A T-S Fuzzy Quaternion-Value Neural Network-Based Data-Driven Generalized Predictive Control Scheme for Mecanum Mobile Robot

Abstract

:1. Introduction

2. Problem Description

3. T-S Fuzzy Quaternion-Value Neural Network Identification

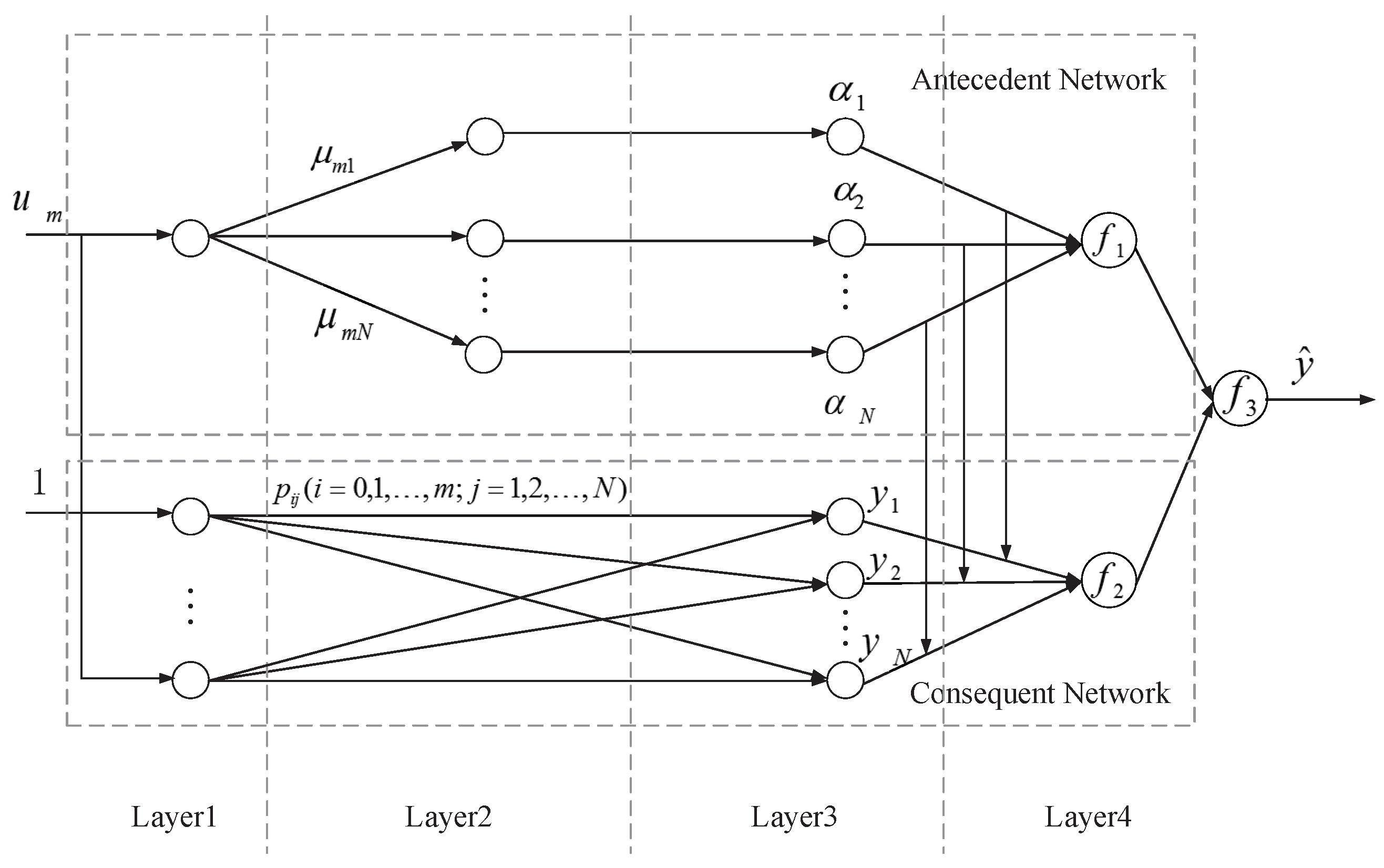

3.1. T-S Fuzzy Quaternion-Value Neural Network

- Layer 1: The first layer is defined by N input variable :where m and n are the dimension of input vector and order of the system, respectively.

- Layer 2: The second layer fuzzifies the data from the first layer and gets the membership function . N denotes the fuzzy partition number of . Then, we use the Gaussian function as the split-activation function because the split-activation function can avoid a large number of singularities in the process of solving [22]. We have:where the initial values and of and are calculated from the fuzzy c-means (FCM) methods [28]. The formula is as follows:The following is the real part for example, and the rest can be obtained in this way:where is a weighted exponent.

- Layer 3: Each node in the antecedent network represents a fuzzy rule. The fuzzy method of single point fuzzy set is adopted for the input value, namely:.where .

- Layer 4: The fourth layer is the output layer and contains three functions, , , . The function sums the fitness of the fuzzy antecedent, and then the function and can calculate the output of the system. We haveConsequently the system forecast output is

3.2. The Learning Algorithm

3.3. Proof of Global Approximation

3.4. Stability Analysis

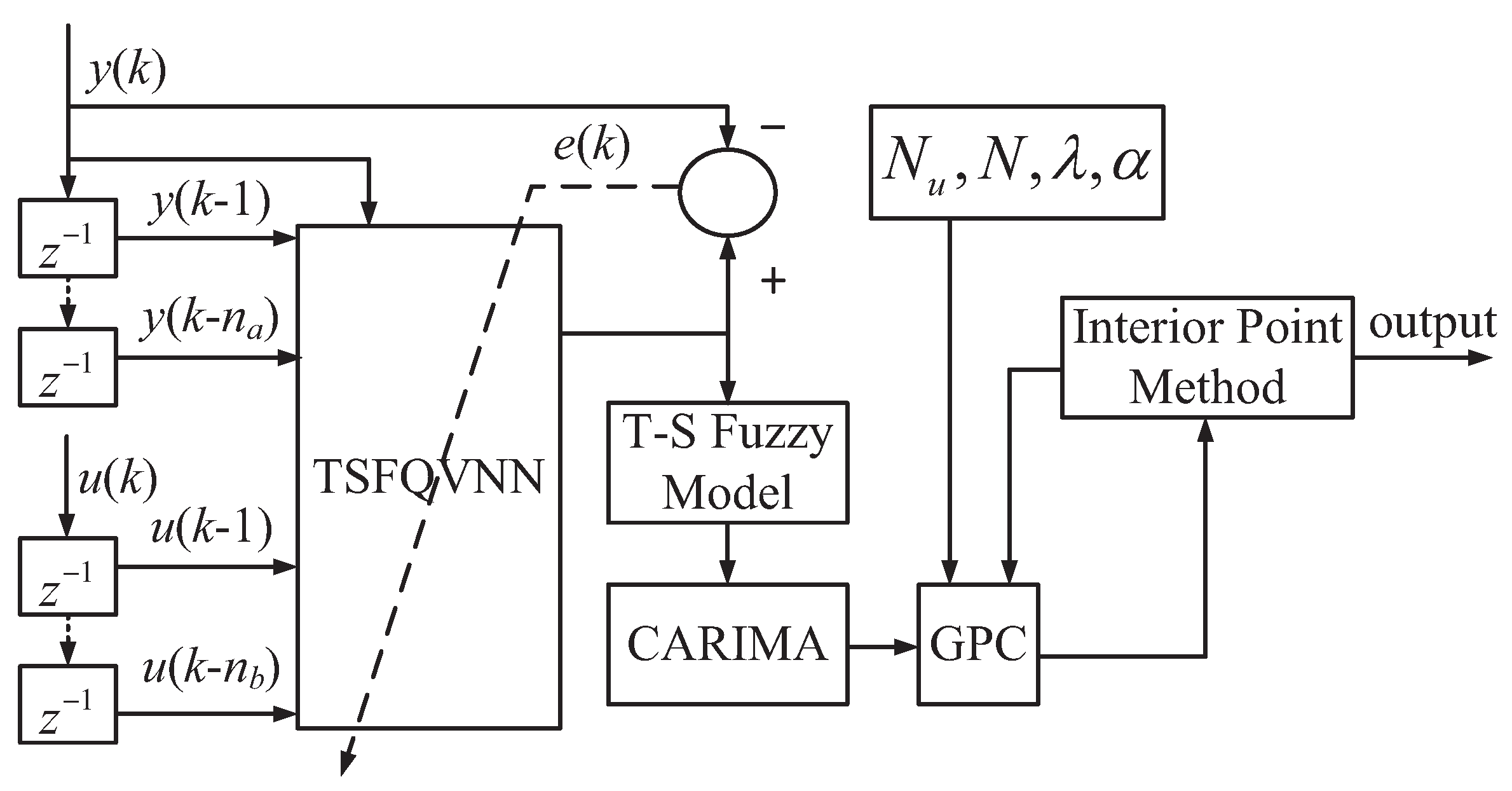

4. Fuzzy Predictive Control Algorithm

- .

- .

- .

5. Simulation Results

5.1. System Identification

5.2. Trajectory Tracking in 3D Space

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, B.H.; Qi, Q. The design of logistics handling robot based on mcu. Appl. Mech. Mater. 2013, 336–338, 1124–1128. [Google Scholar] [CrossRef]

- Wu, H.; Tian, G.H.; Li, Y.; Zhou, F.Y.; Duan, P. Spatial semantic hybrid map building and application of mobile service robot. Robot. Auton. Syst. 2014, 62, 923–941. [Google Scholar] [CrossRef]

- Gao, X.; Acar, L. Using a mobile robot with interpolation and extrapolation method for chemical source localization in dynamic advection-diffusion environment. Int. Conf. Robot. Autom. 2016, 5, 87–97. [Google Scholar] [CrossRef]

- Doering, N.; Poeschl, S.; Gross, H.; Bley, A.; Martin, C.; Boehme, H.J. User-centered design and evaluation of a mobile shopping robot. Int. J. Soc. Robot. 2015, 7, 203–225. [Google Scholar] [CrossRef]

- Takemura, Y.; Yu, O.; Nassiraei, A.A.F.; Sanada, A.; Miyamoto, H. A system design concept based on omnidirectional mobility, safety and modularity for an autonomous mobile soccer robot. J. Bionic Eng. 2008, 5, 121–129. [Google Scholar] [CrossRef]

- de Villiers, M.; Tlale, N.S. Development of a control model for a four wheel mecanum vehicle. J. Dyn. Syst. Meas. Control 2012, 134, 011007. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Yang, X.; Hu, F.; Jiang, A.; Yang, C. Trajectory tracking of an omni-directional wheeled mobile robot using a model predictive control strategy. Appl. Sci. 2018, 5, 231. [Google Scholar] [CrossRef]

- Alakshendra, V.; Chiddarwar, S.S. Adaptive robust control of mecanum-wheeled mobile robot with uncertainties. Nonlinear Dyn. 2017, 87, 2147–2169. [Google Scholar] [CrossRef]

- Conceio, A.S.; Moreira, A.P.; Costa, P.J. Practical approach of modeling and parameters estimation for omnidirectional mobile robots. IEEE/ASME Trans. Mechatronics 2009, 14, 377–381. [Google Scholar] [CrossRef]

- Salih, J.E.M.; Rizon, M.; Yaacob, S.; Adom, A.H.; Mamat, M.R. Designing Omni-Directional Mobile Robot with Mecanum Wheel. Am. J. Appl. Sci. 2006, 3, 1831–1835. [Google Scholar] [CrossRef]

- Lin, L.C.; Shih, H.Y. Modeling and adaptive control of an omnimecanum-wheeled robot. Intell. Control Autom. 2013, 2, 166–179. [Google Scholar] [CrossRef]

- Deng, J. Dynamic neural networks with hybrid structures for nonlinear system identification. Eng. Appl. Artif. Intell. 2013, 26, 281–292. [Google Scholar] [CrossRef]

- Bagherzadeh, S.A. Nonlinear aircraft system identification using artificial neural networks enhanced by empirical mode decomposition. Aerosp. Sci. Technol. 2018, 75, 155–171. [Google Scholar] [CrossRef]

- Rong, H.J.; Sundararajan, N.; Huang, G.B.; Saratchandran, P. Sequential adaptive fuzzy inference system (safis) for nonlinear system identification and prediction. Fuzzy Sets Syst. 2006, 157, 1260–1275. [Google Scholar] [CrossRef]

- Wang, S.; Dou, J.; Liu, Y.; Liu, F. Prediction of chaotic time series based on interval type-2 T-S fuzzy system. J. Comput. Inf. Syst. 2014, 10, 5403–5412. [Google Scholar]

- Cervantes, J.; Yu, W.; Salazar, S.; Chairez, I. Takagi-Sugeno dynamic neuro-fuzzy controller of uncertain nonlinear systems. IEEE Trans. Fuzzy Syst. 2017, 25, 1601–1615. [Google Scholar] [CrossRef]

- Yilmaz, Y.; Oysal, S. Fuzzy wavelet neural network models for prediction and identification of dynamical systems. IEEE Trans. Neural Netw. 2010, 21, 1599–1609. [Google Scholar] [CrossRef]

- Abiyev, R.H.; Kaynak, O.; Kayacan, E. A type-2 fuzzy wavelet neural network for system identification and control. J. Frankl. Inst. 2013, 15, 1658–1685. [Google Scholar] [CrossRef]

- Matsui, N.; Isokawa, T.; Kusamichi, H.; Peper, F.; Nishimura, H. Quaternion neural network with geometrical operators. J. Intell. Fuzzy Syst. 2004, 15, 149–164. [Google Scholar]

- Bei, J.C.; Hua, Z.S.; Gang, C.; Ge, J. Color face recognition based on quaternion zernike moment invariants and quaternion bp neural network. Appl. Mech. Mater. 2011, 446, 1034–1039. [Google Scholar]

- Oyama, K.; Hirose, A. Phasor quaternion neural networks for singular point compensation in polarimetric-interferometric synthetic aperture radar. IEEE Trans. Geosci. Remote Sens. 2019, 57, 2510–2519. [Google Scholar] [CrossRef]

- Parcollet, T.; Morchid, M.; Linares, G. A survey of quaternion neural networks. Artif. Intell. Rev. 2019, 53, 2957–2982. [Google Scholar] [CrossRef]

- Takahashi, K. Remarks on feedforward-feedback controller using simple recurrent quaternion neural network. In Proceedings of the 2018 IEEE Conference on Control Technology and Applications (CCTA), Copenhagen, Denmark, 21–24 August 2018; pp. 1246–1251. [Google Scholar]

- Saoud, L.S.; Ghorbani, R.; Rahmoune, F. Cognitive quaternion valued neural network and some applications. Neurocomputing 2017, 221, 85–93. [Google Scholar] [CrossRef]

- Yuan, Z.; Tian, Y.; Yin, Y.; Wang, S.; Liu, J.; Wu, L. Trajectory tracking control of a four mecanum wheeled mobile platform: An extended state observer-based sliding mode approach. IET Control Theory Appl. 2020, 14, 415–426. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, N.; Li, C.; Zhang, Y.; Lai, X. An adaptive Takagi-Sugeno fuzzy model-based generalized predictive controller for pumpedstorage unit. IEEE Access 2019, 99, 1–13. [Google Scholar] [CrossRef]

- Liu, X.; Liu, J.; Guan, P. Neuro-fuzzy generalized predictive control of boiler steam temperature. J. Control Theory Appl. 2007, 5, 83–88. [Google Scholar] [CrossRef]

- Bezdek, J.C.; Ehrlich, R.; Full, W. FCM: The fuzzy c-means clustering algorithm. Comput. Geosci. 1984, 10, 191–203. [Google Scholar] [CrossRef]

- Wang, L.X.; Mendel, J.M. Fuzzy basis functions, universal approximation, and orthogonal least-squares learning. IEEE Trans. Neural Netw. 1992, 3, 807–814. [Google Scholar] [CrossRef]

- Lorenz, E.N. Deterministic nonperiodic flow. J. Atmos. Sci. 1963, 20, 130–141. [Google Scholar] [CrossRef]

- Chen, G.; Ueta, T. Yet another chaotic attractor. Int. J. Bifurc. Chaos 1999, 9, 1465–1466. [Google Scholar] [CrossRef]

- Xu, M.; Han, M.; Chen, C.L.P.; Qiu, T. Recurrent broad learning systems for time series prediction. IEEE Trans. Cybern. 2020, 50, 1405–1417. [Google Scholar]

| Series | Method | RMSE | SMAPE | NRMSE | |

|---|---|---|---|---|---|

| Lorenz −x(t+1) | TSFLS | ave. | 0.1308 | 0.0143 | |

| std. | |||||

| TSFNN | ave. | 0.7136 | 0.0465 | 0.0079 | |

| std. | 0.0707 | 0.0046 | |||

| TSFQVNN | ave. | 0.0632 | 0.0037 | ||

| std. | |||||

| Lorenz −y(t+1) | TSFLS | ave. | 0.2796 | 0.0330 | 0.0010 |

| std. | 0.0081 | ||||

| TSFNN | ave. | 0.9233 | 0.0543 | 0.0112 | |

| std. | 0.0915 | 0.0054 | 0.0011 | ||

| TSFQVNN | ave. | 0.1008 | 0.0064 | ||

| std. | 0.0022 | ||||

| Lorenz −z(t+1) | TSFLS | ave. | 0.4901 | 0.0140 | 0.0033 |

| std. | 0.0081 | 0.0021 | 0.0018 | ||

| TSFNN | ave. | 0.4959 | 0.0083 | 0.0031 | |

| std. | 0.0492 | ||||

| TSFQVNN | ave. | 0.1119 | 0.0016 | ||

| std. | 0.0022 | ||||

| Series | Method | RMSE | SMAPE | NRMSE | |

|---|---|---|---|---|---|

| Chen −x(t + 1) | TSFLS | ave. | 0.1396 | 0.0064 | |

| std. | 0.0032 | ||||

| TSFNN | ave. | 1.0863 | 0.0606 | 0.0150 | |

| std. | 0.0029 | ||||

| TSFQVNN | ave. | 0.0037 | |||

| std. | 0.0016 | ||||

| Chen −y(t + 1) | TSFLS | ave. | 0.1690 | 0.0065 | |

| std. | 0.0023 | ||||

| TSFNN | ave. | 1.4721 | 0.0711 | 0.0228 | |

| std. | 0.0046 | ||||

| TSFQVNN | ave. | 0.0081 | |||

| std. | 0.0463 | 0.0014 | |||

| Chen −z(t + 1) | TSFLS | ave. | 0.4379 | 0.0110 | 0.0020 |

| std. | 0.0269 | ||||

| TSFNN | ave. | 0.4379 | 0.0065 | 0.0024 | |

| std. | 0.0046 | ||||

| TSFQVNN | ave. | 0.2644 | 0.0043 | 0.0012 | |

| std. | 0.0463 | 0.0028 | 0.0013 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Li, X.; Xiang, G.; Dian, S. A T-S Fuzzy Quaternion-Value Neural Network-Based Data-Driven Generalized Predictive Control Scheme for Mecanum Mobile Robot. Processes 2022, 10, 1964. https://doi.org/10.3390/pr10101964

Ma C, Li X, Xiang G, Dian S. A T-S Fuzzy Quaternion-Value Neural Network-Based Data-Driven Generalized Predictive Control Scheme for Mecanum Mobile Robot. Processes. 2022; 10(10):1964. https://doi.org/10.3390/pr10101964

Chicago/Turabian StyleMa, Congjun, Xiaoying Li, Guofei Xiang, and Songyi Dian. 2022. "A T-S Fuzzy Quaternion-Value Neural Network-Based Data-Driven Generalized Predictive Control Scheme for Mecanum Mobile Robot" Processes 10, no. 10: 1964. https://doi.org/10.3390/pr10101964

APA StyleMa, C., Li, X., Xiang, G., & Dian, S. (2022). A T-S Fuzzy Quaternion-Value Neural Network-Based Data-Driven Generalized Predictive Control Scheme for Mecanum Mobile Robot. Processes, 10(10), 1964. https://doi.org/10.3390/pr10101964