Effect of Acidic Hydrochar on Plastic Crude Oil Produced from Hydrothermal Liquefaction of Waste PVC

Abstract

1. Introduction

2. Material and Methods

2.1. Material

2.2. Hydrothermal Liquefaction Process

2.3. Characterization of Plastic Crude Oils

3. Results and Discussion

3.1. HTL Conversion of Waste Polyvinyl Chloride

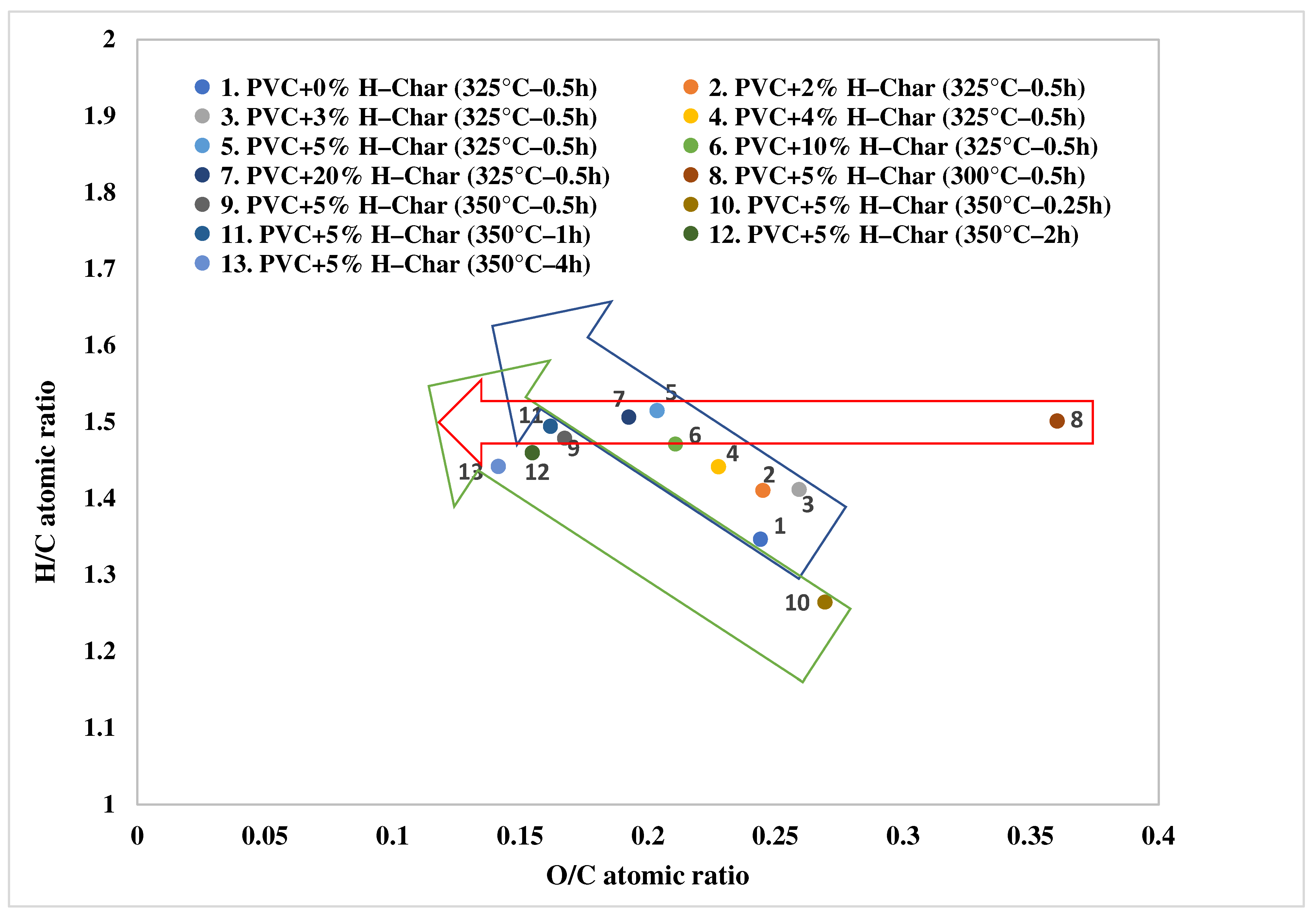

3.2. Elemental Compositional Analysis of HTL Crude Oils

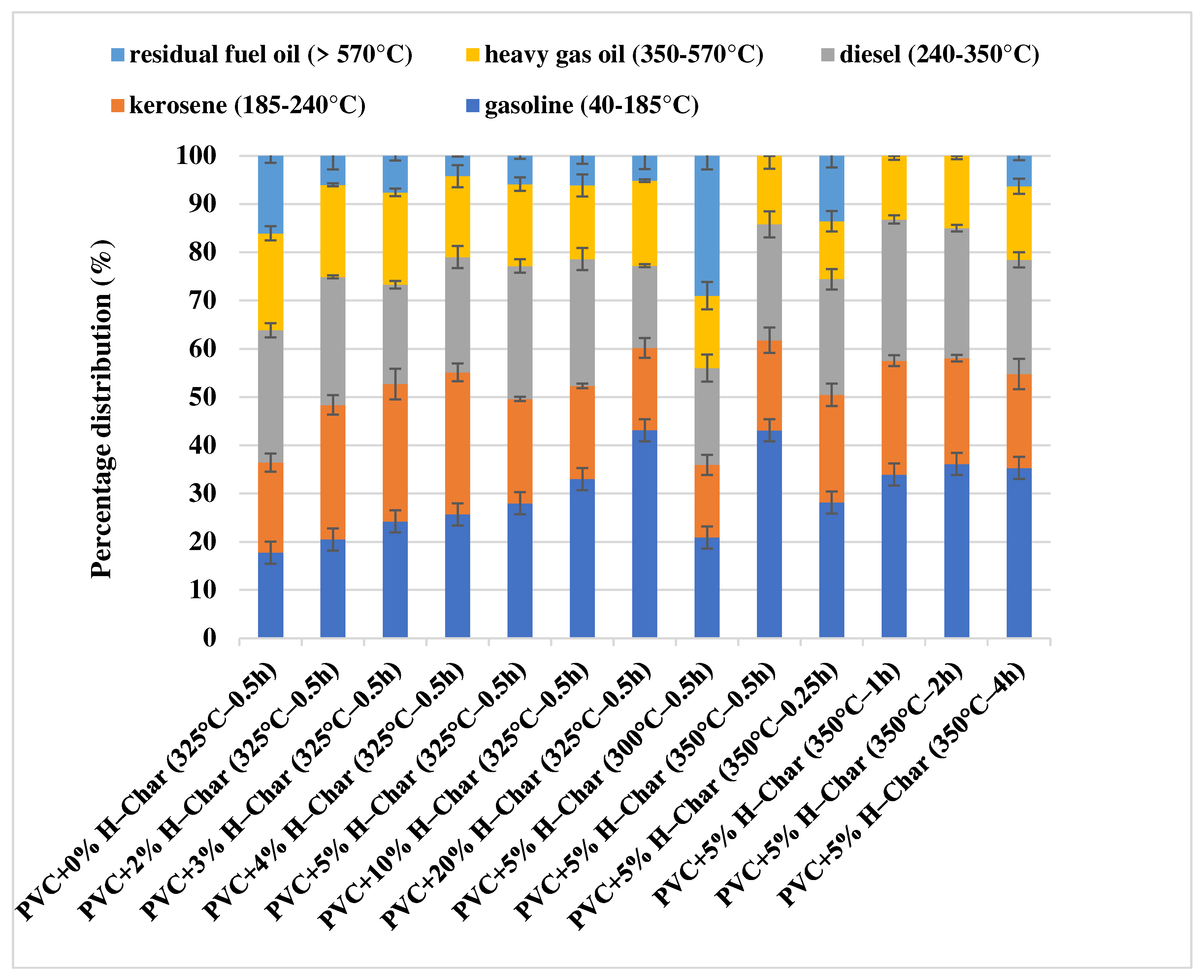

3.3. Boiling Point Distribution of HTL Crude Oils

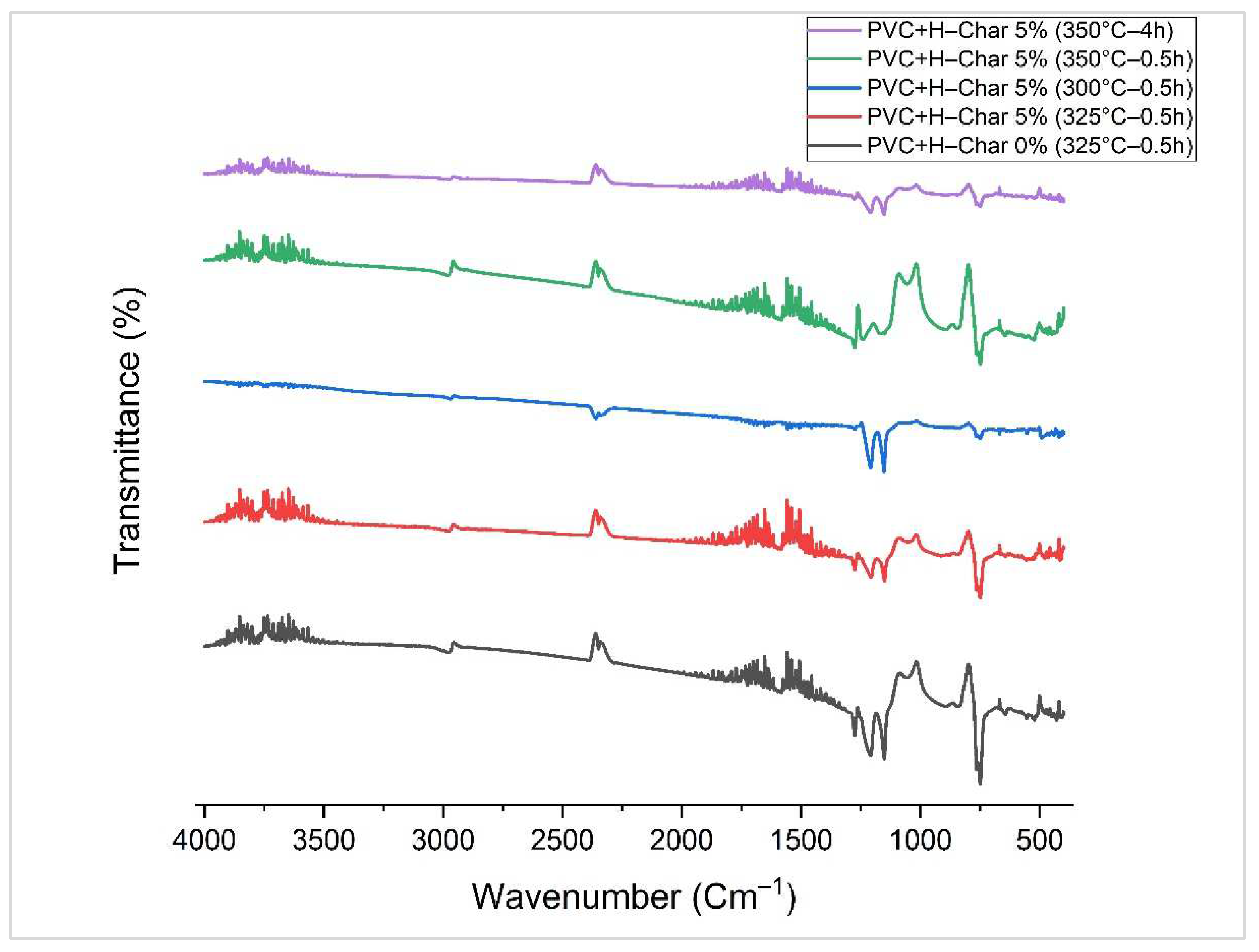

3.4. FTIR Analysis of HTL Crude Oils

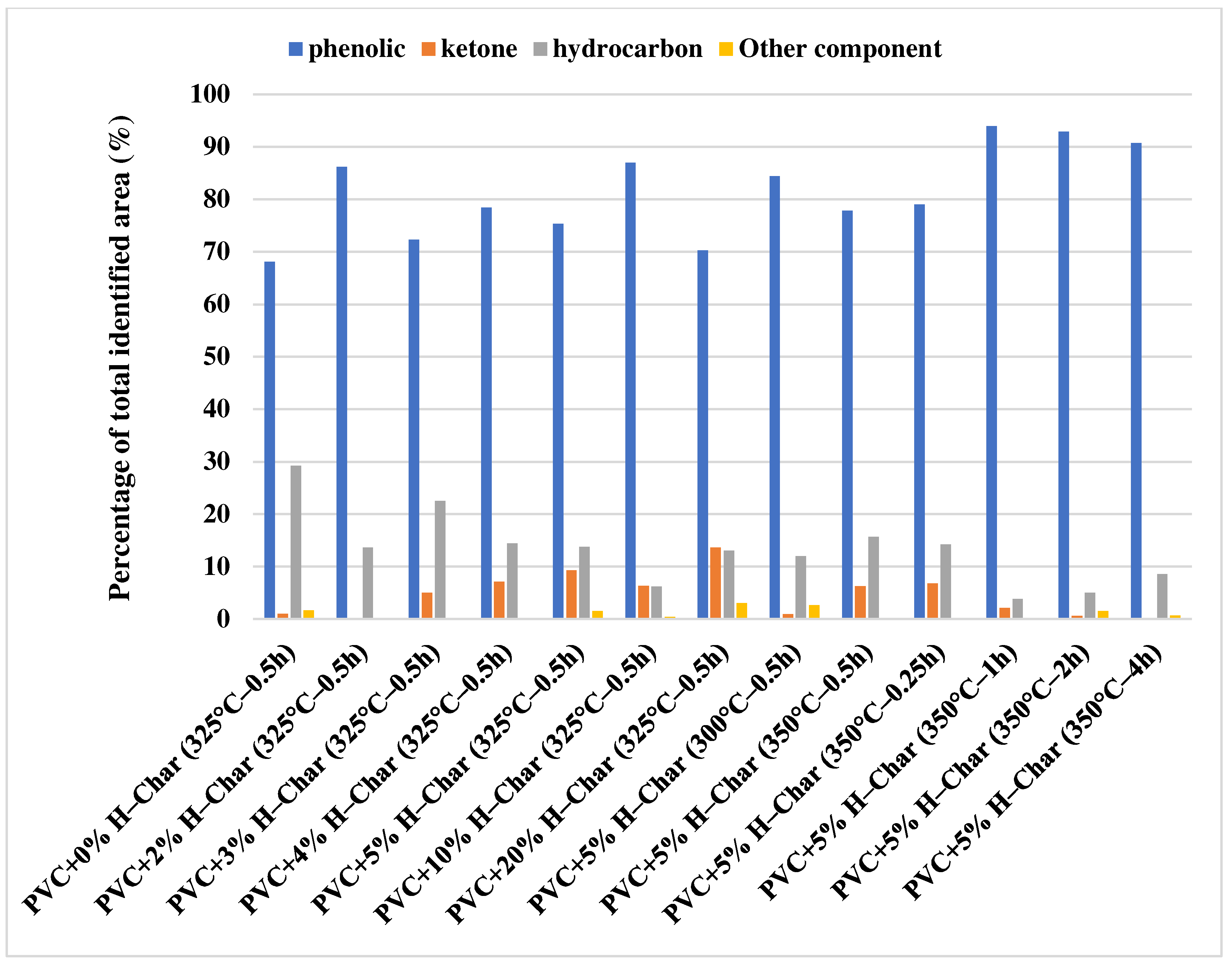

3.5. Chemical Composition of HTL Crude Oils

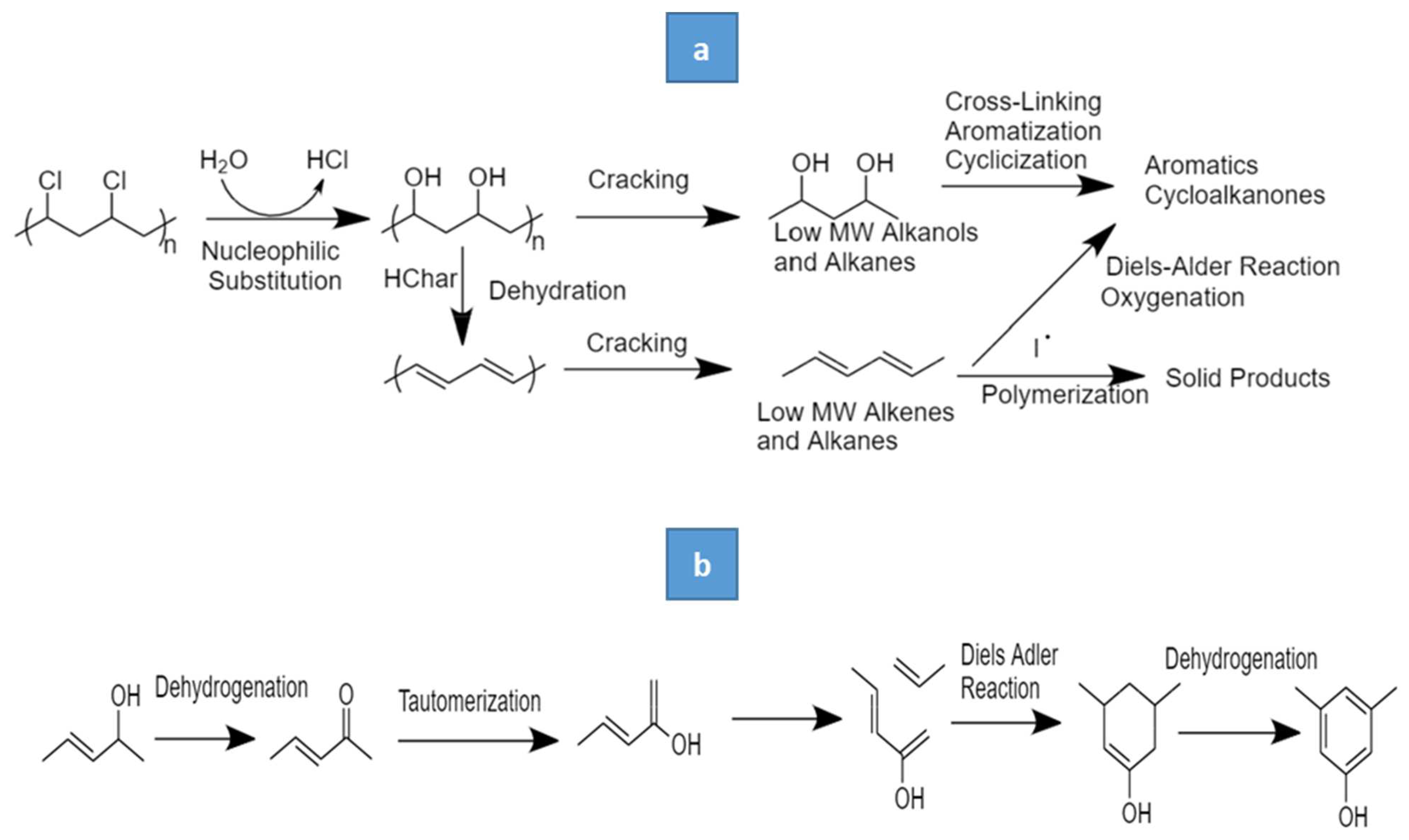

3.6. Proposed HTL Reaction Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jin, H.; Bai, B.; Wei, W.; Chen, Y.; Ge, Z.; Shi, J. Hydrothermal Liquefaction of Polycarbonate (PC) Plastics in Sub-/Supercritical Water and Reaction Pathway Exploration. ACS Sustain. Chem. Eng. 2020, 8, 7039–7050. [Google Scholar] [CrossRef]

- Li, S.; Jiang, C.; Liu, J.; Tao, H.; Meng, X.; Connor, P.; Hui, J.; Wang, S.; Ma, J.; Irvine, J.T. Mechanism of enhanced performance on a hybrid direct carbon fuel cell using sawdust biofuels. J. Power Sources 2018, 383, 10–16. [Google Scholar] [CrossRef]

- Cheng, C.; Zong, S.; Shi, J.; Xue, F.; Zhang, Y.; Guan, X.; Zheng, B.; Deng, J.; Guo, L. Facile preparation of nanosized MoP as cocatalyst coupled with g-C3N4 by surface bonding state for enhanced photocatalytic hydrogen production. Appl. Catal. B Environ. 2020, 265, 118620. [Google Scholar] [CrossRef]

- Ghalandari, V.; Banivaheb, S.; Peterson, J.; Smith, H.; Reza, M.T. Solvothermal liquefaction of waste polyurethane using supercritical toluene in presence of noble metal catalysts. AIChE J. 2022, 68, e17863. [Google Scholar] [CrossRef]

- Vuleta, B. 51+ Plastic Waste Statistics. SeedScientific. Available online: https://seedscientific.com/plastic-waste-statistics/ (accessed on 31 March 2022).

- Miliute-Plepiene, J.; Fråne, A.; Almasi, A.M. Overview of polyvinyl chloride (PVC) waste management practices in the Nordic countries. Clean. Eng. Technol. 2021, 4, 100246. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, J.; Wang, G.; Wang, H.; Sun, M. Thermal and Kinetic Analysis of Coal with Different Waste Plastics (PVC) in Cocombustion. Energy Fuels 2018, 32, 2145–2155. [Google Scholar] [CrossRef]

- Yuan, G.; Chen, D.; Yin, L.; Wang, Z.; Zhao, L.; Wang, J.Y. High efficiency chlorine removal from polyvinyl chloride (PVC) pyrolysis with a gas–liquid fluidized bed reactor. Waste Manag. 2014, 34, 1045–1050. [Google Scholar] [CrossRef]

- Zhou, N.; Levine, M.D.; Price, L. Overview of current energy-efficiency policies in China. Energy Policy 2010, 38, 6439–6452. [Google Scholar] [CrossRef]

- Yu, J.; Sun, L.; Ma, C.; Qiao, Y.; Yao, H. Thermal degradation of PVC: A review. Waste Manag. 2016, 48, 300–314. [Google Scholar] [CrossRef]

- Li, T.; Shen, S.; Cai, B.; Wang, Y.; Peng, X.; Li, Y. High-performance carbon-based solid acid prepared by environmental and efficient recycling of PVC waste for cellulose hydrolysis. RSC Adv. 2016, 6, 91921–91929. [Google Scholar] [CrossRef]

- Banivaheb, S.; Ghalandari, V.; Smith, H.; Reza, M.T. SolvX: Solvothermal conversion of mixed waste plastics in supercritical toluene in presence of Pd/C catalyst. J. Environ. Chem. Eng. 2022, 10, 108622. [Google Scholar] [CrossRef]

- Li, N.; Liu, H.; Cheng, Z.; Yan, B.; Chen, G.; Wang, S. Conversion of plastic waste into fuels: A critical review. J. Hazard. Mater. 2022, 424, 127460. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Jin, H.; Chen, Y.; Ge, Z. Numerical study of H2, CH4, CO, O2 and CO2 diffusion in water near the critical point with molecular dynamics simulation. Comput. Math. Appl. 2021, 81, 759–771. [Google Scholar] [CrossRef]

- Wu, Z.; Ren, Y.; Ou, G.; Jin, H. Influence of special water properties variation on the heat transfer of supercritical water flow around a sphere. Chem. Eng. Sci. 2020, 222, 115698. [Google Scholar] [CrossRef]

- Kruse, A.; Dahmen, N. Water–A magic solvent for biomass conversion. J. Supercrit. Fluids 2015, 96, 36–45. [Google Scholar] [CrossRef]

- Bai, B.; Liu, Y.; Wang, Q.; Zou, J.; Zhang, H.; Jin, H.; Li, X. Experimental investigation on gasification characteristics of plastic wastes in supercritical water. Renew Energy 2019, 135, 32–40. [Google Scholar] [CrossRef]

- Helmer Pedersen, T.; Conti, F. Improving the circular economy via hydrothermal processing of high-density waste plastics. Waste Manag. 2017, 68, 24–31. [Google Scholar] [CrossRef]

- Williams, P.T.; Slaney, E. Analysis of products from the pyrolysis and liquefaction of single plastics and waste plastic mixtures. Resour. Conserv. Recycl. 2007, 51, 754–769. [Google Scholar] [CrossRef]

- Zhao, X.; Zhan, L.; Xie, B.; Gao, B. Products derived from waste plastics (PC, HIPS, ABS, PP and PA6) via hydrothermal treatment: Characterization and potential applications. Chemosphere 2018, 207, 742–752. [Google Scholar] [CrossRef]

- Li, H.; Feng, S.; Yuan, Z.; Wei, Q.; Xu, C.C. Highly efficient liquefaction of wheat straw for the production of bio-polyols and bio-based polyurethane foams. Ind. Crop. Prod. 2017, 109, 426–433. [Google Scholar] [CrossRef]

- Wang, B.; Huang, Y.; Zhang, J. Hydrothermal liquefaction of lignite, wheat straw and plastic waste in sub-critical water for oil: Product distribution. J. Anal. Appl. Pyrolysis 2014, 110, 382–389. [Google Scholar] [CrossRef]

- Zhao, P.; Li, Z.; Li, T.; Yan, W.; Ge, S. The study of nickel effect on the hydrothermal dechlorination of PVC. J. Clean. Prod. 2017, 152, 38–46. [Google Scholar] [CrossRef]

- Xu, X.; Zhu, D.; Wang, X.; Deng, L.; Fan, X.; Ding, Z.; Zhang, A.; Xue, G.; Liu, Y.; Xuan, W.; et al. Transformation of polyvinyl chloride (PVC) into a versatile and efficient adsorbent of Cu(II) cations and Cr(VI) anions through hydrothermal treatment and sulfonation. J. Hazard. Mater. 2022, 423, 126973. [Google Scholar] [CrossRef]

- Zhao, P.; Li, T.; Yan, W.; Yuan, L. Dechlorination of PVC wastes by hydrothermal treatment using alkaline additives. Environ. Technol. 2018, 39, 977–985. [Google Scholar] [CrossRef] [PubMed]

- Hashimoto, K.; Suga, S.; Wakayama, Y.; Funazukuri, T. Hydrothermal dechlorination of PVC in the presence of ammonia. J. Mater. Sci. 2008, 43, 2457–2462. [Google Scholar] [CrossRef]

- Li, T.; Zhao, P.; Lei, M.; Li, Z. Understanding Hydrothermal Dechlorination of PVC by Focusing on the Operating Conditions and Hydrochar Characteristics. Appl. Sci. 2017, 7, 256. [Google Scholar] [CrossRef]

- Sato, Y.; Kato, K.; Takeshita, Y.; Takahashi, K.; Nishi, S. Decomposition of Ployvinylchloride using Supercritical Water. Jpn. J. Appl. Phys. 1998, 37, 6270. [Google Scholar] [CrossRef]

- Kubátová, A.; Lagadec, A.J.; Hawthorne, S. Dechlorination of lindane, dieldrin, tetrachloroethane, trichloroethene, and PVC in subcritical water. Environ. Sci. Technol. 2002, 36, 1337–1343. [Google Scholar] [CrossRef]

- Choi, S.A.; Choi, W.I.; Lee, J.S.; Kim, S.W.; Lee, G.A.; Yun, J.; Park, J.Y. Hydrothermal acid treatment for sugar extraction from Golenkinia sp. Bioresour. Technol. 2015, 190, 408–411. [Google Scholar] [CrossRef]

- Liu, R.; Tian, W.; Kong, S.; Meng, Y.; Wang, H.; Zhang, J. Effects of inorganic and organic acid pretreatments on the hydrothermal liquefaction of municipal secondary sludge. Energy Convers. Manag. 2018, 174, 661–667. [Google Scholar] [CrossRef]

- Zou, S.; Wu, Y.; Yang, M.; Li, C.; Tong, J. Thermochemical Catalytic Liquefaction of the Marine Microalgae Dunaliella tertiolecta and Characterization of Bio-oils. Energy Fuels 2009, 23, 3753–3758. [Google Scholar] [CrossRef]

- Balat, M. Mechanisms of Thermochemical Biomass Conversion Processes. Part 3: Reactions of Liquefaction. Energy Sources Part Recovery Util. Environ. Eff. 2008, 30, 649–659. [Google Scholar] [CrossRef]

- Ross, A.B.; Biller, P.; Kubacki, M.L.; Li, H.; Lea-Langton, A.; Jones, J.M. Hydrothermal processing of microalgae using alkali and organic acids. Fuel 2010, 89, 2234–2243. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Z. Comparison of hydrochar- and pyrochar-based solid acid catalysts from cornstalk: Physiochemical properties, catalytic activity and deactivation behavior. Bioresour. Technol. 2020, 297, 122477. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Wang, X.; Jiang, Y.; Mu, X.; Liu, H. Insights into deactivation mechanism of sulfonated carbonaceous solid acids probed by cellulose hydrolysis. Catal. Today 2019, 319, 25–30. [Google Scholar] [CrossRef]

- Corma, A. From Microporous to Mesoporous Molecular Sieve Materials and Their Use in Catalysis. Chem. Rev. 1997, 97, 2373–2420. [Google Scholar] [CrossRef]

- Nguyen, M.T.; Choi, S.P.; Lee, J.W.; Lee, J.H.; Sim, S.J. Hydrothermal Acid Pretreatment of Chlamydomonas reinhardtii Biomass for Ethanol Production. J. Microbiol. Biotechnol. 2009, 19, 161–166. [Google Scholar] [PubMed]

- Pu, Y.; Hu, F.; Huang, F.; Davison, B.H.; Ragauskas, AJ. Assessing the molecular structure basis for biomass recalcitrance during dilute acid and hydrothermal pretreatments. Biotechnol. Biofuels. 2013, 6, 15. [Google Scholar] [CrossRef]

- Volpe, M.; Luz, F.C.; Saha, N.; Reza, M.T.; Mosonik, M.C.A.; Volpe, R.; Messineo, A. Enhancement of energy and combustion properties of hydrochar via citric acid catalysed secondary char production. Biomass Convers. Biorefinery 2021, 1–12. [Google Scholar] [CrossRef]

- Maniscalco, M.P.; Volpe, M.; Messineo, A. Hydrothermal Carbonization as a Valuable Tool for Energy and Environmental Applications: A Review. Energies 2020, 13, 4098. [Google Scholar] [CrossRef]

- Seshasayee, M.S.; Savage, P.E. Oil from plastic via hydrothermal liquefaction: Production and characterization. Appl. Energy 2020, 278, 115673. [Google Scholar] [CrossRef]

- Liu, Y.; Akula, K.C.; Dandamudi, K.P.R.; Liu, Y.; Xu, M.; Sanchez, A.; Zhu, D.; Deng, S. Effective depolymerization of polyethylene plastic wastes under hydrothermal and solvothermal liquefaction conditions. Chem. Eng. J. 2022, 446, 137238. [Google Scholar] [CrossRef]

- Yang, W.; Li, X.; Liu, S.; Feng, L. Direct hydrothermal liquefaction of undried macroalgae Enteromorpha prolifera using acid catalysts. Energy Convers. Manag. 2014, 87, 938–945. [Google Scholar] [CrossRef]

- Mahesh, D.; Ahmad, S.; Kumar, R.; Chakravarthy, S.R.; Vinu, R. Hydrothermal liquefaction of municipal solid wastes for high quality bio-crude production using glycerol as co-solvent. Bioresour. Technol. 2021, 339, 125537. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.T.; Jin, K.; Linda Wang, N.H. Use of Supercritical Water for the Liquefaction of Polypropylene into Oil. ACS Sustain. Chem. Eng. 2019, 7, 3749–3758. [Google Scholar] [CrossRef]

- Chen, W.T.; Qian, W.; Zhang, Y.; Mazur, Z.; Kuo, C.T.; Scheppe, K.; Schideman, L.C.; Sharma, B.K. Effect of ash on hydrothermal liquefaction of high-ash content algal biomass. Algal. Res. 2017, 25, 297–306. [Google Scholar] [CrossRef]

- Jordan, K.J.; Suib, S.L.; Koberstein, J.T. Determination of the Degradation Mechanism from the Kinetic Parameters of Dehydrochlorinated Poly(vinyl chloride) Decomposition. J. Phys. Chem. B 2001, 105, 3174–3181. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Z.; Feng, L. Effects of reaction parameter on catalytic hydrothermal liquefaction of microalgae into hydrocarbon rich bio-oil. J. Energy Inst. 2021, 94, 22–28. [Google Scholar] [CrossRef]

- Ratha, S.K.; Renuka, N.; Abunama, T.; Rawat, I.; Bux, F. Hydrothermal liquefaction of algal feedstocks: The effect of biomass characteristics and extraction solvents. Renew Sustain. Energy Rev. 2022, 156, 111973. [Google Scholar] [CrossRef]

- Bai, B.; Jin, H.; Fan, C.; Cao, C.; Wei, W.; Cao, W. Experimental investigation on liquefaction of plastic waste to oil in supercritical water. Waste Manag. 2019, 89, 247–253. [Google Scholar] [CrossRef]

- López, A.; de Marco, I.; Caballero, B.M.; Laresgoiti, M.F.; Adrados, A. Dechlorination of fuels in pyrolysis of PVC containing plastic wastes. Fuel Process. Technol. 2011, 92, 253–260. [Google Scholar] [CrossRef]

- Nagai, Y.; Smith, R.L., Jr.; Inomata, H.; Arai, K. Direct observation of polyvinylchloride degradation in water at temperatures up to 500 °C and at pressures up to 700 MPa. J. Appl. Polym. Sci. 2007, 106, 1075–1086. [Google Scholar] [CrossRef]

- Available online: https://metchem.com/ph-adjustment-neutralization-systems (accessed on 1 January 2017).

- Gebre, S.H.; Sendeku, M.G.; Bahri, M. Recent Trends in the Pyrolysis of Non-Degradable Waste Plastics. ChemistryOpen 2021, 10, 1202–1226. [Google Scholar] [CrossRef] [PubMed]

- Panwar, N.L.; Paul, A.S. An overview of recent development in bio-oil upgrading and separation techniques. Environ. Eng. Res. 2021, 26, 200382. [Google Scholar] [CrossRef]

| Sample | C (wt%) | H (wt%) | N (wt%) | S (wt%) | Cl (wt%) | Ash (wt%) |

|---|---|---|---|---|---|---|

| PVC | 34.69 ± 1.34 | 4.18 ± 1.65 | BD * | BD | 52.15 | 9.05 ± 0.45 |

| acidic hydrochar | 59.82 ± 2.15 | 5.23 ± 0.50 | BD | BD | BD | 1.01 ± 0.21 |

| Exp No. | Hydrochar Loading (wt%) | Temperature (°C) | Time (h) | Carbon (%) | Hydrogen (%) | Other Elements * (%) | HHV ** (MJ/kg) |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 325 | 0.5 | 67.62 ± 0.28 | 7.65 ± 0.34 | 22.00 ± 0.32 | 29.84 |

| 2 | 2 | 325 | 0.5 | 69.2 ± 0.58 | 8.2 ± 0.15 | 22.6 ± 0.45 | 31.05 |

| 3 | 3 | 325 | 0.5 | 68.3 ± 1.36 | 8.1 ± 0.29 | 23.6 ± 1.65 | 30.43 |

| 4 | 4 | 325 | 0.5 | 70.2 ± 0.45 | 8.5 ± 0.15 | 21.3 ± 0.53 | 32.05 |

| 5 | 5 | 325 | 0.5 | 71.5 ± 1.05 | 9.1 ± 0.27 | 19.4 ± 0.85 | 33.68 |

| 6 | 10 | 325 | 0.5 | 71.2 ± 0.23 | 8.8 ± 0.13 | 20 ± 0.29 | 33.05 |

| 7 | 20 | 325 | 0.5 | 72.3 ± 0.95 | 9.15 ± 0.23 | 18.55 ± 1.14 | 34.17 |

| 8 | 5 | 300 | 0.5 | 62.25 ± 0.76 | 7.85 ± 0.31 | 29.9 ± 0.97 | 26.91 |

| 9 | 5 | 350 | 0.5 | 74.22 ± 0.74 | 9.22 ± 0.25 | 16.56 ± 0.97 | 35.28 |

| 10 | 5 | 350 | 0.25 | 68.25 ± 0.95 | 7.25 ± 0.28 | 24.5 ± 0.91 | 29.04 |

| 11 | 5 | 350 | 1 | 74.56 ± 0.63 | 9.36 ± 0.32 | 16.08 ± 0.62 | 35.68 |

| 12 | 5 | 350 | 2 | 75.25 ± 1.12 | 9.23 ± 0.43 | 15.52 ± 1.02 | 35.82 |

| 13 | 5 | 350 | 4 | 76.36 ± 0.85 | 9.25 ± 0.25 | 14.39 ± 0.78 | 36.43 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghalandari, V.; Smith, H.; Volpe, M.; Messineo, A.; Reza, T. Effect of Acidic Hydrochar on Plastic Crude Oil Produced from Hydrothermal Liquefaction of Waste PVC. Processes 2022, 10, 2538. https://doi.org/10.3390/pr10122538

Ghalandari V, Smith H, Volpe M, Messineo A, Reza T. Effect of Acidic Hydrochar on Plastic Crude Oil Produced from Hydrothermal Liquefaction of Waste PVC. Processes. 2022; 10(12):2538. https://doi.org/10.3390/pr10122538

Chicago/Turabian StyleGhalandari, Vahab, Hunter Smith, Maurizio Volpe, Antonio Messineo, and Toufiq Reza. 2022. "Effect of Acidic Hydrochar on Plastic Crude Oil Produced from Hydrothermal Liquefaction of Waste PVC" Processes 10, no. 12: 2538. https://doi.org/10.3390/pr10122538

APA StyleGhalandari, V., Smith, H., Volpe, M., Messineo, A., & Reza, T. (2022). Effect of Acidic Hydrochar on Plastic Crude Oil Produced from Hydrothermal Liquefaction of Waste PVC. Processes, 10(12), 2538. https://doi.org/10.3390/pr10122538