A Survey of Vision-Based Methods for Surface Defects’ Detection and Classification in Steel Products

Abstract

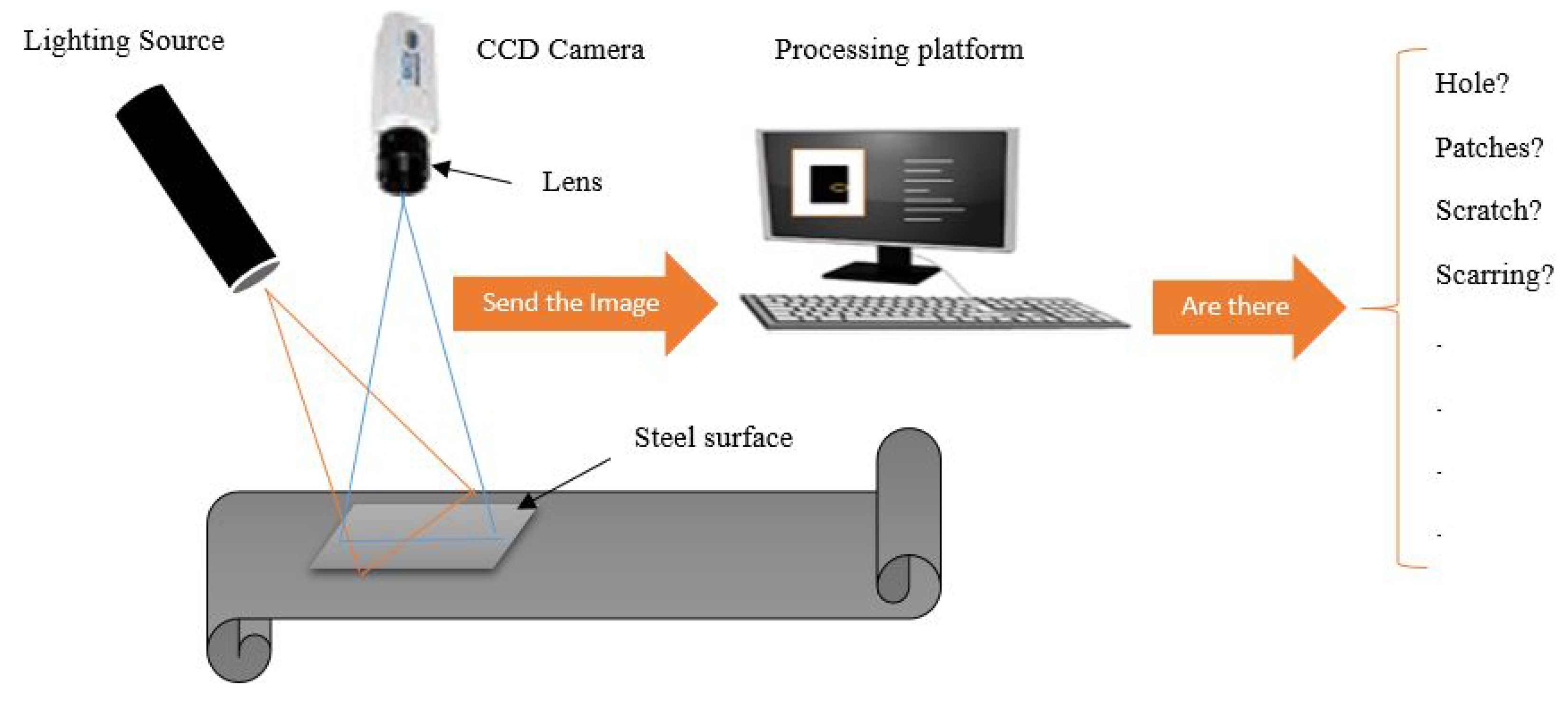

1. Introduction

- 1.

- We provide a comprehensive overview of existing methods for detecting and classifying defects on steel surfaces, encompassing more than 200 studies.

- 2.

- We present an analysis of the performance evaluation of various state-of-the-art algorithms for detecting and classifying defects on steel surfaces.

- 3.

- We discuss evaluation metrics commonly used in steel surface defect detection. By providing insights into these evaluation metrics, the paper aids in assessing the performance of defect detection methods.

- 4.

- We provide an overview of diverse state-of-the-art methods employed in detecting and classifying steel surface defects, emphasizing their strengths and weaknesses.

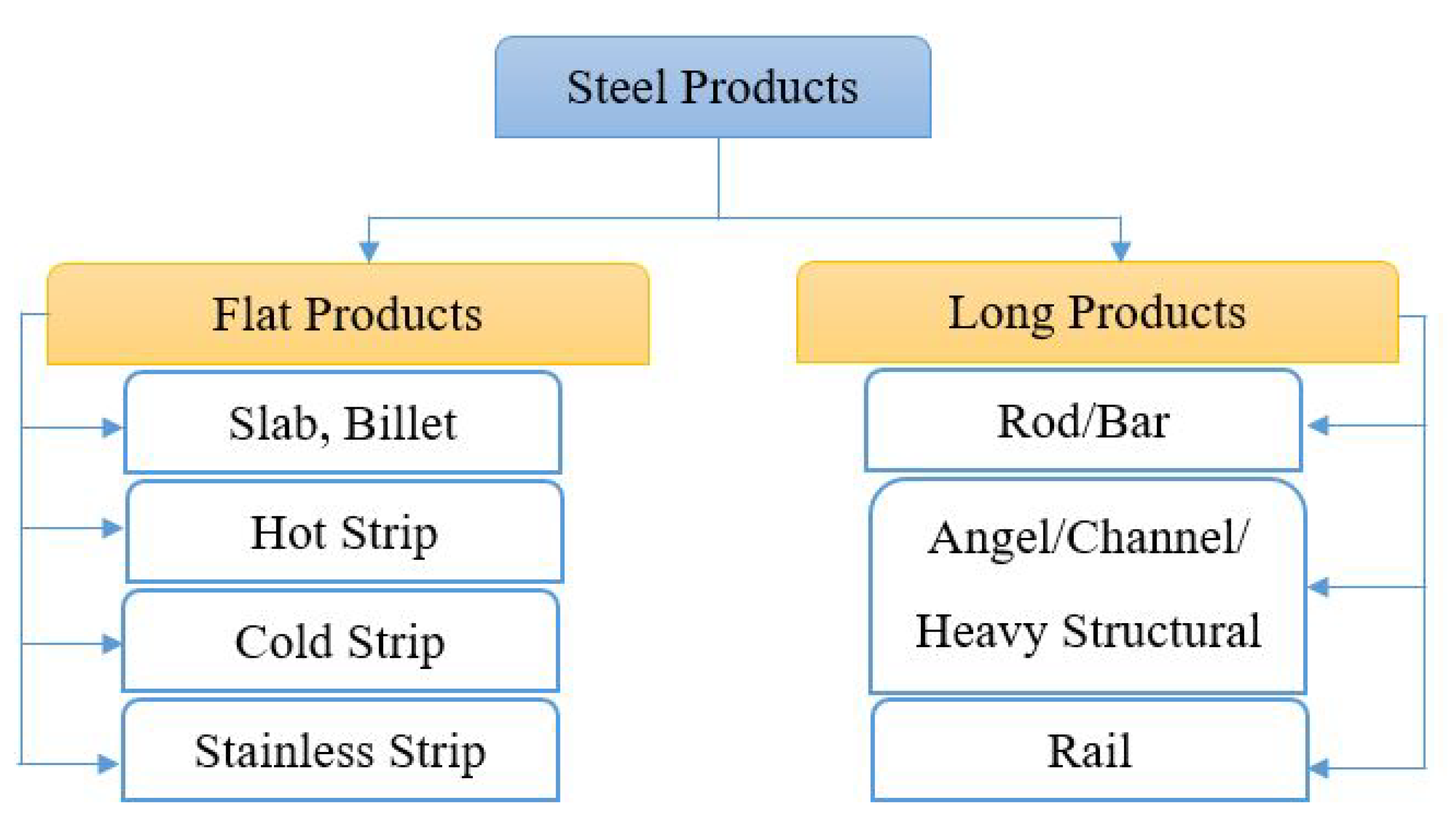

2. Steel and Its Surface Defect Types

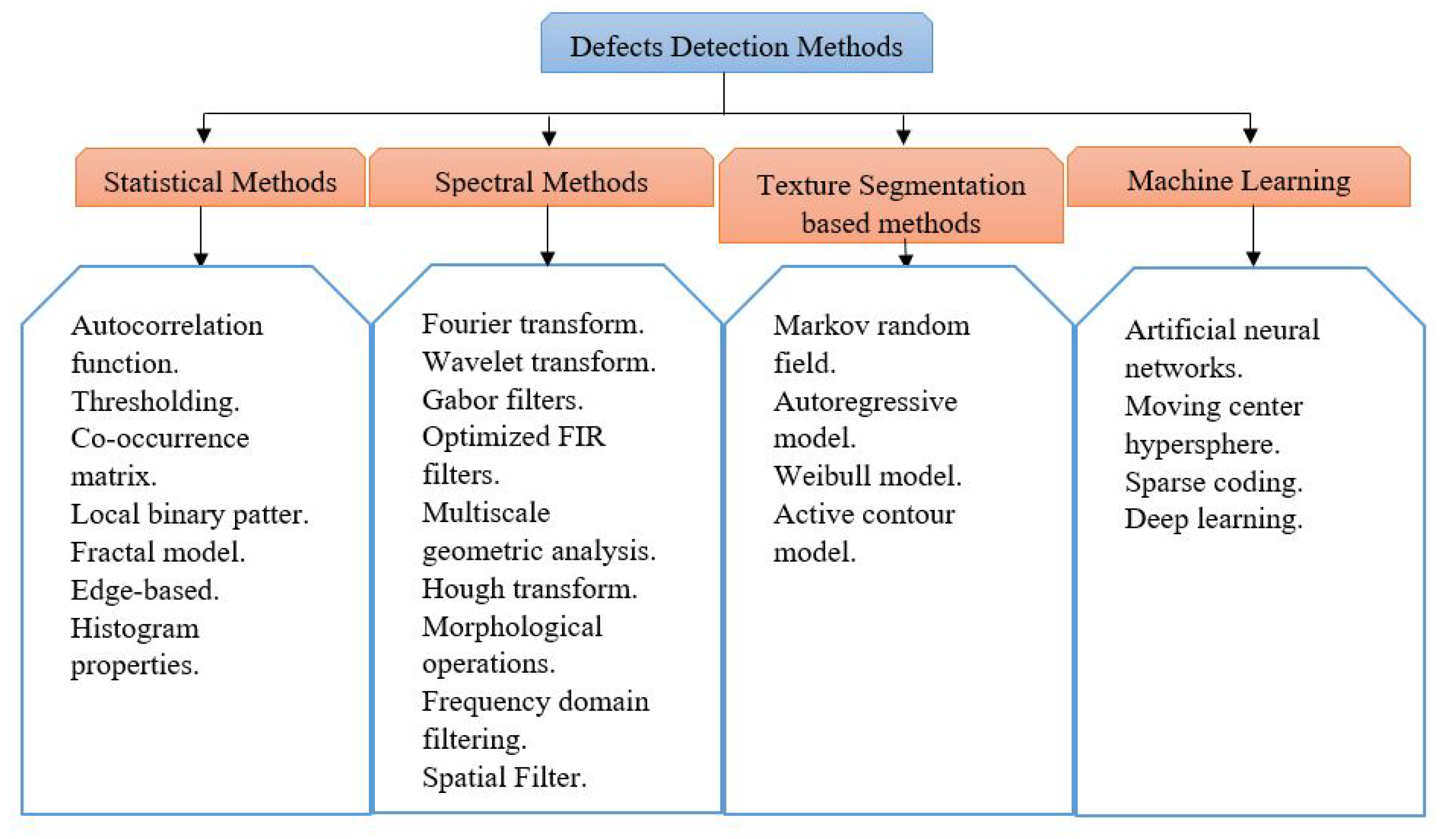

3. Defect Detection Methods

3.1. Statistical Models

3.1.1. Autocorrelation

3.1.2. Thresholding

3.1.3. Gray-Level Co-Occurrence Matrix

3.1.4. Local Binary Pattern

3.1.5. Fractal Model

3.1.6. Edge-Based Features

3.1.7. Histogram Properties

3.2. Spectral Methods

3.2.1. Fourier Transform

3.2.2. Wavelet Transform

3.2.3. Gabor Filter

3.2.4. Optimized FIR Filters

| Methods | Advantages | Disadvantages | Applications |

|---|---|---|---|

| Fourier transform | Expansion and rotation invariance to translation | Lack of localized signal analysis function | [33,65,66] |

| Wavelet transform | Capable of representing local signal features and multiresolution analysis; high detection accuracy, ranging from 83.00% to 97.00% | Hard to choose the wavelet basis; feature correlations between scales can be easily influenced | [53,54,67,68,69] |

| Gabor filters | Appropriate for feature spaces with high dimensions; low computational burden | Difficult to select the best filter parameters | [56,58,59,70] |

| Optimized FIR filters | Suitable, specifically on defects that have subtle intensity variation; they are simple and always stable | Require more memory; limitations to solve the problem of low frequencies | [63,64] |

| Multiscale geometric analysis | Image compression efficiency with less data loss; less details are required | Existing redundancy problem | [66,71,72] |

| Hough transform | Robust against interference and insensitive to noise | Only tracks the direction of edges; information regarding the length of a line segment is lost | [73] |

| Frequency-domain filtering | Suitable for detecting both global and local defects; invariant to translation, expansion, and rotation | Lack of ability for spatial orientation; not suited for detecting random textures | [40,74,75] |

| Morphological operations | Geometric representation of texture images; suitable for random or natural textures; computational simplicity. | Only implemented on non-periodic steel defects | [76,77,78,79] |

| Spatial filter | Its text-based approach is more centralized (the text file segment is separated from the image segmentation) | The best filter parameters are hard to determine; difficult to maintain spatial orientation | [80,81,82,83,84] |

3.2.5. Multiscale Geometric Analysis

3.2.6. Hough Transform

3.2.7. Morphological Operations

3.2.8. Frequency-Domain Analysis

3.2.9. Spatial Filter

3.3. Texture Segmentation-Based Methods

3.3.1. Markov Random Field Model

3.3.2. Autoregressive Model

3.3.3. Weibull Model

3.3.4. Active Contour Model

3.4. Machine Learning-Based Methods

3.4.1. Artificial Neural Networks

3.4.2. Moving Center Hypersphere

3.4.3. Sparse Coding

3.4.4. Deep Learning-Based Steel Surface Defect Detection Methods

Supervised

Unsupervised

Semi-Supervised

4. Comparison of Some Defect Detection Methods

5. Defects Classification Methods

5.1. Supervised Classifiers

5.1.1. K-nearest Neighbors Classifiers

5.1.2. Artificial Neural Network

5.1.3. Support Vector Machines

5.1.4. Discriminant Function

5.1.5. Fuzzy Logic

5.1.6. Deep Learning

5.2. Unsupervised Classifiers

5.2.1. Self-Organizing Map

5.2.2. Learning Vector Quantizer

5.2.3. Deep Autoencoder Network

5.3. Semi-Supervised Classifier

6. Comparison of Some Defect Classification Methods

7. Evaluation Metrics of Defect Detection and Classification Methods

8. Trend Analysis of the Literature

8.1. Literature Analysis of Detection Methods

8.2. Literature Analysis of Classification Methods

9. Conclusions and Future Directions

- A standard image dataset must be used to conduct a performance evaluation of detection and classification algorithms and carry out a fair comparative analysis.

- Although requiring fewer labeled datasets, semi-supervised learning methods have exhibited lower accuracies than supervised learning methods.

- The significant diversity and similarity of various classes of defects make defect classification difficult.

- Augmenting data enhances the performance of defect detection and classification models, particularly on unevenly distributed datasets that are not too large.

- 1.

- There is a need for curating large-scale benchmark datasets comprising diverse steel product types and defect categories and standardized evaluation metrics, including accuracy, precision, recall, and F1-score metrics.

- 2.

- Exploring the integration of advanced machine learning models, such as transformer-based models, graph neural networks, and reinforcement learning, to further improve the accuracy and efficiency of defect detection systems.

- 3.

- Ensuring the robustness and generalization of machine learning models across different production environments and steel product types remains a challenge. Future research could investigate methods for enhancing defect detection systems’ robustness and generalization capabilities, such as transfer learning and data augmentation strategies.

- 4.

- Much expectation for future findings for steel surface defect detection and classification points to investigating models based on supervised learning, specifically deep learning techniques and semi-supervised learning methods, to overcome the challenge of limited training data. This shift toward deep learning techniques is expected to improve outcomes in detecting steel-strip defects in the near future.

- 5.

- One of the problems that can be encountered when designing a steel surface defect detection model is the eventuality of small datasets that often lack diversity. The consequence is the design of biased models that fail to appropriately generalize well to unseen data. This is due to the fact that there is not enough variation in the types, sizes, shapes, and locations of defects present in the dataset. Some of the directions that could be explored to resolve these problems are:

- Augmenting the dataset through usual techniques such as rotation, flipping, cropping, and color adjustments might not be sufficient to increase dataset size and diversity. It is then crucial to find novel data augmentation strategies particularly adapted to steel surface defect detection.

- Designing effective feature representations that capture the relevant characteristics of defects on steel surfaces is crucial. It is a challenge to find suitable features that generalize well and are robust to noise and variations.

- Exploring models that can generalize well from small datasets to unseen data is a significant challenge. Regularization techniques, transfer learning, and domain adaptation methods can help improve generalization performance but require careful adaptation and tuning.

- It will be worth investigating the integration of human expertise into the training and validation process to help improve model performance in the presence of small datasets, where human feedback is leveraged to refine and validate defect detection models.

- The development of benchmark datasets specifically tailored to defect detection on steel surfaces can facilitate the evaluation and comparison of different algorithms and methodologies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Notations | Description |

| ANN | Artificial neural networks |

| BP | Backpropagation |

| CAE | Convolutional autoencoder |

| CCD | Charge-coupled device |

| CNN | Convolution neural networks |

| CPN | Classification priority network |

| DAN | Deep autoencoder network |

| DF | Discriminant function |

| FBNN | Feedback neural networks |

| FFNN | Feedforward neural network |

| FIR | Finite impulse response |

| FL | Fuzzy logic |

| GAN | Generative adversarial network |

| GLCM | Gray-level co-occurrence matrix |

| HOG | Histogram of Oriented Gradients |

| KNN | k-Nearest neighbors |

| LBP | Local binary pattern |

| LVQ | Learning Vector Quantization |

| MCH | Moving Center Hypersphere |

| MGA | Multiscale geometric analysis |

| MLP | Multilayer perceptron |

| MRF | Markov random field |

| PCA | Principal component analysis |

| R-CNN | Region convolutional neural network |

| SOM | Self-organizing map |

| SVM | Support vector machine |

| VGG | Visual Geometry Group |

| YOLOv4 | You Look Only Once Network Version 4 |

| TN | True Negative |

| TP | True Positive |

| FP | False Positive |

| FN | False Negative |

References

- El-Agamy, M.; Awad, M.A.; Sonbol, H.A. Automated inspection of surface defects using machine vision. In Proceedings of the 17th International AMME Conference, Cairo, Egypt, 19–21 April 2016; Volume 19, p. 21. [Google Scholar]

- Andreopoulos, A.; Tsotsos, J.K. 50 years of object recognition: Directions forward. Comput. Vis. Image Underst. 2013, 117, 827–891. [Google Scholar] [CrossRef]

- Duan, X.; Duan, F.; Han, F. Study on surface defect vision detection system for steel plate based on virtual instrument technology. In Proceedings of the 2011 International Conference on Control, Automation and Systems Engineering (CASE), Singapore, 30–31 July 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 1–4. [Google Scholar]

- Xu, K.; Liu, S.; Ai, Y. Application of Shearlet transform to classification of surface defects for metals. Image Vis. Comput. 2015, 35, 23–30. [Google Scholar] [CrossRef]

- He, Y.; Song, K.; Meng, Q.; Yan, Y. An end-to-end steel surface defect detection approach via fusing multiple hierarchical features. IEEE Trans. Instrum. Meas. 2019, 69, 1493–1504. [Google Scholar] [CrossRef]

- Yun, J.P.; Lee, S.J.; Koo, G.; Shin, C.; Park, C. Automatic defect inspection system for steel products with exhaustive dynamic encoding algorithm for searches. Opt. Eng. 2019, 58, 023107. [Google Scholar]

- Wang, H.; Zhang, J.; Tian, Y.; Chen, H.; Sun, H.; Liu, K. A simple guidance template-based defect detection method for strip steel surfaces. IEEE Trans. Ind. Inform. 2018, 15, 2798–2809. [Google Scholar] [CrossRef]

- Chigateri, K.B.; Hebbale, A.M. A steel surface defect detection model using machine learning. In Materials Today: Proceedings; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Nath, V.; Chattopadhyay, C.; Desai, K.A. NSLNet: An improved deep learning model for steel surface defect classification utilizing small training datasets. Manuf. Lett. 2023, 35, 39–42. [Google Scholar] [CrossRef]

- Luo, Q.; Fang, X.; Liu, L.; Yang, C.; Sun, Y. Automated visual defect detection for flat steel surface: A survey. IEEE Trans. Instrum. Meas. 2020, 69, 626–644. [Google Scholar] [CrossRef]

- Luo, Q.; Fang, X.; Su, J.; Zhou, J.; Zhou, B.; Yang, C.; Liu, L.; Gui, W.; Tian, L. Automated visual defect classification for flat steel surface: A survey. IEEE Trans. Instrum. Meas. 2020, 69, 9329–9349. [Google Scholar] [CrossRef]

- Czimmermann, T.; Ciuti, G.; Milazzo, M.; Chiurazzi, M.; Roccella, S.; Oddo, C.M.; Dario, P. Visual-based defect detection and classification approaches for industrial applications—A survey. Sensors 2020, 20, 1459. [Google Scholar] [CrossRef]

- Jin, Q.; Chen, L. A survey of surface defect detection of industrial products based on a small number of labeled data. arXiv 2022, arXiv:2203.05733. [Google Scholar]

- Mordia, R.; Verma, A.K. Visual techniques for defects detection in steel products: A comparative study. Eng. Fail. Anal. 2022, 134, 106047. [Google Scholar] [CrossRef]

- Usamentiaga Fernández, R.; González Lema, D.; Díaz Pedrayes, Ó.; García Martínez, D.F. Automated surface defect detection in metals: A comparative review of object detection and semantic segmentation using deep learning. In Proceedings of the Conference Record-Ias Annual Meeting, Vancouver, BC, Canada, 10–14 October 2021; IEEE Industry Applications Society: Piscataway, NJ, USA, 2021. [Google Scholar]

- Zheng, X.; Zheng, S.; Kong, Y.; Chen, J. Recent advances in surface defect inspection of industrial products using deep learning techniques. Int. J. Adv. Manuf. Technol. 2021, 113, 35–58. [Google Scholar] [CrossRef]

- Neogi, N.; Mohanta, D.K.; Dutta, P.K. Review of vision-based steel surface inspection systems. EURASIP J. Image Video Process. 2018, 2014, 50. [Google Scholar] [CrossRef]

- Song, K.; Yan, Y. A noise robust method based on completed local binary patterns for hot-rolled steel strip surface defects. Appl. Surf. Sci. 2013, 285, 858–864. [Google Scholar] [CrossRef]

- Guha, P. Automated Visual Inspection of Steel Surface, Texture Segmentation and Development of a Perceptual Similarity Measure. Master’s Thesis, Department of Mechanical Engineering, Indian Institute of Technology, Kanpur, India, 2001. [Google Scholar]

- Ibrahim, A.A.M.; Tapamo, J.R. Steel Surface Defect Detection and Classification Using Bag of Visual Words with BRISK. In Proceedings of the Congress on Smart Computing Technologies; Springer: Singapore, 2022; pp. 235–246. [Google Scholar]

- Field, Z.; Miles, J.; Field, A.X. Discovering Statistics Using R; Sage Publications Ltd.: New York, NY, USA, 2006; 992p. [Google Scholar]

- Jiang, Y.; Lin, J.; Cukic, B.; Menzies, T. Variance analysis in software fault prediction models. In Proceedings of the 2009 20th International Symposium on Software Reliability Engineering, Karnataka, India, 16–19 November 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 99–108. [Google Scholar]

- Wang, H.; Khoshgoftaar, T.M.; Van Hulse, J.; Gao, K. Metric selection for software defect prediction. Int. J. Softw. Eng. Knowl. Eng. 2011, 21, 237–257. [Google Scholar] [CrossRef]

- Zhu, D.; Pan, R.; Gao, W.; Zhang, J. Yarn-dyed fabric defect detection based on autocorrelation function and GLCM. Autex Res. J. 2015, 15, 226–232. [Google Scholar] [CrossRef]

- Djukic, D.; Spuzic, S. Statistical discriminator of surface defects on hot rolled steel. In Proceedings of the Image and Vision Computing New Zealand 2007(IVCNZ2007), Hamilton, New Zealand, 5–7 December 2007; pp. 158–163. [Google Scholar]

- Guo, Y.J.; Sun, Z.J.; Sun, H.X.; Song, X.L. Texture feature extraction of steel strip surface defect based on gray level co-occurrence matrix. In Proceedings of the 2015 International Conference on Machine Learning and Cybernetics (ICMLC), Guangzhou, China, 12–15 July 2015; IEEE: Piscataway, NJ, USA, 2015; Volume 1, pp. 217–221. [Google Scholar]

- Zaghdoudi, R.; Seridi, H.; Boudiaf, A. Detection and classification of steel defects using machine vision and SVM classifier. In Proceedings of the 2nd International Conference on Automatic Control, Telecommunication and Signals (ICATS’17), Abdelkrim, Gadda, 7–9 May 2017. [Google Scholar]

- Abukhait, J. An automated surface defect inspection system using local binary patterns and co-occurrence matrix textures based on svm classifier. Jordan J. Electr. Eng. 2018, 4, 100–113. [Google Scholar]

- Wang, J.; Li, Q.; Gan, J.; Yu, H.; Yang, X. Surface defect detection via entity sparsity pursuit with intrinsic priors. IEEE Trans. Ind. Inform. 2019, 16, 141–150. [Google Scholar] [CrossRef]

- Luo, Q.; Sun, Y.; Li, P.; Simpson, O.; Tian, L.; He, Y. Generalized completed local binary patterns for time-efficient steel surface defect classification. IEEE Trans. Instrum. Meas. 2018, 68, 667–679. [Google Scholar] [CrossRef]

- Luo, Q.; Fang, X.; Sun, Y.; Liu, L.; Ai, J.; Yang, C.; Simpson, O. Surface defect classification for hot-rolled steel strips by selectively dominant local binary patterns. IEEE Access 2019, 7, 23488–23949. [Google Scholar] [CrossRef]

- Gyimah, N.K.; Girma, A.; Mahmoud, M.N.; Nateghi, S.; Homaifar, A.; Opoku, D. A Robust Completed Local Binary Pattern (RCLBP) for Surface Defect Detection. In Proceedings of the 2021 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Melbourne, Australia, 17–20 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1927–1934. [Google Scholar]

- Yazdchi, M.; Yazdi, M.; Mahyari, A.G. Steel surface defect detection using texture segmentation based on multifractal dimension. In Proceedings of the 2009 International Conference on Digital Image Processing, Cairo, Egypt, 7–10 November 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 346–350. [Google Scholar]

- Wen, W.; Xia, A. Verifying edges for visual inspection purposes. Pattern Recognit. Lett. 1999, 20, 315–328. [Google Scholar] [CrossRef]

- Kholief, E.A.; Darwish, S.H.; Fors, M.N. Detection of steel surface defect based on machine learning using deep auto-encoder network. In Proceedings of the International Conference on Industrial Engineering and Operations Management Rabat, Morocco, 11–13 April 2017; pp. 218–229. [Google Scholar]

- Thai, B.; Healey, G. Modeling and classifying symmetries using a multiscale opponent color representation. IEEE Trans. Pattern Anal. Mach. Intell. 1998, 20, 1224–1235. [Google Scholar] [CrossRef]

- Pietikäinen, M.; Mäenpää, T.; Viertola, J. Color texture classification with color histograms and local binary patterns. In Proceedings of the Workshop on Texture Analysis in Machine Vision; Citeseer: New York, NY, USA; Volume 1, pp. 109–112.

- Ng, H.F. Automatic thresholding for defect detection. Pattern Recognit. Lett. 2006, 27, 1644–1649. [Google Scholar] [CrossRef]

- Haralick, R.M. Statistical and structural approaches to texture. Proc. IEEE 1979, 67, 786–804. [Google Scholar] [CrossRef]

- Wu, G.; Kwak, H.; Jang, S.; Xu, K.; Xu, J. Design of online surface inspection system of hot rolled strips. In Proceedings of the 2008 IEEE International Conference on Automation and Logistics, Chindao, China, 1–3 September 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 2291–2295. [Google Scholar]

- Ozseven, T.; Özseven, T. Surface defect detection and quantification with image processing methods. In Theoretical Investigations and Applied Studies in Engineering; Ekin Publishing House: Ankara, Turkey, 2019; pp. 63–98. [Google Scholar]

- Ojala, T.; Pietikäinen, M.; Harwood, D. A comparative study of texture measures with classification based on featured distributions. Pattern Recognit. 1996, 29, 51–59. [Google Scholar] [CrossRef]

- Ojala, T.; Pietikainen, M.; Maenpaa, T. Multiresolution gray-scale and rotation invariant texture classification with local binary patterns. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 971–987. [Google Scholar] [CrossRef]

- Chu, M.; Gong, R. Invariant feature extraction method based on smoothed local binary pattern for strip steel surface defect. ISIJ Int. 2015, 55, 1956–1962. [Google Scholar] [CrossRef]

- Aghdam, S.R.; Amid, E.; Imani, M.F. A fast method of steel surface defect detection using decision trees applied to LBP based features. In Proceedings of the 2012 7th IEEE Conference on Industrial Electronics and Applications (ICIEA), Singapore, 18–20 July 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1447–1452. [Google Scholar]

- Chu, M.; Gong, R.; Gao, S.; Zhao, J. Steel surface defects recognition based on multi-type statistical features and enhanced twin support vector machine. Chemom. Intell. Lab. Syst. 2017, 171, 140–150. [Google Scholar] [CrossRef]

- Makaremi, M.; Razmjooy, N.; Ramezani, M. A new method for detecting texture defects based on modified local binary pattern. Signal Image Video Process. 2018, 12, 1395–1401. [Google Scholar] [CrossRef]

- Tajeripour, F.; Kabir, E.; Sheikhi, A. Fabric defect detection using modified local binary patterns. EURASIP J. Adv. Signal Process. 2007, 2008, 783898. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; WH Freeman: New York, NY, USA, 1982; Volume 1. [Google Scholar]

- Umbaugh, S.E. Digital Image Processing and Analysis: Human and Computer Vision Applications with CVIPtools, CRC Press: Boca Raton, FL, USA, 2010.

- Kobayashi, T. BFO meets HOG: Feature extraction based on histograms of oriented pdf gradients for image classification. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Portland, OR, USA, 23–28 June 2013; pp. 747–754. [Google Scholar]

- Bultheel, A. Learning to swim in a sea of wavelets. Bull. Belg. Math.-Soc.-Simon Stevin 1995, 2, 1–45. [Google Scholar] [CrossRef]

- Aarthi, T.; Karthi, M.; Abinesh, M. Detection and analysis of surface defects in metals using wavelet transform. Int. J. Sci. Res. Publ. 2013, 3, 147–158. [Google Scholar]

- Selvi, M.; Jenefa, D. Automated Defect Detection of Steel Surface Using Neural Network Classifier with Co-occurrence Features. Int. J. Adv. Res. Comput. Sci. Softw. Eng. 2014, 4, 60–67. [Google Scholar]

- Özseven, T. Investigation of the effect of spectrogram images and different texture analysis methods on speech emotion recognition. Appl. Acoust. 2018, 142, 70–77. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Choi, D.C.; Yun, J.P.; Park, C.; Kim, S.W. Detection of scratch defects on slab surface. In Proceedings of the 11th International Conference on Control, Automation and Systems, Gyeonggi-do, Republic of Korea, 26–29 October 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 1274–1278. [Google Scholar]

- Yun, J.P.; Choi, S.H.; Seo, B.; Park, C.H.; Kim, S.W. Defects detection of billet surface using optimized gabor filters. IFAC Proc. Vol. 2011, 41, 77–82. [Google Scholar] [CrossRef]

- Choi, D.C.; Jeon, Y.J.; Yun, J.P.; Kim, S.W. Pinhole detection in steel slab images using Gabor filter and morphological features. Appl. Opt. 2011, 50, 5122–5129. [Google Scholar] [CrossRef]

- Choi, D.C.; Jeon, Y.J.; Kim, S.H.; Moon, S.; Yun, J.P.; Kim, S.W. Detection of pinholes in steel slabs using Gabor filter combination and morphological features. ISIJ Int. 2017, 57, 1045–1053. [Google Scholar] [CrossRef]

- Wankhede, P.A.; Gaw, E.R.S.; Khare, N.A. Gabor Filter for Surface Inspection in Metallic Industry. Int. J. Adv. Res. Comput. Sci. Softw. Eng. 2016, 6, 89–92. [Google Scholar]

- Medina, R.; Gayubo, F.; González, L.M.; Olmedo, D.; García-Bermejo, J.G.; Casanova, E.Z.; Perán, J.R. Surface Defects Detection on Rolled Steel Strips by Gabor Filters. In Proceedings of the International Conference on Computer Vision Theory and Applications, Madeira, Portugal, 22–25 January 2008; pp. 479–485. [Google Scholar]

- Kumar, A. Computer-vision-based fabric defect detection: A survey. IEEE Trans. Ind. Electron. 2008, 55, 348–363. [Google Scholar] [CrossRef]

- Kumar, A.; Pang, G.K. Defect detection in textured materials using optimized filters. IEEE Trans. Syst. Man, Cybern. Part (Cybernetics) 2002, 32, 553–570. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Choi, D.C.; Lee, S.J.; Yun, J.P.; Kim, S.W. Steel-surface defect detection using a switching-lighting scheme. Appl. Opt. 2016, 55, 47–57. [Google Scholar] [CrossRef]

- Wiltschi, K.; Pinz, A.; Lindeberg, T. An automatic assessment scheme for steel quality inspection. Mach. Vis. Appl. 2000, 12, 113–128. [Google Scholar] [CrossRef]

- Ai, Y.H.; Xu, K. Surface detection of continuous casting slabs based on curvelet transform and kernel locality preserving projections. J. Iron Steel Res. Int. 2013, 20, 80–86. [Google Scholar] [CrossRef]

- Kaya, K.; Bilgutay, N.M.; Murthy, R. Flaw detection in stainless steel samples using wavelet decomposition. In 1994 Proceedings of IEEE Ultrasonics Symposium, Cannes, France, 31 October–3 November 1994; IEEE: Piscataway, NJ, USA, 1994; Volume 2, pp. 1271–1274. [Google Scholar]

- Yun, J.P.; Choi, S.; Jeon, Y.J.; Choi, D.C.; Kim, S.W. Detection of line defects in steel billets using undecimated wavelet transform. In Proceedings of the 2008 International Conference on Control, Automation and Systems, Seoul, Republic of Korea, 14–17 October 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 1725–1728. [Google Scholar]

- Ghorai, S.; Mukherjee, A.; Gangadaran, M.; Dutta, P.K. Automatic defect detection on hot-rolled flat steel products. IEEE Trans. Instrum. Meas. 2012, 62, 612–621. [Google Scholar] [CrossRef]

- Hu, G.H. Automated defect detection in textured surfaces using optimal elliptical Gabor filters. Optik 2015, 126, 1331–1340. [Google Scholar] [CrossRef]

- Xu, K.; Xu, Y.; Zhou, P.; Wang, L. Application of RNAMlet to surface defect identification of steels. Opt. Lasers Eng. 2018, 105, 110–117. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, Y.H.; Chen, W.H.; Chen, J.J. Image fusion method for strip steel surface detect based on Bandelet-PCNN. Adv. Mater. Res. 2012, 546, 806–810. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Amirfattahi, R.; Sadri, S.; Alirezaee, S.; Ahmadi, M. Detection of steel defect using the image processing algorithms. In Proceedings of the International Conference on Electrical Engineering (Vol. 6, No. 6th International Conference on Electrical Engineering ICEENG 2008, 1–7); Military Technical College: Cairo, Egypt, 2008. [Google Scholar]

- Wu, G. Online Surface Inspection Technology of Cold Rolled Strips; INTECH Open Access Publisher: London, UK, 2010. [Google Scholar]

- Wu, G.; Zhang, H.; Sun, X.; Xu, J.; Xu, K. A bran-new feature extraction method and its application to surface defect recognition of hot rolled strips. In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 2069–2074. [Google Scholar]

- Strom, L.A.; Thurley, M.J. Morphology-based crack detection for steel slabs. IEEE J. Sel. Top. Signal Process. 2012, 6, 866–875. [Google Scholar] [CrossRef]

- Tang, B.; Kong, J.Y.; Wang, X.D.; Jiang, G.Z.; Chen, L. Steel strip surface defects detection based on mathematical morphology. J. Iron Steel Res. 2010, 22, 56–59. [Google Scholar]

- Yazdchi, M.R.; Mahyari, A.G.; Nazeri, A. Detection and classification of surface defects of cold rolling mill steel using morphology and neural network. In Proceedings of the 2008 International Conference on Computational Intelligence for Modelling Control Automation, Vienna, Austria, 10–12 December 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 1071–1076. [Google Scholar]

- Wu, X.Y.; Xu, K.; Xu, J.W. Application of undecimated wavelet transform to surface defect detection of hot rolled steel plates. In Proceedings of the 2008 Congress on Image and Signal Processing, Washington, DC, USA, 27–30 May 2008; IEEE: Piscataway, NJ, USA, 2008; Volume 4, pp. 528–532. [Google Scholar]

- Guan, S. Strip steel defect detection based on saliency map construction using Gaussian pyramid decomposition. ISIJ Int. 2015, 55, 1950–1955. [Google Scholar] [CrossRef]

- Alkapov, R.; Konyshev, A.; Vetoshkin, N.; Valkevich, N.; Kostenetskiy, P. Automatic visible defect detection and classification system prototype development for iron-and-steel works. In Proceedings of the 2018 Global Smart Industry Conference (GloSIC), Chelyabinsk, Russia, 13–15 November 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–8. [Google Scholar]

- Dupont, F.; Odet, C.; Cartont, M. Optimization of the recognition of defects in flat steel products with the cost matrices theory. NDT E Int. 1997, 30, 3–10. [Google Scholar] [CrossRef]

- Guo, J.H.; Meng, X.D.; Xiong, M.D. Study on defection segmentation for steel surface image based on image edge detection and fisher discriminant. J. Physics Conf. Ser. 2006, 48, 364. [Google Scholar] [CrossRef]

- Choi, S.H.; Yun, J.P.; Seo, B.; Park, Y.S.; Kim, S.W. Real-time defects detection algorithm for high-speed steel bar in coil. Proc. World Acad. Sci. Eng. Technol. 2007, 21, 1307–6884. [Google Scholar]

- Shapiro, L.G.; Stockman, G.C. Comput Vision New Jersey; Prentice Hall: Hoboken, NJ, USA, 2001; Volume 3. [Google Scholar]

- Hough, P.V. Method and Means for Recognizing Complex Patterns. U.S. Patent 3,069,654, 1962. Volume 3. [Google Scholar]

- Duan, T.D.; Duc, D.A.; Du, T.L.H. Combining Hough transform and contour algorithm for detecting vehicles’ license-plates. In Proceedings of the 2004 International Symposium on Intelligent Multimedia, Video and Speech Processing, Hong Kong, China, 20–22 October 2004; IEEE: Piscataway, NJ, USA, 2004; pp. 747–750. [Google Scholar]

- Si, X.; Feng, J.; Zhou, J.; Luo, Y. Detection and rectification of distorted fingerprints. IEEE Trans. Pattern Anal. Mach. Intell. 2015, 37, 555–568. [Google Scholar] [CrossRef] [PubMed]

- Gu, S.; Feng, J.; Lu, J.; Zhou, J. Efficient rectification of distorted fingerprints. IEEE Trans. Inf. Forensics Secur. 2017, 13, 156–169. [Google Scholar] [CrossRef]

- Laitinen, T.; Silven, O.; Pietikaeinen, M. Morphological image processing for automated metal strip inspection. In Image Algebra and Morphological Image Processing; SPIE: Washington, DC, USA, 1990; Volume 1350, pp. 241–250. [Google Scholar]

- Liu, M.; Liu, Y.; Hu, H.; Nie, L. Genetic algorithm and mathematical morphology based binarization method for strip steel defect image with non-uniform illumination. J. Vis. Commun. Image Represent. 2016, 37, 70–77. [Google Scholar] [CrossRef]

- Zheng, H.; Kong, L.X.; Nahav, I.S. Automatic inspection of metallic surface defects using genetic algorithms. J. Mater. Process. Technol. 2002, 125, 427–433. [Google Scholar] [CrossRef]

- Jeon, Y.J.; Yun, J.P.; Choi, D.C.; Kim, S.W. Defect detection algorithm for corner cracks in steel billet using discrete wavelet transform. In Proceedings of the 2009 ICCAS-SICE, Fukuoka, Japan, 18–21 August 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 2769–2773. [Google Scholar]

- Lee, D.; Kang, Y.I.; Park, C.; Won, S. Defect detection algorithm in steel billets using morphological top-hat filter. IFAC Proc. Vol. 2009, 42, 209–212. [Google Scholar] [CrossRef]

- Atif, J.; Bloch, I.; Distel, F.; Hudelot, C. Mathematical morphology operators over concept lattices. In Proceedings of the Formal Concept Analysis: 11th International Conference, (ICFCA 2013), Dresden, Germany, 21–24 May 2013; Proceedings 11. Springer: Berlin/Heidelberg, Germany, 2013; pp. 28–43. [Google Scholar]

- Nguyen, A.Q.; Dao, V.T.S.; Shimonomura, K.; Takehara, K.; Etoh, T.G. Toward the ultimate-high-speed image sensor: From 10 ns to 50 ps. Sensors 2018, 18, 2407. [Google Scholar] [CrossRef]

- Merazi-Meksen, T.; Boudraa, M.; Boudraa, B. Mathematical morphology for TOFD image analysis and automatic crack detection. Ultrasonics 2014, 54, 1642–1648. [Google Scholar] [CrossRef]

- Han, B.A.; Xiang, H.Y.; Li, Z.; Huang, J.J. Defects detection of sheet metal parts based on HALCON and region morphology. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2013; Volume 365, pp. 729–732. [Google Scholar]

- Umbaugh, S.E. Digital Image Processing and Analysis: Applications with MATLAB and CVIPtools; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Ünsalan, C.; Erçil, A. Automated inspection of steel structures. In Recent Advances in Mechatronics; Kaynak, O., Tosunoğlu, S., Ang, M., Jr., Eds.; Springer-Verlag Ltd.: Singapore, 1999; pp. 468–480. [Google Scholar]

- Ozdemir, S.; Ercil, A. Markov random fields and Karhunen-Loeve transforms for defect inspection of textile products. In Proceedings of the 1996 IEEE Conference on Emerging Technologies and Factory Automation (ETFA’96), Kauai, HI, USA, 5–6 December 1996; IEEE: Piscataway, NJ, USA, 1996; Volume 2, pp. 697–703. [Google Scholar]

- Hajimowlana, S.H.; Muscedere, R.; Jullien, G.A.; Roberts, J.W. 1D autoregressive modeling for defect detection in web inspection systems. In Proceedings of the 1998 Midwest Symposium on Circuits and Systems (Cat. No. 98CB36268), Notre Dame, Indiana, 9–12 August 1998; IEEE: Piscataway, NJ, USA, 1998; pp. 318–321. [Google Scholar]

- Basu, M.; Lin, Z. Multi-scale modeling of textures. In Proceedings of the 11th IAPR International Conference on Pattern Recognition. Vol. III. Conference C: Image, Speech and Signal Analysis, The Hague, The Netherlands, 30 August–1 September 1992; IEEE Computer Society: Piscataway, NJ, USA, 1992; Volume 1, pp. 421–424. [Google Scholar]

- Serafim, A.L. Multiresolution pyramids for segmentation of natural images based on autoregressive models: Application to calf leather classification. In Proceedings of the IECON’91: 1991 International Conference on Industrial Electronics, Control and Instrumentation, Kobe, Japan, 28 October–1 November 1991; IEEE: Piscataway, NJ, USA, 1991; pp. 1842–1847. [Google Scholar]

- Serafim, A.L. Segmentation of natural images based on multiresolution pyramids linking of the parameters of an autoregressive rotation invariant model. Application to leather defects detection. In Proceedings of the 11th IAPR International Conference on Pattern Recognition. Vol. III. Conference C: Image, Speech and Signal Analysis, The Hague, The Netherlands, 30 August–1 September 1992; IEEE Computer Society: Piscataway, NJ, USA, 1992; Volume 1, pp. 41–44. [Google Scholar]

- Timm, F.; Barth, E. Non-parametric texture defect detection using Weibull features. In Image Processing: Machine Vision Applications IV; SPIE: Washington, DC, USA, 2011; Volume 7877, pp. 150–161. [Google Scholar]

- Liu, K.; Wang, H.; Chen, H.; Qu, E.; Tian, Y.; Sun, H. Steel surface defect detection using a new Haar–Weibull-variance model in unsupervised manner. IEEE Trans. Instrum. Meas. 2017, 66, 2585–2596. [Google Scholar] [CrossRef]

- Wang, L.; Chang, Y.; Wang, H.; Wu, Z.; Pu, J.; Yang, X. An active contour model based on local fitted images for image segmentation. Inf. Sci. 2017, 418, 61–73. [Google Scholar] [CrossRef] [PubMed]

- Cross, G.R.; Jain, A.K. Markov random field texture models. IEEE Trans. Pattern Anal. Mach. Intell. 1983, 1, 25–39. [Google Scholar] [CrossRef] [PubMed]

- Geman, S.; Geman, D. Stochastic relaxation, Gibbs distributions, and the Bayesian restoration of images. IEEE Trans. Pattern Anal. Mach. Intell. 1984, 1, 721–741. [Google Scholar] [CrossRef]

- Hanbay, K.; Talu, M.F. Online/offline detection systems of fabric defects and methods. Sak. Univ. J. Sci. 2014, 18, 49–69. [Google Scholar]

- Ayed, I.B.; Hennane, N.; Mitiche, A. Unsupervised variational image segmentation/classification using a Weibull observation model. IEEE Trans. Image Process. 2006, 15, 3431–3439. [Google Scholar] [CrossRef] [PubMed]

- Kass, M.; Witkin, A.; Terzopoulos, D. Snakes: Active contour models. Int. J. Comput. Vis. 1988, 1, 321–331. [Google Scholar] [CrossRef]

- Freeman, J.A.; Skapura, D.M. Neural Networks: Algorithms, Applications, and Programming Techniques; Addison Wesley Longman Publishing Co., Inc.: Lake St Upper Saddle River, NJ, USA, 1991. [Google Scholar]

- Peng, K.; Zhang, X. Classification technology for automatic surface defects detection of steel strip based on improved BP algorithm. In Proceedings of the 2009 Fifth International Conference on Natural Computation, Tianjin, China, 14–16 August 2009; IEEE: Piscataway, NJ, USA, 2009; Volume 1, pp. 110–114. [Google Scholar]

- Caleb, P.; Steuer, M. Classification of surface defects on hot rolled steel using adaptive learning methods. In Proceedings of the KES’2000. Fourth International Conference on Knowledge-Based Intelligent Engineering Systems and Allied Technologies, Brighton, UK, 30 August–1 September 2000; Proceedings (Cat. No. 00TH8516). IEEE: Piscataway, NJ, USA, 2000; Volume 1, pp. 103–108. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLO9000: Better, faster, stronger. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2017; pp. 7263–7271. [Google Scholar]

- Liu, Y.; Geng, J.; Su, Z.; Zhang, W.; Li, J. Real-time classification of steel strip surface defects based on deep CNNs. In Proceedings of the 2018 Chinese Intelligent Systems Conference; Springer: Singapore, 2019; Volume II, pp. 257–266. [Google Scholar]

- Sun, X.; Gu, J.; Tang, S.; Li, J. Research progress of visual inspection technology of steel products—A review. Appl. Sci. 2018, 8, 2195. [Google Scholar] [CrossRef]

- Wang, X.F.; Huang, D.S.; Du, J.X.; Xu, H.; Heutte, L. Classification of plant leaf images with complicated background. Appl. Math. Comput. 2008, 205, 916–926. [Google Scholar] [CrossRef]

- Chu, M.; Zhao, J.; Liu, X.; Gong, R. Multi-class classification for steel surface defects based on machine learning with quantile hyper-spheres. Chemom. Intell. Lab. Syst. 2017, 168, 15–27. [Google Scholar] [CrossRef]

- Gong, R.; Wu, C.; Chu, M.; Liu, X. The Strip Steel Surface Defect Recognition Based on Multiple Support Vector Hyper-Sphere with Feature and Sample Weights. Steel Res. Int. 2016, 87, 1678–1685. [Google Scholar] [CrossRef]

- Huangpeng, Q.; Duan, X.; Huang, W. Surface Defects Classification Using Transfer Learning and Deep Sparse Coding. In Proceedings of the 2021 40th Chinese Control Conference (CCC), Shanghai, China, 26–28 July 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 2987–2992. [Google Scholar]

- Zhou, S.; Chen, Y.; Zhang, D.; Xie, J.; Zhou, Y. Learning a class-specific and shared dictionary for classifying surface defects of steel sheet. ISIJ Int. 2017, 57, 123–130. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, J.; Hu, L.; Zhang, X.L.; Kong, J.Y. Research on on-line surface defect detection for steel strip based on sparse coding. In Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2012; Volume 548, pp. 749–752. [Google Scholar]

- Zhao, H.; Yang, Z.; Li, J. Detection of metal surface defects based on YOLOv4 algorithm. J. Phys. Conf. Ser. 2021, 1907, 012043. [Google Scholar] [CrossRef]

- Zhou, G.; Sun, H. Defect detection method for steel based on semantic segmentation. In Proceedings of the 2020 IEEE 5th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 12–14 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 975–979. [Google Scholar]

- Dong, H.; Song, K.; He, Y.; Xu, J.; Yan, Y.; Meng, Q. PGA-Net: Pyramid feature fusion and global context attention network for automated surface defect detection. IEEE Trans. Ind. Inform. 2019, 16, 7448–7458. [Google Scholar] [CrossRef]

- Gao, Y.; Gao, L.; Li, X. A hierarchical training-convolutional neural network with feature alignment for steel surface defect recognition. Robot.-Comput.-Integr. Manuf. 2023, 81, 102507. [Google Scholar] [CrossRef]

- Abu, M.; Amir, A.; Lean, Y.H.; Zahri, N.A.H.; Azemi, S.A. The performance analysis of transfer learning for steel defect detection by using deep learning. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; Volume 1755, p. 012041. [Google Scholar]

- Kateb, Y.; Meglouli, H.; Khebli, A. Steel Surface Defect Detection Using Convolutional Neural Network. Alger. J. Signals Syst. 2020, 5, 203–208. [Google Scholar] [CrossRef]

- Chen, R.; Cai, D.; Hu, X.; Zhan, Z.; Wang, S. Defect detection method of aluminum profile surface using deep self-attention mechanism under hybrid noise conditions. IEEE Trans. Instrum. Meas. 2021, 70, 3524509. [Google Scholar] [CrossRef]

- Litvintseva, A.; Evstafev, O.; Shavetov, S. Real-time steel surface defect recognition based on CNN. In Proceedings of the 2021 IEEE 17th International Conference on Automation Science and Engineering (CASE), Lyon, France, 23–27 August 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1118–1123. [Google Scholar]

- Fadli, V.F.; Herlistiono, I.O. Steel surface defect detection using deep learning. Int. J. Innov. Sci. Res. Technol. 2020, 5, 244–250. [Google Scholar]

- Gao, S.; Xia, T.; Hong, G.; Zhu, Y.; Chen, Z.; Pan, E.; Xi, L. An inspection network with dynamic feature extractor and task alignment head for steel surface defect. Measurement 2024, 224, 113957. [Google Scholar] [CrossRef]

- Lian, J.; Jia, W.; Zareapoor, M.; Zheng, Y.; Luo, R.; Jain, D.K.; Kumar, N. Deep-learning-based small surface defect detection via an exaggerated local variation-based generative adversarial network. IEEE Trans. Ind. Inform. 2019, 16, 1343–1351. [Google Scholar] [CrossRef]

- Mujeeb, A.; Dai, W.; Erdt, M.; Sourin, A. Unsupervised surface defect detection using deep autoencoders and data augmentation. In Proceedings of the 2018 International Conference on Cyberworlds (CW), Singapore, 3–5 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 391–398. [Google Scholar]

- Zhao, Z.; Li, B.; Dong, R.; Zhao, P. A surface defect detection method based on positive samples. In PRICAI 2018: Trends in Artificial Intelligence: 15th Pacific Rim International Conference on Artificial Intelligence, Nanjing, China, 28–31 August 2018, Proceedings, Part II 15; Springer International Publishing: Cham, Switzerland, 2018; pp. 473–481. [Google Scholar]

- Mei, S.; Yang, H.; Yin, Z. An unsupervised-learning-based approach for automated defect inspection on textured surfaces. IEEE Trans. Instrum. Meas. 2018, 67, 1266–1277. [Google Scholar] [CrossRef]

- Youkachen, S.; Ruchanurucks, M.; Phatrapomnant, T.; Kaneko, H. Defect segmentation of hot-rolled steel strip surface by using convolutional auto-encoder and conventional image processing. In Proceedings of the 2019 10th International Conference of Information and Communication Technology for Embedded Systems (IC-ICTES), Bangkok, Thailand, 25–27 March 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–5. [Google Scholar]

- Gao, Y.; Gao, L.; Li, X.; Yan, X. A semi-supervised convolutional neural network-based method for steel surface defect recognition. Robot.-Comput.-Integr. Manuf. 2020, 61, 101825. [Google Scholar] [CrossRef]

- Zhang, G.; Pan, Y.; Zhang, L. Semi-supervised learning with GAN for automatic defect detection from images. Autom. Constr. 2021, 128, 103764. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, H.; Chen, J.; Kong, Y.; Zheng, S. A generic semi-supervised deep learning-based approach for automated surface inspection. IEEE Access 2020, 8, 114088–114099. [Google Scholar] [CrossRef]

- Kim, M.S.; Park, T.; Park, P. Classification of steel surface defect using convolutional neural network with few images. In Proceedings of the 2019 12th Asian Control Conference (ASCC), Kitakyushu-shi, Japan, 9–12 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1398–1401. [Google Scholar]

- Xing, J.; Jia, M. A convolutional neural network-based method for workpiece surface defect detection. Measurement 2021, 176, 109185. [Google Scholar] [CrossRef]

- Kou, X.; Liu, S.; Cheng, K.; Qian, Y. Development of a YOLO-V3-based model for detecting defects on steel strip surface. Measurement 2021, 182, 109454. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Q.; Gu, J.; Su, L.; Li, K.; Pecht, M. Visual inspection of steel surface defects based on domain adaptation and adaptive convolutional neural network. Mech. Syst. Signal Process. 2021, 153, 107541. [Google Scholar] [CrossRef]

- Tian, R.; Jia, M. DCC-CenterNet: A rapid detection method for steel surface defects. Measurement 2022, 187, 110211. [Google Scholar] [CrossRef]

- Li, M.; Wang, H.; Wan, Z. Surface defect detection of steel strips based on improved YOLOv4. Comput. Electr. Eng. 2022, 102, 108208. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Li, Z.; Shu, S.; Lang, X.; Zhang, T.; Dong, J. Development of a cross-scale weighted feature fusion network for hot-rolled steel surface defect detection. Eng. Appl. Artif. Intell. 2023, 117, 105628. [Google Scholar] [CrossRef]

- Wang, R.; Liang, F.; Mou, X.; Chen, L.; Yu, X.; Peng, Z.; Chen, H. Development of an Improved YOLOv7-Based Model for Detecting Defects on Strip Steel Surfaces. Coatings 2023, 13, 536. [Google Scholar] [CrossRef]

- Xia, K.; Lv, Z.; Zhou, C.; Gu, G.; Zhao, Z.; Liu, K.; Li, Z. Mixed Receptive Fields Augmented YOLO with Multi-Path Spatial Pyramid Pooling for Steel Surface Defect Detection. Sensors 2023, 23, 5114. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Huang, M.; Gao, Z.; Cao, Z.; Cao, P. MSC-DNet: An efficient detector with multi-scale context for defect detection on strip steel surface. Measurement 2023, 209, 112467. [Google Scholar] [CrossRef]

- Zhao, C.; Shu, X.; Yan, X.; Zuo, X.; Zhu, F. RDD-YOLO: A modified YOLO for detection of steel surface defects. Measurement 2023, 214, 112776. [Google Scholar] [CrossRef]

- Liu, K.; Li, A.; Wen, X.; Chen, H.; Yang, P. September. Steel surface defect detection using GAN and one-class classifier. In Proceedings of the 2019 25th International Conference on Automation and Computing (ICAC), Lancaster, UK, 5–7 September 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Feng, X.; Gao, X.; Luo, L. X-SDD: A new benchmark for hot rolled steel strip surface defects detection. Symmetry 2021, 13, 706. [Google Scholar] [CrossRef]

- Wan, X.; Zhang, X.; Liu, L. An improved VGG19 transfer learning strip steel surface defect recognition deep neural network based on few samples and imbalanced datasets. Appl. Sci. 2021, 11, 2606. [Google Scholar] [CrossRef]

- Zhou, X.; Fang, H.; Fei, X.; Shi, R.; Zhang, J. Edge-aware multi-level interactive network for salient object detection of strip steel surface defects. IEEE Access 2021, 9, 149465–149476. [Google Scholar] [CrossRef]

- Cui, W.; Song, K.; Feng, H.; Jia, X.; Liu, S.; Yan, Y. Autocorrelation Aware Aggregation Network for Salient Object Detection of Strip Steel Surface Defects. IEEE Trans. Instrum. Meas. 2023, 51. [Google Scholar] [CrossRef]

- Yi, L.; Li, G.; Jiang, M. An end-to-end steel strip surface defects recognition system based on convolutional neural networks. Steel Res. Int. 2017, 88, 1600068. [Google Scholar] [CrossRef]

- Ahmed, M.; Hashmi, K.A.; Pagani, A.; Liwicki, M.; Stricker, D.; Afzal, M.Z. Survey and performance analysis of deep learning based object detection in challenging environments. Sensors 2021, 21, 5116. [Google Scholar] [CrossRef]

- Gong, R.; Chu, M.; Yang, Y.; Feng, Y. A multi-class classifier based on support vector hyper-spheres for steel plate surface defects. Chemom. Intell. Lab. Syst. 2019, 188, 70–78. [Google Scholar] [CrossRef]

- Li, J.; Su, Z.; Geng, J.; Yin, Y. Real-time detection of steel strip surface defects based on improved yolo detection network. IFAC-PapersOnLine 2018, 51, 76–81. [Google Scholar] [CrossRef]

- Yun, J.P.; Park, C.; Bae, H.; Hwang, H.; Choi, S. Vertical scratch detection algorithm for high-speed scale-covered steel BIC (Bar in Coil). In Proceedings of the International Conference on Control, Automation and Systems (ICCAS), Gyeonggi-do, Republic of Korea, 27–30 October 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 342–345. [Google Scholar]

- Boudiaf, A.; Moussaoui, A.; Zaghdoudi, R.; Mentouri, Z.; Saadoune, A. An Automatic System to Surface Defect Classification of Hot Rolled Steel. International Symposium on Mechatronics and Renewable Energy, 10–11 December 2018, El-Oued University, Algeria. Available online: https://dspace.univ-eloued.dz/items/46da7189-3707-4a9a-9907-1c858213e393/full (accessed on 11 February 2024).

- Jeon, Y.J.; Choi, D.C.; Lee, S.J.; Yun, J.P.; Kim, S.W. Defect detection for corner cracks in steel billets using a wavelet reconstruction method. JOSA A 2014, 31, 227–237. [Google Scholar] [CrossRef] [PubMed]

- Rithesh, R.N. SVM-KNN: A novel approach to classification based on SVM and KNN. Int. Res. J. Comput. Sci. 2017, 4, AUCS10088. [Google Scholar] [CrossRef]

- Pernkopf, F. Detection of surface defects on raw steel blocks using Bayesian network classifiers. Pattern Anal. Appl. 2004, 7, 333–342. [Google Scholar] [CrossRef]

- Abiodun, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef] [PubMed]

- Sarma, A.S.S.; Janani, R.; Sarma, A.S.V. Detecting the surface defects on hot rolled steel sheets using texture analysis. In Proceedings of the 2013 International Conference on Advanced Electronic Systems (ICAES), Pilani, India, 21–23 September 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 157–159. [Google Scholar]

- Popat, M.; Barai, S.V. Defect Detection and Classification Using Machine Learning Classifier. Available online: http://www.ndt.net/article/wcndt2004/pdf/inprocess_ndt-nde/788_popat.pdf (accessed on 2 February 2024).

- Tang, B.; Kong, J.Y.; Wang, X.D.; Chen, L. Surface inspection system of steel strip based on machine vision. In Proceedings of the 2009 First International Workshop on Database Technology and Applications, Guadeloupe, France, 1–6 March 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 359–362. [Google Scholar]

- Kang, G.W.; Liu, H.B. Surface defects inspection of cold rolled strips based on neural network. In Proceedings of the 2005 International Conference on Machine Learning and Cybernetics, Guangzhou, China, 18–21 August 2005; IEEE: Piscataway, NJ, USA, 2005; Volume 8, pp. 5034–5037. [Google Scholar]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Drucker, H.; Burges, C.J.; Kaufman, L.; Smola, A.; Vapnik, V. Support vector regression machines. Adv. Neural Inf. Process. Syst. 1996, 6, 155–161. [Google Scholar]

- Yu, Y.W.; Yin, G.F.; Du, L.Q. Image classification for steel strip surface defects based on support vector machines. In Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2011; Volume 217, pp. 336–340. [Google Scholar]

- Neogi, N.; Mohanta, D.K.; Dutta, P.K. Defect detection of steel surfaces with global adaptive percentile thresholding of gradient image. J. Inst. Eng. Ser. 2017, 98, 557–565. [Google Scholar] [CrossRef]

- Nikita, K.; Apurva, K.; Aishwarya, L.; Komal, K.; Mulik, V.P. Detection of Defects on Steel Surfaces Using Machine Learning Techniques. Int. J. Res. Eng. Appl. Manag. 2017, 3, 2454–9150. [Google Scholar]

- Jiang, M.; Li, G.; Xie, L.; Xiao, M.; Yi, L. Adaptive classifier for steel strip surface defects. J. Phys. Conf. Ser. 2017, 787, 012019. [Google Scholar] [CrossRef]

- Xiao, M.; Jiang, M.; Li, G.; Xie, L.; Yi, L. An evolutionary classifier for steel surface defects with small sample set. EURASIP J. Image Video Process. 2017, 2017, 48. [Google Scholar] [CrossRef]

- Chu, M.; Liu, X.; Gong, R.; Liu, L. Multi-class classification method using twin support vector machines with multi-information for steel surface defects. Chemom. Intell. Lab. Syst. 2018, 176, 108–118. [Google Scholar] [CrossRef]

- Chu, M.X.; Wang, A.N.; Gong, R.F.; Sha, M. Multi-class classification methods of enhanced LS-TWSVM for strip steel surface defects. J. Iron Steel Res. Int. 2014, 21, 174–180. [Google Scholar] [CrossRef]

- Hu, H.; Li, Y.; Liu, M.; Liang, W. Classification of defects in steel strip surface based on multiclass support vector machine. Multimed. Tools Appl. 2014, 69, 199–216. [Google Scholar] [CrossRef]

- Song, K.; Hu, S.; Yan, Y. Automatic recognition of surface defects on hot-rolled steel strip using scattering convolution network. J. Comput. Inf. Syst. 2014, 10, 3049–3055. [Google Scholar]

- Hu, H.; Liu, Y.; Liu, M.; Nie, L. Surface defect classification in large-scale strip steel image collection via hybrid chromosome genetic algorithm. Neurocomputing 2016, 181, 86–95. [Google Scholar] [CrossRef]

- Huberty, C.J.; Olejnik, S. Applied MANOVA and Discriminant Analysis; John Wiley Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Walker, P.L. Sexing skulls using discriminant function analysis of visually assessed traits. American J. Phys. Anthropol. Off. Publ. Am. Assoc. Phys. Anthropol. 2008, 136, 39–50. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y. Pattern Recognition Techniques Applied to Rust Classification in Steel Structures. Ph.D. Thesis, City University London, London, UK, 2012. [Google Scholar]

- Weiwei, L.; Yunhui, Y.; Jun, L.; Yao, Z.; Hongwei, S. Automated on-line fast detection for surface defect of steel strip based on multivariate discriminant function. In Proceedings of the 2008 Second International Symposium on Intelligent Information Technology Application, Washington, DC, USA, 20–22 December 2008; IEEE: Piscataway, NJ, USA, 2008; Volume 2, pp. 493–497. [Google Scholar]

- Cord, A.; Bach, F.; Jeulin, D. Texture classification by statistical learning from morphological image processing: Application to metallic surfaces. J. Microsc. 2010, 239, 159–166. [Google Scholar] [CrossRef]

- Hines, J.W.; Tsoukalas, L.H.; Uhrig, R.E. MATLAB Supplement to Fuzzy and Neural Approaches in Engineering; John Wiley Sons, Inc.: Hoboken, NJ, USA, 1997. [Google Scholar]

- Nedeljkovic, I. Image classification based on fuzzy logic. Int. Arch. Photogramm. Remote. Sens. Spat. Inf. Sci. 2004, 34, 3–7. [Google Scholar]

- Shitole, C.S.N.; Zahran, O.; Al-Nuaimy, W. Combining fuzzy logic and neural networks in classification of weld defects using ultrasonic time-of-flight diffraction. Insight-Non-Destr. Test. Cond. Monit. 2007, 49, 79–82. [Google Scholar] [CrossRef]

- Azizah, L.M.R.; Umayah, S.F.; Riyadi, S.; Damarjati, C.; Utama, N.A. Deep learning implementation using convolutional neural network in mangosteen surface defect detection. In Proceedings of the 2017 7th IEEE international conference on control system, computing and engineering (ICCSCE), Penang, Malaysia, 24–26 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 242–246. [Google Scholar]

- Luna-Gonzalez, J.A.; Robles-Camarillo, D.; Nakano-Miyatake, M.; Lanz-Mendoza, H.; Meana, H.M.P. A CNN-Based Mosquito Classification Using Image Transformation of Wingbeat Features. In SoMeT; IOS Press: Amsterdam, The Netherlands, 2020; pp. 127–137. [Google Scholar]

- Scherer, D.; Müller, A.; Behnke, S. Evaluation of pooling operations in convolutional architectures for object recognition. In Proceedings of the Artificial Neural Networks—ICANN 2010: 20th International Conference, Thessaloniki, Greece, 15–18 September 2010; Proceedings, Part III 20. Springer: Berlin/Heidelberg, Germany, 2010; pp. 92–101. [Google Scholar]

- Guan, S.; Lei, M.; Lu, H. A steel surface defect recognition algorithm based on improved deep learning network model using feature visualization and quality evaluation. IEEE Access 2020, 8, 49885–49895. [Google Scholar] [CrossRef]

- Kostenetskiy, P.; Alkapov, R.; Vetoshkin, N.; Chulkevich, R.; Napolskikh, I.; Poponin, O. Real-time system for automatic cold strip surface defect detection. FME Trans. 2019, 47, 765–774. [Google Scholar] [CrossRef]

- Konovalenko, I.V.; Maruschak, P.O. Classification of the surface technological defects in rolled metal products with the help of a deep neural network. Mater. Sci. 2021, 56, 779–788. [Google Scholar] [CrossRef]

- Wu, S.; Zhao, S.; Zhang, Q.; Chen, L.; Wu, C. Steel Surface defect classification based on small sample learning. Applied. Sci. 2021, 11, 11459. [Google Scholar] [CrossRef]

- Nagy, A.M.; Czúni, L. Zero-shot learning and classification of steel surface defects. In Proceedings of the Fourteenth International Conference on Machine Vision (ICMV 2021), Rome, Italy, 8–12 November 2021; SPIE: Washington, DC, USA, 2021; Volume 12084, pp. 386–394. [Google Scholar]

- Zhou, F.; Liu, G.; Xu, F.; Deng, H. A generic automated surface defect detection based on a bilinear model. Appl. Sci. 2019, 9, 3159. [Google Scholar] [CrossRef]

- Fu, J.; Zhu, X.; Li, Y. Recognition of surface defects on steel sheet using transfer learning. arXiv 2019, arXiv:1909.03258. [Google Scholar]

- Wang, S.; Xia, X.; Ye, L.; Yang, B. Automatic detection and classification of steel surface defect using deep convolutional neural networks. Metals 2021, 11, 388. [Google Scholar] [CrossRef]

- Nagy, A.M.; Czúni, L. Classification and Fast Few-Shot Learning of Steel Surface Defects with Randomized Network. Appl. Sci. 2022, 12, 3967. [Google Scholar] [CrossRef]

- Masci, J.; Meier, U.; Ciresan, D.; Schmidhuber, J.; Fricout, G. Steel defect classification with max-pooling convolutional neural networks. In Proceedings of the 2012 International Joint Conference on Neural Networks (IJCNN), Brisbane, Australia, 10–15 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1–6. [Google Scholar]

- Zhou, S.; Chen, Y.; Zhang, D.; Xie, J.; Zhou, Y. Classification of surface defects on steel sheet using convolutional neural networks. Mater. Technol. 2017, 51, 123–131. [Google Scholar]

- Deshpande, A.M.; Minai, A.A.; Kumar, M. One-shot recognition of manufacturing defects in steel surfaces. Procedia Manuf. 2020, 48, 1064–1071. [Google Scholar] [CrossRef]

- Prihatno, A.T.; Utama, I.B.K.Y.; Kim, J.Y.; Jang, Y.M. Metal defect classification using deep learning. In Proceedings of the 2021 Twelfth International Conference on Ubiquitous and Future Networks (ICUFN), Jeju Island, Republic of Korea, 17–20 August 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 389–393. [Google Scholar]

- Ibrahim, A.A.; Tapamo, J.R. Transfer learning-based approach using new convolutional neural network classifier for steel surface defects classification. Sci. Afr. 2024, 23, e02066. [Google Scholar] [CrossRef]

- He, D.; Xu, K.; Wang, D. Design of multi-scale receptive field convolutional neural network for surface inspection of hot rolled steels. Image Vis. Comput. 2019, 89, 12–20. [Google Scholar] [CrossRef]

- Niu, S.; Li, B.; Wang, X.; Lin, H. Defect image sample generation with GAN for improving defect recognition. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1611–1622. [Google Scholar] [CrossRef]

- Schlegl, T.; Seeböck, P.; Waldstein, S.M.; Schmidt-Erfurth, U.; Langs, G. Unsupervised anomaly detection with generative adversarial networks to guide marker discovery. In Information Processing in Medical Imaging: 25th International Conference, IPMI 2017, Boone, NC, USA, 25–30 June 2017, Proceedings; Springer International Publishing: Cham, Switzerland, 2017; pp. 146–157. [Google Scholar]

- Yusob, B.; Shamsuddin, S.M.H.; Hamed, H.N.A. Spiking self-organizing maps for classification problem. Procedia Technol. 2013, 11, 57–64. [Google Scholar] [CrossRef][Green Version]

- Kaski, S. Data Exploration Using Self-Organizing Maps. Master’s Thesis, University of Technology, Tokyo, Japan, 1997. [Google Scholar]

- Vesanto, J. Data Exploration Process Based on the Self-Organizing Map; Helsinki University of Technology: Espoo, Finland, 2002. [Google Scholar]

- Asan, U.; Ercan, S. An introduction to self-organizing maps. In Proceedings of the Computational Intelligence Systems in Industrial Engineering: With Recent Theory and Applications; Atlantis Press: Paris, France, 2012; pp. 295–315. [Google Scholar]

- Oja, M.; Kaski, S.; Kohonen, T. Bibliography of self-organizing map (SOM) papers: 1998–2001 addendum. Neural Comput. Surv. 2003, 3, 1–156. [Google Scholar]

- Martins, L.A.; Pádua, F.L.; Almeida, P.E. Automatic detection of surface defects on rolled steel using computer vision and artificial neural networks. In Proceedings of the IECON 2010-36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1081–1086. [Google Scholar]

- Luo, Q.; He, Y. A cost-effective and automatic surface defect inspection system for hot-rolled flat steel. Robot.-Comput.-Integr. Manuf. 2016, 38, 16–30. [Google Scholar] [CrossRef]

- Somervuo, P.; Kohonen, T. Self-organizing maps and learning vector quantization for feature sequences. Neural Process. Lett. 1999, 10, 151–159. [Google Scholar] [CrossRef]

- Di, H.; Ke, X.; Peng, Z.; Dongdong, Z. Surface defect classification of steels with a new semi-supervised learning method. Opt. Lasers Eng. 2019, 117, 40–48. [Google Scholar] [CrossRef]

- Odena, A. Semi-supervised learning with generative adversarial networks. arXiv 2016, arXiv:1606.01583. [Google Scholar]

- He, Y.; Song, K.; Dong, H.; Yan, Y. Semi-supervised defect classification of steel surface based on multi-training and generative adversarial network. Opt. Lasers Eng. 2019, 122, 294–302. [Google Scholar] [CrossRef]

- Zeng, X.; Yin, S.B.; Guo, Y.; Lin, J.R.; Zhu, J.G. A novel semi-supervised feature extraction method and its application in automotive assembly fault diagnosis based on vision sensor data. Sensors 2018, 18, 2545. [Google Scholar] [CrossRef] [PubMed]

- Rao, K.B.; Prasad, G.N.R.; Amudha, S.; Kumar, A.; Prasad, D.V.S.S.S.V.; Mohanavel, V. A Significant Feature Selection to Improve the Accuracy of a Classification Algorithm for Steel Defect. In Proceedings of the 2022 4th International Conference on Inventive Research in Computing Applications (ICIRCA), Coimbatore, India, 21–23 September 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 200–206. [Google Scholar]

- Chu, M.; Gong, R.; Wang, A. Strip steel surface defect classification method based on enhanced twin support vector machine. ISIJ Int. 2014, 54, 119–124. [Google Scholar] [CrossRef][Green Version]

- Fu, G.; Sun, P.; Zhu, W.; Yang, J.; Cao, Y.; Yang, M.Y.; Cao, Y. A deep-learning-based approach for fast and robust steel surface defects classification. Opt. Lasers Eng. 2019, 121, 397–405. [Google Scholar] [CrossRef]

- Zhu, W.; Zhang, H.; Zhang, C.; Zhu, X.; Guan, Z.; Jia, J. Surface defect detection and classification of steel using an efficient Swin Transformer. Adv. Eng. Inform. 2023, 57, 102061. [Google Scholar] [CrossRef]

- Huang, Z.; Wu, J.; Xie, F. Automatic recognition of surface defects for hot-rolled steel strip based on deep attention residual convolutional neural network. Mater. Lett. 2021, 293, 129707. [Google Scholar] [CrossRef]

- Konovalenko, I.; Maruschak, P.; Brezinová, J.; Viňáš, J.; Brezina, J. Steel surface defect classification using deep residual neural network. Metals 2020, 10, 846. [Google Scholar] [CrossRef]

- Demir, K.; Ay, M.; Cavas, M.; Demir, F. Automated steel surface defect detection and classification using a new deep learning-based approach. Neural Comput. Appl. 2023, 35, 8389–8406. [Google Scholar] [CrossRef]

- Hu, X.; Yang, J.; Jiang, F.; Hussain, A.; Dashtipour, K.; Gogate, M. Steel surface defect detection based on self-supervised contrastive representation learning with matching metric. Appl. Soft Comput. 2023, 145, 110578. [Google Scholar] [CrossRef]

- Suvdaa, B.; Ahn, J.; Ko, J. Steel surface defects detection and classification using SIFT and voting strategy. Int. J. Softw. Eng. Its Appl. 2012, 6, 161–166. [Google Scholar]

- Gong, R.; Wu, C.; Chu, M. Steel surface defect classification using multiple hyper-spheres support vector machine with additional information. Chemom. Intell. Lab. Syst. 2018, 172, 109–117. [Google Scholar] [CrossRef]

- Stephen, D.; Lalu, P.P.; Sudheesh, R.S. X-ray Weld Defect Recognition Using Deep Learning Technique. Int. Res. J. Eng. Technol. 2021, 8, 818–823. [Google Scholar]

- Chen, W.; Gao, Y.; Gao, L.; Li, X. A new ensemble approach based on deep convolutional neural networks for steel surface defect classification. Procedia CIRP 2018, 72, 1069–1072. [Google Scholar] [CrossRef]

- He, D.; Xu, K.; Zhou, P. Defect detection of hot rolled steels with a new object detection framework called classification priority network. Comput. Ind. Eng. 2019, 128, 290–297. [Google Scholar] [CrossRef]

- Narkhede, S. Understanding auc-roc curve. Towards Data Sci. 2018, 26, 220–227. [Google Scholar]

- Tharwat, A. Classification assessment methods. Appl. Comput. Inform. 2021, 17, 168–192. [Google Scholar] [CrossRef]

- Lachiche, N.; Ferri, C.; Macskassy, S.A. ROC Analysis in Machine Learning. In Proceedings of the Workshop Associated to ICML, the 23 rd International Conference on Machine Learning, New York, NY, USA, 25–29 June 2006. [Google Scholar]

- Powers, D.M. Evaluation: From precision, recall and F-measure to ROC, informedness, markedness and correlation. arXiv 2020, arXiv:2010.16061. [Google Scholar]

- Sokolova, M.; Japkowicz, N.; Szpakowicz, S. Beyond accuracy, F-score and ROC: A family of discriminant measures for performance evaluation. In Proceedings of the AI 2006: Advances in Artificial Intelligence: 19th Australian Joint Conference on Artificial Intelligence, Hobart, Australia, 4–8 December 2006; Proceedings 19. Springer: Berlin/Heidelberg, Germany, 2006; pp. 1015–1021. [Google Scholar]

| Methods | Strengths | Limitations | Applications |

|---|---|---|---|

| Autocorrelation | Simple to utilize with repetitive textures like textiles | Difficulties in identifying nonlinear relationships; not suitable for textures with randomly arranged textural elements | [24] |

| Thresholding | Easy to understand, simple to implement | A small difference in the background can make defect detection fail | [25] |

| Co-occurrence matrix | Pixels’ spatial relationship can be extracted with different statistical computations | Difficult to referee the optimal displacement selection | [26,27] |

| Local binary pattern | Faster discriminative feature extraction with rotation in gray invariance | Noise and scale change have a significant influence; highly dependent on the gray value of the image’s center point | [28,29,30,31,32] |

| Fractal model | Remains unaffected by significant geometric transformations and variations in lighting | Has limitations on images without self-similarity; unsatisfactory detection rate | [33] |

| Edge-based | Easy to extract low-order features of the image and simple to realize | It is only suitable for images with low resolution; sensitive to noise | [34] |

| Histogram properties | Clarity, invariant to translation and rotation; simple calculations | Poor detection rate for irregular textures less than 70% | [35,36,37,38] |

| Methods | Advantages | Limitations | Applications |

|---|---|---|---|

| Markov random field | It can be easily combined with statistical and spectral methods for the segmentation task | Incapable of identifying small defects and unsuitable for global texture analysis | [100,101] |

| Autoregressive model | It can forecast any recurring patterns in the data; high performance for texture-related problems | Only appropriate for low-resolution images due to increasing memory and computation demands as the image size grows | [102,103,104,105] |

| Weibull model | Has superiority in describing the contrast, shape of textures, and scale | Difficult to detect defects with low contrast or gradual intensity | [106,107] |

| Active contour model | Demonstrates strong performance in detecting both steel pit defects and spot defects; easy to follow an object on subsequent similar images | Difficult to calculate the convergence position due to a lack of constraints; when the image size is too large, this method works slowly | [108] |

| Methods | Advantages | Weaknesses | Applications |

|---|---|---|---|

| Artificial neural networks | Have numerical strength and can perform more than one job at the same time; real-time performance is suitable for industrial use | The training duration of the network is unknown; large-scale feature vectors lead to high calculation cost | [115,116,117,118] |

| Moving center hypersphere | High accuracy and efficiency in classification (93–96%); not sensitive to noise | Difficult to determine the best parameter | [121,122] |

| Sparse coding | It can be used in both input and output phases | The computation time exceeds 45.6 s, rendering it unsuitable for real-time detection | [123,124,125] |

| Deep learning | Effective at producing high-quality results and the quality of work never deteriorates | For better performance, a large quantity of data is required; some DL models that perform well on benchmarked datasets may struggle when they are applied to real-world datasets. | [8,126,127,128,130,132,133,134,136,139,140,141,142,144,145,146,147,148,149,150,151,152,153,154,155,156,157,158,159,160,161] |

| Detection Methods | Reference | Type of Steel | Type of Defects | Size of Dataset | Accuracy % | Advantages | Disadvantages |

|---|---|---|---|---|---|---|---|

| CNN | [162] | Hot-rolled | Crazing, scratches, rolled in scale, pitted surface, patches | 6531 images | 95.63 | Simple computation | The accuracy of outcomes is heavily dependent on the scale of the training dataset |

| Improved YOLO | [163] | Cold-rolled | Scar, scratches, inclusions, burr seams, iron scale defects | 4655 images | 99.00 | High detection rate | Large datasets are required |

| Gradient filter, double thresholding | [164] | Rod/bar | Vertical, scratch | 2444 images | 96.90 | Appropriate for high-dimensional feature space | Complicated to determine the optimal filter parameters |

| HOG, PCA | [165] | Hot-rolled | Inclusion, rolled-in scale, patches, pitted surface, scratches, crazing | 1200 images | 91.12 | PCA needs a small storage space, KNN does not need to create a hypothesis | Many calculations and weakness in distinguishing healthy and defective areas |

| Gabor filter | [59] | Slab surfaces | Pinholes | 968 images | 98.69 | High speed in searching defects with the lowest cost | Much time needed for feature extraction |

| Multifractal | [33] | Cold strip | Dirty surface stain, rust under pickled, sticking, emulsion | 2300 images | 97.90 | It implies a continuous spectrum of exponents for the pattern characterization | Most real textures are not ideal fractals |

| Wavelet, double threshold | [166] | Billet | Corner crack. | 220 images | 97.80 | Very fast computation | Unable to get the information in all directions |

| Methods | Advantages | Limitations | References |

|---|---|---|---|

| Supervised classifiers | Quite simple, and robust; has a good and reliable effect; very helpful in classification problems | A large dataset needs a long computation time to train; dependent on labeled samples; hard to label large steel surface defects. | [1,5,9,11,13,31,65,88,100,165,168,170,172,176,177,178,179,180,181,182,183,184,185,190,197,198,199,200,201,202,203,204,205,206,207,208,209,210,211,212,226,227,228,229,230,231,232] |

| Unsupervised classifiers | Dimensionality reduction can be easily achieved; solve problems by learning from the data and classifying them without any labels | Sensitive to noise and significantly impacted by initial values | [75,116,137,138,173,219,220,233] |

| Semi-supervised classifiers | Stability are achieved with just a few labeled samples | Training requires massive interaction and is of low efficiency | [222,223,224,225,232] |

| Classification Methods | Reference | Type of Steel | Type of Defects | Size of Dataset | Accuracy % | Advantages | Disadvantages |

|---|---|---|---|---|---|---|---|

| INSVHs | [162] | Hot-rolled | Hole, scratch bruise, wave scarring, scale | 3320 images | 97.26 | Suitable for strengthening the effect of important samples | Calculation time was slow; sample was unbalanced |

| SVM | [234] | Hot-rolled | DFBL, DFLS LSBL, LSS | 71 images | 94.74 | A lot of feature vectors from a few images | The performance was not good for all defect samples |

| BYEC | [179] | Hot-rolled | Rolled-in scale, crazing, inclusion patches, scratches, pitted surface | 1800 images | 97.42 | Adaptive to change in steel surface defects’ dataset | Low accuracy when used on a large dataset |

| MHSVM | [235] | Hot-rolled | Scratch, hole scarring, wave scale, bruise | 4120 images | 97.33 | It can learn additional information hidden in defect dataset | In order to achieve a satisfactory result, you have to experiment with a number of different parameter settings. |

| CNN | [236] | Hot-rolled | Pitted surface, inclusion, crazing, rolled-in scale, patches, scratches | 6531 images | 95.63 | The sample size for the inspection of the lot can be increased by the proposed algorithm | For the model training, a significantly large dataset is required. |

| DST-KLPP | [4] | Hot-rolled | Transverse scratches, transverse cracks, scar, pockmarks, chaps, scales, roll imprints, longitudinal scratches, longitudinal cracks | 1273 images | 90.42 | Suitable for image processing of intense noise | Irregular method |

| ARW-NNC | [31] | Hot-rolled | 18 types | 4320 images | 97.62 | Classification algorithm is better | More runtime overheads |

| DCNN | [237] | Hot-rolled | Inclusion, crazing, rolled-in scale, patches, scratches pitted surface | 1800 images | 99.89 | The ensemble strategy improved the recognition rate from the single models | Computation was still too large; noise and low-quality data were ignored |

| KNN | [165] | Hot-rolled | Pitted surface, inclusion, crazing, rolled-in scale, patches, scratches | 1800 images | 91.12 | The method is simple, easy to achieve, and clear | The recognition accuracy is unsatisfactory |

| ANN | [81] | Hot-rolled | Rolled-in scale, pitted surface, inclusion, crazing patches, scratches. | 1800 images | 98.16 | When the layers become too many, the network is prone to overfitting | The network requires a large diversity in training for its operation |

| CPN | [238] | Hot-rolled strip, hot-rolled plates | Water drops, scales, seams, water strains, vertical cracks, horizontal cracks, rolling marks | 7050 images | 94.00 and 96.10 | More sparse and reasonable feature maps can be obtained. | One defect has different morphological characteristics |

| MDTWSVM | [227] | Hot-rolled | Dent, scarring scratch, dirt hole, damaged edge crack. | 2330 images | 96.92 | Defect feature extraction with rotation invariance and scale | It is not suitable when the dataset includes more noise |

| SDC-SN-ELF+MRF | [228] | Hot-rolled | Inclusion, crazing patches, scratches, pitted surface, rolled-in scale. | 1800 images | 97.50 | Light-weight model. | Large dataset and a lot of computational power are required for pre-trained model learning. |

| Classification Methods | Reference | Type of Steel | Type of Defects | Size of Dataset | Accuracy % | Advantages | Disadvantages |

|---|---|---|---|---|---|---|---|

| LVQ | [75] | Hot-rolled | Crack, pits scar, roll-mark shell, cross texture, pseudo-defects | 485 images | 84.00 to 93.00 | Simple structure | The information from every dimension of the input sample is not fully used |

| SOM | [116] | Hot-rolled | Bruise, scratch, rolled-in scale, rolled-in bruise, skin lamination, no defect | 1084 images | 97.00 | Integrating SOM into a real-time inspection system could be valuable for generating new class labels directly correlated to the features | Slow processing time |

| HWV | [107] | Hot-rolled strips | Massive rupture, drops, tar, oil stain, roll marks, white-dot mountain. | 1200 images | 96.20 | Arbitrary type of defect on the homogeneously textured surface can be identified | low contrast, miscellaneous patterns, pseudo-noise interference |

| Classification Methods | Reference | Type of Steel | Type of Defects | Size of Dataset | Accuracy % | Advantages | Disadvantages |

|---|---|---|---|---|---|---|---|

| cDCGAN, Resnet18 | [224] | Hot-rolled | Crazing, patches, pitted surface, inclusion rolled-in scale, scratches. | 1800 images | 99.56 | Require fewer labeled samples | The GAN samples looked slightly fuzzy |

| CAE-SGAN | [222] | Hot-rolled | Longitudinal crack, transverse crack, scar, wrinkle, water mark, scale seam, edge crack, rolling mark | 10,800 images | 98.60 | Full use of steel surface images (labeled and unlabeled images) | Rates of convergence and asymptotic analyses may not capture the complete image |

| PLCNN | [141] | Hot-rolled | Inclusion, patches, pitted surface, rolled-in scale, scratches | 1800 images | 90.70 | Unlabeled data can be used | The scale of the training set is limited in early production |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim, A.A.M.S.; Tapamo, J.-R. A Survey of Vision-Based Methods for Surface Defects’ Detection and Classification in Steel Products. Informatics 2024, 11, 25. https://doi.org/10.3390/informatics11020025

Ibrahim AAMS, Tapamo J-R. A Survey of Vision-Based Methods for Surface Defects’ Detection and Classification in Steel Products. Informatics. 2024; 11(2):25. https://doi.org/10.3390/informatics11020025

Chicago/Turabian StyleIbrahim, Alaa Aldein M. S., and Jules-Raymond Tapamo. 2024. "A Survey of Vision-Based Methods for Surface Defects’ Detection and Classification in Steel Products" Informatics 11, no. 2: 25. https://doi.org/10.3390/informatics11020025

APA StyleIbrahim, A. A. M. S., & Tapamo, J.-R. (2024). A Survey of Vision-Based Methods for Surface Defects’ Detection and Classification in Steel Products. Informatics, 11(2), 25. https://doi.org/10.3390/informatics11020025