Olive Mill by-Products Thermochemical Conversion via Hydrothermal Carbonization and Slow Pyrolysis: Detailed Comparison between the Generated Hydrochars and Biochars Characteristics

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Feedstock Collection and Preparation

2.2. Carbonization Process

2.2.1. Hydrothermal Carbonization

2.2.2. Slow Pyrolysis Carbonization

2.3. Chars Characterization

2.3.1. Solid Yield Determination

2.3.2. Physico-Chemical Characterization of the Produced Hydrochars and Biochars

Proximate, Ultimate and Mineral Composition Analysis

Structure and Morphology

Surface Chemistry

Energy Content

3. Results

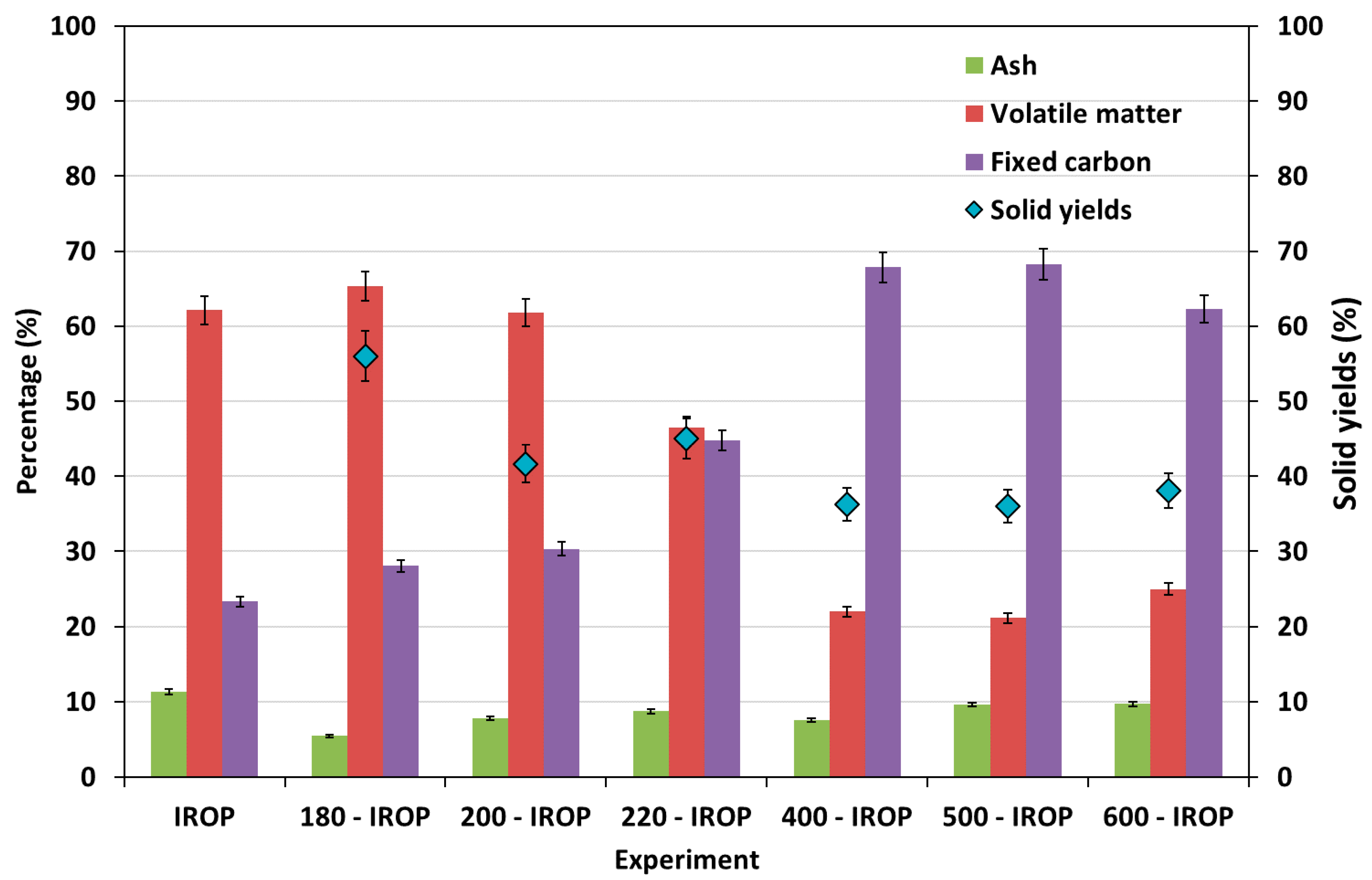

3.1. Carbonization Yield and Proximate Analysis

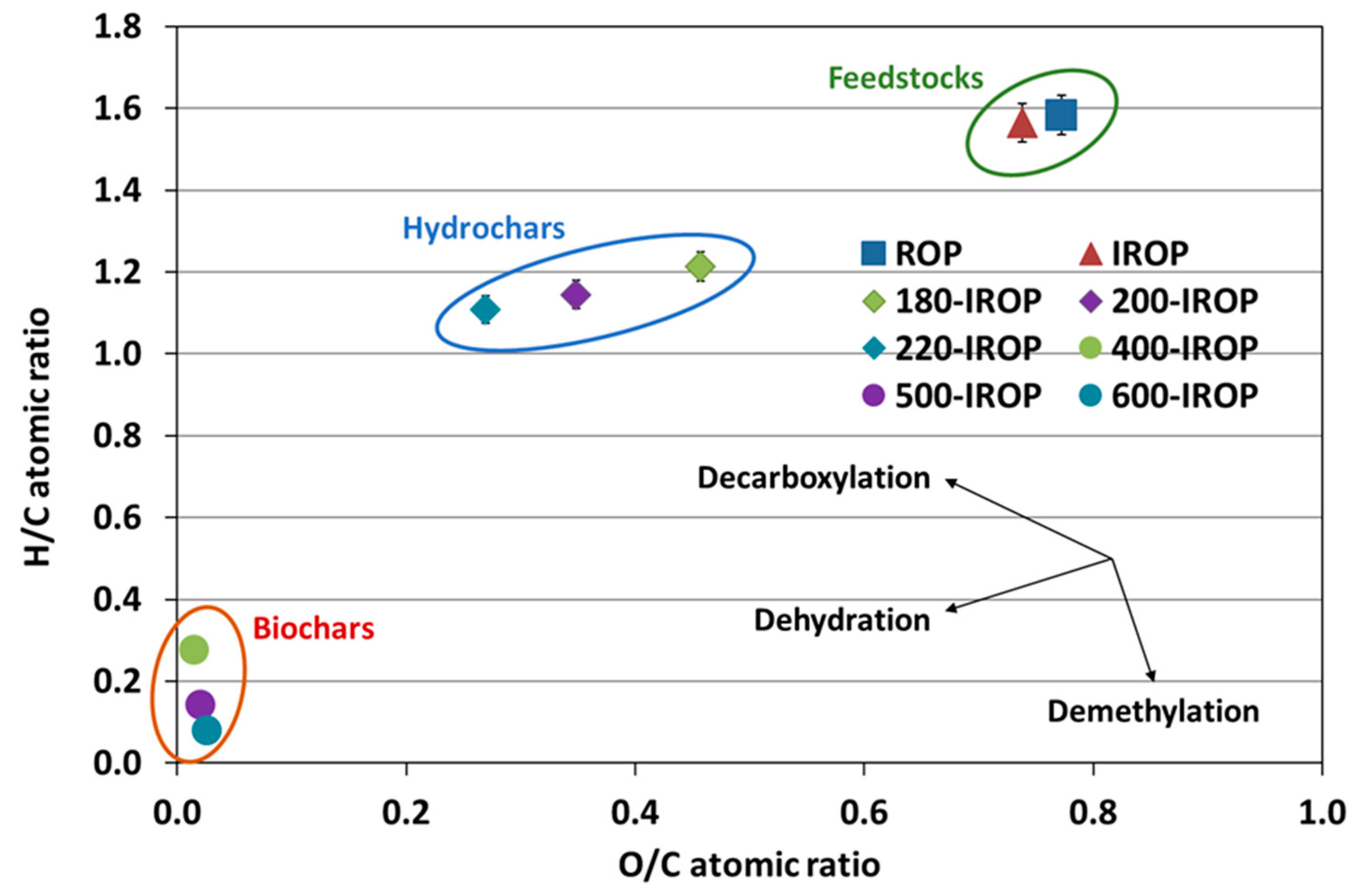

3.2. Ultimate and Elemental Analysis

3.3. Energetic Properties

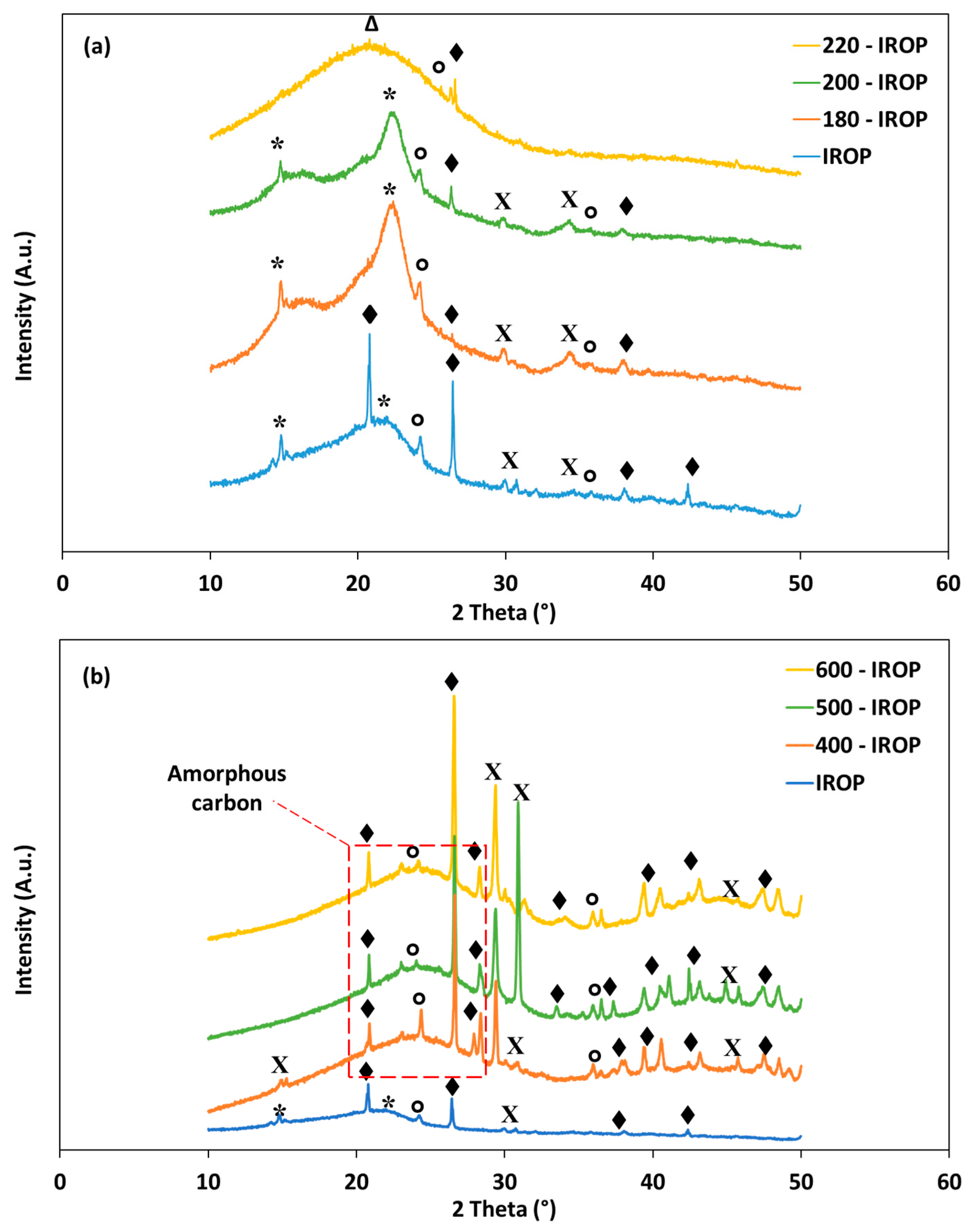

3.4. Morphological Properties

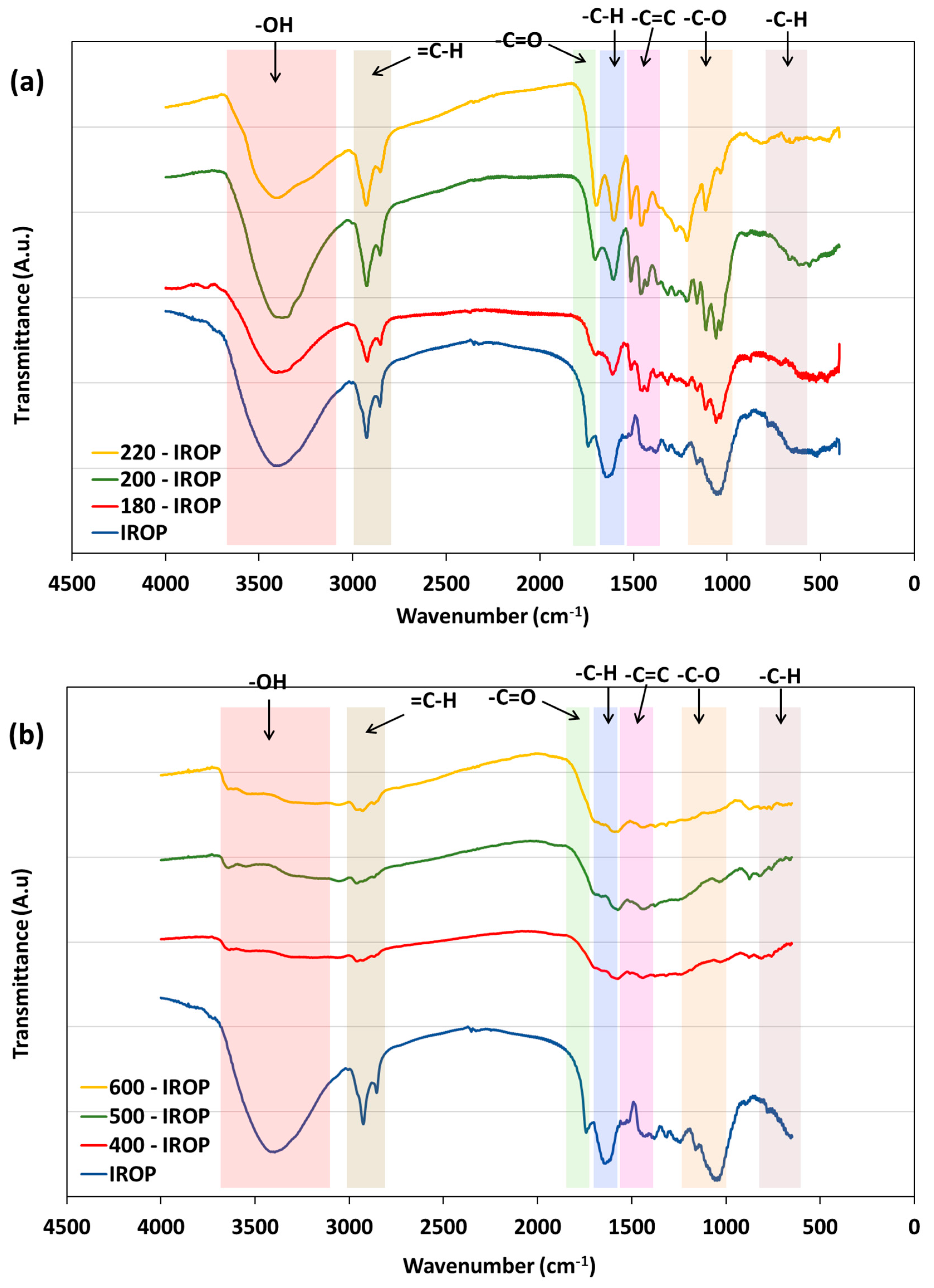

3.5. Surface Chemical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reardon, T.; Barrett, C.B.; Berdegué, J.A.; Swinnen, J.F.M. Agrifood Industry Transformation and Small Farmers in Developing Countries. World Dev. 2009, 37, 1717–1727. [Google Scholar] [CrossRef]

- Kerr, W.A. Agriculture after a year with COVID-19: Any long-term implications for international trade policy? Can. J. Agric. Econ. Can. D’Agroecon. 2021, 69, 261–267. [Google Scholar] [CrossRef]

- Rochman, G.P.; Indratno, I.; Agustina, I.H. Rural Agri-Food Industry Resilience in Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2021, 830, 012063. [Google Scholar] [CrossRef]

- Laura, L.; Osorio, D.R.; Flórez-López, E.; David Grande-Tovar, C.; Flórez-López, E.; Grande-Tovar, C.D.; Trombetta, D. The Potential of Selected Agri-Food Loss and Waste to Contribute to a Circular Economy: Applications in the Food, Cosmetic and Pharmaceutical Industries. Molecules 2021, 26, 515. [Google Scholar]

- Hadroug, S.; Jellali, S.; Jeguirim, M.; Kwapinska, M.; Hamdi, H.; Leahy, J.J.; Kwapinski, W. Static and dynamic investigations on leaching/retention of nutrients from raw poultry manure biochars and amended agricultural soil. Sustainability 2021, 13, 1212. [Google Scholar] [CrossRef]

- Vandeponseele, A.; Draye, M.; Piot, C.; Chatel, G. Subcritical water and supercritical carbon dioxide: Efficient and selective eco-compatible solvents for coffee and coffee by-products valorization. Green Chem. 2020, 22, 8544–8571. [Google Scholar] [CrossRef]

- Hadj Saadoun, J.; Bertani, G.; Levante, A.; Vezzosi, F.; Ricci, A.; Bernini, V.; Lazzi, C. Fermentation of Agri-Food Waste: A Promising Route for the Production of Aroma Compounds. Foods 2021, 10, 707. [Google Scholar] [CrossRef]

- Wahab, M.A.; Hassine, R.B.; Jellali, S. Posidonia oceanica (L.) fibers as a potential low-cost adsorbent for the removal and recovery of orthophosphate. J. Hazard. Mater. 2011, 191, 333–341. [Google Scholar] [CrossRef]

- Hadroug, S.; Jellali, S.; Leahy, J.J.; Kwapinska, M.; Jeguirim, M.; Hamdi, H.; Kwapinski, W. Pyrolysis process as a sustainable management option of poultry manure: Characterization of the derived biochars and assessment of their nutrient release capacities. Water 2019, 11, 2271. [Google Scholar] [CrossRef]

- Bolaji, I.; Nejad, B.; Billham, M.; Mehta, N.; Smyth, B.; Cunningham, E. Multi-criteria decision analysis of agri-food waste as a feedstock for biopolymer production. Resour. Conserv. Recycl. 2021, 172, 105671. [Google Scholar] [CrossRef]

- Abdeshahian, P.; Ascencio, J.J.; Philippini, R.R.; Antunes, F.A.F.; de Carvalho, A.S.; Abdeshahian, M.; dos Santos, J.C.; da Silva, S.S. Valorization of Lignocellulosic Biomass and Agri-food Processing Wastes for Production of Glucan Polymer. Waste Biomass Valoriz. 2020, 12, 2915–2931. [Google Scholar] [CrossRef]

- Beda, A.; Le Meins, J.M.; Taberna, P.L.; Simon, P.; Matei Ghimbeu, C. Impact of biomass inorganic impurities on hard carbon properties and performance in Na-ion batteries. Sustain. Mater. Technol. 2020, 26, e00227. [Google Scholar] [CrossRef]

- Ciszewski, M.; Koszorek, A.; Radko, T.; Szatkowski, P.; Janas, D. Review of the Selected Carbon-Based Materials for Symmetric Supercapacitor Application. J. Electron. Mater. 2018, 48, 717–744. [Google Scholar] [CrossRef]

- Landin-Sandoval, V.J.; Mendoza-Castillo, D.I.; Bonilla-Petriciolet, A.; Aguayo-Villarreal, I.A.; Reynel-Avila, H.E.; Gonzalez-Ponce, H.A. Valorization of agri-food industry wastes to prepare adsorbents for heavy metal removal from water. J. Environ. Chem. Eng. 2020, 8, 104067. [Google Scholar] [CrossRef]

- Fernández-López, J.A.; Miñarro, M.D.; Angosto, J.M.; Fernández-Lledó, J.; Obón, J.M. Adsorptive and Surface Characterization of Mediterranean Agrifood Processing Wastes: Prospection for Pesticide Removal. Agronomy 2021, 11, 561. [Google Scholar] [CrossRef]

- Hadroug, S.; Jellali, S.; Amine, A.; Marzena, A.; Helmi, K.; James, H. Valorization of salt post-modified poultry manure biochars for phosphorus recovery from aqueous solutions: Investigations on adsorption properties and involved mechanism. Biomass Convers. Biorefin. 2021. [Google Scholar] [CrossRef]

- Azzaz, A.A.; Khiari, B.; Jellali, S.; Ghimbeu, C.M.; Jeguirim, M. Hydrochars production, characterization and application for wastewater treatment: A review. Renew. Sustain. Energy Rev. 2020, 127, 109882. [Google Scholar] [CrossRef]

- Jellali, S.; Khiari, B.; Usman, M.; Hamdi, H.; Charabi, Y.; Jeguirim, M. Sludge-derived biochars: A review on the influence of synthesis conditions on pollutants removal efficiency from wastewaters. Renew. Sustain. Energy Rev. 2021, 144, 111068. [Google Scholar] [CrossRef]

- Jellali, S.; Charabi, Y.; Usman, M.; Al-Badi, A.; Jeguirim, M. Investigations on biogas recovery from anaerobic digestion of raw sludge and its mixture with agri-food wastes: Application to the largest industrial estate in Oman. Sustainability 2021, 13, 3698. [Google Scholar] [CrossRef]

- Dutournié, P.; Jeguirim, M.; Khiari, B.; Goddard, M.-L.; Jellali, S. Olive Mill Wastewater: From a Pollutant to Green Fuels, Agricultural Water Source, and Bio-Fertilizer. Part 2: Water Recovery. Water 2019, 11, 768. [Google Scholar] [CrossRef]

- Fan, H.; Gu, J.; Hu, S.; Yuan, H.; Chen, Y. Co-pyrolysis and co-gasification of biomass and polyethylene: Thermal behaviors, volatile products and characteristics of their residues. J. Energy Inst. 2019, 92, 1926–1935. [Google Scholar] [CrossRef]

- Lu, J.S.; Chang, Y.; Poon, C.S.; Lee, D.J. Slow pyrolysis of municipal solid waste (MSW): A review. Bioresour. Technol. 2020, 312, 123615. [Google Scholar] [CrossRef] [PubMed]

- Heidarinejad, Z.; Dehghani, M.H.; Heidari, M.; Javedan, G.; Ali, I.; Sillanpää, M. Methods for preparation and activation of activated carbon: A review. Environ. Chem. Lett. 2020, 18, 393–415. [Google Scholar] [CrossRef]

- Savou, V.; Grause, G.; Kumagai, S.; Saito, Y.; Kameda, T.; Yoshioka, T. Pyrolysis of sugarcane bagasse pretreated with sulfuric acid. J. Energy Inst. 2019, 92, 1149–1157. [Google Scholar] [CrossRef]

- Wang, T.; Zhai, Y.; Zhu, Y.; Li, C.; Zeng, G. A review of the hydrothermal carbonization of biomass waste for hydrochar formation: Process conditions, fundamentals, and physicochemical properties. Renew. Sustain. Energy Rev. 2018, 90, 223–247. [Google Scholar] [CrossRef]

- Azzaz, A.A.; Jeguirim, M.; Marks, E.A.N.; Rad, C.; Jellali, S.; Goddard, M.-L.; Ghimbeu, C.M. Physico-chemical properties of hydrochars produced from raw olive pomace using olive mill wastewater as moisture source. Comptes Rendus. Chim. 2021, 23, 635–652. [Google Scholar] [CrossRef]

- Marks, E.A.N.; Kinigopoulou, V.; Akrout, H.; Azzaz, A.A.; Doulgeris, C.; Jellali, S.; Rad, C.; Sánchez Zulueta, P.; Tziritis, E.; El-Bassi, L.; et al. Potential for Production of Biochar-Based Fertilizers from Olive Mill Waste in Mediterranean Basin Countries: An Initial Assessment for Spain, Tunisia, and Greece. Sustainability 2020, 12, 6081. [Google Scholar] [CrossRef]

- Haddad, K.; Jeguirim, M.; Jerbi, B.; Chouchene, A.; Dutournié, P.; Thevenin, N.; Ruidavets, L.; Jellali, S.; Limousy, L. Olive Mill Wastewater: From a Pollutant to Green Fuels, Agricultural Water Source and Biofertilizer. ACS Sustain. Chem. Eng. 2017, 5, 8988–8996. [Google Scholar] [CrossRef]

- Azzaz, A.A.; Jeguirim, M.; Kinigopoulou, V.; Doulgeris, C.; Goddard, M.-L.; Jellali, S.; Matei Ghimbeu, C. Olive mill wastewater: From a pollutant to green fuels, agricultural and water source and bio-fertilizer—Hydrothermal carbonization. Sci. Total Environ. 2020, 733, 139314. [Google Scholar] [CrossRef]

- Bargaoui, M.; Jellali, S.; Azzaz, A.A.; Jeguirim, M.; Akrout, H. Optimization of hybrid treatment of olive mill wastewaters through impregnation onto raw cypress sawdust and electrocoagulation. Environ. Sci. Pollut. Res. 2020, 28, 24470–24485. [Google Scholar] [CrossRef]

- Thompson, W.; Leege, P. Test methods for the examination of composting and compost. Commun. Soil Sci. Plant Anal. 1998. [Google Scholar]

- Azzaz, A.A.; Jellali, S.; Akrout, H.; Assadi, A.A.; Bousselmi, L. Optimization of a cationic dye removal by a chemically modified agriculture by-product using response surface methodology: Biomasses characterization and adsorption properties. Environ. Sci. Pollut. Res. 2016, 11, 9831–9846. [Google Scholar] [CrossRef]

- DIN. Testing of Solid and Liquid Fuels: Determination of Gross Calorific Value by the Bomb Calorimeter and Calculation of Net Calorific Value—Part 3: Method Using Adiabatic Jacket; Deutsches Institut für Normung (DIN): Berlin, Germany, 2005; pp. 51900–51903. [Google Scholar]

- Olszewski, M.P.; Nicolae, S.A.; Arauzo, P.J.; Titirici, M.M.; Kruse, A. Wet and dry? Influence of hydrothermal carbonization on the pyrolysis of spent grains. J. Clean. Prod. 2020, 260, 121101. [Google Scholar] [CrossRef]

- Arauzo, P.J.; Maziarka, P.A.; Schoder, K.A.; Pfersich, J.; Ronsse, F.; Kruse, A. Influence of sequential HTC pre-treatment and pyrolysis on wet food-industry wastes: Optimisation toward nitrogen-rich hierarchical carbonaceous materials intended for use in energy storage solutions. Sci. Total Environ. 2021, 151648. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, B.; Yao, Y.; Fang, J.; Zhang, M.; Zhou, Y.; Chen, H.; Yang, L. Effects of feedstock type, production method, and pyrolysis temperature on biochar and hydrochar properties. Chem. Eng. J. 2014, 240, 574–578. [Google Scholar] [CrossRef]

- Jeguirim, M.; Chouchène, A.; Réguillon, A.F.; Trouvé, G.; Le Buzit, G. A new valorisation strategy of olive mill wastewater: Impregnation on sawdust and combustion. Resour. Conserv. Recycl. 2012, 59, 4–8. [Google Scholar] [CrossRef]

- Zhang, B.; Heidari, M.; Regmi, B.; Salaudeen, S.; Arku, P.; Thimmannagari, M.; Dutta, A. Hydrothermal carbonization of fruit wastes: A promising technique for generating hydrochar. Energies 2018, 11, 2022. [Google Scholar] [CrossRef]

- Yay, A.S.E.; Birinci, B.; Açıkalın, S.; Yay, K. Hydrothermal carbonization of olive pomace and determining the environmental impacts of post-process products. J. Clean. Prod. 2021, 315, 128087. [Google Scholar]

- Chen, J.; Wang, P.; Ding, L.; Yu, T.; Leng, S.; Chen, J.; Fan, L.; Li, J.; Wei, L.; Li, J.; et al. Journal of Analytical and Applied Pyrolysis The comparison study of multiple biochar stability assessment methods. J. Anal. Appl. Pyrolysis 2021, 156, 105070. [Google Scholar] [CrossRef]

- Jiang, L.; Hu, S.; Xiang, J.; Su, S.; Sun, L.; Xu, K.; Yao, Y. Bioresource Technology Release characteristics of alkali and alkaline earth metallic species during biomass pyrolysis and steam gasification process. Bioresour. Technol. 2012, 116, 278–284. [Google Scholar]

- El-Bassi, L.; Azzaz, A.A.; Jellali, S.; Akrout, H.; Marks, E.A.N.; Ghimbeu, C.M.; Jeguirim, M. Application of olive mill waste-based biochars in agriculture: Impact on soil properties, enzymatic activities and tomato growth. Sci. Total Environ. 2021, 755, 142531. [Google Scholar] [CrossRef]

- Jian, X.; Zhuang, X.; Li, B.; Xu, X.; Wei, Z.; Song, Y.; Jiang, E. Comparison of characterization and adsorption of biochars produced from hydrothermal carbonization and pyrolysis. Environ. Technol. Innov. 2018, 10, 27–35. [Google Scholar] [CrossRef]

- Mahdi, Z.; El Hanandeh, A.; Yu, Q. Influence of Pyrolysis Conditions on Surface Characteristics and Methylene Blue Adsorption of Biochar Derived from Date Seed Biomass. Waste Biomass Valoriz. 2017, 8, 2061–2073. [Google Scholar] [CrossRef]

- Ahmed, A.; Abu Bakar, M.S.; Hamdani, R.; Park, Y.K.; Lam, S.S.; Sukri, R.S.; Hussain, M.; Majeed, K.; Phusunti, N.; Jamil, F.; et al. Valorization of underutilized waste biomass from invasive species to produce biochar for energy and other value-added applications. Environ. Res. 2020, 186, 109596. [Google Scholar] [CrossRef]

- Chouchene, A.; Jeguirim, M.; Favre-Reguillon, A.; Trouvé, G.; Le Buzit, G.; Khiari, B.; Zagrouba, F. Energetic valorisation of olive mill wastewater impregnated on low cost absorbent: Sawdust versus olive solid waste. Energy 2012, 39, 74–81. [Google Scholar] [CrossRef]

- Lucian, M.; Volpe, M.; Gao, L.; Piro, G.; Goldfarb, J.L.; Fiori, L. Impact of hydrothermal carbonization conditions on the formation of hydrochars and secondary chars from the organic fraction of municipal solid waste. Fuel 2018, 233, 257–268. [Google Scholar] [CrossRef]

- Atallah, E.; Kwapinski, W.; Ahmad, M.N.; Leahy, J.J.; Al-Muhtaseb, A.H.; Zeaiter, J. Hydrothermal carbonization of olive mill wastewater: Liquid phase product analysis. J. Environ. Chem. Eng. 2019, 7, 102833. [Google Scholar] [CrossRef]

- Volpe, M.; Fiori, L. From olive waste to solid biofuel through hydrothermal carbonisation: The role of temperature and solid load on secondary char formation and hydrochar energy properties. J. Anal. Appl. Pyrolysis 2017, 124, 63–72. [Google Scholar] [CrossRef]

- Zhao, S.X.; Ta, N.; Wang, X.D. Effect of Temperature on the Structural and Physicochemical Properties of Biochar with Apple Tree Branches as Feedstock Material. Energies 2017, 10, 1293. [Google Scholar] [CrossRef]

- Jeguirim, M.; Trouvé, G. Pyrolysis characteristics and kinetics of Arundo donax using thermogravimetric analysis. Bioresour. Technol. 2009, 100, 4026–4031. [Google Scholar] [CrossRef]

- Gallifuoco, A.; Taglieri, L.; Scimia, F.; Papa, A.A. Biomass and Bioenergy New insights into the evolution of solid and liquid phases during hydrothermal carbonization of lignocellulosic biomasses. Biomass Bioenergy 2019, 121, 122–127. [Google Scholar] [CrossRef]

- Biller, P.; Ross, A.B. Production of biofuels via hydrothermal conversion. In Handbook of Biofuels Production; Elsevier: Amsterdam, The Netherlands, 2016; pp. 509–547. ISBN 9780081004562. [Google Scholar]

- Weisenberger, M.C.; Burgess, J.; Schobert, H.H.; Hower, J.C.; Mountain, B. Thermal properties of Pennsylvania anthracite. Fuel 2020, 266, 117101. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, X.; Liu, X.; Lv, Q.; Zhao, L.; Che, D. Correlations of chemical properties of high-alkali solid fuels: A comparative study between Zhundong coal and biomass. Fuel 2018, 211, 629–637. [Google Scholar] [CrossRef]

- Li, L.; Hale, M.; Olsen, P.; Berge, N.D. Using liquid waste streams as the moisture source during the hydrothermal carbonization of municipal solid wastes. Waste Manag. 2014, 34, 2185–2195. [Google Scholar] [CrossRef]

- Magalh, D.; Gürel, K.; Matsakas, L.; Christakopoulos, P.; Pisano, I.; Leahy, J.J.; Kazanç, F.; Trubetskaya, A. Prediction of yields and composition of char from fast pyrolysis of commercial lignocellulosic materials, organosolv fractionated and torrefied olive stones. Fuel 2021, 289, 119862. [Google Scholar] [CrossRef]

- Sangchoom, W.; Mokaya, R. Valorization of Lignin Waste: Carbons from Hydrothermal Carbonization of Renewable Lignin as Superior Sorbents for CO2 and Hydrogen Storage. ACS Sustain. Chem. Eng. 2015, 3, 1658–1667. [Google Scholar] [CrossRef]

- Volpe, M.; Goldfarb, J.L.; Fiori, L. Hydrothermal carbonization of Opuntia ficus-indica cladodes: Role of process parameters on hydrochar properties. Bioresour. Technol. 2018, 247, 310–318. [Google Scholar] [CrossRef]

- Zhao, L.; Cao, X.; Mašek, O.; Zimmerman, A. Heterogeneity of biochar properties as a function of feedstock sources and production temperatures. J. Hazard. Mater. 2013, 256–257, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Vieira, F.R.; Romero Luna, C.M.; Arce, G.L.A.F.; Ávila, I. Optimization of slow pyrolysis process parameters using a fixed bed reactor for biochar yield from rice husk. Biomass Bioenergy 2020, 132, 105412. [Google Scholar] [CrossRef]

- Teh, Y.Y.; Lee, K.T.; Chen, W.H.; Lin, S.C.; Sheen, H.K.; Tan, I.S. Dilute sulfuric acid hydrolysis of red macroalgae Eucheuma denticulatum with microwave-assisted heating for biochar production and sugar recovery. Bioresour. Technol. 2017, 246, 20–27. [Google Scholar] [CrossRef]

- Zhao, C.; Jiang, E.; Chen, A. Volatile production from pyrolysis of cellulose, hemicellulose and lignin. J. Energy Inst. 2017, 90, 902–913. [Google Scholar] [CrossRef]

- Azzaz, A.A.; Jellali, S.; Jeguirim, M.; Bousselmi, L.; Bengharez, Z.; Akrout, H. Optimization of a cationic dye desorption from a loaded-lignocellulosic biomass: Factorial design experiments and investigation of mechanisms. Comptes Rendus. Chim. 2021, 24, 71–84. [Google Scholar] [CrossRef]

- Pfersich, J.; Arauzo, P.J.; Lucian, M.; Modugno, P.; Titirici, M.M.; Fiori, L.; Kruse, A. Hydrothermal Conversion of Spent Sugar Beets into High-Value Platform Molecules. Molecules 2020, 25, 3914. [Google Scholar] [CrossRef]

- Liang, J.; Liu, Y.; Zhang, J. Effect of Solution pH on the Carbon Microsphere Synthesized by Hydrothermal Carbonization. Procedia Environ. Sci. 2011, 11, 1322–1327. [Google Scholar] [CrossRef][Green Version]

- Ryu, J.; Suh, Y.-W.; Suh, D.J.; Ahn, D.J. Hydrothermal preparation of carbon microspheres from mono-saccharides and phenolic compounds. Carbon N. Y. 2010, 48, 1990–1998. [Google Scholar] [CrossRef]

- Volpe, R.; Messineo, A.; Millan, M.; Volpe, M.; Kandiyoti, R. Assessment of olive wastes as energy source: Pyrolysis, torrefaction and the key role of H loss in thermal breakdown. Energy 2015, 82, 119–127. [Google Scholar] [CrossRef]

- Zhang, S.; Sheng, K.; Yan, W.; Liu, J.; Shuang, E.; Yang, M.; Zhang, X. Bamboo derived hydrochar microspheres fabricated by acid-assisted hydrothermal carbonization. Chemosphere 2021, 263, 128093. [Google Scholar] [CrossRef]

- Qatarneh, A.F.; Dupont, C.; Michel, J.; Simonin, L.; Beda, A.; Matei Ghimbeu, C.; Ruiz-Villanueva, V.; da Silva, D.; Piégay, H.; Franca, M.J. River driftwood pretreated via hydrothermal carbonization as a sustainable source of hard carbon for Na-ion battery anodes. J. Environ. Chem. Eng. 2021, 9, 106604. [Google Scholar] [CrossRef]

- Basso, D.; Weiss-Hortala, E.; Patuzzi, F.; Castello, D.; Baratieri, M.; Fiori, L. Hydrothermal carbonization of off-specification compost: A byproduct of the organic municipal solid waste treatment. Bioresour. Technol. 2015, 182, 217–224. [Google Scholar] [CrossRef]

- Jeguirim, M.; Goddard, M.L.; Tamosiunas, A.; Berrich-Betouche, E.; Azzaz, A.A.; Praspaliauskas, M.; Jellali, S. Olive mill wastewater: From a pollutant to green fuels, agricultural water source and bio-fertilizer. Biofuel production. Renew. Energy 2020, 149, 716–724. [Google Scholar] [CrossRef]

- Igalavithana, A.D.; Choi, S.W.; Dissanayake, P.D.; Shang, J.; Wang, C.H.; Yang, X.; Kim, S.; Tsang, D.C.W.; Lee, K.B.; Ok, Y.S. Gasification biochar from biowaste (food waste and wood waste) for effective CO2 adsorption. J. Hazard. Mater. 2020, 391, 121147. [Google Scholar] [CrossRef] [PubMed]

- Yoo, S.; Kelley, S.S.; Tilotta, D.C.; Park, S. Structural Characterization of Loblolly Pine Derived Biochar by X-ray Diffraction and Electron Energy Loss Spectroscopy. ACS Sustain. Chem. Eng. 2018, 6, 2621–2629. [Google Scholar] [CrossRef]

- Guo, S.; Dong, X.; Wu, T.; Shi, F.; Zhu, C. Characteristic evolution of hydrochar from hydrothermal carbonization of corn stalk. J. Anal. Appl. Pyrolysis 2015, 116, 1–9. [Google Scholar] [CrossRef]

- Sevilla, M.; Fuertes, A.B. The production of carbon materials by hydrothermal carbonization of cellulose. Carbon N. Y. 2009, 47, 2281–2289. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Z.; Zhang, L.; Li, Q.; Li, C.; Chen, G.; Zhang, S.; Liu, Q.; Hu, X. Evolution of the functionalities and structures of biochar in pyrolysis of poplar in a wide temperature range. Bioresour. Technol. 2020, 304, 123002. [Google Scholar] [CrossRef] [PubMed]

- Chouchene, A.; Jeguirim, M.; Trouvé, G.; Favre-Reguillon, A.; Le Buzit, G. Combined process for the treatment of olive oil mill wastewater: Absorption on sawdust and combustion of the impregnated sawdust. Bioresour. Technol. 2010, 101, 6962–6971. [Google Scholar] [CrossRef] [PubMed]

- Saha, N.; Saba, A.; Reza, M.T. Effect of hydrothermal carbonization temperature on pH, dissociation constants, and acidic functional groups on hydrochar from cellulose and wood. J. Anal. Appl. Pyrolysis 2019, 137, 138–145. [Google Scholar] [CrossRef]

- Haddad, K.; Jeguirim, M.; Jellali, S.; Guizani, C.; Delmotte, L.; Bennici, S.; Limousy, L. Combined NMR structural characterization and thermogravimetric analyses for the assessment of the AAEM effect during lignocellulosic biomass pyrolysis. Energy 2017, 134, 10–23. [Google Scholar] [CrossRef]

| C (%) | H (%) | O (%) | N (%) | S (%) | |

|---|---|---|---|---|---|

| IROP | 44.76 | 5.83 | 44.04 | 1.97 | 0.18 |

| 180-IROP | 57.34 | 5.80 | 34.94 | 0.70 | 0.10 |

| 200-IROP | 61.73 | 5.89 | 28.68 | 0.99 | 0.16 |

| 220-IROP | 66.15 | 6.11 | 23.75 | 1.45 | 0.09 |

| 400-IROP | 92.47 | 2.12 | 1.84 | 0.94 | 0.08 |

| 500-IROP | 90.90 | 1.08 | 2.47 | 0.75 | 0.12 |

| 600-IROP | 90.33 | 0.6 | 3.18 | 0.40 | 0.13 |

| Potassium (g/kg) | Sodium (g/kg) | Calcium (g/kg) | Magnesium (g/kg) | Phosphorus (g/kg) | Sum of Minerals (g/kg) | HHV (MJ/kg) | |

|---|---|---|---|---|---|---|---|

| IROP | 5.40 | 0.52 | 0.87 | 0.14 | 0.17 | 7.11 | 18.48 |

| 180-IROP | 0.75 | 0.07 | 0.82 | 0.05 | 0.01 | 1.71 | 19.40 |

| 200-IROP | 0.80 | 0.11 | 0.91 | 0.06 | 0.01 | 1.89 | 22.55 |

| 220-IROP | 1.15 | 0.13 | 0.99 | 0.12 | 0.01 | 2.42 | 28.75 |

| 400-IROP | 2.74 | 0.32 | 1.10 | 0.25 | 0.12 | 4.53 | 25.74 |

| 500-IROP | 3.08 | 0.50 | 1.21 | 0.31 | 0.14 | 5.24 | 27.19 |

| 600-IROP | 3.10 | 0.39 | 1.39 | 0.30 | 0.16 | 5.34 | 29.78 |

| Functional Groups (µmol/g) | Final Solution pH | pHzpc | |||||

|---|---|---|---|---|---|---|---|

| Sample | Carboxylic | Lactonic | Phenolic | Basic | Total | ||

| IROP | 611.62 | 35.47 | 638.48 | 1347.85 | 2633.42 | -- | 5.24 |

| 180-IROP | 360.89 | 9.44 | 493.62 | U.D. | 863.95 | 3.96 | 4.16 |

| 200-IROP | 457.48 | 74.68 | 555.96 | U.D. | 1088.12 | 4.13 | 3.84 |

| 220-IROP | 523.05 | 294 | 438.01 | U.D. | 1255.06 | 4.08 | 3.28 |

| 400-IROP | 65.22 | 24.22 | 71.94 | 76.10 | 237.48 | -- | 8.47 |

| 500-IROP | 26.84 | 8.45 | 99.41 | 134.74 | 269.44 | -- | 9.15 |

| 600-IROP | 12.45 | U.D. | 126.18 | 158.15 | 296.78 | -- | 9.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azzaz, A.A.; Matei Ghimbeu, C.; Jellai, S.; El-Bassi, L.; Jeguirim, M. Olive Mill by-Products Thermochemical Conversion via Hydrothermal Carbonization and Slow Pyrolysis: Detailed Comparison between the Generated Hydrochars and Biochars Characteristics. Processes 2022, 10, 231. https://doi.org/10.3390/pr10020231

Azzaz AA, Matei Ghimbeu C, Jellai S, El-Bassi L, Jeguirim M. Olive Mill by-Products Thermochemical Conversion via Hydrothermal Carbonization and Slow Pyrolysis: Detailed Comparison between the Generated Hydrochars and Biochars Characteristics. Processes. 2022; 10(2):231. https://doi.org/10.3390/pr10020231

Chicago/Turabian StyleAzzaz, Ahmed Amine, Camélia Matei Ghimbeu, Salah Jellai, Leila El-Bassi, and Mejdi Jeguirim. 2022. "Olive Mill by-Products Thermochemical Conversion via Hydrothermal Carbonization and Slow Pyrolysis: Detailed Comparison between the Generated Hydrochars and Biochars Characteristics" Processes 10, no. 2: 231. https://doi.org/10.3390/pr10020231

APA StyleAzzaz, A. A., Matei Ghimbeu, C., Jellai, S., El-Bassi, L., & Jeguirim, M. (2022). Olive Mill by-Products Thermochemical Conversion via Hydrothermal Carbonization and Slow Pyrolysis: Detailed Comparison between the Generated Hydrochars and Biochars Characteristics. Processes, 10(2), 231. https://doi.org/10.3390/pr10020231