Recovery of Household Waste by Generation of Biogas as Energy and Compost as Bio-Fertilizer—A Review

Abstract

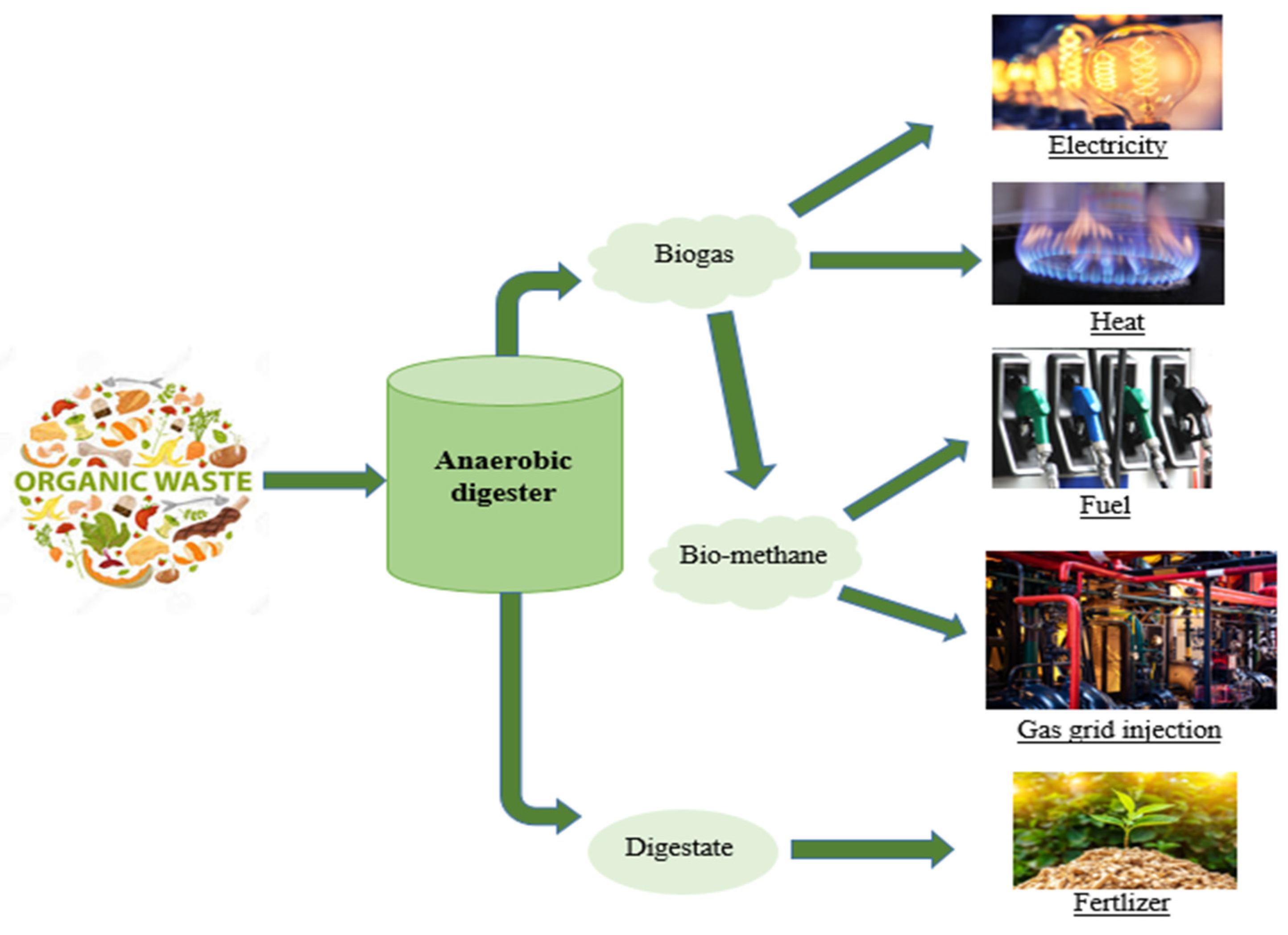

:1. Introduction

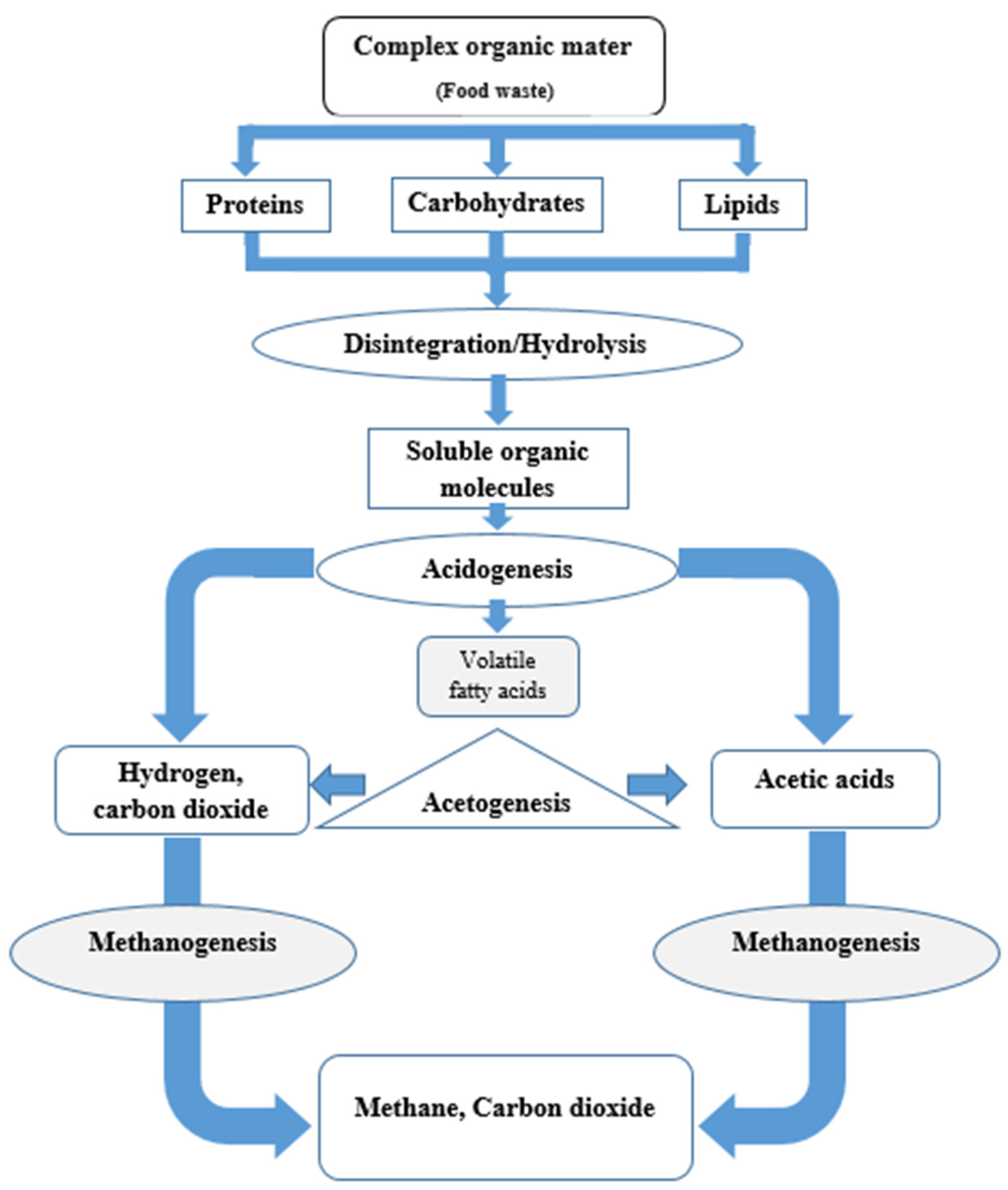

2. The Key Factors of Anaerobic Digestion and Their Impacts

2.1. Temperature

2.2. pH

2.3. Carbon to Nitrogen Ratio C/N

2.4. Organic Loading Rate (OLR)

2.5. Total Solids Content (TS %)

2.6. Volatile Fatty Acid (VFA) Inhibition

2.7. Ammonia Inhibition

3. The Effect of Co-Digestion, Pretreatment Methods, and Mixing Techniques on the AD Process

3.1. Effect of Co-Digestion in the AD System

3.2. Effect of Pretreatment Techniques in the AD System

3.3. Effect of Mixing Methods on the AD Process

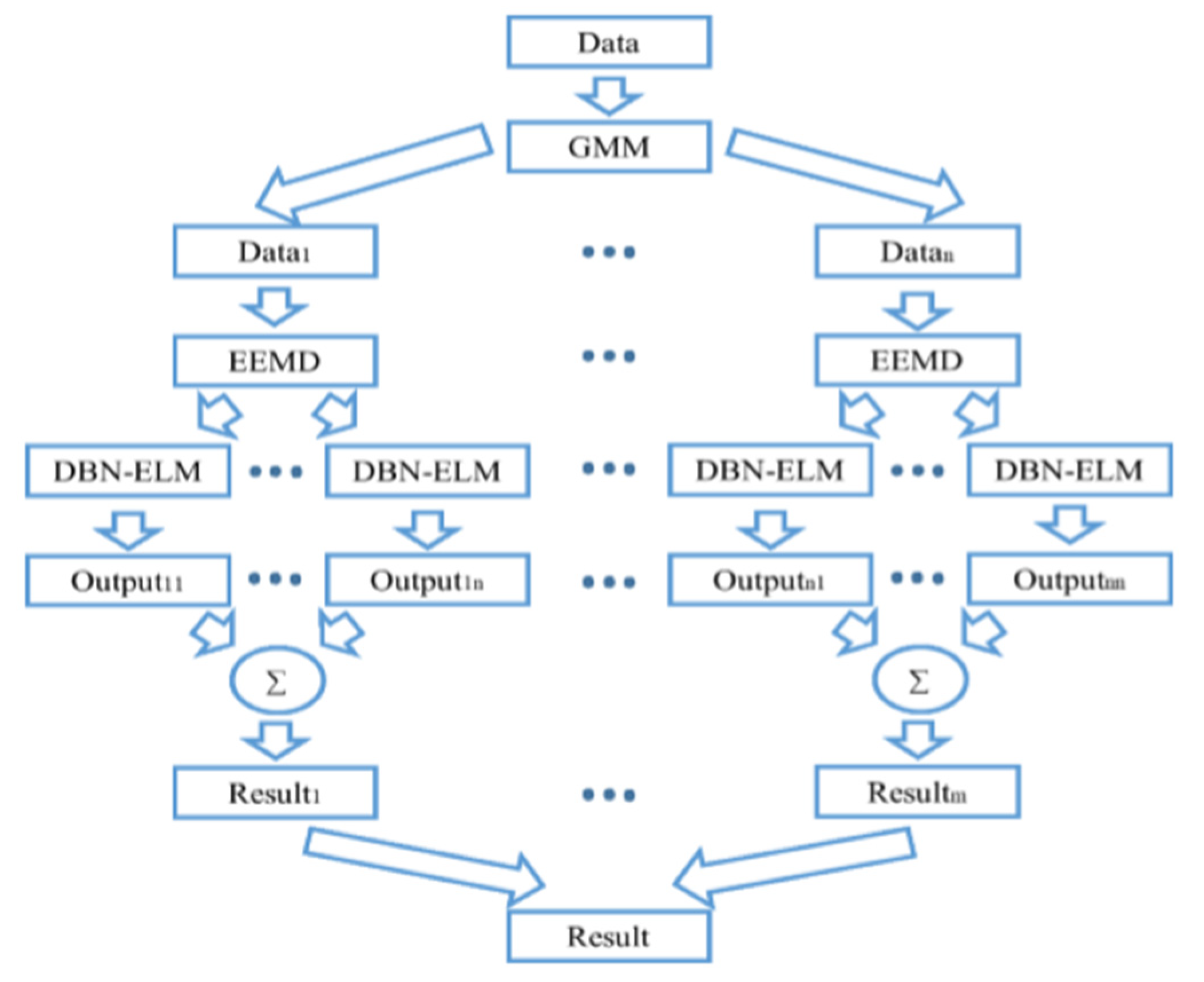

4. Mathematical Modeling of the AD System

5. Discussion and Challenges

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Ministry of Industry, Royaume du Maroc Ministere de I’lndustrie, du Commerce et de I’Economie Verte et Nu-Merique. 2021. Available online: http://www.mcinet.gov.ma/en/content/renewable-energy (accessed on 25 November 2021).

- Xu, F.; Li, Y.; Ge, X.; Yang, L.; Li, Y. Anaerobic digestion of food waste–Challenges and opportunities. Bioresour. Technol. 2018, 247, 1047–1058. [Google Scholar] [CrossRef]

- Srisowmeya, G.; Chakravarthy, M.; Devi, G.N. Critical considerations in two-stage anaerobic digestion of food waste–A review. Renew. Sustain. Energy Rev. 2020, 119, 109587. [Google Scholar] [CrossRef]

- Gallipoli, A.; Braguglia, C.M.; Gianico, A.; Montecchio, D.; Pagliaccia, P. Kitchen waste valorization through a mild-temperature pretreatment to enhance biogas production and fermentability: Kinetics study in mesophilic and thermophilic regimen. J. Environ. Sci. 2020, 89, 167–179. [Google Scholar] [CrossRef]

- Chambre Française de Commerce et D’industrie du Maroc (CFCIM). 2014. Available online: https://www.cfcim.org/magazine/21499#:~:text=7%20M%20tonnes%20de%20d%C3%A9chets,d%C3%A9chets%20industriels%20produits%20sont%20recycl%C3%A9s (accessed on 25 November 2021).

- Caicedo-Concha, D.M.; Sandoval-Cobo, J.J.; Fernando, C.-Q.R.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P.; Sonia, H. The potential of methane production using aged landfill waste in developing countries: A case of study in Colombia. Cogent Eng. 2019, 6, 1664862. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S. Performance evaluation of anaerobic digestion technology for energy recovery from organic fraction of municipal solid waste: A review. Energy 2020, 197, 117253. [Google Scholar] [CrossRef]

- Kim, S.; Lee, Y.; Lin, K.-Y.A.; Hong, E.; Kwon, E.E.; Lee, J. The valorization of food waste via pyrolysis. J. Clean. Prod. 2020, 259, 120816. [Google Scholar] [CrossRef]

- Zhang, J.; Kan, X.; Shen, Y.; Loh, K.-C.; Wang, C.-H.; Dai, Y.; Tong, Y.W. A hybrid biological and thermal waste-to-energy system with heat energy recovery and utilization for solid organic waste treatment. Energy 2018, 152, 214–222. [Google Scholar] [CrossRef]

- Kim, S.; Lee, C.-G.; Kim, Y.T.; Kim, K.-H.; Lee, J. Effect of Pt catalyst on the condensable hydrocarbon content generated via food waste pyrolysis. Chemosphere 2020, 248, 126043. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Samadder, S. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef]

- Mohammadi, A.; Sandberg, M.; Venkatesh, G.; Eskandari, S.; Dalgaard, T.; Joseph, S.; Granström, K. Environmental performance of end-of-life handling alternatives for paper-and-pulp-mill sludge: Using digestate as a source of energy or for biochar production. Energy 2019, 182, 594–605. [Google Scholar] [CrossRef]

- Atelge, M.R.; Atabani, A.E.; Banu, J.R.; Krisa, D.; Kaya, M.; Eskicioglu, C.; Kumar, G.; Lee, C.; Yildiz, Y.Ş.; Unalan, S.; et al. A critical review of pretreatment technologies to enhance anaerobic digestion and energy recovery. Fuel 2020, 270, 117494. [Google Scholar] [CrossRef]

- Ma, C.; Liu, J.; Ye, M.; Zou, L.; Qian, G.; Li, Y.-Y. Towards utmost bioenergy conversion efficiency of food waste: Pretreatment, co-digestion, and reactor type. Renew. Sustain. Energy Rev. 2018, 90, 700–709. [Google Scholar] [CrossRef]

- Ekanthalu, V.S.; Morscheck, G.; Narra, S.; Nelles, M. Hydrothermal Carbonization—A Sustainable Approach to Deal with the Challenges in Sewage Sludge Management. Urban Min. Sustain. Waste Manag. 2020, 293, 293–302. [Google Scholar] [CrossRef]

- Masebinu, S.; Akinlabi, E.; Muzenda, E.; Aboyade, A. A review of biochar properties and their roles in mitigating challenges with anaerobic digestion. Renew. Sustain. Energy Rev. 2019, 103, 291–307. [Google Scholar] [CrossRef]

- Wu, D.; Li, L.; Peng, Y.; Yang, P.; Peng, X.; Sun, Y.; Wang, X. State indicators of anaerobic digestion: A critical review on process monitoring and diagnosis. Renew. Sustain. Energy Rev. 2021, 148, 111260. [Google Scholar] [CrossRef]

- Ma, J.; Frear, C.; Wang, Z.-W.; Yu, L.; Zhao, Q.; Li, X.; Chen, S. A simple methodology for rate-limiting step determination for anaerobic digestion of complex substrates and effect of microbial community ratio. Bioresour. Technol. 2013, 134, 391–395. [Google Scholar] [CrossRef]

- Huang, W.; Wang, Z.; Zhou, Y.; Ng, W.J. The role of hydrogenotrophic methanogens in an acidogenic reactor. Chemosphere 2015, 140, 40–46. [Google Scholar] [CrossRef]

- Negri, C.; Ricci, M.; Zilio, M.; D’Imporzano, G.; Qiao, W.; Dong, R.; Adani, F. Anaerobic digestion of food waste for bio-energy production in China and Southeast Asia: A review. Renew. Sustain. Energy Rev. 2020, 133, 110138. [Google Scholar] [CrossRef]

- Zhang, E.; Li, J.; Zhang, K.; Wang, F.; Yang, H.; Zhi, S.; Liu, G. Anaerobic digestion performance of sweet potato vine and animal manure under wet, semi-dry, and dry conditions. AMB Express 2018, 8, 45. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, G.; Peng, L.; Su, H.; Tan, T. The anaerobic co-digestion of food waste and cattle manure. Bioresour. Technol. 2013, 129, 170–176. [Google Scholar] [CrossRef]

- dos Santos, L.A.; Valença, R.B.; da Silva, L.C.S.; Holanda, S.H.D.B.; Silva, A.; Jucá, J.F.T.; Santos, A.F.M.S. Methane generation potential through anaerobic digestion of fruit waste. J. Clean. Prod. 2020, 256, 120389. [Google Scholar] [CrossRef]

- Oladejo, O.S.; Dahunsi, S.O.; Adesulu-Dahunsi, A.T.; Ojo, S.O.; Lawal, A.I.; Idowu, E.O.; Olanipekun, A.A.; Ibikunle, R.A.; Osueke, C.O.; Ajayi, O.E.; et al. Energy generation from anaerobic co-digestion of food waste, cow dung and piggery dung. Bioresour. Technol. 2020, 313, 123694. [Google Scholar] [CrossRef] [PubMed]

- Perin, J.K.H.; Borth, P.L.B.; Torrecilhas, A.R.; da Cunha, L.S.; Kuroda, E.K.; Fernandes, F. Optimization of methane production parameters during anaerobic co-digestion of food waste and garden waste. J. Clean. Prod. 2020, 272, 123130. [Google Scholar] [CrossRef]

- El Achkar, J.H.; Ziade, R.; Louka, N.; Maroun, R.G.; Hobaika, Z. Treatment of dairy waste by anaerobic digestion to produce methane as green energy. In Proceedings of the 5th International Conference on Renewable Energies for Developing Countries (REDEC), Marrakech, Morocco, 29–30 June 2020. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y. Prediction model of biogas production for anaerobic digestion process of food waste based on LM-BP neural network and particle swarm algorithm optimization. In Proceedings of the Chinese Automation Congress (CAC), Jinan, China, 20–22 October 2017. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X. Soft Measurement for VFA Concentration in Anaerobic Digestion for Treating Kitchen Waste Based on Improved DBN. IEEE Access 2019, 7, 60931–60939. [Google Scholar] [CrossRef]

- Nie, E.; He, P.; Zhang, H.; Hao, L.; Shao, L.; Lü, F. How does temperature regulate anaerobic digestion? Renew. Sustain. Energy Rev. 2021, 150, 111453. [Google Scholar] [CrossRef]

- Czatzkowska, M.; Harnisz, M.; Korzeniewska, E.; Koniuszewska, I. Inhibitors of the methane fermentation process with particular emphasis on the microbiological aspect: A review. Energy Sci. Eng. 2020, 8, 1880–1897. [Google Scholar] [CrossRef] [Green Version]

- Pramanik, S.K.; Suja, F.B.; Zain, S.M.; Pramanik, B.K. The anaerobic digestion process of biogas production from food waste: Prospects and constraints. Bioresour. Technol. Rep. 2019, 8, 100310. [Google Scholar] [CrossRef]

- Li, D.; Song, L.; Fang, H.; Shi, Y.; Li, Y.-Y.; Liu, R.; Niu, Q. Effect of temperature on the anaerobic digestion of cardboard with waste yeast added: Dose-response kinetic assays, temperature coefficient and microbial co-metabolism. J. Clean. Prod. 2020, 275, 122949. [Google Scholar] [CrossRef]

- Ryue, J.; Lin, L.; Kakar, F.L.; Elbeshbishy, E.; Al-Mamun, A.; Dhar, B.R. A critical review of conventional and emerging methods for improving process stability in thermophilic anaerobic digestion. Energy Sustain. Dev. 2020, 54, 72–84. [Google Scholar] [CrossRef]

- Moset, V.; Poulsen, M.; Wahid, R.; Højberg, O.; Møller, H. Mesophilic versus thermophilic anaerobic digestion of cattle manure: Methane productivity and microbial ecology. Microb. Biotechnol. 2015, 8, 787–800. [Google Scholar] [CrossRef]

- Buffière, P.; Dooms, M.; Hattou, S.; Benbelkacem, H. The hydrolytic stage in high solids temperature phased anaerobic digestion improves the downstream methane production rate. Bioresour. Technol. 2018, 259, 111–118. [Google Scholar] [CrossRef] [PubMed]

- Kazimierowicz, J.; Dzienis, L.; Dębowski, M.; Zieliński, M. Optimisation of methane fermentation as a valorisation method for food waste products. Biomass-Bioenergy 2021, 144, 105913. [Google Scholar] [CrossRef]

- Rusín, J.; Chamrádová, K.; Basinas, P. Two-stage psychrophilic anaerobic digestion of food waste: Comparison to conventional single-stage mesophilic process. Waste Manag. 2020, 119, 172–182. [Google Scholar] [CrossRef] [PubMed]

- Cantero, D.; Jara, R.; Navarrete, A.; Pelaz, L.; Queiroz, J.; Rodríguez-Rojo, S.; Cocero, M. Pretreatment Processes of Biomass for Biorefineries: Current Status and Prospects. Annu. Rev. Chem. Biomol. Eng. 2019, 10, 289–310. [Google Scholar] [CrossRef] [Green Version]

- Aguilar-Reynosa, A.; Romaní, A.; Rodríguez-Jasso, R.M.; Aguilar, C.N.; Garrote, G.; Ruiz, H.A. Microwave heating processing as alternative of pretreatment in second-generation biorefinery: An overview. Energy Convers. Manag. 2017, 136, 50–65. [Google Scholar] [CrossRef] [Green Version]

- Kazimierowicz, J.; Zieliński, M.; Dębowski, M. Influence of the Heating Method on the Efficiency of Biomethane Production from Expired Food Products. Fermentation 2021, 7, 12. [Google Scholar] [CrossRef]

- Xu, H.; Li, Y.; Hua, D.; Zhao, Y.; Chen, L.; Zhou, L.; Chen, G. Effect of microaerobic microbial pretreatment on anaerobic digestion of a lignocellulosic substrate under controlled pH conditions. Bioresour. Technol. 2021, 328, 124852. [Google Scholar] [CrossRef]

- Latif, M.A.; Mehta, C.M.; Batstone, D.J. Influence of low pH on continuous anaerobic digestion of waste activated sludge. Water Res. 2017, 113, 42–49. [Google Scholar] [CrossRef]

- Eryildiz, B.; Taherzadeh, M.J. Effect of pH, substrate loading, oxygen, and methanogens inhibitors on volatile fatty acid (VFA) production from citrus waste by anaerobic digestion. Bioresour. Technol. 2020, 302, 122800. [Google Scholar] [CrossRef]

- Caruso, M.C.; Braghieri, A.; Capece, A.; Napolitano, F.; Romano, P.; Galgano, F.; Altieri, G.; Genovese, F. Recent Updates on the Use of Agro-Food Waste for Biogas Production. Appl. Sci. 2019, 9, 1217. [Google Scholar] [CrossRef] [Green Version]

- Rocamora, I.; Wagland, S.T.; Villa, R.; Simpson, E.D.; Fernández, O.; Bajón-Fernández, Y. Dry anaerobic digestion of organic waste: A review of operational parameters and their impact on process performance. Bioresour. Technol. 2020, 299, 122681. [Google Scholar] [CrossRef] [PubMed]

- El Gnaoui, Y.; Karouach, F.; Bakraoui, M.; Barz, M.; EL Bari, H. Mesophilic anaerobic digestion of food waste: Effect of thermal pretreatment on improvement of anaerobic digestion process. Energy Rep. 2020, 6, 417–422. [Google Scholar] [CrossRef]

- Ajayi-Banji, A.A.; Rahman, S.; Sunoj, S.; Igathinathane, C. Impact of corn stover particle size and C/N ratio on reactor performance in solid-state anaerobic co-digestion with dairy manure. J. Air Waste Manag. Assoc. 2020, 70, 436–454. [Google Scholar] [CrossRef]

- Papargyropoulou, E.; Lozano, R.; Steinberger, J.; Wright, N.; bin Ujang, Z. The food waste hierarchy as a framework for the management of food surplus and food waste. J. Clean. Prod. 2014, 76, 106–115. [Google Scholar] [CrossRef]

- Chatterjee, B.; Mazumder, D. Role of stage-separation in the ubiquitous development of Anaerobic Digestion of Organic Fraction of Municipal Solid Waste: A critical review. Renew. Sustain. Energy Rev. 2019, 104, 439–469. [Google Scholar] [CrossRef]

- Wang, X.; Lu, X.; Li, F.; Yang, G. Effects of Temperature and Carbon-Nitrogen (C/N) Ratio on the Performance of Anaerobic Co-Digestion of Dairy Manure, Chicken Manure and Rice Straw: Focusing on Ammonia Inhibition. PLoS ONE 2014, 9, e97265. [Google Scholar] [CrossRef] [Green Version]

- Drennan, M.F.; DiStefano, T.D. High solids co-digestion of food and landscape waste and the potential for ammonia toxicity. Waste Manag. 2014, 34, 1289–1298. [Google Scholar] [CrossRef]

- Nasiruddin, S.M.; Li, Z.; Mang, H.-P.; Zhou, X.; Cheng, S.; Wang, X. Assessment of organic loading rate by using a water tank digester for biogas production in Bangladesh. J. Clean. Prod. 2020, 265, 121688. [Google Scholar] [CrossRef]

- Dębowski, M.; Zieliński, M.; Kisielewska, M.; Kazimierowicz, J. Evaluation of Anaerobic Digestion of Dairy Wastewater in an Innovative Multi-Section Horizontal Flow Reactor. Energies 2020, 13, 2392. [Google Scholar] [CrossRef]

- Megido, L.; Negral, L.; Fernández-Nava, Y.; Suárez-Peña, B.; Ormaechea, P.; Díaz-Caneja, P.; Castrillón, L.; Marañón, E. Impact of organic loading rate and reactor design on thermophilic anaerobic digestion of mixed supermarket waste. Waste Manag. 2021, 123, 52–59. [Google Scholar] [CrossRef]

- Arias, D.E.; Veluchamy, C.; Habash, M.B.; Gilroyed, B.H. Biogas production, waste stabilization efficiency, and hygienization potential of a mesophilic anaerobic plug flow reactor processing swine manure and corn stover. J. Environ. Manag. 2021, 284, 112027. [Google Scholar] [CrossRef]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Improving the sustainability of organic waste management practices in the food-energy-water nexus: A comparative review of anaerobic digestion and composting. Renew. Sustain. Energy Rev. 2018, 89, 151–167. [Google Scholar] [CrossRef]

- Li, H.; Chen, Z.; Fu, D.; Wang, Y.; Zheng, Y.; Li, Q. Improved ADM1 for modelling C, N, P fates in anaerobic digestion process of pig manure and optimization approaches to biogas production. Renew. Energy 2020, 146, 2330–2336. [Google Scholar] [CrossRef]

- Indren, M.; Birzer, C.; Kidd, S.; Medwell, P.R. Effect of total solids content on anaerobic digestion of poultry litter with biochar. J. Environ. Manag. 2020, 255, 109744. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Li, Y.; Jia, S.; Song, Y.; Sun, Y.; Zheng, Z.; Yu, J.; Cui, Z.; Han, Y.; et al. Methane production from the co-digestion of pig manure and corn stover with the addition of cucumber residue: Role of the total solids content and feedstock-to-inoculum ratio. Bioresour. Technol. 2020, 306, 123172. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Jiang, Y.; Wang, S.; Zhang, Y.; Hu, Y.; Hu, Z.-H.; Wu, G.; Zhan, X. Impact of total solids content on anaerobic co-digestion of pig manure and food waste: Insights into shifting of the methanogenic pathway. Waste Manag. 2020, 114, 96–106. [Google Scholar] [CrossRef] [PubMed]

- Arelli, V.; Begum, S.; Anupoju, G.R.; Kuruti, K.; Shailaja, S. Dry anaerobic co-digestion of food waste and cattle manure: Impact of total solids, substrate ratio and thermal pre treatment on methane yield and quality of biomanure. Bioresour. Technol. 2018, 253, 273–280. [Google Scholar] [CrossRef]

- Bi, S.; Westerholm, M.; Qiao, W.; Xiong, L.; Mahdy, A.; Yin, D.; Song, Y.; Dong, R. Metabolic performance of anaerobic digestion of chicken manure under wet, high solid, and dry conditions. Bioresour. Technol. 2020, 296, 122342. [Google Scholar] [CrossRef] [PubMed]

- Di Maria, F.; Barratta, M.; Bianconi, F.; Placidi, P.; Passeri, D. Solid anaerobic digestion batch with liquid digestate recirculation and wet anaerobic digestion of organic waste: Comparison of system performances and identification of microbial guilds. Waste Manag. 2017, 59, 172–180. [Google Scholar] [CrossRef]

- Shi, X.; Lin, J.; Zuo, J.; Li, P.; Li, X.; Guo, X. Effects of free ammonia on volatile fatty acid accumulation and process performance in the anaerobic digestion of two typical bio-wastes. J. Environ. Sci. 2017, 55, 49–57. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, Q.; Wang, X.; Zhou, X.; Zhu, J. Effect of pH on volatile fatty acid production from anaerobic digestion of potato peel waste. Bioresour. Technol. 2020, 316, 123851. [Google Scholar] [CrossRef]

- Liu, N.; Jiang, J. Valorisation of food waste using salt to alleviate inhibition by animal fats and vegetable oils during anaerobic digestion. Biomass-Bioenergy 2020, 143, 105826. [Google Scholar] [CrossRef]

- Wu, Y.; Song, K. Anaerobic co-digestion of waste activated sludge and fish waste: Methane production performance and mechanism analysis. J. Clean. Prod. 2021, 279, 123678. [Google Scholar] [CrossRef]

- Sun, C.; Liu, F.; Song, Z.; Wang, J.; Li, Y.; Pan, Y.; Sheng, T.; Li, L. Feasibility of dry anaerobic digestion of beer lees for methane production and biochar enhanced performance at mesophilic and thermophilic temperature. Bioresour. Technol. 2019, 276, 65–73. [Google Scholar] [CrossRef]

- Ren, Y.; Yu, M.; Wu, C.; Wang, Q.; Gao, M.; Huang, Q.; Liu, Y. A comprehensive review on food waste anaerobic digestion: Research updates and tendencies. Bioresour. Technol. 2018, 247, 1069–1076. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Zhu, N. Progress in inhibition mechanisms and process control of intermediates and by-products in sewage sludge anaerobic digestion. Renew. Sustain. Energy Rev. 2016, 58, 429–438. [Google Scholar] [CrossRef]

- Altinbas, M.; Cicek, O.A. Anaerobic co-digestion of chicken and cattle manures: Free ammonia inhibition. Energy Sources 2019, 41, 1097–1109. [Google Scholar] [CrossRef]

- Akindele, A.A.; Sartaj, M. The toxicity effects of ammonia on anaerobic digestion of organic fraction of municipal solid waste. Waste Manag. 2018, 71, 757–766. [Google Scholar] [CrossRef] [PubMed]

- Mehariya, S.; Patel, A.K.; Obulisamy, P.K.; Punniyakotti, E.; Wong, J.W. Co-digestion of food waste and sewage sludge for methane production: Current status and perspective. Bioresour. Technol. 2018, 265, 519–531. [Google Scholar] [CrossRef]

- Capson-Tojo, G.; Rouez, M.; Crest, M.; Trably, E.; Steyer, J.-P.; Bernet, N.; Delgenès, J.-P.; Escudié, R. Kinetic study of dry anaerobic co-digestion of food waste and cardboard for methane production. Waste Manag. 2017, 69, 470–479. [Google Scholar] [CrossRef]

- Kainthola, J.; Kalamdhad, A.; Goud, V.V. A review on enhanced biogas production from anaerobic digestion of lignocellulosic biomass by different enhancement techniques. Process Biochem. 2019, 84, 81–90. [Google Scholar] [CrossRef]

- Martín, M.; Fernández, R.; Gutiérrez, M.; Siles, J. Thermophilic anaerobic digestion of pre-treated orange peel: Modelling of methane production. Process. Saf. Environ. Prot. 2018, 117, 245–253. [Google Scholar] [CrossRef]

- Hu, Y.-Y.; Wu, J.; Li, H.-Z.; Poncin, S.; Wang, K.-J.; Zuo, J.-E. Study of an enhanced dry anaerobic digestion of swine manure: Performance and microbial community property. Bioresour. Technol. 2019, 282, 353–360. [Google Scholar] [CrossRef] [PubMed]

- Ghanimeh, S.; El-Fadel, M.; Saikaly, P. Performance of thermophilic anaerobic digesters using inoculum mixes with enhanced methanogenic diversity. J. Chem. Technol. Biotechnol. 2018, 93, 207–214. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Sun, Y.; Yu, J.; Zheng, Z.; Li, S.; Cui, Z.; Hao, J.; Li, G. Effects of intermittent mixing mode on solid state anaerobic digestion of agricultural wastes. Chemosphere 2020, 248, 126055. [Google Scholar] [CrossRef]

- Massé, D.I.; Patni, N.K.; Droste, R.L.; Kennedy, K.J. Operation strategies for psychrophilic anaerobic digestion of swine manure slurry in sequencing batch reactors. Can. J. Civ. Eng. 1996, 23, 1285–1294. [Google Scholar] [CrossRef]

- Vesvikar, M.; Varma, R.; Karim, K.; Al-Dahhan, M. Flow pattern visualization in a mimic anaerobic digester: Experimental and computational studies. Water Sci. Technol. 2005, 52, 537–543. [Google Scholar] [CrossRef] [PubMed]

- Rico, C.; Rico, J.L.; Muñoz, N.; Gómez, B.; Tejero, I. Effect of mixing on biogas production during mesophilic anaerobic digestion of screened dairy manure in a pilot plant. Eng. Life Sci. 2011, 11, 476–481. [Google Scholar] [CrossRef]

- Kariyama, I.D.; Zhai, X.; Wu, B. Influence of mixing on anaerobic digestion efficiency in stirred tank digesters: A review. Water Res. 2018, 143, 503–517. [Google Scholar] [CrossRef]

- Karim, K.; Hoffmann, R.; Klasson, K.T.; Al-Dahhan, M. Anaerobic digestion of animal waste: Waste strength versus impact of mixing. Bioresour. Technol. 2005, 96, 1771–1781. [Google Scholar] [CrossRef]

- Lindmark, J.; Thorin, E.; Fdhila, R.B.; Dahlquist, E. Effects of mixing on the result of anaerobic digestion: Review. Renew. Sustain. Energy Rev. 2014, 40, 1030–1047. [Google Scholar] [CrossRef]

- Zhang, J.; Mao, L.; Nithya, K.; Loh, K.-C.; Dai, Y.; He, Y.; Tong, Y.W. Optimizing mixing strategy to improve the performance of an anaerobic digestion waste-to-energy system for energy recovery from food waste. Appl. Energy 2019, 249, 28–36. [Google Scholar] [CrossRef]

- Kaparaju, P.; Buendia, I.; Ellegaard, L.; Angelidakia, I. Effects of mixing on methane production during thermophilic anaerobic digestion of manure: Lab-scale and pilot-scale studies. Bioresour. Technol. 2008, 99, 4919–4928. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.; Szamosi, Z.; Siménfalvi, Z. State of the art on mixing in an anaerobic digester: A review. Renew. Energy 2019, 141, 922–936. [Google Scholar] [CrossRef]

- Shen, F.; Tian, L.; Yuan, H.; Pang, Y.; Chen, S.; Zou, D.; Zhu, B.; Liu, Y.; Li, X. Improving the Mixing Performances of Rice Straw Anaerobic Digestion for Higher Biogas Production by Computational Fluid Dynamics (CFD) Simulation. Appl. Biochem. Biotechnol. 2013, 171, 626–642. [Google Scholar] [CrossRef]

- Wade, M. Not Just Numbers: Mathematical modelling and Its Contribution to Anaerobic Digestion Processes. Processes 2020, 8, 888. [Google Scholar] [CrossRef]

- Kazemi, P.; Bengoa, C.; Steyer, J.-P.; Giralt, J. Data-driven techniques for fault detection in anaerobic digestion process. Process. Saf. Environ. Prot. 2021, 146, 905–915. [Google Scholar] [CrossRef]

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.; Siegrist, H.A.; Vavilin, V.A. The IWA Anaerobic Digestion Model No 1 (ADM1). Water Sci. Technol. 2002, 45, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Ferraro, A.; Massini, G.; Miritana, V.M.; Signorini, A.; Race, M.; Fabbricino, M. A simplified model to simulate bioaugmented anaerobic digestion of lignocellulosic biomass: Biogas production efficiency related to microbiological data. Sci. Total Environ. 2019, 691, 885–895. [Google Scholar] [CrossRef] [PubMed]

- Loganath, R.; Mazumder, D. Development of a Simplified Mathematical Model for Anaerobic Digestion. Sustain. Waste Manag. 2020, 571–578. [Google Scholar] [CrossRef]

- Mirquez, L.D.; Machado-Higuera, M.; Sarabia, M.H. Mathematical modelling and simulation for biogas production from organic waste. Int. J. Eng. Syst. Model. Simul. 2018, 10, 97. [Google Scholar] [CrossRef]

- Manjusha, C.; Beevi, B.S. Mathematical Modeling and Simulation of Anaerobic Digestion of Solid Waste. Procedia Technol. 2016, 24, 654–660. [Google Scholar] [CrossRef] [Green Version]

- Alejo, L.; Atkinson, J.; Guzmán-Fierro, V.; Roeckel, M. Effluent composition prediction of a two-stage anaerobic digestion process: Machine learning and stoichiometry techniques. Environ. Sci. Pollut. Res. 2018, 25, 21149–21163. [Google Scholar] [CrossRef]

- Hu, C.; Yan, B.; Wang, K.-J.; Xiao, X.-M. Modeling the performance of anaerobic digestion reactor by the anaerobic digestion system model (ADSM). J. Environ. Chem. Eng. 2018, 6, 2095–2104. [Google Scholar] [CrossRef]

- Kazimierowicz, J. Legal Regulations and Methods Neutralising Expired Food Products. J. Ecol. Eng. 2018, 19, 217–224. [Google Scholar] [CrossRef]

- Gao, M.; Yang, M.; Ma, X.; Xie, D.; Wu, C.; Wang, Q. Effect of co-digestion of tylosin fermentation dreg and food waste on anaerobic digestion performance. Bioresour. Technol. 2021, 325, 124693. [Google Scholar] [CrossRef]

- Cheng, H.; Li, Y.; Hu, Y.; Guo, G.; Cong, M.; Xiao, B.; Li, Y.-Y. Bioenergy recovery from methanogenic co-digestion of food waste and sewage sludge by a high-solid anaerobic membrane bioreactor (AnMBR): Mass balance and energy potential. Bioresour. Technol. 2021, 326, 124754. [Google Scholar] [CrossRef] [PubMed]

- Begum, S.; Anupoju, G.R.; Eshtiaghi, N. Anaerobic co-digestion of food waste and cardboard in different mixing ratios: Impact of ultrasound pre-treatment on soluble organic matter and biogas generation potential at varying food to inoculum ratios. Biochem. Eng. J. 2021, 166, 107853. [Google Scholar] [CrossRef]

- Karki, R.; Chuenchart, W.; Surendra, K.; Shrestha, S.; Raskin, L.; Sung, S.; Hashimoto, A.; Khanal, S.K. Anaerobic co-digestion: Current status and perspectives. Bioresour. Technol. 2021, 330, 125001. [Google Scholar] [CrossRef]

- Yuan, T.; Shi, X.; Sun, R.; Ko, J.H.; Xu, Q. Simultaneous addition of biochar and zero-valent iron to improve food waste anaerobic digestion. J. Clean. Prod. 2021, 278, 123627. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, J.; Perez, M.; Romero, L.I. Semicontinuous Temperature-Phased Anaerobic Digestion (TPAD) of Organic Fraction of Municipal Solid Waste (OFMSW). Comparison with single-stage processes. Chem. Eng. J. 2016, 285, 409–416. [Google Scholar] [CrossRef]

- Rasapoor, M.; Ajabshirchi, Y.; Adl, M.; Abdi, R.; Gharibi, A. The effect of ultrasonic pretreatment on biogas generation yield from organic fraction of municipal solid waste under medium solids concentration circumstance. Energy Convers. Manag. 2016, 119, 444–452. [Google Scholar] [CrossRef]

- Cesaro, A.; Belgiorno, V.; Siciliano, A.; Guida, M. The sustainable recovery of the organic fraction of municipal solid waste by integrated ozonation and anaerobic digestion. Resour. Conserv. Recycl. 2019, 141, 390–397. [Google Scholar] [CrossRef]

- Brander, M.; Burritt, R.L.; Christ, K.L. Coupling attributional and consequential life cycle assessment: A matter of social responsibility. J. Clean. Prod. 2019, 215, 514–521. [Google Scholar] [CrossRef] [Green Version]

- Bartocci, P.; Zampilli, M.; Liberti, F.; Pistolesi, V.; Massoli, S.; Bidini, G.; Fantozzi, F. LCA analysis of food waste co-digestion. Sci. Total Environ. 2020, 709, 136187. [Google Scholar] [CrossRef] [PubMed]

- Duan, N.; Khoshnevisan, B.; Lin, C.; Liu, Z.; Liu, H. Life cycle assessment of anaerobic digestion of pig manure coupled with different digestate treatment technologies. Environ. Int. 2020, 137, 105522. [Google Scholar] [CrossRef]

- Kumar, M.; Dutta, S.; You, S.; Luo, G.; Zhang, S.; Show, P.L.; Sawarkar, A.D.; Singh, L.; Tsang, D.C. A critical review on biochar for enhancing biogas production from anaerobic digestion of food waste and sludge. J. Clean. Prod. 2021, 305, 127143. [Google Scholar] [CrossRef]

- Yang, S.; McDonald, J.; Hai, F.I.; Price, W.E.; Khan, S.; Nghiem, L.D. Effects of thermal pre-treatment and recuperative thickening on the fate of trace organic contaminants during anaerobic digestion of sewage sludge. Int. Biodeterior. Biodegrad. 2017, 124, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Wang, N.; Huang, D.; Zhang, C.; Shao, M.; Chen, Q.; Liu, J.; Deng, Z.; Xu, Q. Long-term characterization and resource potential evaluation of the digestate from food waste anaerobic digestion plants. Sci. Total Environ. 2021, 794, 148785. [Google Scholar] [CrossRef]

- Zamri, M.; Hasmady, S.; Akhiar, A.; Ideris, F.; Shamsuddin, A.; Mofijur, M.; Fattah, I.M.R.; Mahlia, T. A comprehensive review on anaerobic digestion of organic fraction of municipal solid waste. Renew. Sustain. Energy Rev. 2021, 137, 110637. [Google Scholar] [CrossRef]

- Lauwers, J.; Nimmegeers, P.; Logist, F.; Van Impe, J. Structural identifiability analysis of the Anaerobic Digestion Model No. 1 using a local algebraic observability approach. IFAC-PapersOnLine 2015, 48, 470–475. [Google Scholar] [CrossRef]

- Wickramaarachchi, A.; Rathnasiri, P.; Narayana, M.; Torrijos, M.; Escudie, R. Kinetic Modeling of Dry Anaerobic Co-Digestion of Lignocellulosic Biomass. In Proceedings of the 2019 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 3–5 July 2019. [Google Scholar] [CrossRef]

- Xie, S.; Hai, F.I.; Zhan, X.; Guo, W.; Ngo, H.H.; Price, W.E.; Nghiem, L.D. Anaerobic co-digestion: A critical review of mathematical modelling for performance optimization. Bioresour. Technol. 2016, 222, 498–512. [Google Scholar] [CrossRef] [PubMed]

- Najafi, B.; Ardabili, S.F. Application of ANFIS, ANN, and logistic methods in estimating biogas production from spent mushroom compost (SMC). Resour. Conserv. Recycl. 2018, 133, 169–178. [Google Scholar] [CrossRef]

- Esposito, G.; Frunzo, L.; Panico, A.; Pirozzi, F. Modelling the effect of the OLR and OFMSW particle size on the performances of an anaerobic co-digestion reactor. Process. Biochem. 2011, 46, 557–565. [Google Scholar] [CrossRef]

- Arnell, M.; Astals, S.; Åmand, L.; Batstone, D.J.; Jensen, P.D.; Jeppsson, U. Modelling anaerobic co-digestion in Benchmark Simulation Model No. 2: Parameter estimation, substrate characterisation and plant-wide integration. Water Res. 2016, 98, 138–146. [Google Scholar] [CrossRef] [Green Version]

| Feedstock | pH | TS (%) | VS (%) | Moisture (%) | C/N Ratio | Organic Loading Rate (OLR) | Operating Temperature °C | Methane Yield | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Sweet potato vine | ND | 91.8 | 78.7 | ND | 15.1 | 30 (g-VS/L) | 37 | 200.22 (mL/g VS) | [21] |

| Food waste | 5.2 | 18.5 | 17 | ND | 21.1 | 8 (g-VS/L) | 35 | 2624 mL | [22] |

| Orange bagasse Passion fruit Peel Cashew bagasse | 4.0 3.7 4.2 | 19.2 18.5 29.0 | 95.2 94.0 96.0 | 80.7 81.4 70.9 | 30.1 51.6 28.3 | ND ND ND | 37 37 37 | 299 NmL 115 NmL 186 NmL | [23] |

| Food waste | 7.3 | 16.83 | 82.9 | 81.1 | 11:1 | ND | 26–32 | 16.308 mL | [24] |

| Food waste | 4.3 | 9.11 | 8.53 | ND | ND | 36 | 0.06 | [25] | |

| Sweet lactoserum Acidic lactoserum | 7.2 4.1 | 96 95 | 65 72 | ND ND | ND ND | ND ND | 37 | 0.34 0.06 | [26] |

| Feedstock | Parameter | Observation | References |

|---|---|---|---|

| Meat, vegetables and fruits, dairy waste | Temperature | -A maximum biogas yield was achieved under mesophilic conditions compared to thermophilic | [36] |

| Activated sewage sludge | pH | -A maximum methane production was achieved at pH = 7. -At pH = 5.5 a reduction by 88% of methanogens activity was recorded | [42] |

| Dairy manure, chicken manure, and rice straw | C/N ratio | -An optimal methane potential was achieved at C/N ratio = 25:1 for mesophilic reactors, and at C/N ratio = 35:1 for thermophilic reactors | [50] |

| Swine manure and corn stover | OLR | -the highest biogas yield was obtained , at an OLR value of, | [55] |

| Food waste and pig manure | TS | -the specific methane yield was higher at TS = 15% compared to the value recorded at TS = 20% | [60] |

| Model | Description | Results | Observation | Ref |

|---|---|---|---|---|

| Simplified ADM1 | -The hypotheses were cited in order to reduce the hydrolysis constants. -Using Euler method solver ODE15 for differential equation systems. | -Simple procedure for solving. -Similar trends between the predicted VFA, pH and biogas production and the experimental values. | -The accuracy was not calculated. -The curves of the predicted and experimental results were not close. | [96] |

| AM2 | -Taking into consideration just two steps of the AD (acidogenesis and methanogenesis). | -Predicted methane production with a few key measurements (organic matter and VFA). | -The identification of the parameters was difficult due to the non-linearity of the model. | [95] |

| ADSM | -ADSM was constructed based on ADM1 and systems-thinking methodology. | -Predicted with accuracy VFA, pH, Alk, and methane better than ADM1 under different conditions. | -Some deviations were observed in the simulation of the full-scale AD. -It was fitted only to simulate the wastewater treatment. | [98] |

| Improved ADM1 | -Addition of precipitation equation. -Addition of high TS inhibition function. | -Predicted with accuracy methane production in high TS conditions. -The prediction of inorganic nitrogen was reasonable with the experimental values. -Simulated the change in phosphorus. | -Difficult prediction of COD. -The inorganic nitrogen predicted did not present the experimental trend. -Failed in the simulation of phosphorus fluctuation trends. | [57] |

| Simplified Mathematical model | Four main differential equations describing the four main sub-processes of the AD. | -Simple procedure for solving. | -The simplification of substrate concentration facing the half-velocity constant could affect solution accuracy. -The model did not present the development of other parameters. | [94] |

| LM-BP Neural Network and partical swarm algorithm | -The BP neural network was improved by LM algorithm. -The PSO algorithm was introduced to optimize the parameters of the model. | - Fast minimization of the error function. - High accuracy in the prediction of methane yield was achieved. -Few input variables were introduced to the model (the daily feed volume, TS, VS, pH, VFA, Alk, and the average flow rate of ammonia | -Requirement of a large number of data sets prepared for the training and the test. | [27] |

| Improved DBN | -Classification of data by GMM. -The decomposition of the input signal using EEMD. -The combination of DBN and ELM in order to measure VFA concentration. | -High accuracy of the prediction compared to other models based on partial least squares (SVM, PB). -Automatic extraction of data features. | -Requirement of a large number of data sets and the random initialization of the RBM could slow down the research target. | [28] |

| Adaptive network-based fuzzy inference system (ANFIS) | -few input parameters: C/N ratio, temperature, and retention time. | -Predicted with accuracy 99.96% of the biogas production of AD of spent mushroom compost with wheat straw. | - Requirement of a large number of data sets | [118] |

| Modified model based on ADM1 | - Simulates the disintegration of OFMSW. -Takes into account the peculiarities of a co-digestion process. | - Process failure could be predicted using the combined influence of particle size distribution and OLRs. | - Large particle size = higher OLR to reach digester failure. | [119] |

| BSM2 and ADM1 based model | -A plant-wide simulation. -Co-substrate characterization for ADM1. | -Addition of solid precipitation improve the accuracy. - Revealed the importance of protein loading limit & NH3 inhibition prevention in the digester. | -Using principal component analysis, identify two significant failure modes: NH3 and LCFA inhibition. | [120] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benyahya, Y.; Fail, A.; Alali, A.; Sadik, M. Recovery of Household Waste by Generation of Biogas as Energy and Compost as Bio-Fertilizer—A Review. Processes 2022, 10, 81. https://doi.org/10.3390/pr10010081

Benyahya Y, Fail A, Alali A, Sadik M. Recovery of Household Waste by Generation of Biogas as Energy and Compost as Bio-Fertilizer—A Review. Processes. 2022; 10(1):81. https://doi.org/10.3390/pr10010081

Chicago/Turabian StyleBenyahya, Youssef, Abderrahim Fail, Abdelhakim Alali, and Mohamed Sadik. 2022. "Recovery of Household Waste by Generation of Biogas as Energy and Compost as Bio-Fertilizer—A Review" Processes 10, no. 1: 81. https://doi.org/10.3390/pr10010081

APA StyleBenyahya, Y., Fail, A., Alali, A., & Sadik, M. (2022). Recovery of Household Waste by Generation of Biogas as Energy and Compost as Bio-Fertilizer—A Review. Processes, 10(1), 81. https://doi.org/10.3390/pr10010081