On Reassessment of the HWMA Chart for Process Monitoring

Abstract

:1. Introduction

2. EWMA and HWMA Charts

2.1. EWMA Chart

2.2. HWMA Chart

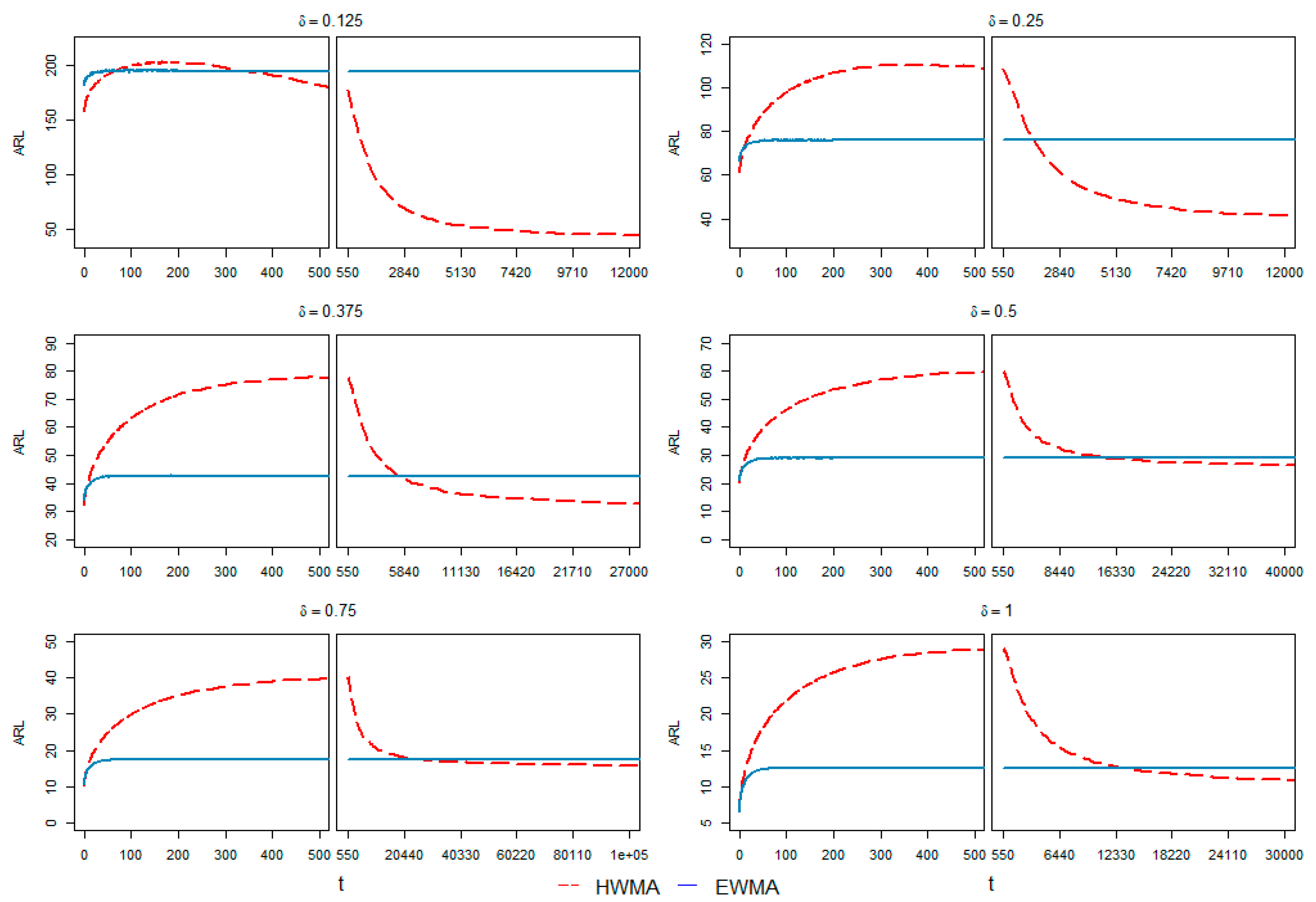

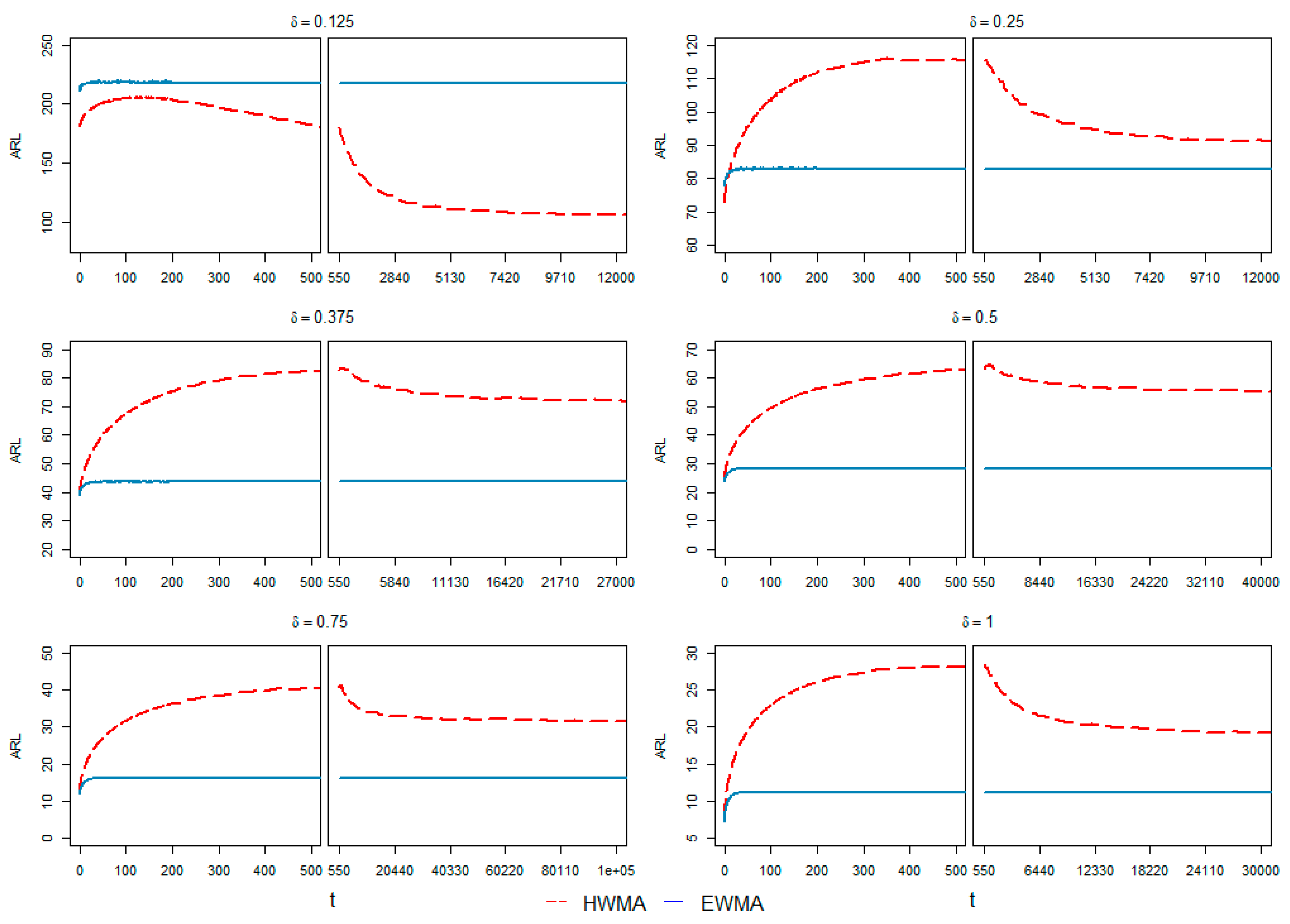

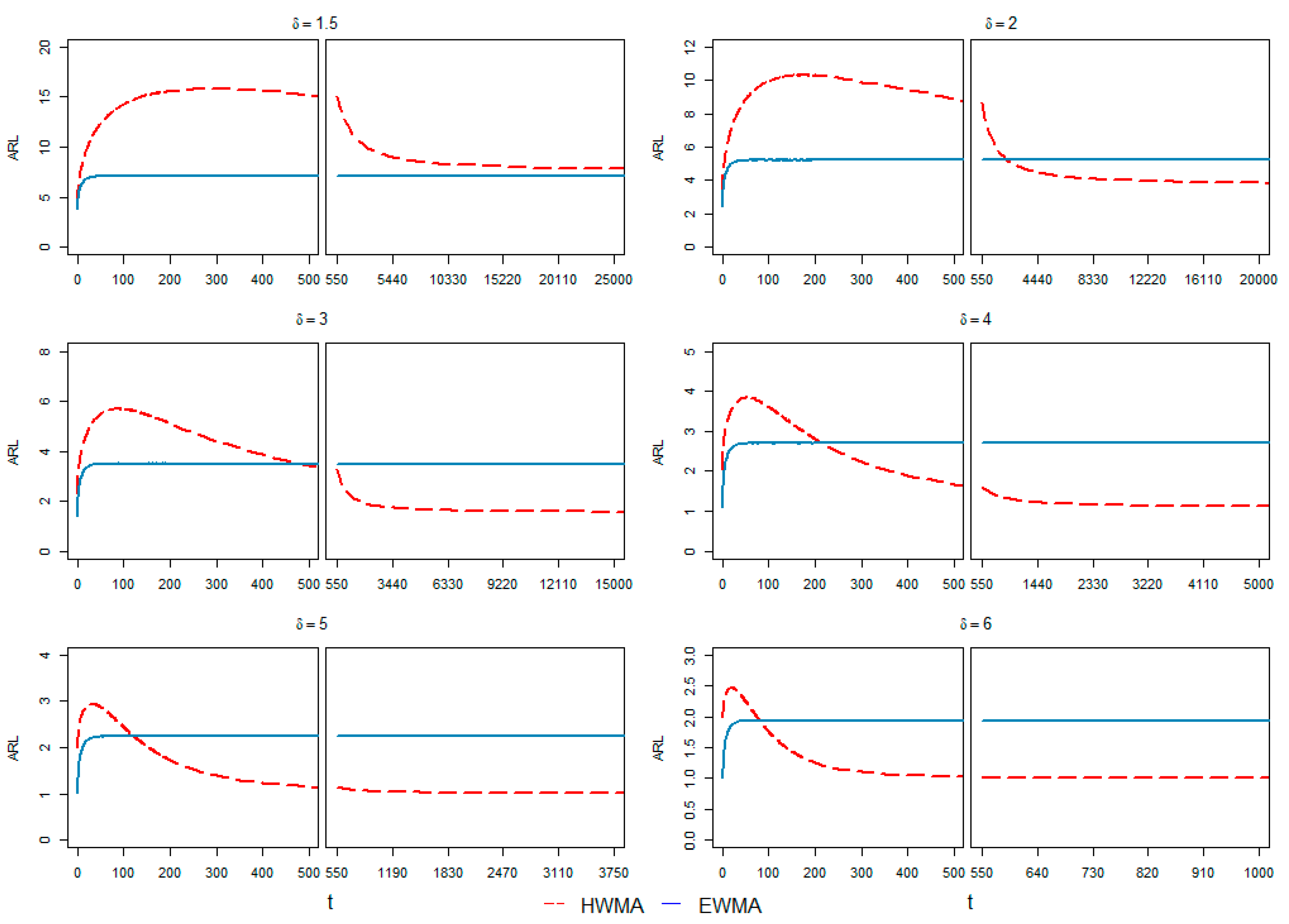

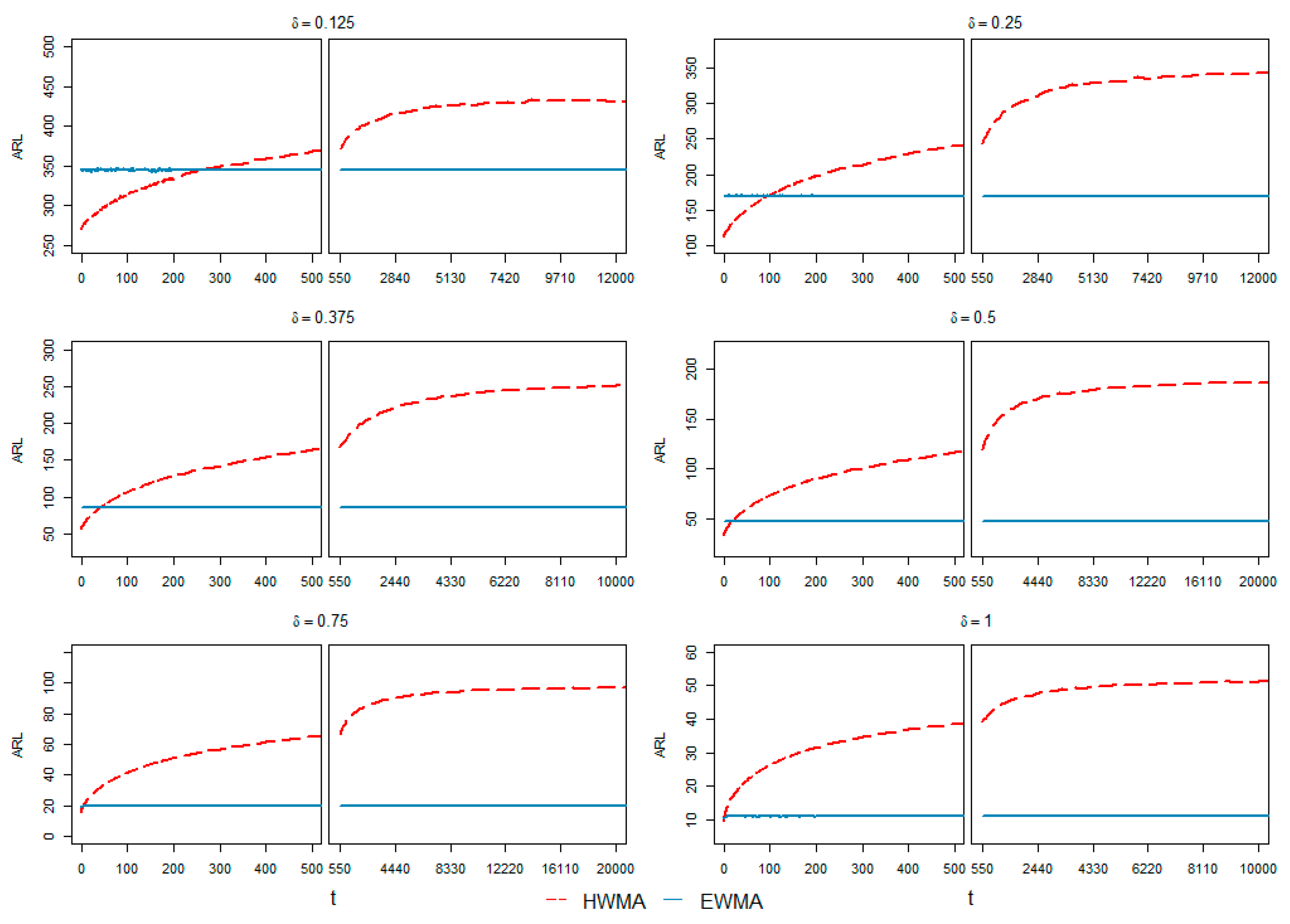

3. Performance Evaluation

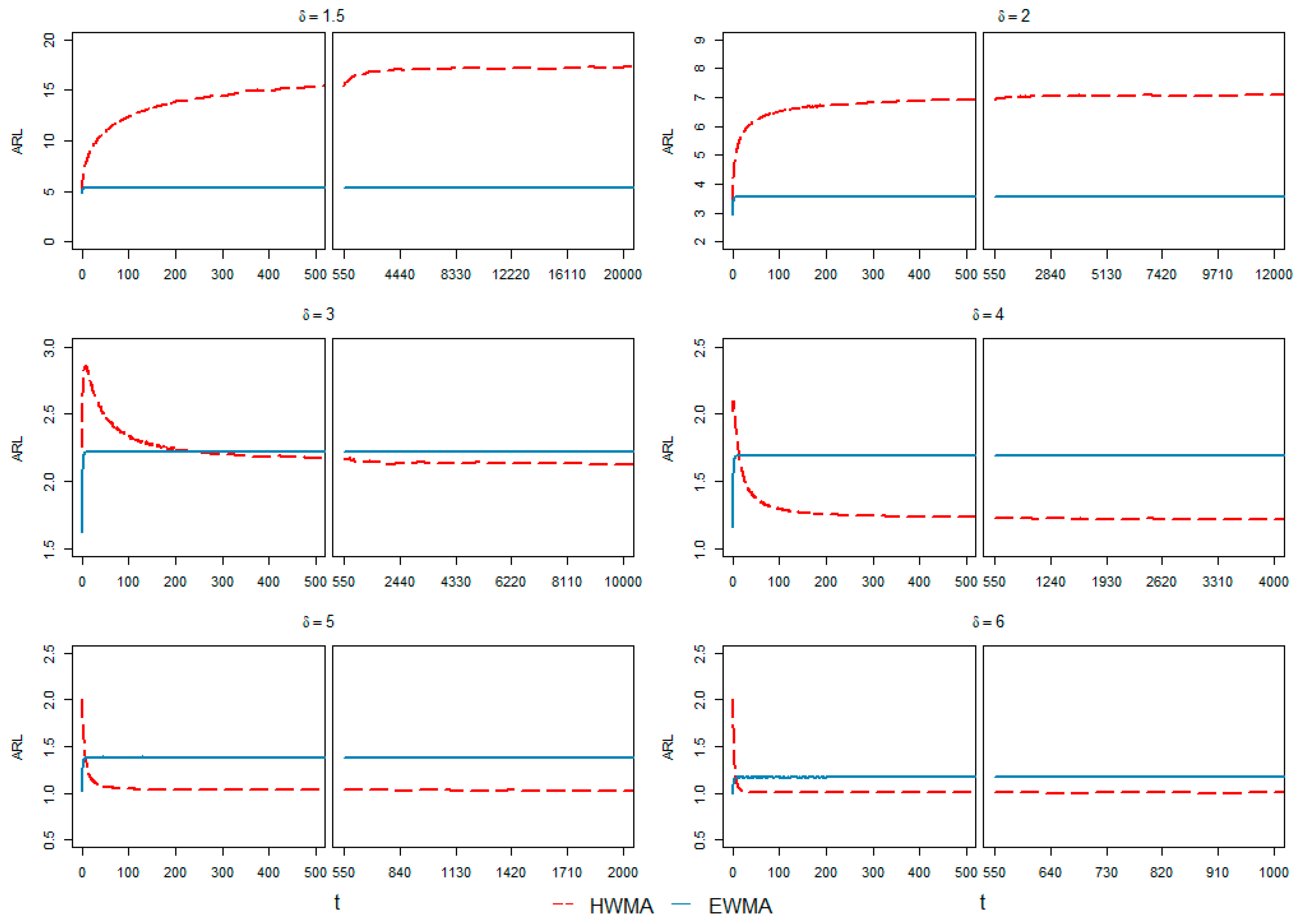

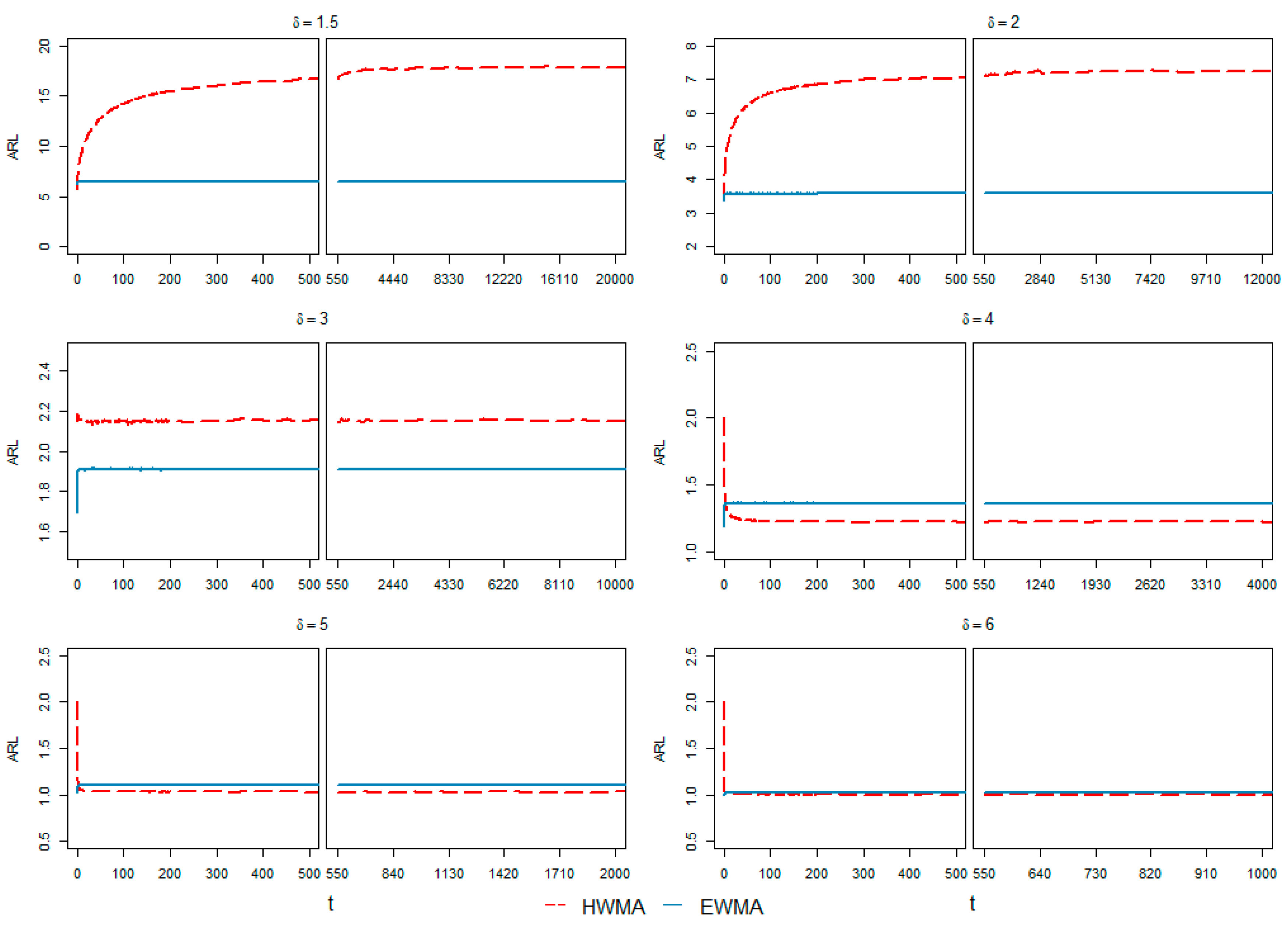

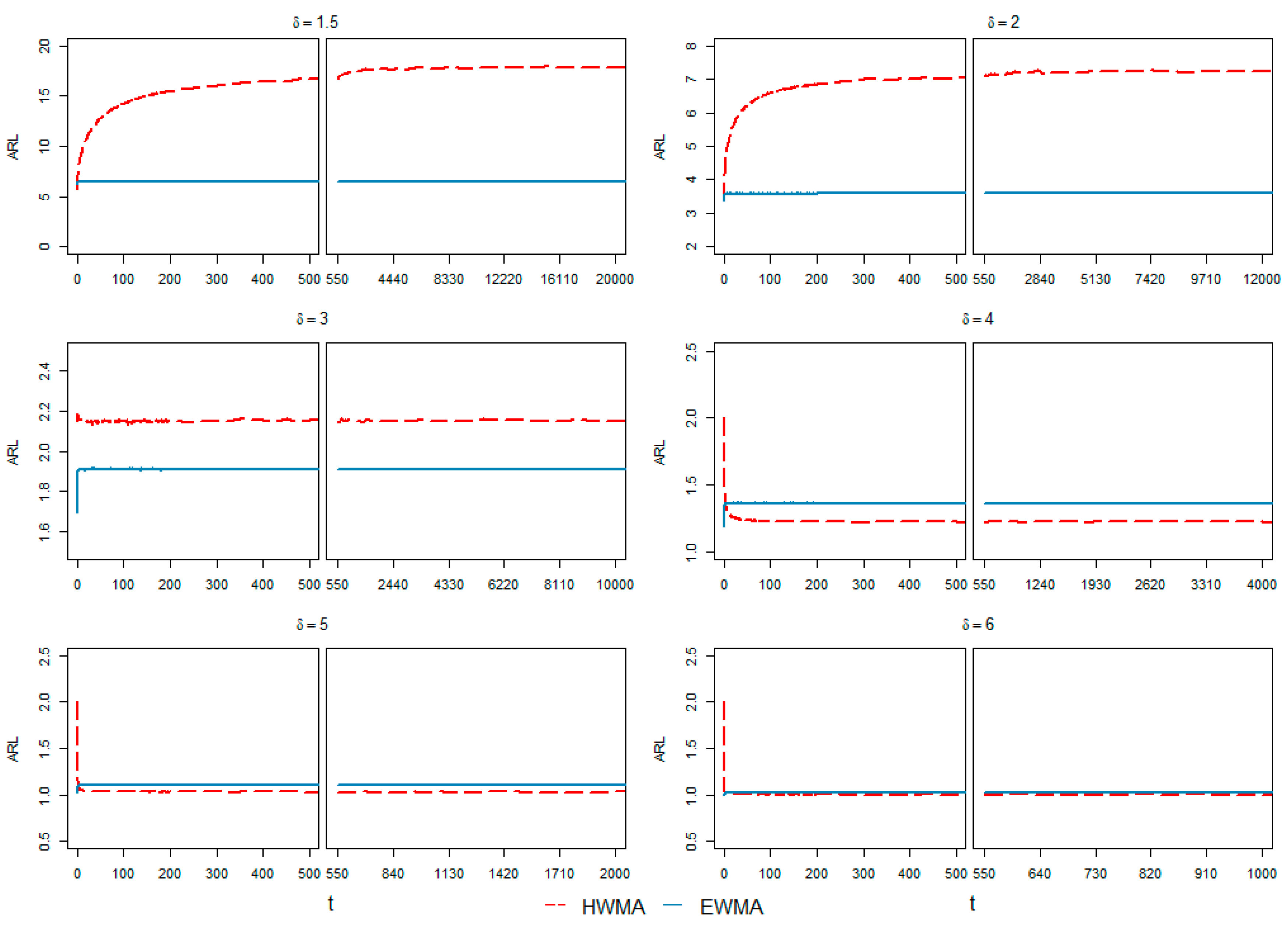

- HWMA0.1 chart is better than EWMA0.1 for , whereas for EWMA0.1 is proven to be superior.

- HWMA0.25 chart is better than EWMA0.25 for , whereas for EWMA0.25 is proven to be superior.

- HWMA0.5 chart is better than EWMA0.5 for , whereas for EWMA0.5 is proven to be superior.

4. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aslam, M.; Rao, G.S.; AL-Marshadi, A.H.; Ahmad, L.; Jun, C.-H. Control charts for monitoring process capability index using median absolute deviation for some popular distributions. Processes 2019, 7, 287. [Google Scholar] [CrossRef] [Green Version]

- Fan, S.-K.S.; Jen, C.-H.; Lee, J.-X. Profile monitoring for autocorrelated reflow processes with small samples. Processes 2019, 7, 104. [Google Scholar] [CrossRef] [Green Version]

- Roberts, S.W. Control Chart Tests Based on Geometric Moving Averages. Technometrics 1959, 1, 239–250. [Google Scholar] [CrossRef]

- Sweet, A.L. Control Charts Using Coupled Exponentially Weighted Moving Averages. IIE Trans. 1986, 18, 26–33. [Google Scholar] [CrossRef]

- Lucas, J.M.; Saccucci, M.S. Exponentially weighted moving average control schemes: Properties and enhancements. Technometrics 1990, 32, 1–12. [Google Scholar] [CrossRef]

- Hamilton, M.D.; Crowder, S.V. Average Run Lengths of EWMA Control Charts for Monitoring a Process Standard Deviation. J. Qual. Technol. 1992, 24, 44–50. [Google Scholar] [CrossRef]

- Gan, F.F. Joint Monitoring of Process Mean and Variance Using Exponentially Weighted Moving Average Control Charts. Technometrics 1995, 37, 446–453. [Google Scholar] [CrossRef]

- Acosta-Mejia, C.A.; Pignatiello, J.J.; Venkateshwara, R.B. A comparison of control charting procedures for monitoring process dispersion. IIE Trans. 1999, 31, 569–579. [Google Scholar] [CrossRef]

- Steiner, S. EWMA Control Charts with Time-Varying Control Limits and Fast Initial Response. J. Qual. Technol. 1999, 31, 75–86. [Google Scholar] [CrossRef]

- Reynolds, J.M.R.; Arnold, J.C. EWMA control charts with variable sample sizes and variable sampling intervals. IIE Trans. 2001, 33, 511–530. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, J.H.; Jun, C.H. An exponentially weighted moving average chart controlling false discovery rate. J. Stat. Comput. Simul. 2014, 84, 1830–1840. [Google Scholar] [CrossRef]

- Abbas, N.; Riaz, M.; Does, R.J.M.M. Enhancing the performance of EWMA charts. Qual. Reliab. Eng. Int. 2011, 27, 821–833. [Google Scholar] [CrossRef] [Green Version]

- Patel, A.K.; Divecha, J. Modified exponentially weighted moving average (EWMA) control chart for an analytical process data. J. Chem. Eng. Mater. Sci. 2011, 2, 12–20. [Google Scholar]

- Abbas, N.; Riaz, M.; Does, R.J.M.M. An EWMA-type control chart for monitoring the process mean using auxiliary information. Commun. Stat.-Theory Methods 2014, 43, 3485–3498. [Google Scholar] [CrossRef] [Green Version]

- Abbasi, S.A.; Riaz, M.; Miller, A.; Ahmad, S.; Nazir, H.Z. EWMA Dispersion Control Charts for Normal and Non-normal Processes. Qual. Reliab. Eng. Int. 2015, 31, 1691–1709. [Google Scholar] [CrossRef]

- Lee, H.; Aslam, M.; Shakeel, Q.; Lee, W.; Jun, C.H. A control chart using an auxiliary variable and repetitive sampling for monitoring process mean. J. Stat. Comput. Simul. 2015, 85, 3289–3296. [Google Scholar] [CrossRef]

- Khan, N.; Aslam, M.; Jun, C.H. Design of a Control Chart Using a Modified EWMA Statistic. Qual. Reliab. Eng. Int. 2017, 33, 1095–1104. [Google Scholar] [CrossRef]

- Herdiani, E.T.; Fandrilla, G.; Sunusi, N. Modified Exponential Weighted Moving Average (EWMA) Control Chart on Autocorrelation Data. J. Phys. Conf. Ser. 2018, 979, 012097. [Google Scholar] [CrossRef]

- Hussain, S.; Song, L.; Ahmad, S.; Riaz, M. New Interquartile Range EWMA Control Charts with Applications in Continuous Stirred Tank Rector Process. Arab. J. Sci. Eng. 2019, 44, 2467–2485. [Google Scholar] [CrossRef]

- Hussain, S.; Song, L.; Ahmad, S.; Riaz, M. On auxiliary information based improved EWMA median control charts. Sci. Iran. 2018, 25, 954–982. [Google Scholar] [CrossRef] [Green Version]

- Abbasi, S.A.; Riaz, M.; Ahmad, S.; Sanusi, R.A.; Abid, M. New Efficient EWMA Variability Charts based on Auxiliary Information. Qual. Reliab. Eng. Int. 2020, 36, 2203–2224. [Google Scholar] [CrossRef]

- Hussain, S.; Song, L.; Ahmad, S.; Riaz, M. On a Class of Mixed EWMA-CUSUM Median Control Charts. Qual. Reliab. Eng. Int. 2020, 36, 910–946. [Google Scholar] [CrossRef]

- Aslam, M.; Bantan, R.A.; Khan, N. Design of S2N—NEWMA control chart for monitoring process having indeterminate production data. Processes 2019, 7, 742. [Google Scholar] [CrossRef] [Green Version]

- Hyder, M.; Mahmood, T.; Butt, M.M.; Raza, S.M.M.; Abbas, N. On the location-based memory type control charts under modified successive sampling scheme. Qual. Reliab. Eng. Int. 2022, 38, 2200–2217. [Google Scholar] [CrossRef]

- Abbas, N. Homogeneously weighted moving average control chart with an application in substrate manufacturing process. Comput. Ind. Eng. 2018, 120, 460–470. [Google Scholar] [CrossRef]

- Adegoke, N.A.; Abbasi, S.; Smith, A.N.H.; Anderson, M.J.; Pawley, M. A Multivariate Homogeneously Weighted Moving Average Control Chart. IEEE Access 2019, 7, 9586–9597. [Google Scholar] [CrossRef]

- Aslam, M.; Khan, M.; Anwar, S.M.; Zaman, B. A homogeneously weighted moving average control chart for monitoring time between events. Qual. Reliab. Eng. Int. 2022, 38, 1013–1044. [Google Scholar] [CrossRef]

- Iqbal, A.; Mahmood, T.; Ali, Z.; Riaz, M. On Enhanced GLM-Based Monitoring: An Application to Additive Manufacturing Process. Symmetry 2022, 14, 122. [Google Scholar] [CrossRef]

- Adegoke, N.A.; Smith, A.N.H.; Anderson, M.J.; Sanusi, R.A.; Pawley, M.D.M. Efficient Homogeneously Weighted Moving Average Chart for Monitoring Process Mean Using an Auxiliary Variable. IEEE Access 2019, 7, 94021–94032. [Google Scholar] [CrossRef]

- Adeoti, O.A.; Koleoso, S.O. A hybrid homogeneously weighted moving average control chart for process monitoring. Qual. Reliab. Eng. Int. 2020, 36, 2170–2186. [Google Scholar] [CrossRef]

- Alevizakos, V.; Chatterjee, K.; Koukouvinos, C. The extended homogeneously weighted moving average control chart. Qual. Reliab. Eng. Int. 2021, 37, 2134–2155. [Google Scholar] [CrossRef]

- Abid, M.; Shabbir, A.; Nazir, H.Z.; Sherwani, R.A.K.; Riaz, M. A double homogeneously weighted moving average control chart for monitoring of the process mean. Qual. Reliab. Eng. Int. 2020, 36, 1513–1527. [Google Scholar] [CrossRef]

- Raza, M.A.; Nawaz, T.; Han, D. On designing distribution-free homogeneously weighted moving average control charts. J. Test. Eval. 2019, 48, 3154–3171. [Google Scholar] [CrossRef]

- Riaz, M.; Abid, M.; Shabbir, A.; Nazir, H.Z.; Abbas, Z.; Abbasi, S.A. A non-parametric double homogeneously weighted moving average control chart under sign statistic. Qual. Reliab. Eng. Int. 2021, 37, 1544–1560. [Google Scholar] [CrossRef]

- Abid, M.; Mei, S.; Nazir, H.Z.; Riaz, M.; Hussain, S. A mixed HWMA-CUSUM mean chart with an application to manufacturing process. Qual. Reliab. Eng. Int. 2021, 37, 618–631. [Google Scholar] [CrossRef]

- Abid, M.; Mei, S.; Nazir, H.Z.; Riaz, M.; Hussain, S.; Abbas, Z. A mixed cumulative sum homogeneously weighted moving average control chart for monitoring process mean. Qual. Reliab. Eng. Int. 2021, 37, 1758–1771. [Google Scholar] [CrossRef]

- Thanwane, M.; Malela-Majika, J.C.; Castagliola, P.; Shongwe, S.C. The effect of measurement errors on the performance of the homogenously weighted moving average. Trans. Inst. Meas. Control 2020, 43, 728–745. [Google Scholar] [CrossRef]

- Thanwane, M.; Shongwe, S.C.; Malela-Majika, J.C.; Aslam, M. Parameter Estimation Effect of the Homogeneously Weighted Moving Average Chart to Monitor the Mean of Autocorrelated Observations with Measurement Errors. IEEE Access 2020, 8, 221352–221366. [Google Scholar] [CrossRef]

- Thanwane, M.; Abbasi, S.A.; Malela-Majika, J.C.; Aslam, M.; Shongwe, S.C. The use of fast initial response features on the homogeneously weighted moving average chart with estimated parameters under the effect of measurement errors. Qual. Reliab. Eng. Int. 2021, 37, 2568–2586. [Google Scholar] [CrossRef]

- Thanwane, M.; Malela-Majika, J.C.; Castagliola, P.; Shongwe, S.C. The effect of measurement errors on the performance of the homogenously weighted moving average X¯ monitoring scheme with estimated parameters. J. Stat. Comput. Simul. 2021, 91, 1306–1330. [Google Scholar] [CrossRef]

- Riaz, M.; Abbas, Z.; Nazir, H.Z.; Abid, M. On the Development of Triple Homogeneously Weighted Moving Average Control Chart. Symmetry 2021, 13, 360. [Google Scholar] [CrossRef]

- Knoth, S.; Tercero-Gómez, V.G.; Khakifirooz, M.; Woodall, W.H. The impracticality of homogeneously weighted moving average and progressive mean control chart approaches. Qual. Reliab. Eng. Int. 2021, 37, 3779–3794. [Google Scholar] [CrossRef]

- Abbas, N.; Zafar, R.F.; Riaz, M.; Hussain, Z. Progressive mean control chart for monitoring process location parameter. Qual. Reliab. Eng. Int. 2013, 29, 357–367. [Google Scholar] [CrossRef]

- Abbas, N.; Riaz, M. Progressive mean as a special case of exponentially weighted moving average: Discussion. Qual. Reliab. Eng. Int. 2022, 38, 2188–2197. [Google Scholar] [CrossRef]

- Mei, Y. Is average run length to false alarm always an informative criterion? Seq. Anal. 2008, 27, 354–376. [Google Scholar] [CrossRef] [Green Version]

- Montgomery, D.C. Introduction to Statistical Quality Control, 8th ed.; John Willey & Sons: New York, NY, USA, 2019. [Google Scholar]

- Alevizakos, V.; Chatterjee, K.; Koukouvinos, C. The triple moving average control chart. J. Comput. Appl. Math. 2021, 384, 113171. [Google Scholar] [CrossRef]

- Alevizakos, V.; Koukouvinos, C. A double progressive mean control chart for monitoring Poisson observations. J. Comput. Appl. Math. 2020, 373, 112232. [Google Scholar] [CrossRef]

- Kenett, R.S.; Pollak, M. On Assessing the Performance of Sequential Procedures for Detecting a Change. Qual. Reliab. Eng. Int. 2012, 28, 500–507. [Google Scholar] [CrossRef]

| or | ||

|---|---|---|

| 0.03 | 2.483 | 2.272 |

| 0.05 | 2.639 | 2.608 |

| 0.10 | 2.824 | 2.938 |

| 0.25 | 3.001 | 3.075 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riaz, M.; Ahmad, S.; Mahmood, T.; Abbas, N. On Reassessment of the HWMA Chart for Process Monitoring. Processes 2022, 10, 1129. https://doi.org/10.3390/pr10061129

Riaz M, Ahmad S, Mahmood T, Abbas N. On Reassessment of the HWMA Chart for Process Monitoring. Processes. 2022; 10(6):1129. https://doi.org/10.3390/pr10061129

Chicago/Turabian StyleRiaz, Muhammad, Shabbir Ahmad, Tahir Mahmood, and Nasir Abbas. 2022. "On Reassessment of the HWMA Chart for Process Monitoring" Processes 10, no. 6: 1129. https://doi.org/10.3390/pr10061129

APA StyleRiaz, M., Ahmad, S., Mahmood, T., & Abbas, N. (2022). On Reassessment of the HWMA Chart for Process Monitoring. Processes, 10(6), 1129. https://doi.org/10.3390/pr10061129