Data-Driven Intelligent Model for the Classification, Identification, and Determination of Data Clusters and Defect Location in a Welded Joint

Abstract

1. Introduction

- (1)

- The k-mean clustering method, which was implemented for data analysis of welded joints with intricate shapes, provides statistically relevant features from NDE data by classifying the dataset into clusters and noise points. To the best of my knowledge, this is the first study to apply the k-mean clustering method for the classification of the dataset from a welded joint with intricate shapes and structures.

- (2)

- The k-mean clustering method provides a visualization schema of the NDE data features of the welded joint considered, showing the clustering means, clustering coefficient, cluster heterogeneity, silhouette score, and the size and measurement in the form of clusters and noise point information.

- (3)

- Finally, the LOF model algorithm is implemented for the detection of flaws due to internal cracks, internal porosity, internal fusion, and internal penetration in the welded joint. To the best of my knowledge, this is the first study to apply the LOF model algorithm for the detection of flaws in welded joints, especially for welded joints with intricate shapes and structures.

- (a)

- Less Waste: The use of modeling and simulation in NDE does not change or alter the structure or composition of a component or structure; therefore, their usage is not restricted and results in no samples wasted, unlike the traditional NDE where samples may be wasted.

- (b)

- Reduced downtime: There is no need to halt operations when using the modeling and simulation approach for the NDE of components and structures because the procedures allow testing to take place while the materials are still in use.

- (c)

- Prevention of accidents: Accidents can be avoided with the aid of modeling and simulation of the NDE process, which also lowers the price of maintenance, replacement, and equipment loss, as well as the need to close down a firm.

- (d)

- We see the NDE and process (and environmental) monitoring being applied seamlessly as Industry 4.0 envisions cyber–physical systems, where they talk with each other in terms of processes, quality, and logistical aspects.

- (e)

- Data collection with NDE at various stages of the value chain can be merged into a “digital twin” of a component or structure, which can be used as a reference for the condition or structural health monitoring later on. For predictive analytics to compute preventative maintenance or a remaining lifetime, machine learning algorithms must be used.

2. The Data-Driven Intelligent Model for Welded Joints

2.1. K-Mean Clustering and the Local Outlier Factor (LOF) Model

- The Euclidean distance is used as both the metric and variance, and for measuring the cluster scatter.

- The number of clusters k, when used as an input parameter; selecting an incorrect value for k, may result in bad results. It is important, therefore, to check the number of clusters in the data set when performing a diagnostic check with the k-mean clustering method.

- Finally, the convergence to a local minimum can have unexpected (“wrong”) results.

- (a)

- Using a distance function such as Euclidean or Manhattan, calculate the distance between P and all of the specified points.

- (b)

- Locate the nearest k (k-nearest neighbor) point. For example, if k = 3, find the distance to the third nearest neighbor.

- (c)

- Locate the k nearest points.

- (d)

- Using the following equation, calculate the local reachability density (lrd), , where reachable distance can be calculated as , is the number of neighbors.

- (e)

- The final step is to compute the local outlier factor, which is as follows, .

2.2. Data Collection for the Implementation of a Data-Driven Intelligent Model

3. Implementation of the Data-Driven Intelligent Model

3.1. The K-Mean Clustering Algorithm for Defect Classification for Welded Joint Data

3.2. Application of LOF Model Algorithm for Flaw Detection in Welded Joints

4. Discussion of the Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmed, F.; Kim, K.Y. Data-driven Weld Nugget Width Prediction with Decision Tree Algorithm. Procedia Manuf. 2017, 10, 1009–1019. [Google Scholar] [CrossRef]

- Aikhuele, D.O. A hybrid-fuzzy model with reliability-based criteria for selecting consumables used in welding dissimilar aluminum alloys joint. Eng. Appl. Sci. Res. 2019, 46, 79–85. [Google Scholar] [CrossRef]

- Albers, A.; Holoch, J.; Revfi, S.; Spadinger, M. Lightweight design in product development: A conceptual framework for continuous support in the development process. Procedia CIRP 2021, 100, 494–499. [Google Scholar] [CrossRef]

- Ali, K.A.; Ahmad, M.I.; Yusup, Y. Issues, impacts, and mitigations of carbon dioxide emissions in the building sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, Z.; Liu, Q.; Liu, X. Smk-Means-an-Improved-Mini-Batch-K-Means-Algorithm. Tech. Sci. Press (TSP) 2018, 56, 365–379. [Google Scholar]

- De Souza, G.C.; Pardal, J.M.; Tavares, S.S.M.; da Cindra Fonseca, M.P.; Ferreira Martins, J.L.; de Moura, E.P.; Filho, I.C. Evaluation of proportion of phases in joints welded from duplex stainless steel pipes by means of non-destructive testing. Weld. Int. 2015, 29, 762–770. [Google Scholar] [CrossRef]

- Eshtayeh, M.; Hijazi, A.; Hrairi, M. Nondestructive Evaluation of Welded Joints Using Digital Image Correlation. J. Nondestruct. Eval. 2015, 34, 37. [Google Scholar] [CrossRef]

- Et-Taleby, A.; Boussetta, M.; Benslimane, M. Faults detection for photovoltaic field based on k-means, elbow, and average silhouette techniques through the segmentation of a thermal image. Int. J. Photoenergy 2020, 2020, 6617597. [Google Scholar] [CrossRef]

- Ikumapayi, O.M.; Akinlabi, E.T. Experimental data on surface roughness and force feedback analysis in friction stir processed AA7075—T651 aluminium metal composites. Data Brief 2019, 23, 103710. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.R.; Kim, Y.H.; Kim, J.Y.; Kim, J.M. Detecting and learning unknown fault states by automatically finding the optimal number of clusters for online bearing fault diagnosis. Appl. Sci. 2019, 9, 2326. [Google Scholar] [CrossRef]

- Kalpana, J.; Rao, P.S.; Rao, P.G. Regression Analysis for Estimating Hardness and Tensile Strength of Vibratory Dissimilar Welded Joint. Int. J. Manag. Technol. Eng. 2018, 8, 3560–3573. [Google Scholar]

- Khan, M.M.R.; Siddique, M.A.B.; Arif, R.B.; Oishe, M.R. ADBSCAN: Adaptive density-based spatial clustering of applications with noise for identifying clusters with varying densities. In Proceedings of the 4th International Conference on Electrical Engineering and Information and Communication Technology, iCEEiCT 2018, Dhaka, Bangladesh, 13–15 September 2018; pp. 107–111. [Google Scholar] [CrossRef]

- Kulis, B.; Jordan, M.I. Revisiting k-means: New algorithms via Bayesian nonparametrics. In Proceedings of the 29th International Conference on Machine Learning, ICML 2012, Madison, WI, USA, 26 June–1 July 2012; Volume 1, pp. 513–520. [Google Scholar]

- Liu, Y.; Yuan, K.; Li, T.; Li, S.; Ren, Y. NDT Method for Line Laser Welding Based on Deep Learning and One-Dimensional Time-Series Data. Appl. Sci. 2022, 12, 7837. [Google Scholar] [CrossRef]

- Lorbeer, B.; Kosareva, A.; Deva, B.; Softić, D.; Ruppel, P.; Küpper, A. Variations on the Clustering Algorithm BIRCH. Big Data Res. 2018, 11, 44–53. [Google Scholar] [CrossRef]

- Lu, Q.Y.; Wong, C.H. Additive manufacturing process monitoring and control by non-destructive testing techniques: Challenges and in-process monitoring. Virtual Phys. Prototyp. 2018, 13, 39–48. [Google Scholar] [CrossRef]

- Nakhla, H.; Shen, J.Y.; Bethea, M. Environmental impacts of using welding gas. J. Technol. Manag. Appl. Eng. 2012, 28, 2–11. [Google Scholar]

- Nidhi Patel, K.A. An Efficient and Scalable Density-based Clustering Algorithm for Normalize Data. Procedia Comput. Sci. 2016, 92, 136–141. [Google Scholar] [CrossRef]

- Othman, Z.; Zamli, I.; Rahaizat, R.A.; Sorooshian, S. Role of industry 4.0 in process strategy. J. Manag. Sci. 2018, 8, 192–198. [Google Scholar] [CrossRef]

- Patel, E.; Kushwaha, D.S. Clustering Cloud Workloads: K-Means vs. Gaussian Mixture Model. Procedia Comput. Sci. 2020, 171, 158–167. [Google Scholar] [CrossRef]

- Pires, I.; Quintino, L.; Amaral, V.; Rosado, T. Reduction of fume and gas emissions using innovative gas metal arc welding variants. Int. J. Adv. Manuf. Technol. 2010, 50, 557–567. [Google Scholar] [CrossRef]

- Posilović, L.; Medak, D.; Milković, F.; Subašić, M.; Budimir, M.; Lončarić, S. Deep learning-based anomaly detection from ultrasonic images. Ultrasonics 2022, 124, 106737. [Google Scholar] [CrossRef]

- Pradhan, R.; Joshi, A.P.; Sunny, M.R.; Sarkar, A. Machine learning models for determination of weldbead shape parameters for gas metal arc welded T-joints—A comparative study. arXiv 2022, arXiv:2206.02794. [Google Scholar]

- Provencal, E.; Laperrière, L. Identification of weld geometry from ultrasound scan data using deep learning. Procedia CIRP 2021, 104, 122–127. [Google Scholar] [CrossRef]

- Rajendran, C.; Srinivasan, K.; Balasubramanian, V.; Balaji, H.; Selvaraj, P. Data set on prediction of friction stir welding parameters to achieve maximum strength of AA2014-T6 aluminium alloy joints. Data Brief 2019, 23, 103735. [Google Scholar] [CrossRef]

- Ranganayakulu, S.V.; Burra, S.G.; Ravi, S. Characterization of Weldments Defects through Non Destructive Evaluation Techniques. Indian J. Sci. Technol. 2017, 10, 1–9. [Google Scholar] [CrossRef][Green Version]

- Rosenthal, S.; Maaß, F.; Kamaliev, M.; Hahn, M.; Gies, S.; Tekkaya, A.E. Lightweight in Automotive Components by Forming Technology. Automot. Innov. 2020, 3, 195–209. [Google Scholar] [CrossRef]

- Sarkar, S.S.; Das, A.; Paul, S.; Mali, K.; Ghosh, A.; Sarkar, R.; Kumar, A. Machine learning method to predict and analyse transient temperature in submerged arc welding. Meas. J. Int. Meas. Confed. 2021, 170, 108713. [Google Scholar] [CrossRef]

- Sorooshian, S.; Panigrahi, S. Impacts of the 4th industrial revolution on industries. Walailak J. Sci. Technol. 2020, 17, 903–915. [Google Scholar] [CrossRef]

- Tripicchio, P.; D’Avella, S. Welding Defect Detection with Deep Learning Architectures. In Engineering Principles—Welding and Residual Stresses; Cozza, K.O.C., Câmara, R., Eds.; IntechOpen Limited: London, UK, 2022. [Google Scholar] [CrossRef]

- Verma, S.; Misra, J.P.; Singh, J.; Batra, U.; Kumar, Y. Prediction of tensile behavior of FS welded AA7039 using machine learning. Mater. Today Commun. 2021, 26, 101933. [Google Scholar] [CrossRef]

- Yang, L.; Liu, Y.; Peng, J. An Automatic Detection and Identification Method of Welded Joints Based on Deep Neural Network. IEEE Access 2019, 7, 164952–164961. [Google Scholar] [CrossRef]

- Yee, L.W.; Teck, T.S.; Sorooshian, S. Impacts of industry 4.0 on Malaysian manufacturing industries. WSEAS Trans. Bus. Econ. 2019, 16, 355–359. [Google Scholar]

- Yu, J.; Zhu, L.; Qin, R.; Zhang, Z.; Li, L.; Huang, T. Combining k-means clustering and random forest to evaluate the gas content of coalbed bed methane reservoirs. Geofluids 2021, 2021, 9321565. [Google Scholar] [CrossRef]

- Zeng, J.; Cao, G.Z.; Peng, Y.P.; Huang, S.D. A weld joint type identification method for visual sensor based on image features and SVM. Sensors 2020, 20, 471. [Google Scholar] [CrossRef] [PubMed]

- Zhou, B.; Pychynski, T.; Reischl, M.; Kharlamov, E.; Mikut, R. Machine learning with domain knowledge for predictive quality monitoring in resistance spot welding. J. Intell. Manuf. 2022, 33, 1139–1163. [Google Scholar] [CrossRef]

| S/N | Predictive Parameters | Data Range | Source |

|---|---|---|---|

| 1 | The temperature in the middle of the weld | 18–20 | [29] and from quality control units |

| 2 | Hardness (HB) | Max. 290 | [30] and from quality control units |

| 3 | Nominal yield strength (MPa) | 420–610 | [30] and from quality control units |

| 4 | Nominal ultimate tensile strength (MPa) | 640–790 | [31] and from quality control units |

| 5 | Impact strength (J) at 20 °C | 30–100 | [29] and from quality control units |

| 6 | Weld length (mm) | 8.53–9.0 | [32] and quality control units |

| 7 | Roughness (μm) | 0.24–1.35 | [33] and quality control units |

| 8 | Porosity area (mm2) | 2.95–7.0 | [34] and quality control units |

| 9 | Bead width (mm) | 4.5–5.2 | [34] and quality control units |

| 10 | Bead area (mm2) | 40.5–46.9 | [35] and quality control units |

| 11 | Porosity ratio (%) | 6.7–15.2 | [35] and quality control units |

| 12 | Crack initiation from weld (mm) | 6.6–14.2 | [34] and quality control units |

| 13 | Groove angle (°) | 45 and 60 | [34] and quality control units |

| 14 | Welding speed (mm/s) | 3–4 | [34] and quality control units |

| 15 | Welding current (A) | 80–140 | [36] and quality control units |

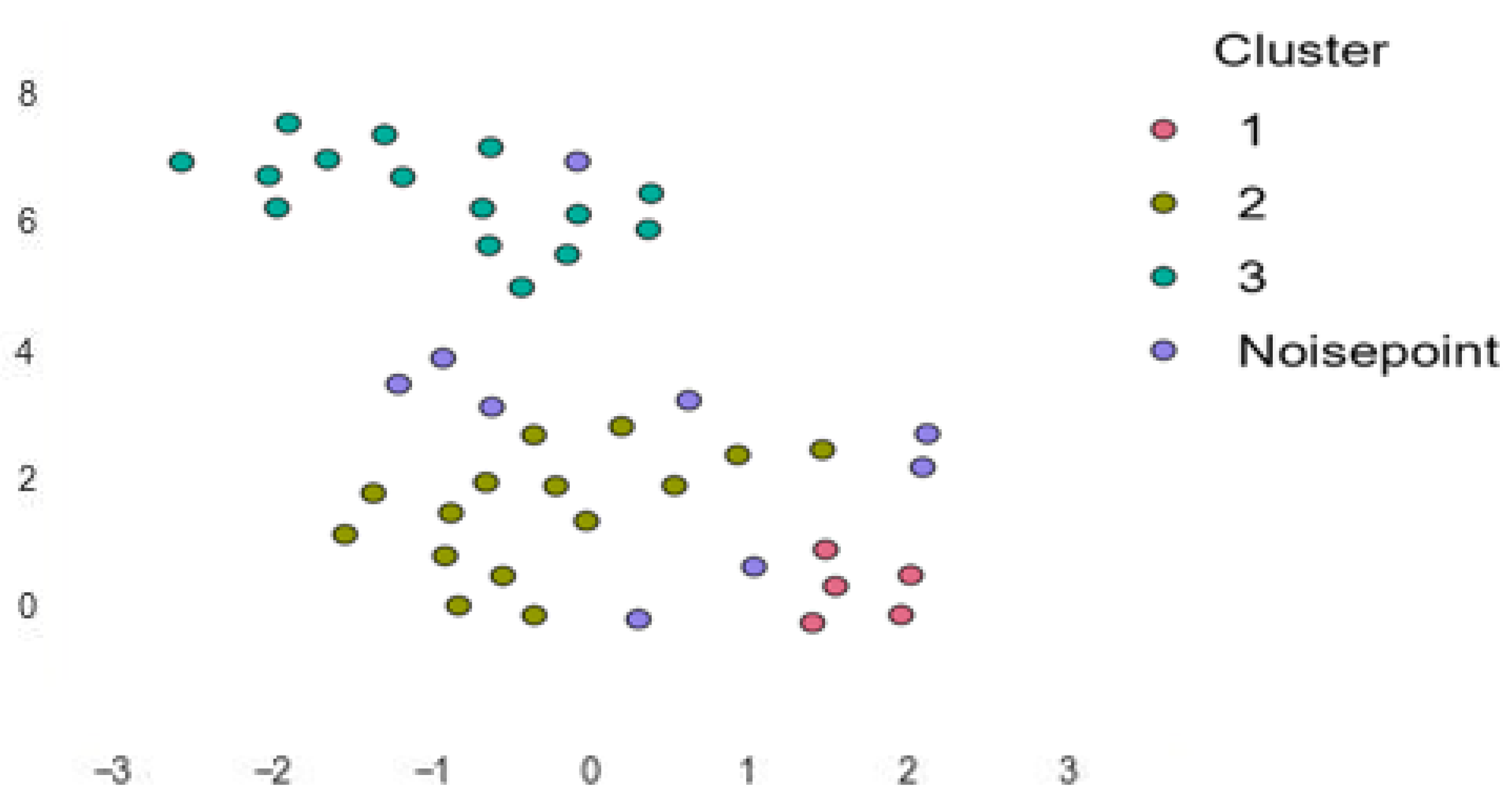

| Cluster Information | ||||

|---|---|---|---|---|

| Cluster | Noise Points | 1 | 2 | 3 |

| Size | 9 | 5 | 15 | 15 |

| Explained proportion within-cluster heterogeneity | 0.000 | 0.073 | 0.506 | 0.421 |

| Within the sum of squares | 0.000 | 8.569 | 59.157 | 49.263 |

| Silhouette score | 0.000 | 0.455 | 0.194 | 0.390 |

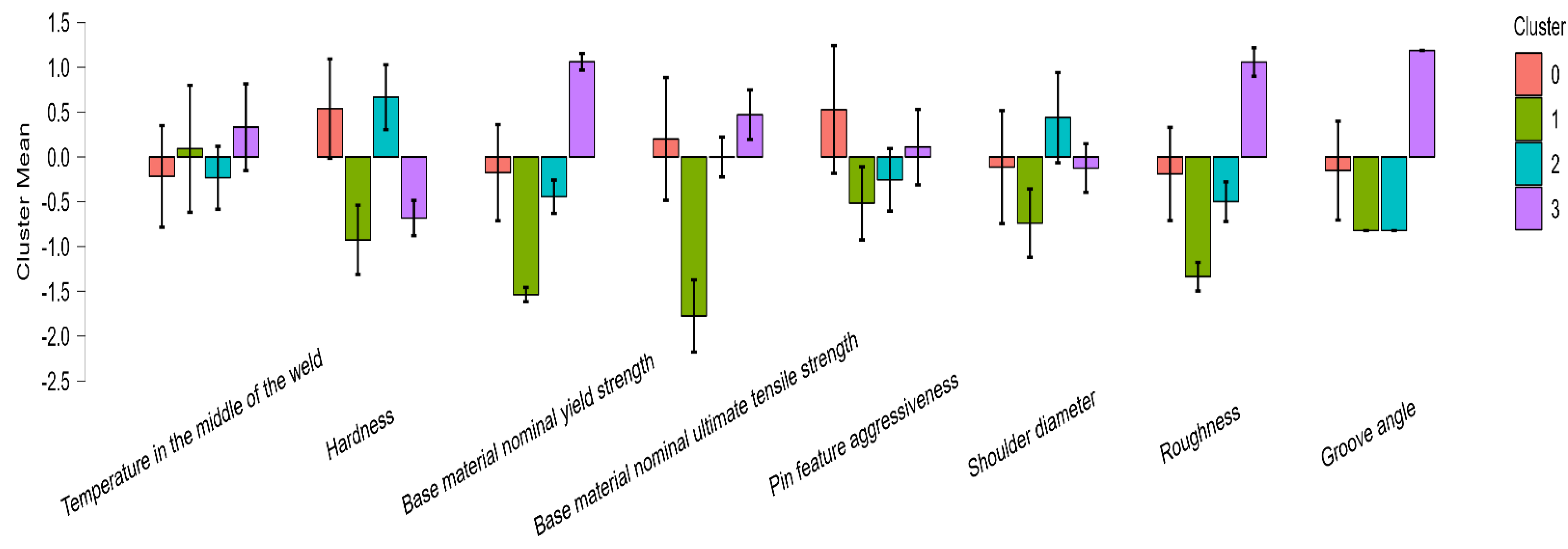

| Cluster Means | ||||||||

|---|---|---|---|---|---|---|---|---|

| The Temperature in the Middle of the Weld | Hardness (HB) | Nominal Yield Strength (MPa) | Nominal Ultimate Tensile Strength (MPa) | Pin Feature Aggressiveness | Shoulder Diameter (mm) | Roughness (μm) | Groove Angle | |

| Cluster 0 | −0.217 | 0.540 | −0.176 | 0.201 | 0.529 | −0.113 | −0.190 | −0.152 |

| Cluster 1 | 0.092 | −0.927 | −1.537 | −1.775 | −0.517 | −0.740 | −1.336 | −0.823 |

| Cluster 2 | −0.232 | 0.667 | −0.444 | 1.465 × 10−8 | −0.256 | 0.439 | −0.500 | −0.823 |

| Cluster 3 | 0.332 | −0.682 | 1.063 | 0.471 | 0.111 | −0.125 | 1.060 | 1.188 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oleka, C.J.; Aikhuele, D.O.; Omorogiuwa, E. Data-Driven Intelligent Model for the Classification, Identification, and Determination of Data Clusters and Defect Location in a Welded Joint. Processes 2022, 10, 1923. https://doi.org/10.3390/pr10101923

Oleka CJ, Aikhuele DO, Omorogiuwa E. Data-Driven Intelligent Model for the Classification, Identification, and Determination of Data Clusters and Defect Location in a Welded Joint. Processes. 2022; 10(10):1923. https://doi.org/10.3390/pr10101923

Chicago/Turabian StyleOleka, Chijioke Jerry, Daniel Osezua Aikhuele, and Eseosa Omorogiuwa. 2022. "Data-Driven Intelligent Model for the Classification, Identification, and Determination of Data Clusters and Defect Location in a Welded Joint" Processes 10, no. 10: 1923. https://doi.org/10.3390/pr10101923

APA StyleOleka, C. J., Aikhuele, D. O., & Omorogiuwa, E. (2022). Data-Driven Intelligent Model for the Classification, Identification, and Determination of Data Clusters and Defect Location in a Welded Joint. Processes, 10(10), 1923. https://doi.org/10.3390/pr10101923