Electrical and Humidity-Sensing Properties of Impedance-Type Humidity Sensors that Were Made of Ag Microwires/PPy/SnO2 Ternary Composites

Abstract

1. Introduction

2. Experimental Methods

2.1. Materials

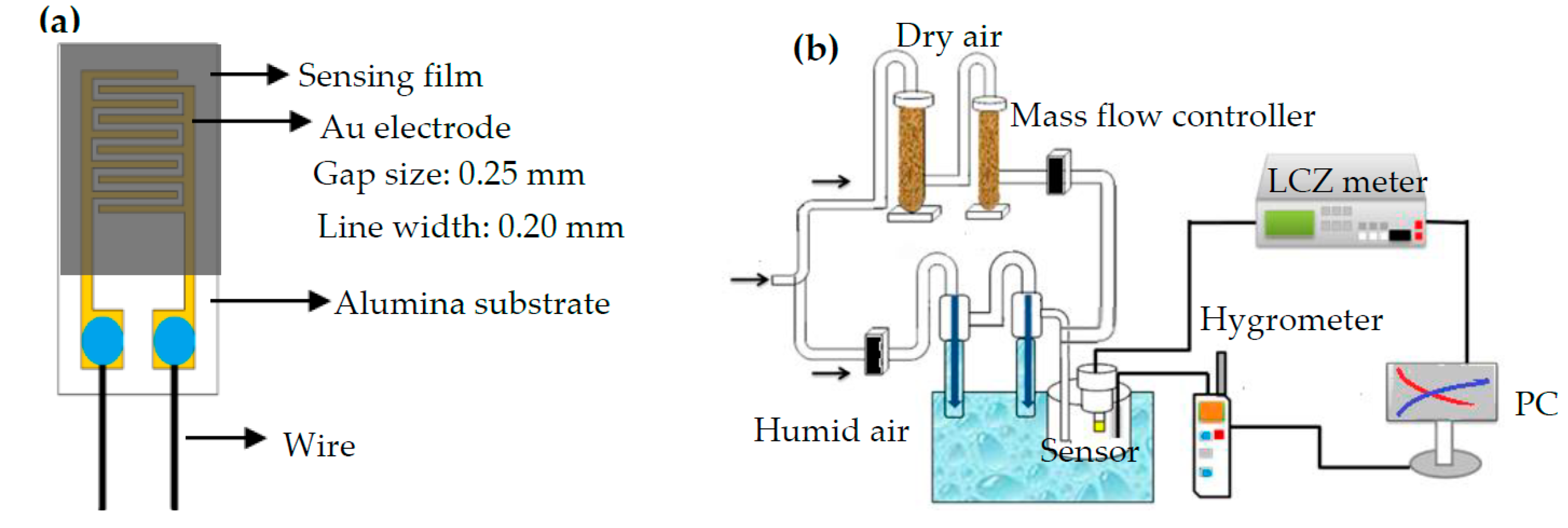

2.2. Fabrication of Humidity Gas Sensors Based on Ag MWs/PPy/SnO2 Ternary Composite and Measurement of Their Humidity-Sensing Properties

2.3. Characterization of Ag MWs/PPy/SnO2 Ternary Composites

3. Results and Discussion

3.1. Characteristics of Ag MWs/PPy/SnO2 Ternary Composite Films

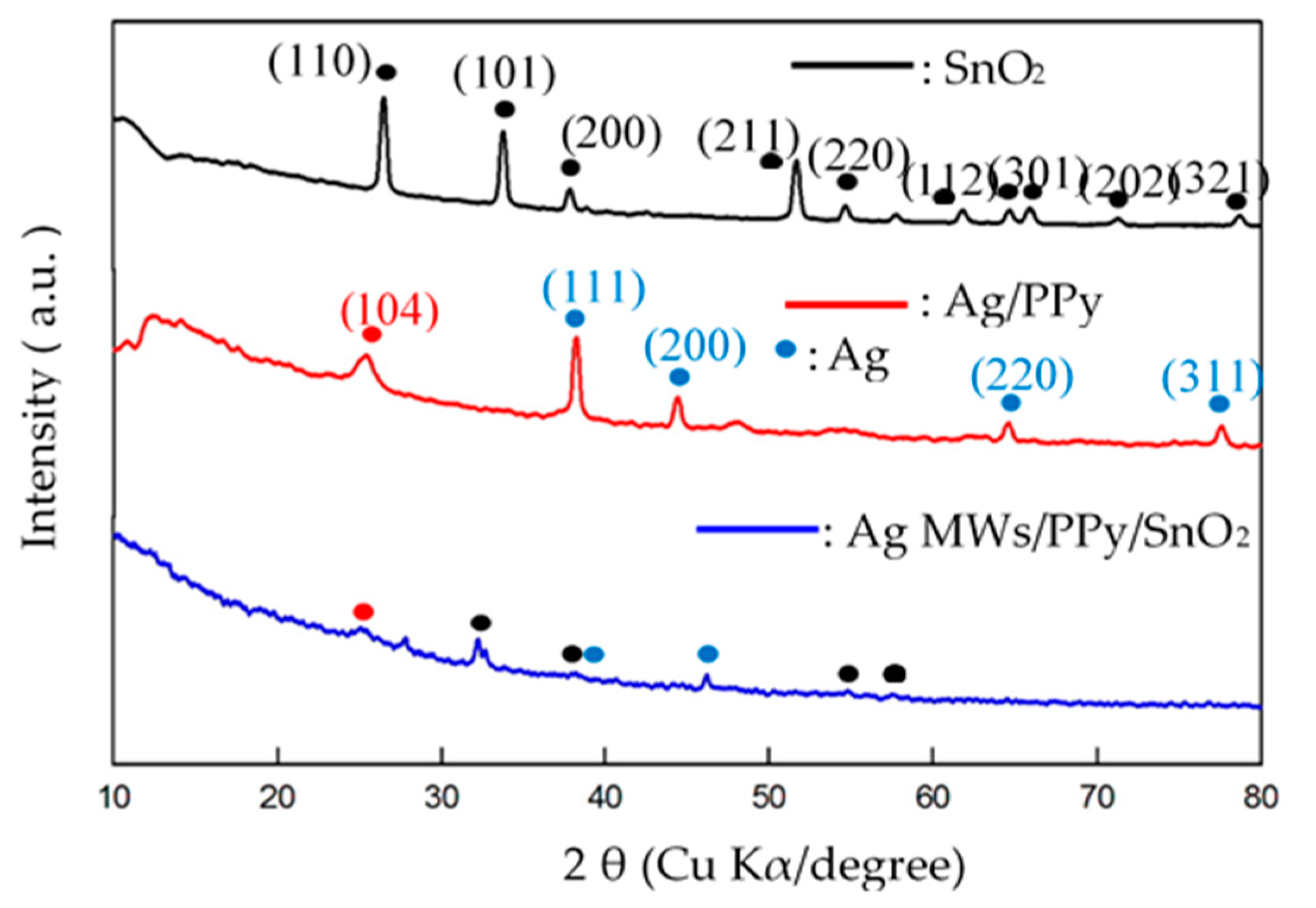

3.1.1. XRD Characterization

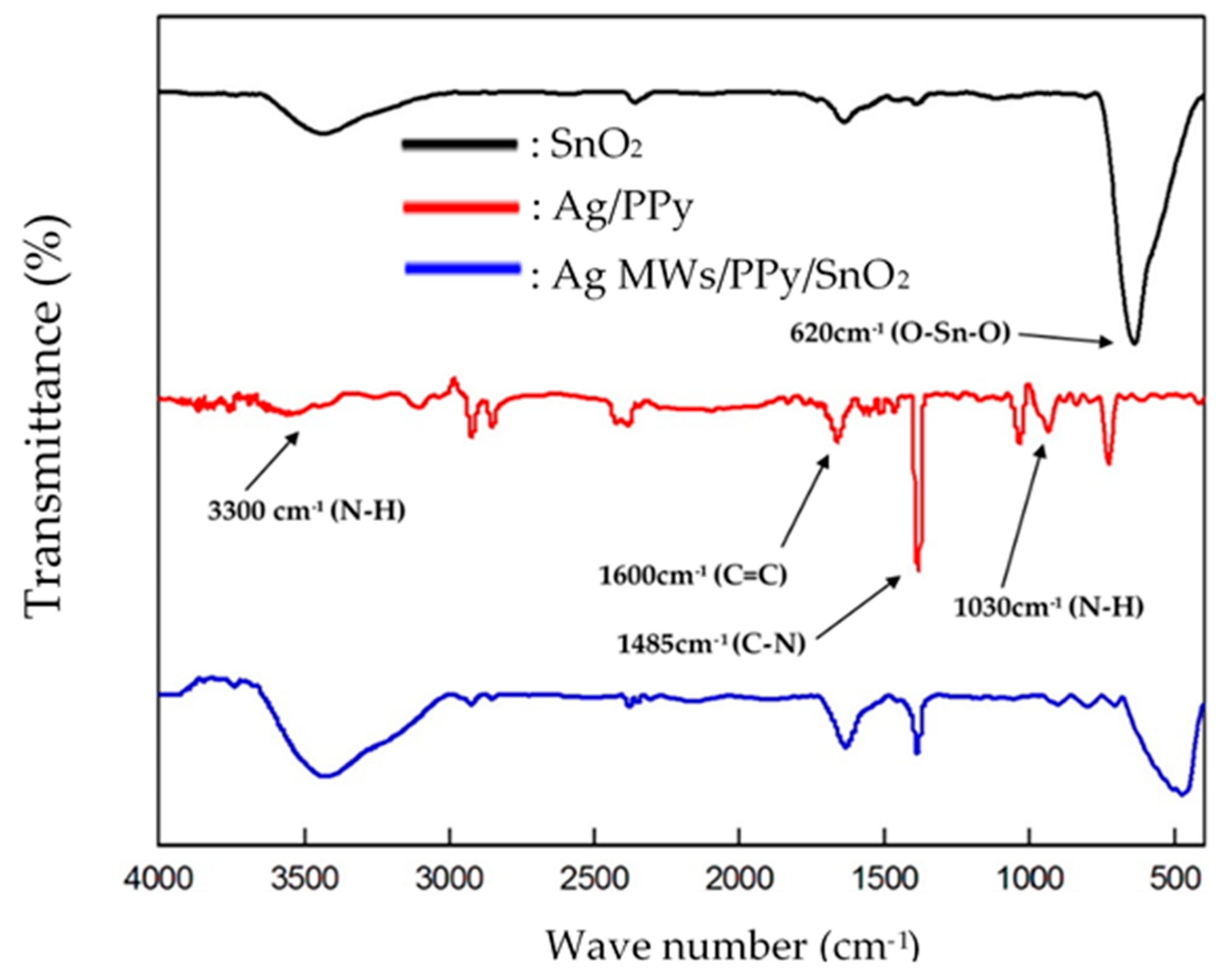

3.1.2. IR Spectra

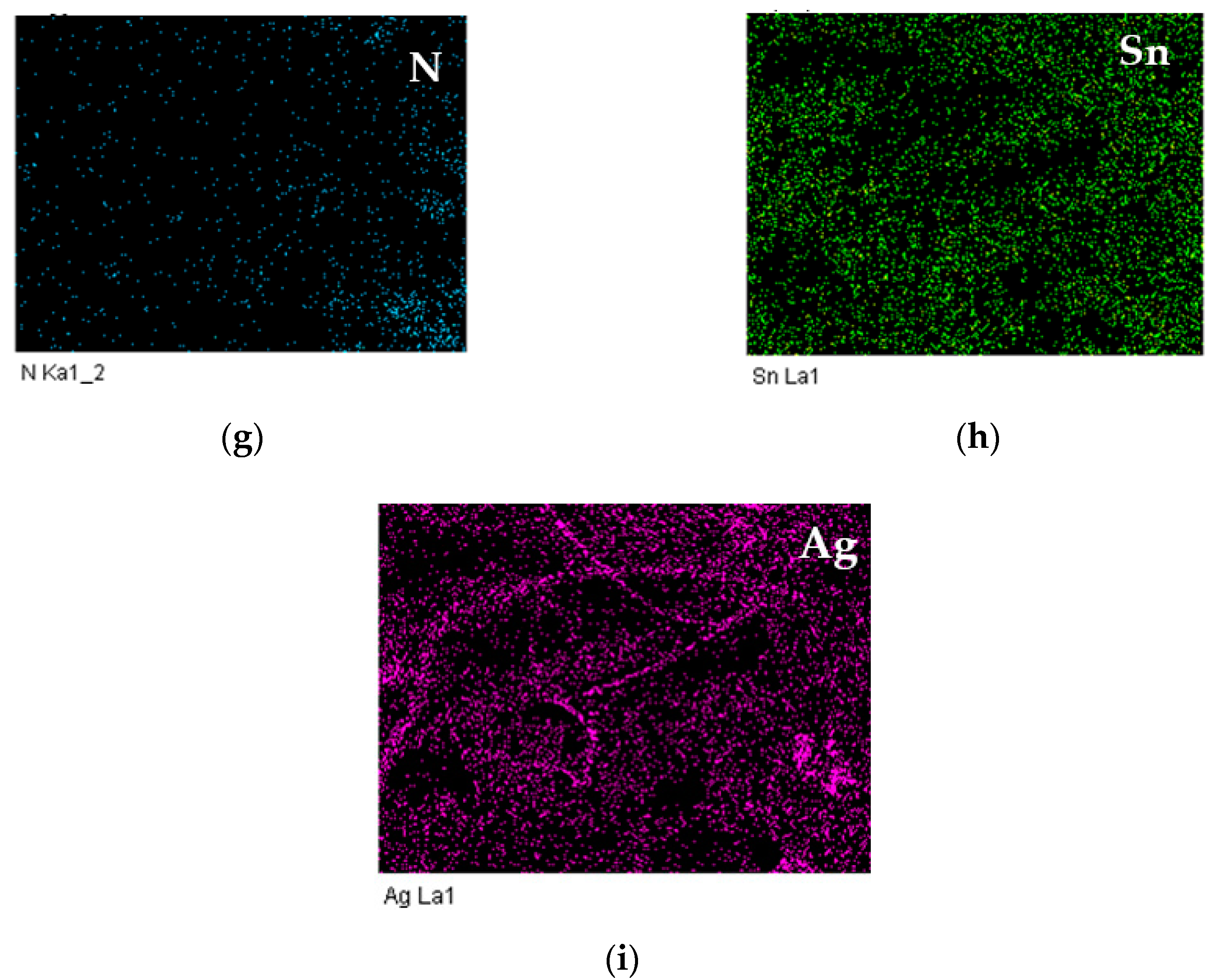

3.1.3. SEM Analyses

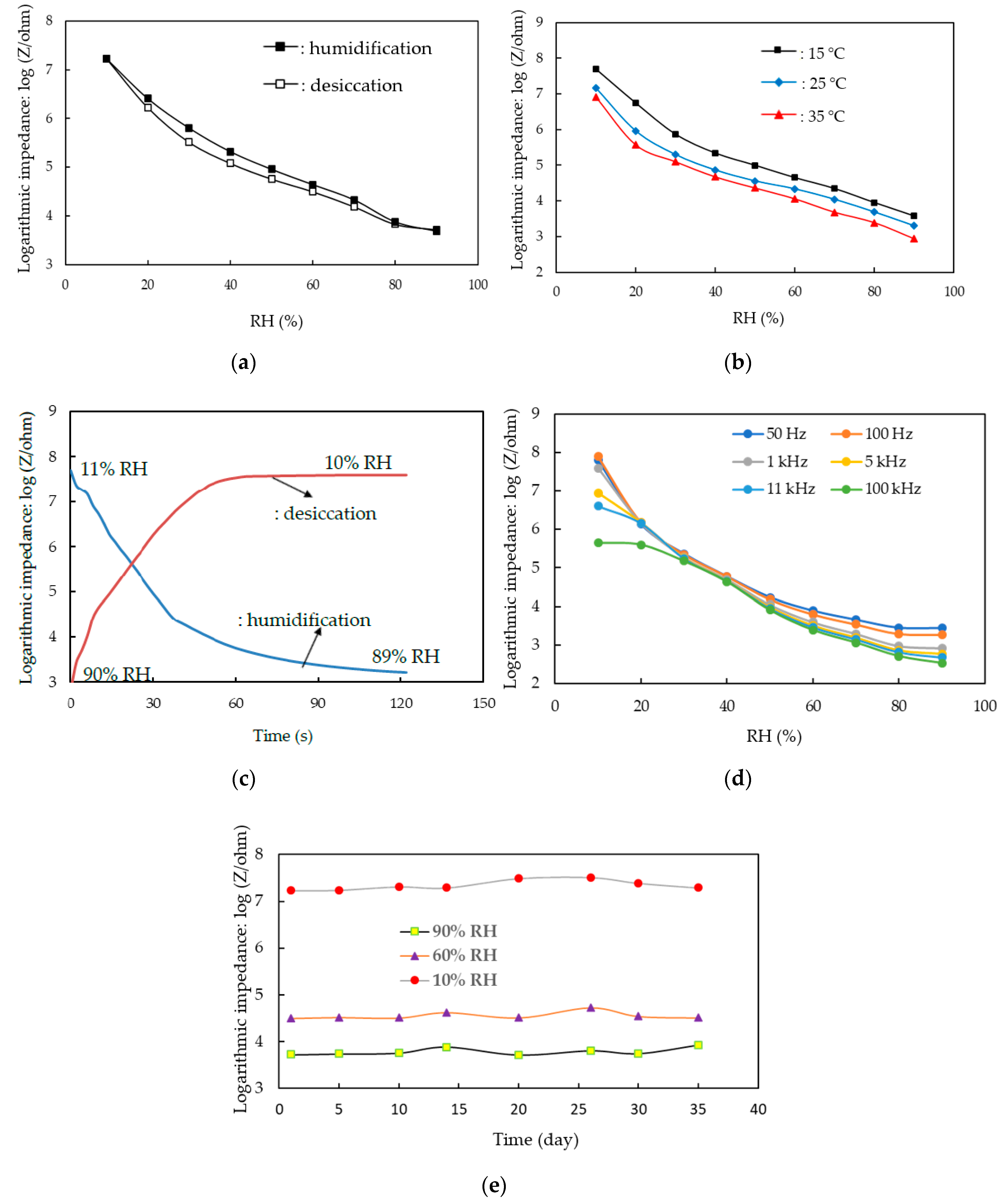

3.2. Electrical and Humidity-Sensing Properties of Humidity Sensors that were Made of Ag MWs/PPy/SnO2 Ternary Composite Films

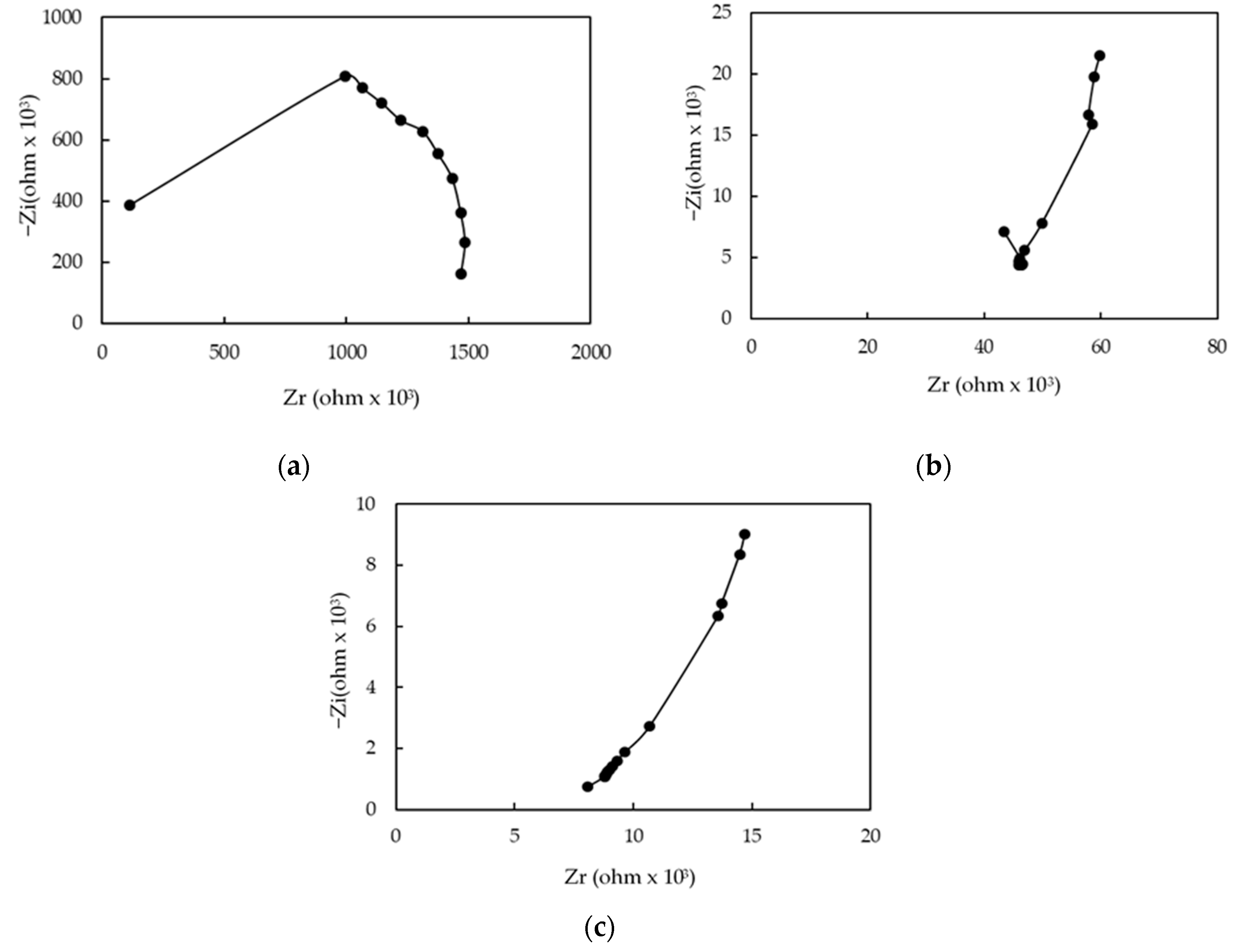

3.3. Humidity-Sensing Mechanism

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Luo, Y.; Kun, Y.; Shi, Y.; Shang, C. Research of radiosonde humidity sensor with temperature compensation function and experimental verification. Sens. Actuators A 2014, 218, 49–59. [Google Scholar] [CrossRef]

- Lee, S.W.; Choi, B.I.; Kim, J.C.; Woo, S.B.; Kim, Y.G.; Yoo, J.; Seo, Y.S. Reduction and compensation of humidity measurement errors at cold temperatures using dual QCM humidity sensors based on graphene oxides. Sens. Actuators B 2019, 284, 386–394. [Google Scholar] [CrossRef]

- Su, P.G.; Chiu, S.R.; Lin, Y.T. Flexibility and electrical and humidity-sensing properties of N-substituted pyrrole derivatives and composite films of Au nanoparticles/N-substituted pyrrole derivatives. Sens. Actuators B 2016, 224, 833–840. [Google Scholar] [CrossRef]

- Narimani, K.; Nayeri, F.D.; Kolahdouz, M.; Ebrahimi, P. Fabrication, modeling and simulation of high sensitivity capacitive humidity sensors based on ZnO nanorods. Sens. Actuator B 2016, 224, 338–343. [Google Scholar] [CrossRef]

- Zhang, D.; Tong, J.; Xia, B.; Xue, Q. Ultrahigh performance humidity sensor based on layer-by-layer self-assembly of graphene oxide/polyelectrolyte nanocomposite film. Sens. Actuators B 2014, 203, 263–270. [Google Scholar] [CrossRef]

- Sakai, Y.; Sadaoka, Y.; Matsuguchi, M. Humidity sensors based on polymer thin films. Sens. Actuators B 1996, 35–36, 85–90. [Google Scholar] [CrossRef]

- Sakai, Y.; Matsuguchi, M.; Hurukawa, T. Humidity sensor using crosslinked poly(chloromethyl styrene). Sens. Actuators B 2000, 66, 135–138. [Google Scholar] [CrossRef]

- Gong, M.S.; Rhee, H.W.; Lee, M.H. Humidity sensor using epoxy resin containing quaternary ammonium salts. Sens. Actuators B 2001, 73, 124–129. [Google Scholar]

- Zampetti, E.; Pantalei, S.; Pecora, A.; Valletta, A.; Maiolo, L.; Minotti, A.; Macagnano, A.; Fortunato, G.; Bearzotti, A. Design and optimization of an ultrathin flexible capacitive humidity sensor. Sens. Actuators B 2009, 143, 302–307. [Google Scholar] [CrossRef]

- Cha, J.R.; Gong, M.S. Preparation of epoxy/polyelectrolyte IPNs for flexible polyimide-based humidity sensors and their properties. Sens. Actuators B 2013, 178, 656–662. [Google Scholar] [CrossRef]

- Rittersma, Z.M.; Splinter, A.; Bodecker, A.; Benecke, W. A novel surface-micromachined capacitive porous silicon humidity sensor. Sens. Actuators B 2000, 68, 210–217. [Google Scholar] [CrossRef]

- Blank, T.A.; Eksperiandova, L.P.; Belikov, K.N. Recent trends of ceramic humidity sensors development: A review. Sens. Actuators B 2016, 228, 416–442. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, Y.; Li, P.; Zhang, Y. Facile fabrication of MoS2-modified SnO2 hybrid nanocomposite for ultrasensitive humidity sensing. ACS Appl. Mater. Interfaces 2016, 8, 14142–14149. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Zong, X.; Wu, Z.; Zhang, Y. Hierarchical self-assembled SnS2 nanoflower/Zn2SnO4 hollow sphere nanohybrid for humidity-sensing applications. ACS Appl. Mater. Interfaces 2018, 10, 32631–32639. [Google Scholar] [CrossRef] [PubMed]

- Taccola, S.; Greco, F.; Zucca, A.; Innocenti, C.; de Julián Fernández, C.; Campo, G.; Sangregorio, C.; Mazzolai, B.; Mattoli, V. Characterization of free-standing PEDOT: Pss/iron oxide nanoparticle composite thin films and application as conformable humidity sensors. ACS Appl. Mater. Interfaces 2013, 5, 6324–6332. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Tong, J.; Xia, B. Humidity-sensing properties of chemically reduced graphene oxide/polymer nanocomposite film sensor based on layer-by-layer nano self-assembly. Sens. Actuators B 2014, 197, 66–72. [Google Scholar] [CrossRef]

- Zhang, D.; Zong, X.; Wu, Z. Fabrication of tin disulfide/graphene oxide nanoflower on flexible substrate for ultrasensitive humidity sensing with ultralow hysteresis and good reversibility. Sens. Actuators B 2019, 287, 398–407. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, D.; Li, P.; Zong, X.; Dong, G. Facile fabrication of high-performance QCM humidity sensor based on layer-by-layer self-assembled polyaniline/graphene oxide nanocomposite film. Sens. Actuators B 2018, 255, 1869–1877. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, Z.; Yang, Z.; Song, X. High-performance flexible self-powered tin disulfide nanoflowers/reduced graphene oxide nanohybrid-based humidity sensor driven by triboelectric nanogenerator. Nano Energy 2020, 67, 104251. [Google Scholar] [CrossRef]

- Kuang, Q.; Lao, C.; Wang, Z.L.; Xie, Z.; Zheng, L. High-sensitivity humidity sensor based on a single SnO2 nanowire. J. Am. Chem. Soc. 2007, 129, 6070–6071. [Google Scholar] [CrossRef]

- Das, S.; Jayaraman, V. SnO2: A comprehensive review on structures and gas sensors. Prog. Mater. Sci. 2014, 66, 112–255. [Google Scholar] [CrossRef]

- Zhen, Y.; Sun, F.H.; Zhang, M.; Jia, K.; Lia, L.; Xue, Q. Ultrafast breathing humidity sensing properties of low-dimensional Fe-doped SnO2 flower-like spheres. RSC Adv. 2016, 6, 27008–27015. [Google Scholar] [CrossRef]

- Zhang, D.; Chang, H.; Li, P.; Liu, R.; Xue, Q. Fabrication and characterization of an ultrasensitive humidity sensor based on metal oxide/graphene hybrid nanocomposite. Sens. Actuators B 2016, 225, 233–240. [Google Scholar] [CrossRef]

- Tomer, V.K.; Devi, S.; Malik, R.; Nehra, S.P.; Duhan, S. Fast response with high performance humidity sensing of Ag-SnO2/SBA-15 nanohybrid sensors. Microporous Mesoporous Mater. 2016, 219, 240–248. [Google Scholar] [CrossRef]

- Ismail, A.S.; Mamat, M.H.; Malek, M.F.; Yusoff, M.M.; Mohamed, R.; Sin, N.M.; Suriani, A.B.; Rusop, M. Heterogeneous SnO2/ZnO nanoparticulate film: Facile synthesis and humidity sensing capability. Mater. Sci. Semicond. Process. 2018, 81, 127–138. [Google Scholar] [CrossRef]

- Tai, W.P.; Oh, J.H. Fabrication and humidity sensing properties of nanostructured TiO2-SnO2 thin films. Sens. Actuators B 2002, 85, 154–157. [Google Scholar] [CrossRef]

- Roy, A.; Pandey, N.K.; Shakya, V.; Kumar, A. Humidity Sensor Based on Synthesized WO3–SnO2 Nanocomposites. Energy Environ. Focus 2013, 2, 126–132. [Google Scholar] [CrossRef]

- Chen, Y.; Pei, Y.; Jiang, Z.; Shi, Z.; Xu, J.; Wu, D.; Xu, T.; Tian, Y.; Wang, X.; Li, X. Humidity sensing properties of the hydrothermally synthesized WS2-modified SnO2 hybrid nanocomposite. Appl. Surf. Sci. 2018, 447, 325–330. [Google Scholar] [CrossRef]

- Tomer, V.K.; Duhan, S. A facile nanocasting synthesis of mesoporous Ag-doped SnO2 nanostructures with enhanced humidity sensing performance. Sens. Actuators B 2016, 223, 750–760. [Google Scholar] [CrossRef]

- Zhuo, M.; Chen, Y.; Sun, J.; Zhang, H.; Guo, D.; Zhang, H.; Li, Q.; Wang, T.; Wan, Q. Humidity sensing properties of a single Sb doped SnO2 nanowire field effect transistor. Sens. Actuators B 2013, 186, 78–83. [Google Scholar] [CrossRef]

- Song, X.; Qi, Q.; Zhang, T.; Wang, C. A humidity sensor based on KCl-doped SnO2 nanofibers. Sens. Actuators B 2009, 138, 368–373. [Google Scholar] [CrossRef]

- Yin, M.; Yang, F.; Wang, Z.; Zhu, M.; Liu, M.; Xu, X.; Li, Z. A Fast Humidity Sensor Based on Li+-Doped SnO2 One-Dimensional Porous Nanofibers. Materials 2017, 10, 535. [Google Scholar] [CrossRef] [PubMed]

- Tomer, V.K.; Adhyapak, P.V.; Duhan, S.; Mulla, I.S. Humidity sensing properties of Ag-loaded mesoporous silica SBA-15 nanocomposites prepared via hydrothermal process. Microporous Mesoporous Mater. 2014, 197, 140–147. [Google Scholar] [CrossRef]

- Ho, T.A.; Jun, T.S.; Kim, Y.S. Material and NH3-sensing properties of polypyrrole-coated tungsten oxide nanofibers. Sens. Actuators B 2013, 185, 523–529. [Google Scholar] [CrossRef]

- Chen, A.; Wang, H.; Li, X. One-step process to fabricate Ag–polypyrrole coaxial nanocables. Chem. Commun. 2005, 14, 1863–1864. [Google Scholar] [CrossRef]

- Yang, X.; Lu, Y. Preparation of polypyrrole-coated silver nanoparticles by one-step UV-induced polymerization. Mater. Lett. 2005, 59, 2484–2487. [Google Scholar] [CrossRef]

- Zhao, C.; Zhao, Q.; Zhao, Q.Z.; Qiu, J.; Zhu, C.; Guo, S. Preparation and optical properties of Ag/PPy composite colloids. J. Photochem. Photobiol. A Chem. 2007, 187, 146–151. [Google Scholar] [CrossRef]

- Jradi, S.; Balan, L.; Zeng, X.H.; Plain, J.; Lougnot, D.J.; Royer, P.; Bachelot, R.; Akil, S.; Soppera, O.; Vidal, L. Spatially controlled synthesis of silver nanoparticles and nanowires by photosensitized reduction. Nanotechnology 2010, 21, 095605. [Google Scholar] [CrossRef]

- Breimer, M.A.; Yevgeny, G.; Sy, S.; Sadik, O.S. Incorporation of metal nanoparticles in photopolymerized organic conducting polymers: A mechanistic insight. Nano Lett. 2001, 1, 305–308. [Google Scholar] [CrossRef]

- Kiani, G.; Nourizad, A.; Nosrati, R. In-situ chemical synthesis of polypyrrole/silver nanocomposite for the use as a room temperature ammonia gas sensor. Fibers Polym. 2018, 19, 2188–2194. [Google Scholar] [CrossRef]

- Su, P.G.; Huang, L.N. Humidity sensors based on TiO2 nanoparticles /polypyrrole composite thin films. Sens. Actuators B 2007, 123, 501–507. [Google Scholar] [CrossRef]

- Liu, S.; Tang, Z.R.; Sun, Y.; Colmenares, J.C.; Xu, Y.J. One-dimension-based spatially ordered architectures for solar energy conversion. Chem. Soc. Rev. 2015, 44, 5053–5075. [Google Scholar] [CrossRef] [PubMed]

- Chi, Y.; Yuan, Q.; Hou, S.; Zhao, Z. Synthesis and characterization of mesoporous ZnTiO3 rods via a polyvinylpyrrolidone assisted sol-gel method. Ceram. Int. 2016, 42, 5094–5099. [Google Scholar] [CrossRef]

- Su, P.G.; Yang, L.Y. NH3 gas sensor based on Pd/SnO2/RGO ternary composite operated at room-temperature. Sens. Actuators B 2016, 223, 202–208. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, J.; Fei, T.; Liu, S.; Zhang, T. SnO2 nanoparticles-reduced graphene oxide nanocomposites for NO2 sensing at low operating temperature. Sens. Actuators B 2014, 190, 472–478. [Google Scholar] [CrossRef]

- Liu, R.; Li, D.; Wang, C.; Li, N.; Li, Q.; Lü, X.; Spendelow, J.S.; Wu, G. Core–shell structured hollow SnO2–polypyrrole nanocomposite anodes with enhanced cyclic performance for lithium-ion batteries. Nano Energy 2014, 6, 73–81. [Google Scholar] [CrossRef]

- Allen, N.S.; Murray, K.S.; Fleming, R.J. Physical properties of polypyrrole films containing trisoxalatometallate anions and prepared from aqueous solution. Synth. Met. 1997, 87, 237–247. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, S.; Kimura, K. Superlattice formation from polydisperse Ag nanoparticles by a vapor-diffusion method. Angew. Chem. Int. Ed. 2006, 45, 5662–5665. [Google Scholar] [CrossRef] [PubMed]

- Amalric-Popescu, D.; Bozon-Verduraz, F. Infrared studies on SnO2 and Pd/SnO2. Catal. Today 2001, 70, 139–154. [Google Scholar] [CrossRef]

- Bhat, N.V.; Gadre, A.P.; Bambole, V.A. Investigation of electropolymerized polypyrrole composite film: Characterization and application to gas sensor. J. Appl. Polym. Sci. 2003, 88, 22–29. [Google Scholar] [CrossRef]

- Henry, M.C.; Hsueh, C.C.; Timko, B.P.; Freund, M.S. Reaction of pyrrole and chlorauric acid a new route to composite colloids. J. Electrochem. Soc. 2001, 148, D155–D162. [Google Scholar]

- Feng, C.D.; Sun, S.L.; Wang, H.; Segre, C.U.; Stetter, J.R. Humidity sensing properties of Nafion and sol–gel derived SiO2/Nafion composite thin films. Sens. Actuators B 1997, 40, 217–222. [Google Scholar]

- Wang, J.; Lin, Q.; Zhang, T.; Zhou, R.; Xu, B. Humidity sensor based on composite material of nano-BaTiO3 and polymer RMX. Sens. Actuators B 2002, 81, 248–253. [Google Scholar]

- Wang, J.; Xu, B.K.; Ruan, S.P.; Wang, S.P. Preparation and electrical properties of humidity sensing films of BaTiO3/polystrene sulfonic sodium. Mater. Chem. Phys. 2003, 78, 746–750. [Google Scholar]

- Casalbore-Miceli, G.; Yang, M.J.; Camaioni, N.; Mari, C.M.; Li, Y.; Sun, H.; Ling, M. Investigations on the ion transport mechanism in conduction polymer films. Solid State Ionics 2000, 131, 311–321. [Google Scholar]

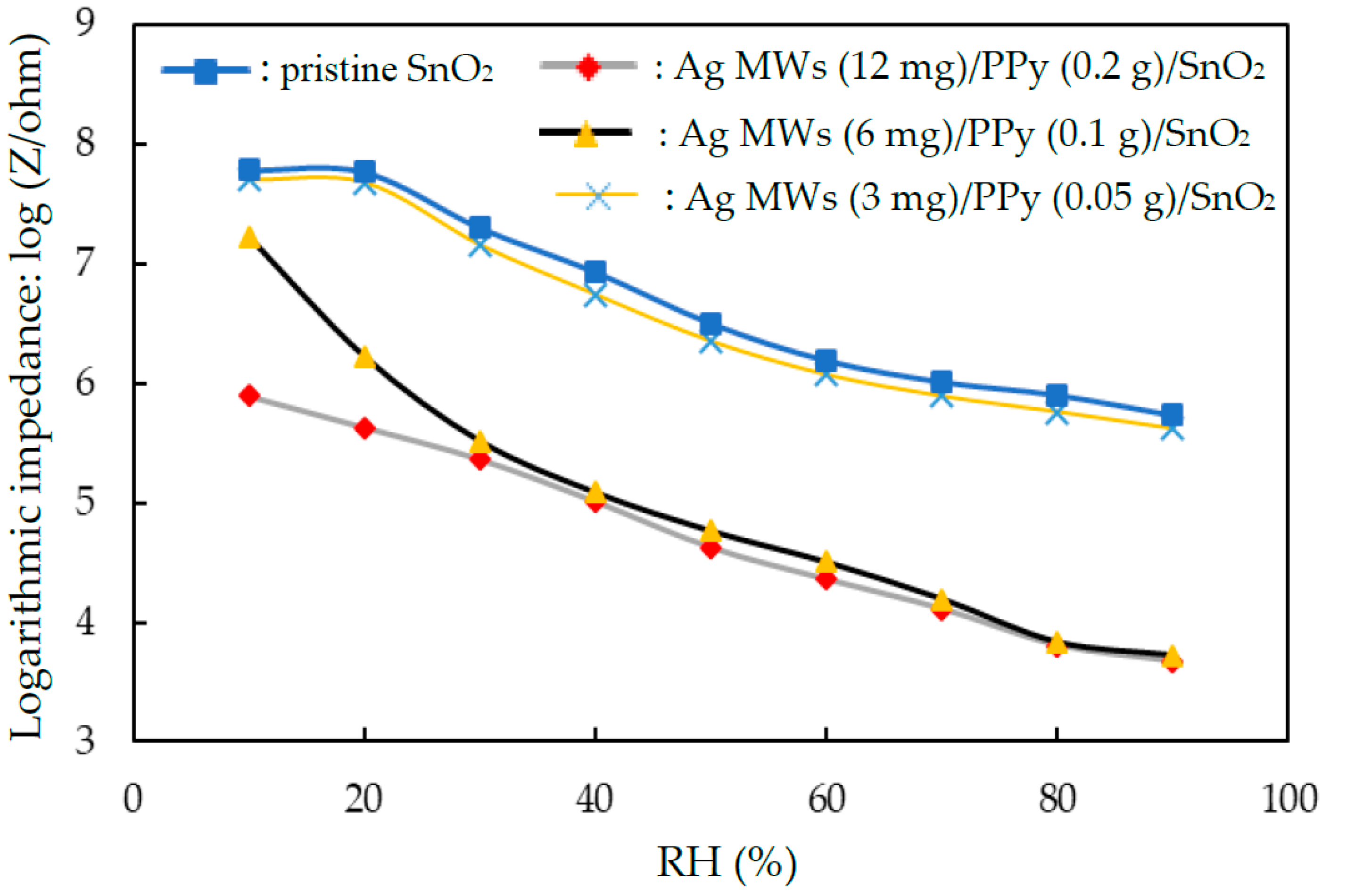

| Materials | Sensitivity a (log Z/% RH) | Linearity b (R2) |

|---|---|---|

| Pristine SnO2 c | −0.0259 | 0.9470 |

| Ag MWs (12 mg)/PPy (0.2 g)/SnO2 | −0.0292 | 0.9932 |

| Ag MWs (6 mg)/PPy (0.1 g)/SnO2 | −0.0407 | 0.9303 |

| Ag MWs (3 mg)/PPy (0.05 g)/SnO2 | −0.0288 | 0.9581 |

| Sensing Material | Working Range (% RH) | Sensitivity | Hysteresis (% RH) | Response Time (s) | Ref. |

|---|---|---|---|---|---|

| Fe-doped SnO2 | 11–95 | 6479.5 a | − | 1 | [22] |

| RGO/SnO2 | 11–97 | 1604.89 pF/% RH | 1.8 | 102 | [23] |

| Ag-SnO2/SBA-15 | 11–98 | − | 0.9 | 5 | [24] |

| ZnO/SnO2 | 40–90 | 90.56 b | − | 3 min | [25] |

| TiO2-SnO2 | 20–90 | − | − | 20 | [26] |

| WO3-SnO2 | 10–90 | 2.63 MΩ/% RH | − | 121 | [27] |

| WS2-SnO2 | 0–95 | 23,900.4 c | − | 250 | [28] |

| Ag-doped SnO2 | 11–98 | 4 order d | 1 | 4 | [29] |

| Sb-doped SnO2 | 22–40 | − | − | − | [30] |

| KCl-doped SnO2 | 11–95 | 4 order d | − | 5 | [31] |

| Li+-doped SnO2 | 33–85 | 36.3 a | − | 1 | [32] |

| Ag MWs/PPy/SnO2 | 10–90 | 0.0407 e | <1.8 | 46 | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, P.-G.; Lu, P.-H. Electrical and Humidity-Sensing Properties of Impedance-Type Humidity Sensors that Were Made of Ag Microwires/PPy/SnO2 Ternary Composites. Chemosensors 2020, 8, 92. https://doi.org/10.3390/chemosensors8040092

Su P-G, Lu P-H. Electrical and Humidity-Sensing Properties of Impedance-Type Humidity Sensors that Were Made of Ag Microwires/PPy/SnO2 Ternary Composites. Chemosensors. 2020; 8(4):92. https://doi.org/10.3390/chemosensors8040092

Chicago/Turabian StyleSu, Pi-Guey, and Ping-Hsiang Lu. 2020. "Electrical and Humidity-Sensing Properties of Impedance-Type Humidity Sensors that Were Made of Ag Microwires/PPy/SnO2 Ternary Composites" Chemosensors 8, no. 4: 92. https://doi.org/10.3390/chemosensors8040092

APA StyleSu, P.-G., & Lu, P.-H. (2020). Electrical and Humidity-Sensing Properties of Impedance-Type Humidity Sensors that Were Made of Ag Microwires/PPy/SnO2 Ternary Composites. Chemosensors, 8(4), 92. https://doi.org/10.3390/chemosensors8040092