Numerical Investigation on the Impact of Tailings Slurry on Catch Dams Built at the Downstream of a Breached Tailings Pond

Abstract

:1. Introduction

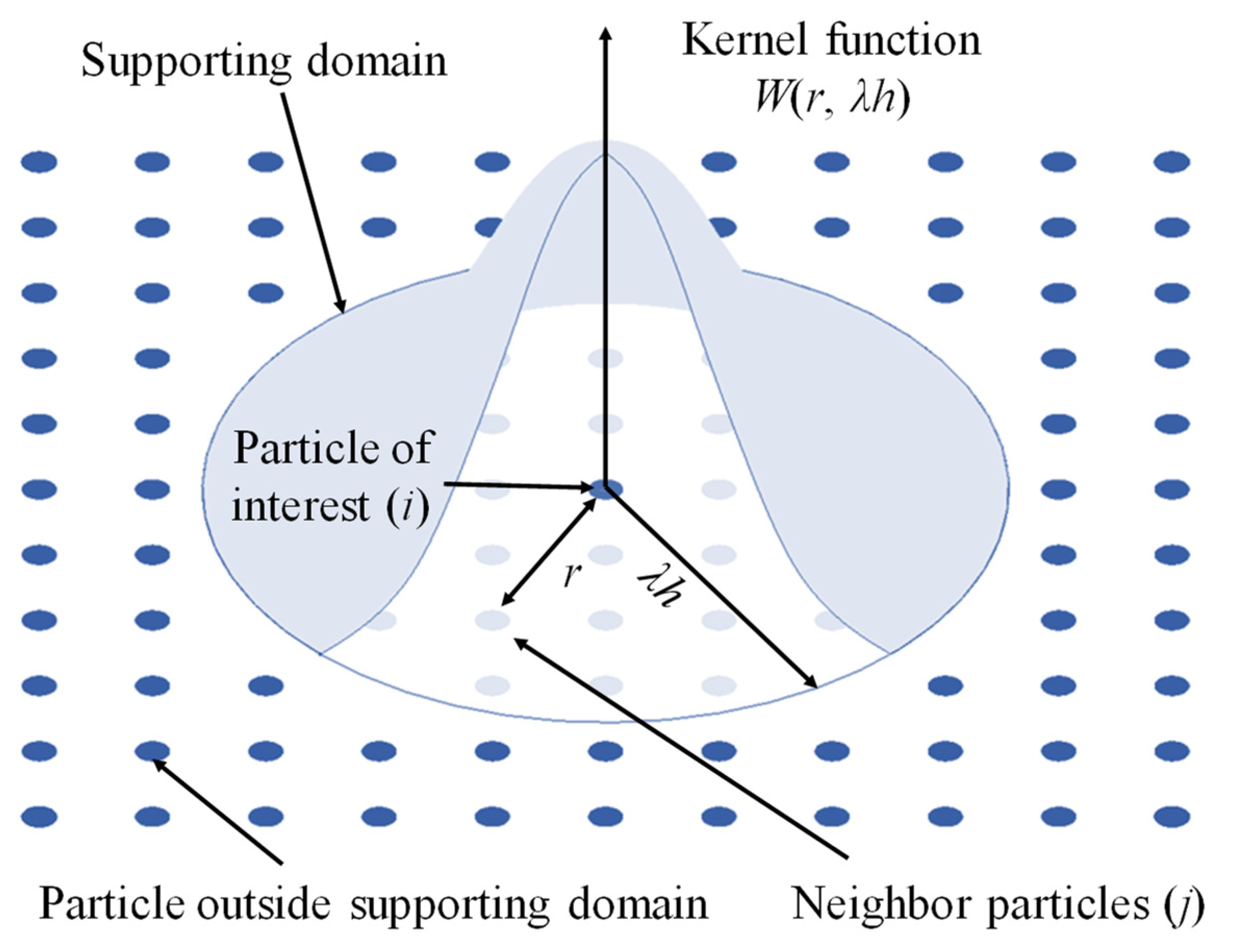

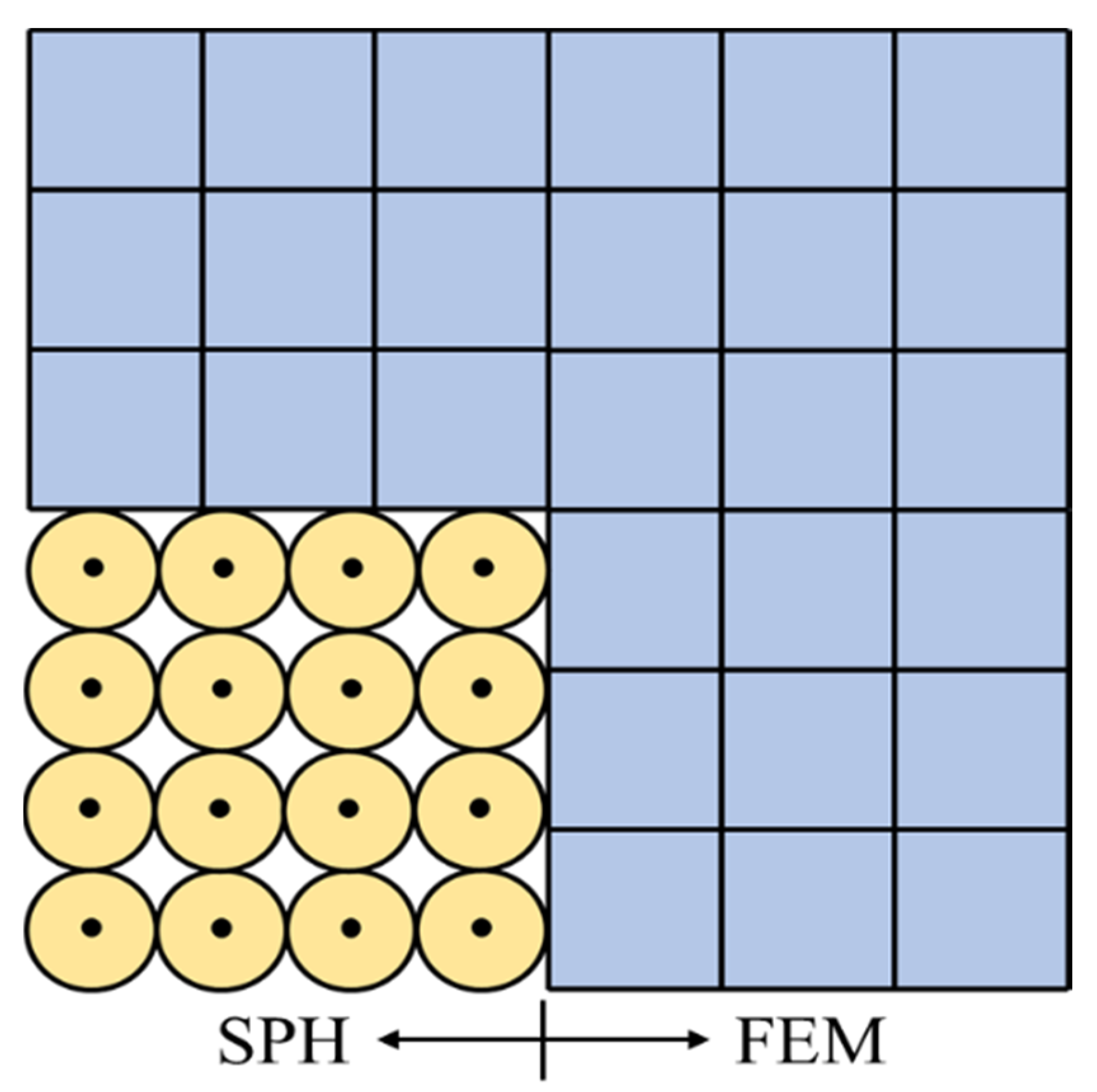

2. Numerical Code

3. Numerical Simulations of Dynamic Interaction between Tailings Flow and A Catch Dam

3.1. Numerical Models

3.2. Numerical Results

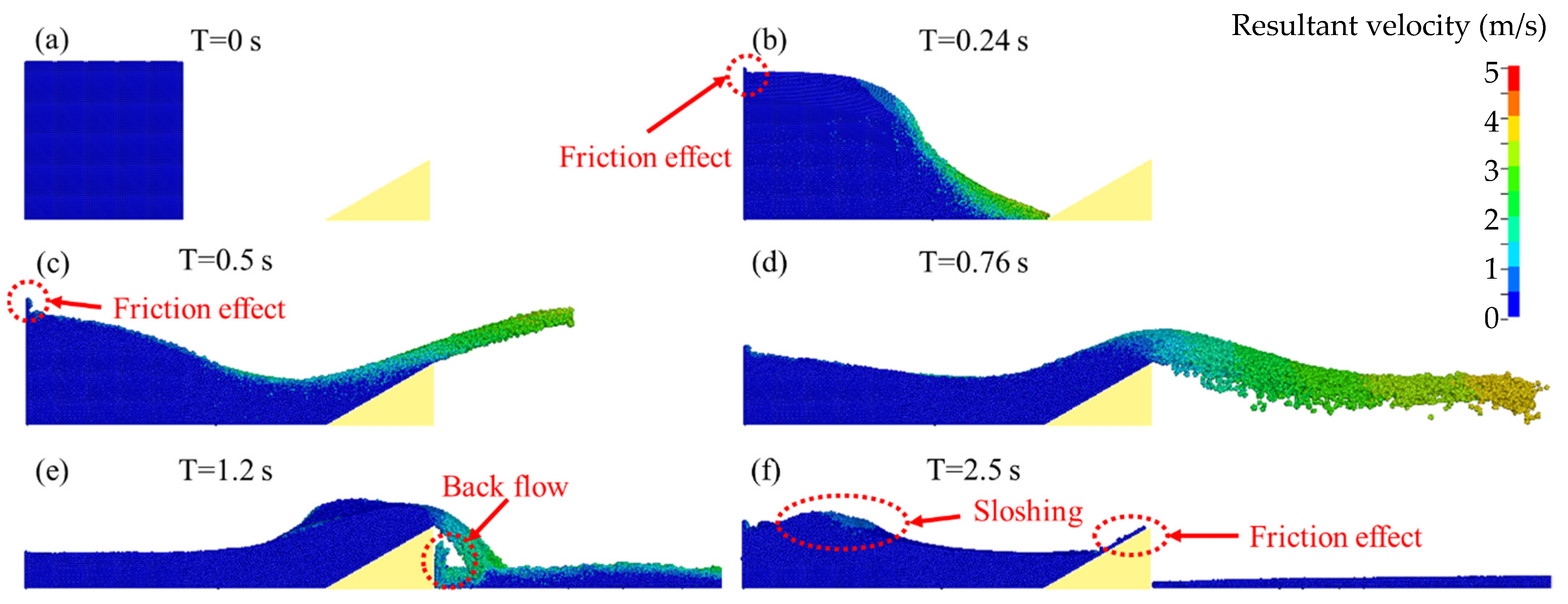

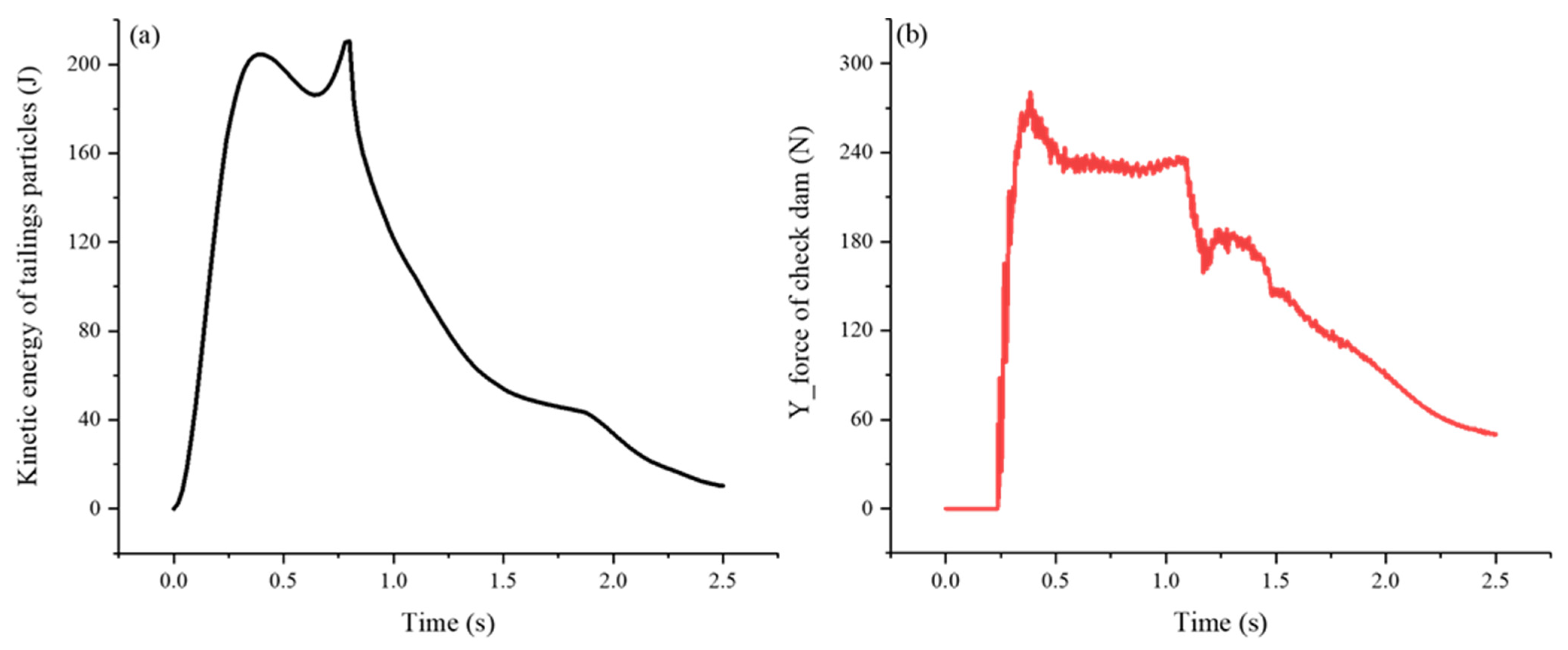

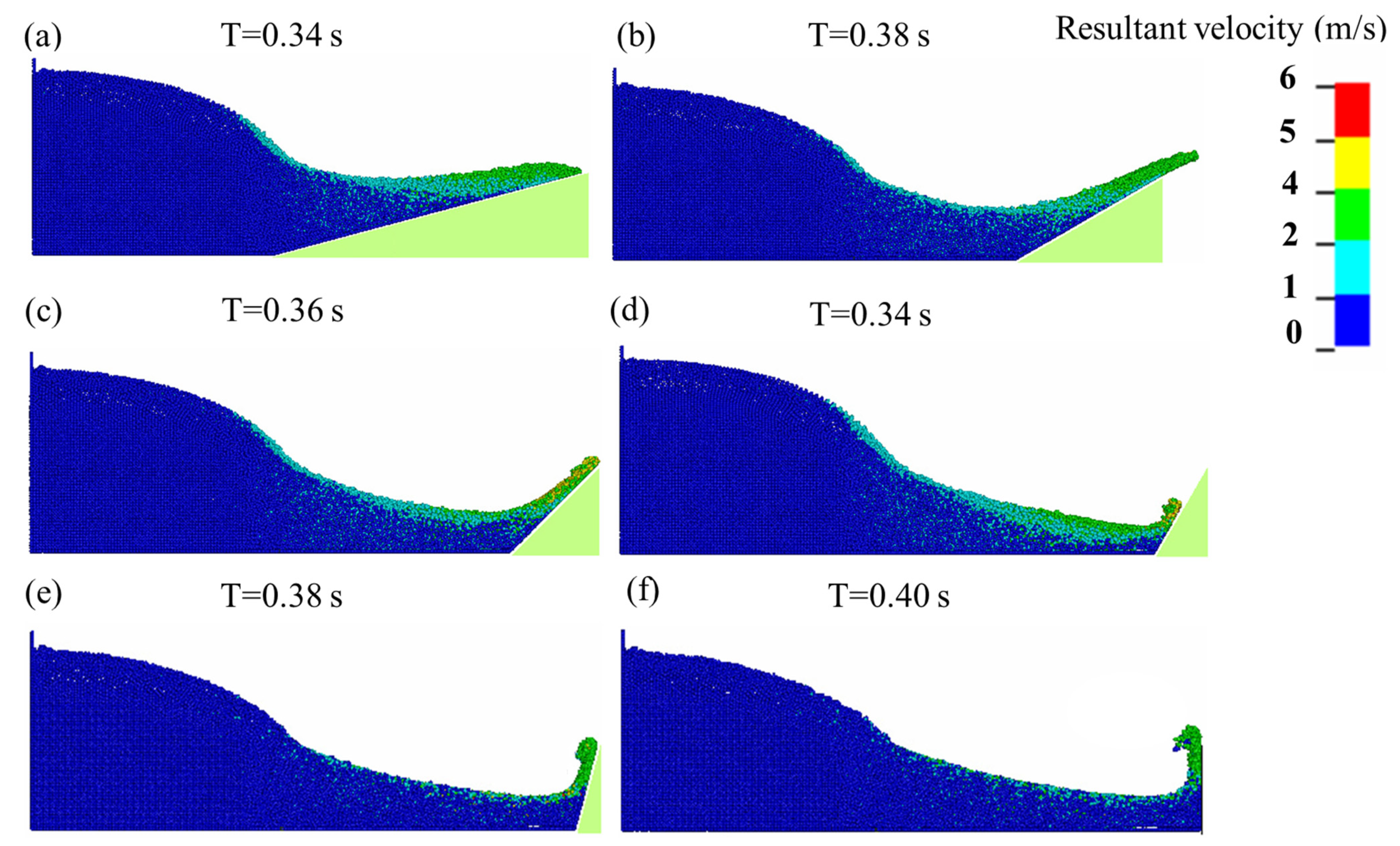

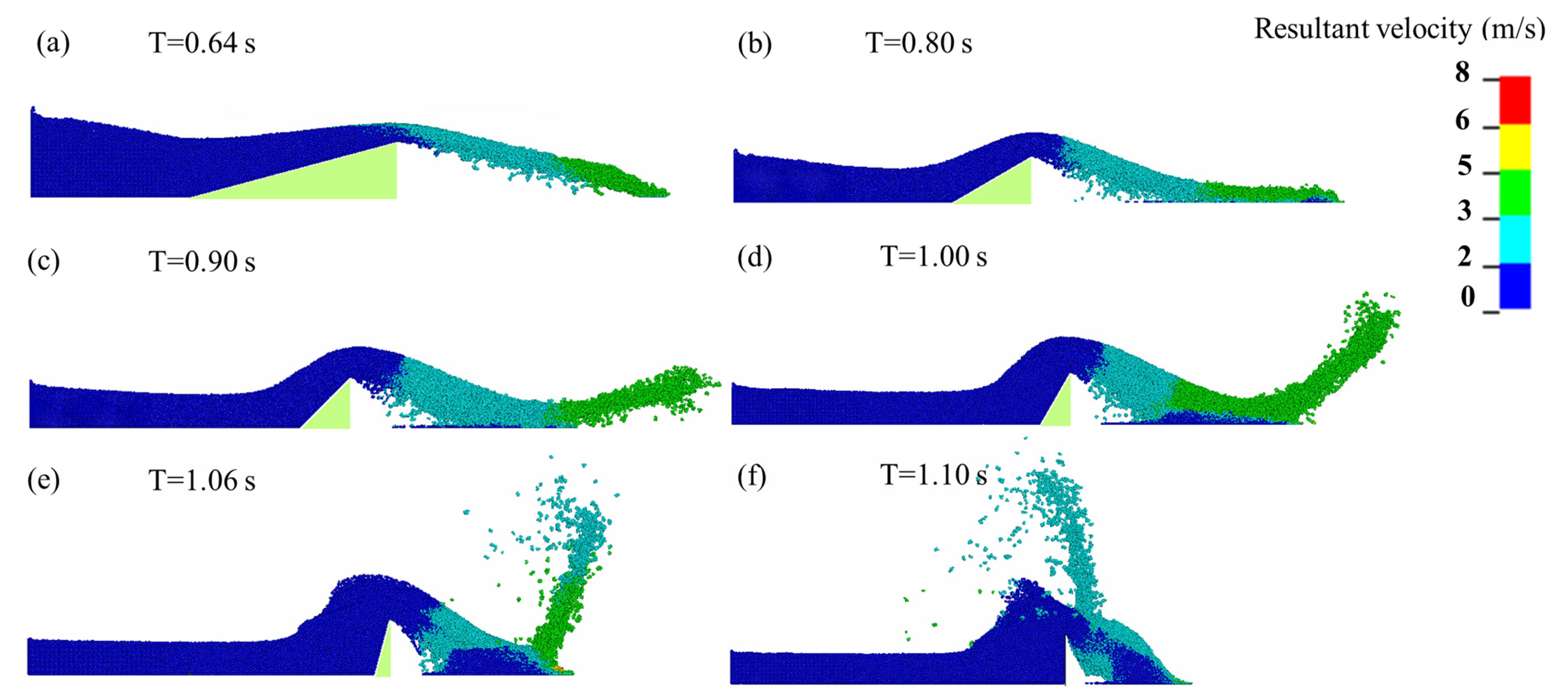

- Stage 1: Initiation. This stage starts at the breach onset of the tailings dam at T = 0 s and ends at T = 0.38 s when the kinetic energy and impacting forces reach their first peak values. Upon the breach of the tailings dam at T = 0 s, the front part of the tailings tends to flow, driven by the potential energy. Once started, the movement of the tailings particles accelerates upon their residual potential energy and the pushing forces exercised by the upper and back particles. Subsequently, the kinetic energy continuously increases with time. At T = 0.24 s, the front line of the tailings flood reaches the toe of the catch dam. The upstream slope of the catch dam starts to receive an impacting force. After then, the tailings slurry flows upward over the upstream slope of the catch dam. A part of the kinetic energy has to be transferred into the potential energy required to allow the rising of the tailings particles. This leads to a decreased pace in the increase of kinetic energy until a peak value at T = 0.38 s when the impacting force also reaches its first peak value.

- Stage 2: Peak stage. This stage starts at T = 0.38 s when the kinetic energy and impacting forces reach their first peak values, and ends at T = 0.76 s when the front line of the tailings flow touches the floor. In this stage, the kinetic energy and impacting force first exhibit a decrease from their peak values and then an increase until a second peak value. At T = 0.50 s, the front of the tailings flow rises to the maximum height of 37 cm. At T = 0.76 s, the front line of the tailings flow touches the floor and the kinetic energy starts to decrease. Despite their changes with time, the magnitudes of kinetic energy and impacting force remain at relatively high levels.

- Stage 3: Ebb. This stage starts at T = 0.76 s when the kinetic energy starts to decrease, and ends at T = 1.2 s when the crest of the tailings flood starts to retreat back toward the tailings pond. During this stage, the kinetic energy continuously decreases while the impacting force keeps almost constant.

- Stage 4: Sloshing. This stage starts from T = 1.2 s when the crest of the tailings flood starts to retreat toward the tailings pond. In this stage, the crest of the tailings slurry can first move back toward the tailings pond, and after, it can then move forward toward the catch dam. This back-and-forth can take several rounds until an equilibrium is reached. Despite these back-and-forth movements, the kinetic energy and impacting forces decrease with time.

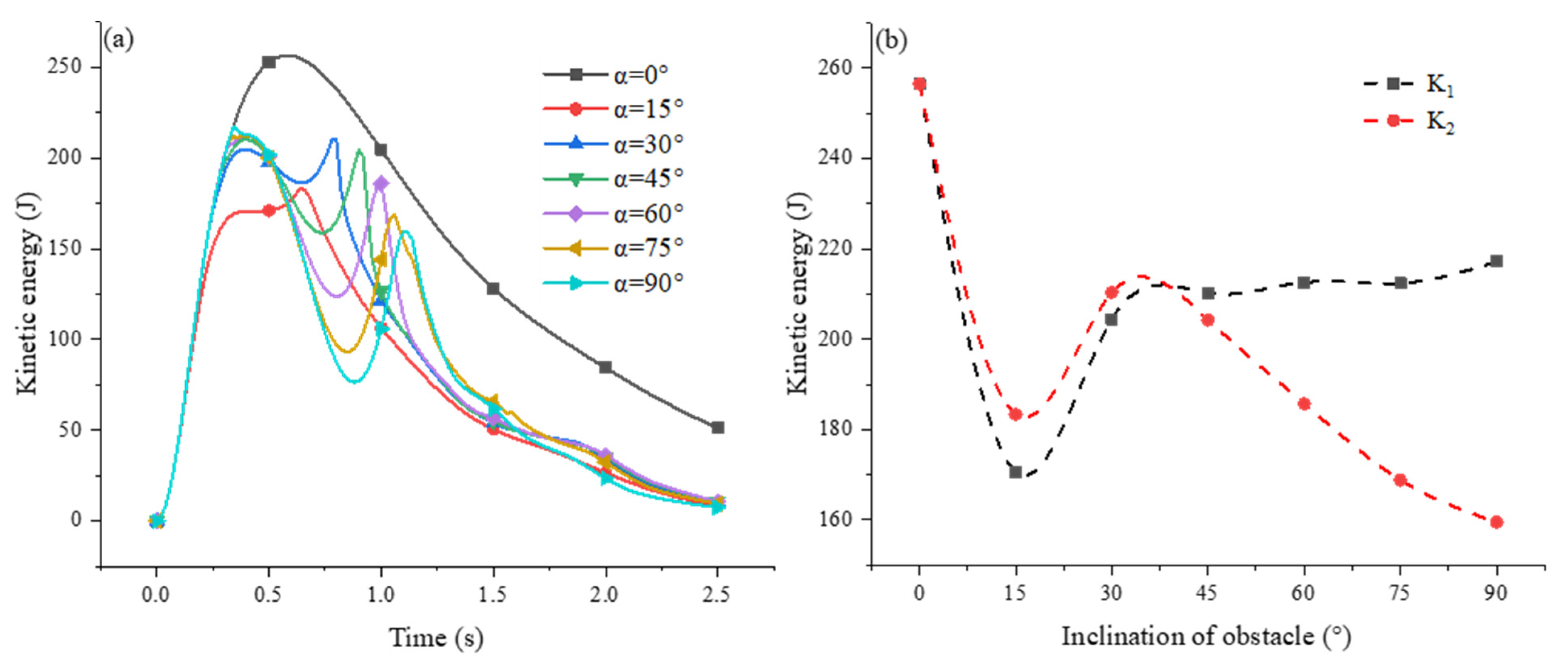

4. Discussion

5. Conclusions

- Stage 1, called “initiation”, tailings particles start to move and accelerate.

- Stage 2, called the “peak stage”, the kinetic energy and impacting force first exhibit a decrease and then an increase until second peak values.

- Stage 3, called the “ebb”, the kinetic energy decreases and the crest of the tailings flood retreats back toward the tailings pond.

- Stage 4, called “sloshing”, the crest of the tailings slurry can first move back toward the tailings pond, and then forward toward the catch dam.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

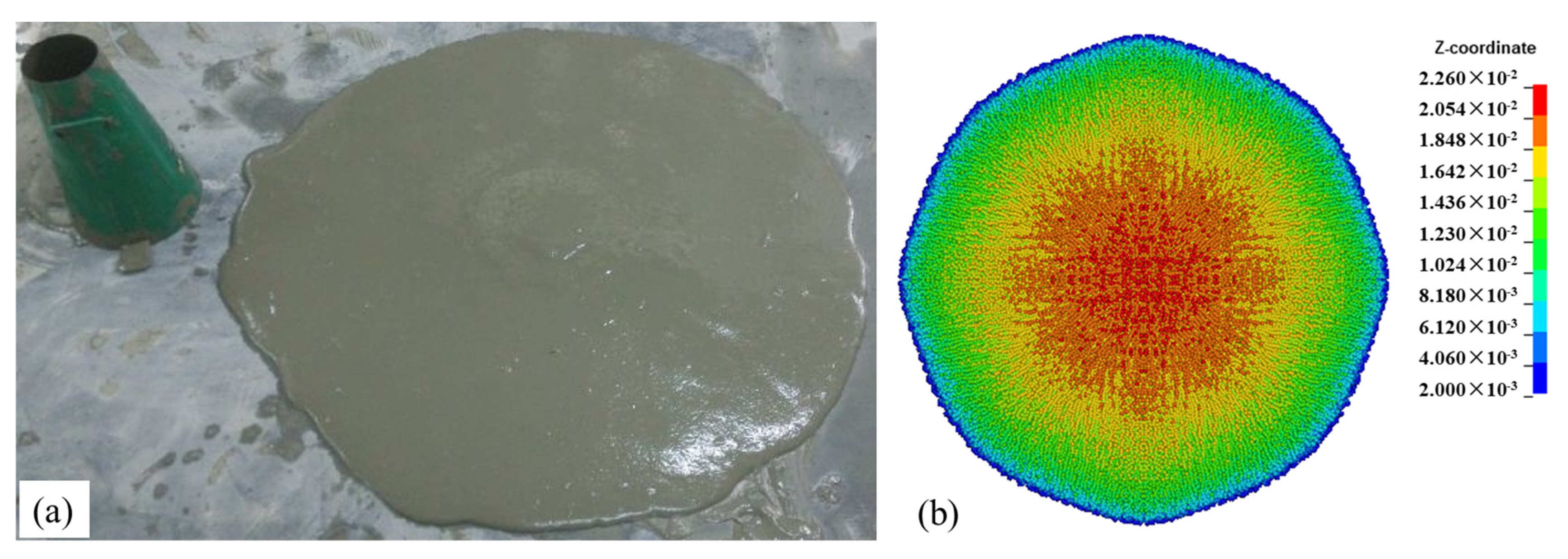

Appendix A. Applicability of LS-DYNA to Simulate the Rheological Behavior of Tailings Slurry

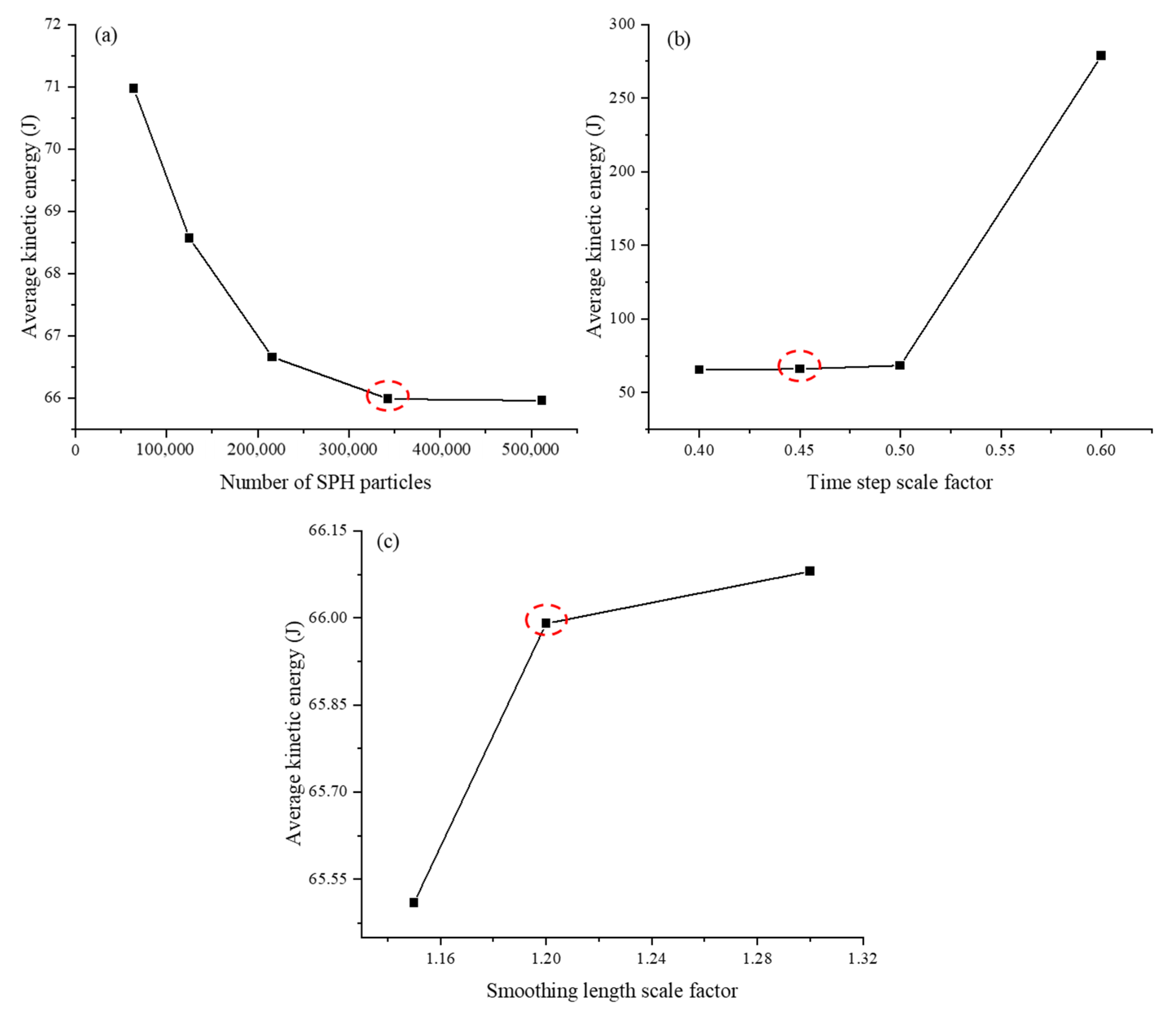

Appendix B. Sensitivity Analyses of SPH Simulations

References

- Jones, H.; Boger, D.V. Sustainability and waste management in the resource industries. Ind. Eng. Chem. Res. 2012, 51, 10057–10065. [Google Scholar] [CrossRef]

- Hasanpour, A.; Istrati, D.; Buckle, I. Coupled SPH–FEM Modeling of Tsunami-Borne Large Debris Flow and Impact on Coastal Structures. J. Mar. Sci. Eng. 2021, 9, 1068. [Google Scholar] [CrossRef]

- Aubertin, M.; Li, L.; Arnoldi, S.; Belem, T.; Bussière, B.; Benzaazoua, M.; Simon, R. Interaction between backfill and rock mass in narrow stopes. Soil Rock Am. 2003, 2, 1157–1164. [Google Scholar]

- Li, L.; Aubertin, M.; Simon, R.; Bussière, B.; Belem, T. Modeling arching effects in narrow backfilled stopes with FLAC. FLAC Numer. Modeling Geomech. 2003, 211–219. [Google Scholar]

- Li, L.; Aubertin, M.; Belem, T. Formulation of a three dimensional analytical solution to evaluate stresses in backfilled vertical narrow openings. Can. Geotech. J. 2005, 42, 1705–1717. [Google Scholar] [CrossRef]

- Li, L.; Aubertin, M. A modified solution to assess the required strength of exposed backfill in mine stopes. Can. Geotech. J. 2012, 49, 994–1002. [Google Scholar] [CrossRef]

- Li, L.; Aubertin, M. An improved method to assess the required strength of cemented backfill in underground stopes with an open face. Int. J. Min. Sci. Technol. 2014, 24, 549–558. [Google Scholar] [CrossRef]

- Li, L. Analytical solution for determining the required strength of a side-exposed mine backfill containing a plug. Can. Geotech. J. 2014, 51, 508–519. [Google Scholar] [CrossRef]

- Li, L. Generalized solution for mining backfill design. Int. J. Geomech. 2014, 14, 04014006. [Google Scholar] [CrossRef]

- Liu, G.; Li, L.; Yang, X.; Guo, L. Stability analyses of vertically exposed cemented backfill: A revisit to Mitchell’s physical model tests. Int. J. Min. Sci. Technol. 2016, 26, 1135–1144. [Google Scholar] [CrossRef]

- Liu, G.; Li, L.; Yang, X.; Guo, L. Required strength estimation of a cemented backfill with the front wall exposed and back wall pressured. Int. J. Min. Miner. Eng. 2018, 9, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Yang, P.; Li, L.; Aubertin, M. A new solution to assess the required strength of mine backfill with a vertical exposure. Int. J. Geomech. 2017, 17, 04017084. [Google Scholar] [CrossRef]

- Li, X.; Zhou, S.; Zhou, Y.; Min, C.; Cao, Z.; Du, J.; Luo, L.; Shi, Y. Durability evaluation of phosphogypsum-based cemented backfill through drying-wetting cycles. Minerals 2019, 9, 321. [Google Scholar] [CrossRef] [Green Version]

- Pagé, P.; Li, L.; Yang, P.; Simon, R. Numerical investigation of the stability of a base-exposed sill mat made of cemented backfill. Int. J. Rock Mech. Min. Sci. 2019, 114, 195–207. [Google Scholar] [CrossRef]

- Zhou, S.; Li, X.; Zhou, Y.; Min, C.; Shi, Y. Effect of phosphorus on the properties of phosphogypsum-based cemented backfill. J. Hazard. Mater. 2020, 399, 122993. [Google Scholar] [CrossRef]

- Keita, A.M.T.; Jahanbakhshzadeh, A.; Li, L. Numerical analysis of the stability of arched sill mats made of cemented backfill. Int. J. Rock Mech. Min. Sci. 2021, 140, 104667. [Google Scholar] [CrossRef]

- Wang, R.; Zeng, F.; Li, L. Stability analyses of side-exposed backfill considering mine depth and extraction of adjacent stope. Int. J. Rock Mech. Min. Sci. 2021, 142, 104735. [Google Scholar] [CrossRef]

- Wang, R.; Li, L. Time-dependent stability analyses of side-exposed backfill considering creep of surrounding rock mass. Rock Mech. Rock Eng. 2022, 1–25. [Google Scholar] [CrossRef]

- Tardif-Drolet, M.; Li, L.; Pabst, T.; Zagury, G.J.; Mermillod-Blondin, R.; Genty, T. Revue de la réglementation sur la valorisation des résidus miniers hors site au Québec. Environ. Rev. 2020, 28, 32–44. [Google Scholar] [CrossRef]

- Vick, S.G. Planning, Design, and Analysis of Tailings Dams; BiTech Publishers Ltd.: Vancouver, BC, Canada, 1990. [Google Scholar]

- Fourie, A. Preventing catastrophic failures and mitigating environmental impacts of tailings storage facilities. Procedia Earth Planet. Sci. 2009, 1, 1067–1071. [Google Scholar] [CrossRef] [Green Version]

- Villavicencio, G.; Espinace, R.; Palma, J.; Fourie, A.; Valenzuela, P. Failures of sand tailings dams in a highly seismic country. Can. Geotech. J. 2014, 51, 449–464. [Google Scholar] [CrossRef]

- Stefaniak, K.; Wróżyńska, M. On possibilities of using global monitoring in effective prevention of tailings storage facilities failures. Environ. Sci. Pollut. Res. 2018, 25, 5280–5297. [Google Scholar] [CrossRef] [PubMed]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062. [Google Scholar] [CrossRef] [Green Version]

- Bussière, B. Colloquium 2004: Hydrogeotechnical properties of hard rock tailings from metal mines and emerging geoenvironmental disposal approaches. Can. Geotech. J. 2007, 44, 1019–1052. [Google Scholar] [CrossRef]

- Lyu, Z.; Chai, J.; Xu, Z.; Qin, Y.; Cao, J. A comprehensive review on reasons for tailings dam failures based on case history. Adv. Civ. Eng. 2019, 2019, 4159306. [Google Scholar] [CrossRef]

- WISE. Chronology of Major Tailings Dam Failures. WISE Uranium Project. Available online: https://www.wise-uranium.org/mdaf.html (accessed on 16 June 2019).

- Azam, S.; Li, Q. Tailings Dam Failures: A Review of the Last One Hundred Years. Geotech. News 2010, 28, 50–54. [Google Scholar]

- Oboni, F.; Oboni, C. Factual and Foreseeable Reliability of Tailings Dams and Nuclear Reactors: A Societal Acceptability Perspective. Tailings Mine Waste 2013, 6–9. [Google Scholar]

- Fell, R.; MacGregor, P.; Stapledon, D.; Bell, G.; Foster, M. Geotechnical Engineering of Dams, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Kossoff, D.; Dubbin, W.E.; Alfredsson, M.; Edwards, S.J.; Macklin, M.G.; Hudson-Edwards, K.A. Mine tailings dams: Characteristics, failure, environmental impacts, and remediation. Appl. Geochem. 2014, 51, 229–245. [Google Scholar] [CrossRef] [Green Version]

- Chovan, K.M.; Julien, M.R.; Ingabire, É.-P.; Masengo, E.; Lépine, T.; James, M.; Lavoie, P. Risk assessment for tailings management. CIM J. 2021, 12, 9–24. [Google Scholar] [CrossRef]

- Van Niekerk, H.J.; Viljoen, M.J. Causes and consequences of the Merriespruit and other tailings-dam failures. Land Degrad. Dev. 2005, 16, 201–212. [Google Scholar] [CrossRef]

- PBC. Independent Expert Engineering Investigation and Review Panel: Report on Mount Polley Tailings Storage Facility Breach. 2015. Available online: https://www.mountpolleyreviewpanel.ca/final-report (accessed on 30 January 2015).

- Berchtold, A.E.; Price, M.H.H. Responsible Mining in British Colombia: Guidelines towards Best Practice; SkeenaWild Conservation Trust: Terrace, BC, Canada, 2018. [Google Scholar]

- Eisenhammer, S.; Nogueira, M. A view of the Samarco mine, owned by Vale SA and BHP Billiton Ltd., in Mariana, Brazil. REUTERS/Washington Alves. 12 April 2016. Available online: https://www.reuters.com/world/americas/socio-environmental-damage-brazils-samarco-dam-disaster-high-67-bln-study-says-2021-11-03/ (accessed on 4 November 2021).

- Aires, U.R.V.; Santos, B.S.M.; Coelho, C.D.; da Silva, D.D.; Calijuri, M.L. Changes in land use and land cover as a result of the failure of a mining tailings dam in Mariana, MG, Brazil. Land Use Policy 2018, 70, 63–70. [Google Scholar] [CrossRef]

- Rotta, L.H.S.; Alcântara, E.; Park, E.; Negri, R.G.; Lin, Y.N.; Bernardo, N.; Mendes, T.S.G.; Filho, C.R.S. The 2019 Brumadinho tailings dam collapse: Possible cause and impacts of the worst human and environmental disaster in Brazil. Int. J. Appl. Earth Obs. Geoinf. 2020, 90, 102119. [Google Scholar]

- Blight, G.E. Destructive mudflows as a consequence of tailings dyke failures. Proc. Inst. Civ. Eng. Geotech. Eng. 1997, 125, 9–18. [Google Scholar] [CrossRef]

- Glotov, V.E.; Chlachula, J.; Glotova, L.P.; Little, E. Causes and environmental impact of the gold-tailings dam failure at Karamken, the Russian Far East. Eng. Geol. 2018, 245, 236–247. [Google Scholar] [CrossRef]

- ACB. Dam Safety; Canadian Dam Association/Association Canadienne des Barrages: Markham, ON, Canada, 2007. [Google Scholar]

- Jing, X.; Chen, Y.; Williams, D.J.; Serna, M.L.; Zheng, H. Overtopping failure of a reinforced tailings dam: Laboratory investigation and forecasting model of dam failure. Water 2019, 11, 315. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Yuan, L.; Yang, H.; An, H.; Wang, G. Tailings dam safety monitoring and early warning based on spatial evolution process of mud-sand flow. Saf. Sci. 2020, 124, 104579. [Google Scholar] [CrossRef]

- Blight, G.E. Geotechnical Engineering for Mine Waste Storage Facilities; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Aubertin, M.; Bussière, B.; Bernier, L. Environnement et Gestion des Rejets Miniers; Presses Internationales Polytechnique: Montréal, QC, Canada, 2002. [Google Scholar]

- Benzaazoua, M.; Bussière, B.; Demers, I.; Aubertin, M.; Fried, É.; Blier, A. Integrated mine tailings management by combining environmental desulphurization and cemented paste backfill: Application to mine Doyon, Quebec, Canada. Min. Eng. 2008, 21, 330–340. [Google Scholar] [CrossRef]

- Bussière, B.; Guittonny, M. (Eds.) Hard Rock Mine Reclamation From Prediction to Management of Acid Mine Drainage; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Zhang, B.; Muraleetharan, K.K.; Liu, C.Y. Liquefaction of unsaturated sands. Int. J. Geomech. 2016, 16, D4015002. [Google Scholar] [CrossRef]

- Yuan, B.; Wang, F.Y.; Jin, Y.J. Study on the model for tailing dam breaking and its application. China Safety Sci. J. 2008, 18, 169–172. (In Chinese) [Google Scholar]

- Chen, D.Q.; He, F.; Wang, L.G. Numerical calculation of the railings dam failure in Fengcheng City. Met. Mine 2009, 10, 74–80. (In Chinese) [Google Scholar]

- Guo, C.Y.; Tang, Z.Y. Study on the tailings dam break model. J. Saf. Sci. Technol. 2010, 6, 63–67. (In Chinese) [Google Scholar]

- Li, H.G.; Wang, H.G.; Liu, H. Discussions on maximum impact distance of noncoal mine tailings dam failure. Nonferrous Met. Eng. Res. 2011, 32, 12–15. (In Chinese) [Google Scholar]

- Zhuo, Q.F.; Yuan, W.J.; Lin, J. Analysis for the tailings dam break in Fujian Province. Min. Metall. Eng. 2011, 31, 16–19. (In Chinese) [Google Scholar]

- Wang, L.L.; Jiang, G.S.; Lu, X.J. Application of dam failure model to the risk evaluation of tailing dams. Saf. Environ. Eng. 2012, 19, 33–36. (In Chinese) [Google Scholar] [CrossRef]

- Yuan, Z.Y. Numerical calculation of tailings dam-break and its influence on downstream areas. Met. Mine 2012, 8, 156–159. (In Chinese) [Google Scholar]

- Xu, K.; Zhao, Y.S.; Zhang, Q. Numerical analysis for the tailings dam break. Ind. Saf. Environ. Prot. 2012, 38, 28–43. (In Chinese) [Google Scholar]

- Jin, J.X.; Liang, L.; Wu, F.Y. Dam break simulation of tailings dam and forecast of impact range. Met. Mine 2013, 3, 141–144. (In Chinese) [Google Scholar]

- Tang, Y.L.; Cao, X.Y.; Yin, T.T. On the dam breaking emergency saving measures of a mining-tailing stockpile at the upstream Dahuofang Reservoir. J. Saf. Environ. 2013, 13, 180–185. (In Chinese) [Google Scholar]

- Nie, Z.D.; Liu, J.; Chen, P.; Guo, Y.; Liu, W.; Xiong, J.L.; Liu, Y. A case study on environmental risk assessment method of mine tailings collapse. Environ. Sci. Technol. 2014, 37, 550–554. (In Chinese) [Google Scholar]

- Liu, H. An Experimental and Numerical Study of Runout from a Tailings Dam Failure. Ph.D. Thesis, The University of Western Australia, Crawley, Australia, 2018. [Google Scholar]

- Souza, T.F.; Teixeira, S.H.C. Simulation of tailings release in dam break scenarios using physical models. REM-Int. Eng. J. 2019, 72, 385–393. [Google Scholar] [CrossRef]

- Mahdi, A.; Shakibaeinia, A.; Dibike, Y.B. Numerical modelling of oil-sands tailings dam breach runout and overland flow. Sci. Total Environ. 2020, 703, 134568. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.; Tang, L.; Chen, C. Three-dimensional numerical simulation of mud flow from a tailing dam failure across complex terrain. Nat. Hazards Earth Syst. Sci. 2020, 20, 727–741. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Jing, X.; Chen, Y.; Pan, C.; Wang, W. Tailings dam break: The influence of slurry with different concentrations downstream. Front. Earth Sci. 2021, 9, 726336. [Google Scholar] [CrossRef]

- Zhang, Y. Leakage of tailing sands in Heilongjiang continued: 10 interception dams have been set up to stop the leakage, and there is no safety risk to the tailings. Available online: https://baijiahao.baidu.com/s?id=1662654431312090219&wfr=spider&for=pc. (accessed on 31 March 2020). (In Chinese).

- Soares-Frazão, S.; Zech, Y. Experimental study of dam-break flow against an isolated obstacle. J. Hydraul. Res. 2007, 45 (Suppl. 1), 27–36. [Google Scholar] [CrossRef]

- Soares-Frazão, S.; Zech, Y. Dam-break flow through an idealised city. J. Hydraul. Res. 2008, 46, 648–658. [Google Scholar] [CrossRef] [Green Version]

- Ozmen-Cagatay, H.; Kocaman, S. Dam-break flow in the presence of obstacle: Experiment and CFD simulation. Eng. Appl. Comput. Fluid Mech. 2011, 5, 541–552. [Google Scholar] [CrossRef] [Green Version]

- Xu, X. An improved SPH approach for simulating 3D dam-break flows with breaking waves. Comput. Methods Appl. Mech. Eng. 2016, 311, 723–742. [Google Scholar] [CrossRef]

- Issakhov, A.; Zhandaulet, Y.; Nogaeva, A. Numerical simulation of dam break flow for various forms of the obstacle by VOF method. Int. J. Multiph. Flow 2018, 109, 191–206. [Google Scholar] [CrossRef]

- Saghi, H.; Lakzian, E. Effects of using obstacles on the dam-break flow based on entropy generation analysis. Eur. Phys. J. Plus 2019, 134, 237. [Google Scholar] [CrossRef]

- Chen, H.-X.; Li, J.; Feng, S.-J.; Gao, H.-Y.; Zhang, D.-M. Simulation of interactions between debris flow and check dams on threedimensional terrain. Eng. Geol. 2019, 251, 48–62. [Google Scholar] [CrossRef]

- Jeong, S.; Lee, K. Analysis of the impact force of debris flows on a check dam by using a coupled Eulerian-Lagrangian (CEL) method. Comput. Geotech. 2019, 116, 103214. [Google Scholar] [CrossRef]

- Huang, Y.; Jin, X.; Ji, J. Effects of Barrier Stiffness on Debris Flow Dynamic Impact—I: Laboratory Flume Test. Water 2022, 14, 177. [Google Scholar] [CrossRef]

- Huang, Y.; Jin, X.; Ji, J. Effects of barrier stiffness on debris flow dynamic Impact—II: Numerical simulation. Water 2022, 14, 182. [Google Scholar] [CrossRef]

- Abdelrazek, A.M.; Kimura, I.; Shimizu, Y. Simulation of three-dimensional rapid free-surface granular flow past different types of obstructions using the SPH method. J. Glaciol. 2016, 62, 335–347. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Tian, S.; Hu, B.; Xu, Z.; Chen, J.; Kong, X. Evolution pattern of tailings flow from dam failure and the buffering effect of Debris Blocking Dams. Water 2019, 11, 2388. [Google Scholar] [CrossRef] [Green Version]

- Zeng, Q.-Y.; Pan, J.-P.; Sun, H.-Z. SPH simulation of structures impacted by tailings debris flow and its application to the buffering effect analysis of debris checking dams. Math. Probl. Eng. 2020, 2020, 9304921. [Google Scholar] [CrossRef]

- Wang, S.; Mei, G.; Xie, X.; Guo, L. The influence of the instantaneous collapse of tailings pond on downstream facilities. Adv. Civ. Eng. 2021, 2021, 4253315. [Google Scholar] [CrossRef]

- Hallquist, J.O. LS-DYNA Keyword User’s Manual; Version 970; Livermore Software Technology Corporation: Livermore, CA, USA, 2007. [Google Scholar]

- Lucy, L.B. A numerical approach to the testing of the fission hypothesis. Astron. J. 1977, 82, 1013–1024. [Google Scholar] [CrossRef]

- Gingold, R.A.; Monaghan, J.J. Smoothed particle hydrodynamics: Theory and application to non-spherical stars. Mon. Not. R. Astron. Soc. 1977, 181, 375–389. [Google Scholar] [CrossRef]

- Shao, S.; Lo, E.Y.M. Incompressible SPH method for simulating Newtonian and non-Newtonian flows with a free surface. Adv. Water Resour. 2003, 26, 787–800. [Google Scholar] [CrossRef]

- Antoci, C.; Gallati, M.; Sibilla, S. Numerical simulation of fluid–structure interaction by SPH. Comput. Struct. 2007, 85, 879–890. [Google Scholar] [CrossRef]

- Atif, M.M.; Chi, S.-W.; Grossi, E.; Shabana, A.A. Evaluation of breaking wave effects in liquid sloshing problems: ANCF/SPH comparative study. Nonlinear Dyn. 2019, 97, 45–62. [Google Scholar] [CrossRef]

- Liu, G.R.; Liu, M.B. Smoothed Particle Hydrodynamics: A Meshfree Particle Method; World Scientific Publishing Co Pte: Singapore, 2003. [Google Scholar]

- Yang, Y.; Li, J. SPH-FE-Based Numerical simulation on dynamic characteristics of structure under water waves. J. Mar. Sci. Eng. 2020, 8, 630. [Google Scholar] [CrossRef]

- Jiang, H.; Zhao, H.; Gao, K.; Wang, O.; Wang, Y.; Meng, D. Numerical investigation of hard rock breakage by high-pressure water jet assisted indenter impact using the coupled SPH/FEM method. Powder Technol. 2020, 376, 176–186. [Google Scholar] [CrossRef]

- Koneshwaran, S.; Thambiratnam, D.P.; Gallage, C. Blast response of segmented bored tunnel using coupled SPH–FE method. Structures 2015, 2, 58–71. [Google Scholar] [CrossRef] [Green Version]

- Pashkov, A. Simulation of the forming of large double curvature parts on contact-type shot peening installations. Russ. Metall. 2021, 13, 1821–1828. [Google Scholar] [CrossRef]

- Gao, F. Study on Affections of Pipeline Diameter to the Transportation Characteristics of Backfilling Slurry of Unclassified Tailings Inner Pipe; Hebei United University: Tangshan, China, 2015. [Google Scholar]

- Dinçer, A.E. Investigation of the sloshing behavior due to seismic excitations considering two-way coupling of the fluid and the structure. Water 2019, 11, 2664. [Google Scholar] [CrossRef] [Green Version]

- Sanapala, V.M.R.; Velusamy, K.; Patnaik, B.S.V. Numerical simulation of parametric liquid sloshing in a horizontally baffled rectangular container. J. Fluids Struct. 2018, 76, 229–250. [Google Scholar] [CrossRef]

- Calvetti, F.; di Prisco, C.G.; Vairaktaris, E. DEM assessment of impact forces of dry granular masses on rigid barriers. Acta Geotech. 2017, 12, 129–144. [Google Scholar] [CrossRef]

- Aubertin, M. Waste Rock Disposal to Improve the Geotechnical and Geochemical Stability of Piles; 23rd World Mining Congress and Expo 2013; Canadian Institute of Mining, Metallurgy and Petroleum (CIM): Westmount, QC, Canada, 2013. [Google Scholar]

- Pashias, N.; Boger, D.V.; Summers, J.; Glenister, D.J. A fifty cent rheometer for yield stress measurement. J. Rheol. 1996, 40, 1179–1189. [Google Scholar] [CrossRef]

- Zheng, J.; Li, L. Experimental study of the “short-term” pressures of uncemented paste backfill with different solid contents for barricade design. J. Clean. Prod. 2020, 275, 123068. [Google Scholar] [CrossRef]

- Shen, W.; Zhao, T.; Zhao, J.; Dai, F.; Zhou, G.G.D. Quantifying the impact of dry debris flow against a rigid barrier by DEM analyses. Eng. Geol. 2018, 241, 86–96. [Google Scholar] [CrossRef]

- Giannaros, E.; Kotzakolios, A.; Kostopoulos, V.; Campoli, G. Hypervelocity impact response of CFRP laminates using smoothed particle hydrodynamics method: Implementation and validation. Int. J. Impact Eng. 2019, 123, 56–69. [Google Scholar] [CrossRef]

- Lee, S.; Hong, J.W. Parametric studies on smoothed particle hydrodynamic simulations for accurate estimation of open surface flow force. Int. J. Nav. Archit. Ocean Eng. 2020, 12, 85–101. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Li, L. Numerical Investigation on the Impact of Tailings Slurry on Catch Dams Built at the Downstream of a Breached Tailings Pond. Processes 2022, 10, 898. https://doi.org/10.3390/pr10050898

Zhou S, Li L. Numerical Investigation on the Impact of Tailings Slurry on Catch Dams Built at the Downstream of a Breached Tailings Pond. Processes. 2022; 10(5):898. https://doi.org/10.3390/pr10050898

Chicago/Turabian StyleZhou, Shitong, and Li Li. 2022. "Numerical Investigation on the Impact of Tailings Slurry on Catch Dams Built at the Downstream of a Breached Tailings Pond" Processes 10, no. 5: 898. https://doi.org/10.3390/pr10050898

APA StyleZhou, S., & Li, L. (2022). Numerical Investigation on the Impact of Tailings Slurry on Catch Dams Built at the Downstream of a Breached Tailings Pond. Processes, 10(5), 898. https://doi.org/10.3390/pr10050898