The Characteristic of High-Speed Centrifugal Refrigeration Compressor with Different Refrigerants via CFD Simulation

Abstract

:1. Introduction

1.1. Development Overview of Magnetic Levitation Centrifugal Compressor

1.2. Motivation and Objective

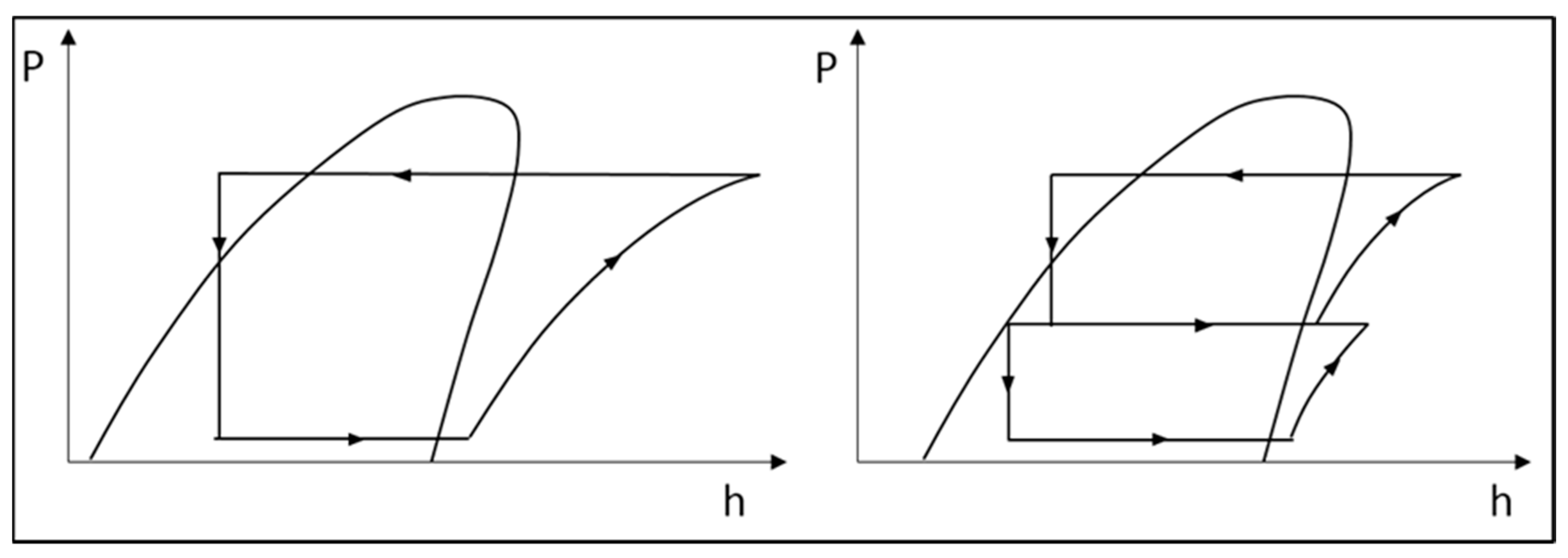

1.3. Magnetic Levitation Centrifugal Compressor Operating Principle

1.4. Magnetic Levitation Centrifugal Compressor Structure

- Inlet zone

- 2.

- Impeller zone

- 3.

- Diffuser zone

- 4.

- Volute zone

1.5. Adoption of Refrigerant

1.6. Part Load

A = COP at 100% load

B = COP at 75% load

C = COP at 50% load

D = COP at 25% load

1.7. Literature Review

1.7.1. References about Compressor

1.7.2. References about Refrigerant

2. Materials and Methods

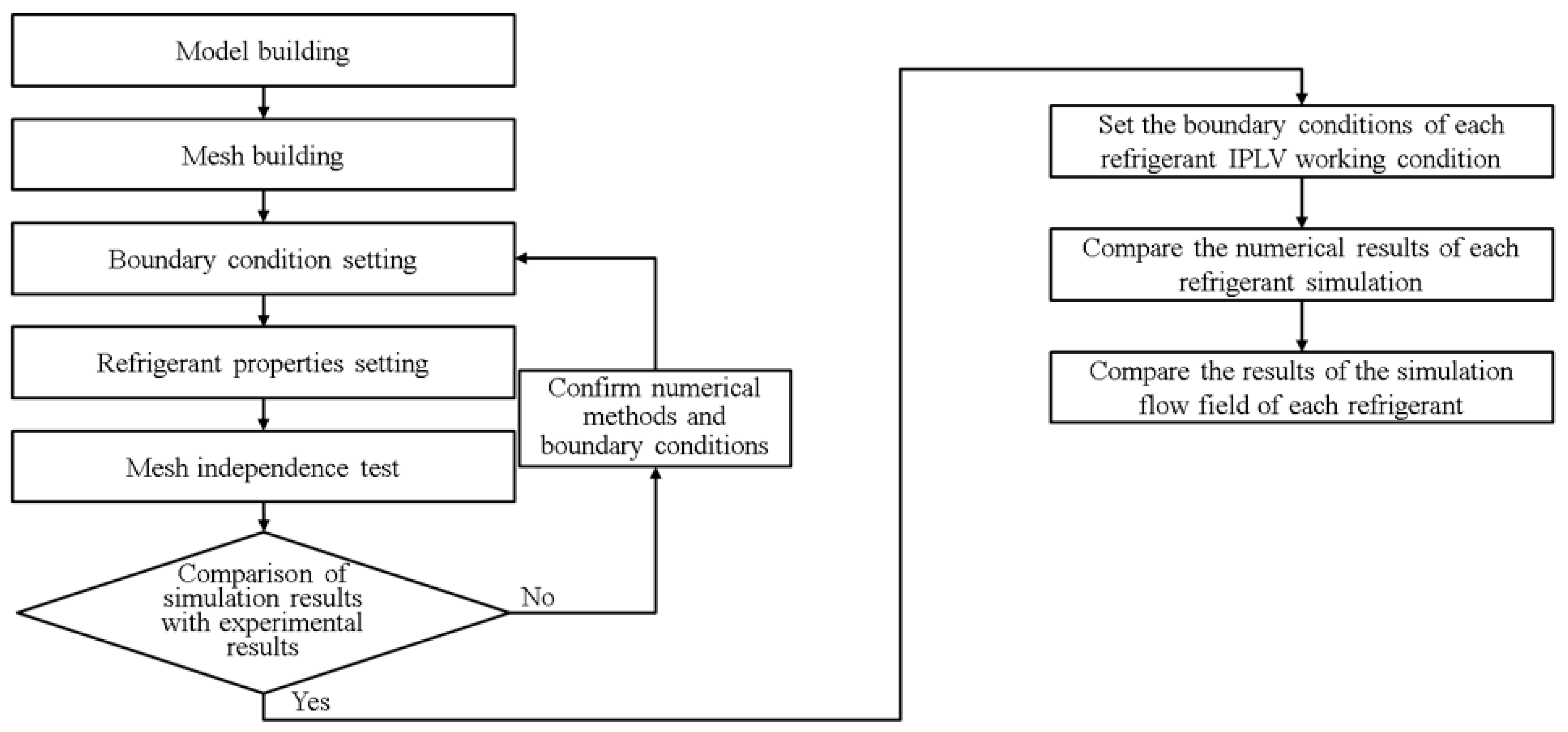

2.1. Research Method

2.2. Execution Procedure

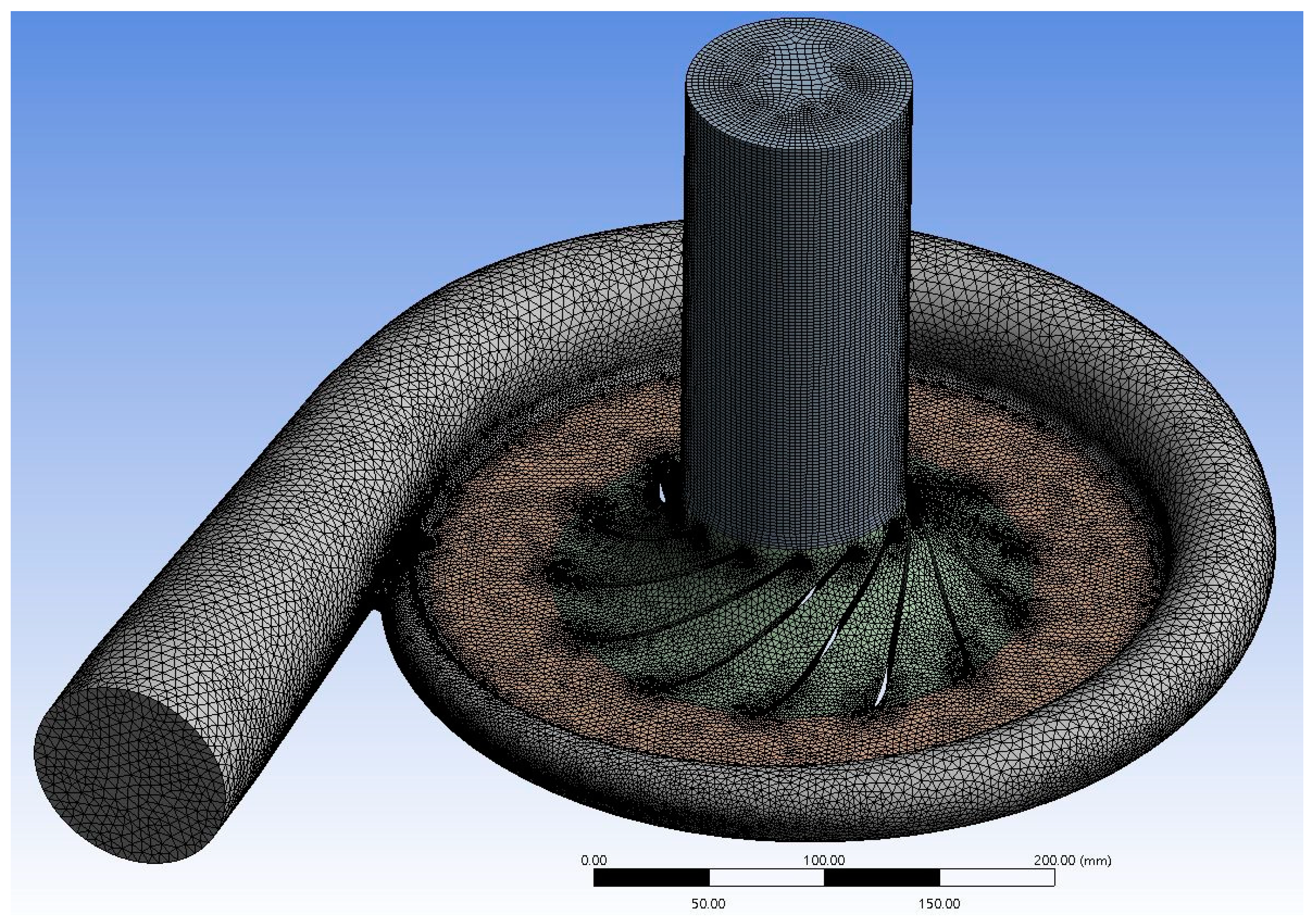

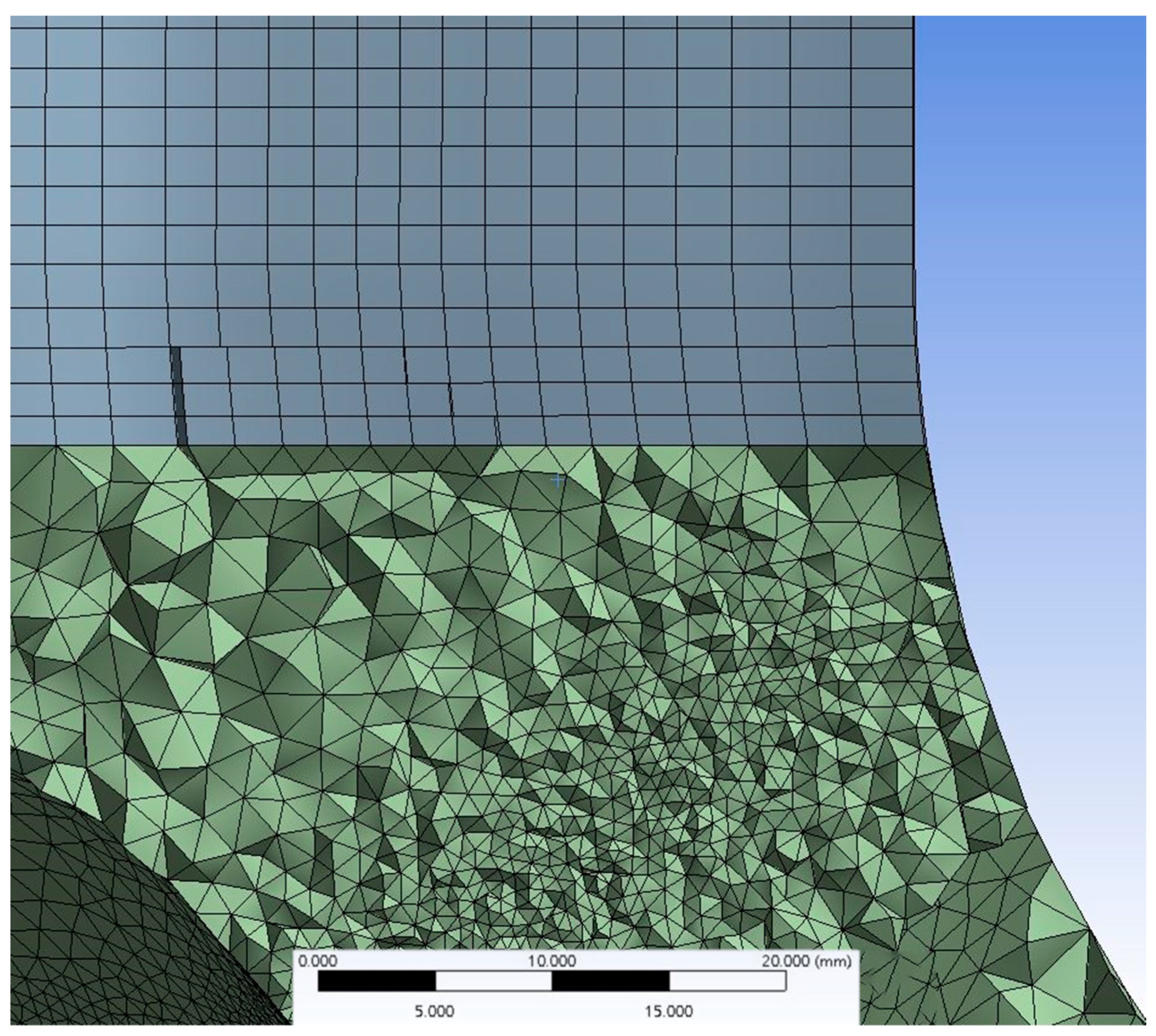

2.2.1. Meshing

2.2.2. Boundary Condition Setting

- Steady-state flow field

- Smooth adiabatic wall surface

- Leakage loss is ignored

- The gravity effect is ignored.

2.2.3. Refrigerant Properties Setting

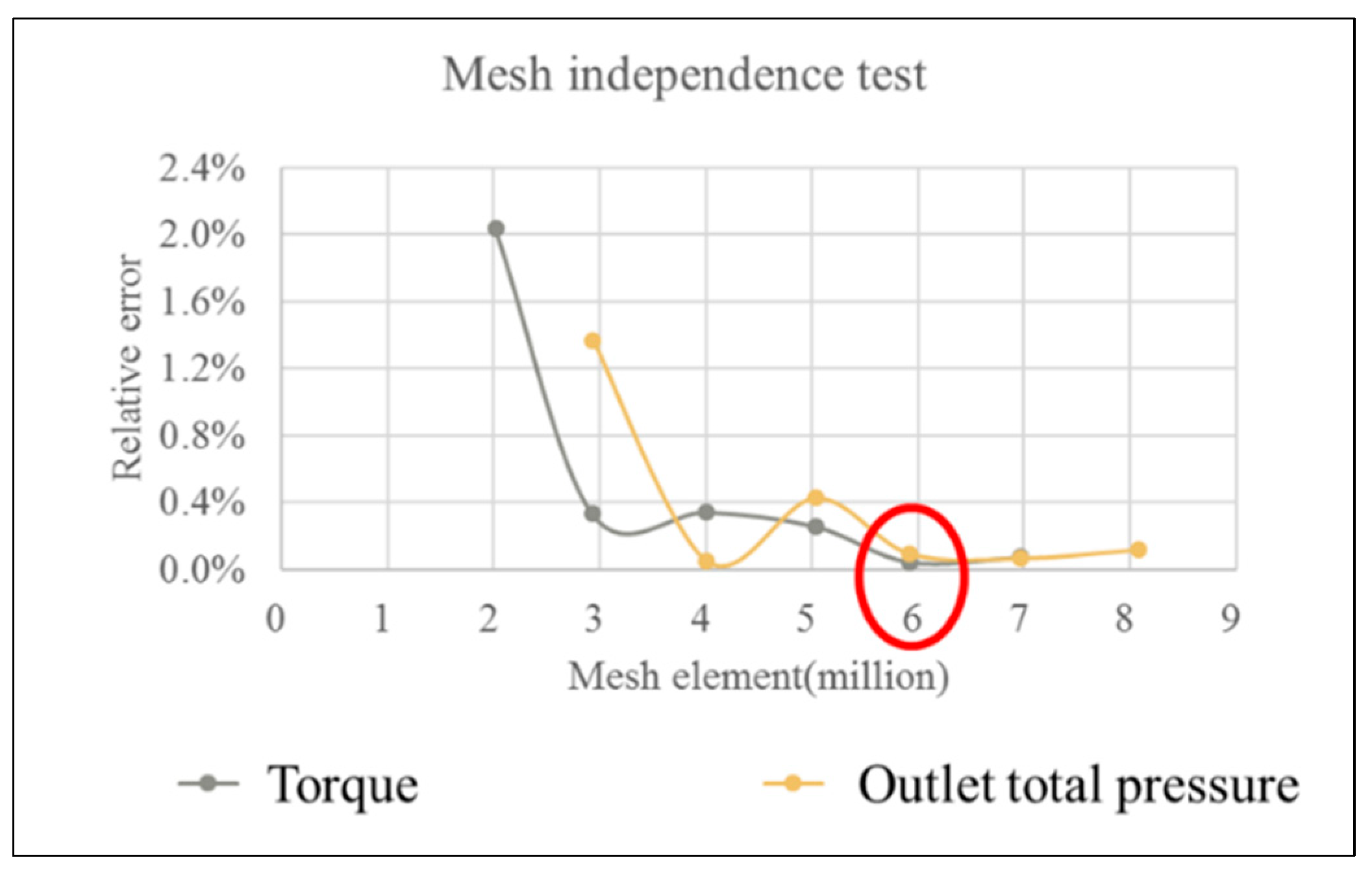

2.2.4. Mesh Independence Test

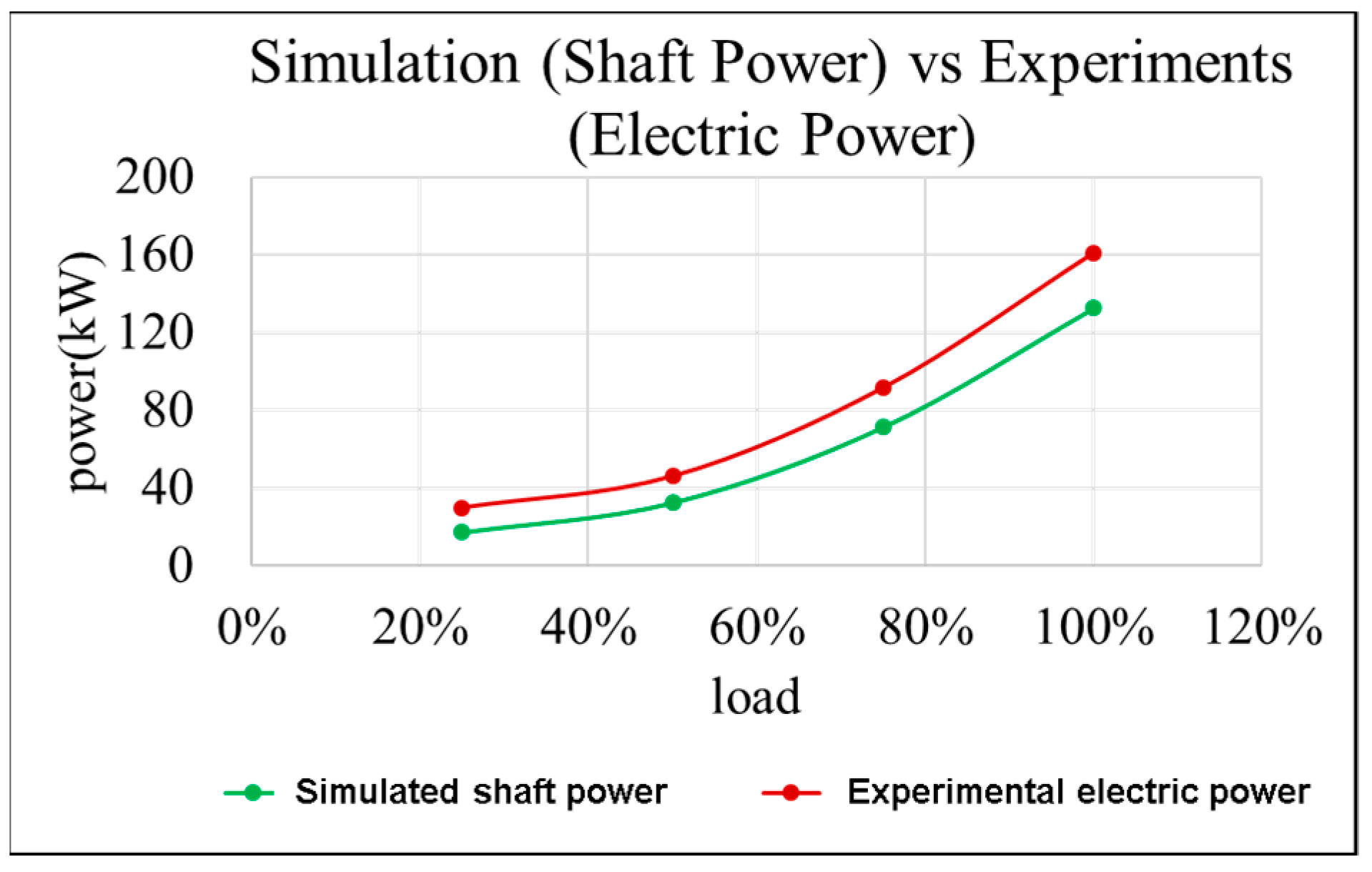

2.2.5. Comparison of Simulation and Experimental Results

3. Results and Discussion

3.1. Refrigerant Replacement Simulation Analysis—Equation Description

- (1)

- Total Pressure Ratio

- (2)

- Isentropic Efficiency

- (3)

- Shaft Power

Torque = Torque of Impeller (N)

ω = Rotating Speed of Impeller (rad/s)

- (4)

- COP (Coefficient of Performance)

Q_e = Refrigeration capacity (kW) Shaft Power = Shaft Power (kW)

- (5)

- IPLV (Integrated Part Load Value)

A = COP at 100% load B = COP at 75% load

C = COP at 50% load D = COP at 25% load

3.2. Refrigerant Replacement Simulation Analysis—Numerical Simulation Result

3.2.1. Total Pressure Ratio Comparison

3.2.2. Isentropic Efficiency Comparison

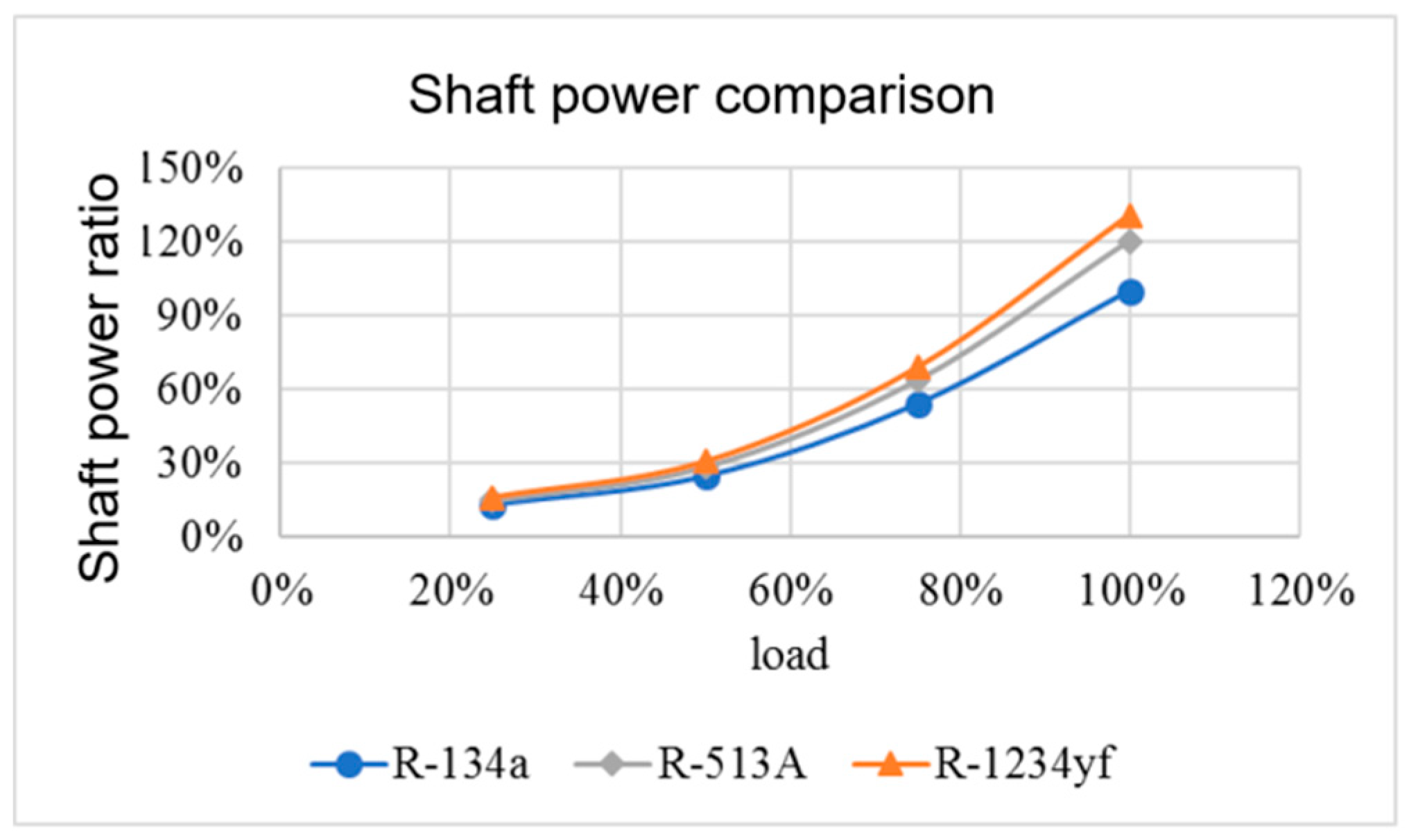

3.2.3. Shaft Power Comparison

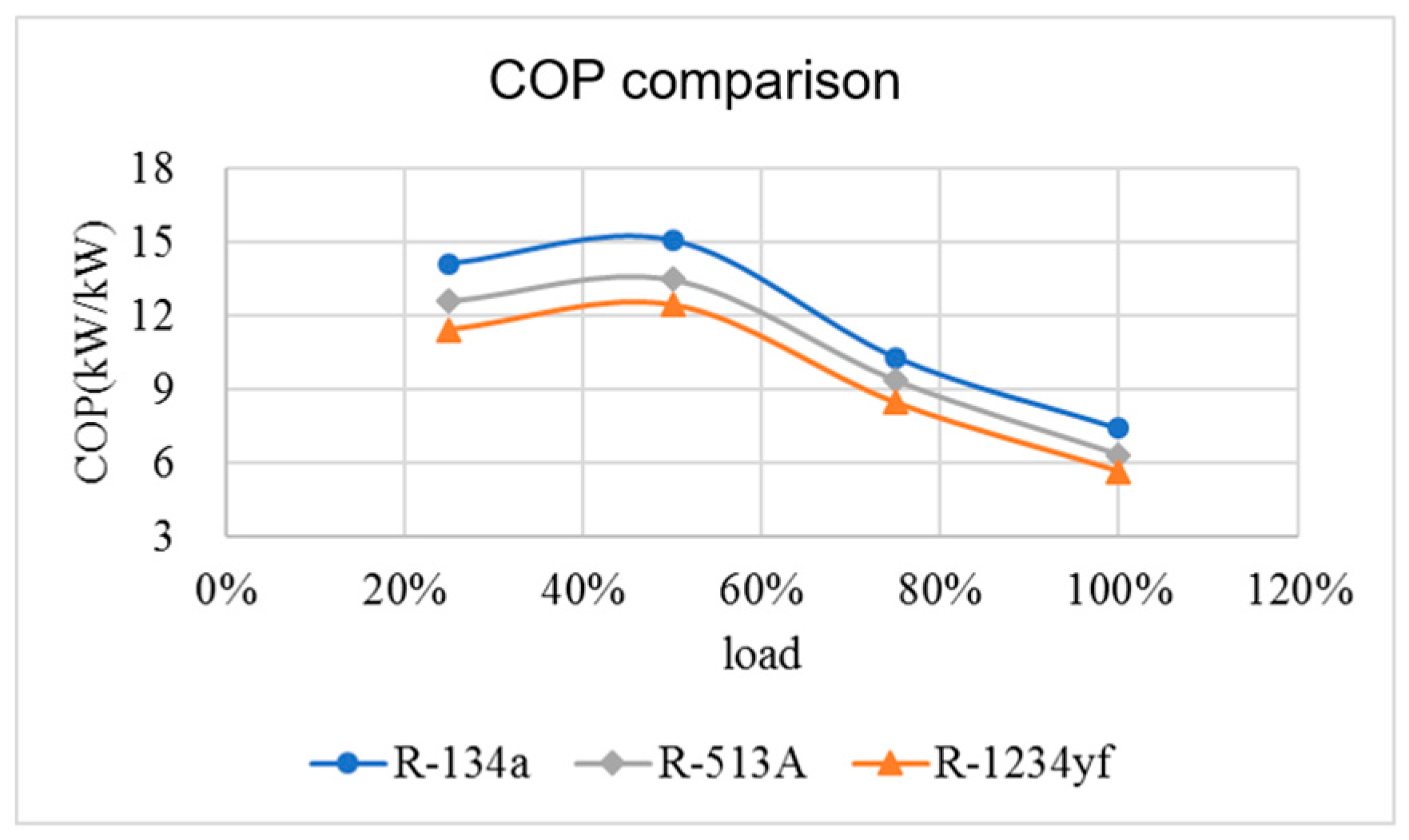

3.2.4. COP Comparison

3.2.5. IPLV Comparison

3.3. Refrigerant Replacement Simulation Analysis—Flow Field Simulation Result

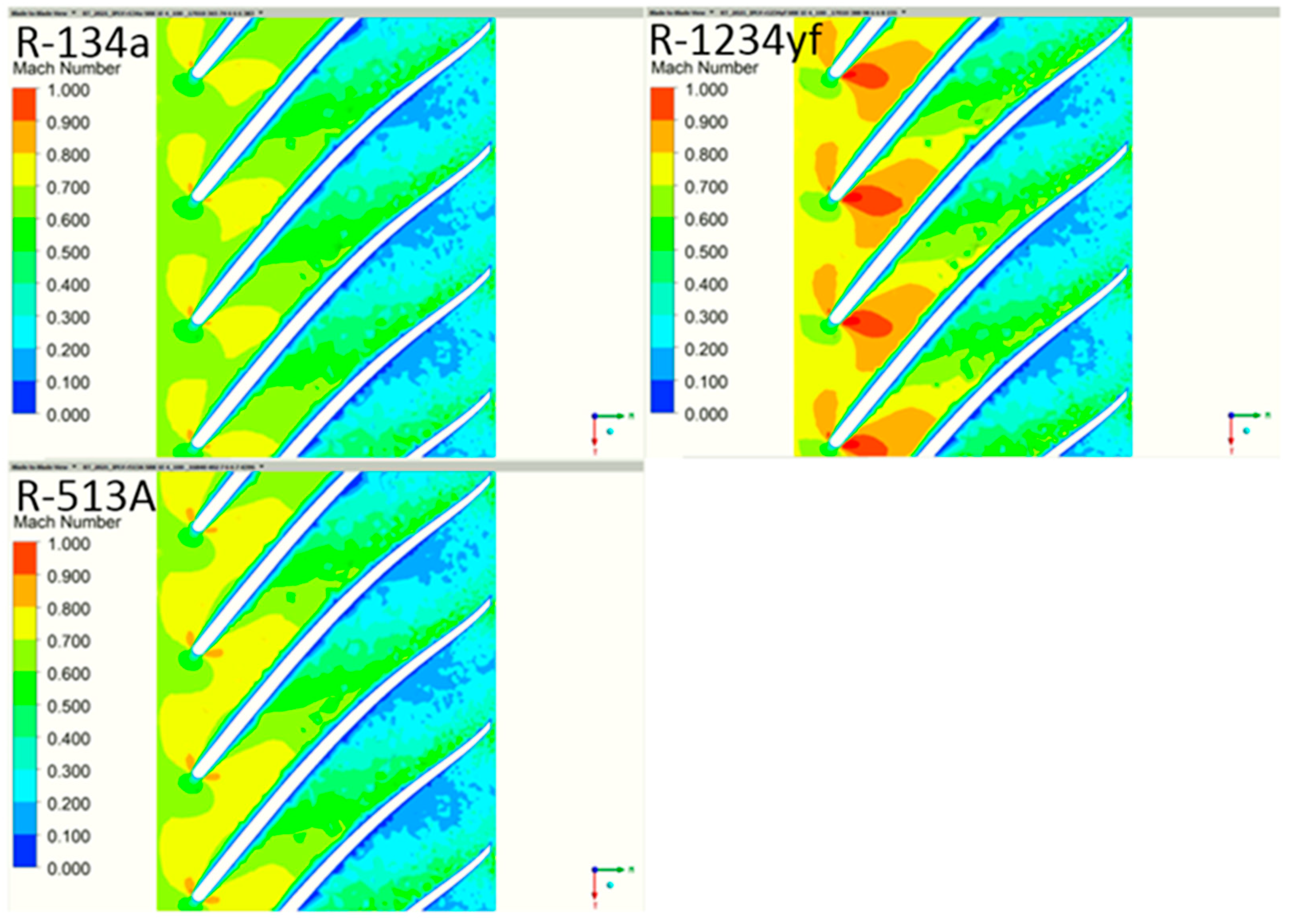

3.3.1. Inter-Blade Flow Field Simulation Result

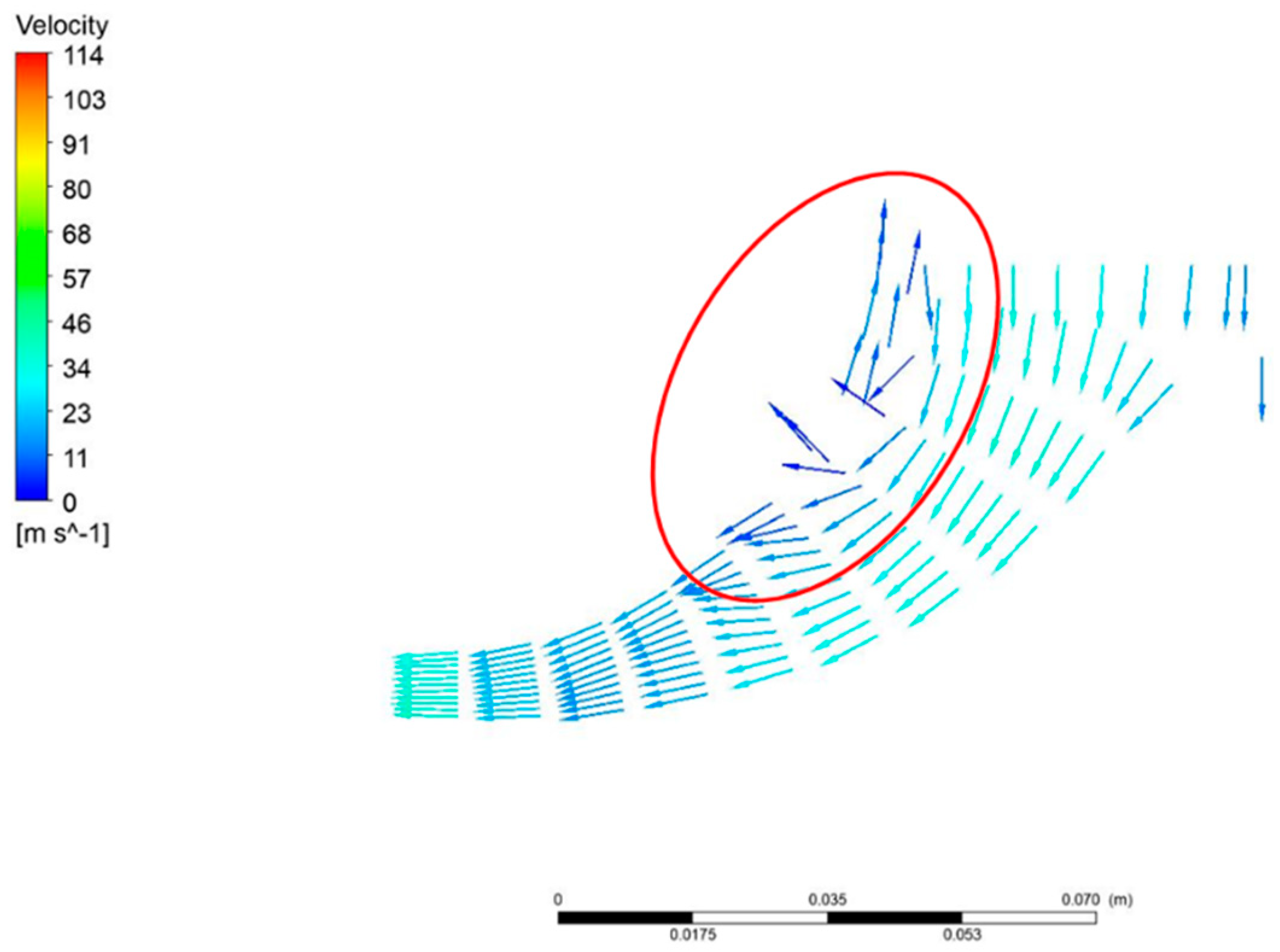

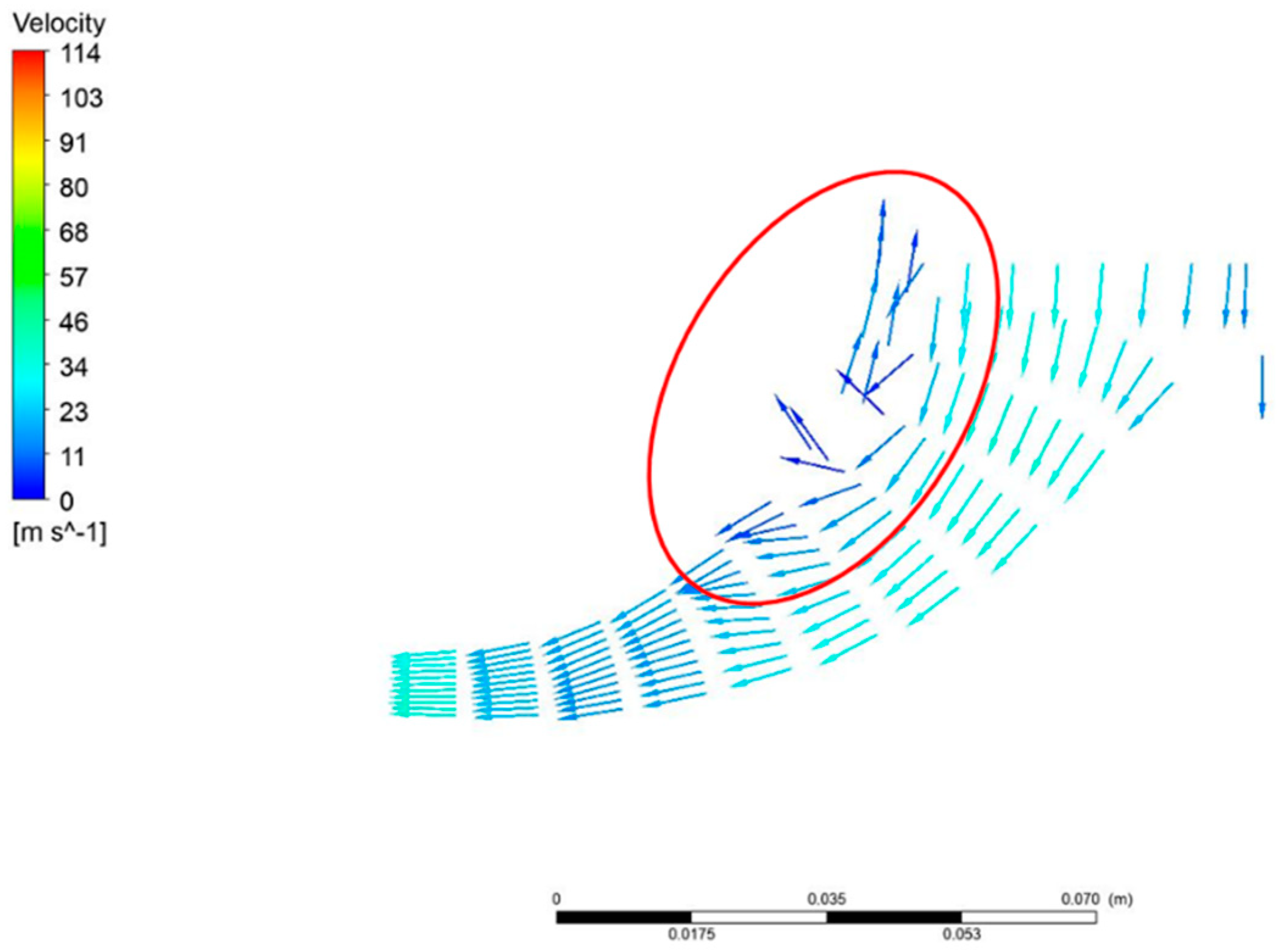

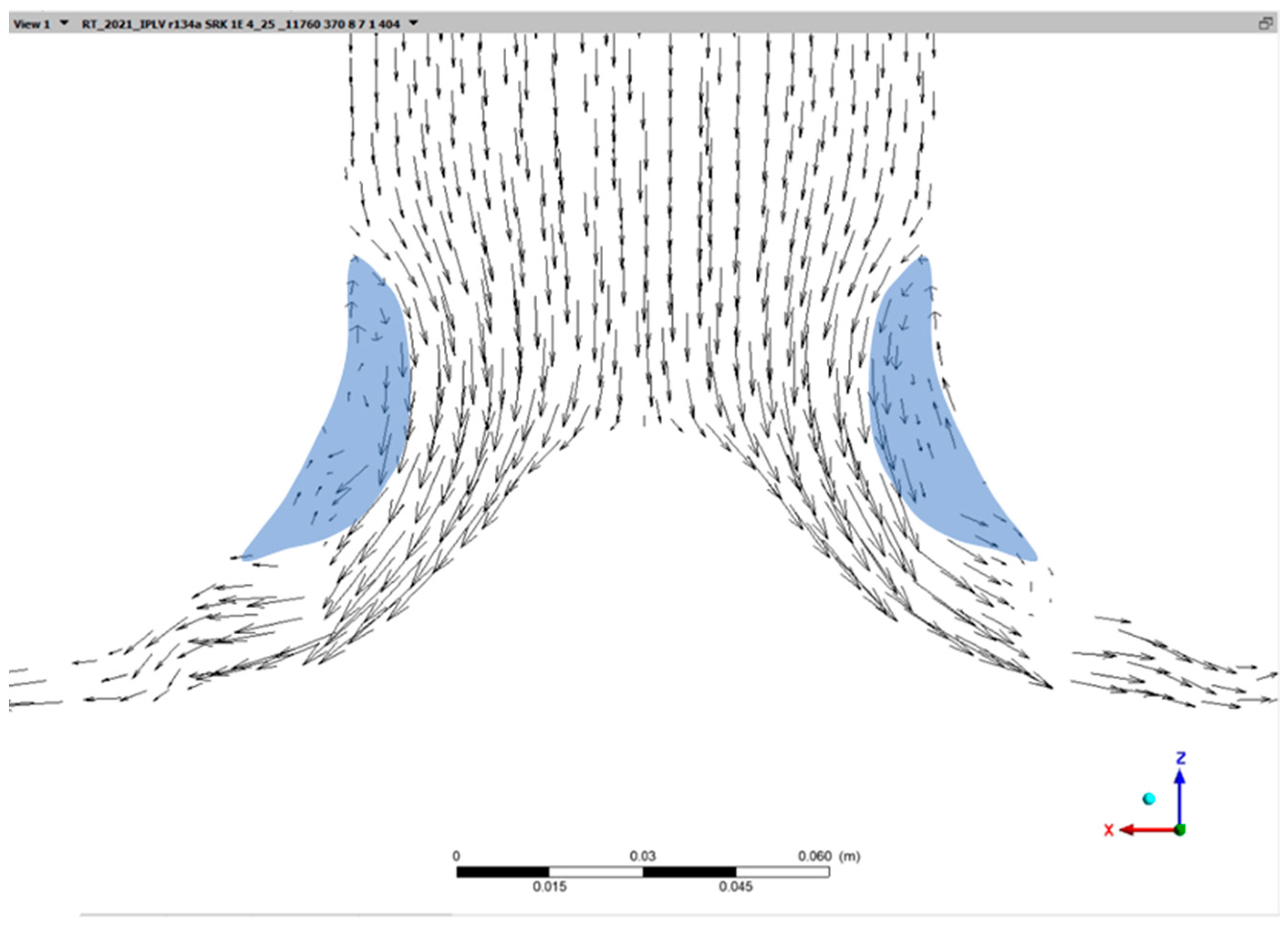

3.3.2. Flow Field on Meridian Plane Analysis Result

4. Discussion and Conclusions

4.1. According to the Numerical Analysis Result of Various Refrigerants in IPLV Condition

- (a)

- In full load condition of R-1234yf and R-513A refrigerant compared to R-134a refrigerant, the isentropic efficiency of R-1234yf refrigerant is reduced by 13.21%, and the isentropic efficiency of R-513A refrigerant is reduced by 9.97%.

- (b)

- The first cause for the decrease in isentropic efficiency under full load is excessive refrigerant flow. The compressor operating point is located at or near the choke point.

- (c)

- In 75%, 50%, and 25% part-load conditions, the refrigerants have very close isentropic efficiencies. The COP is higher than that in full load conditions. Therefore, the IPLV difference of various refrigerants is smaller than the full load COP difference.

- (d)

- In IPLV conditions, the total pressure ratio of R-1234yf is higher than R-134a refrigerant by 2.1%~8.3%. The total pressure ratio of R-513A is higher than R-134a refrigerant by about 2.4% under 75%~25% load and lower than R-134a refrigerant by 2.2% under full load.

- (e)

- R-1234yf and R-513A refrigerants have smaller enthalpy differences in terms of shaft power. A higher refrigerant flow is required so that the shaft work is a little higher than R-134a refrigerant by 31%~23% and 20%~15%.

- (f)

- In the 25% load condition, various refrigerants have worse isentropic efficiency. The first cause is the swirls near the shroud at the impeller’s eye, the phenomenon is similar to the compressor flow field pattern when it is close to the Surge Point.

4.2. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- UNEP. Amendment to the Montreal Protocol on Substances That Deplete the Ozone Layer, Kigali, no. 1522 UNTS 3; 26 ILM 1550; UNEP: Nairobi, Kenya, 2016. [Google Scholar]

- Park, J.H.; Shin, Y.; Chung, J.T. Performance Prediction of Centrifugal Compressor for Drop-In Testing Using Low Global Warming Potential Alternative Refrigerants and Performance Test Codes. Energies 2017, 10, 2043. [Google Scholar] [CrossRef] [Green Version]

- ASHRAE 34-2019; Designation and Safety Classification of Refrigerants. ASHRAE: Peachtree Corners, GA, USA, 2019; Volume 2019, pp. 1–52. Available online: www.ashrae.org (accessed on 1 May 2022).

- Lemmon, E.; Huber, M.; McLinden, M. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.1; NIST Standard Reference Data Series (NIST NSRDS); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013. Available online: https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=912382 (accessed on 1 May 2022).

- Hodnebrog, Ø.; Etminan, M.; Fuglestvedt, J.S.; Marston, G.; Myhre, G.; Nielsen, C.J.; Shine, K.P.; Wallington, T.J. Global warming potentials and radiative efficiencies of halocarbons and related compounds: A comprehensive review. Rev. Geophys. 2013, 51, 300–378. [Google Scholar] [CrossRef] [Green Version]

- Bell, I.H.; Domanski, P.A.; McLinden, M.O.; Linteris, G.T. The hunt for nonflammable refrigerant blends to replace R-134a. Int. J. Refrig. 2019, 104, 484–495. [Google Scholar] [CrossRef] [PubMed]

- AHRI 550/590; Standard for Performance Rating of Water-Chilling and Heat Pump Water-Heating Packages Using the Vapor Compression Cycle. AHRI: Arlington, VA, USA, 2011; Volume 590, p. 74.

- Ghenaiet, A.; Khalfallah, S. Assessment of some stall-onset criteria for centrifugal compressors. Aerosp. Sci. Technol. 2019, 88, 193–207. [Google Scholar] [CrossRef]

- Velásquez, E.I.G. Determination of a suitable set of loss models for centrifugal compressor performance prediction. Chin. J. Aeronaut. 2017, 30, 1644–1650. [Google Scholar] [CrossRef]

- Zhang, C.; Dong, X.; Liu, X.; Sun, Z.; Wu, S.; Gao, Q.; Tan, C. A method to select loss correlations for centrifugal compressor performance prediction. Aerosp. Sci. Technol. 2019, 93, 1–15. [Google Scholar] [CrossRef]

- Zhao, D.; Hua, Z.; Dou, M.; Huangfu, Y. Control oriented modeling and analysis of centrifugal compressor working characteristic at variable altitude. Aerosp. Sci. Technol. 2018, 72, 174–182. [Google Scholar] [CrossRef]

- Kim, C.; Son, C. Comparative Study on Steady and Unsteady Flow in a Centrifugal Compressor Stage. Int. J. Aerosp. Eng. 2019, 2019, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Yang, C.; Shi, X.; Yang, C.; Chen, J. Two stall stages in a centrifugal compressor with a vaneless diffuser. Aerosp. Sci. Technol. 2021, 110, 106496. [Google Scholar] [CrossRef]

- Tiwari, R.; Bordoloi, D.; Dewangan, A. Blockage and cavitation detection in centrifugal pumps from dynamic pressure signal using deep learning algorithm. Meas. J. Int. Meas. Confed. 2021, 173, 108676. [Google Scholar] [CrossRef]

- Semlitsch, B.; Mihaescu, M. Flow phenomena leading to surge in a centrifugal compressor. Energy 2016, 103, 572–587. [Google Scholar] [CrossRef]

- Galindo, J.; Gil, A.; Navarro, R.; Tarí, D. Analysis of the impact of the geometry on the performance of an automotive centrifugal compressor using CFD simulations. Appl. Therm. Eng. 2019, 148, 1324–1333. [Google Scholar] [CrossRef]

- Sun, J.; Li, W.; Cui, B. Energy and exergy analyses of R513a as a R134a drop-in replacement in a vapor compression refrigeration system. Int. J. Refrig. 2020, 112, 348–356. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, H.; Meng, Z.; Qin, Y. Experimental study on R1234yf/R134a mixture (R513A) as R134a replacement in a domestic refrigerator. Appl. Therm. Eng. 2019, 146, 540–547. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Belman-Flores, J.M.; Makhnatch, P.; Navarro-Esbrí, J.; Barroso-Maldonado, J.M. Experimental exergy analysis of R513A to replace R134a in a small capacity refrigeration system. Energy 2018, 162, 99–110. [Google Scholar] [CrossRef]

- Velasco, F.; Illán-Gómez, F.; García-Cascales, J. Energy efficiency evaluation of the use of R513A as a drop-in replacement for R134a in a water chiller with a minichannel condenser for air-conditioning applications. Appl. Therm. Eng. 2021, 182, 115915. [Google Scholar] [CrossRef]

- Al-Sayyab, A.K.S.; Mota-Babiloni, A.; Navarro-Esbrí, J. Novel compound waste heat-solar driven ejector-compression heat pump for simultaneous cooling and heating using environmentally friendly refrigerants. Energy Convers. Manag. 2021, 228, 113703. [Google Scholar] [CrossRef]

- Pérez-García, V.; Mota-Babiloni, A.; Navarro-Esbrí, J. Influence of operational modes of the internal heat exchanger in an experimental installation using R-450A and R-513A as replacement alternatives for R-134a. Energy 2019, 189, 116348. [Google Scholar] [CrossRef]

- Wang, C.-C. An overview for the heat transfer performance of HFO-1234yf. Renew. Sustain. Energy Rev. 2013, 19, 444–453. [Google Scholar] [CrossRef]

- Janković, Z.; Atienza, J.S.; Suárez, J.A.M. Thermodynamic and heat transfer analyses for R1234yf and R1234ze(E) as drop-in replacements for R134a in a small power refrigerating system. Appl. Therm. Eng. 2015, 80, 42–54. [Google Scholar] [CrossRef]

- ANSYS. ANSYS CFX-Solver Theory Guide. Release 14.0; ANSYS: Canonsburg, PA, USA, 2011; Volume 15317, pp. 724–746. Available online: http://www1.ansys.com/customer/content/documentation/140/cfx_thry.pdf (accessed on 1 May 2022).

- Acharya, R. Investigation of Differences in Ansys Solvers CFX and Fluent; KTH Royal Institute of Technology: Stockholm, Sweden, 2016. [Google Scholar]

| Change Refrigerant | Equipment Cost | Operating Cost |

|---|---|---|

| Direct replacement | Low | High |

| Redesign | High | Low |

| Refrigerant | R134a | R1234yf | R1234ze(E) | R513A |

|---|---|---|---|---|

| Type | HFC-134a | HFO-1234yf | HFO-1234ze | HFO-1234yf/HFC-134a (56/44) |

| Molar Mass (kg/kmol) | 102.032 | 114.042 | 114.04 | 108.43 |

| Critical Temperature (K) | 374.26 | 367.85 | 382.51 | 368.06 |

| Critical Pressure (kPa) | 4059 | 3382.2 | 3634.9 | 3647.8 |

| Critical Volume (m3/mol) | 2.008 × 10−4 | 2.39808 × 10−4 | 2.043987 × 10−3 | 2.21092 × 10−4 |

| Acentric Factor | 0.326 | 0.276 | 0.313 | - |

| Boling Temperature (K) | 247.04 | 243.365 | 254.177 | 243.68 |

| ODP | 0 | 0 | 0 | 0 |

| GWP100 | 1430 | ≤1 | ≤1 | 573 |

| Safety Classifications | A1 | A2L | A2L | A1 |

| Low Toxicity | High Toxicity | |

|---|---|---|

| High Flammability | A3 | B3 |

| Low Flammability | A2 | B2 |

| A2L | B2L | |

| Nonflammable | A1 | B1 |

| Refrigerant | R134a | ||

| Rotating Speed(RPM) | 17010 | ||

| Inlet Total Temperature (℃) | 6.6 | ||

| Inlet Total Pressure (kPa) | 365.74 | ||

| Outlet Mass Flow Rate (kg/s) | 6.383 | ||

| Turbulence Model | k-epsilon | k-omega | SST |

| CPU Time (min) | 154 | 150 | 163 |

| Total Pressure Ratio | 2.42 | 2.47 | 2.47 |

| Torque (N·m) | 74.47 | 74.55 | 74.57 |

| Outlet Total Temperature (℃) | 39.08 | 39.37 | 39.38 |

| Outlet Total Pressure (kPa) | 886.41 | 901.36 | 901.77 |

| Isentropic Compression Efficiency (%) | 90.56 | 92.18 | 92.20 |

| Name | Setting Conditions and Parameters | ||||

|---|---|---|---|---|---|

| Working Fluid | R134a | ||||

| IPLV Load | 100% | 75% | 50% | 25% | |

| Inlet | Total Temperature (°C) | 6.6 | 6.8 | 7 | 7 |

| Total Pressure (kPa) | 365.74 | 368.26 | 370.80 | 370.80 | |

| Outlet | Mass Flow Rate (kg/s) | 100% | 70% | 44% | 22% |

| Rotating Speed | Rated Speed (rpm) | 100% | 86% | 72% | 69% |

| Turbulence Model | k-omega turbulence model (k-ω) | ||||

| Discretization Method | Specified Blend Factor (0.5) | ||||

| Load, % | Simulated Total Pressure Ratio | Experimental Total Pressure Ratio | Relative Error |

|---|---|---|---|

| 100% | 2.47 | 2.40 | 2.73% |

| 75% | 2.00 | 1.97 | 1.48% |

| 50% | 1.64 | 1.61 | 1.89% |

| 25% | 1.60 | 1.55 | 3.54% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, K.-S.; Ho, K.-Y.; Hsiao, W.-C.; Kuan, Y.-D. The Characteristic of High-Speed Centrifugal Refrigeration Compressor with Different Refrigerants via CFD Simulation. Processes 2022, 10, 928. https://doi.org/10.3390/pr10050928

Hung K-S, Ho K-Y, Hsiao W-C, Kuan Y-D. The Characteristic of High-Speed Centrifugal Refrigeration Compressor with Different Refrigerants via CFD Simulation. Processes. 2022; 10(5):928. https://doi.org/10.3390/pr10050928

Chicago/Turabian StyleHung, Kuo-Shu, Kung-Yun Ho, Wei-Chung Hsiao, and Yean-Der Kuan. 2022. "The Characteristic of High-Speed Centrifugal Refrigeration Compressor with Different Refrigerants via CFD Simulation" Processes 10, no. 5: 928. https://doi.org/10.3390/pr10050928

APA StyleHung, K.-S., Ho, K.-Y., Hsiao, W.-C., & Kuan, Y.-D. (2022). The Characteristic of High-Speed Centrifugal Refrigeration Compressor with Different Refrigerants via CFD Simulation. Processes, 10(5), 928. https://doi.org/10.3390/pr10050928