduce people’s willingness to choose positive strategies” [

56], but is relatively complex. These findings indicate that when the shared manufacturing supply chain is in an optimistic state, improving the pessimism of the shared platform can help the shared manufacturing supply chain quality synergy improvement, but excessive optimism of the shared manufacturing supply chain hinders the Pareto improvement of the shared system.

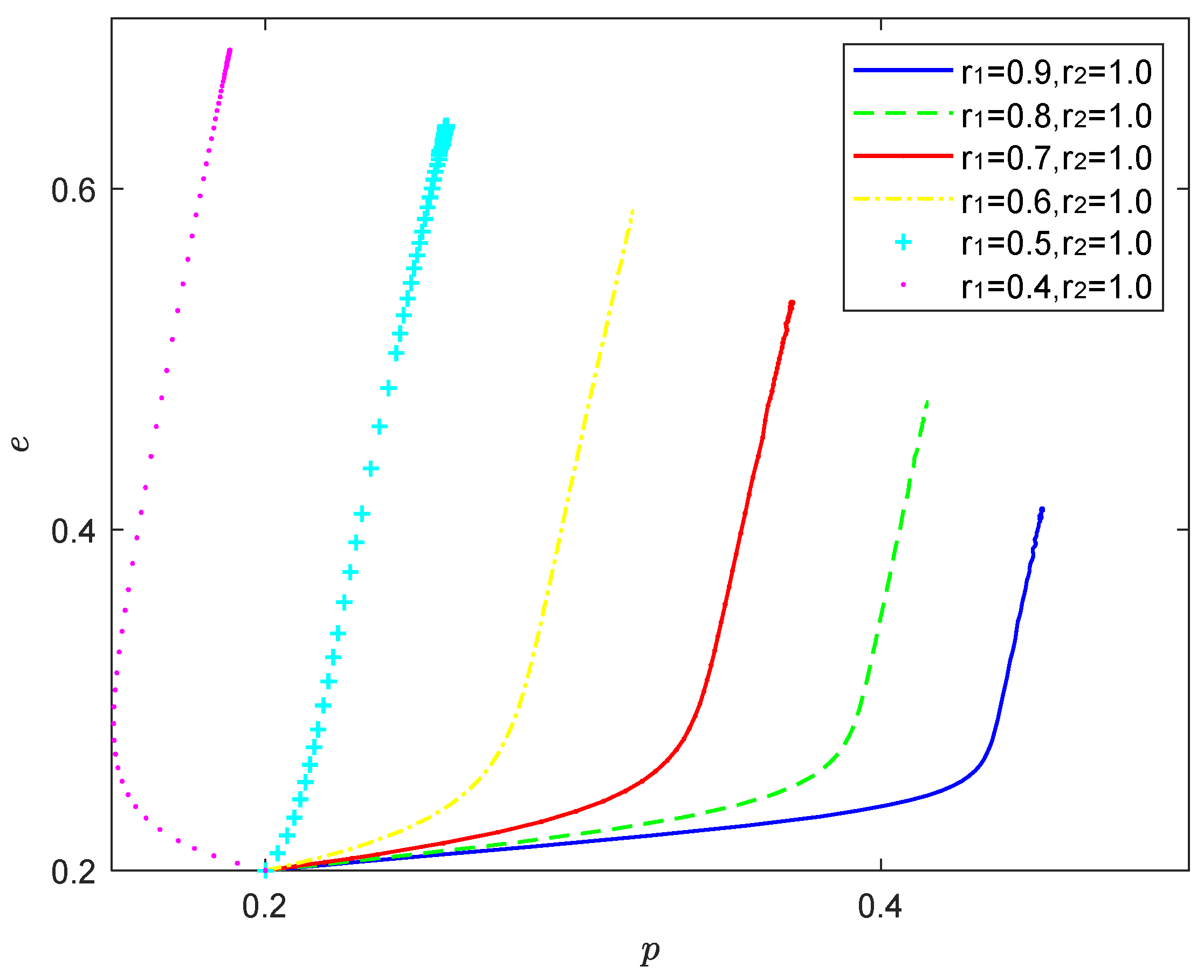

6.5. (Pessimistic, Optimistic) State Analysis

Figure 7 displays the equilibrium strategy when the shared manufacturing supply chain is pessimistic and the shared platform is optimistic, i.e., when

. As illustrated in

Figure 7, when the shared platform’s optimism was certain, as the shared manufacturing supply chain pessimism kept deepening, the probability of the shared manufacturing supply chain choosing quality innovation synergy kept increasing; meanwhile, the rate of convergence of the shared platform evolution to the unregulated strategy kept increasing, and the mixed strategy Nash equilibrium point kept moving toward the lower-left corner of the chart. Comparing

Figure 7a–c, it can be seen that as the shared manufacturing platform optimism deepened, the rate of convergence of the shared manufacturing supply chain and shared platform strategy evolution kept accelerating, the position of the hybrid strategy Nash equilibrium point kept moving to the right in a direction close to the horizontal axis of the chart, and the system strategy evolution kept converging to a state of (quality innovation synergy, no regulation).

This conclusion suggests that, when the shared platform is in an optimistic mood, improving the pessimistic mood of the shared manufacturing supply chain helps the shared manufacturing supply chain undergo quality synergy improvement, and as the optimistic mood of the shared platform keeps deepening, the system strategy evolution will eventually converge to a state of (quality innovation synergy, no regulation). When the shared manufacturing supply chain is highly self-regulated and the shared manufacturing supply chain is safe and stable, the shared platform can choose to save the cost of cost reduction and choose not to regulate, so that it can realize the strategy combination of (quality innovation synergy, no regulation) to maximize social benefits; therefore, the strategy combination of (quality innovation synergy, no regulation) is not the theoretical optimal strategy combination but the realistic optimum. This strategy combination (quality innovation synergy, no regulation) is not theoretically optimal but realistically optimal.

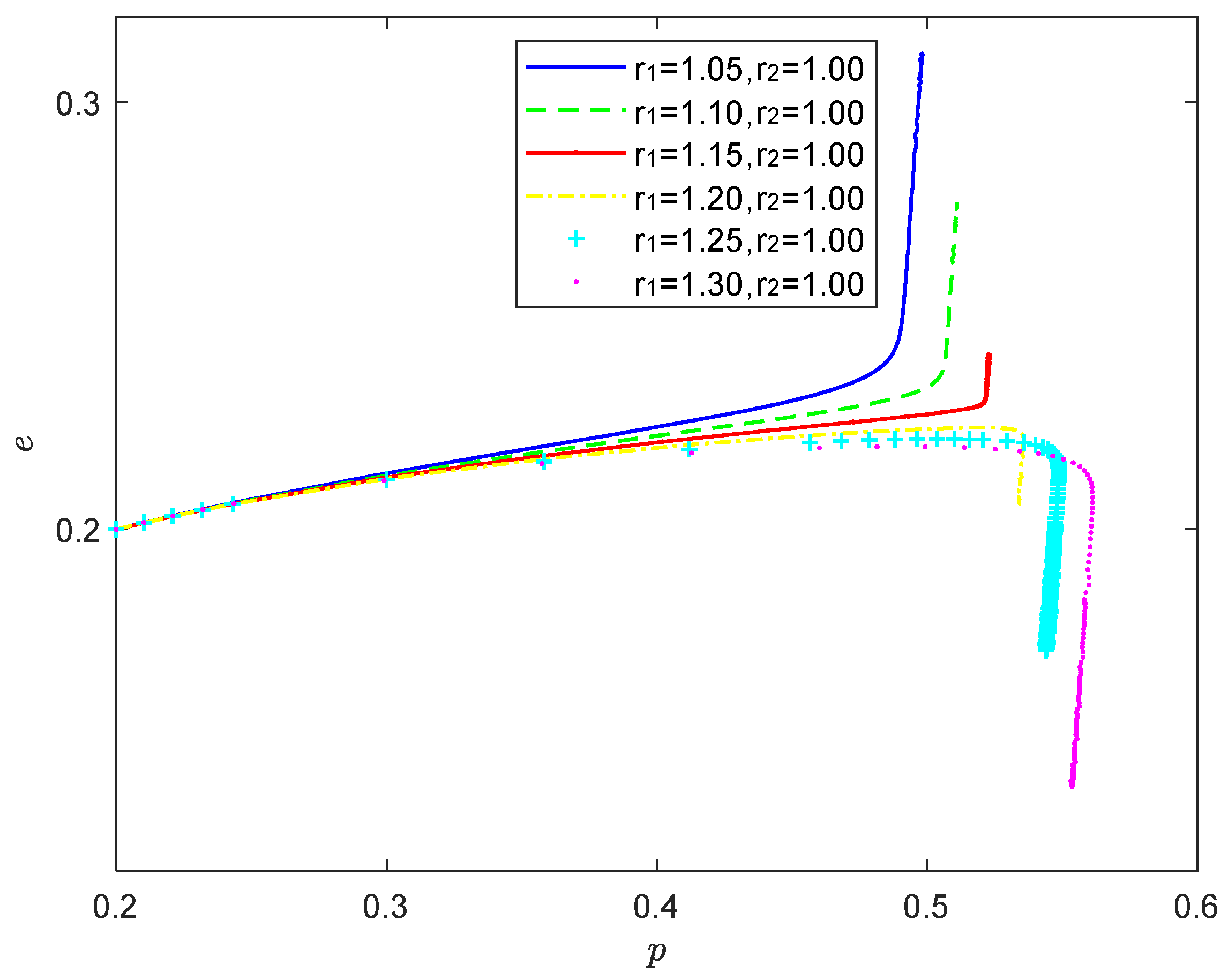

6.6. (Optimistic, Rational) State Analysis

Figure 8 presents the equilibrium strategy when the shared manufacturing supply chain is optimistic and the shared platform is rational, i.e., when

. From

Figure 8, as the optimism of the shared manufacturing supply chain deepened, the probability of quality innovation synergy in the shared manufacturing supply chain decreased, the probability of shared platform regulation increased, and the position of the mixed strategy Nash equilibrium point kept moving to the upper-left corner of the chart. When the optimism of shared manufacturing supply chain was too deep; that is, when

, the probability of quality innovation synergy of shared manufacturing supply chain rose, then fell. This indicates that that an appropriate level of optimism helps the probability of the shared manufacturing supply chain QI synergy, while excessive optimism makes the system strategy evolution converge to a state of (negative QI synergy, regulation), which consumes the cost of regulation and cannot guarantee the probability of shared manufacturing supply chain QI synergy, and the strategic combination of (negative QI synergy, regulation) is the less realistic strategy combination.

6.7. (Pessimistic, Rational) State Analysis

Figure 9 depicts the equilibrium strategy when the shared manufacturing supply chain is pessimistic and the shared platform is rational, i.e., at

. As can be seen from

Figure 9, as the pessimism of the shared manufacturing supply chain deepened, the probability of quality innovation synergy in the shared manufacturing supply chain decreased and the probability of shared platform regulation increased. Specifically, the shared platform regulation strategy maintained an upward evolutionary trajectory when

and a downward evolutionary trajectory when

. Moderate pessimism could make the shared manufacturing supply chain maintain a certain sense of danger, and then actively carry out quality innovation synergy. Once the pessimism was too deep, it was counterproductive. This indicates that the participants should maintain moderate pessimism, and excessive pessimism reduces the enthusiasm of participants to choose positive strategies.

6.8. (Rational, Optimistic) State Analysis

Figure 10 reflects the equilibrium strategy when the shared manufacturing supply chain is rational and the shared platform is optimistic, i.e., when

. From

Figure 10, the probability of quality innovation synergy in the shared manufacturing supply chain and the probability of shared platform regulation both kept decreasing as the optimism of shared platform deepened. The position of the hybrid strategy Nash equilibrium point kept moving downwards. When the optimism of the shared platform was too deep, i.e., when

, the probability of shared platform regulation was almost zero, and the probability of quality innovation synergy in the shared manufacturing supply chain was also low. The motivation for shared manufacturing supply chain quality innovation synergy was lower and the shared platform more often chose to do nothing, which may lead to the disorderly development of the shared system or even a quality crisis.

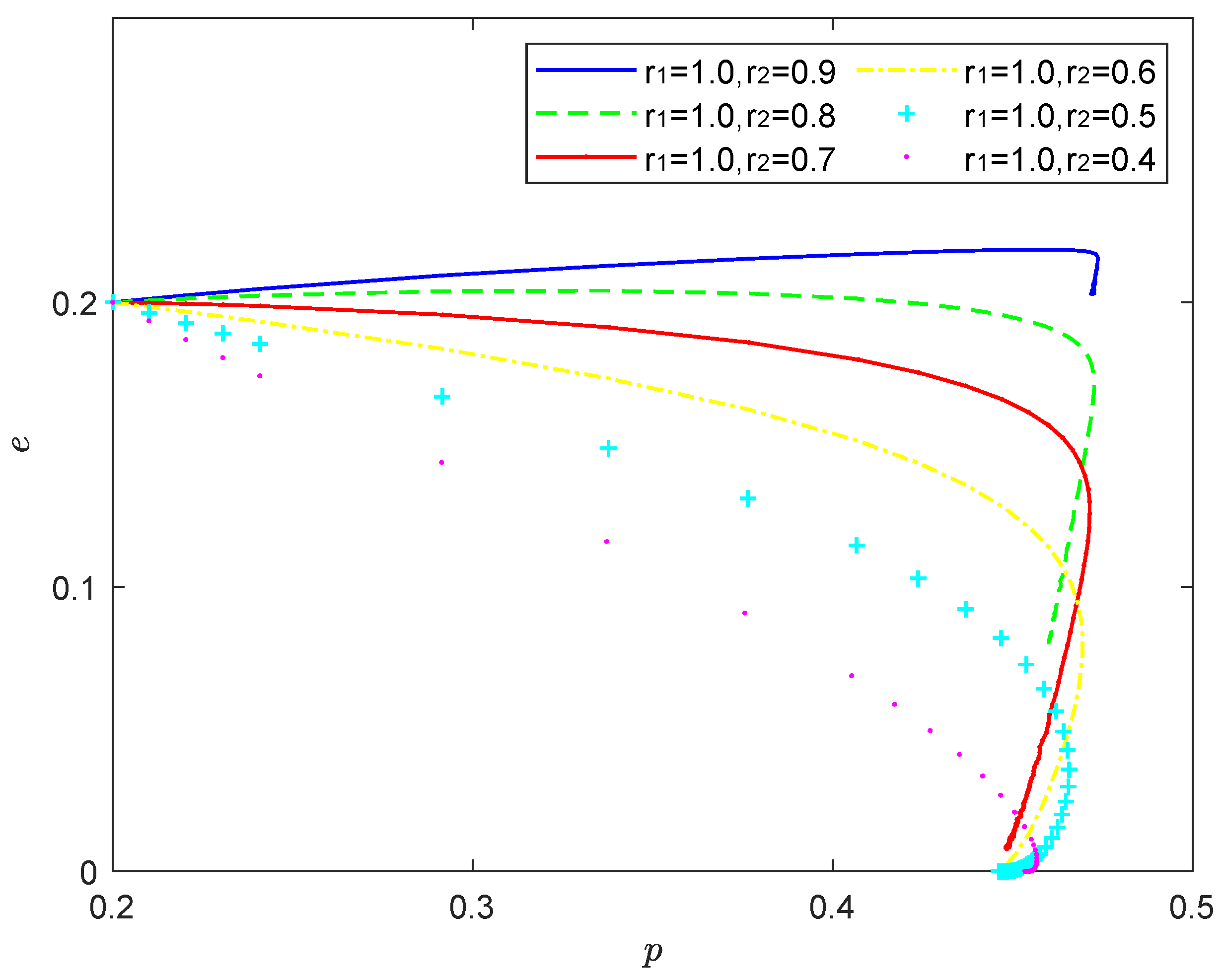

6.9. (Rational, Pessimistic) State Analysis

Figure 11 demonstrates the equilibrium strategy when the shared manufacturing supply chain is rational and the shared platform is pessimistic, i.e., at

. As illustrated in

Figure 11, the probability of quality innovation synergy in the shared manufacturing supply chain and the probability of shared platform regulation both kept increasing as the pessimism of the shared platform deepened. The position of the mixed strategy Nash equilibrium point kept moving upwards. When the pessimism of the shared platform reached a certain level, i.e.,

, the probability of shared manufacturing supply chain quality innovation synergy remained at a certain level, and the probability of shared platform regulation almost converged to 1. The shared platform could better assume its own regulatory responsibilities and the enthusiasm of shared manufacturing supply chain quality innovation synergy did not reach a high level, but due to the regulatory deterrence of the shared platform, the enthusiasm for shared manufacturing supply chain quality innovation synergy also maintained a certain level, and the shared system maintained a relatively healthy trend in its development.