Effects of Container Design on the Temperature and Moisture Content Distribution in Pork Patties during Microwave Heating: Experiment and Numerical Simulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

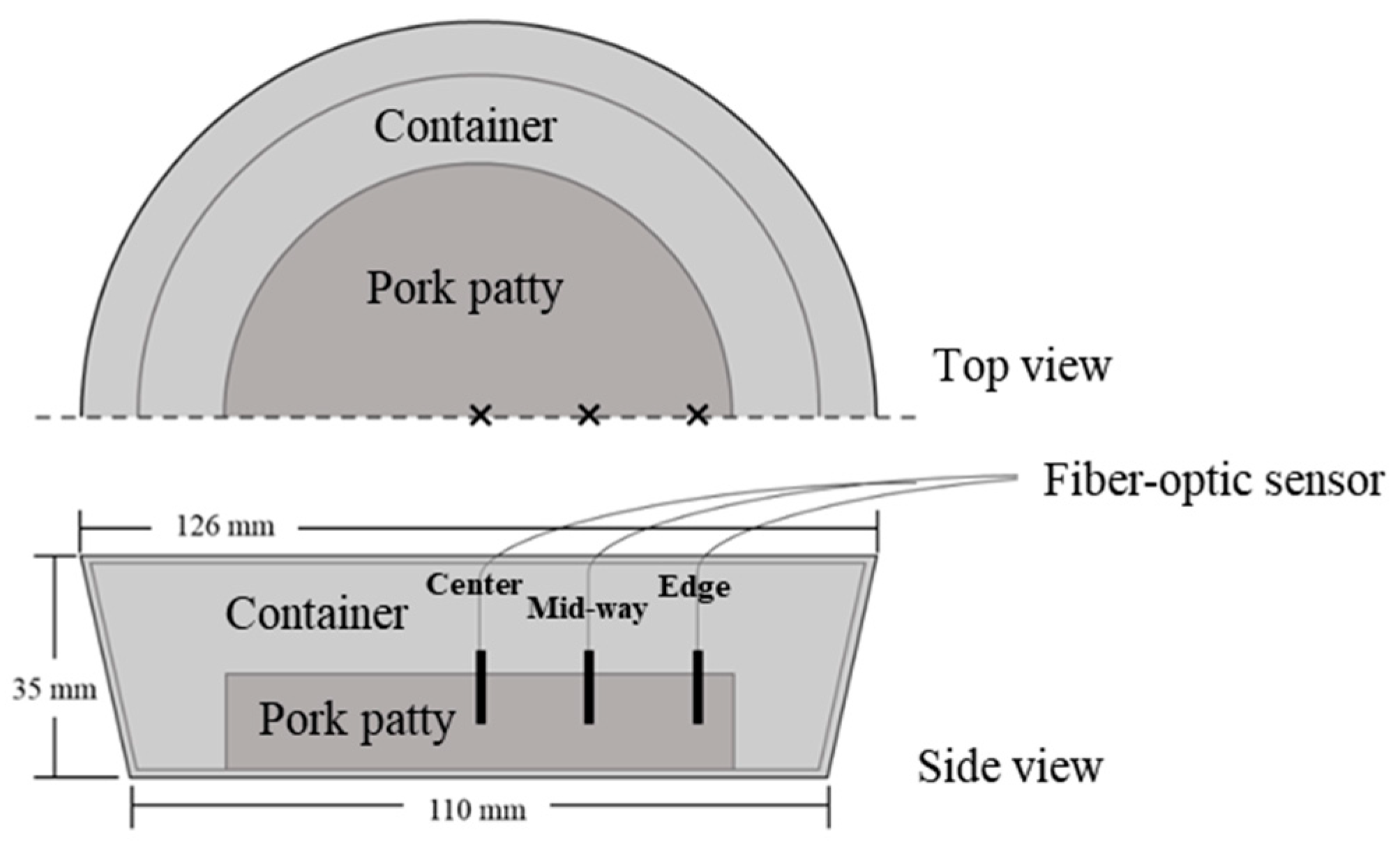

2.2. Microwave Heating and Temperature Measurement

2.3. Moisture Content

2.4. Scanning Electron Microscopy

2.5. Statistical Analyses

3. Numerical Simulation

3.1. Governing Equations

3.2. Development of COMSOL Model

- It was assumed that the magnetron would run at a single frequency of 2.45 GHz.

- Since the fan continuously ventilated the oven cavity, it was assumed that the air temperature would remain constant throughout the microwave heating process.

- It was assumed that all water can be evaporated when the boiling point is reached.

- Structure changes such as shrinks or expands are assumed not to take place during the microwave heating.

- Some model parameters assigned constant values in the model based on the existing literature, and are assumed to be constant with the temperature change during the microwave heating.

- The simulation focused on evaluating the temperature distribution of the patty. Due to the limitation of the computational power to deal with the multi-phase physics models, the flow pattern and the temperature of the air were assumed to be constant, and the major calculation power was allocated to estimate the temperature distribution of the patty based on the physical changes in the patty, such as the heat generation, phase transition, evaporation, and diffusion of water.

3.3. Model Accuracy Measurement

4. Results and Discussion

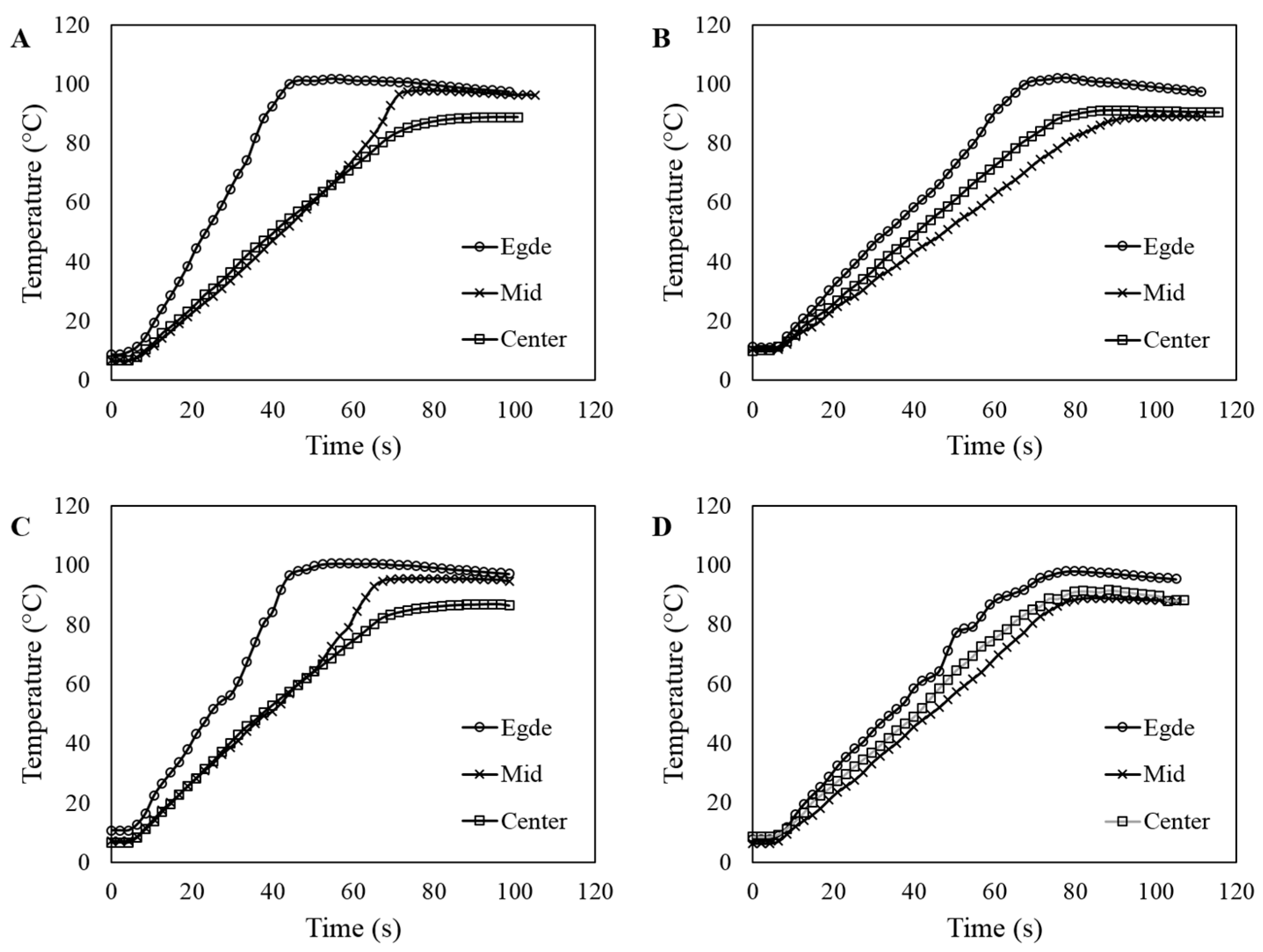

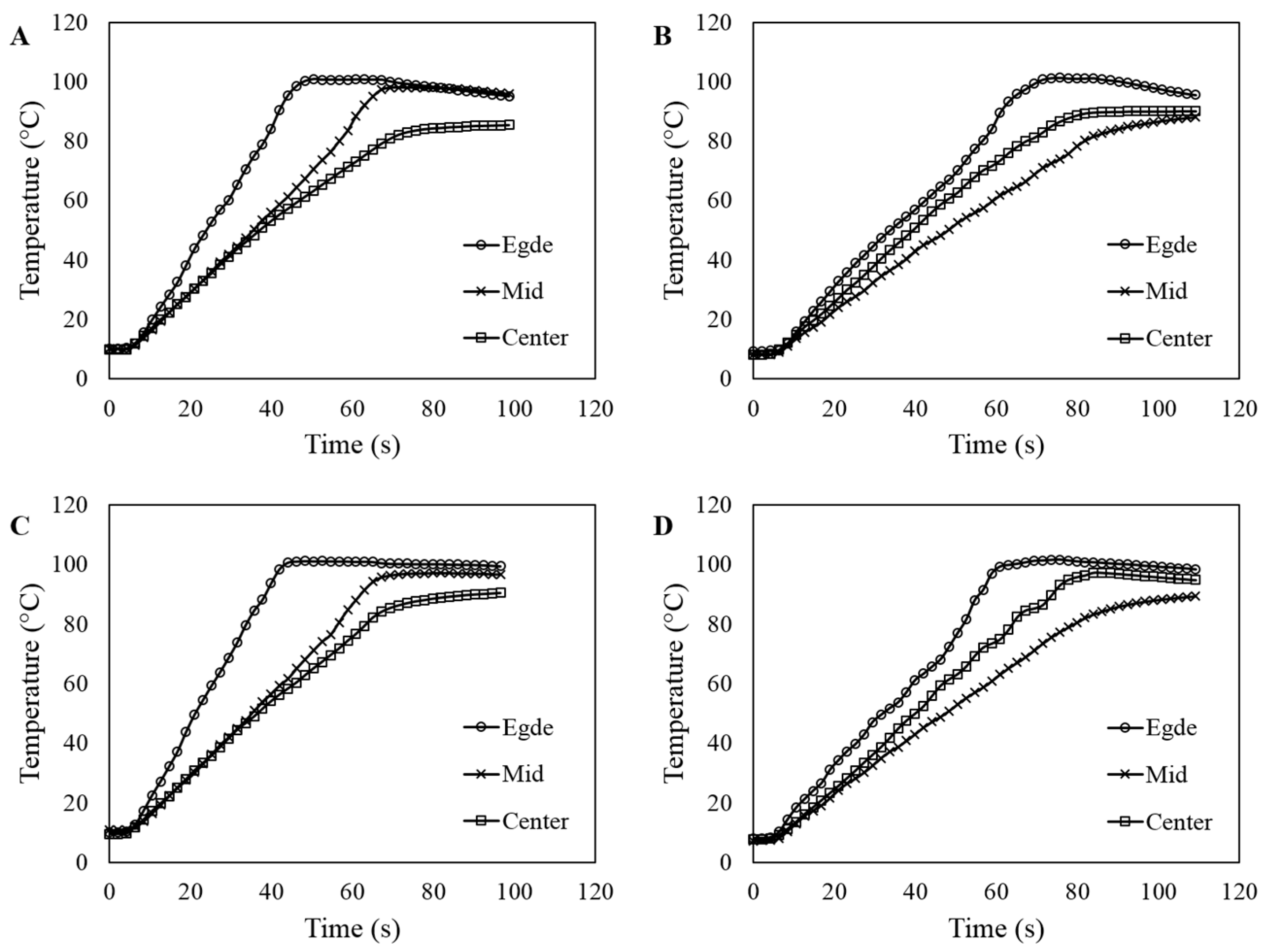

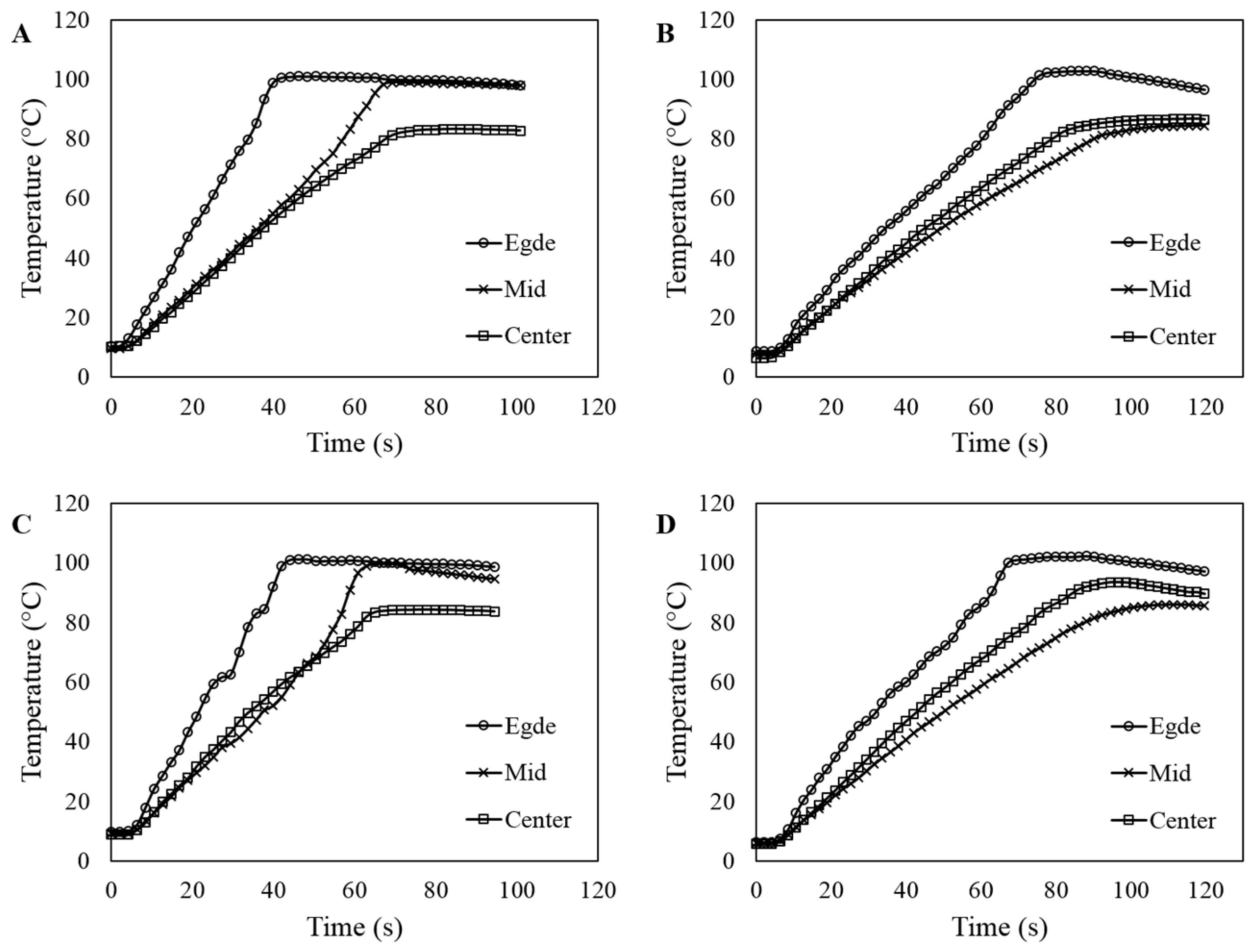

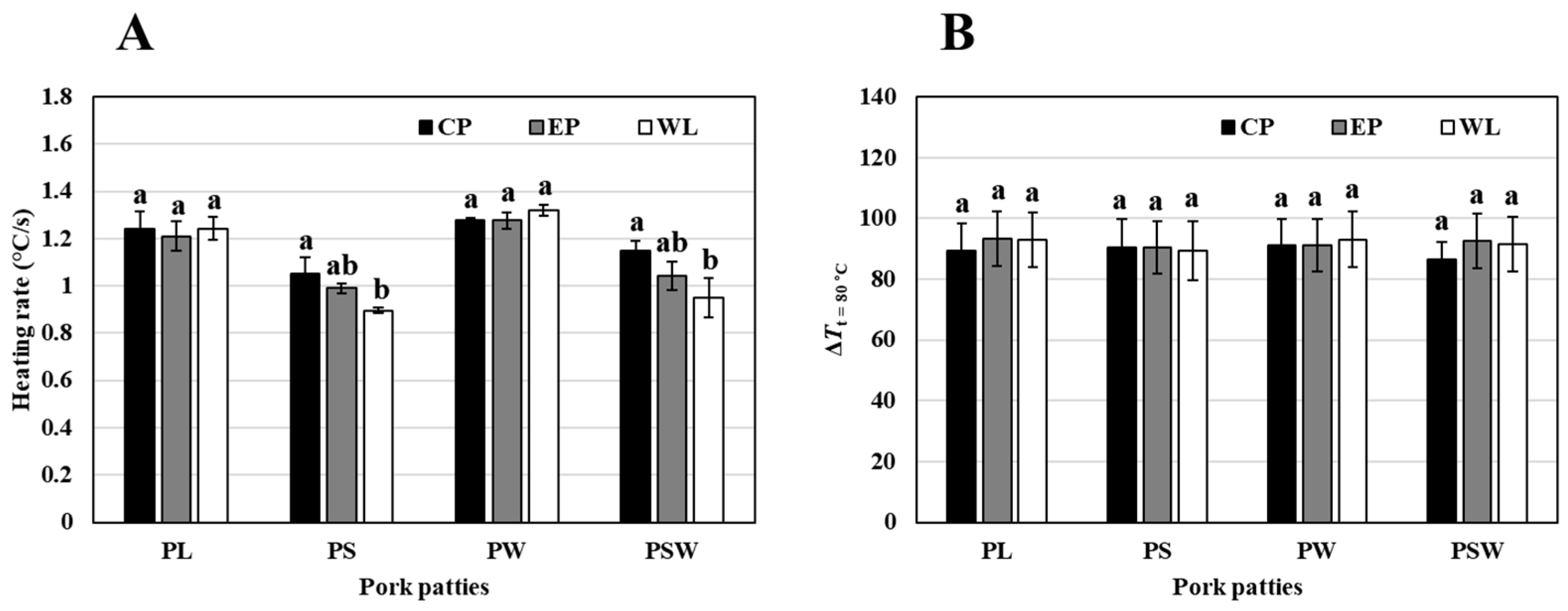

4.1. Effect of Pork Patty Composition and Container Design on Temperature Profiles

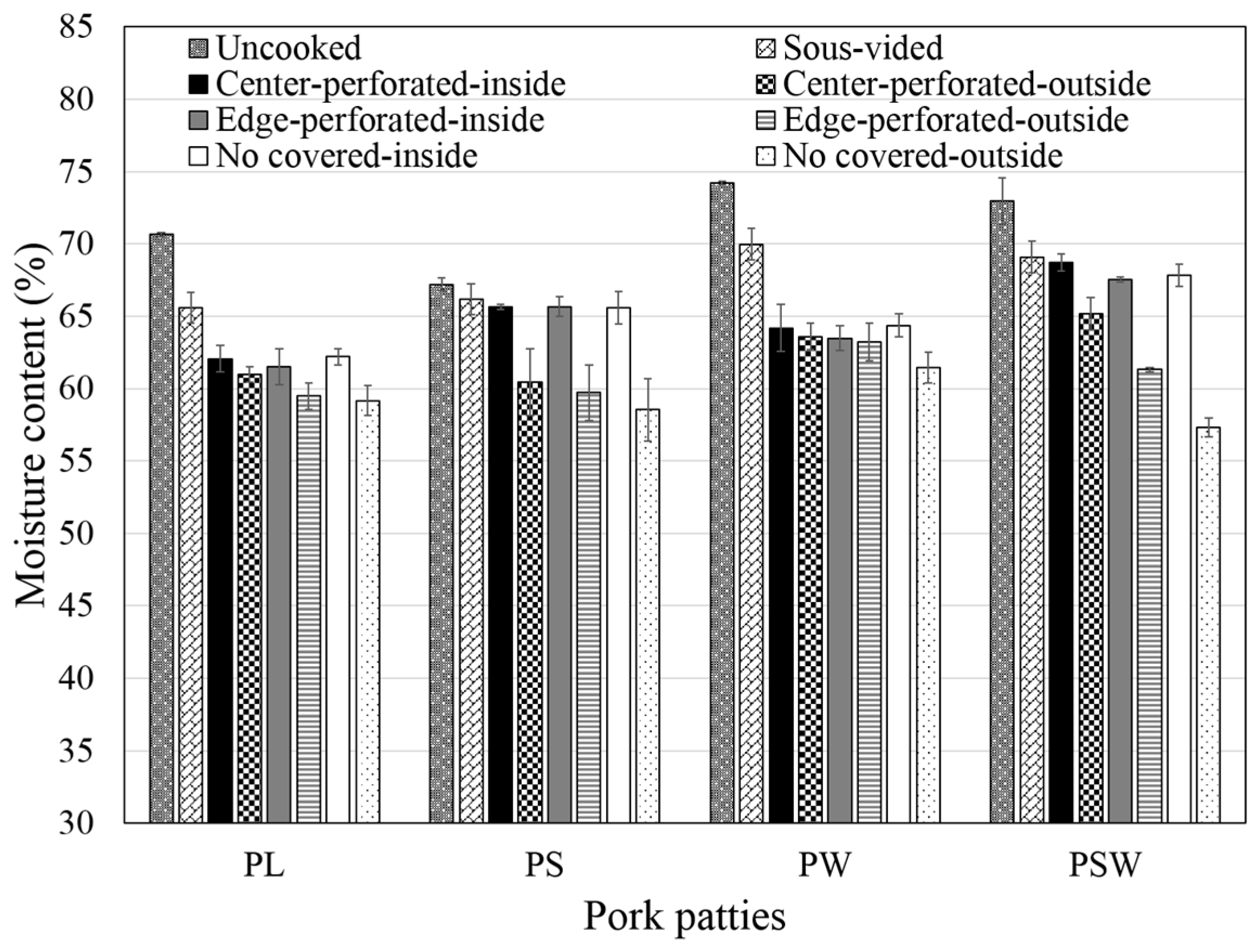

4.2. Effect of the Pork Patty Composition and Container Design on Moisture Content the Tem

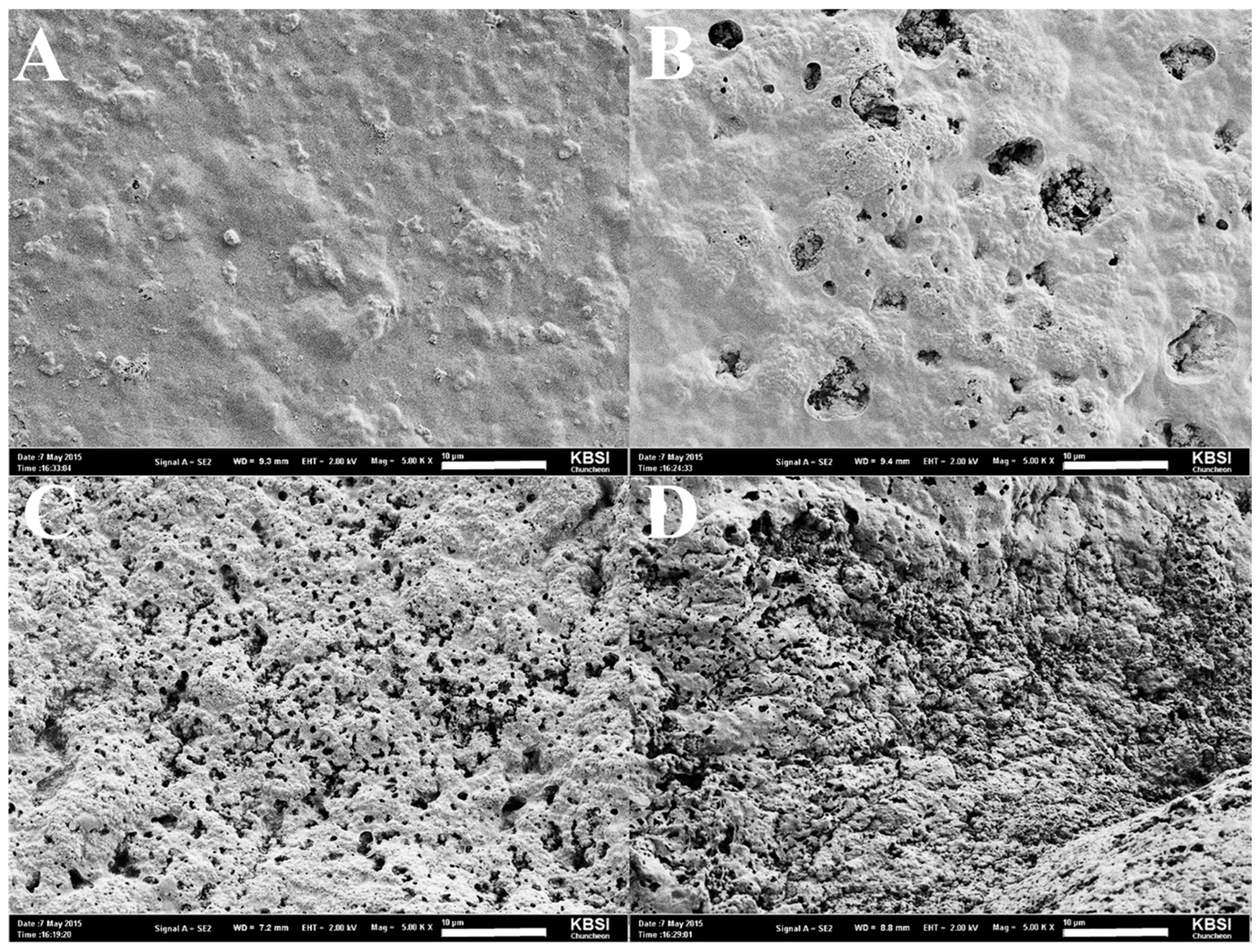

4.3. Microstructural Observation

4.4. Spatial Power Density and Electric Field Distribution by Simulation

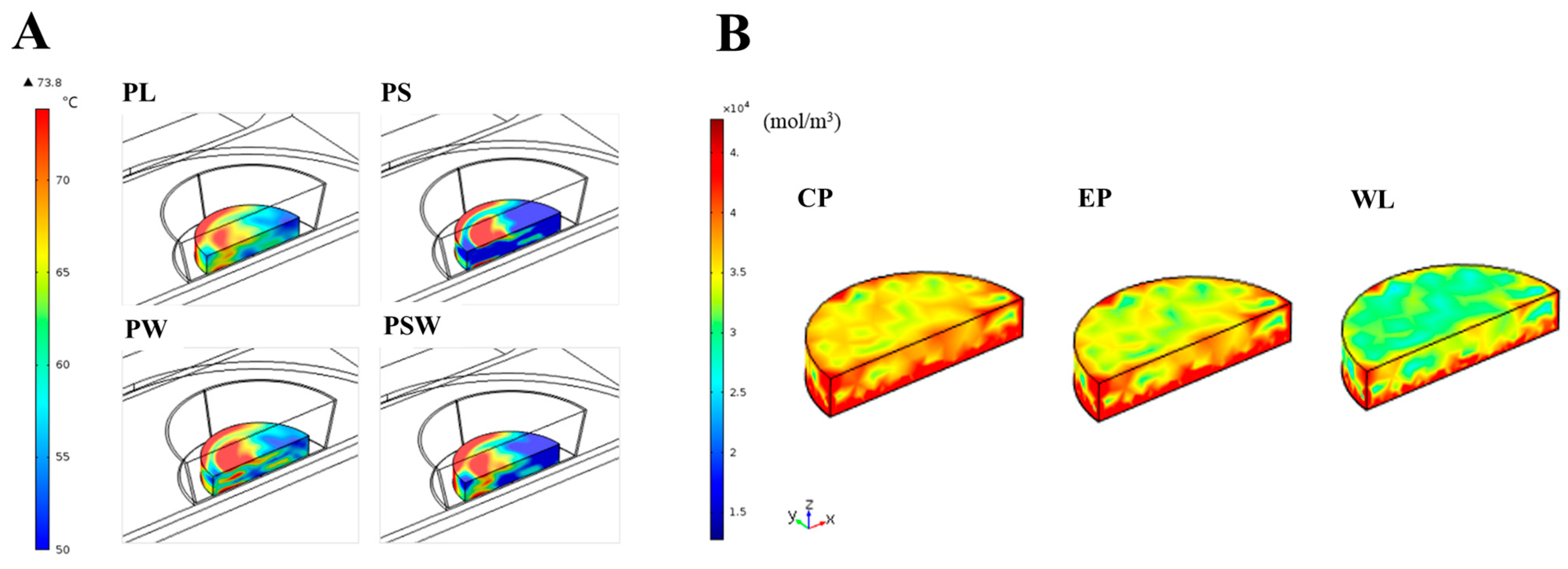

4.5. Spatial Temperature Profile and Moisture Distribution by Simulation

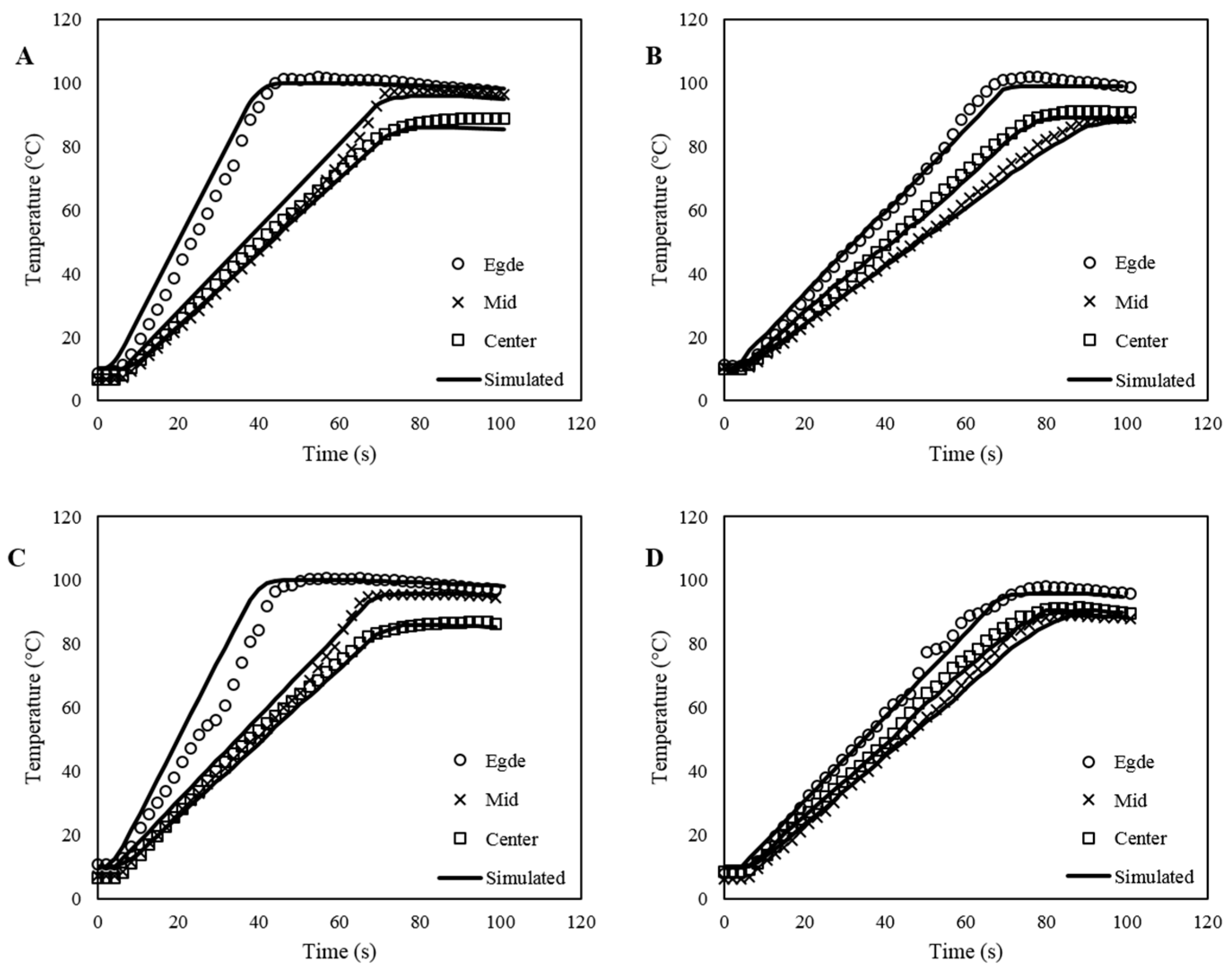

4.6. Simulated Temperature Profile and Validation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave food processing—A review. Food Res. Int. 2013, 52, 243–261. [Google Scholar] [CrossRef]

- Liu, S.; Fukuoka, M.; Sakai, N. A finite element model for simulating temperature distributions in rotating food during microwave heating. J. Food Eng. 2013, 115, 49–62. [Google Scholar] [CrossRef]

- Zhang, M.; Tang, J.; Mujumdar, A.S.; Wang, S. Trends in microwave-related drying of fruits and vegetables. Trends Food Sci. Technol. 2006, 17, 524–534. [Google Scholar] [CrossRef]

- Salazar-González, C.; Martín-González, S.; Fernanda, M.; López-Malo, A.; Sosa-Morales, M.E. Recent studies related to microwave processing of fluid foods. Food Bioproc. Technol. 2012, 5, 31–46. [Google Scholar] [CrossRef]

- Campanone, L.A.; Zaritzky, N.E. Mathematical analysis of microwave heating process. J. Food Eng. 2005, 69, 359–368. [Google Scholar] [CrossRef]

- Datta, A.K.; Geedipalli, S.S.; Almeida, M.F. Microwave combination heating. Food Technol. 2005, 59, 36–40. [Google Scholar]

- Kutlu, N.; Pandiselvam, R.; Saka, I.; Kamiloglu, A.; Sahni, P.; Kothakota, A. Impact of different microwave treatments on food texture. J. Texture Stud. 2021. (early view). [Google Scholar] [CrossRef] [PubMed]

- Ryynänen, S.; Ohlsson, T. Microwave Heating Uniformity of Ready Meals as Affected by Placement, Composition, and Geometry. J. Food Sci. 1996, 61, 620–624. [Google Scholar] [CrossRef]

- Zhang, H.; Datta, A.K. Microwave power absorption in single-and multiple-item foods. Food Bioprod. Process. 2003, 81, 257–265. [Google Scholar] [CrossRef]

- Geedipalli, S.; Rakesh, V.; Datta, A.K. Modeling the heating uniformity contributed by a rotating turntable in microwave ovens. J. Food Eng. 2007, 82, 359–368. [Google Scholar] [CrossRef]

- Rakesh, V.; Seo, Y.; Datta, A.K.; McCarthy, K.L.; McCarthy, M.J. Heat transfer during microwave combination heating: Computational modeling and MRI experiments. AIChE J. 2010, 56, 2468–2478. [Google Scholar] [CrossRef]

- Vilayannur, R.S.; Puri, V.M.; Anantheswaran, R.C. Size and shape effect on nonuniformity of temperature and moisture distributions in microwave heated food materials: Part I simulation. J. Food Process Eng. 1998, 21, 209–233. [Google Scholar] [CrossRef]

- Kelen, A.; Ress, S.; Nagy, T.; Pallai, E.; Pintye-Hodi, K. Mapping of temperature distribution in pharmaceutical microwave vacuum drying. Powder Technol. 2006, 162, 133–137. [Google Scholar] [CrossRef]

- Lespinard, A.R.; Arballo, J.R.; Badin, E.E.; Mascheroni, R.H. Comparative study between conventional and microwave-assisted pasteurization of packaged milk by finite element modeling. J. Food Process. Preserv. 2019, 43, e14207. [Google Scholar] [CrossRef]

- Vadivambal, R.; Jayas, D.S. Non-uniform temperature distribution during microwave heating of food materials—A review. Food Bioprocess Technol. 2010, 3, 161–171. [Google Scholar] [CrossRef]

- Ozen, B.F.; Floros, J.D. Effects of emerging food processing techniques on the packaging materials. Trends Food Sci. Technol. 2001, 12, 60–67. [Google Scholar] [CrossRef]

- Ozkoc, S.O.; Sumnu, G.; Sahin, S. Chapter 20—Recent Developments in Microwave Heating. In Emerging Technologies for Food Processing, 2nd ed.; Sun, D.W., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 361–383. [Google Scholar] [CrossRef]

- Pitchai, K.; Chen, J.; Birla, S.; Gonzalez, R.; Jones, D.; Subbiah, J. A microwave heat transfer model for a rotating multi-component meal in a domestic oven: Development and validation. J. Food Eng. 2014, 128, 60–71. [Google Scholar] [CrossRef]

- Roohi, R.; Hashemi, S.M.B. Experimental, heat transfer and microbial inactivation modeling of microwave pasteurization of carrot slices as an efficient and clean process. Food Bioprod. Process. 2020, 121, 113–122. [Google Scholar] [CrossRef]

- Datta, A.K.; Anantheswaran, R.C. Handbook of Microwave Technology for Food Application, 1st ed.; CRC Press: New York, NY, USA, 2001. [Google Scholar]

- Chen, J.; Pitchai, K.; Birla, S.; Negahban, M.; Jones, D.; Subbiah, J. Heat and mass transport during microwave heating of mashed potato in domestic oven—Model development, validation, and sensitivity analysis. J. Food Sci. 2014, 79, E1991–E2004. [Google Scholar] [CrossRef]

- Klinbun, W.; Rattanadecho, P. Numerical study of initially frozen rice congee with thin film resonators package in microwave domestic oven. J. Food Process Eng. 2022, 45, e13924. [Google Scholar] [CrossRef]

- Thuto, W.; Banjong, K. Investigation of Heat and Moisture Transport in Bananas during Microwave Heating Process. Processes 2019, 7, 545. [Google Scholar] [CrossRef]

- Hou, L.; Li, R.; Wang, S.; Datta, A.K. Numerical analysis of heat and mass transfers during intermittent microwave drying of Chinese jujube (Zizyphus jujuba Miller). Food Bioprod. Process 2021, 129, 10–23. [Google Scholar] [CrossRef]

- Gulati, T.; Datta, A.K.; Ranjbaran, M. Selective heating and enhanced boiling in microwave heating of multicomponent (solid–liquid) foods. J. Food Process Eng. 2020, 43, e13320. [Google Scholar] [CrossRef]

- Ni, H.; Datta, A.K.; Parmeswar, R. Moisture loss as related to heating uniformity in microwave processing of solid foods. J. Food Process Eng. 1999, 22, 367–382. [Google Scholar] [CrossRef]

- Ollinger-Snyder, P.; El-Gazzar, F.; Matthews, M.E.; Marth, E.H.; Unklesbay, N. Thermal destruction of Listeria monocytogenes in ground pork prepared with and without soy hulls. J. Food Prot. 1995, 58, 573–576. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC; Association of Official Analytical Chemists: Arlington, TX, USA, 1990. [Google Scholar]

- Campañone, L.A.; Bava, J.A.; Mascheroni, R.H. Modeling and process simulation of controlled microwave heating of foods by using of the resonance phenomenon. Appl. Therm. Eng. 2014, 73, 914–923. [Google Scholar] [CrossRef]

- Tuta, S.; Palazoğlu, T.K. Finite element modeling of continuous-flow microwave heating of fluid foods and experimental validation. J. Food Eng. 2017, 192, 79–92. [Google Scholar] [CrossRef]

- Navarrete, A.; Mato, R.B.; Cocero, M.J. A predictive approach in modeling and simulation of heat and mass transfer during microwave heating. Application to SFME of essential oil of Lavandin Super. Chem. Eng. Sci. 2012, 68, 192–201. [Google Scholar] [CrossRef]

- ASHRAE. ASHRAE Handbook—Refrigeration; American Society of Heating: Peachtree Corners, GA, USA, 2006; Chapter 9; pp. 9.1–9.31. [Google Scholar]

- Sipahioglu, O.; Barringer, S.A.; Taub, I.; Prakash, A. Modeling the dielectric properties of ham as a function of temperature and composition. J. Food Sci. 2003, 68, 904–909. [Google Scholar] [CrossRef]

- Ngadi, M.; Dev, S.R.; Raghavan, V.G.; Kazemi, S. Dielectric properties of pork muscle. Int. J. Food Prop. 2015, 18, 12–20. [Google Scholar] [CrossRef]

- Risman, P.O. Metal in the microwave oven. Microw. World 1992, 13, 28–35. [Google Scholar]

- Risman, P.O. (Swedish Institute for Food Research, Göteborg, Sweden); Ohlsson, T. (Swedish Institute for Food Research, Göteborg, Sweden). Field concentrations in dielectric wedges. Personal communication, 1995. [Google Scholar]

- Jeong, J.Y.; Lee, E.S.; Choi, J.H.; Lee, J.Y.; Kim, J.M.; Min, S.G.; Chae, Y.C.; Kim, C.J. Variability in temperature distribution and cooking properties of ground pork patties containing different fat level and with/without salt cooked by microwave energy. Meat Sci. 2007, 75, 415–422. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Chen, Q.; Chen, J. Comparison of heating performance between inverter and cycled microwave heating of foods using a coupled multiphysics-kinetic model. J. Microw. Power Electromagn. Energy 2021, 55, 45–65. [Google Scholar] [CrossRef]

- Engelder, D.S.; Buffler, C.R. Measuring dielectric properties of food products at microwave frequencies. Microw. World 1991, 12, 6–15. [Google Scholar]

- Dong, J.; Kou, X.; Liu, L.; Hou, L.; Li, R.; Wang, S. Effect of water, fat, and salt contents on heating uniformity and color of ground beef subjected to radio frequency thawing process. Innov. Food Sci. Emerg. Technol. 2021, 68, 102604. [Google Scholar] [CrossRef]

- Sakai, N.; Mao, W.; Koshima, Y.; Watanabe, M. A method for developing model food system in microwave heating studies. J. Food Eng. 2005, 66, 525–531. [Google Scholar] [CrossRef]

- Burfoot, D.; Griffin, W.J.; James, S.J. Microwave pasteurisation of prepared meals. J. Food Eng. 1988, 8, 145–156. [Google Scholar] [CrossRef]

- McDonnell, C.K.; Allen, P.; Duggan, E.; Arimi, J.M.; Casey, E.; Duane, G.; Lyng, J.G. The effect of salt and fibre direction on water dynamics, distribution and mobility in pork muscle: A low field NMR study. Meat Sci. 2013, 95, 51–58. [Google Scholar] [CrossRef]

- Regier, M.; Schubert, H. Microwave processing. In Thermal Technologies in Food Processing; Richardson, P., Ed.; CRC Press: New York, NY, USA, 2001; p. 294. [Google Scholar]

- Salvi, D.; Boldor, D.; Aita, G.M.; Sabliov, C.M. COMSOL Multiphysics model for continuous flow microwave heating of liquids. J. Food Eng. 2011, 104, 422–429. [Google Scholar] [CrossRef]

- Dibben, D. Electromagnetics: Fundamental aspects and numerical modeling. In Handbook of Microwave Technology for Food Application, 1st ed.; CRC Press: New York, NY, USA, 2001; pp. 25–56. [Google Scholar]

- Zhang, H.; Datta, A.K. Electromagnetics of microwave heating: Magnitude and uniformity of energy absorption in an oven. In Handbook of Microwave Technology for Food Application, 1st ed.; CRC Press: New York, NY, USA, 2001; pp. 57–92. [Google Scholar]

- Chen, J.; Pitchai, K.; Birla, S.; Jones, D.; Negahban, M.; Subbiah, J. Modeling heat and mass transport during microwave heating of frozen food rotating on a turntable. Food Bioprod. Process. 2016, 99, 116–127. [Google Scholar] [CrossRef]

| Sample | Raw Material | Moisture Contents (%) | Salt Contents (%) | Ash Content (%) | pH |

|---|---|---|---|---|---|

| PL | Pork Loin | 70.65 ± 0.14 | 0.04 ± 0.01 | 1.06 ± 0.04 | 5.67 ± 0.14 |

| PS | Pork Loin + 2% salt | 67.20 ± 0.44 | 2.04 ± 0.03 | 3.07 ± 0.05 | 5.67 ± 0.11 |

| PW | Pork Loin + 10% water | 74.21 ± 0.13 | 0.03 ± 0.01 | 0.95 ± 0.08 | 5.68 ± 0.08 |

| PSW | Pork Loin + 2% salt + 10% water | 72.99 ± 1.60 | 2.02 ± 0.02 | 2.93 ± 0.03 | 5.69 ± 0.10 |

| Sample | Thermal Conductivity (k) (W/m K) | Density (P) (kg/m3) | Specific Heat (Cp) (J/kg K) | Dielectric Constant (εr) | Dielectric Loss (ε0) |

|---|---|---|---|---|---|

| PL | 0.4189 | 948.3 | 3463.4 | 48.21 | 18.44 |

| PS | 0.4220 | 949.0 | 3474.4 | 46.82 | 19.56 |

| PW | 0.4417 | 953.6 | 3544.0 | 49.18 | 17.46 |

| PSW | 0.4371 | 952.5 | 3527.8 | 48.41 | 17.95 |

| Sample | Container Design | Average RMSE (°C) | Average R2 |

|---|---|---|---|

| PL | CP | 4.46 | 0.94 |

| EP | 8.41 | 0.93 | |

| WL | 18.39 | 0.91 | |

| PS | CP | 13.92 | 0.90 |

| EP | 14.56 | 0.90 | |

| WL | 21.20 | 0.89 | |

| PW | CP | 6.85 | 0.92 |

| EP | 8.62 | 0.94 | |

| WL | 16.83 | 0.91 | |

| PSW | CP | 13.67 | 0.89 |

| EP | 16.32 | 0.92 | |

| WL | 22.96 | 0.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, H.; Lee, M.G.; Yoon, W.B. Effects of Container Design on the Temperature and Moisture Content Distribution in Pork Patties during Microwave Heating: Experiment and Numerical Simulation. Processes 2022, 10, 2382. https://doi.org/10.3390/pr10112382

Jung H, Lee MG, Yoon WB. Effects of Container Design on the Temperature and Moisture Content Distribution in Pork Patties during Microwave Heating: Experiment and Numerical Simulation. Processes. 2022; 10(11):2382. https://doi.org/10.3390/pr10112382

Chicago/Turabian StyleJung, Hwabin, Myeong Gi Lee, and Won Byong Yoon. 2022. "Effects of Container Design on the Temperature and Moisture Content Distribution in Pork Patties during Microwave Heating: Experiment and Numerical Simulation" Processes 10, no. 11: 2382. https://doi.org/10.3390/pr10112382

APA StyleJung, H., Lee, M. G., & Yoon, W. B. (2022). Effects of Container Design on the Temperature and Moisture Content Distribution in Pork Patties during Microwave Heating: Experiment and Numerical Simulation. Processes, 10(11), 2382. https://doi.org/10.3390/pr10112382