Study on Mechanical Properties of Cement-Improved Frozen Soil under Uniaxial Compression Based on Discrete Element Method

Abstract

:1. Introduction

2. Experimental Analysis on Uniaxial Compressive Strength of Cement-Modified Frozen Soil

2.1. The Preparation of Test Samples and the Experiment

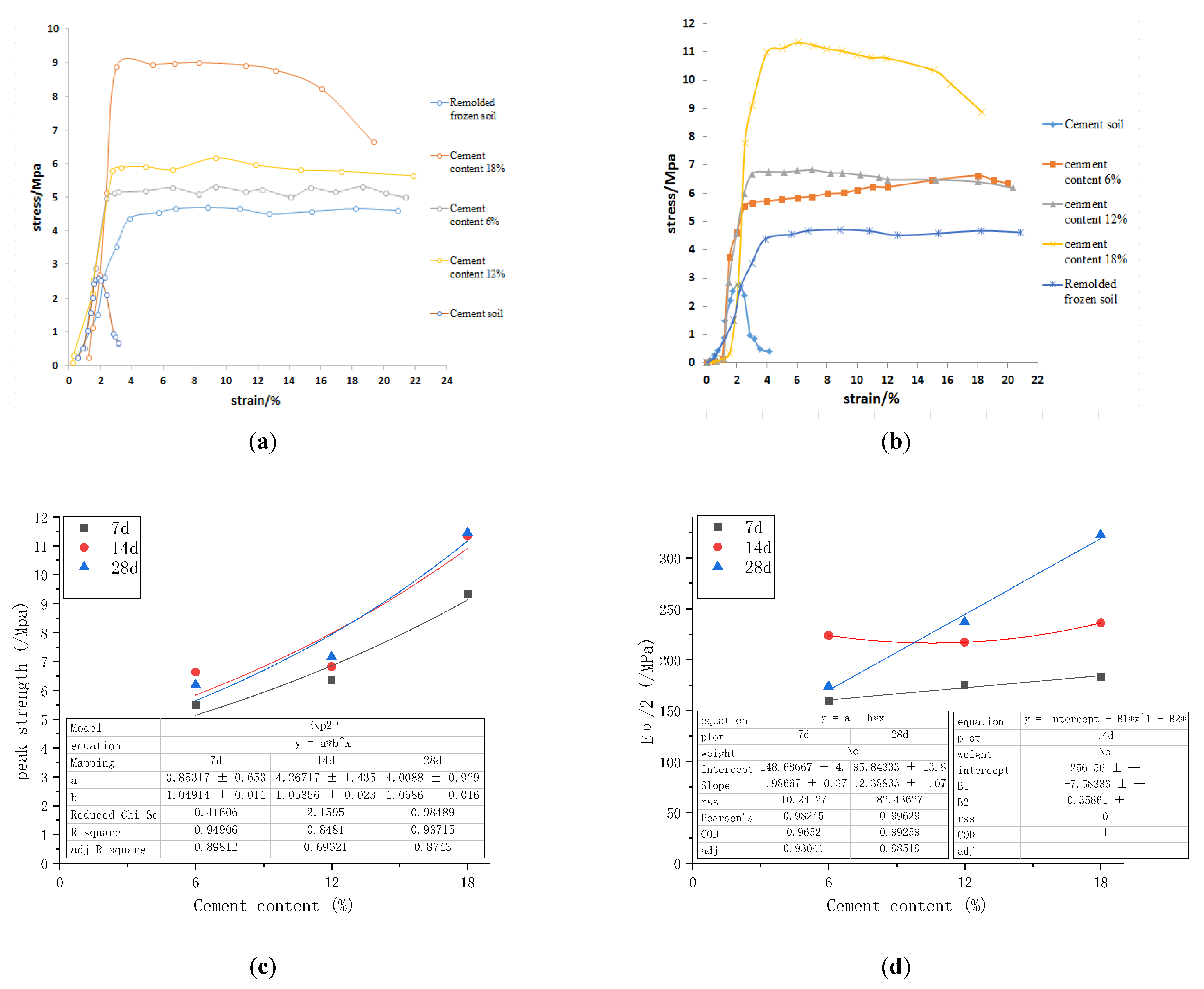

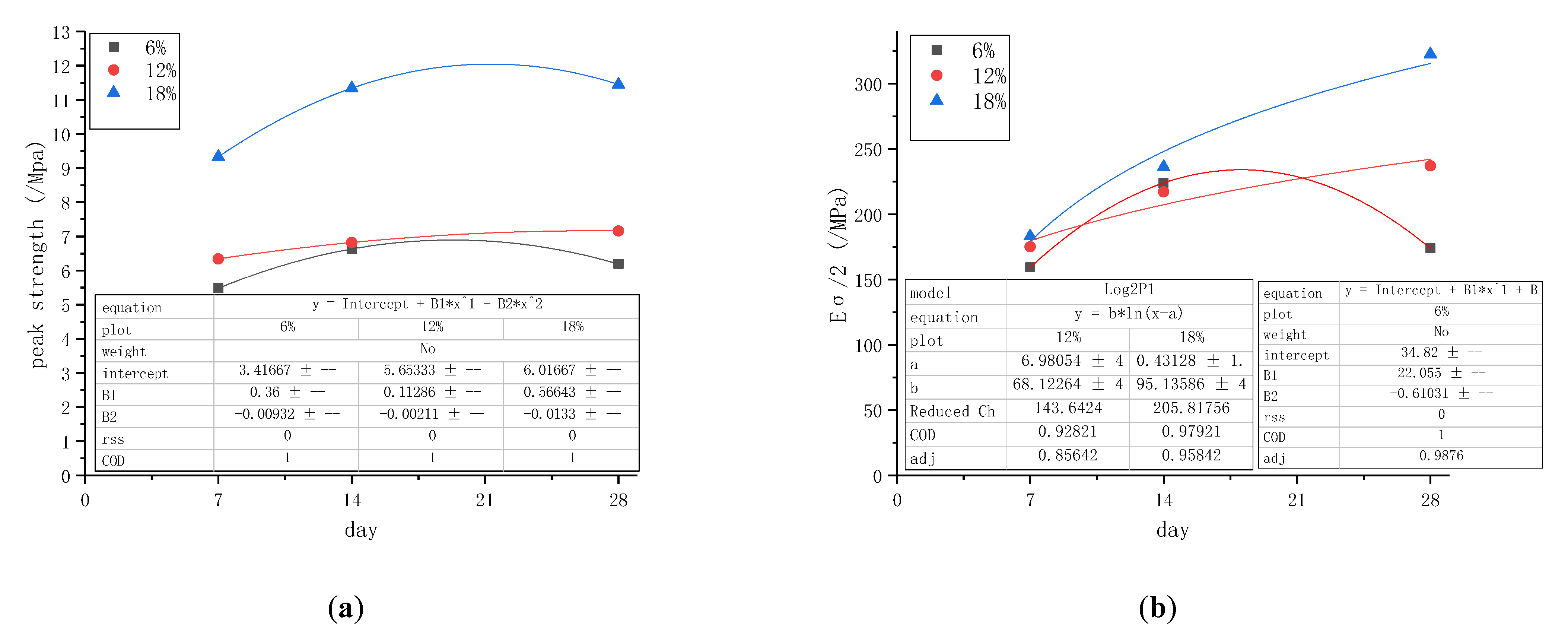

2.2. Experimental Results and Analyses

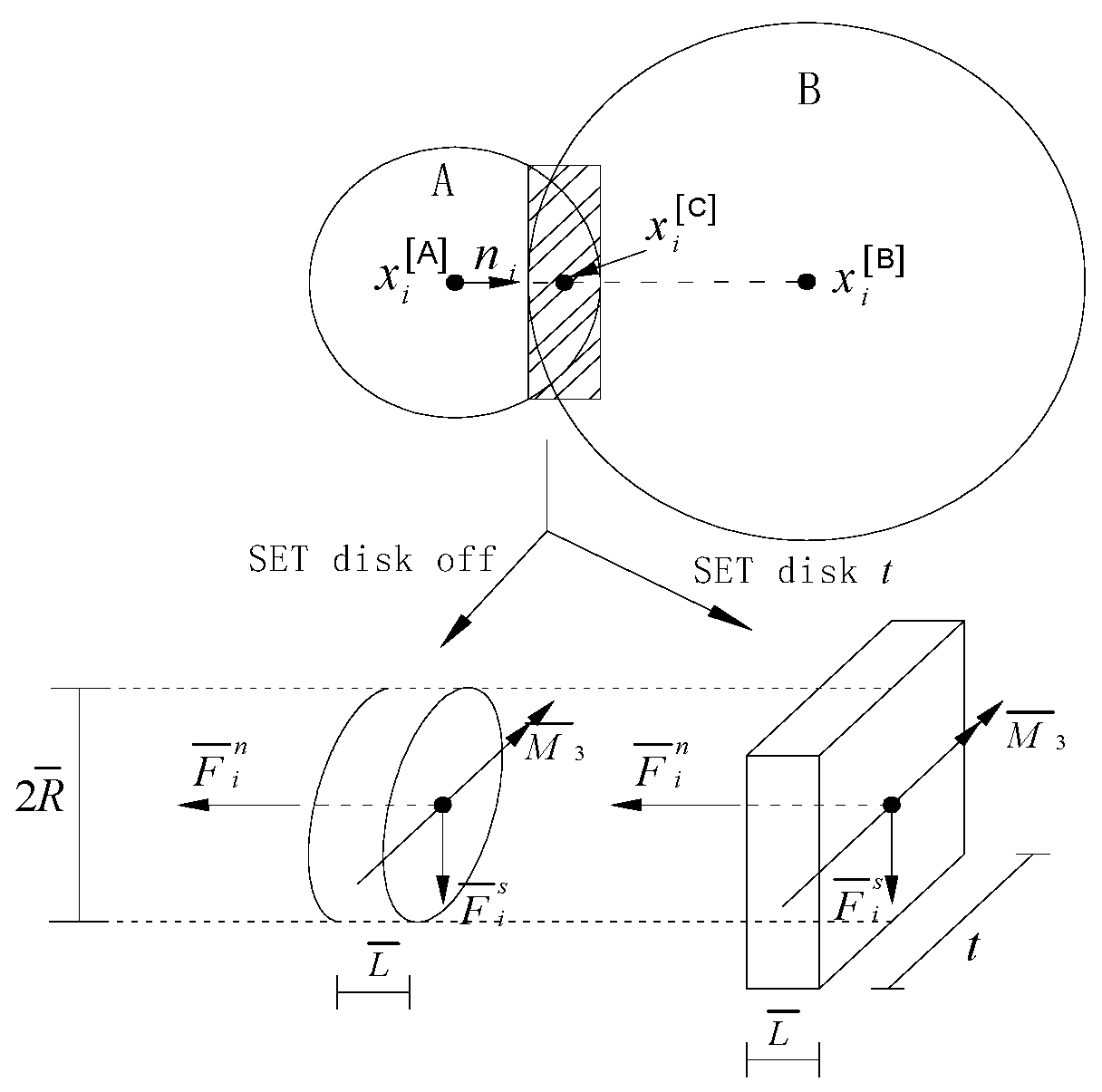

3. PFC3D Particle Flow Numerical Simulation

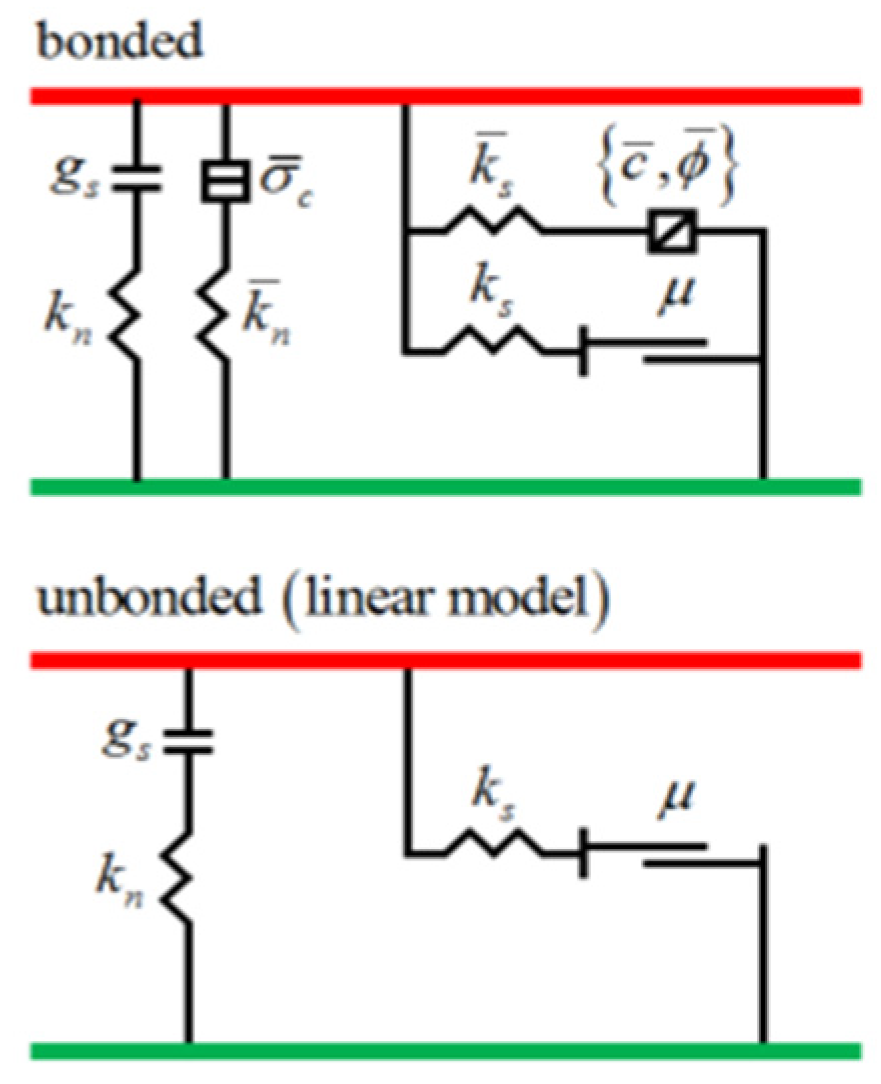

3.1. Model Establishment

3.2. Initial Value Setting of Model Meso-Parameters

3.3. Model Meso-Parameter Calibration

- Adjust the effective modulus of soil particles (emod) and viscous equivalent modulus (pb_emod) to fit and reshape frozen soil, Eσ/2. Adjust the phase strength (pb_tension) and tangential strength (pb_coh) of the soil particle bonding method and fit the peak stress and strain of the reshaped frozen soil. Adjust the soil particle stiffness ratio (kratio) and viscous stiffness ratio (pb_kratio) to fit the post-peak curve shape.

- Adjust the effective modulus of cement particles (emod) and viscous equivalent modulus (pb_emod) to fit and improve frozen soil, Eσ/2. Adjust the phase strength (pb_tension) and tangential strength (pb_coh) of the cement particle bonding method, and fit the peak stress and strain of the improved frozen soil. Adjust the cement particle stiffness ratio (kratio) and viscous stiffness ratio (pb_kratio) to fit the post-peak curve shape.

- Adjust the friction angle (fa) and friction coefficient (fric) to match the failure form in the same way as the sample.

- After adjustment, the above parameters need to be fine-tuned again in order to achieve a similar stress–strain curve.

3.4. Analysis of Numerical Simulation Test Results

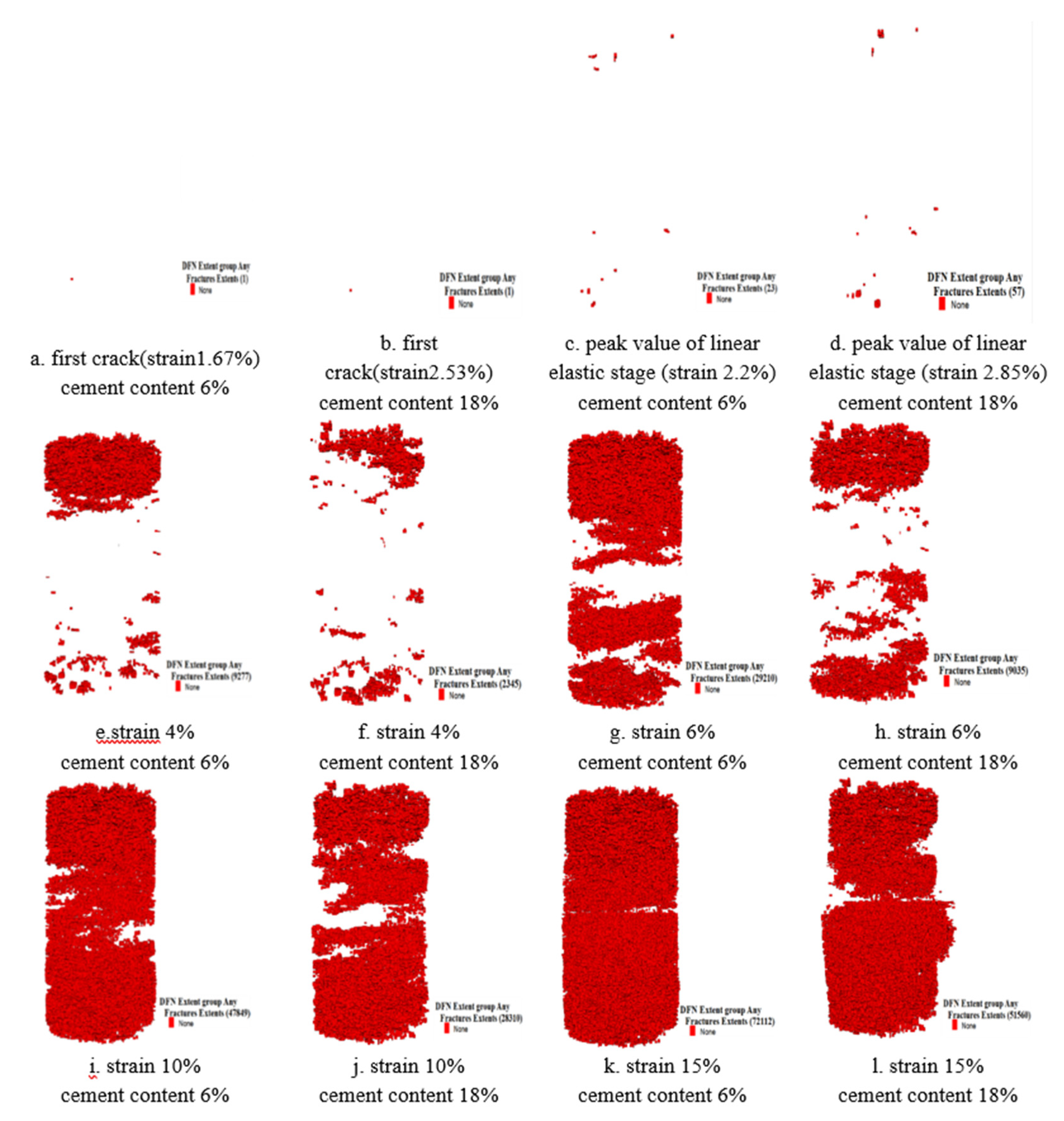

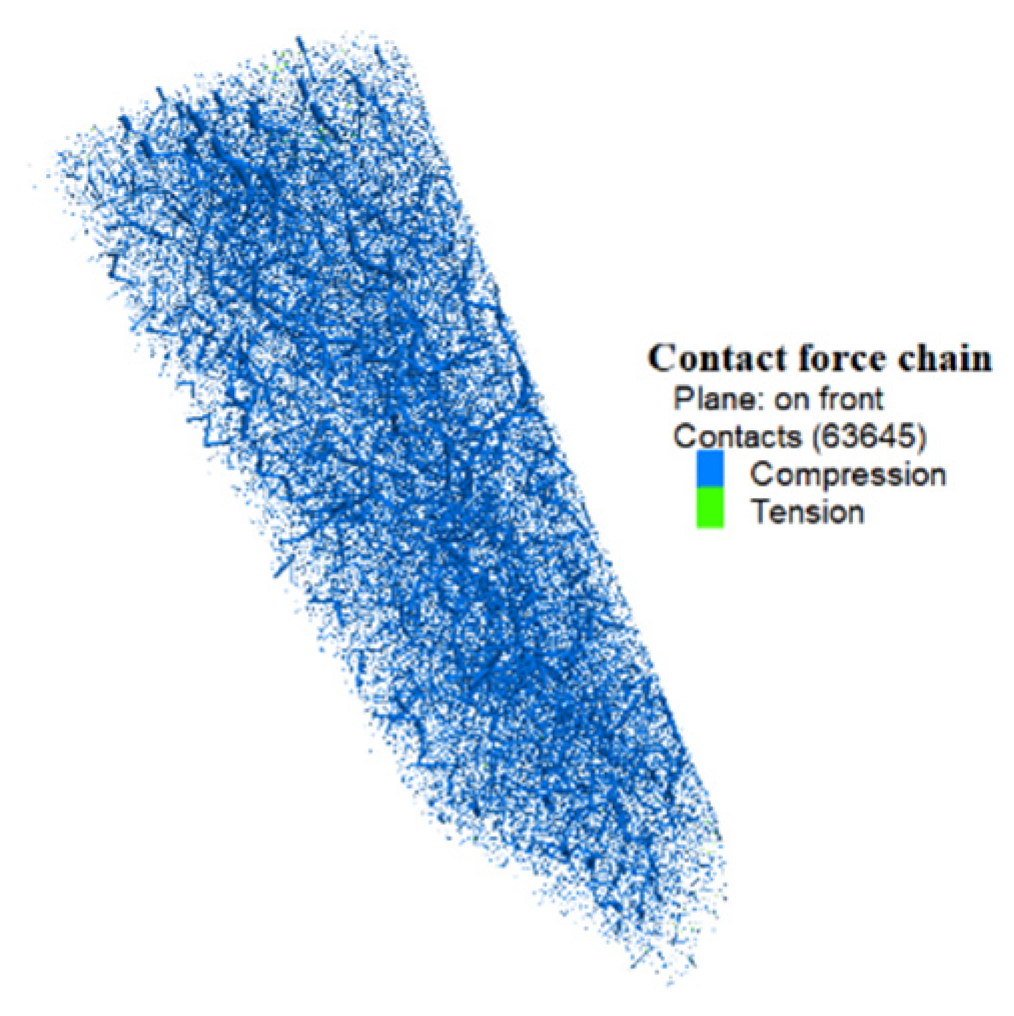

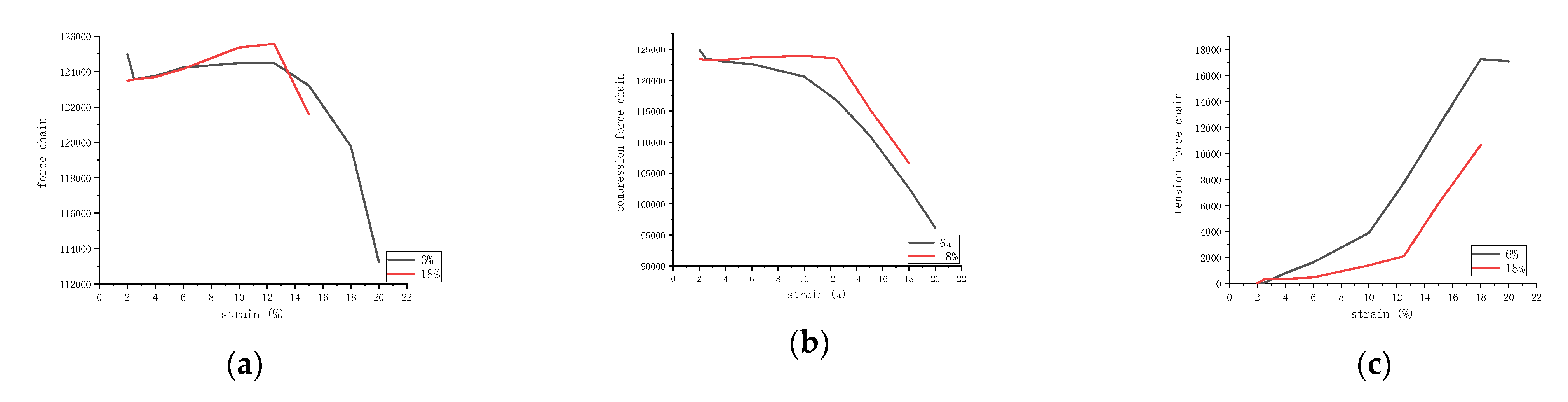

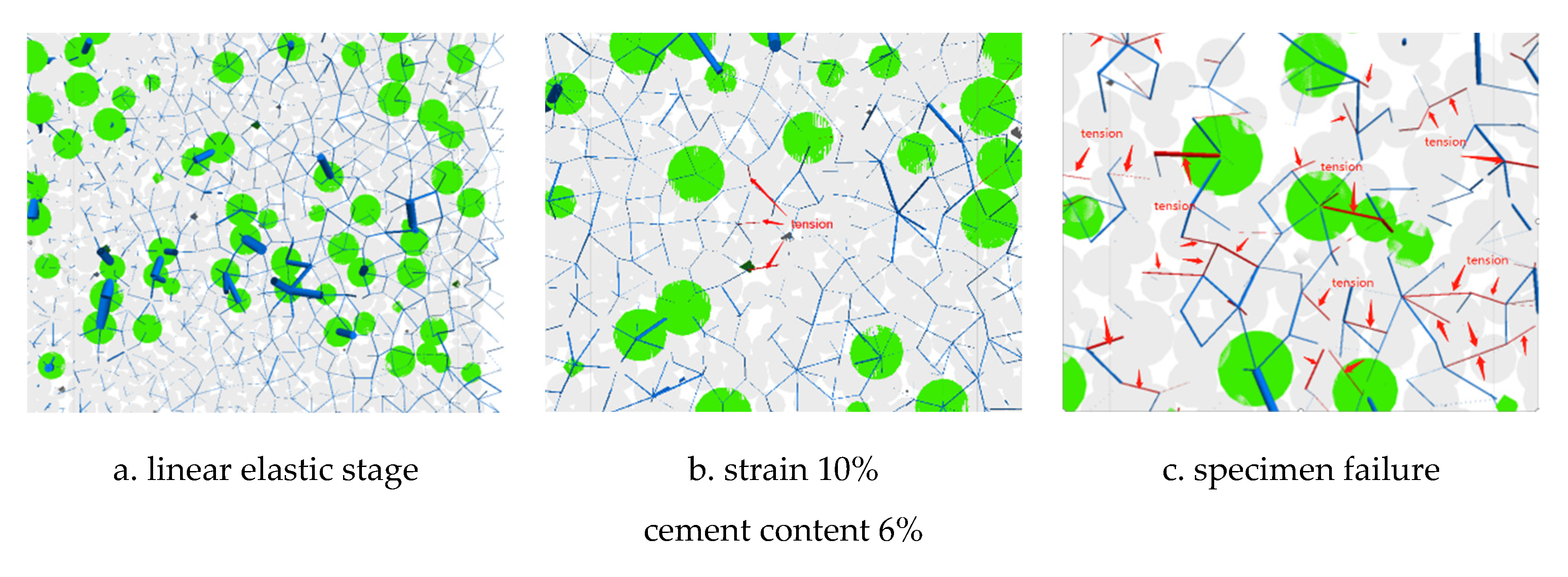

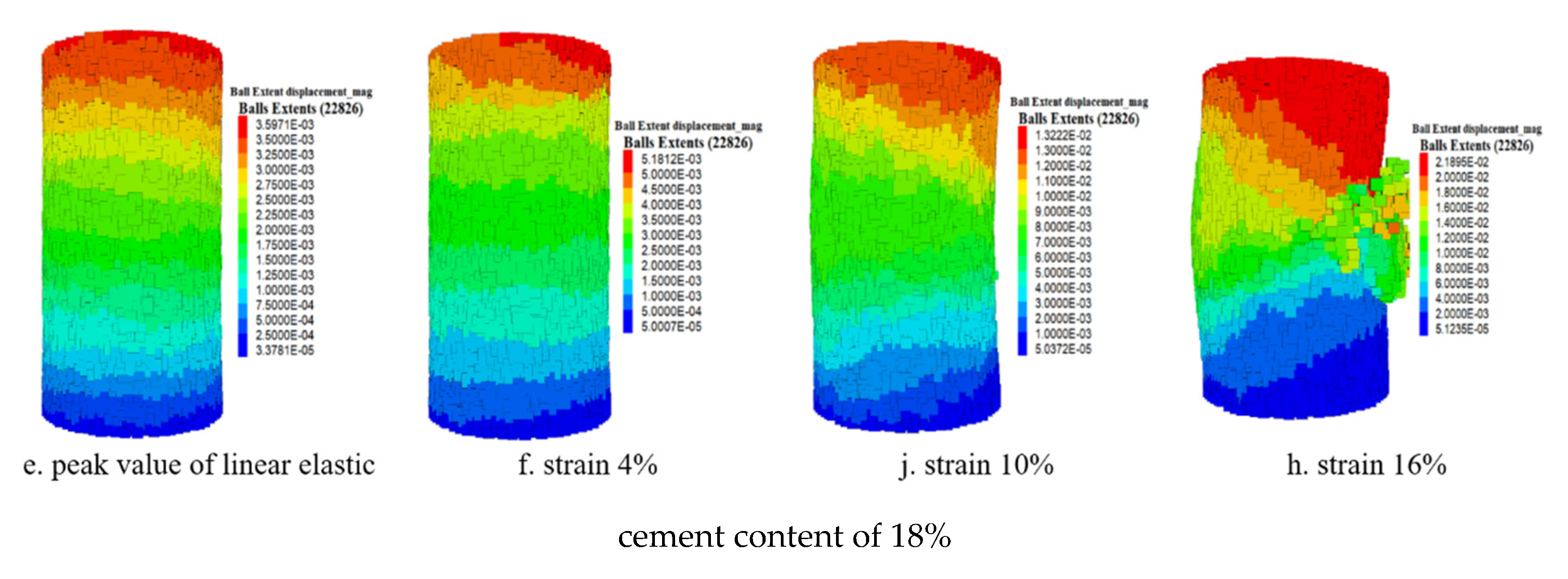

3.5. Comparative Analysis of Cracks, Stress Fields and Particle Displacement Fields

4. Conclusions

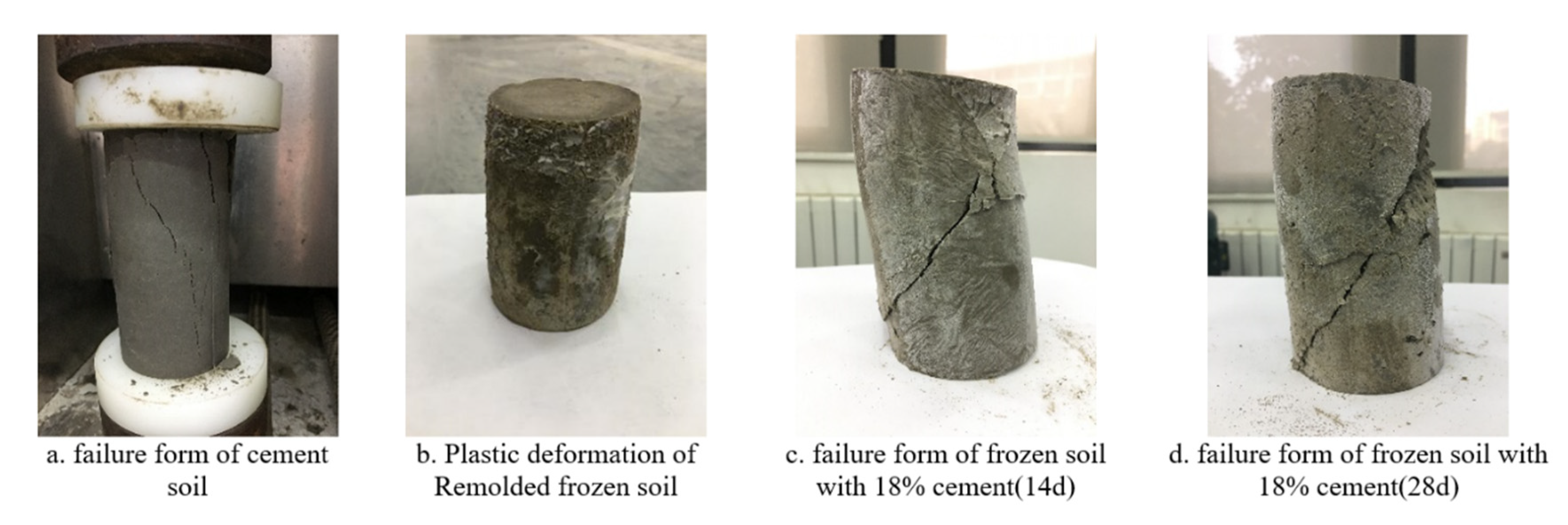

- In the laboratory test, the order of cement-improved frozen soil in terms of peak strength is: cement soil < remolded frozen soil < 6% cement-modified frozen soil < 12% cement-modified frozen soil < 18% cement-modified frozen soil. With the increase in cement content, the curve changes from “linear elastic deformation-strain strengthening-plastic deformation-tensile failure” to “linear elastic deformation-strain strengthening-tensile shear failure”.

- Under the same loading conditions, the initial location of the cracks in the samples with different cement contents is basically the same, and the increase in cement content can prolong the time of crack occurrence. With the same strain level, the number of cracks in the sample decreases with the increase in cement content.

- The stress field of the sample is in compression at the linear elastic stage, and the tensile stress chain is activated continuously with loading. At the linear elastic stage and strain strengthening state, new compressive stress chains are increasingly activated. For samples with a high cement content, more compressive stress chains are activated and less tensile stress chains are activated; when the activated tensile stress is smaller, the position of the tensile stress activation is differentiated due to different cement contents. When the specimen is damaged, the 6% specimen is mainly damaged by tensile plastic failure, and the 18% specimen is damaged by tensile shear failure.

- The force chains in the stress field are not evenly distributed in the sample, and the coarse pressure force chains only exist on the cement particles. With the progress of loading, the tensile stress first appears in the connection of soil particles. When the pressure force chains of the cement particles in the sample are damaged or the tensile force chains between particles appear, this indicates that the sample is damaged.

- With different cement contents, the development of a particle displacement field is different. The sample with 18% cement content has obvious delamination dislocation, with a smaller deformation in the transverse direction, mainly concentrated in the axial direction, while the 6% sample has no delamination dislocation, and has a larger deformation in the transverse and axial directions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Prisinski, J.R.; Bhattacharja, S. Effectiveness of Portland cement and lime in stabilizing clay soils. J. Transport. Res. Rep. 1999, 1, 215–227. [Google Scholar] [CrossRef]

- Shihata, S.A.; Baghdadi, Z.A. Simplified Method to Assess Freeze-Thaw Durability of Soil Cement. J. Mater. Civ. Eng. 2001, 13, 243–247. [Google Scholar] [CrossRef]

- Croft, J.B. The influence of soil mineralogical composition on cement stabilization. Geotechnique 1967, 17, 119–135. [Google Scholar] [CrossRef]

- Qiang, M.; Li, S.; Qianyun, S. Experimental Study on the Mechanical Properties of Fly Ash Cement soil. Univ. Shanghai Sci. Technol. 2017, 39, 490–496. [Google Scholar]

- Da-Shuang, W.; Jun-Jie, Y.; Meng-Rong, D.; Xiao-Teng, S.; Xiao-Pian, W. Laboratory Test on the Prediction of Cement Soil Strength. Period. Ocean. Univ. China 2018, 48, 96–102. [Google Scholar]

- Yixin, T.; Hanlong, L.; Wei, Z. Study on engineering properties of cement-stabilized soil. Chiness J. Geotech. Eng. 2000, 22, 549–554. [Google Scholar]

- Huang, X.; Ning, J.G.; Guo, Y.; Zhu, B.L. Effect of cement content on the structural formation of stabilized soil. Chin. J. Geotech. Eng. 2006, 28, 436–441. [Google Scholar]

- Wang, J.; Ding, G.-Y.; Pan, L.-Y.; Cai, Y.-Q.; Gao, Y.-F. Study of mechanics behavior and constitutive model of cemented soil under static triaxial tests. Rock Soil Mech. 2010, 31, 67–72. [Google Scholar]

- Liang, R.-W.; Zhang, M.; Bai, X.-H. Analysis of laboratory test results of cemented soil. Rock Soil Mech. 2001, 22, 91–93. [Google Scholar]

- Horpibulsuk, S.; Miura, N.; Nagaraj, T.S. Clay-water/cement ratio identity for cement admixed soft clays. J. Geotech. Geoenviron. Eng. 2005, 131, 187–192. [Google Scholar] [CrossRef]

- Niu, Y.-Q.; Wang, X.; Liao, M.-K.; Jiang, D.-J.; Liu, D.-R. Experimental study on triaxial strength and deformation characteristics of frozen-improved loess. Chin. J. Geotech. Eng. 2016, 38, 198–203. [Google Scholar]

- Yin, Z.-H.; Zhang, J.-M.; Zhang, H.; Wang, H.-L. Water transformation law of cement improved frozen soil and its effect on strength. J. Harbin Inst. Technol. 2021, 53, 136–144. [Google Scholar]

- Chai, M.; Zhang, J. Improvement of Compressibility and Thaw-Settlement Properties of Warm and Ice-Rich Frozen Soil with Cement and Additives. Materials 2019, 12, 1068. [Google Scholar] [CrossRef] [Green Version]

- Chai, M.; Zhang, H.; Zhang, J.; Zhang, Z. Effect of cement additives on unconfined compressive strength of warm and ice-rich frozen soil. Constr. Build. Mater. 2017, 149, 861–868. [Google Scholar] [CrossRef]

- Ma, H.; Zhang, Z.; Yue, F.; Fan, Y. Strength variation law of frozen cement-treated silty clay. Sci. Technol. Eng. 2018, 18, 291–296. [Google Scholar]

- Cundall, P.A. A computer model for simulating progressive large scale movements in blocky rock systems. In Proceedings of the Symposium of the International Society for Rock Mechanics, Nancy, France, 4–6 October 1971; Volume I. Number 8. [Google Scholar]

- Burman, B.C. A discrete numerical-model for granular assemblies. Géotechnique 1980, 30, 331–334. [Google Scholar]

- Bock, H.; Bluemling, P.; Konietzky, H. Study of the micro-mechanical behaviour of the Opalinus Clay: An example of co-operation across the ground engineering disciplines. Bull. Eng. Geol. Environ. 2006, 65, 195–207. [Google Scholar] [CrossRef]

- Vardoulakis, I.; Mühlhaus, H.B. The thickness of shear bands in granular materials. Geotechnique 1987, 37, 271–283. [Google Scholar]

- Geng, L.; Huang, Z.-Q.; Miao, Y. Meso-mechanics Simulation Triaxial Test of Coarse-grained Soil. J. Civ. Eng. Manag. 2011, 28, 24–29. [Google Scholar]

- Ning, L.; Yue, G. Particle Flow Simulation of Triaxial Test of Transparent Sand. In Proceedings of the National Academic Conference on Engineering Geology, Xining, China, 2 August 2011; pp. 311–317. [Google Scholar]

- Liu, Y.; Zhu, J.; Yan, B. Meso-mechanical simulation study on triaxial test of coarse—Grained soil based on DEM. J. Railw. Sci. Eng. 2014, 4, 58–62. [Google Scholar]

- Jensen, R.P.; Bosscher, P.J.; Plesha, M.E.; Edil, T.B. DEM simulation of granular media-structure interface: Effects of surface roughness and particle shape. Int. J. Numer. Numer. Anal. Methods Geomech. 1999, 23, 531–547. [Google Scholar] [CrossRef]

- Yang, B.; Yue, J.; Lei, S. A study on the effects of microparameters on macroproperties for specimens created by bonded particles. Eng. Comput. 2006, 23, 607–631. [Google Scholar] [CrossRef]

- Dop, A.; Pac, B. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar]

- Utili, S.; Nova, R. DEM analysis of bonded granular geomaterials. Int. J. Numer. Anal. Methods Geomech. 2010, 32, 1997–2031. [Google Scholar] [CrossRef]

- Zhang, C.; Gu, S.; Wang, X. Research on Relationship between Macro-parameters and Micro-parameters of Rock-soil Samples Based on PFC. Subgrade Eng. 2020, 6, 47–53. [Google Scholar]

- Liu, C.; Chen, X.X.; Zhang, W.; Wang, S. Study on the Calibration Process of Parallel Bonding Meso-structure Parameter in PFC Numerical Simulation. Value Eng. 2017, 36, 204–207. [Google Scholar]

| Soil Layer | ρ (kg/m3) | ω0 (%) | e | ωd (%) | ωP (%) | ωL (%) | IP (%) | IL |

|---|---|---|---|---|---|---|---|---|

| silty clay | 1780 | 36 | 1.13 | 28 | 23.5 | 37 | 14 | 0.86 |

| Soil Type | Particle Composition | ||||

|---|---|---|---|---|---|

| Grit | Powder Particle | Cosmid | |||

| grain size/mm | 0.5~0.25 | 0.25~0.075 | 0.075~0.005 | <0.005 | |

| comparative content/% | 0 | 13.1 | 61.2 | 25.7 | |

| Sample (W%-T) | Intensity/MPa | Peak Strength/MPa | Failure Strain/% | Eσ/2/MPa |

|---|---|---|---|---|

| 40-10 | 4.71 | 4.89 | 8.84 | 110.05 |

| Sample (W%-I%-day) | Intensity/MPa | Peak Strength/MPa | Failure Strain/% | Eσ/2/MPa |

|---|---|---|---|---|

| 40-18-7 | 2.60 | 2.60 | 1.88 | 97.01 |

| 40-18-14 | 2.79 | 2.79 | 2.15 | 112.5 |

| 40-18-24 | 3.26 | 3.26 | 2.04 | 116.43 |

| Sample (W%-T-I%-day) | Intensity/MPa | Peak Strength/MPa | Failure Strain/% | Eσ/2/MPa |

|---|---|---|---|---|

| 40-10-6-7 | 5.34 | 5.48 | 19.03 | 159.30 |

| 40-10-6-14 | 6.35 | 6.63 | 18.00 | 223.97 |

| 40-10-6-28 | 6.02 | 6.19 | 18.01 | 173.88 |

| 40-10-12-7 | 5.77 | 6.34 | 10.01 | 175.14 |

| 40-10-12-14 | 6.19 | 6.82 | 8.12 | 217.20 |

| 40-10-12-28 | 6.21 | 7.16 | 8.16 | 237.09 |

| 40-10-18-7 | 6.23 | 9.33 | 9.12 | 183.14 |

| 40-10-18-14 | 8.89 | 11.34 | 9.03 | 236.25 |

| 40-10-18-28 | 9.01 | 11.45 | 7.01 | 322.54 |

| Particle Name | Article Size Range (mm) | Density (kg/m3) |

|---|---|---|

| cement | 2.2 × 10−3–2.8 × 10−3 | 3150 |

| soil1 | 1.25 × 10−3–1.6 × 10−3 | 1780 |

| soil2 | 1.6 × 10−3–2.0 × 10−3 | 1780 |

| Keyword | Symbol | Description | Initial Value |

|---|---|---|---|

| mod | modulus [force/area] | 48 × 106 | |

| emod | Effective modulus [force/area] | 48 × 106 | |

| kratio | Normal-to-shear stiffness ratio | 1 | |

| tension | Tensile strength [stress] | 2.4 × 106 | |

| Cohesion | Cohesion [stress] | 1.2 × 106 | |

| fric | friction coefficient [-] | 0.5 | |

| fa | friction angle [degrees] | 20 | |

| pb_emod | bond Effective modulus | 46 × 106 | |

| pb_kratio | bond Normal-to-shear stiffness ratio | 1 | |

| pb_tension | bond Tensile strength [stress] | 2.4 × 106 | |

| pb_coh | bond Cohesion strength [stress] | 1.2 × 106 | |

| pb_fric | bond friction coefficient | 0.5 | |

| pb_fa | bond friction angle [degrees] | 20 | |

| pb_rmul | radius multiplier [-] | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, F.; Song, L.; Yue, F. Study on Mechanical Properties of Cement-Improved Frozen Soil under Uniaxial Compression Based on Discrete Element Method. Processes 2022, 10, 324. https://doi.org/10.3390/pr10020324

Ding F, Song L, Yue F. Study on Mechanical Properties of Cement-Improved Frozen Soil under Uniaxial Compression Based on Discrete Element Method. Processes. 2022; 10(2):324. https://doi.org/10.3390/pr10020324

Chicago/Turabian StyleDing, Fei, Lei Song, and Fengtian Yue. 2022. "Study on Mechanical Properties of Cement-Improved Frozen Soil under Uniaxial Compression Based on Discrete Element Method" Processes 10, no. 2: 324. https://doi.org/10.3390/pr10020324

APA StyleDing, F., Song, L., & Yue, F. (2022). Study on Mechanical Properties of Cement-Improved Frozen Soil under Uniaxial Compression Based on Discrete Element Method. Processes, 10(2), 324. https://doi.org/10.3390/pr10020324