An Iterative Conceptual Design Process for Modular Product Based on Sustainable Analysis and Creative Template Method

Abstract

:1. Introduction

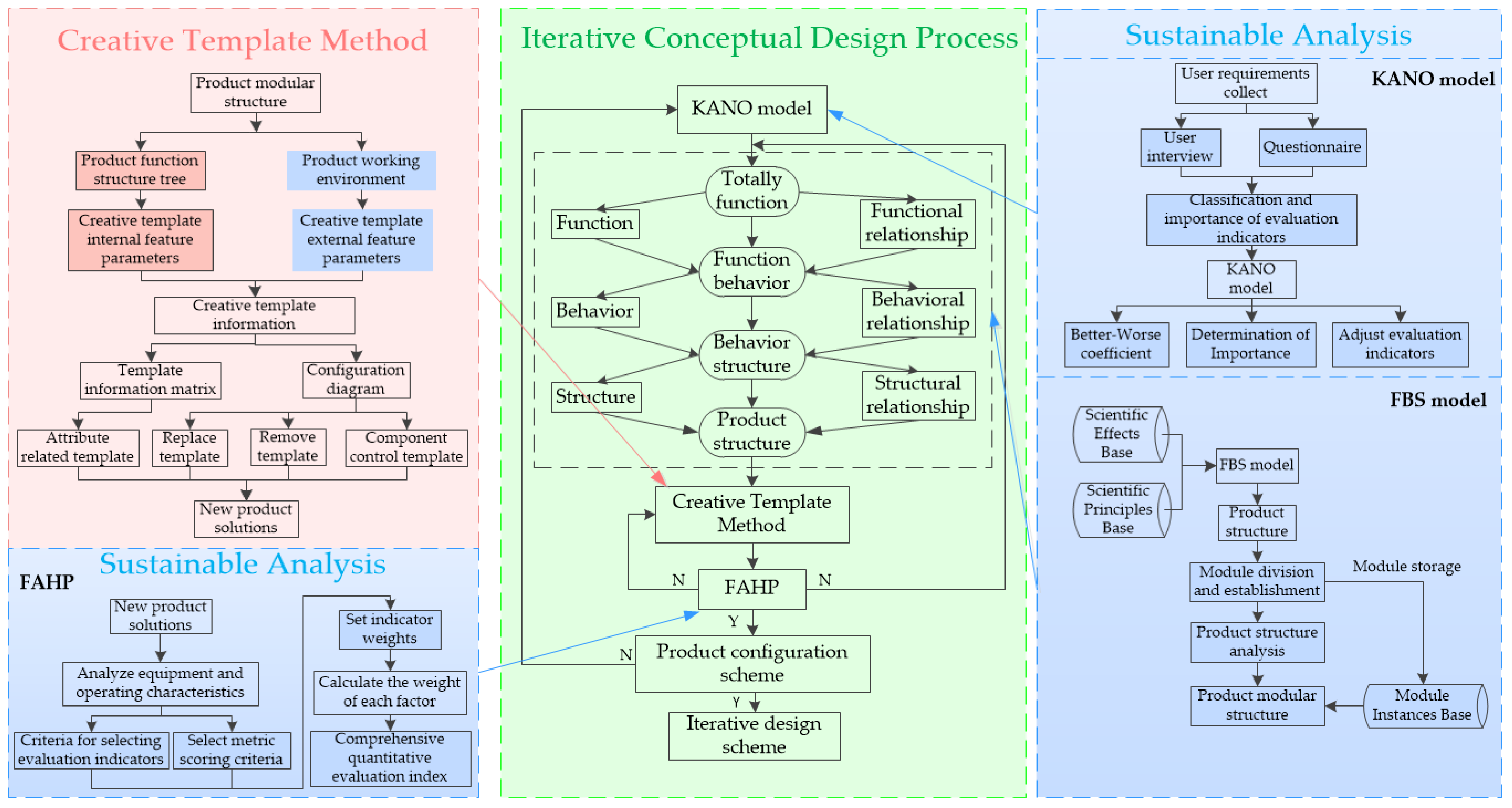

2. S-KFCF Iterative Conceptual Design Process

3. Methodology

3.1. Sustainable Analysis in Conceptual Design

3.1.1. User Requirements and Satisfaction Analysis

3.1.2. FBS Model

3.1.3. Fuzzy Analytic Hierarchy Process

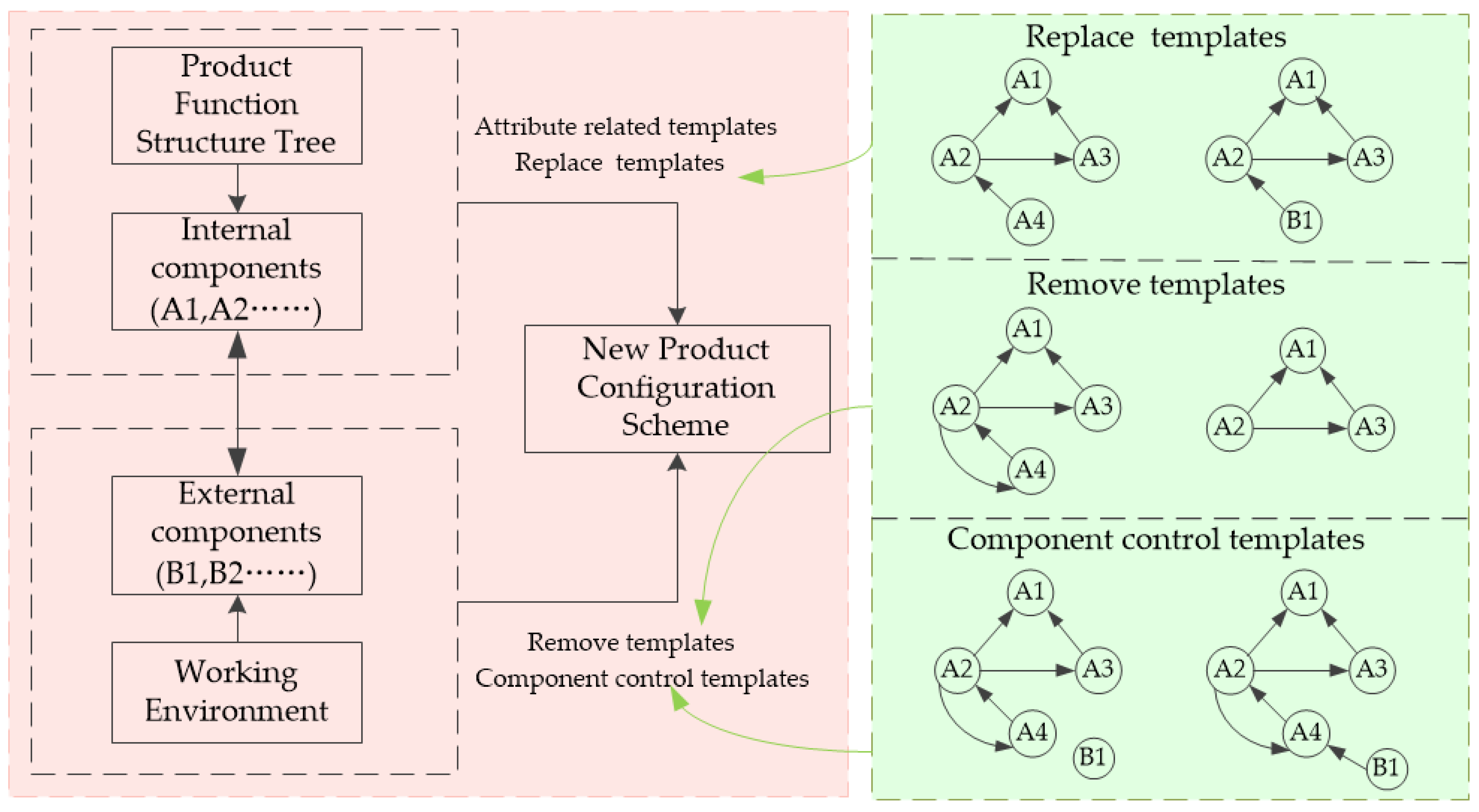

3.2. Creative Template Method

4. Results

4.1. User Requirements and Satisfaction Analysis

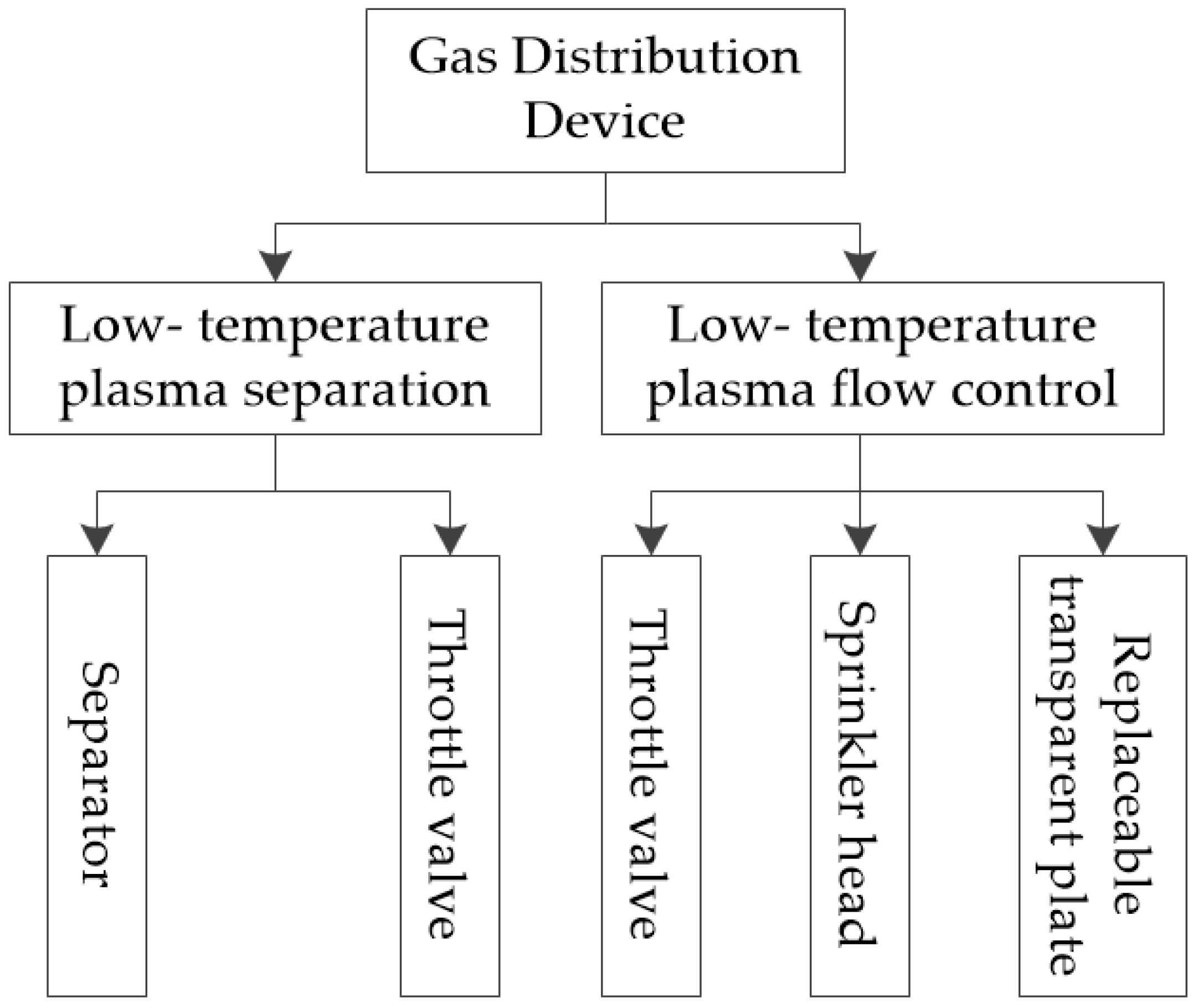

4.2. FBS Map of Low-Temperature Plasma Deposition Device

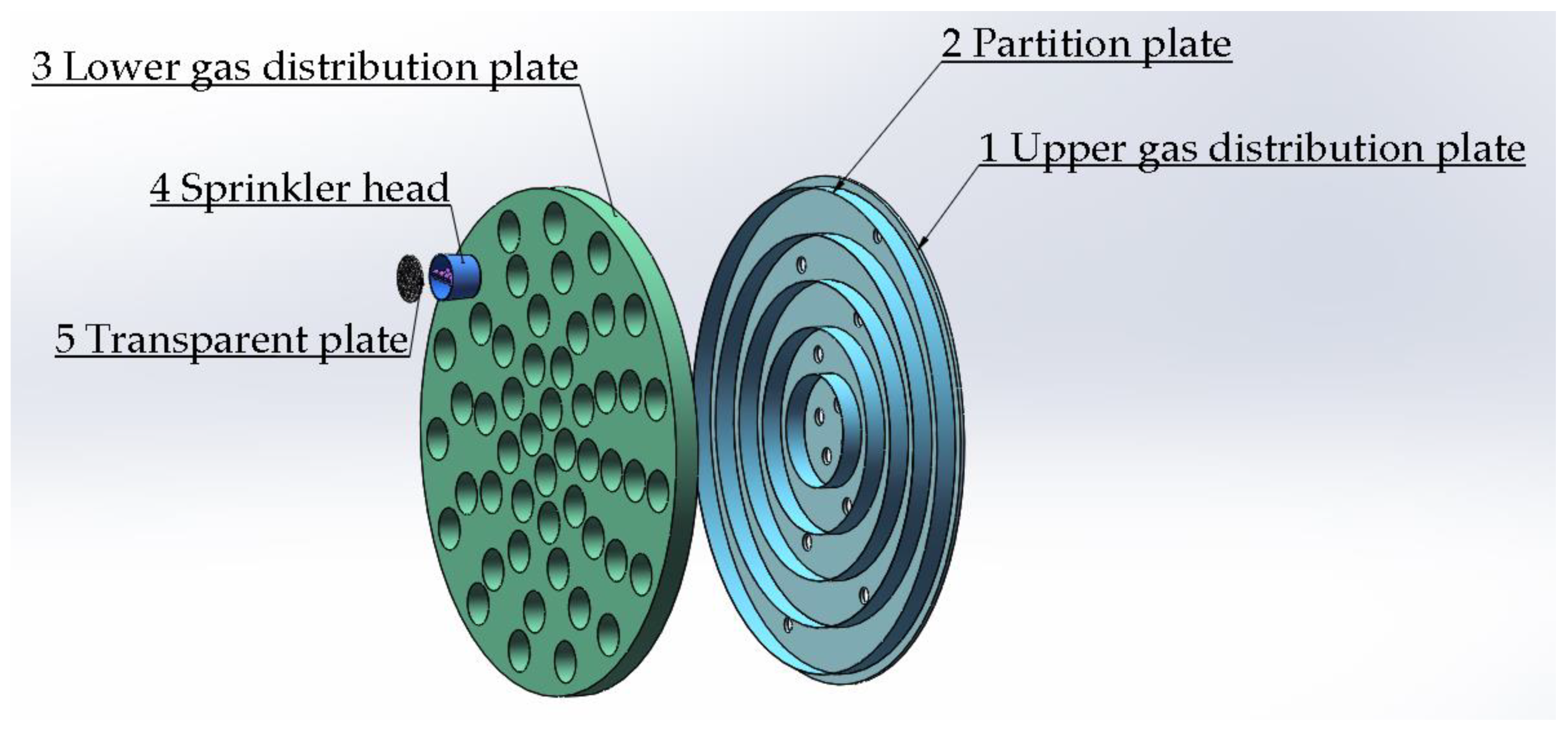

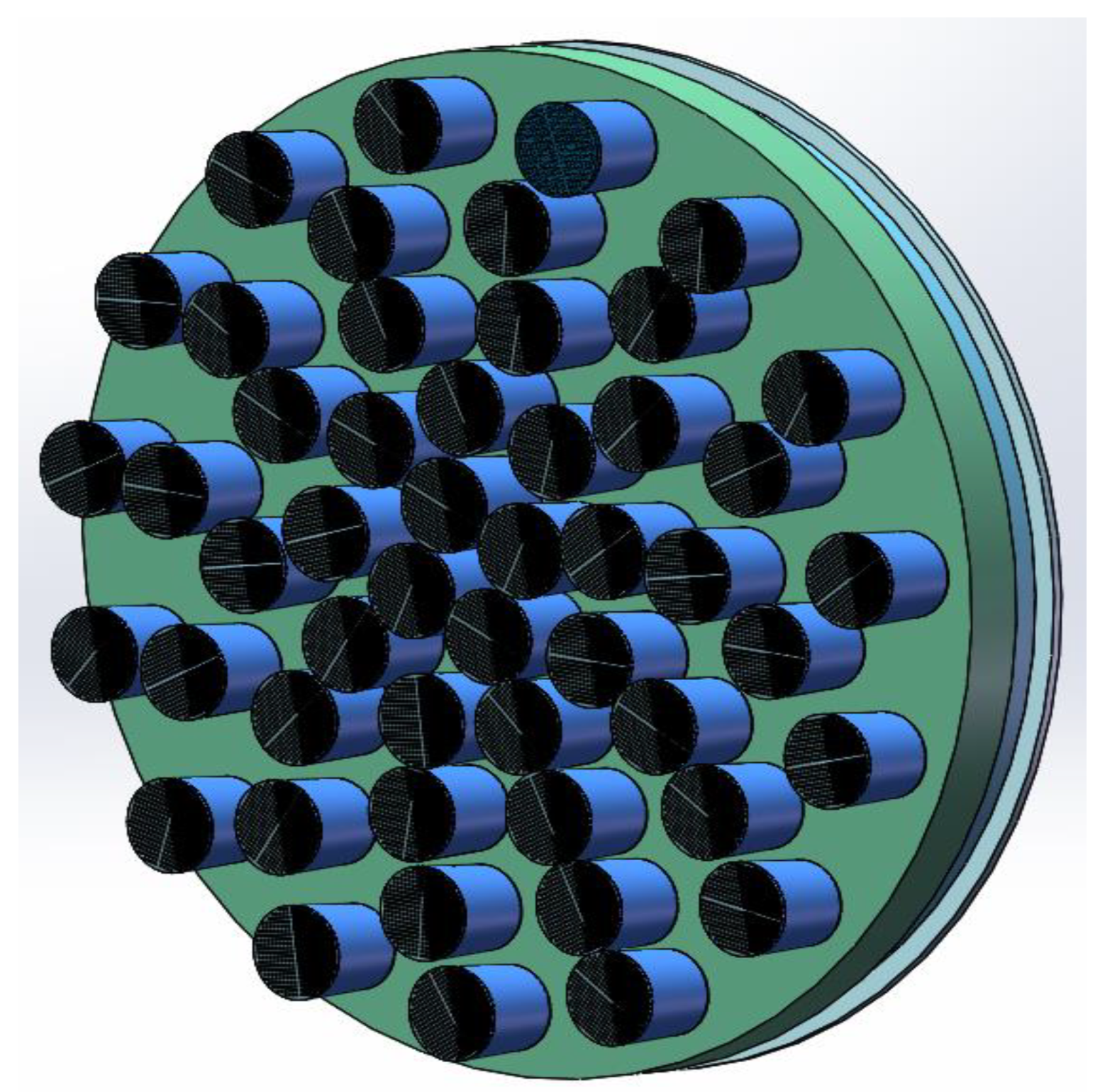

4.3. Iterative Conceptual Design of Low-Temperature Plasma Deposition Device

4.4. FAHP Scheme Evaluation

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Question | Enjoyed It | As It Should Be | No Matter | Reluctantly Accepted | Disgusted |

|---|---|---|---|---|---|

| The device adopts gas mixing system, your review is: | |||||

| Without this feature, your review is: | |||||

| The device can maintain a good vacuum degree, your review is: | |||||

| Without this feature, your review is: | |||||

| The device can generate stable low-temperature plasma, your review is: | |||||

| Without this feature, your review is: | |||||

| The device adopts a low-temperature plasma gas distribution uniform device. Your review is: | |||||

| Without this feature, your review is: | |||||

| The device adopts the visual design of low-temperature plasma parameters. Your review is: | |||||

| Without this feature, your review is: | |||||

| The device adopts exhaust gas pollution treatment device. Your review is: | |||||

| Without this feature, your review is: |

Appendix B

| Grading Criteria | Description |

|---|---|

| 0.1 | The latter is extremely important than the former |

| 0.3 | The latter is obviously more important than the former |

| 0.5 | The latter is equally important than the former |

| 0.7 | The former is obviously more important than the latter |

| 0.9 | The former is extremely important than the latter |

| 0.2/0.4/0.6/0.8 are intermediate values | |

References

- Areiszewski, T.; Zlotin, B. Ideation/TRIZ: Innovation Key to Competitive Advantage and Growth; Ideation International Inc.: Farmington Hills, MI, USA, 2001. [Google Scholar]

- Savransky, S.D. Engineering of Creativity: Introduction to TRIZ Methodology of Inventive Problem Solving; CRC Press: Boca Raton, FL, USA, 2000; p. 408. [Google Scholar]

- Cristiano, J.J.; Liker, J.K.; White, C.C. Customer-driven product development through quality function deployment in the US and Japan. J. Prod. Innovat. Manag. 2000, 17, 286–308. [Google Scholar] [CrossRef]

- Sawaguchi, M. Effective Approaches to Solving Technical Problems by Combining TRIZ with VE. In Proceedings of the TRIZCON2000, Nashua, NH, USA, 30 April–2 May 2000. [Google Scholar]

- Schuh, G.; Assmus, D.; Paulukuhn, L.; Weber, P. Modular requirement management in product development. In Proceedings of the ECEC 2003: 10th European Concurrent Engineering Conference 2003: Concurrent Engineering: Ten Years On, Plymouth, UK, 14–16 April 2003; pp. 135–138. [Google Scholar]

- Asión-Suñer, L.; López-Forniés, I. Modular Design: Product Design Opportunities and a Case Analysis; Cavas-Martínez, F., Eynard, B., Fernández Cañavate, F.J., Fernández-Pacheco, D.G., Morer, P., Nigrelli, V., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 596–609. [Google Scholar]

- Gao, H.H.; Zhang, Y.Y. Application of Modular Design Method in Product Design. In Proceedings of the 2020 International Conference on Intelligent Design (ICID), Xi’an, China, 11–13 December 2020; pp. 292–297. [Google Scholar]

- Uhlenbrock, L.; Sixt, M.; Tegtmeier, M.; Schulz, H.; Hagels, H.; Ditz, R.; Strube, J. Natural Products Extraction of the Future-Sustainable Manufacturing Solutions for Societal Needs. Processes 2018, 6, 177. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Park, C.; Lee, H. The Effect of Incremental Innovation and Switching-Over to Architectural Innovation on the Sustainable Performance of Firms: The Case of the NAND Flash Memory Industry. Sustainability 2019, 11, 7105. [Google Scholar] [CrossRef] [Green Version]

- Clark, G.; Kosoris, J.; Hong, L.N.; Crul, M. Design for Sustainability: Current Trends in Sustainable Product Design and Development. Sustainability 2009, 1, 409–424. [Google Scholar] [CrossRef]

- Bai, Z.H.; Mu, L.; Lin, H.C. Green Product Design Based on the Bio-TRIZ Multi-Contradiction Resolution Method. Sustainability 2020, 12, 4276. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Zhao, W.; Guo, X.; Hu, H.C.; Fu, C.; Liu, Y. Multi-Indicators Decision for Product Design Solutions: A TOPSIS-MOGA Integrated Model. Processes 2022, 10, 303. [Google Scholar] [CrossRef]

- Guo, X.; Liu, Y.; Zhao, W.; Wang, J.; Chen, L. Supporting resilient conceptual design using functional decomposition and conflict resolution. Adv. Eng. Inform. 2021, 48, 101262. [Google Scholar] [CrossRef]

- Chen, W.; Wu, Z.; Jie, W.; Ling, C.; Xin, G.; Kai, Z. Strategy of Innovative Design Based on Requirements and Conflicts Solving. J. Sichuan Univ. 2016, 4, 168–174. [Google Scholar]

- Guo, X.; Zhao, W.; Hu, H.C.; Li, L.; Liu, Y.; Wang, J.; Zhang, K. A smart knowledge deployment method for the conceptual design of low-carbon products. J. Clean. Prod. 2021, 321, 128994. [Google Scholar] [CrossRef]

- Zhang, K.; Zhao, W.; Guo, X.; Chen, L. Research on Smart Knowledge Application Methods for Green Manufacturing. In Proceedings of the 16th IEEE International Conference on Automation Science and Engineering (CASE), Online, 20–21 August 2020; pp. 294–299. [Google Scholar]

- Rostetter, R.; Jenni, B.; Eggmann, S.; Meyer, J.T.; Schmitt, K.U. Implementing an Interprofessional User-centered Design Approach to Develop a Beside Leg Exercise Device. Technol. Health Care. 2022, 1–12. [Google Scholar] [CrossRef]

- Xuan, J.; Xu, B.; Li, B. Design Method for Visually Impaired People Travel Aids Based on Kano Model. In Proceedings of the 2021 2nd International Conference on Intelligent Design (ICID), Xi’an, China, 19 October 2021; pp. 417–421. [Google Scholar]

- Goldenberg, J.; Mazursky, D. Creativity in Product Innovation; Cambridge University Press: Cambridge, UK, 2002; pp. 94–96. [Google Scholar]

- Ishizaka, A. Comparison of Fuzzy Logic, AHP, FAHP and Hybrid Fuzzy AHP for New Supplier Selection and Its Performance Analysis. Int. J. Integr. Supply Manag. 2014, 9, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Acharya, S.; Ghadge, K.; Ranjan, B.; Devadula, S.; Chakrabarti, A. Evaluating the effectiveness of InDeaTe tool in supporting design for sustainability. Artif. Intell. Eng. Des. Anal. Manuf. 2020, 34, 45–54. [Google Scholar] [CrossRef]

- Carrara, P.; Morandi, W.; Tandoi, E. Building A Green Development Roadmap Using 5RS and TRIZ. Acta. Tech. Napoc. Ser. 2021, 64, 465–474. [Google Scholar]

- Ahrens, M.; Hehenberger, P. Empathic-Design Assisted by the KANO Method: A Human-Centered Design Method for Medical Devices Considering Patients. In Proceedings of the 20th International Conference on Engineering Design (ICED 15), Politecnico di Milano, Italy, 27–30 July 2015. [Google Scholar]

- Ji-wen, C. Product innovative design based on variant space FBS ontology mapping. CIMS 2013, 19, 2671–2679. [Google Scholar]

- Hsieh, H. Applying TRIZ and Fuzzy AHP Based on Lean Production to Develop an Innovative Design of a New Shape for Machine Tools. Information 2015, 6, 89–110. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.Q.; Xie, Z.W.; Ren, S.D.; Ye, D.F.; Zhan, M.; Zhao, Y.W. Conduction Transformation-Based Coordination Method for Conflict in Product Adaptive Design Driven by Functional Requirements. Appl. Sci. 2021, 11, 11757. [Google Scholar] [CrossRef]

- Cascini, G.; Fantoni, G.; Montagna, F. Situating needs and requirements in the FBS framework. Des. Stud. 2013, 34, 636–662. [Google Scholar] [CrossRef]

- Vinogradova-Zinkevic, I.; Podvezko, V.; Zavadskas, E.K. Comparative Assessment of the Stability of AHP and FAHP Methods. Symmetry 2021, 13, 479. [Google Scholar] [CrossRef]

- Lin, C. Application of fuzzy Delphi method (FDM) and fuzzy analytic hierarchy process (FAHP) to criteria weights for fashion design scheme evaluation. Int. J. Cloth. Sci. Technol. 2013, 25, 171–183. [Google Scholar] [CrossRef]

- Rodman, G.S.A.S. The Innovation Algorithm: TRIZ, Systematic Innovation and Technical Creativity; Technical Innovation Ctr.: Wuhan, China, 2008; p. 245. [Google Scholar]

- Rich, J. Brainstorm: Tap into Your Creativity to Generate Awesome Ideas and Remarkable Results; Career Press: Wayne, NJ, USA, 2003; p. 187. [Google Scholar]

- Chang, W.C.; Van, Y.T. Researching design trends for the redesign of product form. Des. Stud. 2003, 24, 173–180. [Google Scholar] [CrossRef]

- Ahmed, K.M.; Allam, T.M.; El-Sayed, H.A.; Soliman, H.M.; Ward, S.A.; Saied, E.M. Design, Construction and Characterization of AC Atmospheric Pressure Air Non-Thermal Plasma Jet. J. Fusion Energy 2014, 33, 627–633. [Google Scholar] [CrossRef]

- Jun, K.H. Enhancement of Cleanliness and Deposition Rate by Understanding the Multiple Roles of the Showerhead Electrode in a Capacitively Coupled Plasma Reactor. Coatings 2021, 11, 999. [Google Scholar]

- Knapek, C.A.; Konopka, U.; Mohr, D.P.; Huber, P.; Lipaev, A.M.; Thomas, H.M. “Zyflex”: Next generation plasma chamber for complex plasma research in space. Rev. Sci. Instrum. 2021, 92, 103505. [Google Scholar] [CrossRef] [PubMed]

- Muchtiar, Y.; Mufti, D.; Yosri, V. Quality Improvement of Industrial Products Bungo Mayang to Customer Satisfaction with The Kano Model Approach. In Proceedings of the 4th Engineering Science and Technology International Conference (ESTIC), Padang, Indonesia, 28–29 August 2018; Volume 248. [Google Scholar]

- Takagi, S.; Uesu, H. A questionnaire analysis by fuzzy reasoning for undergraduate students in mathematics lectures applying the Kano model. In Proceedings of the 2014 Joint 7th International Conference on Soft Computing and Intelligent Systems (SCIS) and 15th International Symposium on Advanced Intelligent Systems (ISIS), Kitakyushu, Japan, 3–4 December 2014; pp. 851–854. [Google Scholar]

- Zhong, S. Hierarchical Analysis of Regional Cultural and Creative Product Demand Based on Fuzzy Kano Model. Ecol. Environ. Conserv. 2020, 179, 2007. [Google Scholar] [CrossRef]

- Liang, Q.; Wang, R.; Yang, M.; Ding, Y.; Wang, C. A green, low-cost method to prepare GaN films by plasma enhanced chemical vapor deposition. Thin Solid Films 2020, 710, 138266. [Google Scholar] [CrossRef]

- Ko, Y.T. Modeling an Innovative Green Design Method for Sustainable Products. Sustainability 2020, 12, 3351. [Google Scholar] [CrossRef] [Green Version]

- Min, A.; Lee, J.H. A Conceptual Framework for the Externalization of Ecological Wisdom: The Case of Traditional Korean Gardens. Sustainability 2019, 11, 5298. [Google Scholar] [CrossRef] [Green Version]

- Ren, S.D.; Gui, F.Z.; Zhao, Y.W.; Zhan, M.; Wang, W.L.; Zhou, J.Q. An Extenics-Based Scheduled Configuration Methodology for Low-Carbon Product Design in Consideration of Contradictory Problem Solving. Sustainability 2021, 13, 5859. [Google Scholar] [CrossRef]

- Eberhardt, L.; van Stijn, A.; Stranddorf, L.K.; Birkved, M.; Birgisdottir, H. Environmental Design Guidelines for Circular Building Components: The Case of the Circular Building Structure. Sustainability 2021, 13, 5621. [Google Scholar] [CrossRef]

- Vinodh, S.; Kamala, V.; Jayakrishna, K. Integration of ECQFD, TRIZ, and AHP for innovative and sustainable product development. Appl. Math. Model. 2014, 38, 2758–2770. [Google Scholar] [CrossRef]

- Hapuwatte, B.M.; Jawahir, I.S. A total life cycle approach for developing predictive design methodologies to optimize product performance. Sustain. Manuf. Glob. Circ. Econ. 2019, 33, 11–18. [Google Scholar] [CrossRef]

| Serial No. | Factor | Weights |

|---|---|---|

| 1 | Gas mixing system | 0.1642 |

| 2 | Vacuum degree is excellent | 0.1532 |

| 3 | Stable low-temperature plasma generation | 0.2015 |

| 4 | Low-temperature plasma gas distribution uniform | 0.2029 |

| 5 | Low-temperature plasma parameters are visible | 0.1248 |

| 6 | Exhaust gas pollution treatment | 1.1465 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Yu, M.; Zhao, W.; Zhang, K.; Chen, J.; Guo, X. An Iterative Conceptual Design Process for Modular Product Based on Sustainable Analysis and Creative Template Method. Processes 2022, 10, 1095. https://doi.org/10.3390/pr10061095

Zhou J, Yu M, Zhao W, Zhang K, Chen J, Guo X. An Iterative Conceptual Design Process for Modular Product Based on Sustainable Analysis and Creative Template Method. Processes. 2022; 10(6):1095. https://doi.org/10.3390/pr10061095

Chicago/Turabian StyleZhou, Junyu, Miao Yu, Wu Zhao, Kai Zhang, Jun Chen, and Xin Guo. 2022. "An Iterative Conceptual Design Process for Modular Product Based on Sustainable Analysis and Creative Template Method" Processes 10, no. 6: 1095. https://doi.org/10.3390/pr10061095

APA StyleZhou, J., Yu, M., Zhao, W., Zhang, K., Chen, J., & Guo, X. (2022). An Iterative Conceptual Design Process for Modular Product Based on Sustainable Analysis and Creative Template Method. Processes, 10(6), 1095. https://doi.org/10.3390/pr10061095