Paper-Based Vapor Detection of Formaldehyde: Colorimetric Sensing with High Sensitivity

Abstract

:1. Introduction

2. Experimental Methods

2.1. Materials

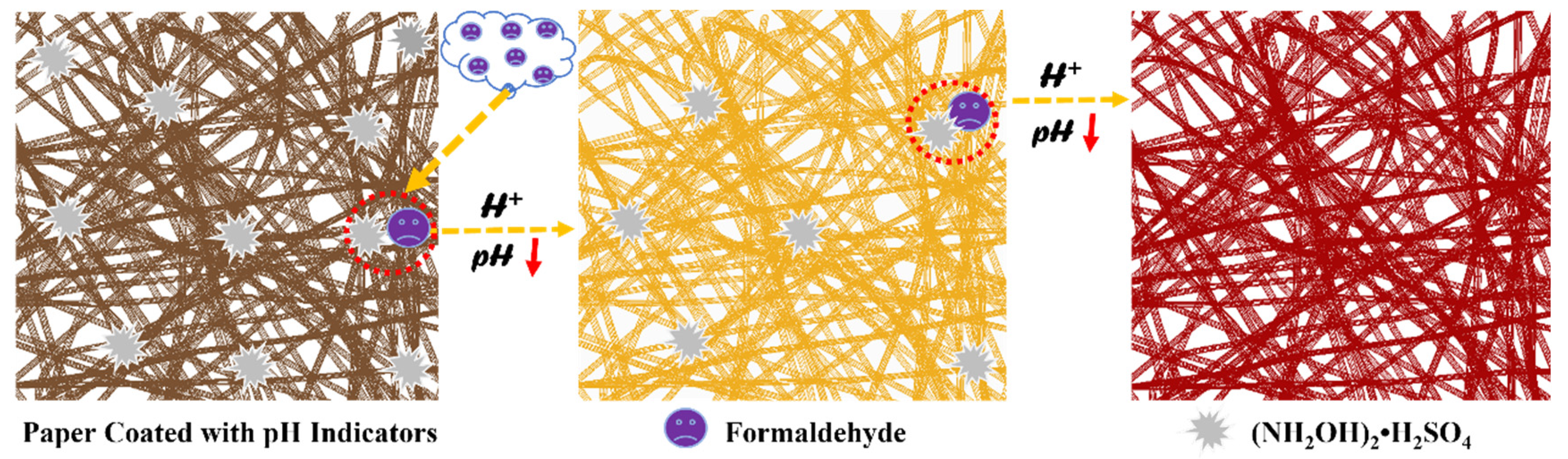

2.2. Fabrication of Colorimetric Sensing Strips

2.3. Construction of an Environment Chamber for FA Vapor Generation and Sensor Testing

2.4. Measurement of Color Change

3. Results and Discussions

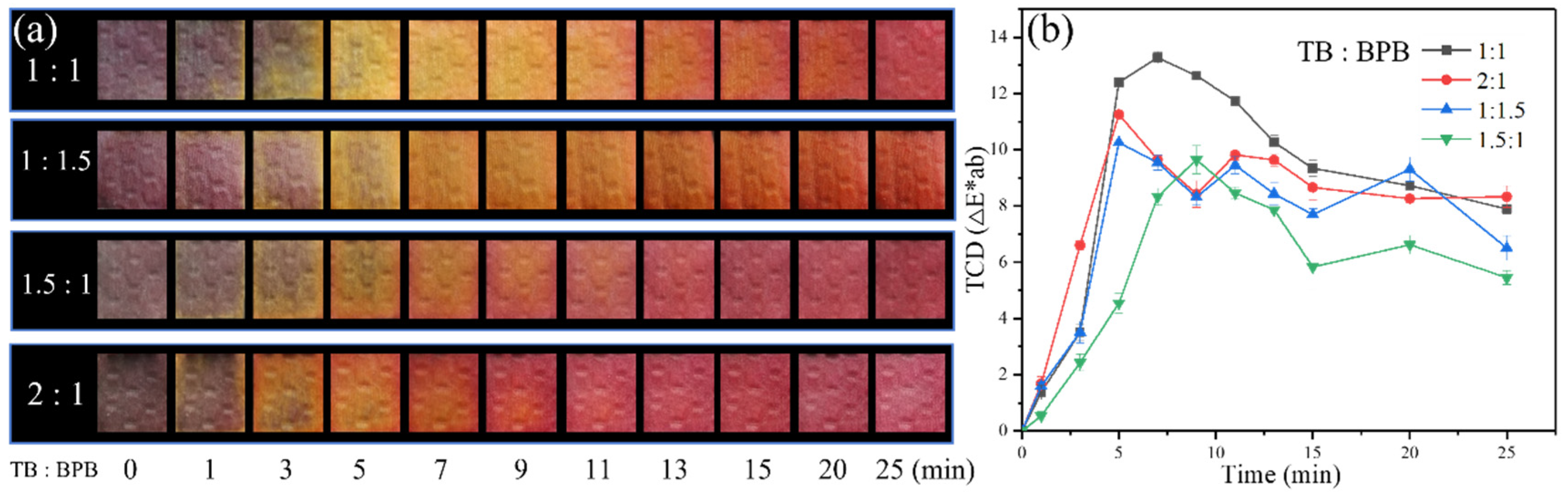

3.1. Effect of TB/BPB Ratio on Colorimetric Sensing

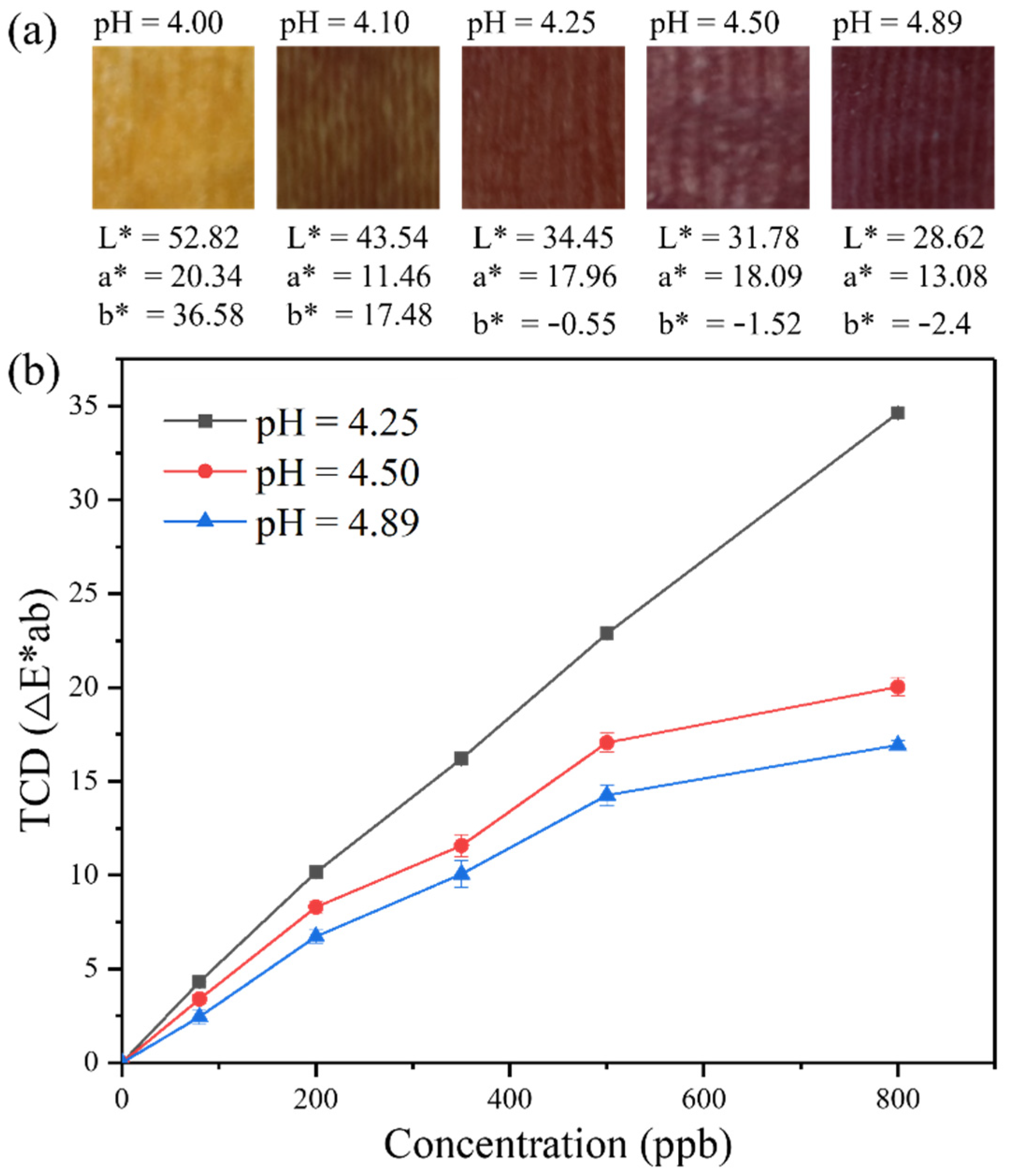

3.2. Effect of Initial pH on Colorimetric Sensing

3.3. Quantitative Assessment of the Sensitivity of Colorimetric Sensing

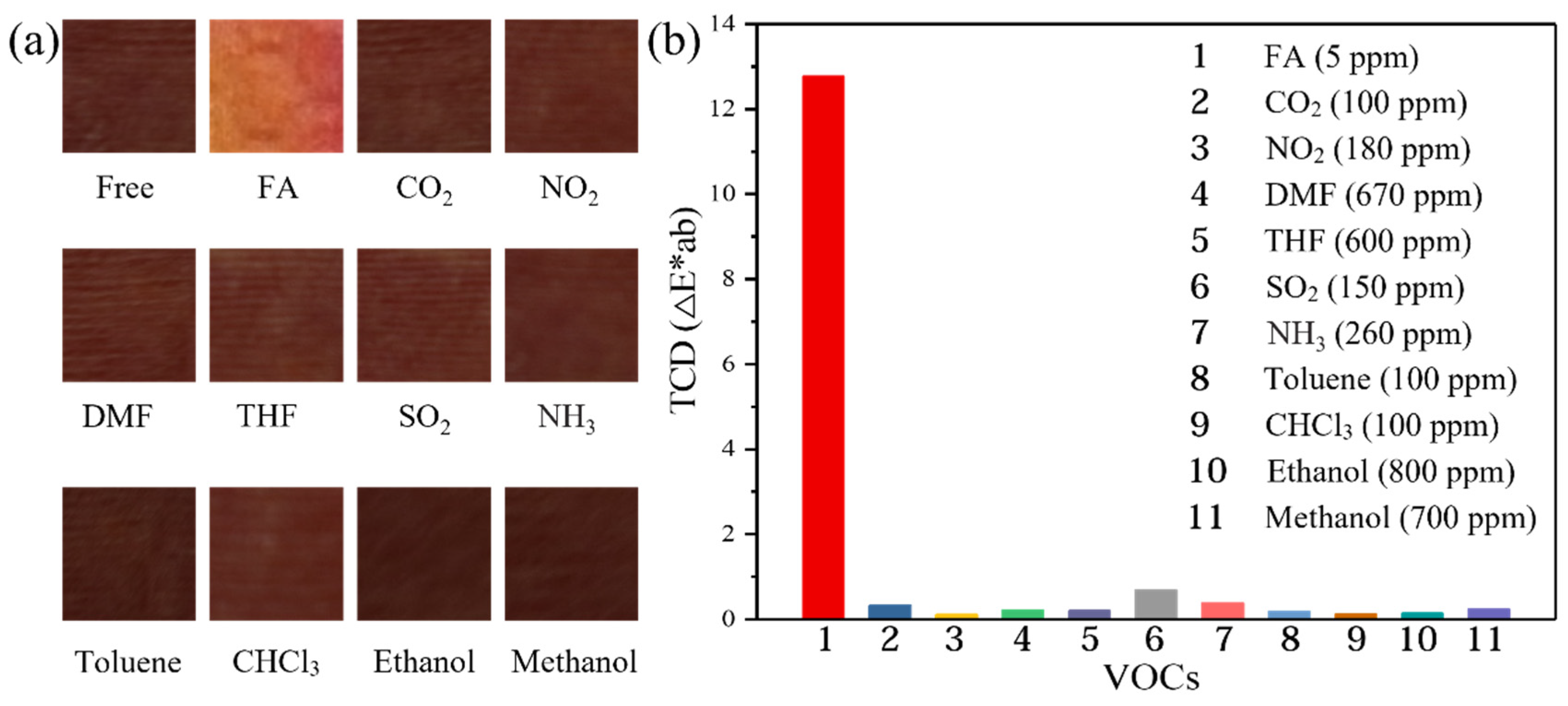

3.4. Assessment of the Selectivity of Colorimetric Sensing

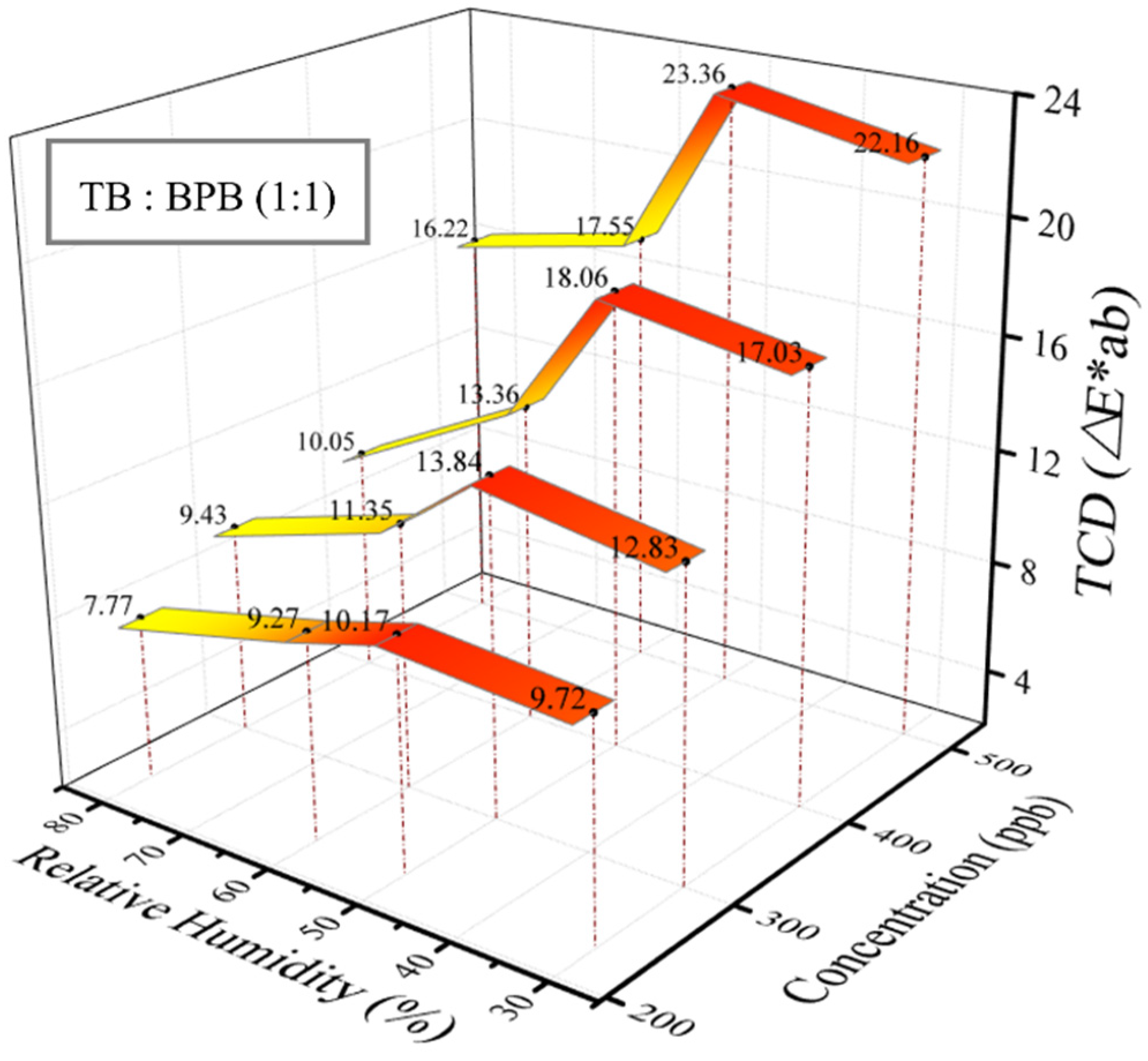

3.5. Effect of Humidity on Colorimetric Sensing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Broek, J.V.D.; Cerrejon, D.K.; Pratsinis, S.E.; Güntner, A.T. Selective formaldehyde detection at ppb in indoor air with a portable sensor. J. Hazard. Mater. 2020, 399, 123052. [Google Scholar] [CrossRef]

- Wi, S.; Kim, M.G.; Myung, S.W.; Baik, Y.K.; Lee, K.B.; Song, H.S.; Kwak, M.J.; Kim, S. Evaluation and analysis of volatile organic compounds and formaldehyde emission of building products in accordance with legal standards: A statistical experimental study. J. Hazard. Mater. 2020, 393, 122381. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Qi, Y.; Yang, Z.; Han, H.; Jiang, Y.; Du, W.; Zhang, X.; Zhang, J.; Dai, Z.; Wu, L. Recent advances and perspectives on constructing metal oxide semiconductor gas sensing materials for efficient formaldehyde detection. J. Mater. Chem. C 2020, 8, 13169–13188. [Google Scholar] [CrossRef]

- Bo, Z.; Yuan, M.; Mao, S.; Chen, X.; Yan, J.H.; Cen, K.F. Decoration of vertical graphene with tin dioxide nanoparticles for highly sensitive room temperature formaldehyde sensing. Sens. Actuators B 2018, 256, 1011–1020. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Li, J.Y.; Peng, L.; Ma, M.; Gao, D.J.; Bi, J.; Wu, J.T. Formaldehyde sensing with a parts-per-billion limit of detection by dielectric properties and crystal symmetry optimization in BiFeO3-based p-type solid solution. Sens. Actuators B 2021, 344, 130314. [Google Scholar] [CrossRef]

- Cui, X.J.; Fang, G.Z.; Jiang, L.Q.; Wang, S. Kinetic spectrophotometric method for rapid determination of trace formaldehyde in foods. Anal. Chim. Acta 2007, 590, 253–259. [Google Scholar] [CrossRef]

- Gong, C.M.; Huang, W.; Liu, J.J.; Wei, F.X.; Yu, J.W.; Si, X.K.; Liu, F.H.; Li, Y.F. Detection and analysis of formaldehyde and unburned methanol emissions from a direct-injection spark-ignition methanol engine. Fuel 2018, 221, 188–195. [Google Scholar] [CrossRef]

- Yang, M.; Ospina, M.; Tse, C.; Toth, S.; Caudill, S.P.; Vesper, H.W. Ultraperformance liquid chromatography tandem mass spectrometry method to determine formaldehyde hemoglobin adducts in humans as biomarker for formaldehyde exposure. Chem. Res. Toxicol. 2017, 30, 1592–1598. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Calestani, D.; Mosca, R.; Zanichelli, M.; Villani, M.; Zappettini, A. Aldehyde detection by ZnO tetrapod-based gas sensors. J. Mater. Chem. 2011, 21, 15532–15536. [Google Scholar] [CrossRef]

- Devkota, J.; Ohodnicki, P.R.; Greve, D.W. SAW sensors for chemical vapors and gases. Sensors 2017, 17, 801. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xie, H.F.; Sheng, C.H.; Chen, X.; Wang, X.Y.; Li, Z.; Zhou, J. Multi-wall carbon nanotube gas sensors modified with amino-group to detect low concentration of formaldehyde. Sens. Actuators B 2012, 168, 34–38. [Google Scholar] [CrossRef]

- Duan, W.; Liu, A.; Li, Q.; Li, Z.W.; Wen, C.Y.; Cai, Z.X.; Tang, S.M.; Li, X.Y.; Zeng, J.B. Toward ultrasensitive and fast colorimetric detection of indoor formaldehyde across the visible region using cetyltrimethylammonium chloride-capped bone-shaped gold nanorods as “chromophores”. Analyst 2019, 144, 4582–4588. [Google Scholar] [CrossRef] [PubMed]

- Liao, C.L.; Shi, J.F.; Zhang, M.; Dalapati, R.; Tian, Q.Y.; Chen, S.; Wang, C.Y.; Zang, L. Optical chemosensors for the gas phase detection of aldehydes: Mechanism, material design, and application. Mater. Adv. 2021, 2, 6213–6245. [Google Scholar] [CrossRef]

- Guo, X.L.; Chen, Y.; Jiang, H.L.; Qiu, X.B.; Yu, D.L. Smartphone-based microfluidic colorimetric sensor for gaseous formaldehyde determination with high sensitivity and selectivity. Sensors 2018, 18, 3141. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.F.; Zan, H.W.; Lu, C.J.; Meng, H.F.; Soppera, O. A low-cost miniaturized colorimetric sensor with vertically-stacked semi-transparent finger-type organic photo detector for formaldehyde sensing. Org. Electron. 2019, 73, 115–121. [Google Scholar] [CrossRef]

- Engel, L.; Benito-Altamirano, I.; Tarantik, K.R.; Pannek, C.; Dold, M.; Prades, J.D.; Wöllenstein, J. Printed sensor labels for colorimetric detection of ammonia, formaldehyde and hydrogen sulfide from the ambient air. Sens. Actuators B 2021, 330, 129281. [Google Scholar] [CrossRef]

- Meng, Q.H.; Han, T.; Wang, G.Q.; Zheng, N.; Cao, C.X.; Xie, S.A. Preparation of a natural dye doped Ormosil coating for the detection of formaldehyde in the optical gas sensor. Sens. Actuators B 2014, 196, 238–244. [Google Scholar] [CrossRef]

- Wang, X.Q.; Li, Y.; Li, X.Q.; Yu, J.Y.; Al Deyab, S.S.; Ding, B. Equipment-free chromatic determination of formaldehyde by utilizing pararosaniline-functionalized cellulose nanofibrous membranes. Sens. Actuators B 2014, 203, 333–339. [Google Scholar] [CrossRef]

- Wang, X.F.; Si, Y.; Wang, J.L.; Ding, B.; Yu, J.Y.; Al Deyab, S.S. A facile and highly sensitive colorimetric sensor for the detection of formaldehyde based on electro-spinning/netting nano-fiber/nets. Sens. Actuators B 2012, 163, 186–193. [Google Scholar] [CrossRef]

- Nakano, N.; Nagashima, K. An automatic monitor of formaldehyde in air by a monitoring tape method. J. Environ. Monit. 1999, 1, 255–258. [Google Scholar] [CrossRef] [PubMed]

- Hauksson, I.; Pontén, A.; Gruvberger, B.; Isaksson, M.; Engfeldt, M.; Bruze, M. Skincare products containing low concentrations of formaldehyde detected by the chromotropic acid method cannot be safely used in formaldehyde-allergic patients. Br. J. Dermatol. 2016, 174, 371–379. [Google Scholar] [CrossRef] [PubMed]

- Pretto, A.; Milani, M.R.; Cardoso, A.A. Colorimetric determination of formaldehyde in air using a hanging drop of chromotropic acid. J. Environ. Monit. 2000, 2, 566–570. [Google Scholar] [CrossRef]

- Wang, X.Q.; Si, Y.; Mao, X.; Li, Y.; Yu, J.Y.; Wang, H.P.; Ding, B. Colorimetric sensor strips for formaldehyde assay utilizing fluoral-p decorated polyacrylonitrile nanofibrous membranes. Analyst 2013, 138, 5129–5136. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.S.; Guan, M.T.; Yan, X.X.; Lei, Y.Y.; Shen, X.; Luo, L.Q.; He, H.B. Gold nanorods assisted silver mirror reaction for consecutive color change based on-site visual semi-quantification of indoor formaldehyde. Atmos. Environ. 2021, 246, 118101. [Google Scholar] [CrossRef]

- Li, J.W.; Wang, Y.; Zhang, Q.H.; Huo, D.Q.; Hou, C.J.; Zhou, J.; Luo, H.B.; Yang, M. New application of old methods: Development of colorimetric sensor array based on Tollen’s reagent for the discrimination of aldehydes based on Tollen’s reagent. Anal. Chim. Acta 2020, 1096, 138–147. [Google Scholar] [CrossRef] [PubMed]

- Chaiendoo, K.; Sooksin, S.; Kulchat, S.; Promarak, V.; Tuntulani, T.; Ngeontae, W. A new formaldehyde sensor from silver nanoclusters modified Tollens’ reagent. Food Chem. 2018, 255, 41–48. [Google Scholar] [CrossRef]

- Ishihara, S.; Labuta, J.; Nakanishi, T.; Tanaka, T.; Kataura, H. Amperometric detection of sub-ppm formaldehyde using single-walled carbon nanotubes and hydroxylamines: A referenced chemiresistive system. ACS Sens. 2017, 2, 1405–1409. [Google Scholar] [CrossRef] [PubMed]

- Wen, C.Y.; Chen, Y.Z.; Liu, R.S.; Huang, J.K.; Wang, D.W.; Cao, Z.J.; Meteku, B.; Zeng, J.B. Matrix colorimetry for high-resolution visual detection of free cyanide with Au@Au-Ag yolk-shell nanoparticles. J. Mater. Chem. C 2021, 9, 4661–4669. [Google Scholar] [CrossRef]

- Gralak, B.; Tayeb, G.; Enoch, S. Morpho butterflies wings color modeled with lamellar grating theory. Opt. Express 2001, 9, 567–578. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Domingo, M.Á.; Melgosa, M.; Okajima, K.; Medina, V.J.; Collado-Montero, F.J. Spectral image processing for museum lighting using CIE LED illuminants. Sensors 2019, 19, 5400. [Google Scholar] [CrossRef] [Green Version]

- Pedreschi, F.; Moyano, P.; Kaack, K.; Granby, K. Color changes and acrylamide formation in fried potato slices. Food Res. Int. 2005, 38, 1–9. [Google Scholar] [CrossRef]

- Szlosek, D.; Currie, D. Application and mechanism of malonic acid as a green alternative for protein-crosslinking. Green Sustain. Chem. 2016, 6, 110–115. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, C.; Zhang, M.; Gao, N.; Tian, Q.; Shi, J.; Chen, S.; Wang, C.; Zang, L. Paper-Based Vapor Detection of Formaldehyde: Colorimetric Sensing with High Sensitivity. Chemosensors 2021, 9, 335. https://doi.org/10.3390/chemosensors9120335

Liao C, Zhang M, Gao N, Tian Q, Shi J, Chen S, Wang C, Zang L. Paper-Based Vapor Detection of Formaldehyde: Colorimetric Sensing with High Sensitivity. Chemosensors. 2021; 9(12):335. https://doi.org/10.3390/chemosensors9120335

Chicago/Turabian StyleLiao, Chenglong, Miao Zhang, Nan Gao, Qingyun Tian, Jiangfan Shi, Shuai Chen, Chuanyi Wang, and Ling Zang. 2021. "Paper-Based Vapor Detection of Formaldehyde: Colorimetric Sensing with High Sensitivity" Chemosensors 9, no. 12: 335. https://doi.org/10.3390/chemosensors9120335

APA StyleLiao, C., Zhang, M., Gao, N., Tian, Q., Shi, J., Chen, S., Wang, C., & Zang, L. (2021). Paper-Based Vapor Detection of Formaldehyde: Colorimetric Sensing with High Sensitivity. Chemosensors, 9(12), 335. https://doi.org/10.3390/chemosensors9120335