An Effective Temperature Control Method for Dividing-Wall Distillation Columns

Abstract

:1. Introduction

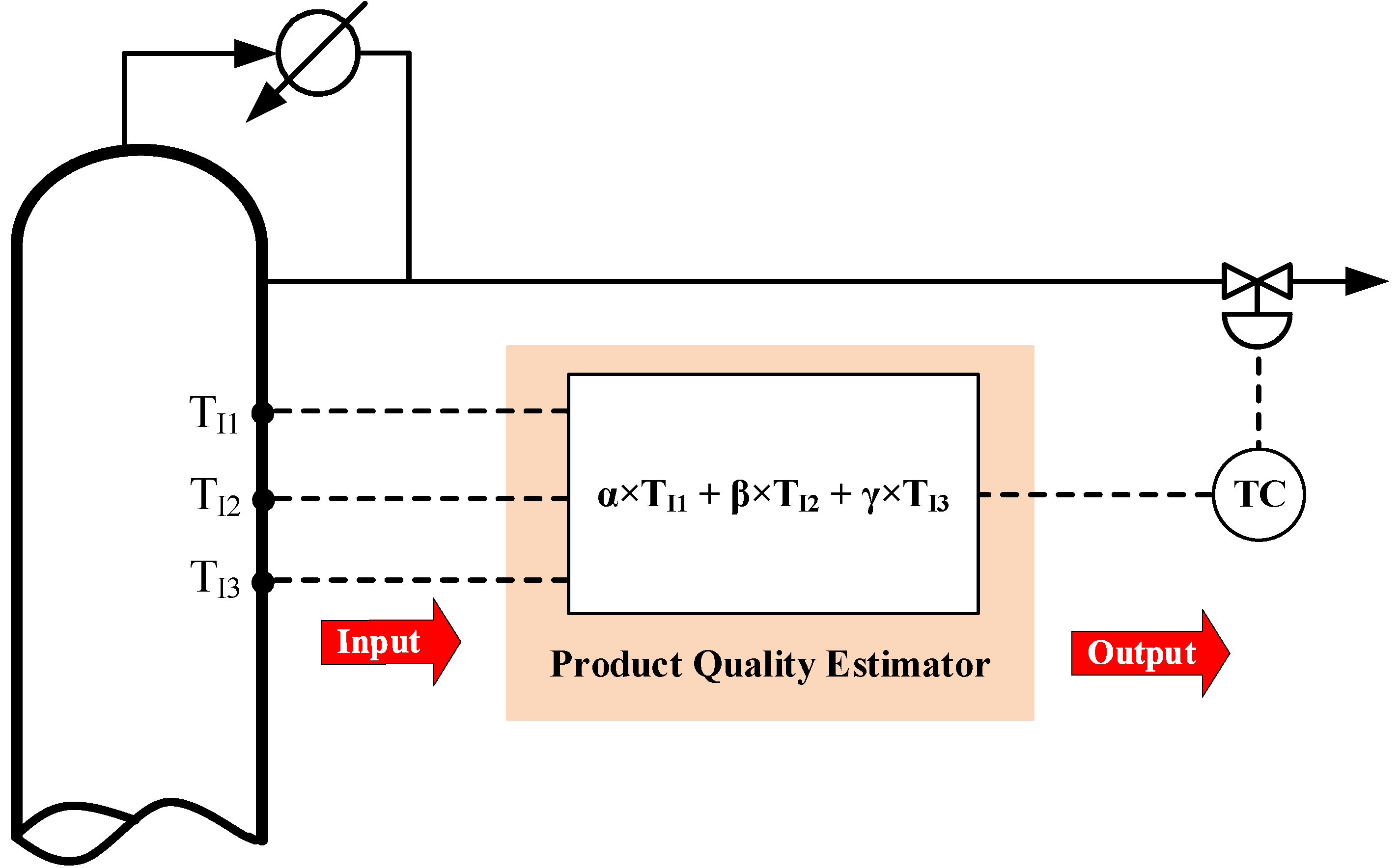

2. Structure and Design Method of the Proposed PQE

2.1. Structure of the PQE

2.2. Design Method of the PQE

3. Example I: Operation of an EPB Petlyuk DWDC

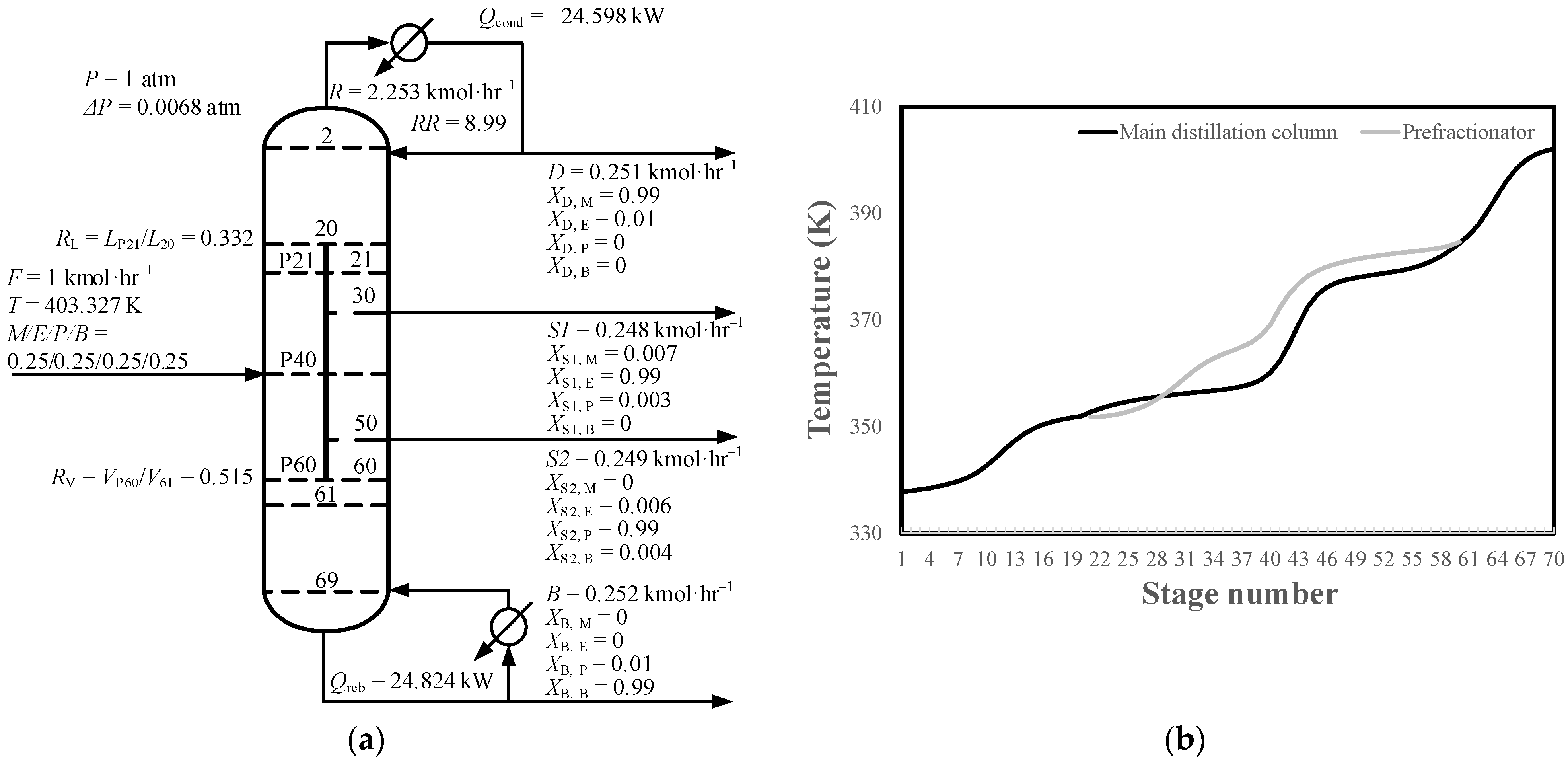

3.1. Process Design of the EPB Petlyuk DWDC

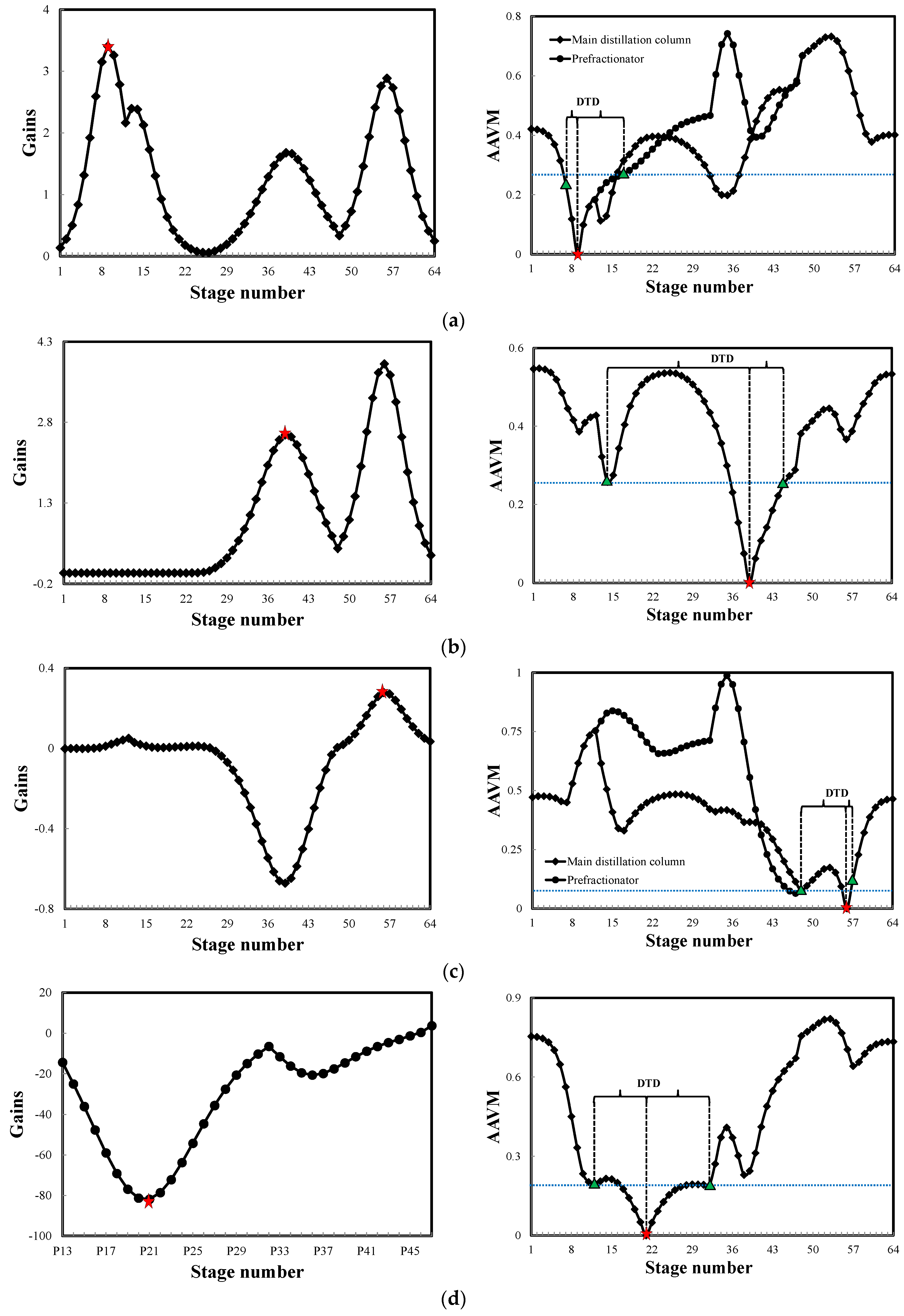

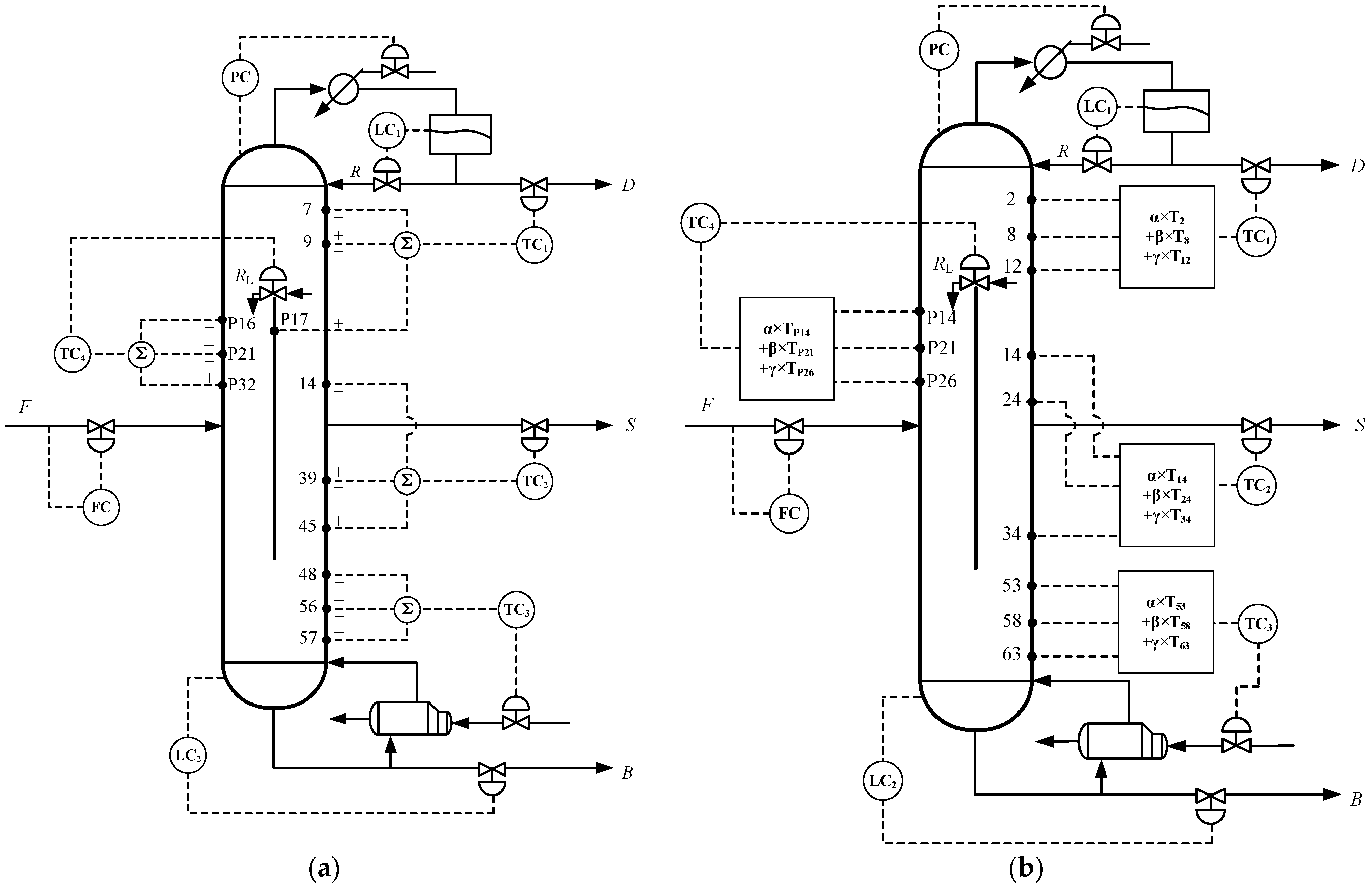

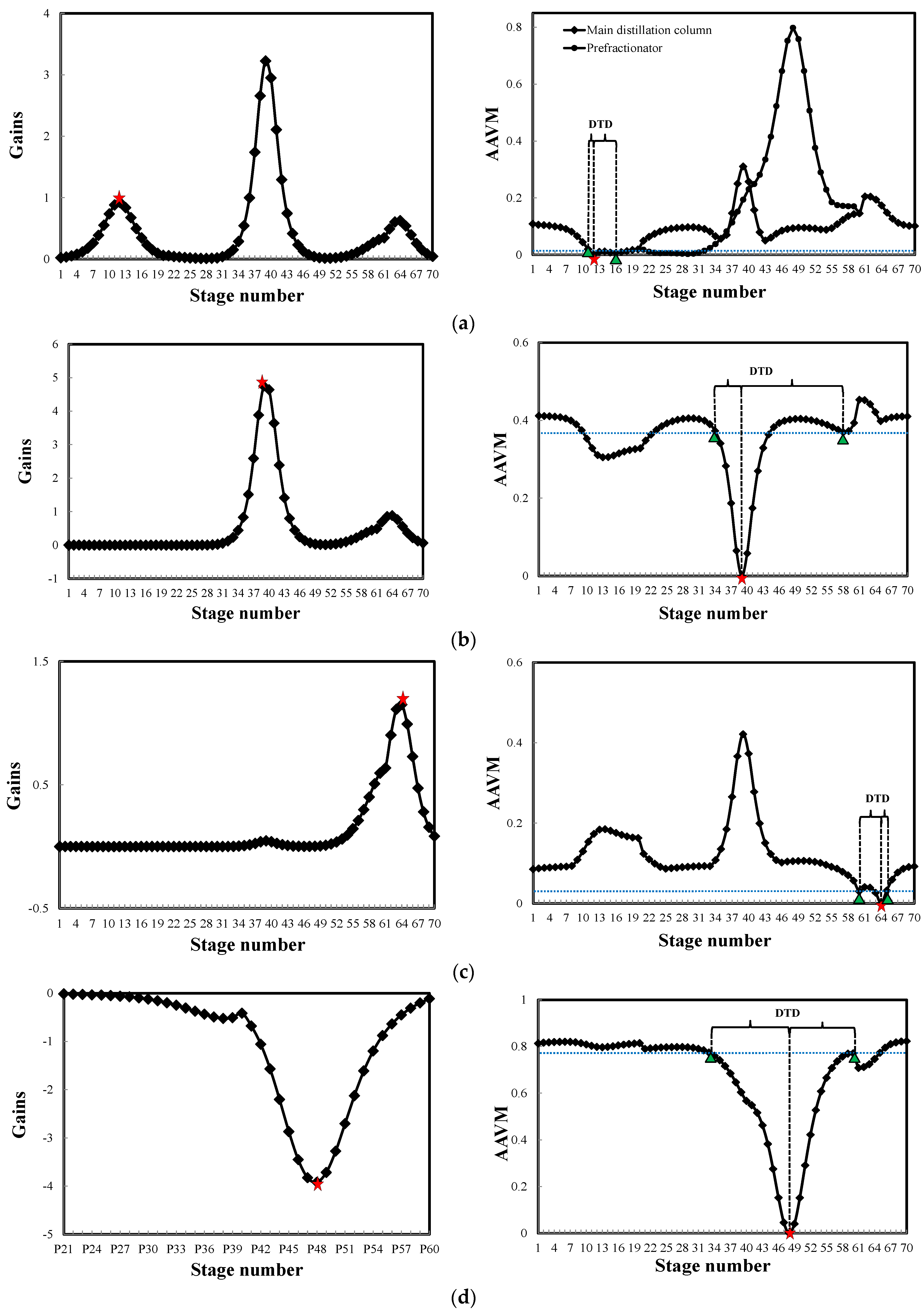

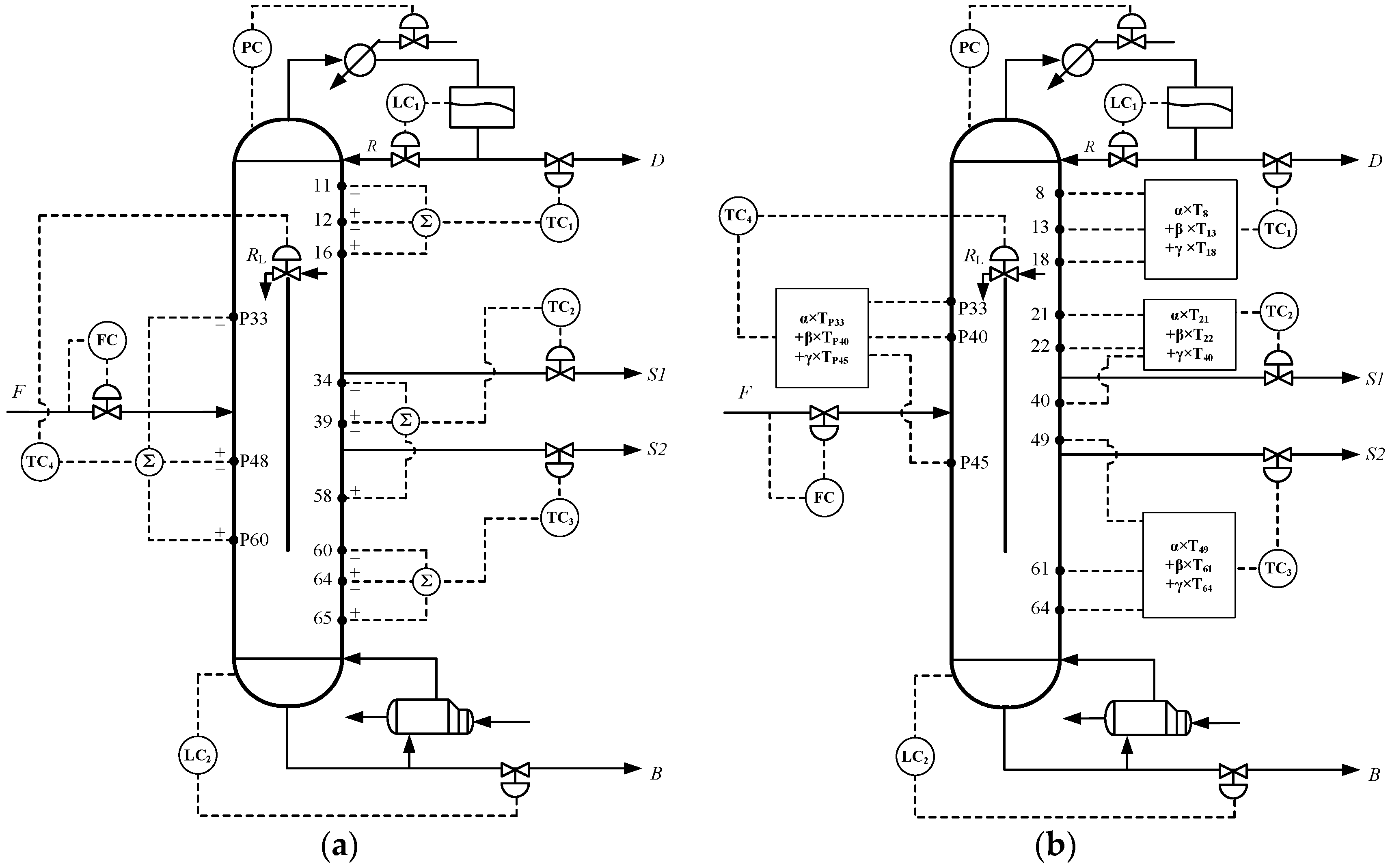

3.2. Derivation of the DTDC Scheme

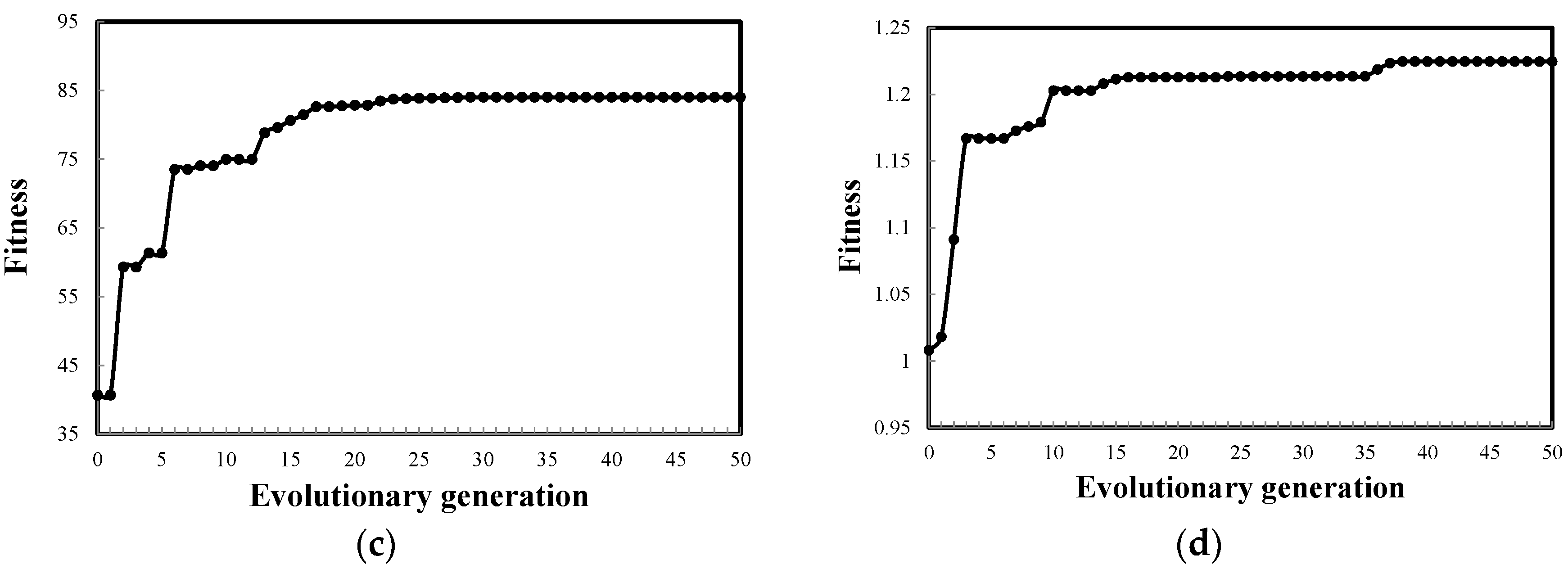

3.3. Derivation of the TC-PQE Scheme

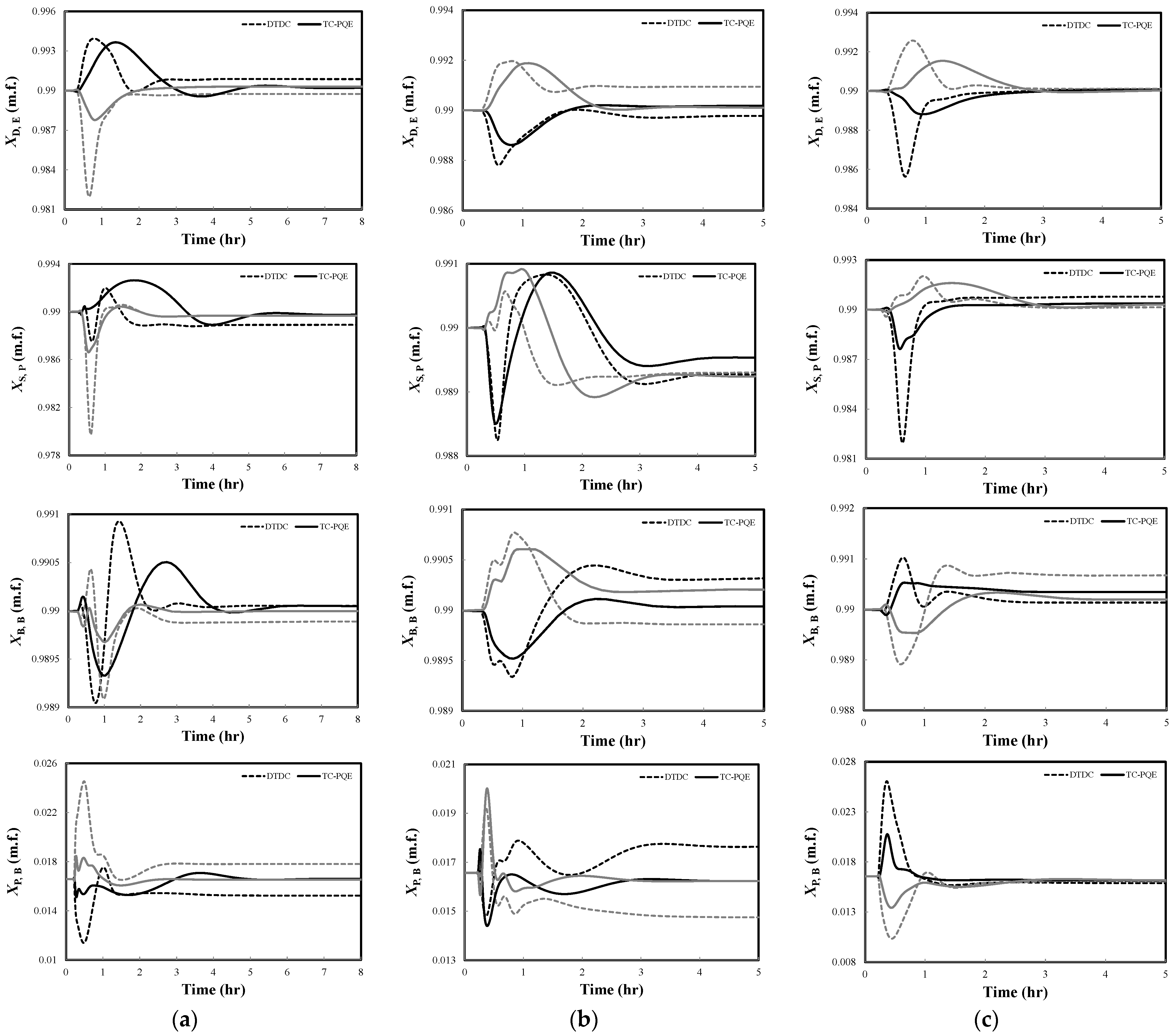

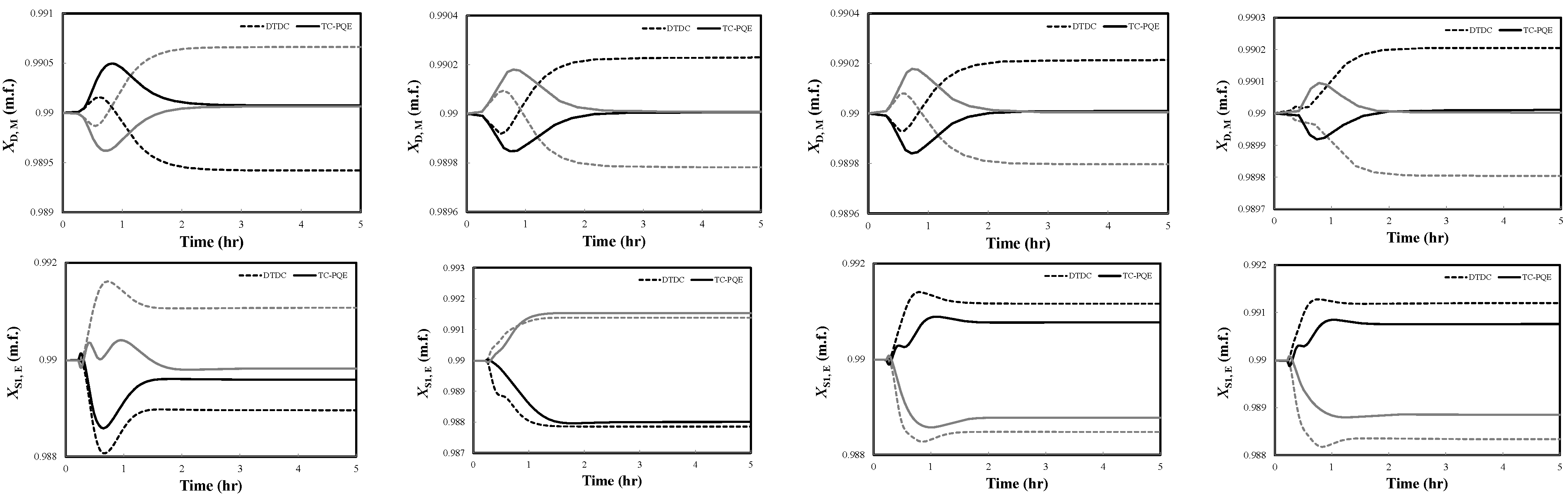

3.4. Comparison between the DTDC and TC-PQE Schemes

4. Example II: Operation of a MEPB Kaibel DWDC

4.1. Process Design of the MEPB Kaibel DWDC

4.2. Derivation of the DTDC Scheme

4.3. Derivation of the TC-PQE Scheme

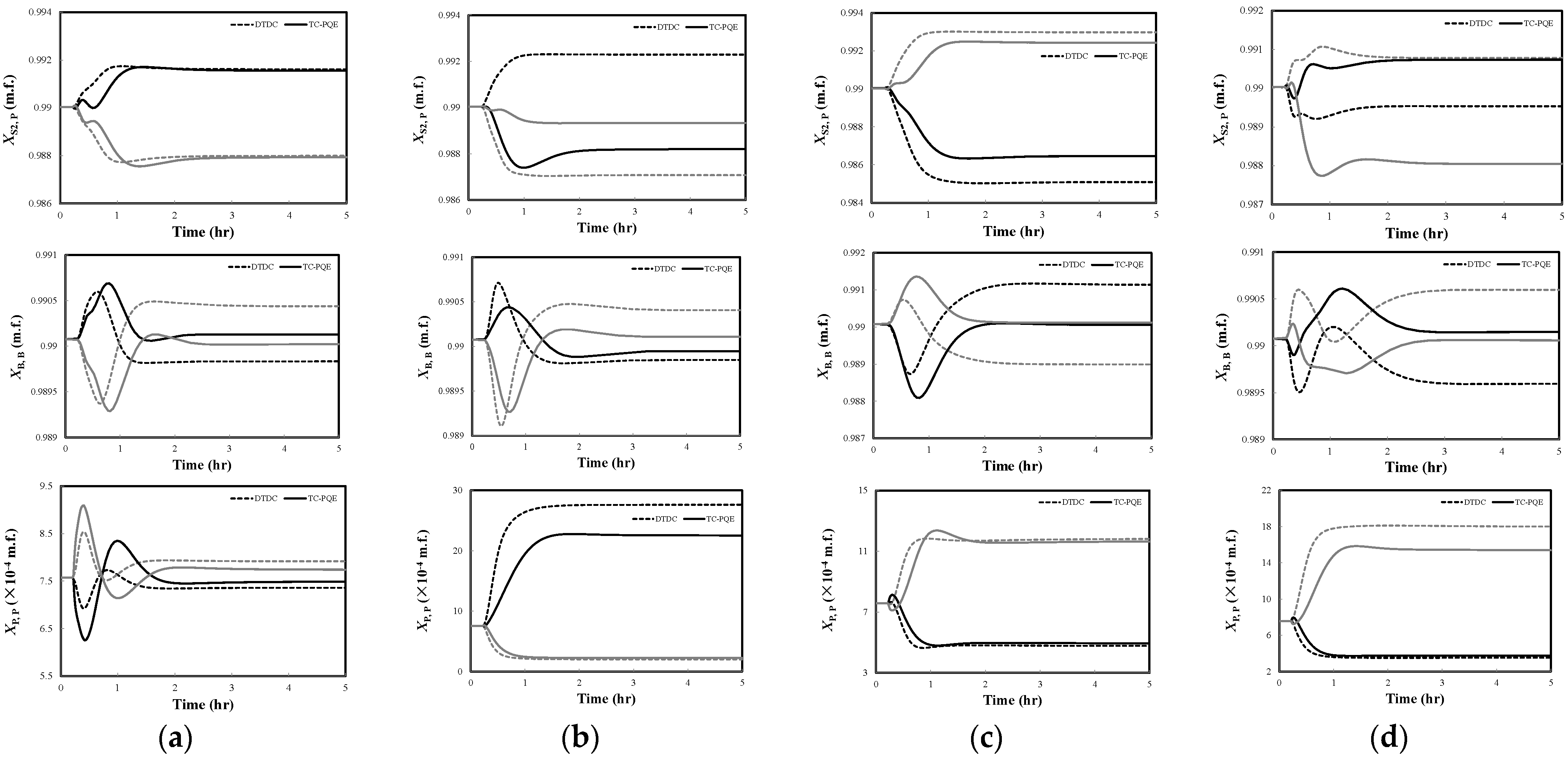

4.4. Comparison between the DTDC and TC-PQE Schemes

5. Discussion

6. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Gao, Z.; Nguang, S.; Kong, D. Advances in modeling, monitoring, and control for complex industrial systems. Complexity 2019, 2019, 2975083. [Google Scholar]

- Gao, Z.; Chen, M.Z.Q.; Zhang, D. Special issue on “Advances in condition monitoring, optimization and control for complex industrial processes”. Processes 2021, 9, 664. [Google Scholar] [CrossRef]

- Dejanović, I.; Matijašević, L.; Olujić, Ž. Dividing wall column—A breakthrough towards sustainable distilling. Chem. Eng. Process. 2010, 49, 559–580. [Google Scholar] [CrossRef]

- Dejanović, I.; Matijašević, L.; Halvorsen, I.J.; Skogestad, S.; Jansen, H.; Kaibel, B.; Olujić, Ž. Designing four-product dividing wall columns for separation of a multicomponent aromatics mixture. Chem. Eng. Res. Des. 2011, 89, 1155–1167. [Google Scholar] [CrossRef]

- Qian, X.; Jia, S.; Huang, K.; Chen, H.; Yuan, Y.; Zhang, L. Optimal design of kaibel dividing wall columns based on improved particle swarm optimization methods. J. Clean. Prod. 2020, 273, 123041. [Google Scholar] [CrossRef]

- Kiss, A.A.; Bildea, C.S. A control perspective on process intensification in dividing-wall columns. Chem. Eng. Process. 2011, 50, 281–292. [Google Scholar] [CrossRef]

- Dwivedi, D.; Halvorsen, I.J.; Skogestad, S. Control structure selection for three-product petlyuk (dividing-wall) column. Chem. Eng. Process. 2013, 64, 57–67. [Google Scholar] [CrossRef]

- Dwivedi, D.; Halvorsen, I.J.; Skogestad, S. Control structure selection for four-product petlyuk column. Chem. Eng. Process. 2013, 67, 49–59. [Google Scholar] [CrossRef]

- Kiss, A.A.; Rewagad, R.R. Energy efficient control of a BTX dividing-wall column. Comput. Chem. Eng. 2011, 35, 2896–2904. [Google Scholar] [CrossRef]

- Yuan, Y.; Huang, K.; Chen, H.; Qian, X.; Zang, L.; Zhang, L.; Wang, S. Comparing composition control structures for Kaibel distillation columns. Processes 2020, 8, 218. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.J.; Wong, D.S.H. Controllability and energy efficiency of a high-purity divided wall column. Chem. Eng. Sci. 2007, 62, 1010–1025. [Google Scholar] [CrossRef]

- Jia, S.; Qian, X.; Yuan, X.; Skogestad, S. Control structure comparison for three-product petlyuk column. Chin. J. Chem. Eng. 2018, 26, 1621–1630. [Google Scholar] [CrossRef]

- Kim, K.; Lee, M.; Park, S. Two-point temperature control structure selection for dividing-wall distillation columns. Ind. Eng. Chem. Res. 2012, 51, 15683–15695. [Google Scholar] [CrossRef]

- Fan, G.; Jiang, W.; Qian, X. Comparison of stabilizing control structures for four-product kaibel column. Chem. Eng. Res. Des. 2016, 109, 675–685. [Google Scholar] [CrossRef]

- Villegas-Uribe, C.A.; Alcάntara-Avila, J.R.; Medina-Herrera, N.; Gόmez-Gonzάlez, R.; Tututi-Avila, S. Temperature control of a kaibel, agrawal and sargent dividing-wall distillation columns. Chem. Eng. Process. 2021, 159, 108248. [Google Scholar] [CrossRef]

- Qian, X.; Liu, R.; Huang, K.; Chen, H.; Yuan, Y.; Zhang, L.; Wang, S. Comparison of temperature control and temperature difference control for a Kaibel dividing wall column. Processes 2019, 7, 773. [Google Scholar] [CrossRef] [Green Version]

- Ling, H.; Luyben, W.L. Temperature control of the BTX divided-wall column. Ind. Eng. Chem. Res. 2010, 49, 189–203. [Google Scholar] [CrossRef]

- Wu, N.; Huang, K.; Luan, S. Operation of dividing-wall distillation columns. 2. A double temperature difference control scheme. Ind. Eng. Chem. Res. 2013, 52, 5365–5383. [Google Scholar] [CrossRef]

- Yuan, Y.; Huang, K.; Chen, H.; Zhang, L.; Wang, S. Configuring effectively double temperature difference control schemes for distillation columns. Ind. Eng. Chem. Res. 2017, 56, 9143–9155. [Google Scholar] [CrossRef]

- Pan, H.; Wu, X.; Qiu, J.; He, G.; Ling, H. Pressure compensated temperature control of kaibel divided-wall column. Chem. Eng. Sci. 2019, 203, 321–332. [Google Scholar] [CrossRef]

- Luyben, W.L. Distillation Design and Control Using Aspen Simulation; John Wiley & Sons: New York, NY, USA, 2006. [Google Scholar]

- Gao, R.; Gao, Z. Pitch control for wind turbine systems using optimization, estimation and compensation. Renew. Energy 2016, 91, 501–515. [Google Scholar] [CrossRef]

| System | Control Loop | TI1 | TI2 | TI3 | α | β | γ |

|---|---|---|---|---|---|---|---|

| Example I | Top | T2 | T8 | T12 | 2.5436 | −3.5962 | 1.7618 |

| Sidestream | T14 | T24 | T34 | 2.1465 | 4.1458 | −3.7670 | |

| Bottom | T53 | T58 | T63 | −1.3321 | 3.5541 | −1.5087 | |

| Prefractionator | TP14 | TP21 | TP26 | −1.5082 | 3.5383 | −1.9755 | |

| Example II | Top | T8 | T13 | T18 | −2.9537 | −1.2432 | 2.2666 |

| Upper sidestream | T21 | T22 | T40 | −4.9737 | −4.9668 | 2.0480 | |

| Lower sidestream | T49 | T61 | T64 | −0.6192 | −2.2745 | 3.2625 | |

| Prefractionator | TP33 | TP40 | TP45 | −4.0334 | 3.7216 | −2.9252 |

| System | Scheme | Control Loop | AAVM | Static Gain |

|---|---|---|---|---|

| Example I | TC-PQE | Top | 0.0264 | 1.7027 |

| Sidestream | 0.1600 | 1.2830 | ||

| Bottom | 0.0262 | 0.5210 | ||

| Prefractionator | 0.0142 | 0.4235 | ||

| DTDC | Top | 0.0412 | 1.0155 | |

| Sidestream | 0.2633 | 0.9806 | ||

| Bottom | 0.0387 | 0.2620 | ||

| Prefractionator | 0.0757 | 0.2832 | ||

| Example II | TC-PQE | Top | 0.0014 | 1.8430 |

| Upper sidestream | 0.3435 | 9.5064 | ||

| Lower sidestream | 0.0119 | 2.3020 | ||

| Prefractionator | 0.8165 | 7.8350 | ||

| DTDC | Top | 0.0218 | 0.6165 | |

| Upper sidestream | 0.7426 | 8.7710 | ||

| Lower sidestream | 0.0529 | 0.7140 | ||

| Prefractionator | 1.5454 | 7.4735 |

| System | Scheme | Controller | KC | TI (min) |

|---|---|---|---|---|

| Example I | TC-PQE | TC1 | 5.30 | 38.28 |

| TC2 | 14.88 | 27.72 | ||

| TC3 | 2.78 | 9.24 | ||

| TC4 | 1.28 | 18.48 | ||

| DTDC | TC1 | 0.91 | 36.96 | |

| TC2 | 0.75 | 23.76 | ||

| TC3 | 0.36 | 10.56 | ||

| TC4 | 0.31 | 30.36 | ||

| Example II | TC-PQE | TC1 | 3.27 | 15.84 |

| TC2 | 31.31 | 13.20 | ||

| TC3 | 8.35 | 25.08 | ||

| TC4 | 7.92 | 22.44 | ||

| DTDC | TC1 | 0.27 | 15.84 | |

| TC2 | 0.30 | 13.20 | ||

| TC3 | 2.45 | 30.36 | ||

| TC4 | 0.34 | 18.48 |

| Scenario | Product Purity | Steady-State Deviation (mol%) | |

|---|---|---|---|

| TC-PQE | DTDC | ||

| +20% ZE | XD, E | 2.32 × 10−4 | 8.76 × 10−4 |

| XS, P | −2.26 × 10−4 | −10.89 × 10−4 | |

| XB, B | 0.44 × 10−4 | 0.57 × 10−4 | |

| XP, B | 0.14 × 10−4 | −13.32 × 10−4 | |

| −20% ZE | XD, E | 3.08 × 10−4 | −2.54 × 10−4 |

| XS, P | −3.35 × 10−4 | −3.51 × 10−4 | |

| XB, B | 0.03 × 10−4 | −1.05 × 10−4 | |

| XP, B | −0.39 × 10−4 | 12.35 × 10−4 | |

| +20% ZP | XD, E | 1.80 × 10−4 | −2.29 × 10−4 |

| XS, P | −4.75 × 10−4 | −7.46 × 10−4 | |

| XB, B | 0.45 × 10−4 | 3.24 × 10−4 | |

| XP, B | −3.29 × 10−4 | 10.80 × 10−4 | |

| −20% ZP | XD, E | 0.99 × 10−4 | 9.35 × 10−4 |

| XS, P | −7.56 × 10−4 | −6.85 × 10−4 | |

| XB, B | 2.10 × 10−4 | −1.36 × 10−4 | |

| XP, B | −3.36 × 10−4 | −18.21 × 10−4 | |

| +20% ZB | XD, E | 0.41 × 10−4 | 0.91 × 10−4 |

| XS, P | 3.72 × 10−4 | 7.88 × 10−4 | |

| XB, B | 3.50 × 10−4 | 1.41 × 10−4 | |

| XP, B | −4.08 × 10−4 | −6.87 × 10−4 | |

| −20% ZB | XD, E | 0.29 × 10−4 | 1.27 × 10−4 |

| XS, P | 3.02 × 10−4 | 1.41 × 10−4 | |

| XB, B | 2.09 × 10−4 | 6.79 × 10−4 | |

| XP, B | −3.93 × 10−4 | −5.02 × 10−4 | |

| Example I | Example II | |||

|---|---|---|---|---|

| TC-PQE | DTDC | TC-PQE | DTDC | |

| +ZM | – | – | 40% | 38% |

| −ZM | – | – | −40% | −40% |

| +ZE | 22% | 20% | 28% | 28% |

| −ZE | −44% | −32% | −58% | −30% |

| +ZP | 30% | 28% | 26% | 20% |

| −ZP | −28% | −26% | −50% | −40% |

| +ZB | 36% | 32% | 42% | 40% |

| −ZB | −40% | −34% | −30% | −42% |

| Scenario | Product Purity | Steady-State Deviation (mol%) | Scenario | Product Purity | Steady-State Deviation (mol%) | ||

|---|---|---|---|---|---|---|---|

| TC-PQE | DTDC | TC-PQE | DTDC | ||||

| +20% ZM | XD, M | 0.74 × 10−4 | −5.81 × 10−4 | +20% ZP | XD, M | 0.10 × 10−4 | 2.18 × 10−4 |

| XS1, E | −3.99 × 10−4 | −10.29× 10−4 | XS1, E | 7.80 × 10−4 | 11.71 × 10−4 | ||

| XS2, P | 15.21 × 10−4 | 15.76 × 10−4 | XS2, P | −35.73 × 10−4 | −49.46 × 10−4 | ||

| XB, B | 0.51 × 10−4 | −2.42 × 10−4 | XB, B | −0.18 × 10−4 | 10.58 × 10−4 | ||

| XP, B | −0.08 × 10−4 | −0.21 × 10−4 | XP, B | −2.63 × 10−4 | −2.80 × 10−4 | ||

| −20% ZM | XD, M | 0.63 × 10−4 | 6.66 × 10−4 | −20% ZP | XD, M | 0.04 × 10−4 | −2.04 × 10−4 |

| XS1, E | −1.66 × 10−4 | 10.87 × 10−4 | XS1, E | −12.08 × 10−4 | −15.06 × 10−4 | ||

| XS2, P | −21.02 × 10−4 | −20.42 × 10−4 | XS2, P | 23.90 × 10−4 | 29.45 × 10−4 | ||

| XB, B | −0.53 × 10−4 | 3.60 × 10−4 | XB, B | 0.44 × 10−4 | −10.87 × 10−4 | ||

| XP, B | 0.17 × 10−4 | 0.34 × 10−4 | XP, B | 4.08 × 10−4 | 4.25 × 10−4 | ||

| +20% ZE | XD, M | 0.06 × 10−4 | 2.36 × 10−4 | +20% ZB | XD, M | 0.14 × 10−4 | 2.05 × 10−4 |

| XS1, E | −19.76 × 10−4 | −21.36 × 10−4 | XS1, E | 7.74 × 10−4 | 12.14 × 10−4 | ||

| XS2, P | −18.27 × 10−4 | 22.55 × 10−4 | XS2, P | 7.14 × 10−4 | −4.99 × 10−4 | ||

| XB, B | −1.31 × 10−4 | −2.25 × 10−4 | XB, B | 0.74 × 10−4 | −4.80 × 10−4 | ||

| XP, B | 14.94 × 10−4 | 20.05 × 10−4 | XP, B | −3.81 × 10−4 | −4.04 × 10−4 | ||

| −20% ZE | XD, M | 0.06 × 10−4 | −2.20 × 10−4 | −20% ZB | XD, M | 0.02 × 10−4 | −1.96 × 10−4 |

| XS1, E | 15.34 × 10−4 | 13.96 × 10−4 | XS1, E | −11.39 × 10−4 | −16.51 × 10−4 | ||

| XS2, P | −6.99 × 10−4 | −29.64 × 10−4 | XS2, P | −19.80 × 10−4 | 7.50 × 10−4 | ||

| XB, B | 0.40 × 10−4 | 3.30 × 10−4 | XB, B | −0.28 × 10−4 | 5.16 × 10−4 | ||

| XP, B | −5.29 × 10−4 | −5.55 × 10−4 | XP, B | 7.78 × 10−4 | 10.40 × 10−4 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Tao, X.; Huang, K.; Chen, H.; Qian, X. An Effective Temperature Control Method for Dividing-Wall Distillation Columns. Processes 2022, 10, 1018. https://doi.org/10.3390/pr10051018

Yuan Y, Tao X, Huang K, Chen H, Qian X. An Effective Temperature Control Method for Dividing-Wall Distillation Columns. Processes. 2022; 10(5):1018. https://doi.org/10.3390/pr10051018

Chicago/Turabian StyleYuan, Yang, Xinyi Tao, Kejin Huang, Haisheng Chen, and Xing Qian. 2022. "An Effective Temperature Control Method for Dividing-Wall Distillation Columns" Processes 10, no. 5: 1018. https://doi.org/10.3390/pr10051018

APA StyleYuan, Y., Tao, X., Huang, K., Chen, H., & Qian, X. (2022). An Effective Temperature Control Method for Dividing-Wall Distillation Columns. Processes, 10(5), 1018. https://doi.org/10.3390/pr10051018