Production of Oil and Phenolic-Rich Extracts from Mauritia flexuosa L.f. Using Sequential Supercritical and Conventional Solvent Extraction: Experimental and Economic Evaluation †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

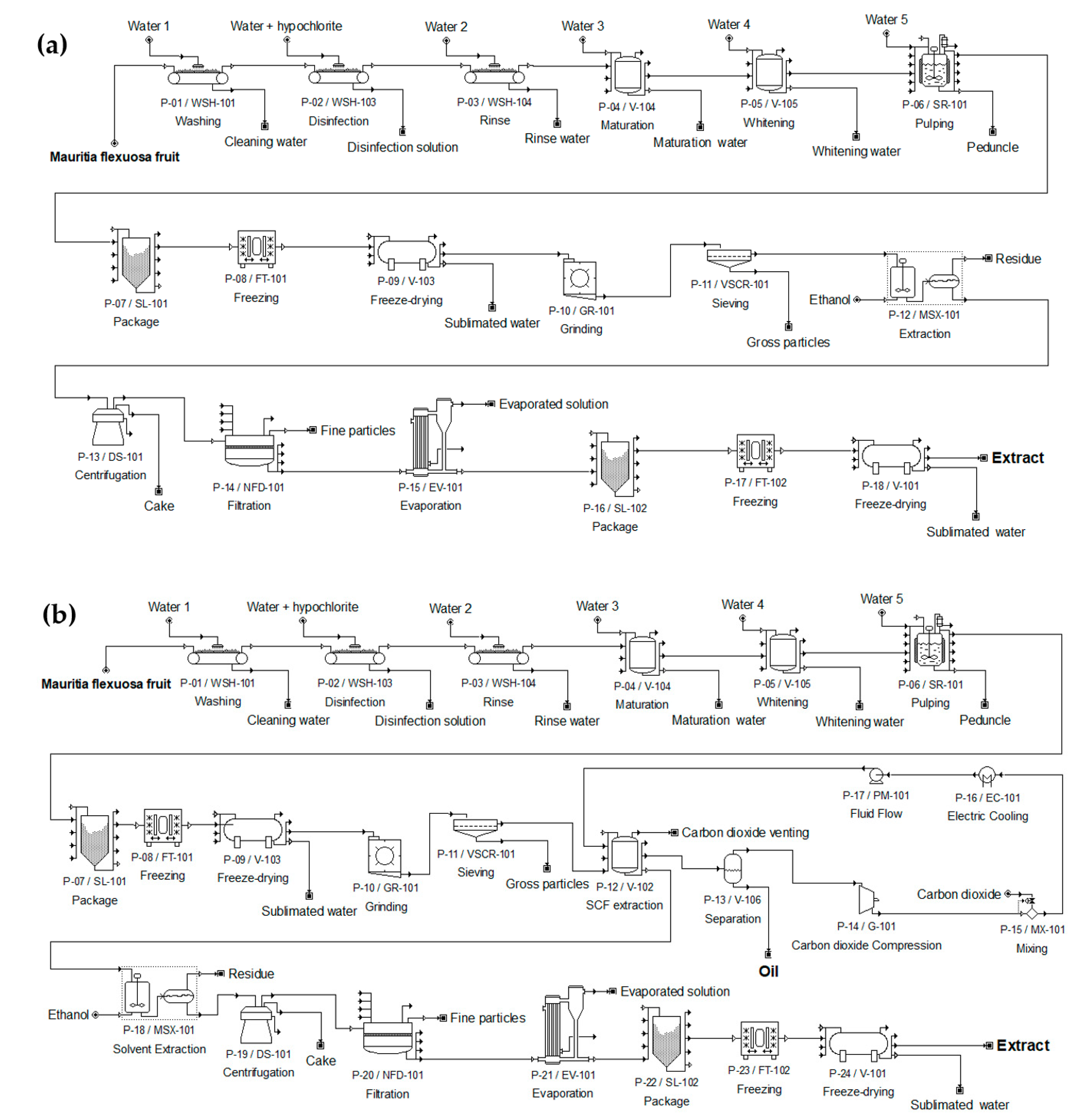

2.2. Single-Stage Process and Two-Stage Sequential Process

2.3. Total Phenolic and Flavonoid Content

2.4. Process Simulation Model

2.5. Economic Evaluation

2.6. Sensitivity Study

2.7. Statistical Analysis

3. Results and Discussion

3.1. Experimental Results

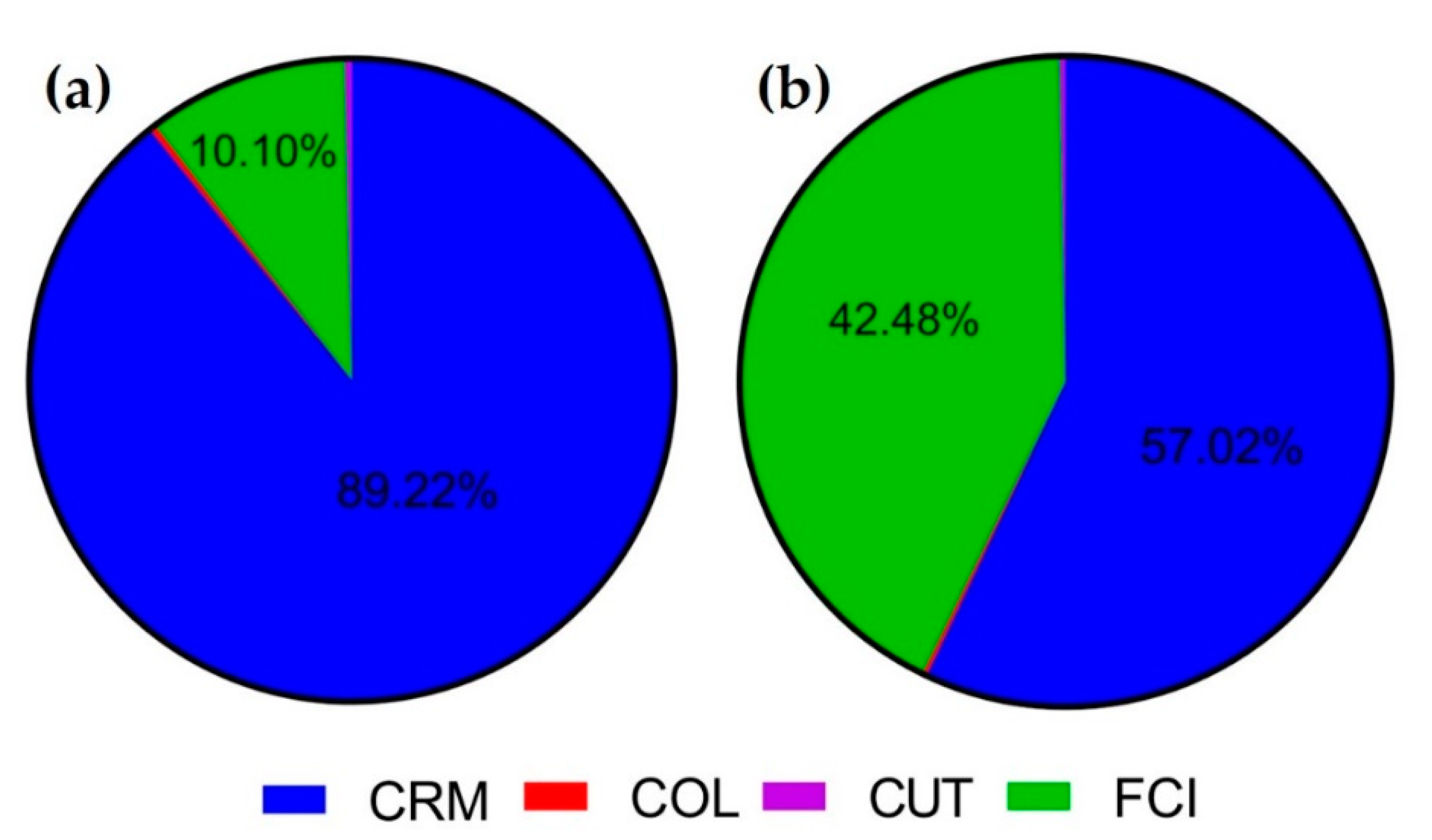

3.2. Economic Evaluation of the Extraction Processes

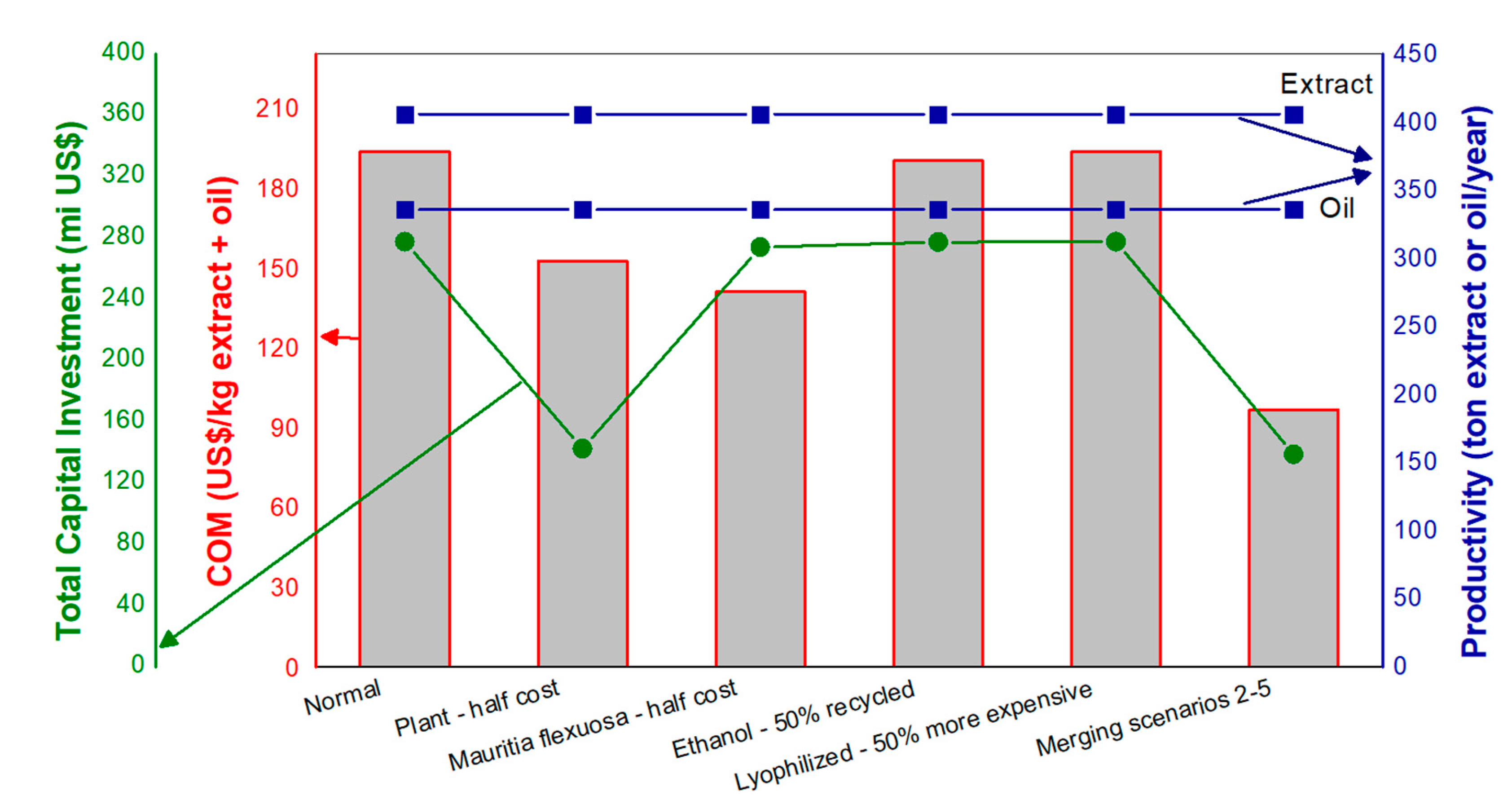

3.3. Sensitivity Study and Comparison between Extraction Methods

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CAGR | Compound annual growth rate |

| CE | Catechin equivalents |

| COL | Cost of operational labor |

| COM | Cost of manufacturing |

| COU | Cost of utilities |

| CRM | Cost of raw material |

| CSE | Conventional solvent extraction |

| CUT | Cost of utilities |

| FCI | Fixed capital investment |

| FSE | Fluid supercritical extraction |

| GAE | Gallic acid equivalents |

| GEY | Global extraction yield |

| GM | Gross margin |

| IRR | Internal rate of return after taxes |

| NPV | Net present value at 7% |

| PBT | Payback time |

| ROI | Return on investment |

| S/F | Mass ratio of solvent to feed |

References

- Pereira Freire, J.A.; Barros, K.B.N.T.; Lima, L.K.F.; Martins, J.M.; de Araújo, Y.C.; da Silva Oliveira, G.L.; de Souza Aquino, J.; Ferreira, P.M.P. Phytochemistry Profile, Nutritional Properties and Pharmacological Activities of Mauritia flexuosa. J. Food Sci. 2016, 81, R2611–R2622. [Google Scholar] [CrossRef]

- Cândido, T.L.N.; Silva, M.R.; Agostini-Costa, T.S. Bioactive compounds and antioxidant capacity of buriti (Mauritia flexuosa L.f.) from the Cerrado and Amazon biomes. Food Chem. 2015, 177, 313–319. [Google Scholar] [CrossRef] [PubMed]

- Best, I.; Casimiro-Gonzales, S.; Portugal, A.; Olivera-Montenegro, L.; Aguilar, L.; Muñoz, A.M.; Ramos-Escudero, F. Phytochemical Screening and DPPH Radical Scavenging Activity of Three Morphotypes of Mauritia flexuosa L.f. from Peru, and Thermal Stability of a Milk-Based Beverage Enriched with Carotenoids from These Fruits. Heliyon 2020, 6, e05209. [Google Scholar] [CrossRef] [PubMed]

- Abreu-Naranjo, R.; Paredes-Moreta, J.G.; Granda-Albuja, G.; Iturralde, G.; González-Paramás, A.M.; Alvarez-Suarez, J.M. Bioactive Compounds, Phenolic Profile, Antioxidant Capacity and Effectiveness against Lipid Peroxidation of Cell Membranes of Mauritia flexuosa L. Fruit Extracts from Three Biomes in the Ecuadorian Amazon. Heliyon 2020, 6, e05211. [Google Scholar] [CrossRef] [PubMed]

- Cunha, M.A.E.; Neves, R.F.; Souza, J.N.S.; França, L.F.; Araújo, M.E.; Brunner, G.; Machado, N.T. Supercritical Adsorption of Buriti Oil (Mauritia flexuosa Mart.) in γ-Alumina: A Methodology for the Enriching of Anti-Oxidants. J. Supercrit. Fluids 2012, 66, 181–191. [Google Scholar] [CrossRef]

- De Aquino, J.S.; Soares, J.K.B.; Magnani, M.; Stamford, T.C.M.; de Mascarenhas, R.J.; Tavares, R.L.; Stamford, T.L.M. Effects of Dietary Brazilian Palm Oil (Mauritia flexuosa L.) on Cholesterol Profile and Vitamin A and E Status of Rats. Molecules 2015, 20, 9054–9070. [Google Scholar] [CrossRef] [Green Version]

- Pérez, M.M.; Gonçalves, E.C.S.; Salgado, J.C.S.; de Rocha, M.S.; de Almeida, P.Z.; Vici, A.C.; da Infante, J.C.; Guisán, J.M.; Rocha-Martin, J.; Pessela, B.C.; et al. Production of Omegas-6 and 9 from the Hydrolysis of Açaí and Buriti Oils by Lipase Immobilized on a Hydrophobic Support. Molecules 2018, 23, E3015. [Google Scholar] [CrossRef] [Green Version]

- Faustino Pereira, Y.; do Socorro Costa, M.; Relison Tintino, S.; Esmeraldo Rocha, J.; Fernandes Galvão Rodrigues, F.; de Sá Barreto Feitosa, M.K.; de Menezes, I.R.A.; Douglas Melo Coutinho, H.; da Costa, J.G.M.; de Sousa, E.O. Modulation of the Antibiotic Activity by the Mauritia flexuosa (Buriti) Fixed Oil against Methicillin-Resistant Staphylococcus Aureus (MRSA) and Other Multidrug-Resistant (MDR) Bacterial Strains. Pathogens 2018, 7, E98. [Google Scholar] [CrossRef] [Green Version]

- Koolen, H.H.F.; da Silva, F.M.A.; Gozzo, F.C.; de Souza, A.Q.L.; de Souza, A.D.L. Antioxidant, Antimicrobial Activities and Characterization of Phenolic Compounds from Buriti (Mauritia flexuosa L.f.) by UPLC–ESI-MS/MS. Food Res. Int. 2013, 51, 467–473. [Google Scholar] [CrossRef] [Green Version]

- Resende, L.M.; Franca, A.S.; Oliveira, L.S. Buriti (Mauritia flexuosa L.f.) Fruit by-Products Flours: Evaluation as Source of Dietary Fibers and Natural Antioxidants. Food Chem. 2019, 270, 53–60. [Google Scholar] [CrossRef]

- Pereira, G.S.; Freitas, P.M.; Basso, S.L.; de Moreira Araújo, P.; Rodrigues dos Santos, R.; Conde, C.F.; Pereira, E.F.D.; Haverroth, M.; Amaral, A.M.F. Quality Control of the Buriti oil (Mauritia flexuosa L.f.) for Use in 3-Phase Oil Formulation for Skin Hydration. Int. J. Phytocosmet. Nat. Ingred. 2018, 5, 1. [Google Scholar] [CrossRef] [Green Version]

- Nobre, C.B.; de Sousa, E.O.; de Lima Silva, J.M.F.; Melo Coutinho, H.D.; da Costa, J.G.M. Chemical Composition and Antibacterial Activity of Fixed Oils of Mauritia flexuosa and Orbignya speciosa Associated with Aminoglycosides. Eur. J. Integr. Med. 2018, 23, 84–89. [Google Scholar] [CrossRef]

- Nutraceuticals Market Size, Share & Trends Analysis Report by Product (Dietary Supplements, Functional Food, Functional Beverages), by Region (North America, Europe, APAC, CSA, MEA), and Segment Forecasts, 2021–2030. Available online: https://www.grandviewresearch.com/industry-analysis/nutraceuticals-market (accessed on 15 January 2022).

- Santori, G.; Di Nicola, G.; Moglie, M.; Polonara, F. A Review Analyzing the Industrial Biodiesel Production Practice Starting from Vegetable Oil Refining. Appl. Energy 2012, 92, 109–132. [Google Scholar] [CrossRef] [Green Version]

- More, P.R.; Arya, S.S. Intensification of Bio-Actives Extraction from Pomegranate Peel Using Pulsed Ultrasound: Effect of Factors, Correlation, Optimization and Antioxidant Bioactivities. Ultrason. Sonochem. 2020, 72, 105423. [Google Scholar] [CrossRef]

- Zabot, G.L.; Moraes, M.N.; Carvalho, P.I.N.; Meireles, M.A.A. New Proposal for Extracting Rosemary Compounds: Process Intensification and Economic Evaluation. Ind. Crops Prod. 2015, 77, 758–771. [Google Scholar] [CrossRef]

- Martínez, J.; de Aguiar, A.C.; da Machado, A.P.F.; Barrales, F.M.; Viganó, J.; dos Santos, P. 2.51—Process Integration and Intensification. In Comprehensive Foodomics; Cifuentes, A., Ed.; Elsevier: Oxford, UK, 2021; pp. 786–807. ISBN 978-0-12-816396-2. [Google Scholar]

- Best, I.; Olivera-Montenegro, L.; Cartagena-Gonzales, Z.; Arana-Copa, O.; Zabot, G. Techno-Economic evaluation of the production of oil and phenolic-rich extracts from Mauritia flexuosa L.f. using sequential supercritical and conventional solvent extraction. In Proceedings of the 2nd International Electronic Conference on Foods—“Future Foods and Food Technologies for a Sustainable World”, online, 15–30 October 2021; MDPI: Basel, Switzerland, 2021. [Google Scholar]

- Veggi, P.C.; Cavalcanti, R.N.; Meireles, M.A.A. Production of Phenolic-Rich Extracts from Brazilian Plants Using Supercritical and Subcritical Fluid Extraction: Experimental Data and Economic Evaluation. J. Food Eng. 2014, 131, 96–109. [Google Scholar] [CrossRef] [Green Version]

- Farías-Campomanes, A.M.; Rostagno, M.A.; Meireles, M.A.A. Production of Polyphenol Extracts from Grape Bagasse Using Supercritical Fluids: Yield, Extract Composition and Economic Evaluation. J. Supercrit. Fluids 2013, 77, 70–78. [Google Scholar] [CrossRef]

- Ochoa, S.; Durango-Zuleta, M.M.; Felipe Osorio-Tobón, J. Techno-Economic Evaluation of the Extraction of Anthocyanins from Purple Yam (Dioscorea Alata) Using Ultrasound-Assisted Extraction and Conventional Extraction Processes. Food Bioprod. Process. 2020, 122, 111–123. [Google Scholar] [CrossRef]

- De Aguiar, A.C.; Osorio-Tobón, J.F.; Viganó, J.; Martínez, J. Economic Evaluation of Supercritical Fluid and Pressurized Liquid Extraction to Obtain Phytonutrients from Biquinho Pepper: Analysis of Single and Sequential-Stage Processes. J. Supercrit. Fluids 2020, 165, 104935. [Google Scholar] [CrossRef]

- Peters, M.; Timmerhaus, K.; West, R.; Peters, M. Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 2002; ISBN 978-0-07-239266-1. [Google Scholar]

- Smith, R. Chemical Process Design and Integration; Wiley: Chichester, UK; Hoboken, NJ, USA, 2005; ISBN 978-0-471-48680-0. [Google Scholar]

- Green, D.W.; Perry, R.H. Perry’s Chemical Engineers’ Handbook, 8th ed.; McGraw-Hill Education: Berkshire, UK, 2008; ISBN 978-0-07-142294-9. [Google Scholar]

- Turton, R. Analysis, Synthesis and Design of Chemical Processes; Pearson Education: Upper Saddle River, NJ, USA, 2012. [Google Scholar]

- Rocha-Uribe, J.A.; Novelo-Pérez, J.I.; Araceli Ruiz-Mercado, C. Cost Estimation for CO2 Supercritical Extraction Systems and Manufacturing Cost for Habanero Chili. J. Supercrit. Fluids 2014, 93, 38–41. [Google Scholar] [CrossRef]

- Lachos-Perez, D.; Buller, L.S.; Sganzerla, W.G.; Ody, L.P.; Zabot, G.L.; Forster-Carneiro, T. Sequential Hydrothermal Process for Production of Flavanones and Sugars from Orange Peel: An Economic Assessment. Biofuels Bioprod. Bioref. 2021, 15, 202–217. [Google Scholar] [CrossRef]

- Nobre, C.B.; Sousa, E.O.; Camilo, C.J.; Machado, J.F.; Silva, J.M.F.L.; Filho, J.R.; Coutinho, H.D.M.; Costa, J.G.M. Antioxidative Effect and Phytochemical Profile of Natural Products from the Fruits of “Babaçu” (Orbignia speciose) and “Buriti” (Mauritia flexuosa). Food Chem. Toxicol. 2018, 121, 423–429. [Google Scholar] [CrossRef] [PubMed]

- Chañi-Paucar, L.O.; Yali, E.T.; Maceda Santivañez, J.C.; Garcia, D.A.; Jonher, J.C.F.; Angela, A.; Meireles, M. Supercritical Fluid Extraction from Aguaje (Mauritia flexuosa) Pulp: Overall Yield, Kinetic, Fatty Acid Profile, and Qualitative Phytochemical Profile. Open Food Sci. J. 2021, 13, 1–11. [Google Scholar] [CrossRef]

- Barbosa, R.I.; Lima, A.D.; Mourão Junior, M. Biometria de frutos do buriti (Mauritia flexuosa L.F.—Arecaceae): Produção de polpa e óleo em uma área de savana em Roraima. Embrapa Amaz. Orient.-Artig. Periódico Indexado 2010, 5, 71–85. [Google Scholar]

- Pereira-Freire, J.A.; da Oliveira, G.L.S.; Lima, L.K.F.; Ramos, C.L.S.; Arcanjo-Medeiros, S.R.; de Lima, A.C.S.; Teixeira, S.A.; de Oliveira, G.A.L.; Nunes, N.M.F.; Amorim, V.R.; et al. In Vitro and Ex Vivo Chemopreventive Action of Mauritia flexuosa Products. Evid. Based Complement. Alternat. Med. 2018, 2018, e2051279. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Galviz-Quezada, A.; Ochoa-Aristizábal, A.M.; Arias Zabala, M.E.; Ochoa, S.; Osorio-Tobón, J.F. Valorization of Iraca (Carludovica palmata, Ruiz & Pav.) Infructescence by Ultrasound-Assisted Extraction: An Economic Evaluation. Food Bioprod. Process. 2019, 118, 91–102. [Google Scholar] [CrossRef]

- De Aguiar, A.C.; Osorio-Tobón, J.F.; Silva, L.P.S.; Barbero, G.F.; Martínez, J. Economic Analysis of Oleoresin Production from Malagueta Peppers (Capsicum frutescens) by Supercritical Fluid Extraction. J. Supercrit. Fluids 2018, 133, 86–93. [Google Scholar] [CrossRef]

- Rosa, P.T.V.; Meireles, M.A.A. Rapid Estimation of the Manufacturing Cost of Extracts Obtained by Supercritical Fluid Extraction. J. Food Eng. 2005, 67, 235–240. [Google Scholar] [CrossRef]

- Plant Extracts Market by Type (Phytomedicines & Herbal Extracts, Spices, Essential Oils, Flavors & fragrances), Application (Pharmaceutical & Dietary Supplements, Food & Beverages, Cosmetics), Sources, and Region—Forecast to 2026. Available online: https://www.marketsandmarkets.com/Market-Reports/plant-extracts-market-942.html (accessed on 15 January 2022).

- Osorio-Tobón, J.F.; Carvalho, P.I.N.; Rostagno, M.A.; Meireles, M.A.A. Process Integration for Turmeric Products Extraction Using Supercritical Fluids and Pressurized Liquids: Economic Evaluation. Food Bioprod. Process. 2016, 98, 227–235. [Google Scholar] [CrossRef]

- Vieira, G.S.; Cavalcanti, R.N.; Meireles, M.A.A.; Hubinger, M.D. Chemical and Economic Evaluation of Natural Antioxidant Extracts Obtained by Ultrasound-Assisted and Agitated Bed Extraction from Jussara Pulp (Euterpe edulis). J. Food Eng. 2013, 119, 196–204. [Google Scholar] [CrossRef] [Green Version]

- Náthia-Neves, G.; Vardanega, R.; Meireles, M.A.A. Extraction of Natural Blue Colorant from Genipa americana L. Using Green Technologies: Techno-Economic Evaluation. Food Bioprod. Process. 2019, 114, 132–143. [Google Scholar] [CrossRef]

- Vlysidis, A.; Binns, M.; Webb, C.; Theodoropoulos, C. A Techno-Economic Analysis of Biodiesel Biorefineries: Assessment of Integrated Designs for the Co-Production of Fuels and Chemicals. Energy 2011, 36, 4671–4683. [Google Scholar] [CrossRef]

- Chañi-Paucar, L.O.; Johner, J.C.F.; Zabot, G.L.; Meireles, M.A.A. Technical and Economic Evaluation of Supercritical CO2 Extraction of Oil from Sucupira Branca Seeds. J. Supercrit. Fluids 2022, 181, 105494. [Google Scholar] [CrossRef]

- Kurambhatti, C.; Kumar, D.; Rausch, K.D.; Tumbleson, M.E.; Singh, V. Improving Technical and Economic Feasibility of Water Based Anthocyanin Recovery from Purple Corn Using Staged Extraction Approach. Ind. Crops Prod. 2020, 158, 112976. [Google Scholar] [CrossRef]

- Johner, J.; Hatami, T.; Zabot, G.; Meireles, M.A. Kinetic Behavior and Economic Evaluation of Supercritical Fluid Extraction of Oil from Pequi (Caryocar brasiliense) for Various Grinding Times and Solvent Flow Rates. J. Supercrit. Fluids 2018, 140, 188–195. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Lyophilized pulp—1st step | |

| Lyophilized yield | 36.17 g/100 g whole fruit |

| Lyophilization temperature | −50 °C |

| Time | 3–4 h |

| Pressure | ≥50 Pa |

| Conventional solvent extraction (80% ethanol)—2nd step | |

| Extraction yield | 87.3 g ground and lyophilized pulp/100 g lyophilized pulp |

| Temperature | 30 °C |

| Time | 1 h |

| S/F | 10 m ethanol/1 g lyophilized pulp |

| Lyophilized extract—3rd step | |

| Lyophilized yield | 85.44 g lyophilized extract/100 g lyophilized pulp |

| Lyophilization temperature | −50 °C |

| Time | 3–4 h |

| Pressure | ≥50 Pa |

| Parameter | Value |

|---|---|

| Lyophilized pulp—1st step | |

| Lyophilized yield | 36.17 g/100 g whole fruit |

| Lyophilization temperature | −50 °C |

| Time | 3–4 h |

| Pressure | ≥50 Pa |

| Oil extract—2nd step | |

| Extraction yield | 38.85 g oil/100 g lyophilized pulp |

| Temperature | 80 °C |

| Extraction time | 1 h |

| Pressure | 2 × 107 Pa |

| CO2 flow rate | 42 g CO2/min |

| Lyophilized extract–3rd step | |

| Lyophilized yield | 47.418 g lyophilized extract/100 g lyophilized pulp |

| Lyophilization temperature | −50 °C |

| Extraction time | 3–4 h |

| Pressure | ≥50 Pa |

| Equipment | N a | Unit Base Cost (USD) | CSE Plant | SFE+CSE Plant | ||

|---|---|---|---|---|---|---|

| Number of Equipment | Total Base Cost (USD) | Number of Equipment | Total Base Cost (USD) | |||

| Sorting machine b | 0.89 | 3900.00 | 1 | 1,824,167.05 | 1 | 1,824,167.05 |

| Immersion washer (washed) b | 0.53 | 3937.74 | 2 | 306,391.73 | 2 | 306,391.73 |

| Immersion washer (rinsed) b | 0.53 | 3937.74 | 2 | 306,391.73 | 2 | 306,391.73 |

| Rinse tank b | 0.53 | 4000.00 | 4 | 622,472.23 | 4 | 622,472.23 |

| Water boiler (maturation) b | 0.59 | 2500.00 | 4 | 588,843.66 | 4 | 588,843.66 |

| Water boiler (bleached) b | 0.59 | 2500.00 | 4 | 588,843.66 | 4 | 588,843.66 |

| Automatic pulper b | 0.60 | 1895.73 | 5 | 598,062.38 | 5 | 598,062.38 |

| Automatic packaging machine b | 0.60 | 1650.00 | 1 | 104,107.96 | 1 | 104,107.96 |

| Freezing tunnel b | 0.63 | 2500.00 | 1 | 194,061.78 | 1 | 194,061.78 |

| Lyophilizer b | 0.65 | 20,000.00 | 1 | 1,782,501,88 | 1 | 1,782,501,88 |

| Roller mill b | 0.91 | 5700.00 | 1 | 3,061,081.24 | 1 | 3,061,081.24 |

| Industrial sieve b | 0.91 | 1700.00 | 1 | 912,954.05 | 1 | 912,954.05 |

| Extraction tank b | 0.82 | 2000.00 | 1 | 576,806.30 | ||

| 1500.00 | 1 | 432,604.73 | ||||

| Supercritical CO2 equipment c | 0.60 | 2,520,106.41 | - | - | 1 | 159,007,964.56 |

| Centrifuge b | 0.71 | 7000.00 | 7 | 5,665,644.11 | 4 | 3,237,510.92 |

| Plate filter b | 0.66 | 1500.00 | 1 | 143,248.89 | - | - |

| 700.00 | - | - | 1 | 66,849.48 | ||

| Evaporator b | 0.59 | 10,000.00 | 6 | 706,612.39 | 3 | 353,306.19 |

| Lyophilizer b | 0.65 | 15,000.00 | 1 | 1,336,876.41 | - | - |

| 10,000.00 | - | - | 1 | 891,250.94 | ||

| Conveyor belts b | 0.89 | 769.00 | 24 | 8,632,519.77 | 24 | 8,632,519.77 |

| Centrifugal pump b | 0.55 | 900.00 | 5 | 201,007.62 | 5 | 201,007.62 |

| Total | - | - | 28,152,594.81 | - | 183,712,893.54 | |

| Pameter | Value |

|---|---|

| Fixed Capital Investment (FCI) | |

| CSE plant a | USD 28,152,594.00 |

| SFE+CSE plant a | USD 183,712,894,00 |

| Depreciation rate b | 10%/year |

| Maintenance rate b | 6%/year |

| Project lifetime | 25 years |

| Inflation | 4%/year |

| Low NPV interest | 7% |

| Depreciation period | 25 years |

| Loan period for equipment | 12 years |

| Loan interest for equipment | 7%/year |

| Loan | 100% |

| Cost of operational labor (COL) | |

| Wage (with administration and benefits) c | USD 4.91/h |

| Number of workers per shift | 8 |

| Operational time | 7920 h/year |

| Cost of Raw Material (CRM) | |

| Mauritia flexuosa L.f. a | 15.63 USD/kg |

| Industrial CO2 a | 0.033 USD/kg |

| Ethanol 80% a | 0.53 USD/kg |

| Cost of utilities (COU) | |

| Electricity | 0.1183 USD/kW.h |

| Steam | 12 USD/ton |

| Water | 1.63 USD/ton |

| CSE | SFE+CSE | Reference | |

|---|---|---|---|

| Global extraction yield (%) | 13.84% (extract) | 44.85% (oil) 13.8% (extract) | - |

| Total phenolics (µg GAE/g extract) | 3423.94 ± 24.93 | 28800.95 ± 1180.37 * | Best et al. [3] |

| Total flavonoids (µg CE/g extract) | 165.34 ± 4.11 | 390.82 ± 21.11 * | Best et al. [3] |

| Scenario | Condition | COM (USD/kg) | GM (%) | ROI (%) | PBT (Year) | IRR (%) | NPV (USD) (at 7% Interest) |

|---|---|---|---|---|---|---|---|

| 1 | Normal | 126.47 | NA | NA | NA | NA | NA |

| 2 | Plant—half cost | 120.09 | NA | NA | NA | NA | NA |

| 3 | M. flexuosa—half cost | 73.06 | 26.94 | 33.46 | 2.99 | 42.42 | 123,274,000.00 |

| 4 | Ethanol—50% recycled | 123.44 | NA | NA | NA | NA | NA |

| 5 | Lyophilized extract—50% more expensive | 126.47 | 15.68 | 27.97 | 3.57 | 34.30 | 103,938,000.00 |

| 6 | Merging scenarios 2–5 | 63.63 | 57.58 | 161.53 | 0.62 | 324.14 | 417,069,000.00 |

| Scenario | Condition | COM (USD/kg) | GM (%) | ROI (%) | PBT (Year) | IRR (%) | NPV (USD) (at 7% Interest) |

|---|---|---|---|---|---|---|---|

| 1 | Normal | 193.38 | 19.73 | 15.54 | 6.43 | 16.48 | 193,979,000.00 |

| 2 | Plant—half cost | 152.30 | 36.78 | 35.38 | 2.83 | 45.55 | 416,182,000.00 |

| 3 | M. flexuosa—half cost | 140.75 | 41.57 | 24.29 | 4.12 | 28.83 | 457,940,000.00 |

| 4 | Ethanol—50% recycled | 190.01 | 21.13 | 16.10 | 6.21 | 17.27 | 210,877,000.00 |

| 5 | Lyophilized extract—50% more expensive | 193.38 | 46.94 | 35.13 | 2.85 | 45.08 | 800,105,000.00 |

| 6 | Merging scenarios 2–5 | 96.31 | 73.34 | 92.91 | 1.08 | 152.58 | 1,294,690,000.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Best, I.; Cartagena-Gonzales, Z.; Arana-Copa, O.; Olivera-Montenegro, L.; Zabot, G. Production of Oil and Phenolic-Rich Extracts from Mauritia flexuosa L.f. Using Sequential Supercritical and Conventional Solvent Extraction: Experimental and Economic Evaluation. Processes 2022, 10, 459. https://doi.org/10.3390/pr10030459

Best I, Cartagena-Gonzales Z, Arana-Copa O, Olivera-Montenegro L, Zabot G. Production of Oil and Phenolic-Rich Extracts from Mauritia flexuosa L.f. Using Sequential Supercritical and Conventional Solvent Extraction: Experimental and Economic Evaluation. Processes. 2022; 10(3):459. https://doi.org/10.3390/pr10030459

Chicago/Turabian StyleBest, Ivan, Zaina Cartagena-Gonzales, Oscar Arana-Copa, Luis Olivera-Montenegro, and Giovani Zabot. 2022. "Production of Oil and Phenolic-Rich Extracts from Mauritia flexuosa L.f. Using Sequential Supercritical and Conventional Solvent Extraction: Experimental and Economic Evaluation" Processes 10, no. 3: 459. https://doi.org/10.3390/pr10030459

APA StyleBest, I., Cartagena-Gonzales, Z., Arana-Copa, O., Olivera-Montenegro, L., & Zabot, G. (2022). Production of Oil and Phenolic-Rich Extracts from Mauritia flexuosa L.f. Using Sequential Supercritical and Conventional Solvent Extraction: Experimental and Economic Evaluation. Processes, 10(3), 459. https://doi.org/10.3390/pr10030459