Thermodynamic Characteristics Study with Pyrolysis Steam Coupled Multi-Stage Condensers

Abstract

:1. Introduction

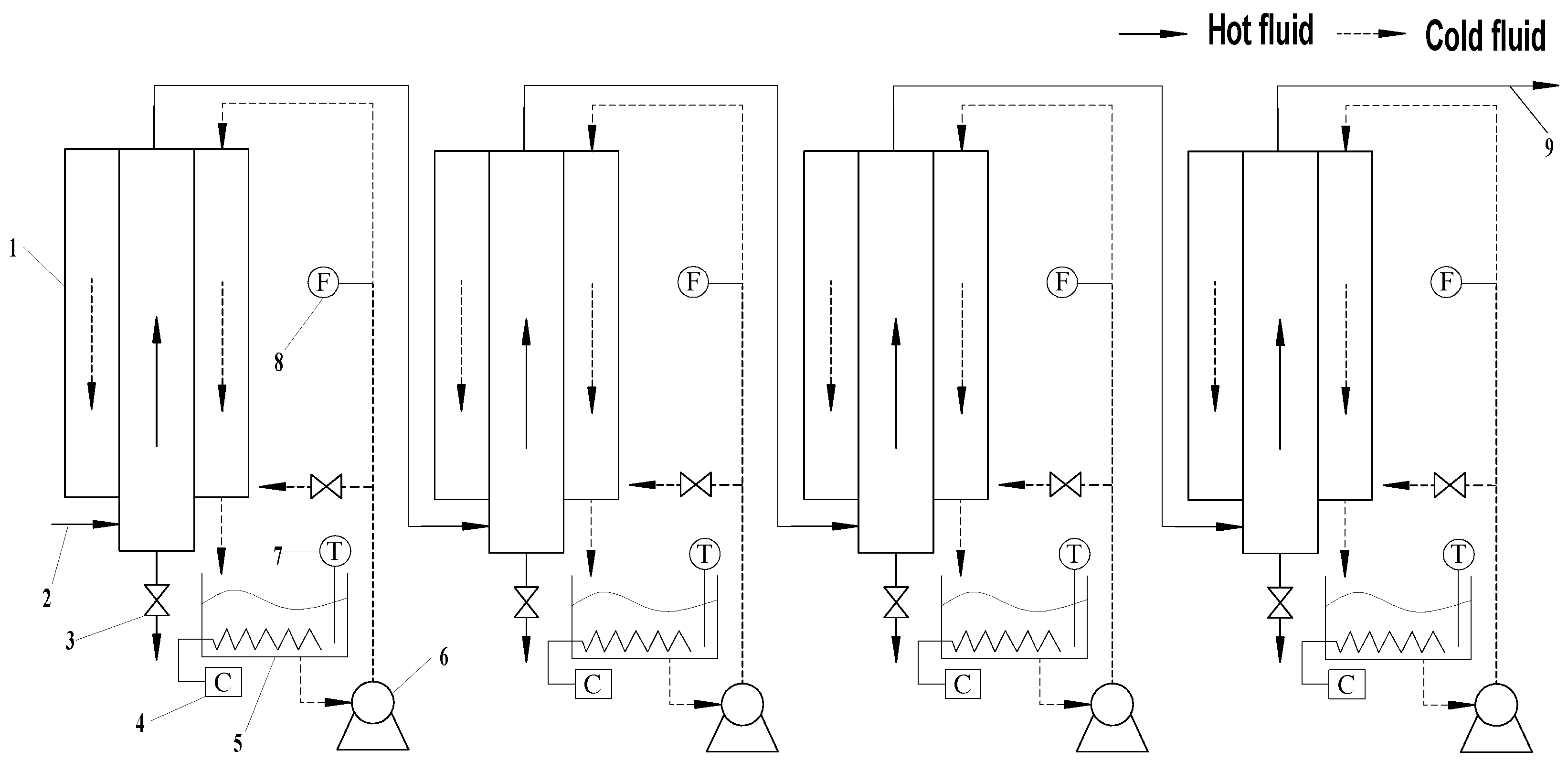

2. Design

3. Thermodynamic Equilibrium Model Development

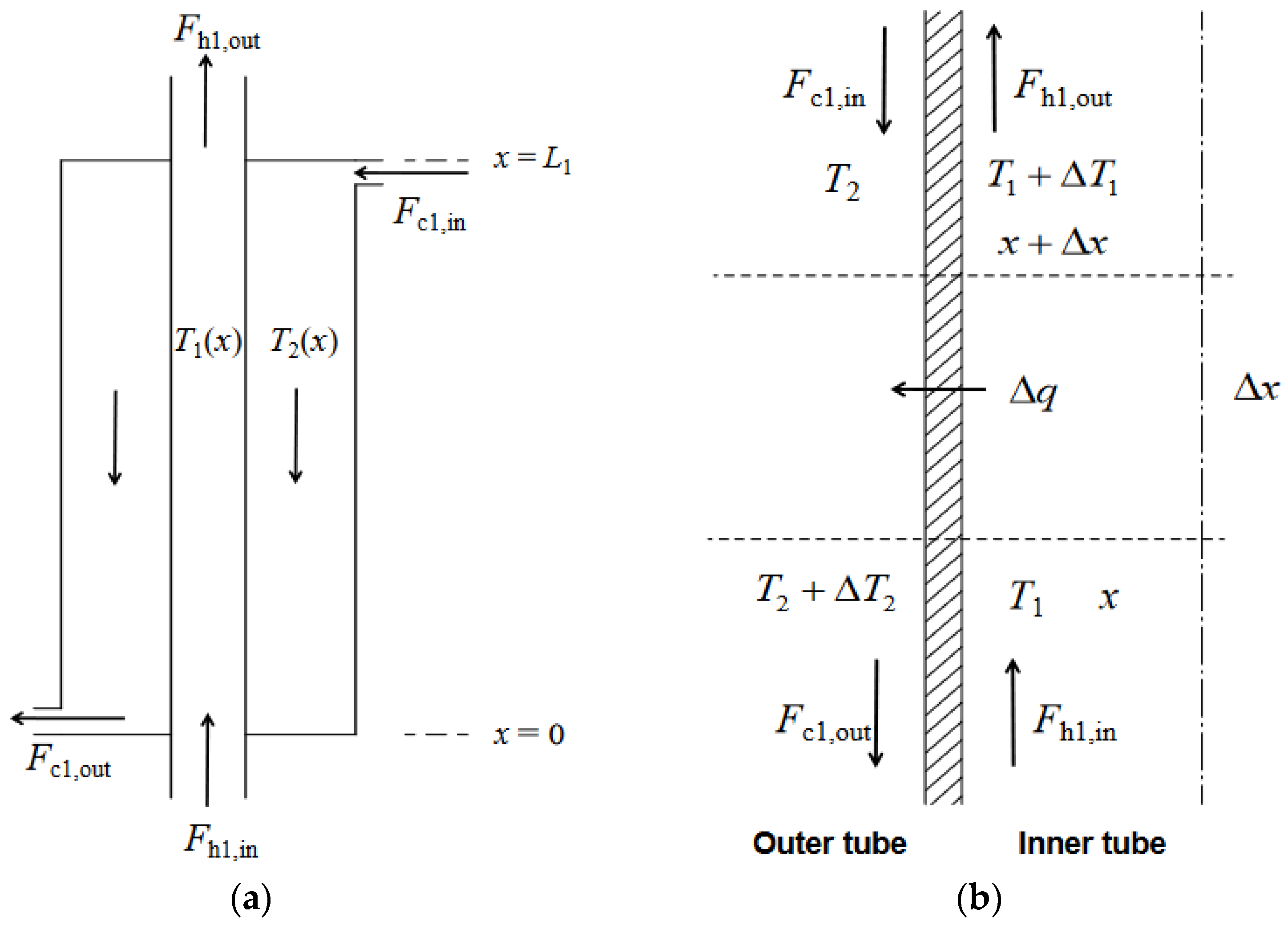

3.1. Single Condenser Model

3.2. Model and Solution Method of Pyrolysis Steam Coupled Multi-Stage Condensers

4. Numerical Simulation

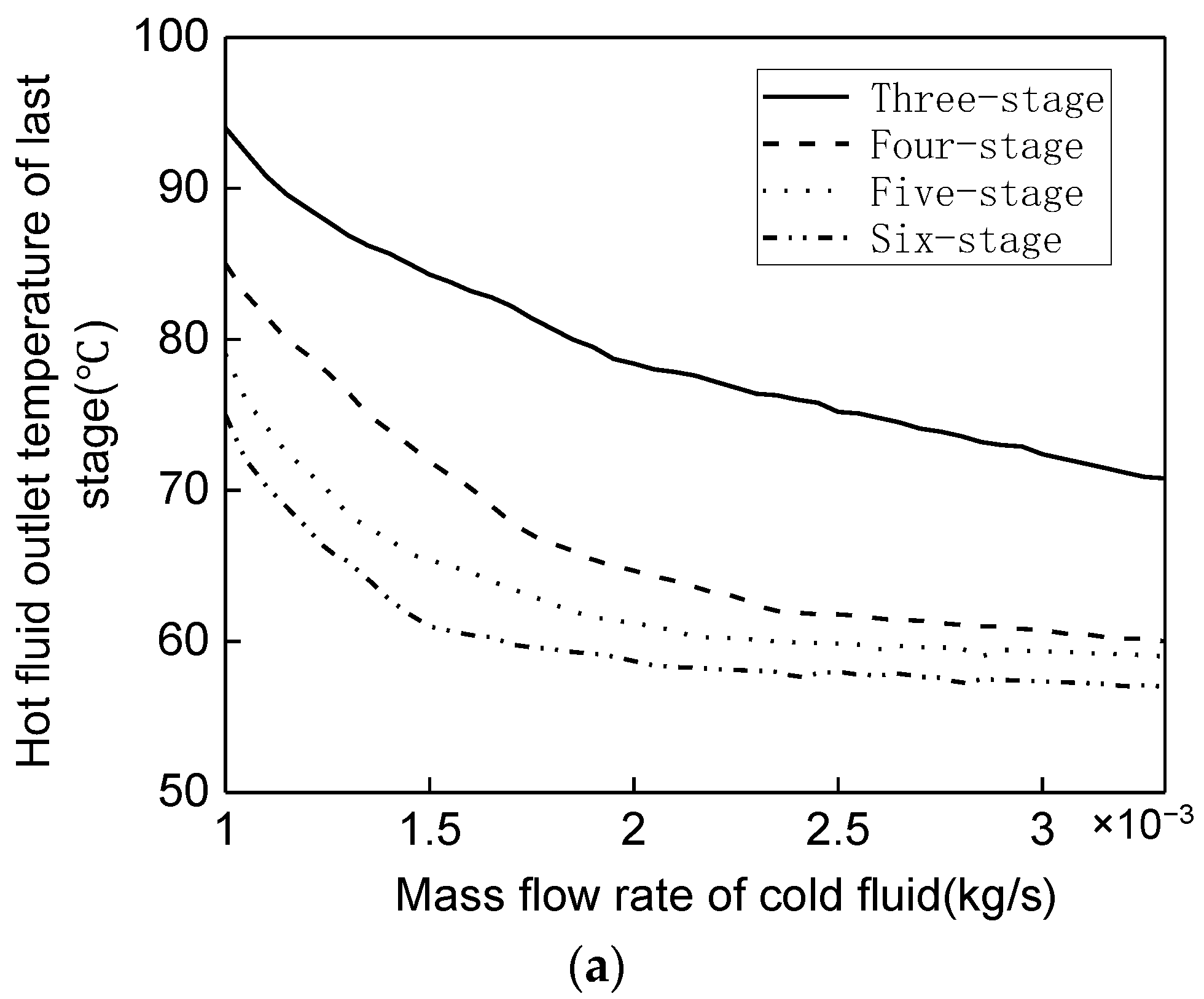

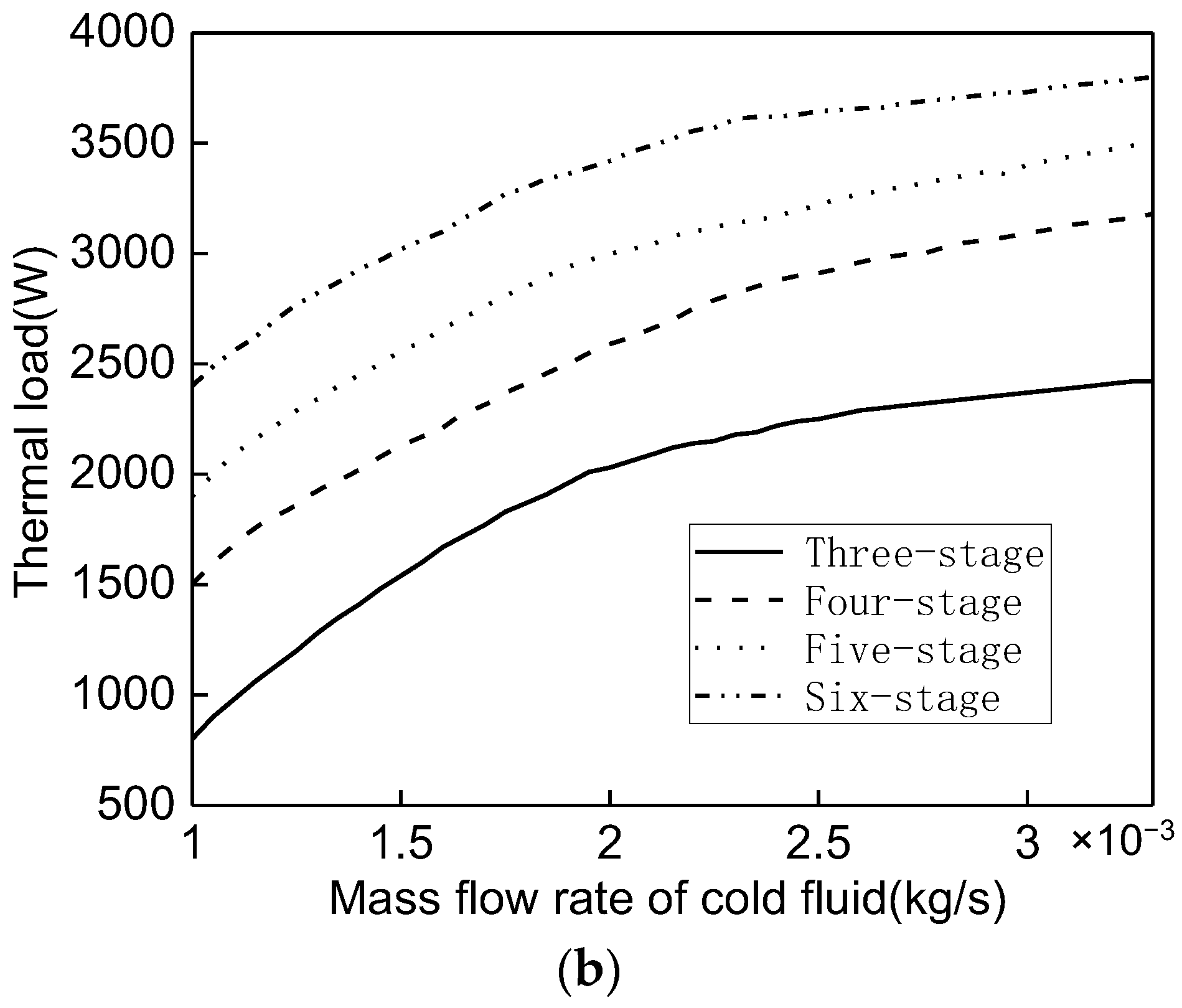

4.1. Scheme Comparison

4.2. Thermodynamic Characteristics

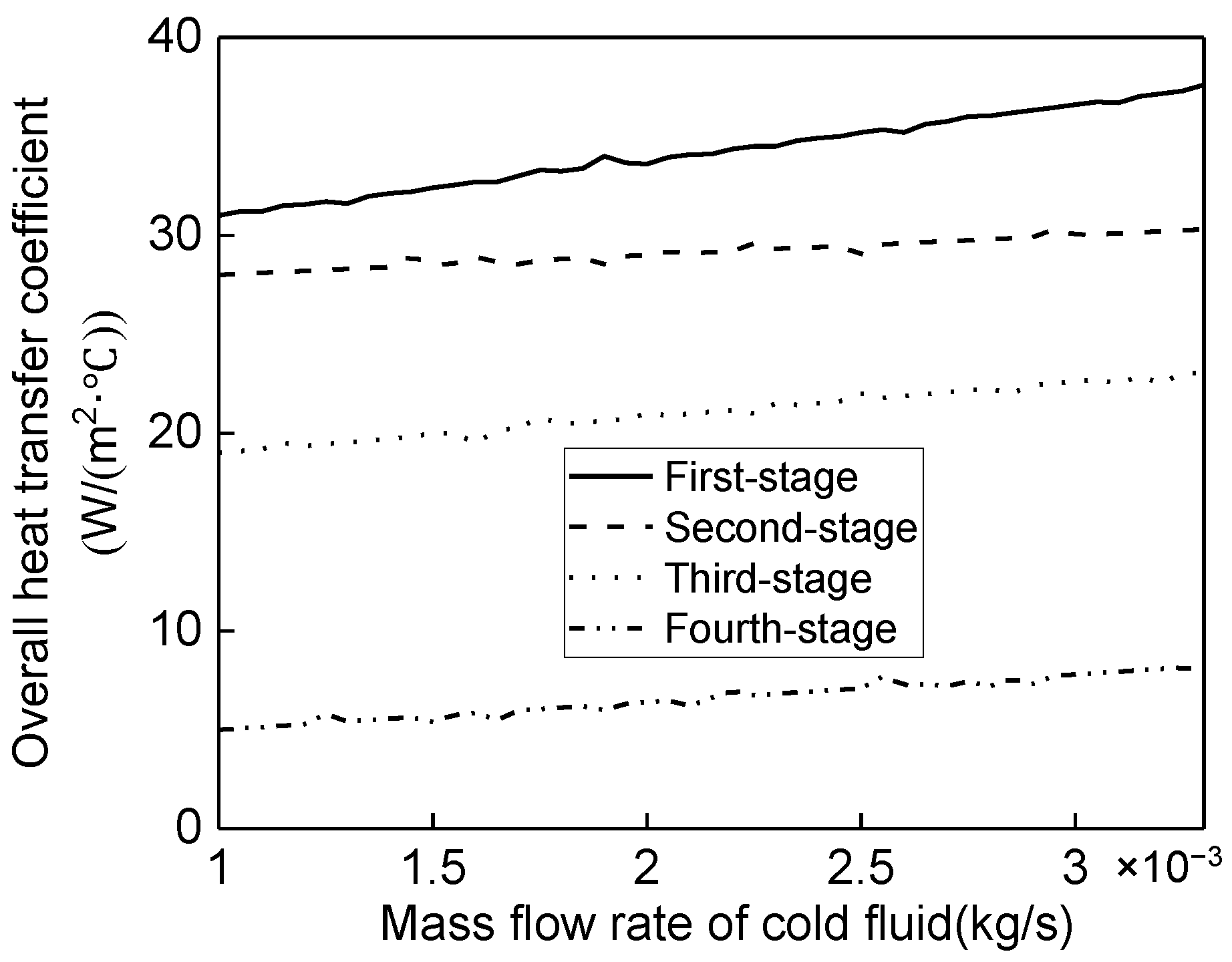

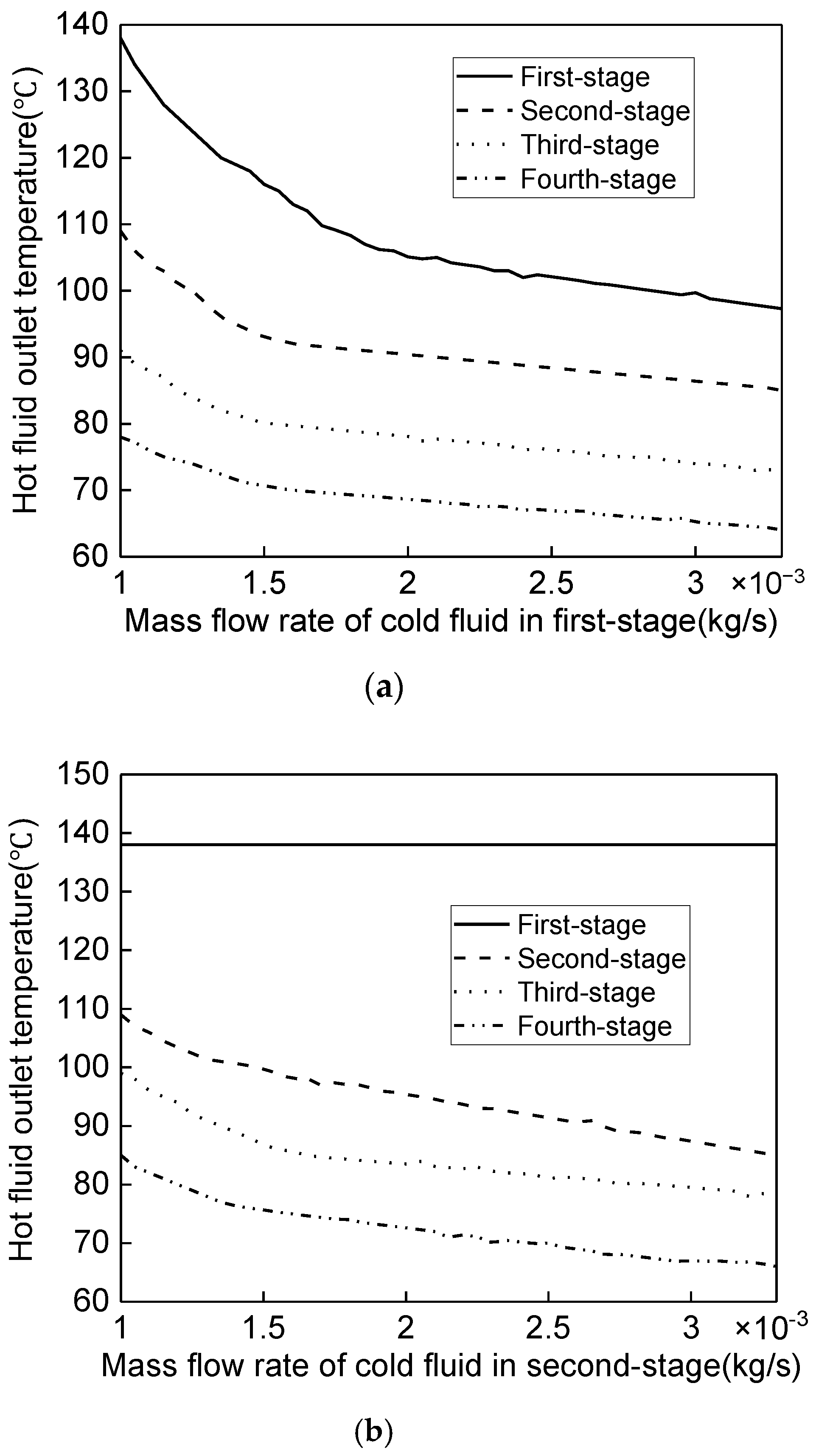

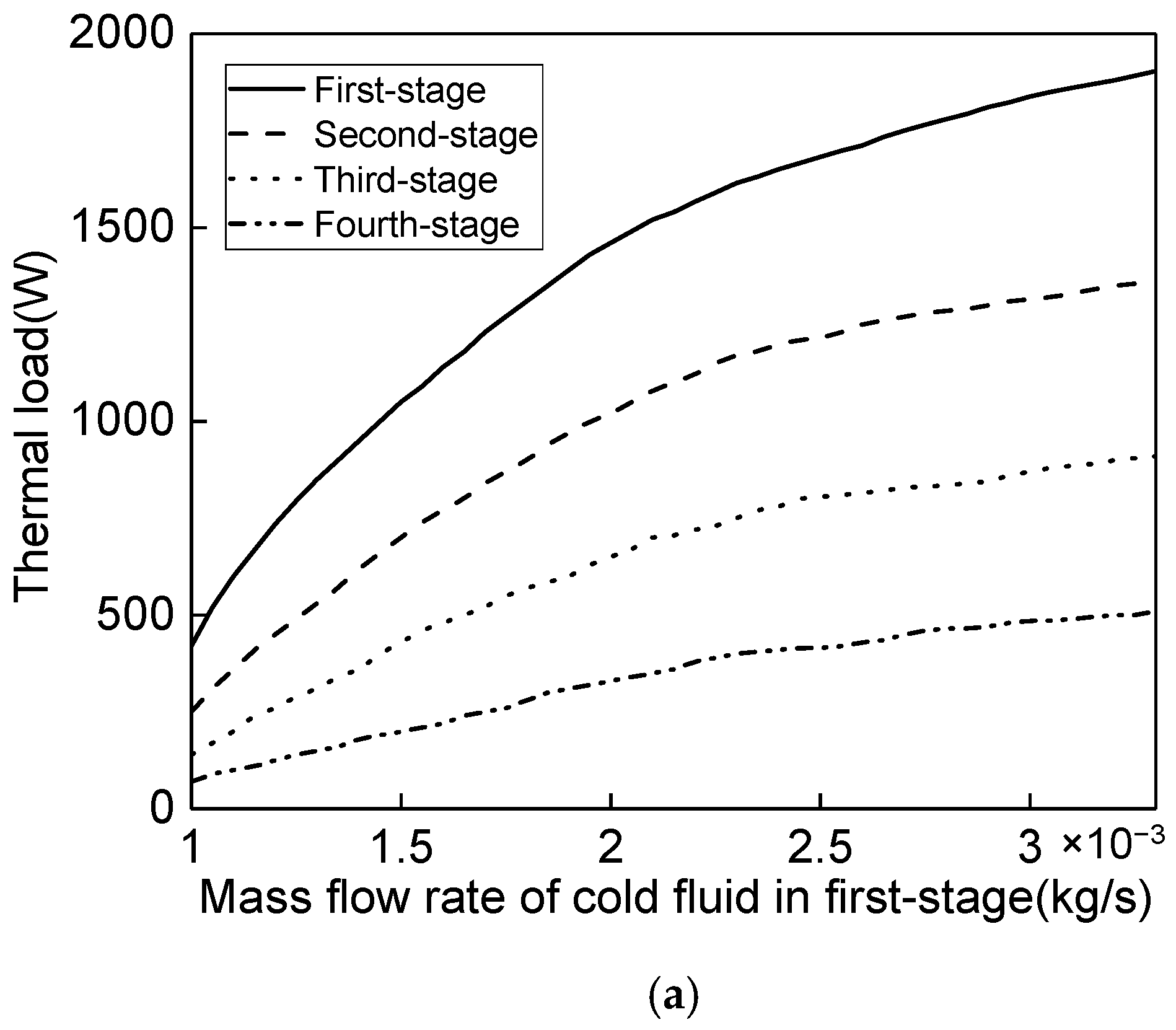

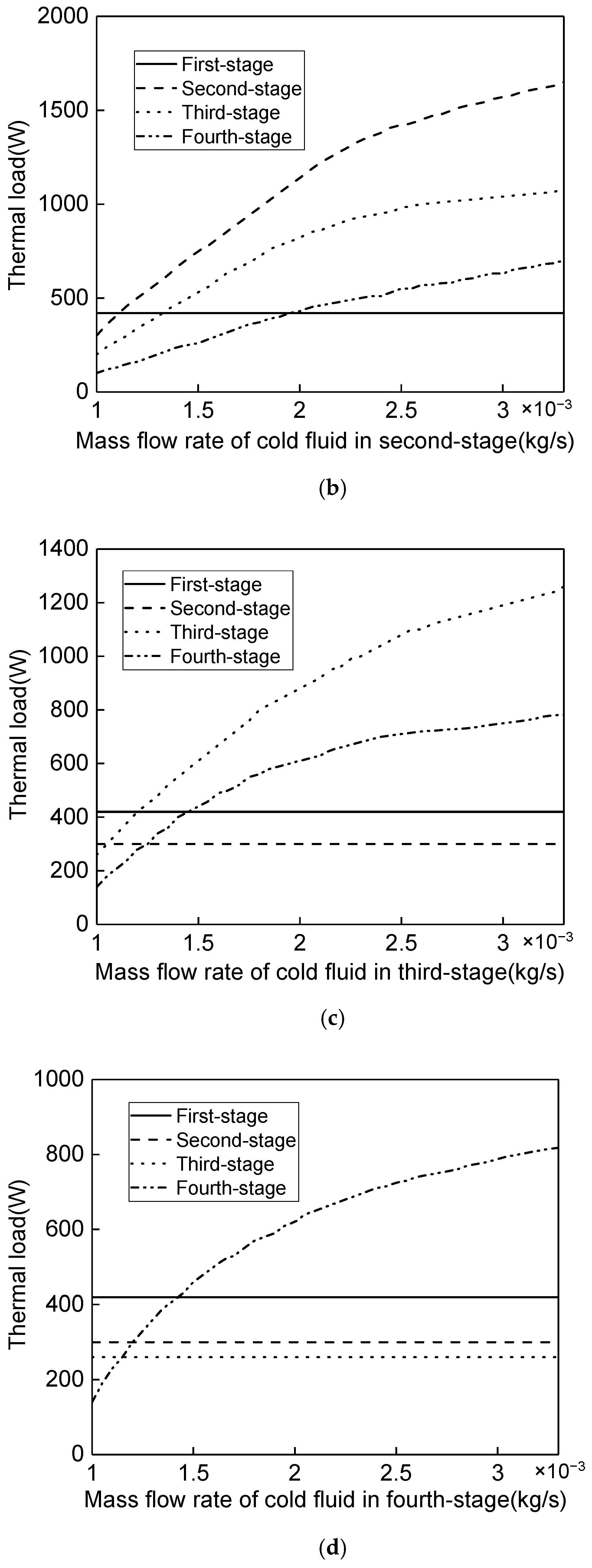

4.3. Operation Characteristics

5. Experimental Verification

5.1. Apparatus and Method

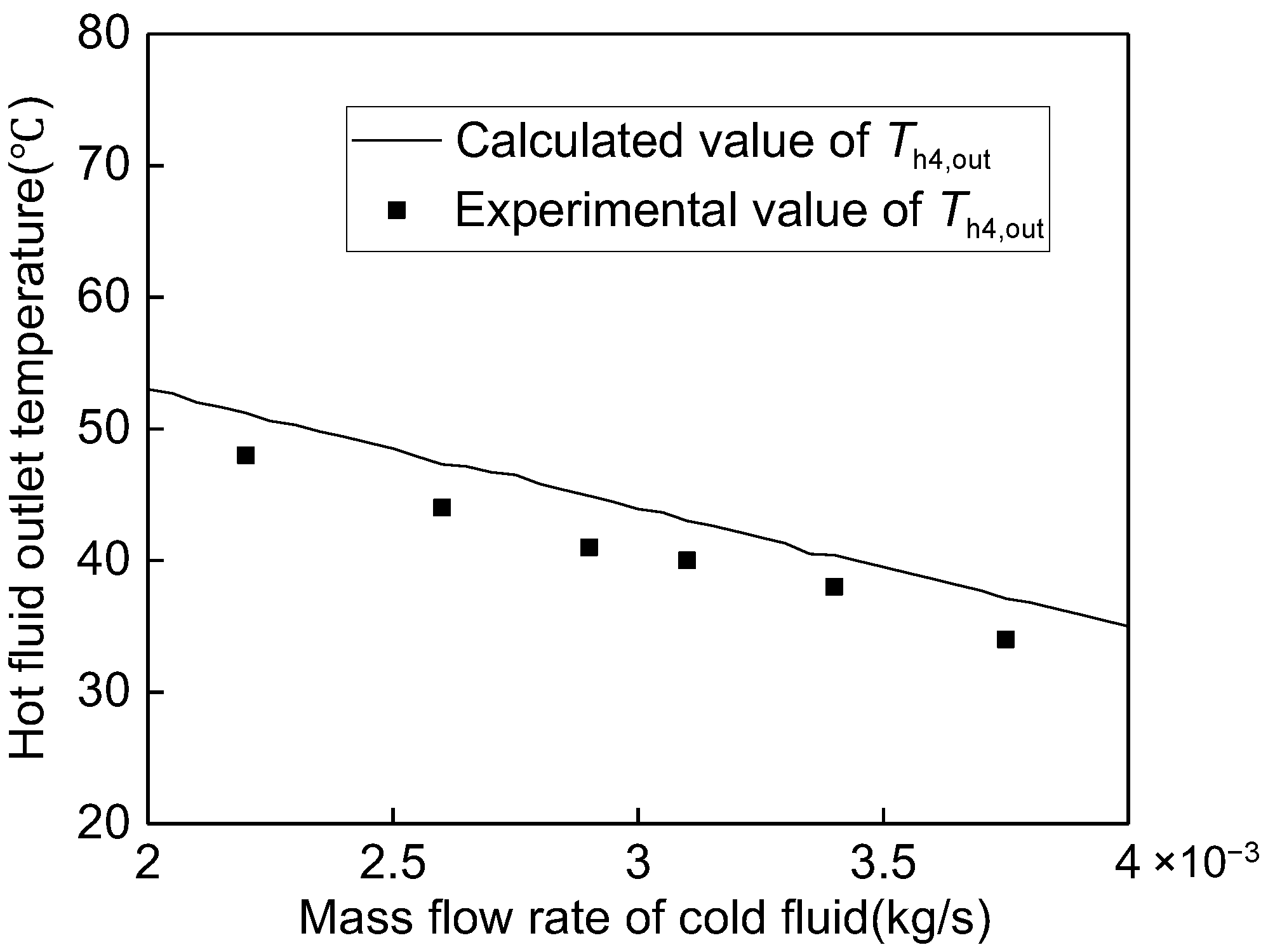

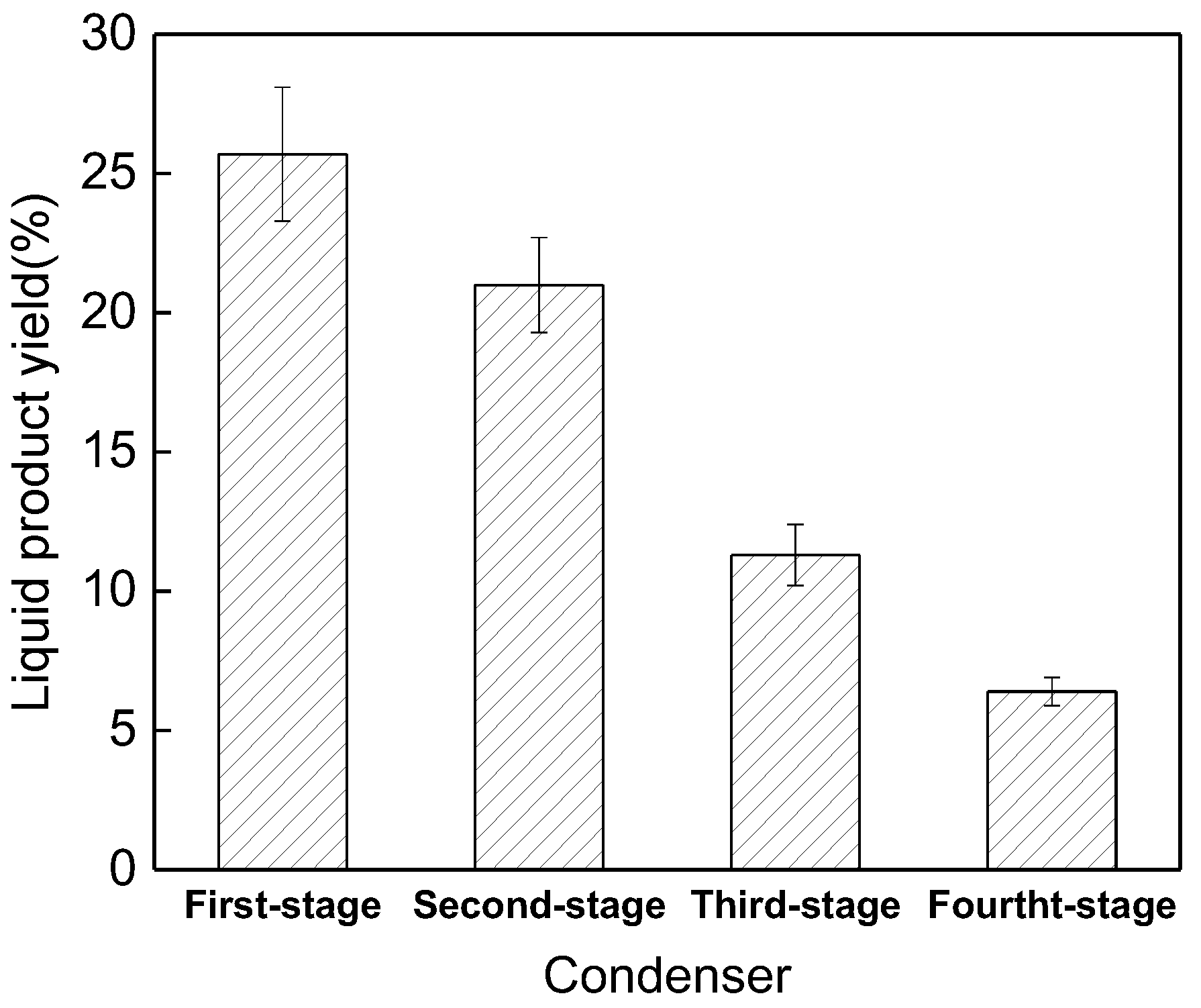

5.2. Results and Discussion

6. Conclusions

- (1)

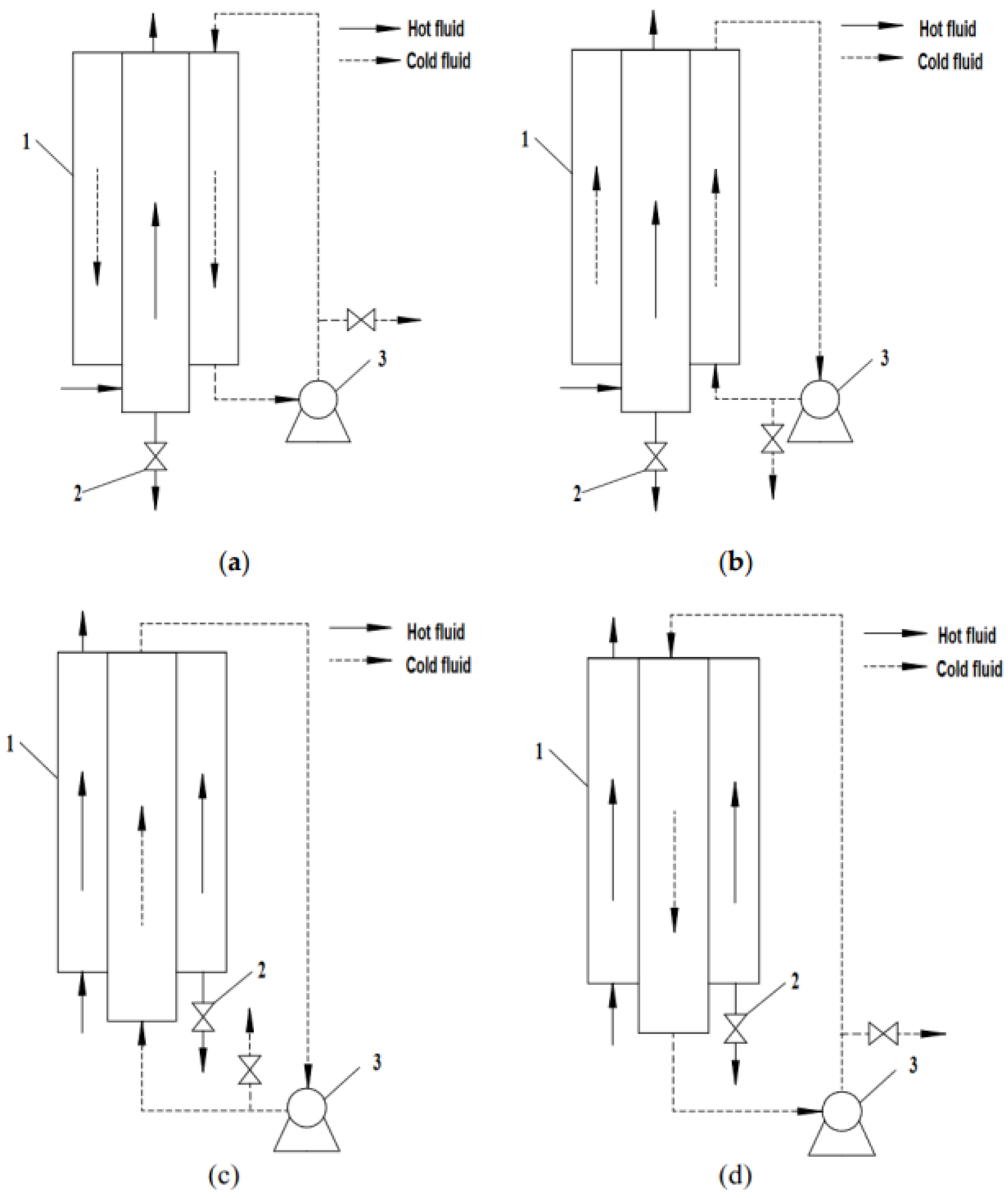

- According to the flow direction of the cold and hot fluids, and the structural characteristics of the dual tube heat exchanger, four condensation schemes of pyrolysis steam convective heat exchange were proposed to achieve rapid condensation and recover liquid products.

- (2)

- The single condenser models of the four schemes were established. Based on the control micro-element, the heat transfer disciplines of the internal fluids were obtained with the help of the heat transfer differential equation. The numerical simulation results showed that the convective heat transfer effect of the cold and hot fluids in Scheme 1 was best. At the same time, with the help of the concept of the model compound, the pyrolysis steam coupled multi-stage condensers model was proposed. The thermodynamic characteristics of with four different numbers of the condensers in series were also simulated. The results showed that when the number of condensers in series was four, the heat transfer process of the system reached saturation, and the heat exchange of the cold and hot fluids was completely realized, and it was of little significance to continue to connect more condensers in series for the condensation of pyrolysis steam.

- (3)

- Further calculations were carried out for the four-stage condensers, and the basic thermodynamic and operation characteristics were obtained. The results showed that in order to quickly reduce the hot fluid outlet temperature, the key was to increase the mass flow rate of the cold fluid in the first-stage condenser. While the mass flow rates of the cold fluid in the subsequent condensers increased a lot, the hot fluid outlet temperature may still be higher. The first-stage condenser was critical to the heat transfer efficiency of the entire system.

- (4)

- The four-stage condensers experimental apparatus was set up and experimental verification was carried out. The results showed that the calculated values obtained by the developed model were in good agreement with the measured values, and the deviation did not exceed 10%, better than the results of the literature [12,27]. At the same time, the liquid product yields of each condenser at the fixed conditions were obtained, which also showed the importance of the first-stage condenser.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbols | |

| F | fluid |

| cpc1,in | average constant pressure specific heat capacity of the fluid in the outer tube, kJ/(kg·°C) |

| cph1 | average constant pressure specific heat capacity of the fluid in the inner tube, kJ/(kg·°C) |

| D | diameter of the inner tube, m |

| K | overall heat transfer coefficient, W/(m2·°C) |

| mc1,in | mass flow rate of fluid in the outer tube, kg/s |

| mh1 | mass flow rate of fluid in the inner tube, kg/s |

| S | cross-sectional area of the inner tube, m2 |

| T | temperature, °C |

| t | time, s |

| v | average fluid velocity, m/s |

| Δq | thermal energy of the micro-element section, J |

| Δx | length of the micro-element section, J |

| Greek Letters | |

| ρ | density, kg/m3 |

| Subscripts | |

| c | cold fluid |

| hot | hot fluid |

| in | parameters of the fluid inlet |

| out | parameters of the fluid outlet |

| 1 | first-stage condenser |

References

- Zhang, Z.Y.; Ju, R.; Zhou, H.T.; Chen, H.W. Migration characteristics of heavy metals during sludge pyrolysis. Waste Manag. 2021, 120, 25–32. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Si, H. Experimental study on feeding characteristics of conical bottom pneumatic spout feeder for biomass pyrolysis. Chem. Eng. Process. 2021, 166, 108490. [Google Scholar] [CrossRef]

- Koshelev, M.M.; Ulyanov, V.V.; Kharchuk, S.E. Study of the Fractional Composition of Liquid Products of Pyrolysis of Solid Organic Waste in Liquid Lead. Theor. Found. Chem. Eng. 2021, 55, 671–676. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, D.C.; Si, H. A three-stage heating system of dual-fuel controlled by negative feedback for fluidized bed fast pyrolysis. Sustain. Energy Technol. 2021, 46, 101228. [Google Scholar] [CrossRef]

- Liu, L.S.; Zhang, X.Y.; Zhao, R.X.; Song, G.J.; Tian, L. Pyrolysis of Phragmites hirsuta study on pyrolysis characteristics, kinetic and thermodynamic analyses. Int. J. Energ. Res. 2021, 45, 15200–15216. [Google Scholar] [CrossRef]

- Gulec, F.; Simsek, E.H.; Sari, H.T. Prediction of Biomass Pyrolysis Mechanisms and Kinetics: Application of the Kalman Filter. Chem. Eng. Technol. 2021, 45, 167–177. [Google Scholar] [CrossRef]

- Bai, Y.; Qi, J.Y.; Si, H. Analytical study on the Heat-Transfer Characteristics of a Fluidized Bed Reactor Heated by Multi-Stage Resistance. Chem. Eng. Process. 2021, 164, 108395. [Google Scholar] [CrossRef]

- Song, Y.; Liang, H.B.; Chen, Z.X.; Ma, J. Mechanism of Low Temperature Pyrolysis of Oily Sludge A Case Study of Daqing Oilfield CHINA. Fresenius Environ. Bull. 2021, 30, 5954–5960. [Google Scholar]

- Tuntsev, D.V.; Shaikhutdinova, A.R. Mathematical description of the process of condensation of pyrolysis fuel during fast pyrolysis of woody biomass. Energy Source Part A 2020, 42, 1599–1607. [Google Scholar] [CrossRef]

- Zhu, X.F.; Luo, Z.J.; Zhu, X.F. Novel insights into the enrichment of phenols from walnut shell pyrolysis loop: Torrefaction coupled fractional condensation. Waste Manag. 2021, 131, 462–470. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Macquarrie, D.J.; De Bruyn, M.; Budarin, V.L.; Hunt, A.J.; Gronnow, M.J.; Fan, J.; Shuttleworth, P.S.; Clark, J.H.; Matharu, A.S. Low-temperature microwave-assisted pyrolysis of waste office paper and the application of bio-oil as an Al adhesive. Green Chem. 2021, 131, 462–470. [Google Scholar] [CrossRef]

- Wang, J.X.; Zhang, S.P.; Chen, M.Z.; Feng, Y.H.; Zhang, H.Y. Fractional condensation of pyrolysis oil from fast pyrolysis of food waste digestate for enrichment of high value-added nitrogen-containing components. J. Anal. Appl. Pyrol. 2022, 166, 105609. [Google Scholar] [CrossRef]

- Gooty, A.T. Fractional Condensation of Bio-Oil Vapors; The University of Western Ontario: London, ON, Canada, 2013. [Google Scholar]

- Lei, Z.; Hao, S.; Lei, Z.; Yang, J. Gas-Modified Pyrolysis Coke for in Situ Catalytic Cracking of Coal Tar. ACS Omega 2020, 5, 14911–14923. [Google Scholar] [CrossRef]

- Upham, D.C.; Agarwal, V.; Khechfe, A.; Snodgrass, Z.R.; Gordon, M.J.; Metiu, H.; McFarland, E.W. Catalytic molten metals for the direct conversion of methane to hydrogen and separable carbon. Science 2017, 358, 917–920. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Anderson, E.M.; Stone, M.L.; Katahira, R.; Reed, M.; Beckham, G.T.; Roman-Leshkov, Y. Flowthrough Reductive Catalytic Fractionation of Biomass. Joule 2017, 1, 613–622. [Google Scholar] [CrossRef] [Green Version]

- Li, N.; Fan, X.D.; Wang, X.Y.; Deng, H.; Zhang, K.; Zhang, X.G.; Han, Q.Y.; Lv, Y.; Liu, Z.W. Autophagy-Related 5 Gene rs510432 Polymorphism Is Associated with Hepatocellular Carcinoma in Patients with Chronic Hepatitis B Virus Infection. Immunol. Investig. 2019, 48, 378–391. [Google Scholar] [CrossRef] [PubMed]

- Sakakibara, H.; Usui, H.; Suzuki, K.; Kotani, T.; Aoki, H.; Kuroki, K. Model Construction and a Possibility of Cupratelike Pairing in a New d(9) Nickelate Superconductor (Nd, Sr)NiO2. Phys. Rev. Lett. 2020, 125, 077003. [Google Scholar] [CrossRef]

- Heidari, M.; Dutta, A.; Acharya, B.; Mahmud, S. A review of the current knowledge and challenges of hydrothermal carbonization for biomass conversion. J. Energy Inst. 2019, 92, 1779–1799. [Google Scholar] [CrossRef]

- Belbessai, S.; Azara, A.; Abatzoglou, N. Recent Advances in the Decontamination and Upgrading of Waste Plastic Pyrolysis Products: An Overview. Processes 2022, 10, 733. [Google Scholar] [CrossRef]

- Liu, T.B.; Qin, X.W.; Li, Q.Y. An optimal fourth-order family of modified Cauchy methods for finding solutions of nonlinear equations and their dynamical behavior. Open Math. 2019, 17, 1567–1598. [Google Scholar] [CrossRef]

- Bridgwater, A.V.; Peacocke, G.V.C. Fast pyrolysis processes for biomass. Renew. Sustain. Energy Rev. 2000, 4, 1–73. [Google Scholar] [CrossRef]

- Zi, Z.W. Petrochemical Design Manual; Chemical Industry Press: Beijing, China, 2015. (In Chinese) [Google Scholar]

- Jeng, J.S.; Wu, C.M. Fabrication of solution-processed nitrogen-doped niobium zinc tin oxide thin film transistors using ethanolamine additives. J. Alloy Compd. 2017, 729, 370–378. [Google Scholar] [CrossRef]

- Quan, H.Y.; Wang, L.Y.; Wang, Z.N.; Mei, X.D.; Ning, J.; She, D.M. Application of N-Acylimidazoles in the Claisen Condensation Reaction. ChemistrySelect 2020, 5, 7222–7226. [Google Scholar] [CrossRef]

- Li, X.Y.; Lin, B.N.; Li, H.B.; Yu, Q.; Ge, Y.; Jin, X.; Liu, X.H.; Zhou, Y.H.; Xiao, J.P. Carbon doped hexagonal BN as a highly efficient metal-free base catalyst for Knoevenagel condensation reaction. Appl. Catal. B Environ. 2018, 239, 254–259. [Google Scholar] [CrossRef]

- Li, C.; Zhang, C.T.; Hu, X. Biochar catalyzing polymerization of the volatiles from pyrolysis of poplar wood. Int. J. Energy Res. 2021, 45, 13936–13951. [Google Scholar] [CrossRef]

| Outer Diameter, mm | Inner Diameter, mm | Thickness, mm | Heat Transfer Height, mm | Effective Heat Transfer Area, m2 |

|---|---|---|---|---|

| 80 | 40 | 3 | 700 | 0.1 |

| Parameter | Value |

|---|---|

| Thermal energy entering the inner tube from the x section | mh1cph1T1Δt |

| Thermal energy flowing out of the outer tube from the x section | mc1,incpc1,in(T2 + ΔT2)Δt |

| Thermal energy flowing out of the outer tube from the x + Δx section | mh1cph1(T1 + ΔT1)Δt |

| Thermal energy entering the inner tube from the x + Δx section | mc1,incpc1,inT2Δt |

| Thermal energy from the inner tube to the outer tube | Δq = K(πD△x) (T1 − T2)Δt |

| Compound | Content, % | Physical Properties at the Qualitative Temperature | |||

|---|---|---|---|---|---|

| Specific Heat Capacity, kJ/(kg·°C) | Density, kg/m3 | Dynamic Viscosity, 10−5 Pa·s | Thermal Conductivity, W/(m·°C) | ||

| Acetic acid | 16.67 | 2.176 | 0.398 | 0.016 | 0.048 |

| Ethyl acetate | 5.76 | 1.943 | 0.143 | 1.731 | 0.049 |

| Resorcinol | 4.93 | 2.559 | 0.427 | 1.278 | 0.031 |

| 2,5-diethoxy tetrahydrofuran | 2.52 | 1.879 | 0.212 | 0.015 | 0.039 |

| 7-hydroxy-3- Methylcyclopent -7-enone | 2.02 | 2.438 | 0.268 | 0.012 | 0.034 |

| 7-methoxyphenyl acetate | 1.99 | 3.311 | 0.166 | 0.015 | 0.044 |

| 4-propenyl-7- methoxyphenol | 1.82 | 2.252 | 0.145 | 0.019 | 0.032 |

| 4-hydroxy-7-methoxybenzaldehyde | 6.74 | 1.781 | 0.181 | 0.016 | 0.061 |

| Catechol | 5.84 | 3.933 | 0.242 | 0.013 | 0.035 |

| Furan aldehyde | 4.93 | 1.344 | 0.221 | 0.019 | 0.065 |

| 3-methoxybenzaldehyde | 2.77 | 3.801 | 0.187 | 0.014 | 0.043 |

| Phenol | 2.54 | 1.943 | 0.455 | 0.016 | 0.041 |

| 7-methoxy-4 -methyl phenol | 1.84 | 1.478 | 0.153 | 1.514 | 0.039 |

| Water | 38.31 | 3.715 | 0.912 | 0.054 | 0.062 |

| Specific Heat Capacity, kJ/(kg·°C) | Density, kg/m3 | Dynamic Viscosity, 10−5 Pa·s | Thermal Conductivity, W/(m·°C) |

|---|---|---|---|

| 2.883 | 0.529 | 0.249 | 0.053 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Y.; Ma, Y.; Ke, C.; Cheng, W.; Guo, G.; Zhao, P.; Cao, C.; Liao, L.; Yang, X.; Fan, Z. Thermodynamic Characteristics Study with Pyrolysis Steam Coupled Multi-Stage Condensers. Processes 2022, 10, 2030. https://doi.org/10.3390/pr10102030

Bai Y, Ma Y, Ke C, Cheng W, Guo G, Zhao P, Cao C, Liao L, Yang X, Fan Z. Thermodynamic Characteristics Study with Pyrolysis Steam Coupled Multi-Stage Condensers. Processes. 2022; 10(10):2030. https://doi.org/10.3390/pr10102030

Chicago/Turabian StyleBai, Yong, Yunfeng Ma, Changjun Ke, Wang Cheng, Guangyan Guo, Peng Zhao, Can Cao, Lifen Liao, Xuebo Yang, and Zhongwei Fan. 2022. "Thermodynamic Characteristics Study with Pyrolysis Steam Coupled Multi-Stage Condensers" Processes 10, no. 10: 2030. https://doi.org/10.3390/pr10102030

APA StyleBai, Y., Ma, Y., Ke, C., Cheng, W., Guo, G., Zhao, P., Cao, C., Liao, L., Yang, X., & Fan, Z. (2022). Thermodynamic Characteristics Study with Pyrolysis Steam Coupled Multi-Stage Condensers. Processes, 10(10), 2030. https://doi.org/10.3390/pr10102030