The Application of Breakthrough Pressure in the Evaluation of the Sealing Ability of Cement–Casing Interface and Cement Matrix in Underground Gas-Storage Wells

Abstract

:1. Introduction

2. Interfacial Transition Zone

3. Breakthrough-Pressure-Prediction Model

3.1. Breakthrough Pressure of Matrix

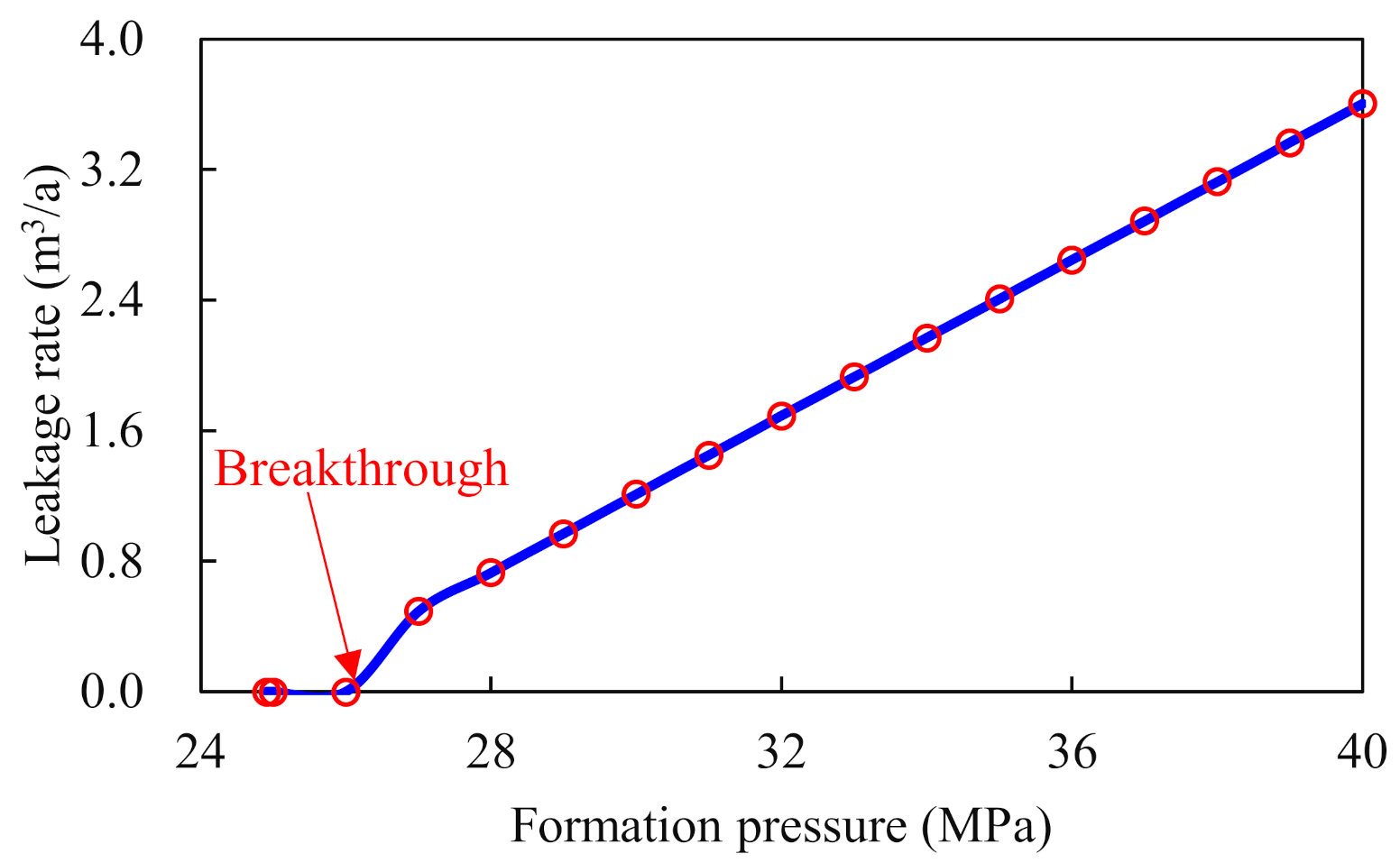

3.2. Breakthrough Pressure of ITZ

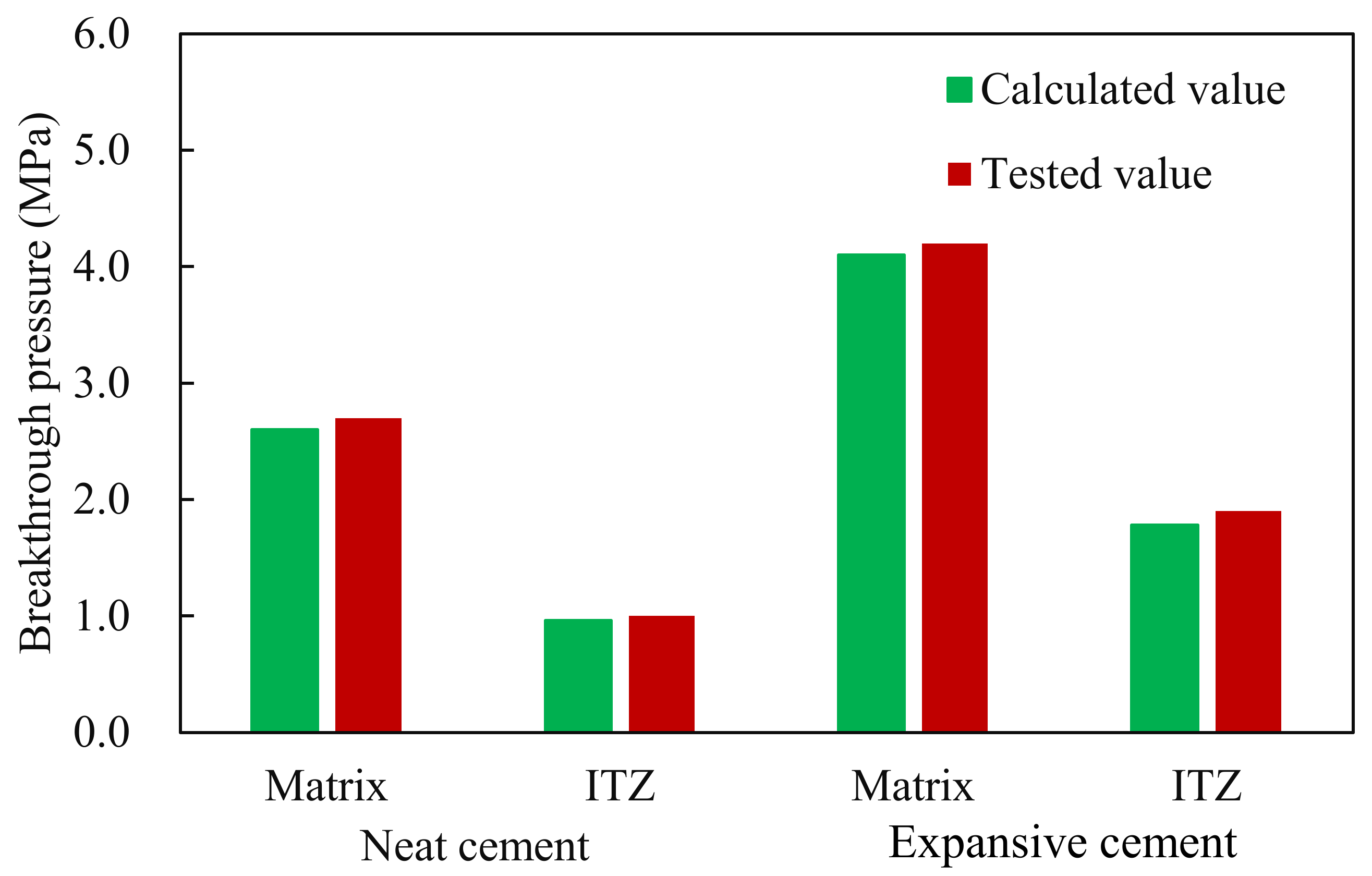

4. Model Verification

4.1. Contact Angle

4.2. Verification Method

- Step 1: Measure the gas permeability of the cement matrix by the gas-permeability method.

- Step 2: Use Equation (2) to calculate the breakthrough pressure of the cement matrix ().

- Step 3: Measure the gas permeability of the ITZ and use Equation (7) to calculate the permeability of the ITZ ().

- Step 4: Use Equation (9) to calculate the breakthrough pressure of the ITZ .

- Step 5: Put the cured specimen of the ITZ-testing mold (Figure 3) into the core holder and apply a confining pressure that is double the matrix breakthrough pressure ().

- Step 6: Apply the of the ITZ to the specimen as a test of the pressure difference. If no bubbles appear after waiting for 10 h, then increase the pressure by 0.1 MPa. Repeat this step until bubbles appear and record the pressure difference.

5. Factors Influencing Breakthrough Pressure

5.1. Drilling Fluid

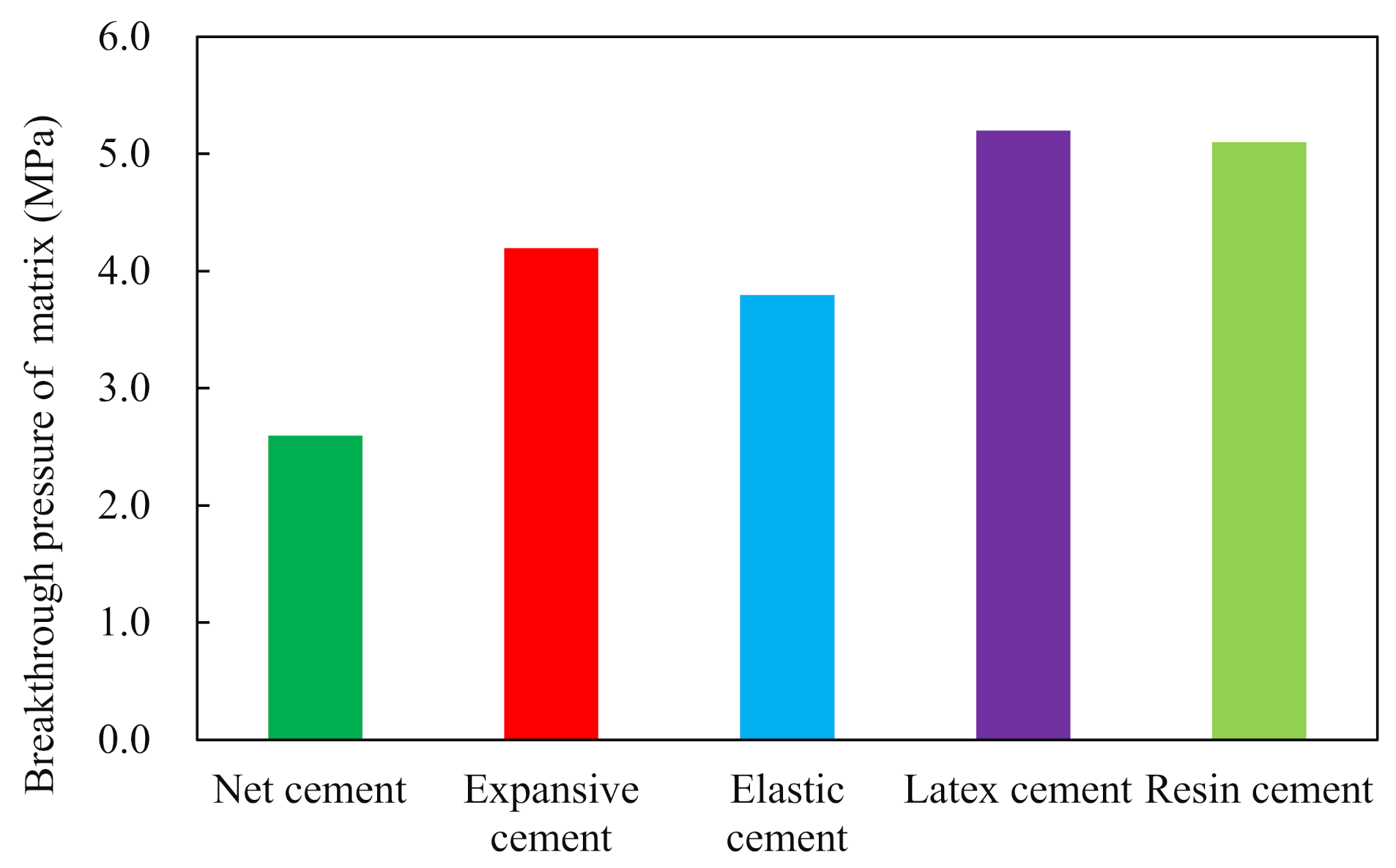

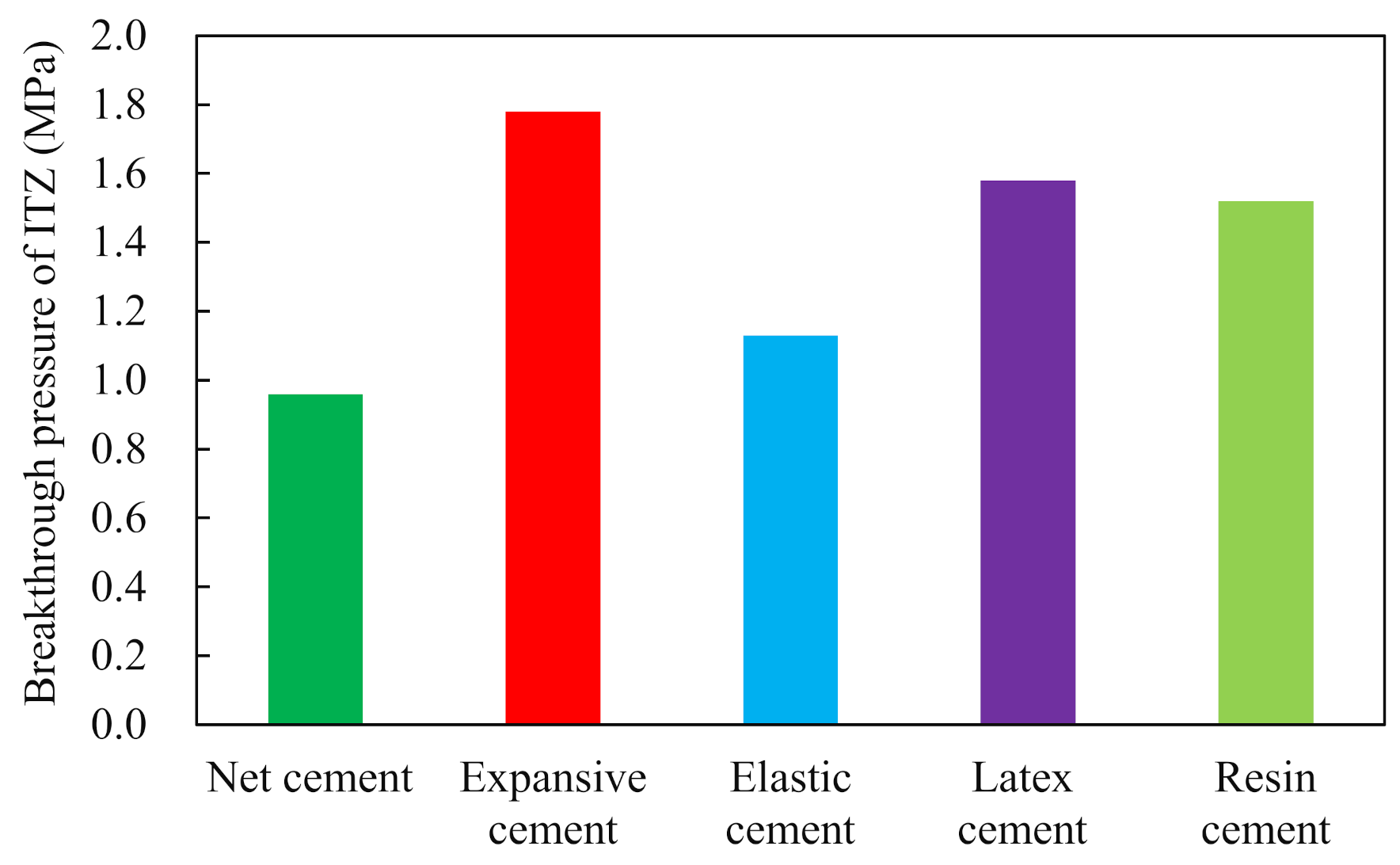

5.2. Cement Slurries

6. Application

7. Conclusions

- Compared with water-based drilling fluid, oil-based fluid decreased the breakthrough pressure of the ITZ by changing the contact angle. The pressure could be increased by fluid flushing.

- The breakthrough pressure of the matrix of latex and resin cement was higher than that of expansive cement, whereas the breakthrough pressure of the ITZ of latex and resin was lower than that of expansive cement. Expansive cement had a better performance in interface sealing.

- The ITZ had a dominant role in the leakage of the cement–casing interface. Continuous injection of natural gas increased the pore pressure of the formation, leading to an increase of leakage in the cement–casing-interface sheath.

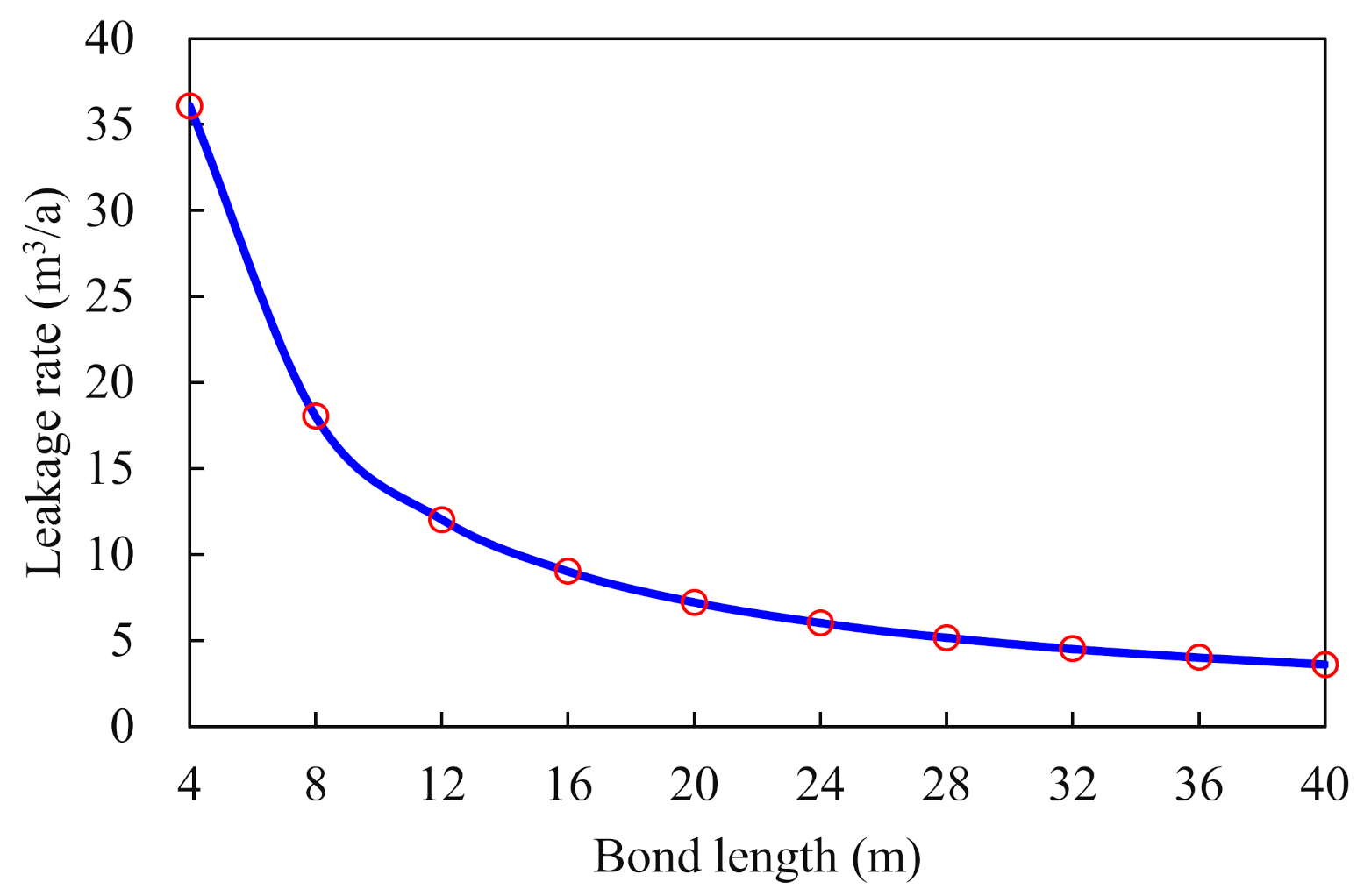

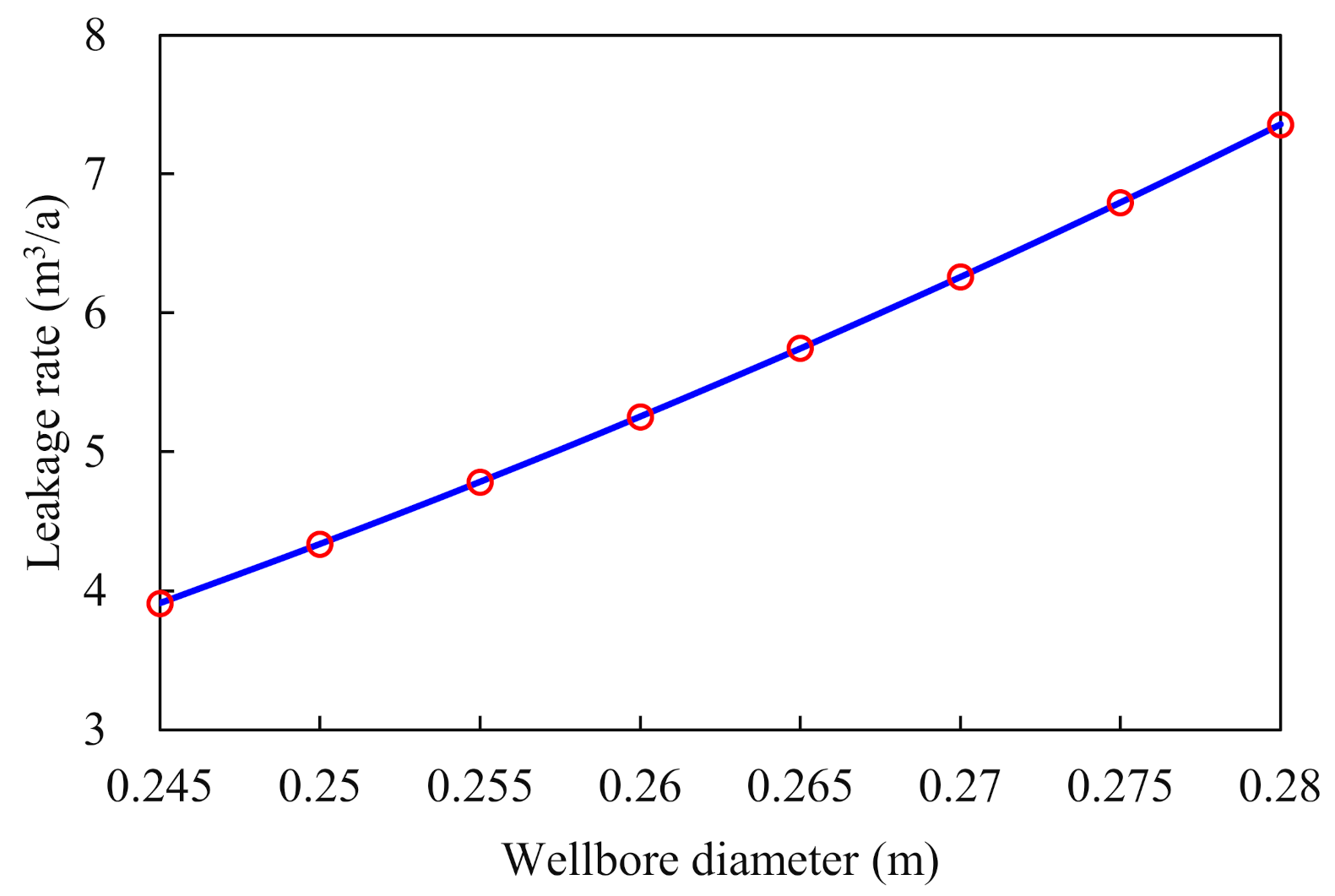

- A longer effective bonding length, higher gas viscosity and smaller enlargement rate of the hole diameter led to a smaller leakage rate of the cement sheath-casing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Becker, S.; Bouzdine-Chameeva, T.; Jaegler, A. The carbon neutrality principle: A case study in the French spirits sector. J. Clean. Prod. 2020, 274, 122739. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Yan, Y.; Wang, P.; Yan, X. A risk analysis model for underground gas storage well integrity failure. J. Loss Prev. Process Ind. 2019, 62, 103951. [Google Scholar] [CrossRef]

- Zhang, H.; Shen, R.; Yuan, G.; Ba, Z.; Hu, Y. Cement sheath integrity analysis of underground gas storage well based on elastoplastic theory. J. Pet. Sci. Eng. 2017, 159, 818–829. [Google Scholar] [CrossRef]

- Benge, G. Improving wellbore seal integrity in CO2 injection wells. Energy Procedia 2009, 1, 3523–3529. [Google Scholar] [CrossRef] [Green Version]

- Torsæter, M.; Todorovic, J.; Lavrov, A. Structure and debonding at cement–steel and cement–rock interfaces: Effect of geometry and materials. Constr. Build. Mater. 2015, 96, 164–171. [Google Scholar] [CrossRef]

- Nelson, E.B.; Guillot, D. Well Cementing, 2nd ed.; Schlumberger: Sugar Land, TX, USA, 2006. [Google Scholar]

- Yang, X.; Kuru, E.; Gingras, M.; Iremonger, S.; Chase, P.; Lin, Z. Characterization of the microstructure of the cement/casing interface using esem and micro-CT scan techniques. SPE J. 2021, 26, 1131–1143. [Google Scholar] [CrossRef]

- Lavrov, A.; Panduro, E.A.C.; Torsæter, M. Synchrotron Study of Cement Hydration: Towards Computed Tomography Analysis of Interfacial Transition Zone. Energy Procedia 2017, 114, 5109–5117. [Google Scholar] [CrossRef]

- Zeng, Y.; Lu, P.; Zhou, S.; Sang, L.; Liu, R.; Tao, Q.; Qian, T. A new prediction model for hydrostatic pressure reduction of anti-gas channeling cement slurry based on large-scale physical modeling experiments. J. Pet. Sci. Eng. 2018, 172, 259–268. [Google Scholar] [CrossRef]

- Xu, L.; Ye, W.; Chen, Y.; Chen, B.; Cui, Y. A new approach for determination of gas breakthrough in saturated materials with low permeability. Eng. Geol. 2018, 241, 121–131. [Google Scholar] [CrossRef]

- Song, J.; Zhang, D. Comprehensive Review of Caprock-Sealing Mechanisms for Geologic Carbon Sequestration. Environ. Sci. Technol. 2012, 47, 9–22. [Google Scholar] [CrossRef]

- He, S.; Li, Z.; Yang, E.-H. Quantitative characterization of anisotropic properties of the interfacial transition zone (ITZ) between microfiber and cement paste. Cem. Concr. Res. 2019, 122, 136–146. [Google Scholar] [CrossRef]

- Hussin, A.; Poole, C. Petrography evidence of the interfacial transition zone (ITZ) in the normal strength concrete containing granitic and limestone aggregates. Constr. Build. Mater. 2011, 25, 2298–2303. [Google Scholar] [CrossRef]

- Gao, Y.; De Schutter, G.; Ye, G.; Huang, H.; Tan, Z.; Wu, K. Characterization of ITZ in ternary blended cementitious composites: Experiment and simulation. Constr. Build. Mater. 2013, 41, 742–750. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Crumbie, A.K.; Laugesen, P. The Interfacial Transition Zone (ITZ) Between Cement Paste and Aggregate in Concrete. Interface Sci. 2004, 12, 411–421. [Google Scholar] [CrossRef]

- Bentur, A.; Diamond, S.; Mindess, S. The microstructure of the steel fibre-cement interface. J. Mater. Sci. 1985, 20, 3610–3620. [Google Scholar] [CrossRef]

- Neubauer, C.; Jennings, H.; Garboczi, E. A three-phase model of the elastic and shrinkage properties of mortar. Adv. Cem. Based Mater. 1996, 4, 6–20. [Google Scholar] [CrossRef]

- Rusch, D.W.; Sabins, F.; Aslakson, J. Microannulus Leaks Repaired with Pressure-Activated Sealant. In Proceedings of the SPE Eastern Regional Meeting, Charleston, WV, USA, 15–17 September 2004. [Google Scholar]

- Bachu, S.; Bennion, D.B. Experimental assessment of brine and/or CO2 leakage through well cements at reservoir conditions. Int. J. Greenh. Gas Control 2009, 3, 494–501. [Google Scholar] [CrossRef]

- Wen, M.; Liu, Z.; Gao, X.; Li, Y. Asymptotic Model of Breakthrough Pressure in Partially Saturated Porous Media with Microvisualization Step-by-Step Breakthrough Experiments. Energy Fuels 2020, 35, 1594–1604. [Google Scholar] [CrossRef]

- Tennis, P.D.; Jennings, H.M. A model for two types of calcium silicate hydrate in the microstructure of Portland cement pastes. Cem. Concr. Res. 2000, 30, 855–863. [Google Scholar] [CrossRef]

- Mills, R.H. Factors influencing cessation of hydration in water cured cement pastes. In Transportation Research Information Services; Highway Research Board: Washington, DC, USA, 1966. [Google Scholar]

- Koichi, M.; Tetsuya, I.; Toshiharu, K. Multi-scale modeling of concrete performance -Integrated material and structural mechanics_decrypted. J. Adv. Concr. Technol. 2003, 1, 91–126. [Google Scholar]

- He, G.; Tang, H. Reservoir Physical (Second); Petroleum Industry Press: Beijing, China, 2016. [Google Scholar]

- Chaube, R.; Kishi, T.; Maekawa, K. Modelling of Concrete Performance: Hydration, Microstructure and Mass Transport; CRC Press: London, UK, 1999. [Google Scholar]

- Goboncan, V.C.; Dillenbeck, R.L. Real-time cement expansion/shrinkage testing under downhole conditions for enhanced annular isolation. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 19–21 February 2003. [Google Scholar]

- Xu, B.; Yuan, B.; Wang, Y.; Zeng, S.; Yang, Y. Nanosilica-latex reduction carbonation-induced degradation in cement of CO2 geological storage wells. J. Nat. Gas Sci. Eng. 2019, 65, 237–247. [Google Scholar] [CrossRef]

- Yang, Y.; Yuan, B.; Wang, Y.; Zhang, S.; Zhu, L. Carbonation resistance cement for CO2 storage and injection wells. J. Pet. Sci. Eng. 2016, 146, 883–889. [Google Scholar] [CrossRef]

- Jarrahian, A.; Aghel, B.; Heidaryan, E. On the viscosity of natural gas. Fuel 2015, 150, 609–618. [Google Scholar] [CrossRef]

| Sample | Constituents (Additive to Cement Ratio) (wt. %) | ||||||

|---|---|---|---|---|---|---|---|

| Cement | Expensive Agent | Stabilizer | Drag Reducer | Filtrate Reducer | De-Foamer | Retarder | |

| Neat cement | 100 | 0 | 4 | 0.75 | 3.5 | 1 | 3 |

| Expansive cement | 4 | ||||||

| Cement Slurries | km (×10−19 m2) | kt (×10−19 m2) | θ (°) |

|---|---|---|---|

| Neat cement | 5.82 | 15.10 | 56.45 |

| Expansive cement | 2.33 | 2.71 | 59.30 |

| Parameter | Depth (m) | Caprock (m) | Formation Pressure (MPa) | Interfacial Tension (×10−3 N/m) | Contact Angle (°) | Viscosity (×10−3 Pa·s) |

|---|---|---|---|---|---|---|

| Value | 2310 | 40 | 12.6 | 34.1 | 35 | 0.02 |

| Parameter | km (×10−19 m2) | kt (×10−19 m2) | pmbt (MPa) | pITZbt (MPa) | Bonding Strength (MPa) |

|---|---|---|---|---|---|

| Value | 2.42 | 2.84 | 4.85 | 1.80 | 4.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Li, L.; Yu, W.; Zhou, Y.; Zhu, K.; Yuan, B. The Application of Breakthrough Pressure in the Evaluation of the Sealing Ability of Cement–Casing Interface and Cement Matrix in Underground Gas-Storage Wells. Processes 2022, 10, 620. https://doi.org/10.3390/pr10040620

Yang Y, Li L, Yu W, Zhou Y, Zhu K, Yuan B. The Application of Breakthrough Pressure in the Evaluation of the Sealing Ability of Cement–Casing Interface and Cement Matrix in Underground Gas-Storage Wells. Processes. 2022; 10(4):620. https://doi.org/10.3390/pr10040620

Chicago/Turabian StyleYang, Yan, Lukuan Li, Wenyan Yu, Yan Zhou, Kuanliang Zhu, and Bin Yuan. 2022. "The Application of Breakthrough Pressure in the Evaluation of the Sealing Ability of Cement–Casing Interface and Cement Matrix in Underground Gas-Storage Wells" Processes 10, no. 4: 620. https://doi.org/10.3390/pr10040620

APA StyleYang, Y., Li, L., Yu, W., Zhou, Y., Zhu, K., & Yuan, B. (2022). The Application of Breakthrough Pressure in the Evaluation of the Sealing Ability of Cement–Casing Interface and Cement Matrix in Underground Gas-Storage Wells. Processes, 10(4), 620. https://doi.org/10.3390/pr10040620