Analysis of Laser Cutting Process for Different Diagonal Material Shapes

Abstract

1. Introduction

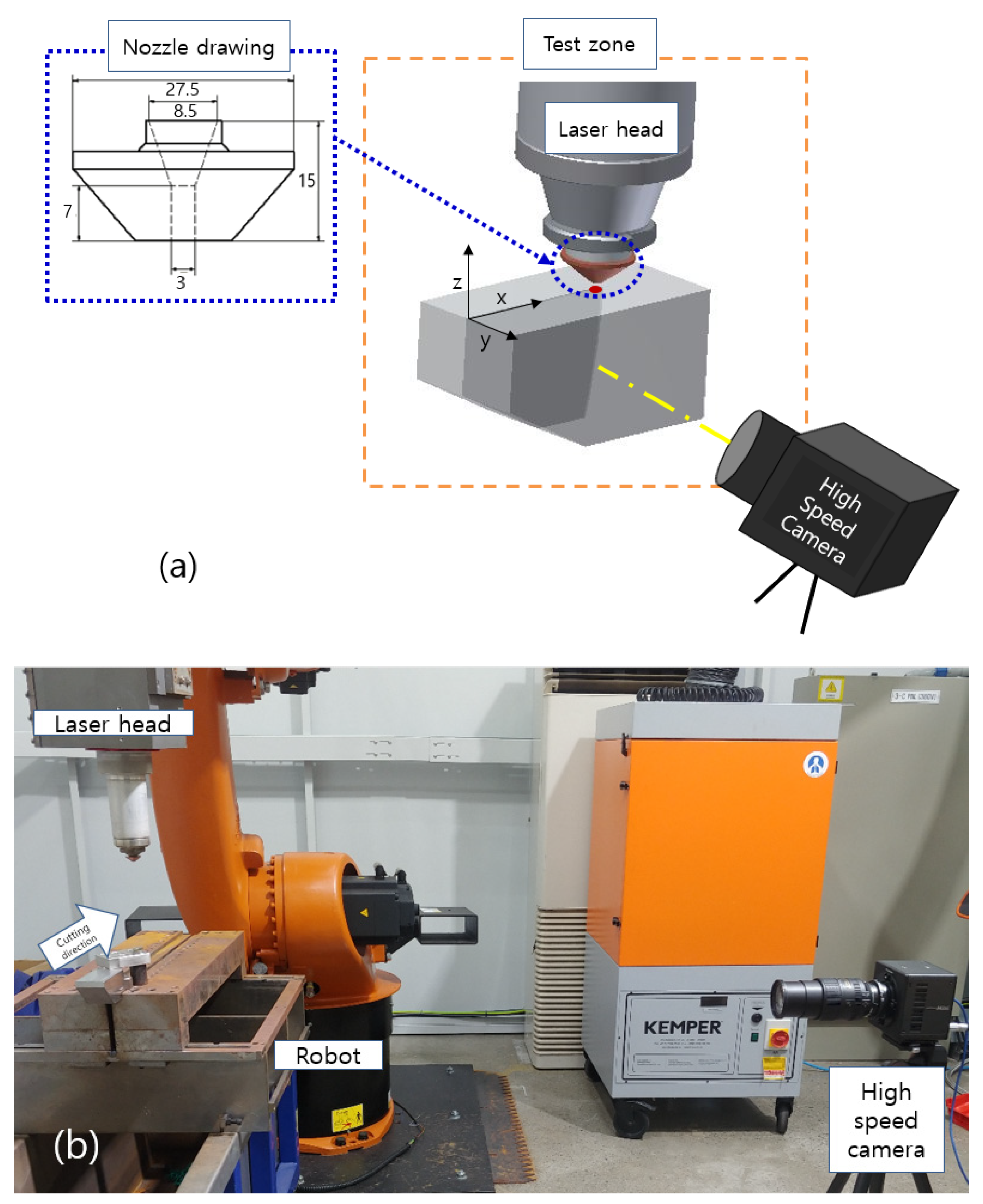

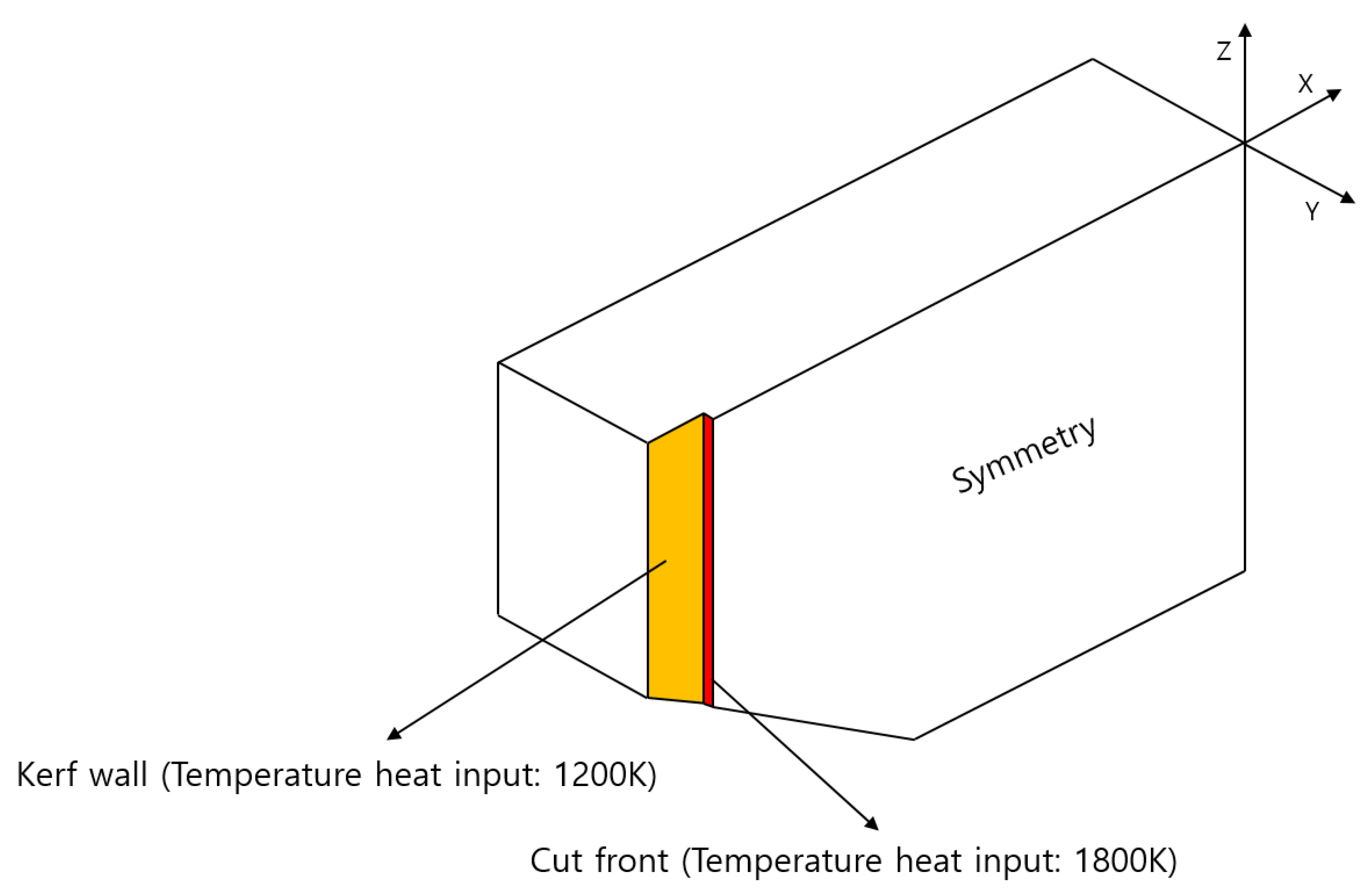

2. Experimental Procedure

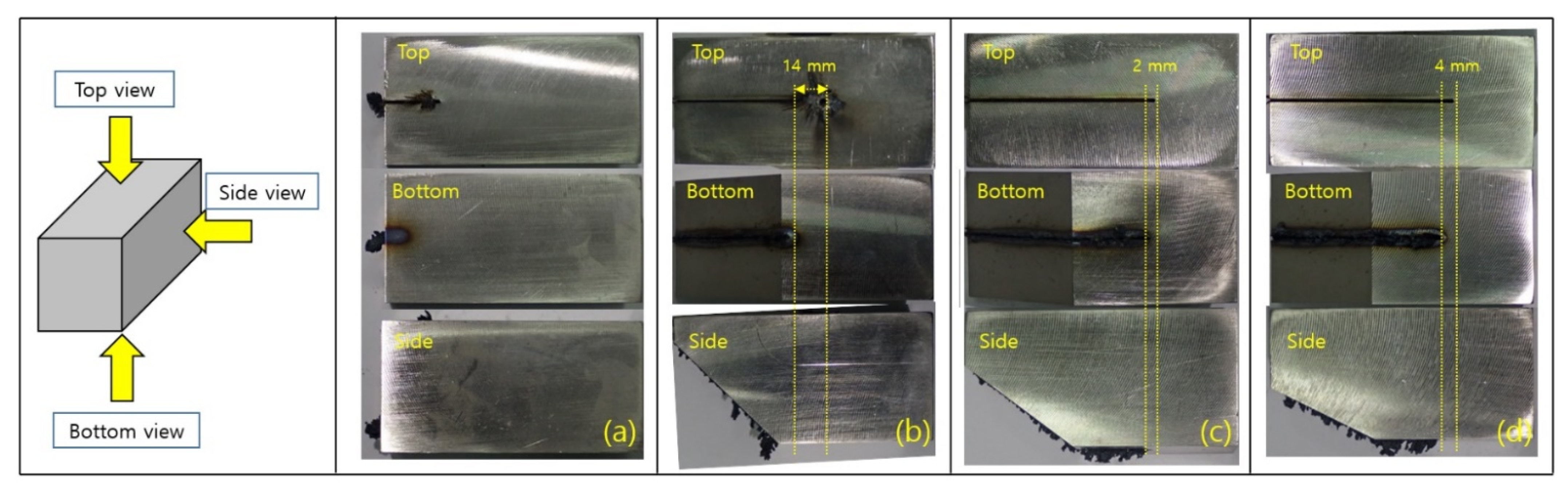

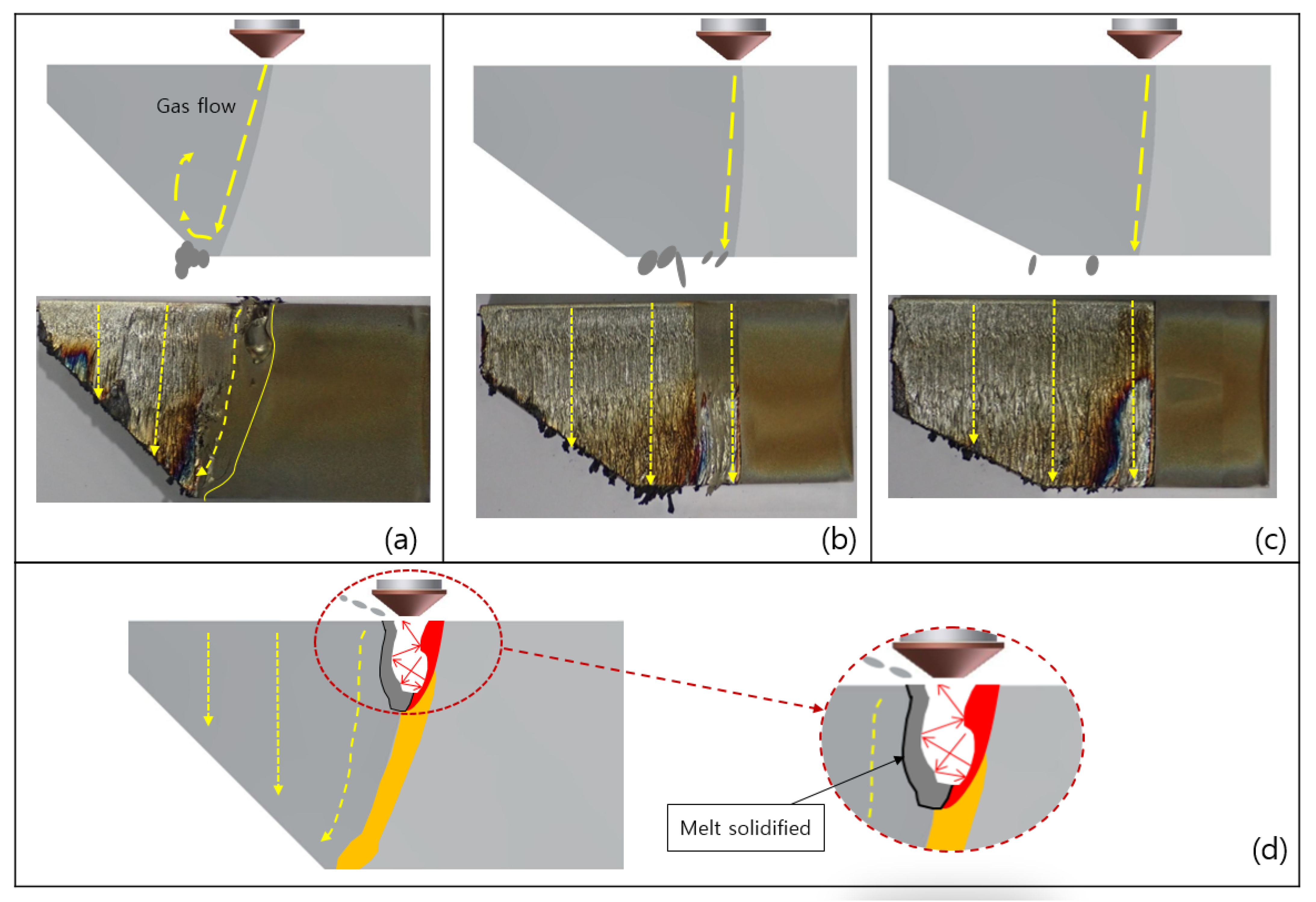

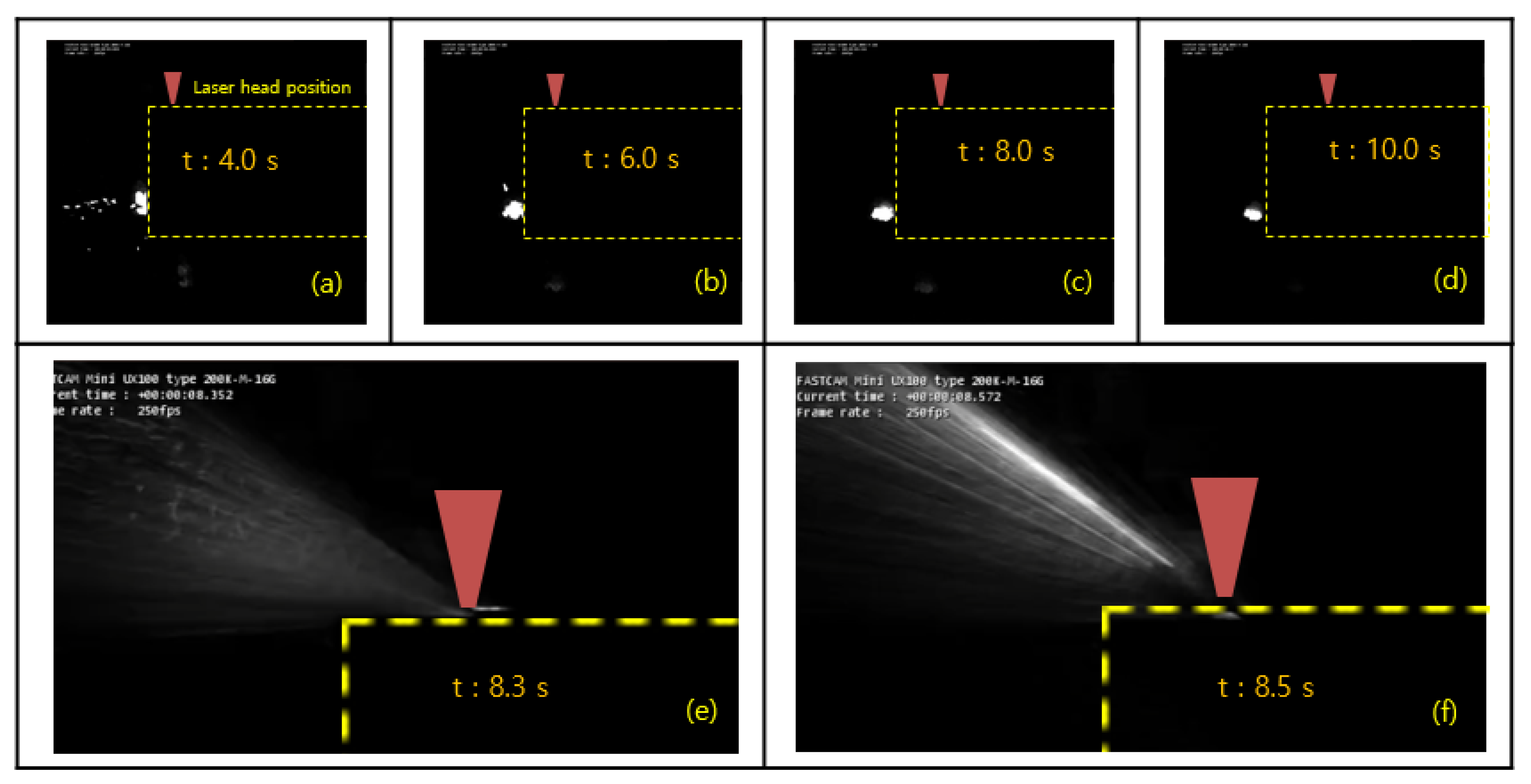

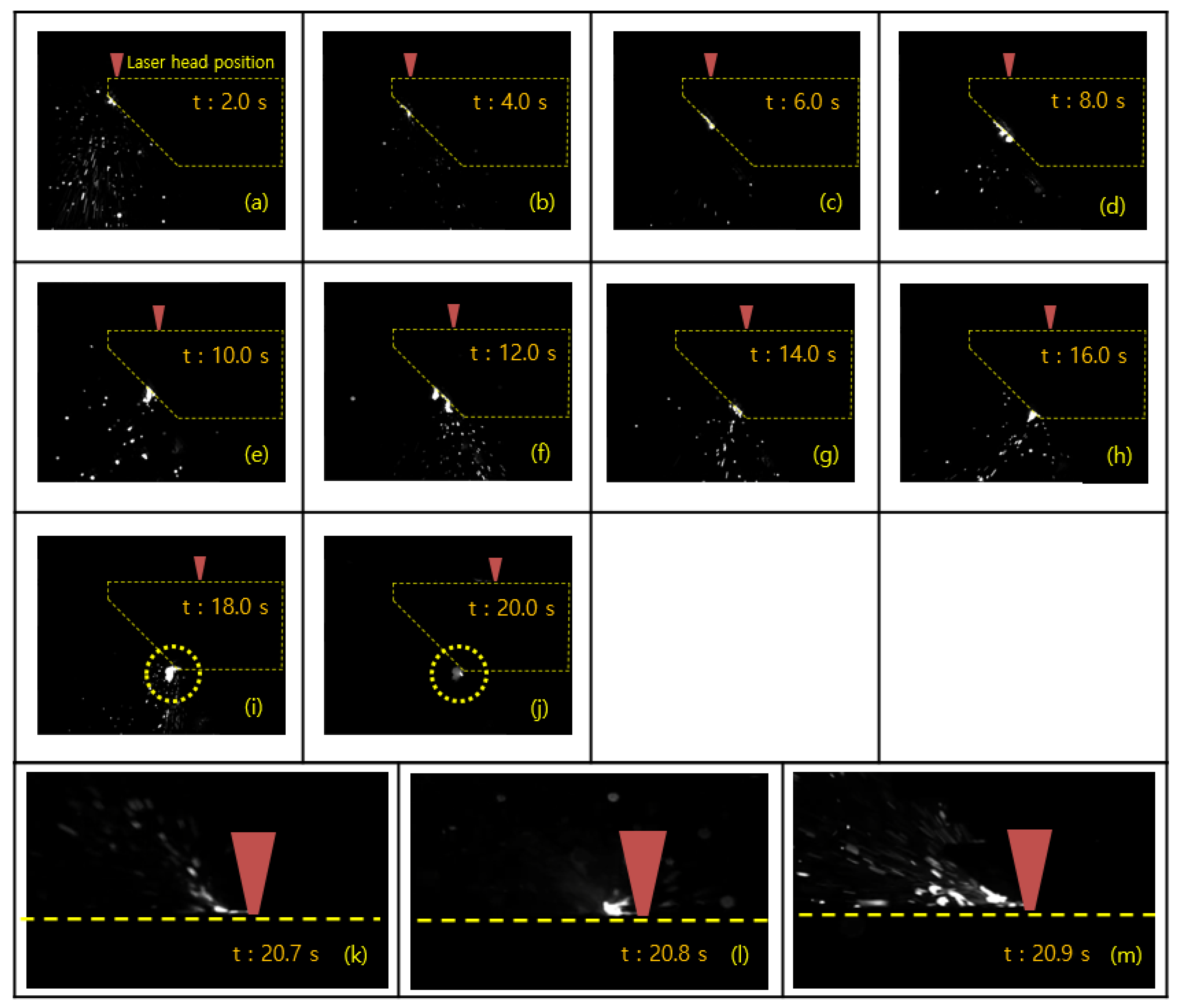

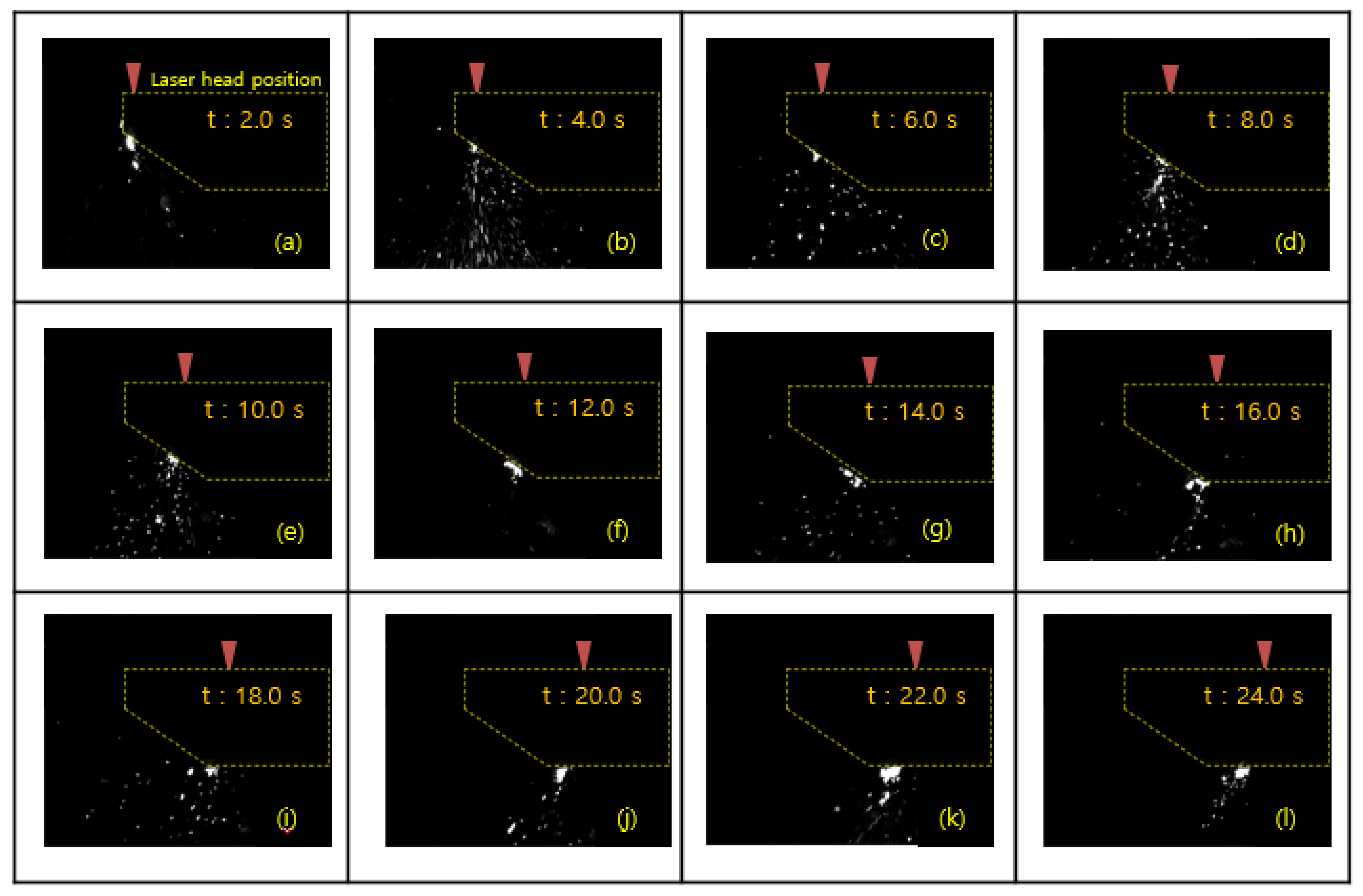

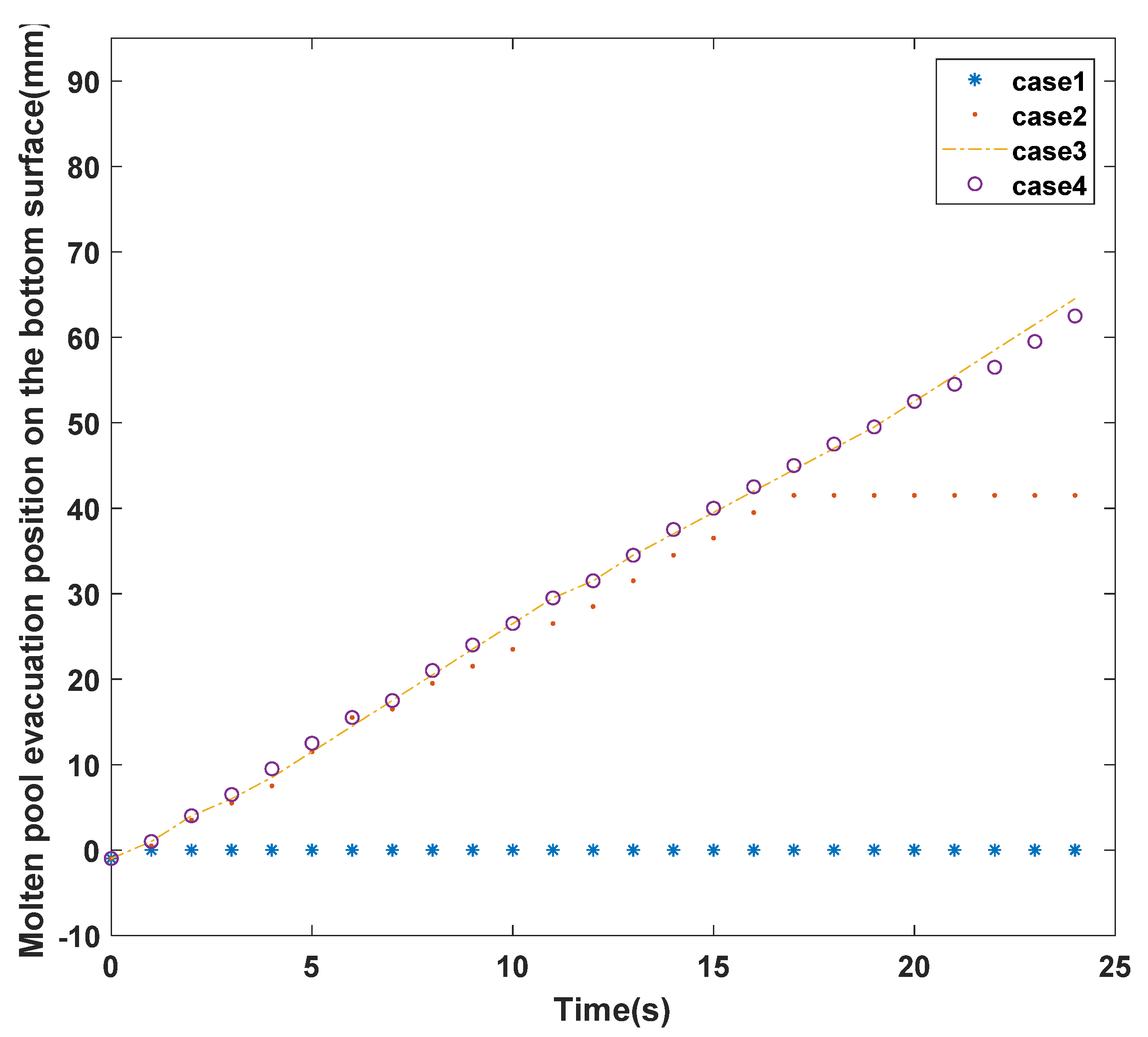

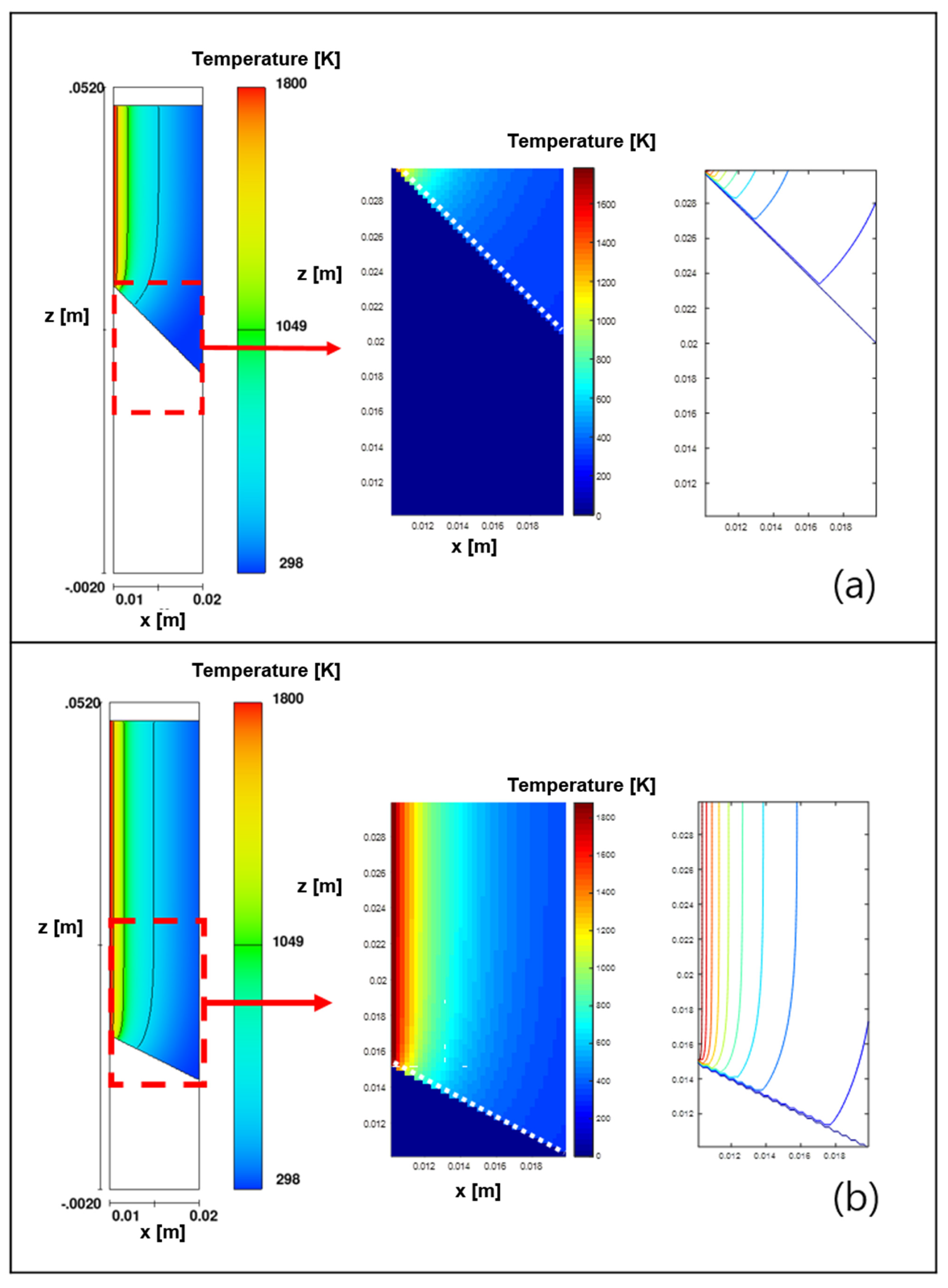

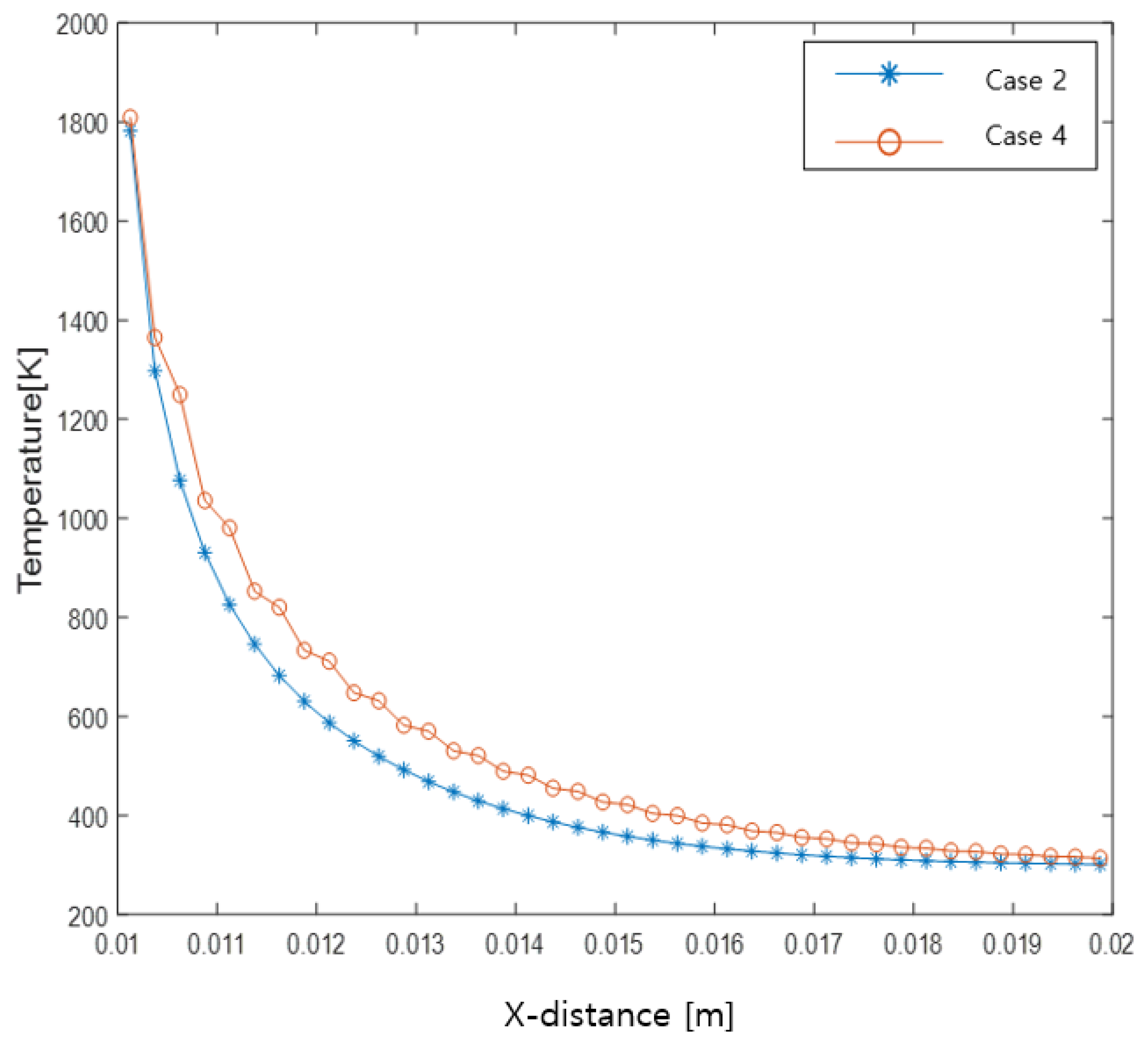

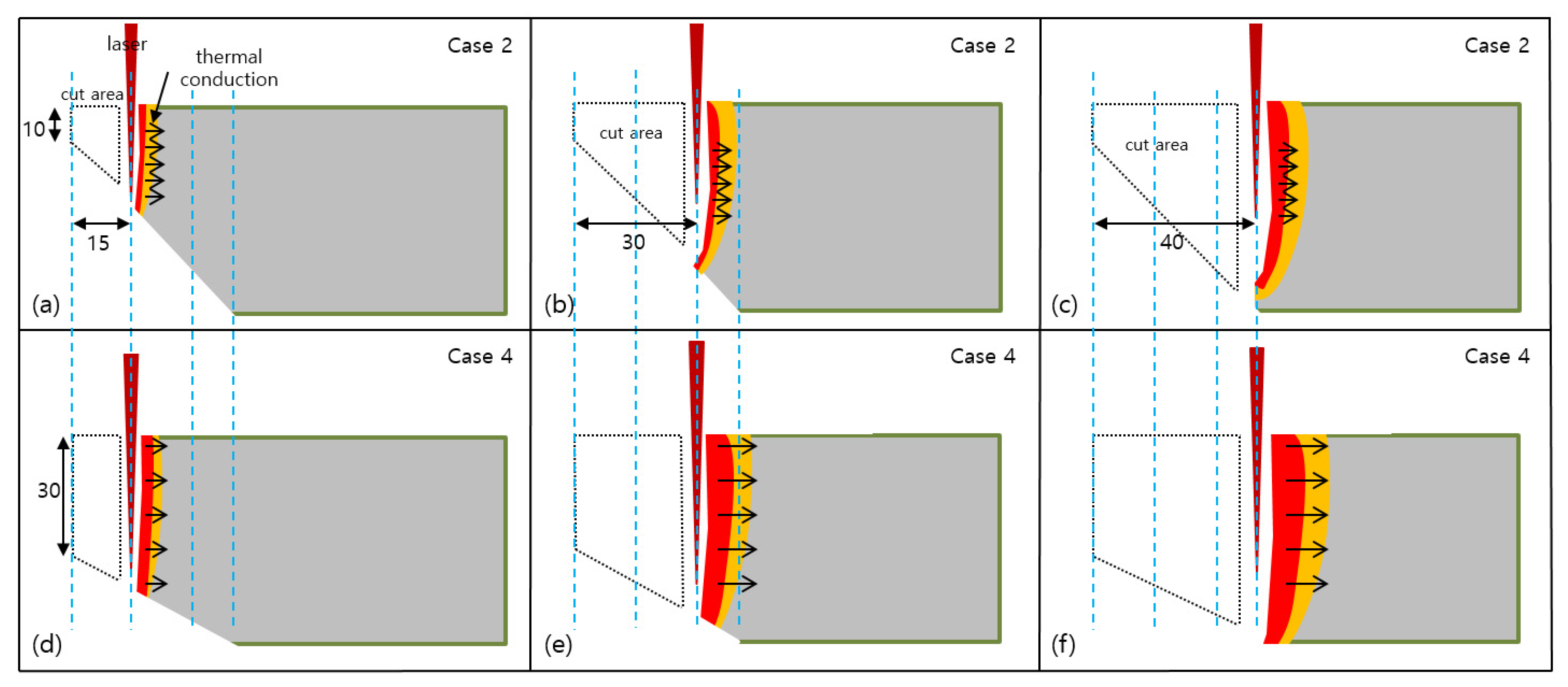

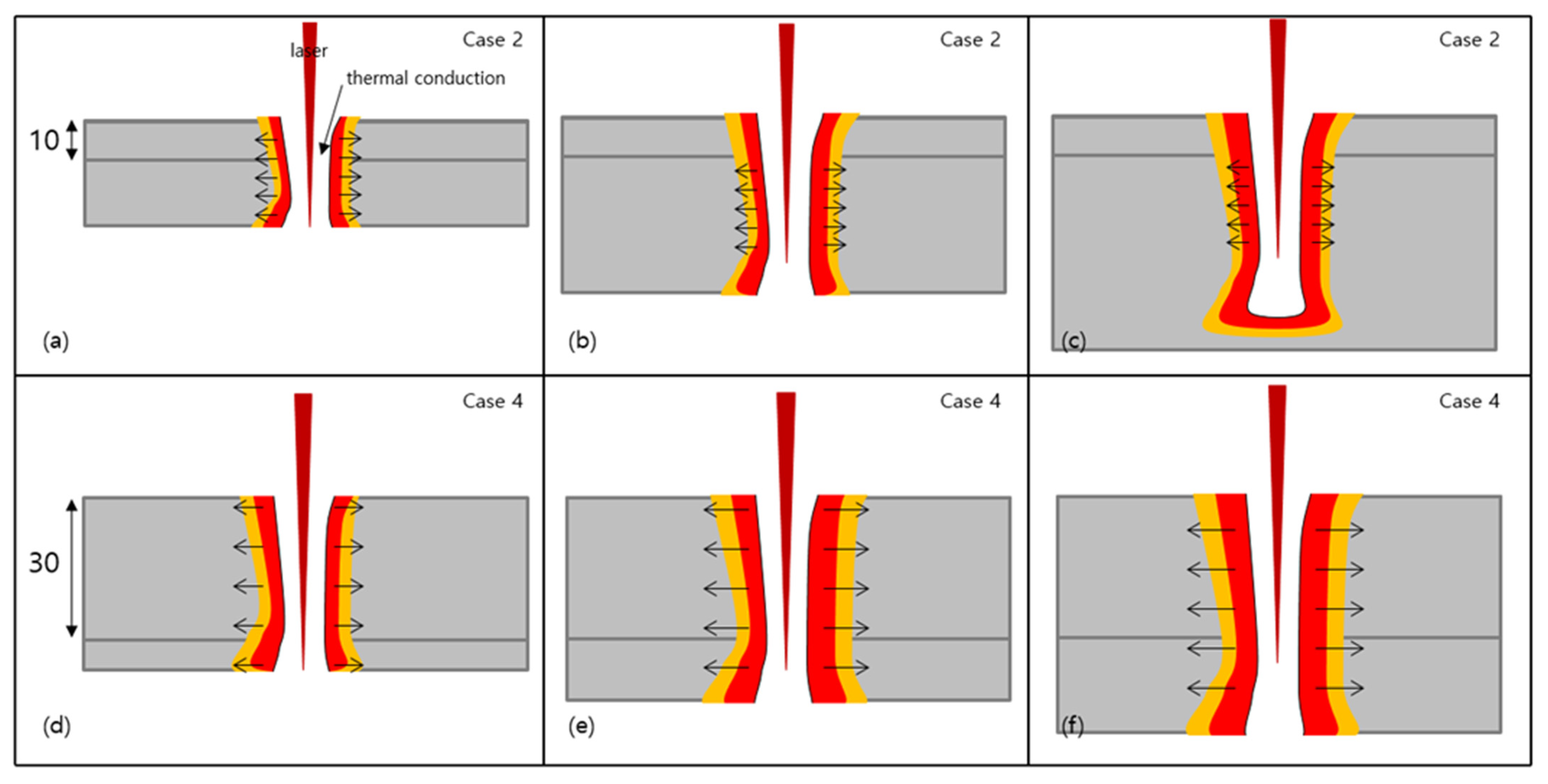

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lind, J.; Fetzer, F.; Blazquez-Sanchez, D.; Weidensdörfer, J.; Weber, R.; Graf, T. Geometry and absorptance of the cutting fronts during laser beam cutting. Laser Applications. 2020, 32, 032015. [Google Scholar] [CrossRef]

- Haddadi, E.; Moradi, M.; Karimzad Ghavidel, A.; Karimzad Ghavidel, A.; Meiabadi, S. Experimental and parametric evaluation of cut quality characteristics in CO2 laser cutting of polystyrene. Optik 2019, 184, 103–114. [Google Scholar] [CrossRef]

- Chau, M.Q. An overview study on the laser technology and applications in the mechanical and machine manufacturing industry. JMERD 2019, 42, 16–20. [Google Scholar] [CrossRef]

- Riveiro, A.; Quintero, F.; Lusquiñosb, F.; Val, J.; Comesaña, R.; Boutinguiza, M.; Poub, J. Experimental study on the CO2 laser cutting of carbon fiber reinforced plastic composite. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1400–1409. [Google Scholar] [CrossRef]

- Tamura, K.; Ishigami, R.; Yamagishi, R. Laser cutting of thick steel plates and simulated steel components using a 30-kW fiber laser. J. Nucl. Sci. Technol. 2016, 53, 916–920. [Google Scholar] [CrossRef]

- Naresh; Khatak, P. Laser cutting technique: A literature review. Materials Today. 2022, 56, 2484–2489. [Google Scholar] [CrossRef]

- Seo, Y.; Pyo, S.; Lee, D. Experimental investigation of laser cutting on cement composites. Welding and Joining. 2019, 37, 226–230. [Google Scholar] [CrossRef]

- Li, M.; Li, S.; Yang, X.; Zhang, Y.; Liang, Z. Fiber laser cutting of CFRP laminates with single- and multi-pass strategy: A feasibility study. Opt. Laser Technol. 2018, 107, 443–453. [Google Scholar] [CrossRef]

- Tzanakakis, E.-G.C.; Skoulas, E.; Pepelassi, E.; Koidis, P.; Tzoutzas, I.G. The use of lasers in dental materials: A review. Materials 2021, 14, 3370. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Yang, R.; Liu, T.; Yan, Y. Analysis of kerf quality on ultrafast laser cutting of anode material for lithium-ion battery. Opt. Lasers Eng. 2019, 118, 14–21. [Google Scholar] [CrossRef]

- Fushimi, T.; Kitazawa, M.; Endo, M.; Yamaguchi, S.; Nanri, K.; Fujioka, T. Parametric studies on improved laser cutting performance of magnesium alloy with two flow nozzles. Jpn. J. Appl. Phys. 2004, 43, 5347–5351. [Google Scholar] [CrossRef]

- Riveiro, A.; Quintero, F.; Boutinguiza, M.; Val, J.D.; Comesaña, R.; Lusquiños, F.; Pou, J. Laser cutting: A review on the influence of assist gas. Materials 2019, 12, 157. [Google Scholar] [CrossRef]

- Darwish, M.; Mrňa, L.; Orazi, L.; Reggiani, B. Numerical modeling and Schlieren visualization of the gas-assisted laser cutting under various operating stagnation pressures. Int. J. Heat Mass Transf. 2020, 147, 118965. [Google Scholar] [CrossRef]

- Orazi, L.; Darwish, M.; Reggiani, B. Investigation on the inert gas-assisted laser cutting performances and quality using supersonic nozzles. Metals 2021, 9, 1257. [Google Scholar] [CrossRef]

- Darwish, M.; Orazi, L.; Reggiani, B. Numerical analysis of the gas-assisted laser cutting flow from various supersonic nozzles. J. Manuf. Process. 2020, 56, 382–389. [Google Scholar] [CrossRef]

- Man, H.C.; Duan, J.; Yue, T.M. Analysis of the dynamic characteristics of gas flow inside a laser cut kerf under high cut-assist gas pressure. J. Phys. D 1999, 32, 1469–1477. [Google Scholar] [CrossRef]

- Tuladhar, U.; Ahn, S.-H.; Cho, D.-W.; Kim, D.-H.; Ahn, S.; Kim, S.; Bae, S.-H.; Park, T.-K. Analysis of gas flow dynamics in thermal cut kerf using a numerical and experimental approach for nozzle selection. Processes 2022, 10, 1951. [Google Scholar] [CrossRef]

- Christophe, J.; Planquart, P. Diagnostics for laser cutting efficiency using computational fluid dynamics. Procedia Manuf. 2019, 29, 375–382. [Google Scholar] [CrossRef]

- Kovalev, O.B.; Yudin, P.V.; Zaitsev, A.V. Modeling of flow separation of assist gas as applied to laser cutting of thick sheet metal. Appl. Math. Model. 2009, 33, 3730–3745. [Google Scholar] [CrossRef]

- Madić, M.; Petrović, G.; Petković, D.; Antucheviciene, J.; Marinković, D. Application of a Robust Decision-Making Rule for Comprehensive Assessment of Laser Cutting Conditions and Performance. Machines 2022, 10, 153. [Google Scholar] [CrossRef]

- Tuladhar, U.; Ahn, S.-H.; Cho, D.-W.; Kim, D.-H.; Ahn, S.; Kim, S.; Bae, S.-H.; Park, T.-K. Numerical modeling of an impinging jet flow inside a thermal cut kerf using CFD and schlieren method. Appl. Sci. 2022, 12, 9557. [Google Scholar] [CrossRef]

- Cho, D.-W.; Choi, J.; Lee, S.; Shin, D. Analysis of gas flow behavior in the laser cutting process using the schlieren method and image processing. J. Weld. Join. 2020, 38, 569–575. [Google Scholar] [CrossRef]

- Kim, D.; Cho, D.; Jo, Y.; Suh, J.; Choi, K.; Kim, R.; Ahn, S. Characteristic Analysis of Double Arcing on the Top Surface of STS304 in Plasma Arc Piercing. J. Weld. Join. 2021, 39, 427–434. [Google Scholar] [CrossRef]

- Sim, A.; Chun, E.; Cho, D.; Chun, E.-J.; Cho, D.-W. Numerical Simulation of Surface Softening Behavior for Laser Heat Treated Cu-Bearing Medium Carbon Steel. Met. Mater. Int. 2020, 26, 1207–1217. [Google Scholar] [CrossRef]

- Kong, F.; Santhanakrishnan, S.; Lin, D.; Kovacevic, R. Modeling of temperature field and grain growth of a dual phase steel DP980 in direct diode laser heat treatment. J. Mater. Process. Technol. 2009, 209, 5596–6003. [Google Scholar] [CrossRef]

| Fe | C | Si | Mn | P | S | Cr | Ni | Mo | N | Co | Cu | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| composition | 71.636 | 0.016 | 0.37 | 1.50 | 0.021 | 0.003 | 18.24 | 8.12 | 0.01 | 0.044 | 0.03 | 0.01 |

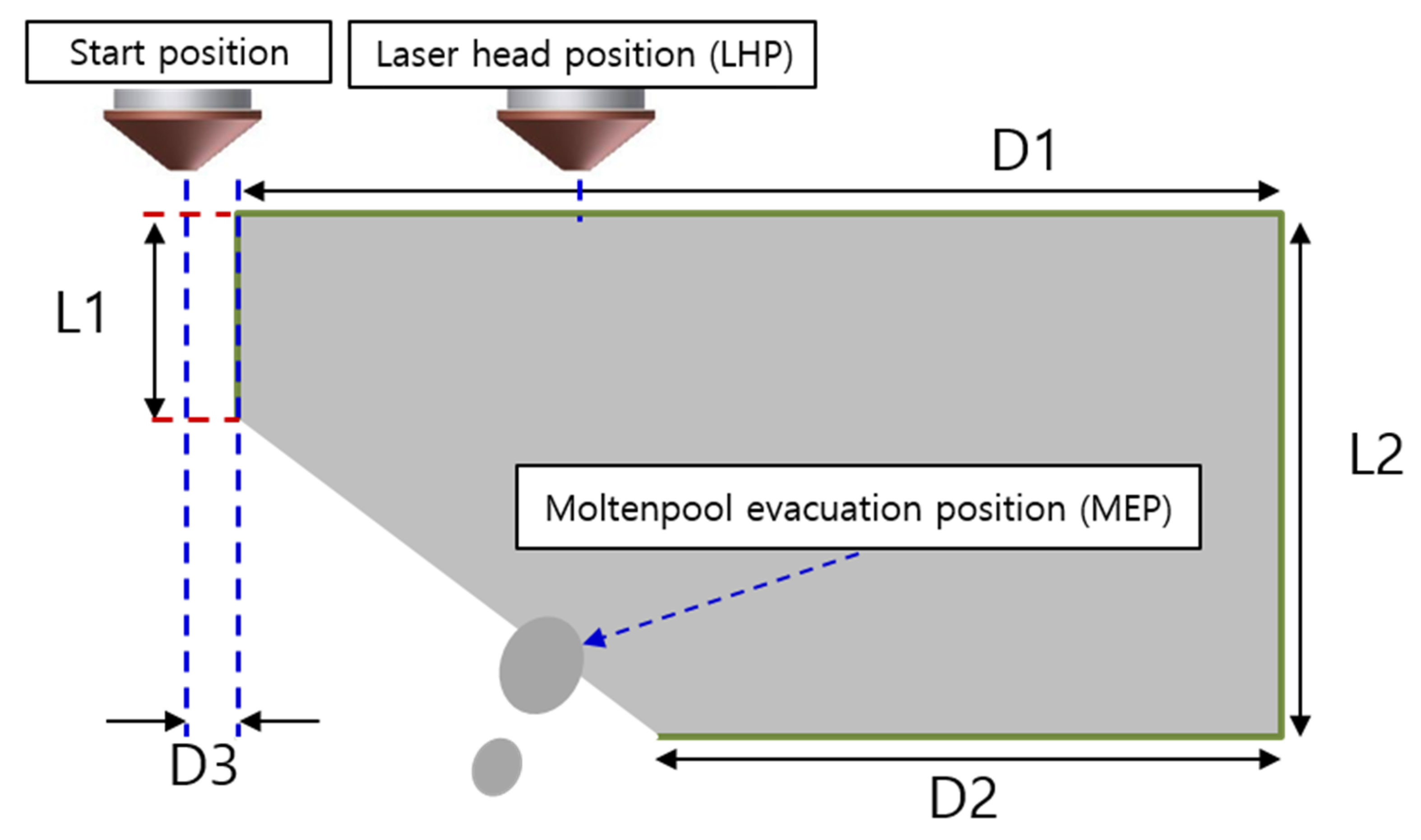

| Case | L1 (mm) | L2 (mm) | D1 (mm) | D2 (mm) | D3 (mm) | Cutting Speed (mm/s) |

|---|---|---|---|---|---|---|

| Case1 | 50 | 50 | 100 | 100 | 1 | 2.3 |

| Case2 | 10 | 50 | 100 | 60 | 1 | 2.9 |

| Case3 | 20 | 50 | 100 | 60 | 1 | 2.9 |

| Case4 | 30 | 50 | 100 | 60 | 1 | 2.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.; Kim, R.; Song, D.; Cho, D.-W.; Suh, J.; Kim, S.; Ahn, S.-H. Analysis of Laser Cutting Process for Different Diagonal Material Shapes. Processes 2022, 10, 2743. https://doi.org/10.3390/pr10122743

Choi J, Kim R, Song D, Cho D-W, Suh J, Kim S, Ahn S-H. Analysis of Laser Cutting Process for Different Diagonal Material Shapes. Processes. 2022; 10(12):2743. https://doi.org/10.3390/pr10122743

Chicago/Turabian StyleChoi, Jungsoo, Ryoonhan Kim, Danbi Song, Dae-Won Cho, Jeong Suh, Seonmin Kim, and Sang-Hyun Ahn. 2022. "Analysis of Laser Cutting Process for Different Diagonal Material Shapes" Processes 10, no. 12: 2743. https://doi.org/10.3390/pr10122743

APA StyleChoi, J., Kim, R., Song, D., Cho, D.-W., Suh, J., Kim, S., & Ahn, S.-H. (2022). Analysis of Laser Cutting Process for Different Diagonal Material Shapes. Processes, 10(12), 2743. https://doi.org/10.3390/pr10122743