Foaming with scCO2 and Impregnation with Cinnamaldehyde of PLA Nanocomposites for Food Packaging

Abstract

:1. Introduction

2. Materials and Chemicals

2.1. Materials and PLA Nanocomposite Preparation

2.2. Foaming with scCO2 and Impregnation with Ci of PLA Foams

2.3. Characterization of PLA Nanocomposite Foams

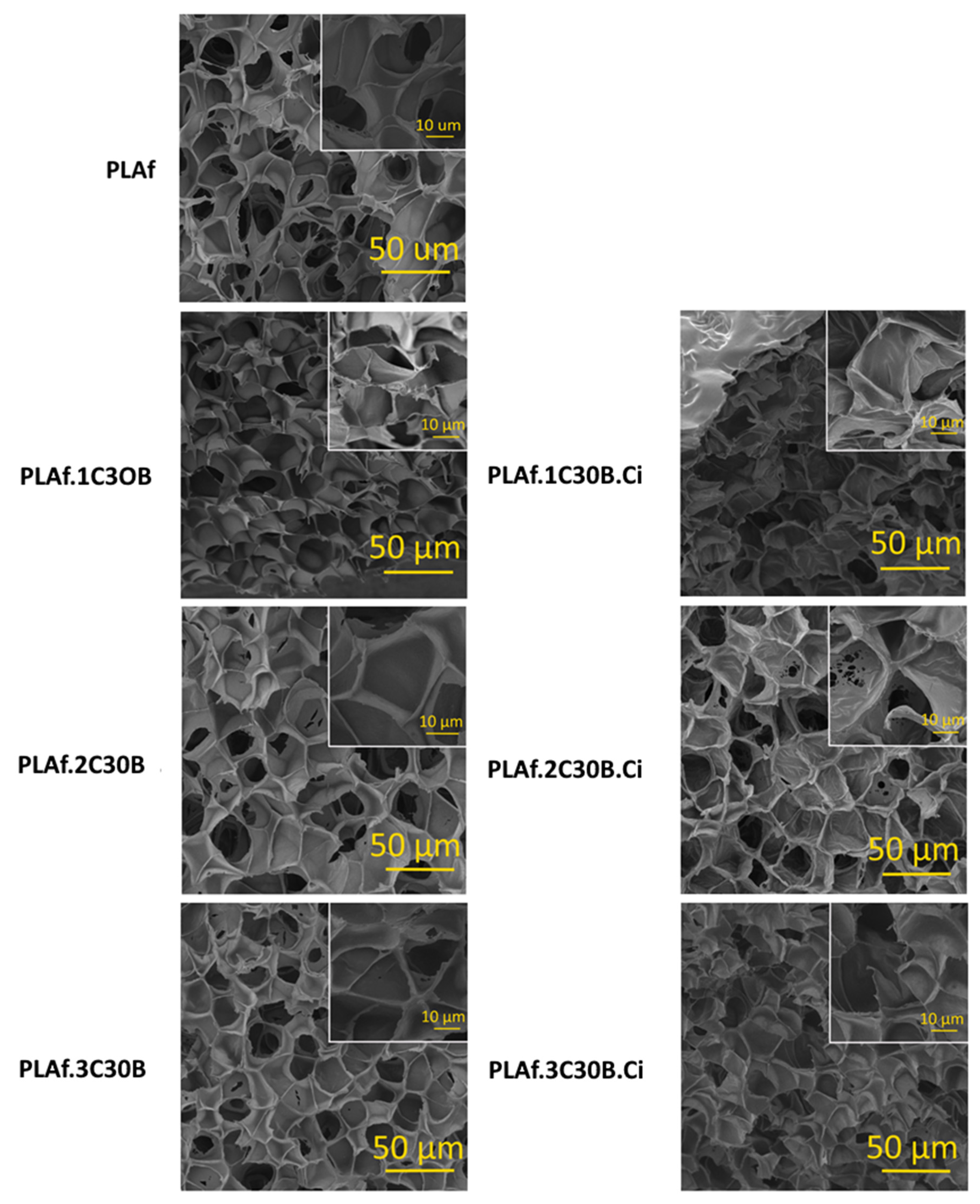

2.3.1. Morphological Analysis

2.3.2. Structural Analysis through Attenuated Total Reflectance Fourier Transform Infrared (ATR-FTIR) Spectroscopy

2.3.3. Thermal Properties

2.3.4. Study of the Release Kinetics

3. Results and Discussion

3.1. Relation between Nanoclay Content, Ci Incorporation, and PLA Nanocomposite Foam Morphology

3.2. Structural Properties of PLA Nanocomposite Foams

3.3. Thermal Characterization of the PLA Nanocomposite Foams

| Sample | Tcc (°C) | ΔHcc (J g−1) | Tm1 (°C) | Tm2 (°C) | ΔHm (J g1) | Xc (%) | Tonset (°C) | Td1 (°C) | Td2 (°C) |

|---|---|---|---|---|---|---|---|---|---|

| PLAf | - | - | 154 | - | 52.4 | 56 | 326 | - | 367 |

| PLAf.Ci | 115 | 8.4 | 143 | 148 | 20.7 | 15 | 167 | 173 | 366 |

| PLAf.1C30B | - | - | 154 | - | 44.4 | 48 | 330 | - | 366 |

| PLAf.2C30B | - | - | 151 | 161 | 35.2 | 39 | 323 | - | 365 |

| PLAf.3C30B | - | - | 150 | 162 | 39.4 | 44 | 328 | - | 365 |

| PLAf.1C30B.Ci | 117 | 6.3 | 142 | 150 | 27.7 | 27 | 148 | 153 | 366 |

| PLAf.2C30B.Ci | - | - | 143 | 153 | 17.1 | 21 | 154 | 187 | 366 |

| PLAf.3C30B.Ci | - | - | 143 | 149 | 23.8 | 30 | 165 | 172 | 366 |

3.4. Study of the Cinnamaldehyde Release Kinetics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sharma, S.; Barkauskaite, S.; Jaiswal, A.K.; Jaiswal, S. Essential Oils as Additives in Active Food Packaging. Food Chem. 2021, 343, 128403. [Google Scholar] [CrossRef] [PubMed]

- Perumal, A.B.; Huang, L.; Nambiar, R.B.; He, Y.; Li, X.; Sellamuthu, P.S. Application of Essential Oils in Packaging Films for the Preservation of Fruits and Vegetables: A Review. Food Chem. 2022, 375, 131810. [Google Scholar] [CrossRef] [PubMed]

- Hosseini, S.F.; Ghaderi, J.; Gómez-Guillén, M.C. Tailoring Physico-Mechanical and Antimicrobial/Antioxidant Properties of Biopolymeric Films by Cinnamaldehyde-Loaded Chitosan Nanoparticles and Their Application in Packaging of Fresh Rainbow Trout Fillets. Food Hydrocoll. 2022, 124, 107249. [Google Scholar] [CrossRef]

- Thongsrikhem, N.; Taokaew, S.; Sriariyanun, M.; Kirdponpattara, S. Antibacterial Activity in Gelatin-Bacterial Cellulose Composite Film by Thermally Crosslinking with Cinnamaldehyde towards Food Packaging Application. Food Packag. Shelf Life 2022, 31, 100766. [Google Scholar] [CrossRef]

- Okolieocha, C.; Raps, D.; Subramaniam, K.; Altstädt, V. Microcellular to Nanocellular Polymer Foams: Progress (2004–2015) and Future Directions—A Review. Eur. Polym. J. 2015, 73, 500–519. [Google Scholar] [CrossRef]

- Hoc, D.; Haznar-Garbacz, D. Foams as Unique Drug Delivery Systems. Eur. J. Pharm. Biopharm. 2021, 167, 73–82. [Google Scholar] [CrossRef]

- Lee, L.Y.; Ranganath, S.H.; Fu, Y.; Zheng, J.L.; Lee, H.S.; Wang, C.H.; Smith, K.A. Paclitaxel Release from Micro-Porous PLGA Disks. Chem. Eng. Sci. 2009, 64, 4341–4349. [Google Scholar] [CrossRef]

- Löbmann, K.; Svagan, A.J. Cellulose Nanofibers as Excipient for the Delivery of Poorly Soluble Drugs. Int. J. Pharm. 2017, 533, 285–297. [Google Scholar] [CrossRef] [PubMed]

- Mensitieri, G. Foams and Their Applications. Supercrit. Fluid Sci. Technol. 2021, 9, 1–20. [Google Scholar] [CrossRef]

- Clifford, A.A.; Williams, J.R. Introduction to Supercritical Fluids and Their Applications. In Supercritical Fluid Methods and Protocols; Humana Press: Totowa, NJ, USA, 2000; pp. 1–16. [Google Scholar]

- Kumar, R.; Thakur, A.K.; Banerjee, N.; Chaudhari, P. A Critical Review on the Particle Generation and Other Applications of Rapid Expansion of Supercritical Solution. Int. J. Pharm. 2021, 608, 121089. [Google Scholar] [CrossRef]

- Carvalho, V.S.; Dias, A.L.B.; Rodrigues, K.P.; Hatami, T.; Mei, L.H.I.; Martínez, J.; Viganó, J. Supercritical Fluid Adsorption of Natural Extracts: Technical, Practical, and Theoretical Aspects. J. CO2 Util. 2022, 56, 101865. [Google Scholar] [CrossRef]

- Ahangari, H.; King, J.W.; Ehsani, A.; Yousefi, M. Supercritical Fluid Extraction of Seed Oils—A Short Review of Current Trends. Trends Food Sci. Technol. 2021, 111, 249–260. [Google Scholar] [CrossRef]

- Champeau, M.; Thomassin, J.M.; Tassaing, T.; Jérôme, C. Drug Loading of Polymer Implants by Supercritical CO2 Assisted Impregnation: A Review. J. Control. Release 2015, 209, 248–259. [Google Scholar] [CrossRef] [PubMed]

- Rojas, A.; Torres, A.; Galotto, M.J.; Guarda, A.; Julio, R. Supercritical Impregnation for Food Applications: A Review of the Effect of the Operational Variables on the Active Compound Loading. Crit. Rev. Food Sci. Nutr. 2020, 60, 1290–1301. [Google Scholar] [CrossRef] [PubMed]

- Sarver, J.A.; Kiran, E. Foaming of Polymers with Carbon Dioxide—The Year-in-Review—2019. J. Supercrit. Fluids 2021, 173, 105166. [Google Scholar] [CrossRef]

- Di Maio, E.; Kiran, E. Foaming of Polymers with Supercritical Fluids and Perspectives on the Current Knowledge Gaps and Challenges. J. Supercrit. Fluids 2018, 134, 157–166. [Google Scholar] [CrossRef]

- Nofar, M.; Park, C.B. Poly (Lactic Acid) Foaming. Prog. Polym. Sci. 2014, 39, 1721–1741. [Google Scholar] [CrossRef]

- Han, Z.Z.; Zhang, Y.C.; Yang, W.M.; Xie, P.C. Advances in Microcellular Foam Processing of PLA. Key Eng. Mater. 2016, 717, 68–72. [Google Scholar] [CrossRef]

- Tsimpliaraki, A.; Tsivintzelis, I.; Marras, S.I.; Zuburtikudis, I.; Panayiotou, C. The Effect of Surface Chemistry and Nanoclay Loading on the Microcellular Structure of Porous Poly(d,l Lactic Acid) Nanocomposites. J. Supercrit. Fluids 2011, 57, 278–287. [Google Scholar] [CrossRef]

- Villegas, C.; Arrieta, M.P.; Rojas, A.; Torres, A.; Faba, S.; Toledo, M.J.; Gutierrez, M.A.; Zavalla, E.; Romero, J.; Galotto, M.J.; et al. PLA/Organoclay Bionanocomposites Impregnated with Thymol and Cinnamaldehyde by Supercritical Impregnation for Active and Sustainable Food Packaging. Compos. Part B Eng. 2019, 176, 107336. [Google Scholar] [CrossRef]

- Lopresti, F.; Botta, L.; Scaffaro, R.; Bilello, V.; Settanni, L.; Gaglio, R. Antibacterial Biopolymeric Foams: Structure–Property Relationship and Carvacrol Release Kinetics. Eur. Polym. J. 2019, 121, 109298. [Google Scholar] [CrossRef]

- Gaglio, R.; Botta, L.; Garofalo, G.; Miceli, A.; Settanni, L.; Lopresti, F. Carvacrol Activated Biopolymeric Foam: An Effective Packaging System to Control the Development of Spoilage and Pathogenic Bacteria on Sliced Pumpkin and Melon. Food Packag. Shelf Life 2021, 28, 100633. [Google Scholar] [CrossRef]

- Villegas, C.; Torres, A.; Rios, M.; Rojas, A.; Romero, J.; de Dicastillo, C.L.; Valenzuela, X.; Galotto, M.J.; Guarda, A. Supercritical Impregnation of Cinnamaldehyde into Polylactic Acid as a Route to Develop Antibacterial Food Packaging Materials. Food Res. Int. 2017, 99, 650–659. [Google Scholar] [CrossRef] [PubMed]

- Milovanovic, S.; Markovic, D.; Mrakovic, A.; Kuska, R.; Zizovic, I.; Frerich, S.; Ivanovic, J. Supercritical CO2—Assisted Production of PLA and PLGA Foams for Controlled Thymol Release. Mater. Sci. Eng. C 2019, 99, 394–404. [Google Scholar] [CrossRef]

- Xu, L.-Q.; Huang, H.-X. Foaming of Poly(Lactic Acid) Using Supercritical Carbon Dioxide as Foaming Agent: Influence of Crystallinity and Spherulite Size on Cell Structure and Expansion Ratio. Ind. Eng. Chem. Res. 2014, 53, 2277–2286. [Google Scholar] [CrossRef]

- Ambrosio-Martín, J.; Fabra, M.J.; Lopez-Rubio, A.; Lagaron, J.M. Melt Polycondensation to Improve the Dispersion of Bacterial Cellulose into Polylactide via Melt Compounding: Enhanced Barrier and Mechanical Properties. Cellulose 2015, 22, 1201–1226. [Google Scholar] [CrossRef]

- Galotto, M.J.; Torres, A.; Guarda, A.; Moraga, N.; Romero, J. Experimental and Theoretical Study of LDPE versus Different Concentrations of Irganox 1076 and Different Thickness. Food Res. Int. 2011, 44, 566–574. [Google Scholar] [CrossRef]

- Mathematical Models of Drug Release. In Strategies to Modify the Drug Release from Pharmaceutical Systems; Elsevier: Amsterdam, The Netherlands, 2015; pp. 63–86. [CrossRef]

- Milovanovic, S.; Djuris, J.; Dapčević, A.; Medarevic, D.; Ibric, S.; Zizovic, I. Soluplus®, Eudragit®, HPMC-AS Foams and Solid Dispersions for Enhancement of Carvedilol Dissolution Rate Prepared by a Supercritical CO2 Process. Polym. Test. 2019, 76, 54–64. [Google Scholar] [CrossRef]

- Santos-Rosales, V.; Ardao, I.; Goimil, L.; Gomez-Amoza, J.L.; García-González, C.A. Solvent-Free Processing of Drug-Loaded Poly(ε-Caprolactone) Scaffolds with Tunable Macroporosity by Combination of Supercritical Foaming and Thermal Porogen Leaching. Polymers 2021, 13, 159. [Google Scholar] [CrossRef]

- Litauszki, K.; Kmetty, Á. Characterization of Chemically Foamed Poly(Lactic Acid). IOP Conf. Ser. Mater. Sci. Eng. 2020, 903, 012018. [Google Scholar] [CrossRef]

- Morlin, B.; Litauszki, K.; Petrény, R.; Kmetty, Á.; Mészáros, L. Characterization of Polylactic Acid-Based Nanocomposite Foams with Supercritical CO2. Measurement 2021, 178, 109385. [Google Scholar] [CrossRef]

- Guanghong, H.; Yue, W. Microcellular Foam Injection Molding Process. In Some Critical Issues for Injection Molding; Wang, J., Ed.; InTech: London, UK, 2012; ISBN 978-953-51-0297-7. [Google Scholar]

- Aionicesei, E.; Škerget, M.; Knez, Ž. Measurement of CO2 Solubility and Diffusivity in Poly(l-Lactide) and Poly(d,l-Lactide-Co-Glycolide) by Magnetic Suspension Balance. J. Supercrit. Fluids 2008, 47, 296–301. [Google Scholar] [CrossRef]

- Tomasko, D.L.; Li, H.; Liu, D.; Han, X.; Wingert, M.J.; Lee, L.J.; Koelling, K.W. A Review of CO2 Applications in the Processing of Polymers. Ind. Eng. Chem. Res. 2003, 42, 6431–6456. [Google Scholar] [CrossRef]

- Ivanovic, J.; Knauer, S.; Fanovich, A.; Milovanovic, S.; Stamenic, M.; Jaeger, P.; Zizovic, I.; Eggers, R. Supercritical CO2 Sorption Kinetics and Thymol Impregnation of PCL and PCL-HA. J. Supercrit. Fluids 2016, 107, 486–498. [Google Scholar] [CrossRef]

- Keshtkar, M.; Nofar, M.; Park, C.B.; Carreau, P.J. Extruded PLA/Clay Nanocomposite Foams Blown with Supercritical CO2. Polymer 2014, 55, 4077–4090. [Google Scholar] [CrossRef]

- Colton, J.S.; Suh, N.P. The Nucleation of Microcellular Thermoplastic Foam with Additives: Part I: Theoretical Considerations. Polym. Eng. Sci. 1987, 27, 485–492. [Google Scholar] [CrossRef]

- Torres, A.; Ilabaca, E.; Rojas, A.; Rodríguez, F.; Galotto, M.J.; Guarda, A.; Villegas, C.; Romero, J. Effect of Processing Conditions on the Physical, Chemical and Transport Properties of Polylactic Acid Films Containing Thymol Incorporated by Supercritical Impregnation. Eur. Polym. J. 2017, 89, 195–210. [Google Scholar] [CrossRef]

- López de Dicastillo, C.; Bruna, J.; Torres, A.; Alvarado, N.; Guarda, A.; Galotto, M.J. A Traditional Aboriginal Condiment as an Antioxidant Agent in the Development of Biodegradable Active Packaging. J. Appl. Polym. Sci. 2017, 134, 44692. [Google Scholar] [CrossRef]

- López de Dicastillo, C.; Villegas, C.; Garrido, L.; Roa, K.; Torres, A.; Galotto, M.; Rojas, A.; Romero, J. Modifying an Active Compound’s Release Kinetic Using a Supercritical Impregnation Process to Incorporate an Active Agent into PLA Electrospun Mats. Polymers 2018, 10, 479. [Google Scholar] [CrossRef] [Green Version]

- De Souza, A.C.; Dias, A.M.A.; Sousa, H.C.; Tadini, C.C. Impregnation of Cinnamaldehyde into Cassava Starch Biocomposite Films Using Supercritical Fluid Technology for the Development of Food Active Packaging. Carbohydr. Polym. 2014, 102, 830–837. [Google Scholar] [CrossRef] [Green Version]

- Bocz, K.; Tábi, T.; Vadas, D.; Sauceau, M.; Fages, J.; Marosi, G. Characterisation of Natural Fibre Reinforced PLA Foams Prepared by Supercritical CO2 Assisted Extrusion. Express Polym. Lett. 2016, 10, 771–779. [Google Scholar] [CrossRef] [Green Version]

- Cerro, D.; Bustos, G.; Villegas, C.; Buendia, N.; Truffa, G.; Godoy, M.P.; Rodríguez, F.; Rojas, A.; Galotto, M.J.; Constandil, L.; et al. Effect of Supercritical Incorporation of Cinnamaldehyde on Physical-Chemical Properties, Disintegration and Toxicity Studies of PLA/Lignin Nanocomposites. Int. J. Biol. Macromol. 2021, 167, 255–266. [Google Scholar] [CrossRef] [PubMed]

- Akgün, M.; Başaran, İ.; Suner, S.C.; Oral, A. Geraniol and Cinnamaldehyde as Natural Antibacterial Additives for Poly(Lactic Acid) and Their Plasticizing Effects. J. Polym. Eng. 2020, 40, 38–48. [Google Scholar] [CrossRef]

- Di, Y.; Iannace, S.; di Maio, E.; Nicolais, L. Poly(Lactic Acid)/Organoclay Nanocomposites: Thermal, Rheological Properties and Foam Processing. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 689–698. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Kelnar, I.; Luyt, A.S. Effect of Layered Silicates on the Thermal Stability of PCL/PLA Microfibrillar Composites. Polym. Test. 2016, 50, 9–14. [Google Scholar] [CrossRef]

- Huang, A.; Yu, P.; Jing, X.; Mi, H.-Y.; Geng, L.-H.; Chen, B.-Y.; Peng, X.-F. The Effect of Talc on the Mechanical, Crystallization and Foaming Properties of Poly(Lactic Acid). J. Macromol. Sci. Part B 2016, 55, 908–924. [Google Scholar] [CrossRef]

- Jeong, E.J.; Park, C.K.; Kim, S.H. Fabrication of Microcellular Polylactide/Modified Silica Nanocomposite Foams. J. Appl. Polym. Sci. 2020, 137, 48616. [Google Scholar] [CrossRef]

- Borkotoky, S.S.; Dhar, P.; Katiyar, V. Biodegradable Poly (Lactic Acid)/Cellulose Nanocrystals (CNCs) Composite Microcellular Foam: Effect of Nanofillers on Foam Cellular Morphology, Thermal and Wettability Behavior. Int. J. Biol. Macromol. 2018, 106, 433–446. [Google Scholar] [CrossRef]

- Muhoza, B.; Xia, S.; Cai, J.; Zhang, X.; Duhoranimana, E.; Su, J. Gelatin and Pectin Complex Coacervates as Carriers for Cinnamaldehyde: Effect of Pectin Esterification Degree on Coacervate Formation, and Enhanced Thermal Stability. Food Hydrocoll. 2019, 87, 712–722. [Google Scholar] [CrossRef]

- Canales, D.; Montoille, L.; Rivas, L.M.; Ortiz, J.A.; Yañez-S, M.; Rabagliati, F.M.; Ulloa, M.T.; Alvarez, E.; Zapata, P.A. Fungicides Films of Low-Density Polyethylene (LDPE)/Inclusion Complexes (Carvacrol and Cinnamaldehyde) Against Botrytis Cinerea. Coatings 2019, 9, 795. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Cui, H.; Muhoza, B.; Duhoranimana, E.; Xia, S.; Hayat, K.; Hussain, S.; Tahir, M.U.; Zhang, X. Fabrication of Low Environment-Sensitive Nanoparticles for Cinnamaldehyde Encapsulation by Heat-Induced Gelation Method. Food Hydrocoll. 2020, 105, 105789. [Google Scholar] [CrossRef]

- Velásquez, E.; Espinoza, S.; Valenzuela, X.; Garrido, L.; Galotto, M.J.; Guarda, A.; López de Dicastillo, C. Effect of Organic Modifier Types on the Physical–Mechanical Properties and Overall Migration of Post-Consumer Polypropylene/Clay Nanocomposites for Food Packaging. Polymers 2021, 13, 1502. [Google Scholar] [CrossRef]

- Trongchuen, K.; Ounkaew, A.; Kasemsiri, P.; Hiziroglu, S.; Mongkolthanaruk, W.; Wannasutta, R.; Pongsa, U.; Chindaprasirt, P. Bioactive Starch Foam Composite Enriched with Natural Antioxidants from Spent Coffee Ground and Essential Oil. Starch Stärke 2018, 70, 1700238. [Google Scholar] [CrossRef]

- Olejnik, A.; Kapuscinska, A.; Schroeder, G.; Nowak, I. Physico-Chemical Characterization of Formulations Containing Endomorphin-2 Derivatives. Amino Acids 2017, 49, 1719–1731. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moodley, T.; Singh, M. Polymeric Mesoporous Silica Nanoparticles for Combination Drug Delivery In Vitro. Biointerface Res. Appl. Chem. 2020, 11, 11905–11919. [Google Scholar] [CrossRef]

- Michailidou, G.; Christodoulou, E.; Nanaki, S.; Barmpalexis, P.; Karavas, E.; Vergkizi-Nikolakaki, S.; Bikiaris, D.N. Super-Hydrophilic and High Strength Polymeric Foam Dressings of Modified Chitosan Blends for Topical Wound Delivery of Chloramphenicol. Carbohydr. Polym. 2019, 208, 1–13. [Google Scholar] [CrossRef]

- Villegas, C.; Torres, A.; Bruna, J.; Bustos, M.I.; Díaz-Barrera, A.; Romero, J.; Rojas, A.; Guarda, A. Obtaining Active Polylactide (PLA) and Polyhydroxybutyrate (PHB) Blends Based Bionanocomposites Modified with Graphene Oxide and Supercritical Carbon Dioxide (ScCO2)-Assisted Cinnamaldehyde: Effect on Thermal-Mechanical, Disintegration and Mass Transport Properties. Polymers 2021, 13, 3968. [Google Scholar] [CrossRef]

- Tezcaner, A.; Keskin, D. Bioactive Agent Delivery in Bone Tissue Regeneration. In Active Implants and Scaffolds for Tissue Regeneration; Springer: Berlin/Heidelberg, Germany, 2010; pp. 193–223. [Google Scholar]

- Goimil, L.; Braga, M.E.M.; Dias, A.M.A.; Gómez-Amoza, J.L.; Concheiro, A.; Alvarez-Lorenzo, C.; de Sousa, H.C.; García-González, C.A. Supercritical Processing of Starch Aerogels and Aerogel-Loaded Poly(ε-Caprolactone) Scaffolds for Sustained Release of Ketoprofen for Bone Regeneration. J. CO2 Util. 2017, 18, 237–249. [Google Scholar] [CrossRef]

| Sample | C30B Content (wt.%) | dmin (µm) | dmax (µm) | daver (µm) | ρc (1012 Pores cm−3) |

|---|---|---|---|---|---|

| PLAf | 0 | 13.9 | 30.9 | 23.4 ± 4.0 | 74.0 |

| PLAf.1C30B | 1 | 14.1 | 32.4 | 22.7 ± 6.9 | 140.7 |

| PLAf.1C30B.Ci | 1 | 14.1 | 34.8 | 21.9 ± 7.3 | 169.6 |

| PLAf.2C30B | 2 | 18.3 | 30.2 | 22.1 ± 5.6 | 141.8 |

| PLAf.2C30B.Ci | 2 | 17.5 | 28.1 | 21.0 ± 6.7 | 171.3 |

| PLAf.3C30B | 3 | 16.9 | 27.2 | 21.9 ± 3.9 | 143.9 |

| PLAf.3C30B.Ci | 3 | 15.6 | 26.1 | 20.1 ± 4.1 | 173.4 |

| Kinetic Release Models | Higuchi | Korsmeyer–Peppas | |||||

|---|---|---|---|---|---|---|---|

| Sample | KP/FS | R2 | n | k | R2 | n | k |

| PLAf.Ci | 57 ± 3 | 0.985 | 0.5 | 0.33 | 0.989 | 0.20 | 0.43 |

| PLAf.1C30B.Ci | 46 ± 3 | 0.893 | 0.5 | 0.39 | 0.919 | 0.27 | 0.49 |

| PLAf.2C30B.Ci | 51 ± 3 | 0.895 | 0.5 | 0.30 | 0.920 | 0.24 | 0.38 |

| PLAf.3C30B.Ci | 57 ± 1 | 0.946 | 0.5 | 0.35 | 0.974 | 0.23 | 0.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojas, A.; Torres, A.; López de Dicastillo, C.; Velásquez, E.; Villegas, C.; Faba, S.; Rivera, P.; Guarda, A.; Romero, J.; Galotto, M.J. Foaming with scCO2 and Impregnation with Cinnamaldehyde of PLA Nanocomposites for Food Packaging. Processes 2022, 10, 376. https://doi.org/10.3390/pr10020376

Rojas A, Torres A, López de Dicastillo C, Velásquez E, Villegas C, Faba S, Rivera P, Guarda A, Romero J, Galotto MJ. Foaming with scCO2 and Impregnation with Cinnamaldehyde of PLA Nanocomposites for Food Packaging. Processes. 2022; 10(2):376. https://doi.org/10.3390/pr10020376

Chicago/Turabian StyleRojas, Adrián, Alejandra Torres, Carol López de Dicastillo, Eliezer Velásquez, Carolina Villegas, Simón Faba, Patricia Rivera, Abel Guarda, Julio Romero, and María José Galotto. 2022. "Foaming with scCO2 and Impregnation with Cinnamaldehyde of PLA Nanocomposites for Food Packaging" Processes 10, no. 2: 376. https://doi.org/10.3390/pr10020376

APA StyleRojas, A., Torres, A., López de Dicastillo, C., Velásquez, E., Villegas, C., Faba, S., Rivera, P., Guarda, A., Romero, J., & Galotto, M. J. (2022). Foaming with scCO2 and Impregnation with Cinnamaldehyde of PLA Nanocomposites for Food Packaging. Processes, 10(2), 376. https://doi.org/10.3390/pr10020376