Effect of Spray Parameters on Electrical Characteristics of Printed Layer by Morphological Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Electro-Conductive Ink

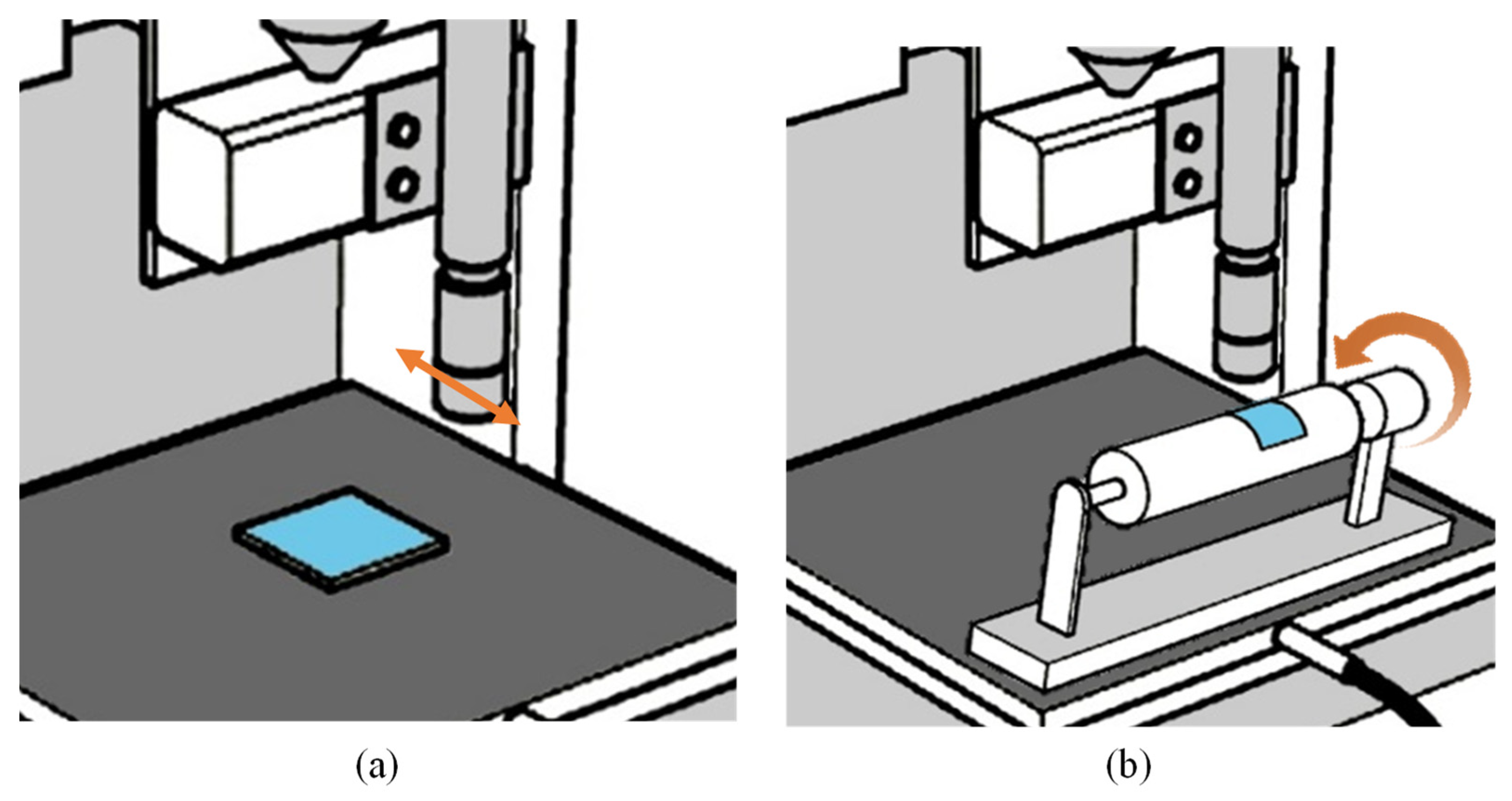

2.3. Spray Printing

2.4. Characterization

3. Results

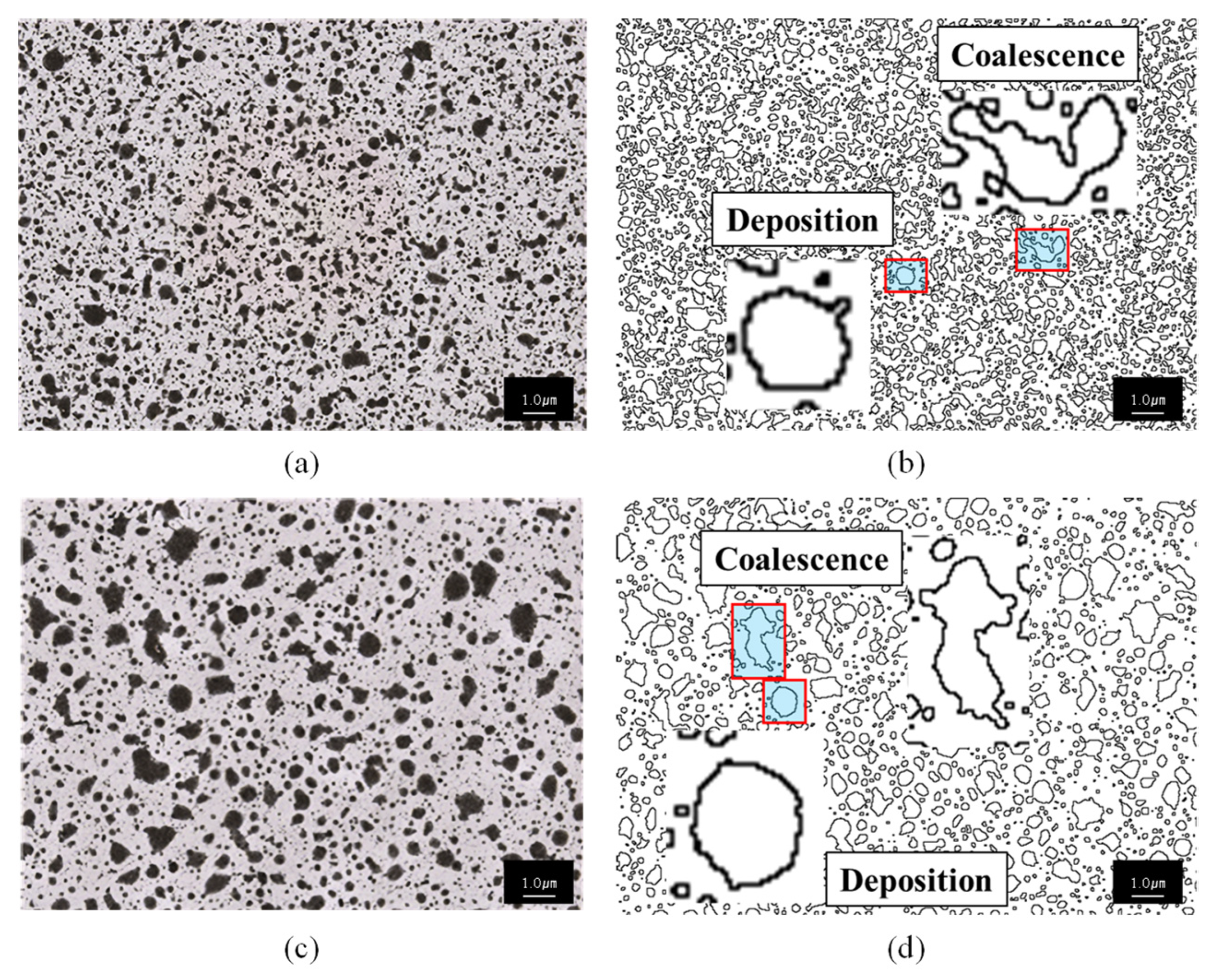

3.1. Effect of Nozzle Diameter

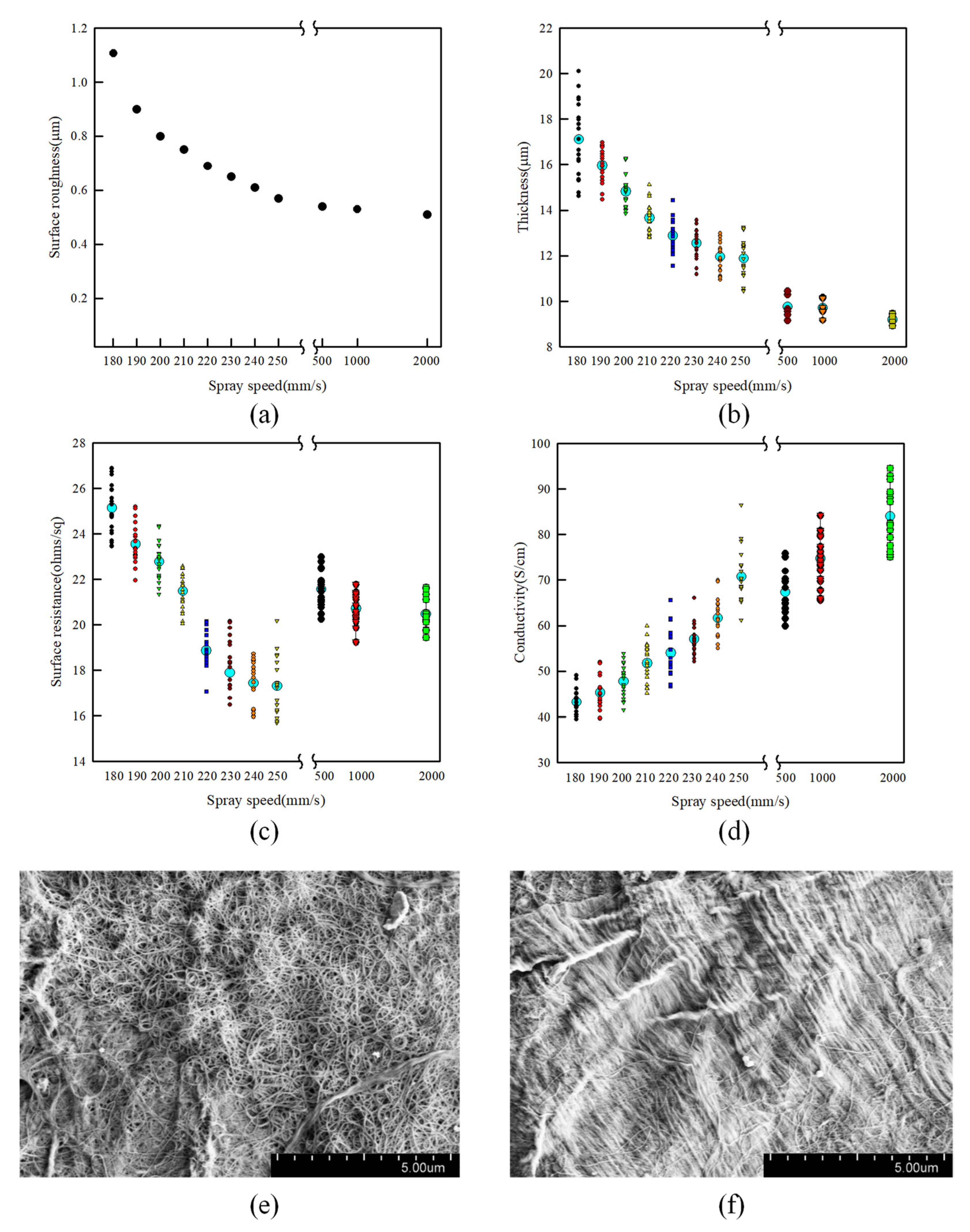

3.2. Effect of Spraying Speed

3.3. Effect of Spray Amount

3.4. Effect of Distance of the Nozzle to Substrate (DNS)

3.5. Effect of Nozzle Pressure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rong, Q.; Lei, W.; Liu, M. Conductive Hydrogels as Smart Materials for Flexible Electronic Devices. Chem. A Eur. J. 2018, 24, 16930–16943. [Google Scholar] [CrossRef]

- Baeg, K.-J.; Lee, J. Flexible Electronic Systems on Plastic Substrates and Textiles for Smart Wearable Technologies. Adv. Mater. Technol. 2020, 5, 2000071. [Google Scholar] [CrossRef]

- Xie, Y.; Gao, S.; Eslamian, M. Fundamental Study on the Effect of Spray Parameters on Characteristics of P3HT:PCBM Active Layers Made by Spray Coating. Coatings 2015, 5, 488–510. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Wu, R.; Huang, J.; Yu, J. Color-tunable and high-efficiency organic light-emitting diode by adjusting exciton bilateral migration zone. Appl. Phys. Lett. 2013, 103, 133307. [Google Scholar] [CrossRef]

- Shi, W.; Yu, J.; Huang, W.; Yu, X.; Zheng, Y. Performance enhancement of poly(3-hexylthiophene) organic field-effect transistor by inserting poly(methylmethacrylate) buffer layer. Appl. Phys. Lett. 2013, 102, 111607. [Google Scholar] [CrossRef]

- Russo, A.; Ahn, B.Y.; Adams, J.J.; Duoss, E.B.; Bernhard, J.T.; Lewis, J.A. Pen-on-Paper Flexible Electronics. Adv. Mater. 2011, 23, 3426–3430. [Google Scholar] [CrossRef]

- Janeczek, K.; Serzysko, T.; Jakubowska, M.; Kozioł, G.; Młożniak, A. Mechanical durability of RFID chip joints assembled on flexible substrates. Solder. Surf. Mt. Technol. 2012, 24, 206–215. [Google Scholar] [CrossRef]

- Yu, J.; Yuan, Z.; Han, S.; Ma, Z. Size-selected growth of transparent well-aligned ZnO nanowire arrays. Nanoscale Res. Lett. 2012, 7, 517. [Google Scholar] [CrossRef] [Green Version]

- De Rossi, D. A logical step. Nat. Mater. 2007, 6, 328–329. [Google Scholar] [CrossRef]

- Li, C.; Han, J.; Ahn, C.H. Flexible biosensors on spirally rolled micro tube for cardiovascular in vivo monitoring. Biosens. Bioelectron. 2007, 22, 1988–1993. [Google Scholar] [CrossRef]

- Lee, S.; Koo, J.; Kang, S.-K.; Park, G.; Lee, Y.J.; Chen, Y.-Y.; Lim, S.A.; Lee, K.-M.; Rogers, J.A. Metal microparticle—Polymer composites as printable, bio/ecoresorbable conductive inks. Mater. Today 2018, 21, 207–215. [Google Scholar] [CrossRef]

- Xu, J.; Guo, H.; Ding, H.; Wang, Q.; Tang, Z.; Li, Z.; Sun, G. Printable and Recyclable Conductive Ink Based on a Liquid Metal with Excellent Surface Wettability for Flexible Electronics. ACS Appl. Mater. Interfaces 2021, 13, 7443–7452. [Google Scholar] [CrossRef]

- Denneulin, A.; Bras, J.; Blayo, A.; Neuman, C. Substrate pre-treatment of flexible material for printed electronics with carbon nanotube based ink. Appl. Surf. Sci. 2011, 257, 3645–3651. [Google Scholar] [CrossRef]

- Park, S.; Vosguerichian, M.; Bao, Z. A review of fabrication and applications of carbon nanotube film-based flexible electronics. Nanoscale 2013, 5, 1727–1752. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube–polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Shaghaleh, H.; Xu, X.; Wang, S. Current progress in production of biopolymeric materials based on cellulose, cellulose nanofibers, and cellulose derivatives. RSC Adv. 2018, 8, 825–842. [Google Scholar] [CrossRef] [Green Version]

- Lamm, M.E.; Li, K.; Qian, J.; Wang, L.; Lavoine, N.; Newman, R.; Gardner, D.J.; Li, T.; Hu, L.; Ragauskas, A.J.; et al. Recent Advances in Functional Materials through Cellulose Nanofiber Templating. Adv. Mater. 2021, 33, 2005538. [Google Scholar] [CrossRef]

- Chen, C.; Bu, X.; Feng, Q.; Li, D. Cellulose Nanofiber/Carbon Nanotube Conductive Nano-Network as a Reinforcement Template for Polydimethylsiloxane Nanocomposite. Polymers 2018, 10, 1000. [Google Scholar] [CrossRef] [Green Version]

- Luo, E.Z.; Heun, S.; Kennedy, M.; Wollschläger, J.; Henzler, M. Surface roughness and conductivity of thin Ag films. Phys. Rev. B 1994, 49, 4858–4865. [Google Scholar] [CrossRef]

- Marom, H.; Eizenberg, M. The effect of surface roughness on the resistivity increase in nanometric dimensions. J. Appl. Phys. 2006, 99, 123705. [Google Scholar] [CrossRef]

- Dalmas, F.; Dendievel, R.; Chazeau, L.; Cavaillé, J.-Y.; Gauthier, C. Carbon nanotube-filled polymer composites. Numerical simulation of electrical conductivity in three-dimensional entangled fibrous networks. Acta Mater. 2006, 54, 2923–2931. [Google Scholar] [CrossRef]

- Liu, H.; Hsieh, Y.-L. Ultrafine fibrous cellulose membranes from electrospinning of cellulose acetate. J. Polym. Sci. Part B Polym. Phys. 2002, 40, 2119–2129. [Google Scholar] [CrossRef]

- Chatterjee, K.; Tabor, J.; Ghosh, T.K. Electrically Conductive Coatings for Fiber-Based E-Textiles. Fibers 2019, 7, 51. [Google Scholar] [CrossRef] [Green Version]

- Beecher, P.; Servati, P.; Rozhin, A.; Colli, A.; Scardaci, V.; Pisana, S.; Hasan, T.; Flewitt, A.J.; Robertson, J.; Hsieh, G.W.; et al. Ink-jet printing of carbon nanotube thin film transistors. J. Appl. Phys. 2007, 102, 043710. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Qian, L.; Xiong, H.; Chan, T.L. Effects of operating conditions on droplet deposition onto surface of atomization impinging spray. Surf. Coat. Technol. 2009, 203, 1733–1740. [Google Scholar] [CrossRef]

- Timalsina, Y.P.; Horning, A.; Spivey, R.F.; Lewis, K.M.; Kuan, T.S.; Wang, G.C.; Lu, T.M. Effects of nanoscale surface roughness on the resistivity of ultrathin epitaxial copper films. Nanotechnology 2015, 26, 075704. [Google Scholar] [CrossRef] [PubMed]

- Vardelle, M.; Vardelle, A.; Fauchais, P. Spray parameters and particle behavior relationships during plasma spraying. J. Therm. Spray Technol. 1993, 2, 79–91. [Google Scholar] [CrossRef]

- Yamamoto, N.; John Hart, A.; Garcia, E.J.; Wicks, S.S.; Duong, H.M.; Slocum, A.H.; Wardle, B.L. High-yield growth and morphology control of aligned carbon nanotubes on ceramic fibers for multifunctional enhancement of structural composites. Carbon 2009, 47, 551–560. [Google Scholar] [CrossRef]

- Tiwari, S.; Takashima, W.; Nagamatsu, S.; Balasubramanian, S.K.; Prakash, R. A comparative study of spin coated and floating film transfer method coated poly (3-hexylthiophene)/poly (3-hexylthiophene)-nanofibers based field effect transistors. J. Appl. Phys. 2014, 116, 094306. [Google Scholar] [CrossRef] [Green Version]

- Hsieh, M.C.; Kim, C.; Nogi, M.; Suganuma, K. Electrically conductive lines on cellulose nanopaper for flexible electrical devices. Nanoscale 2013, 5, 9289–9295. [Google Scholar] [CrossRef]

| Spray Parameter | Nozzle Diameter (mm (Ø)) | Spray Speed (mm/s) | The Amount of Sprayed Ink (mL) | Distance of Nozzle to Substrate (cm) | Nozzle Pressure (kPa) |

|---|---|---|---|---|---|

| Value | 0.4, 0.7 | 180, 190, 200, 210, 220, 230, 240, 250, 500, 1000, 2000 | 5, 10, 15, 20, 25 | 10, 12, 14, 16, 18 | 50, 55, 60 |

| 0.4 Ø | 0.7 Ø | |

|---|---|---|

| Number of droplets | 1755 | 1252 |

| Surface roughness (μm) | 0.95 | 1.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, G.H.; Shin, E.A.; Jung, J.Y.; Lee, J.Y.; Lee, C.K. Effect of Spray Parameters on Electrical Characteristics of Printed Layer by Morphological Study. Processes 2022, 10, 999. https://doi.org/10.3390/pr10050999

Kim GH, Shin EA, Jung JY, Lee JY, Lee CK. Effect of Spray Parameters on Electrical Characteristics of Printed Layer by Morphological Study. Processes. 2022; 10(5):999. https://doi.org/10.3390/pr10050999

Chicago/Turabian StyleKim, Gye Hyeon, Eun Ae Shin, Je Young Jung, Jun Young Lee, and Chang Kee Lee. 2022. "Effect of Spray Parameters on Electrical Characteristics of Printed Layer by Morphological Study" Processes 10, no. 5: 999. https://doi.org/10.3390/pr10050999

APA StyleKim, G. H., Shin, E. A., Jung, J. Y., Lee, J. Y., & Lee, C. K. (2022). Effect of Spray Parameters on Electrical Characteristics of Printed Layer by Morphological Study. Processes, 10(5), 999. https://doi.org/10.3390/pr10050999