NO2 Detection Using Hierarchical WO3 Microflower-Based Gas Sensors: Comprehensive Study of Sensor Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis of WO3 Microflowers by the Microwave-Assisted Hydrothermal Method

- (a)

- Different amounts of K2SO4 (0 g, 1 g, 2 g, 3 g, and 4 g; referred to as MF-WO3-K0, MF-WO3-K1, MF-WO3-K2, MF-WO3-K3, and MF-WO3-K4, respectively) were used. The HCl concentration was 3M, and the synthesis time was 30 min.

- (b)

- Different HCl concentrations (0 M, 1 M, 2 M, 3 M, and 4 M; referred to as MF-WO3-H0, MF-WO3-H1, MF-WO3-H2, MF-WO3-H3, and MF-WO3-H4, respectively) were tested. The amount of K2SO4 used was 2 g, and the synthesis time was 30 min.

- (c)

- Different synthesis times (15 min, 30 min, 60 min, 90 min, and 120 min; referred to as MF-WO3-T15, MF-WO3-T30, MF-WO3-T60, MF-WO3-T90, and MF-WO3-T120, respectively) were examined. The amount of K2SO4 used was 2 g, and the HCl concentration was 3 M.

2.2. Structural, Morphological, and Thermal Characterization of the WO3 Microflowers

2.3. Methods for Gas Sensor Measurements

3. Results and Discussion

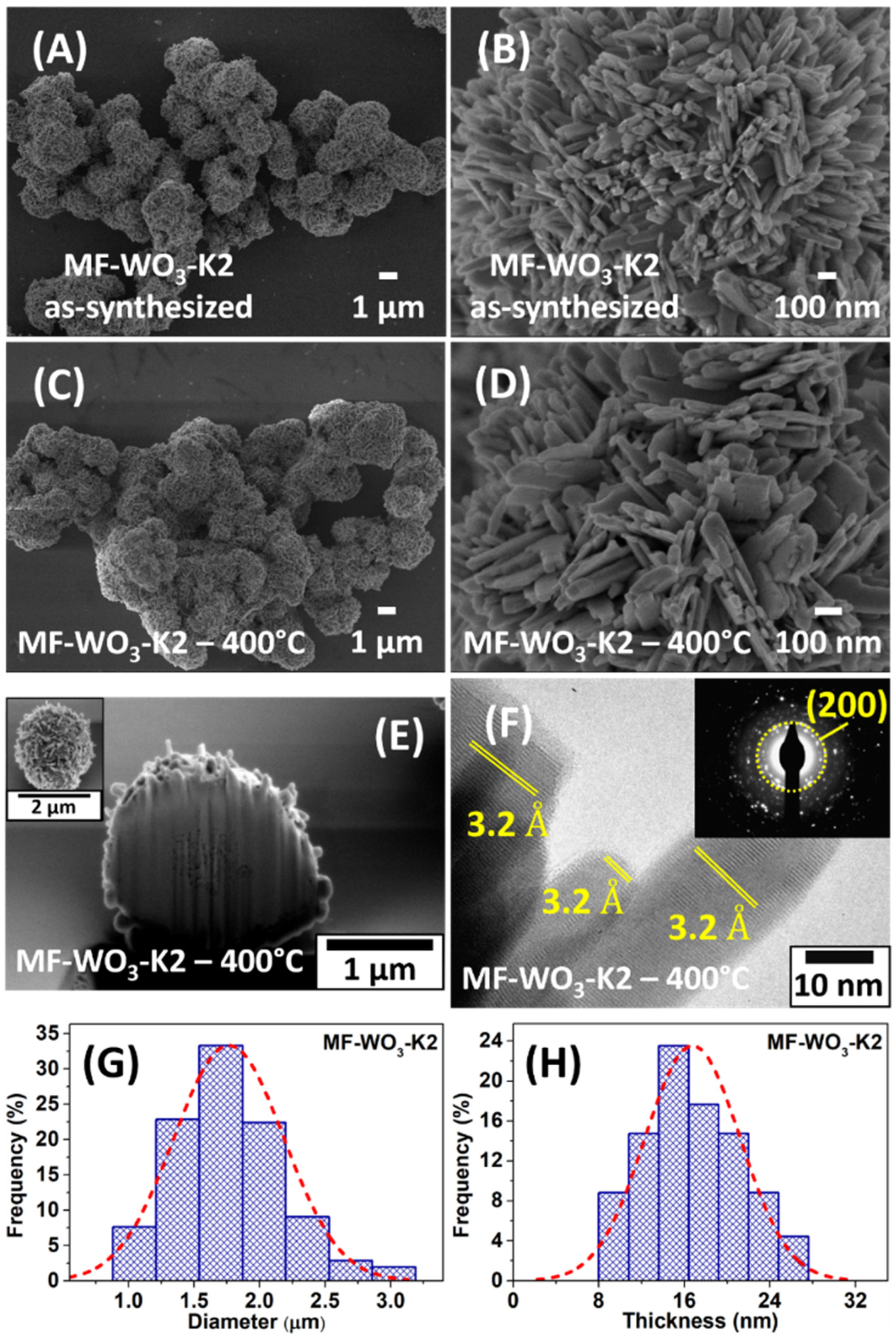

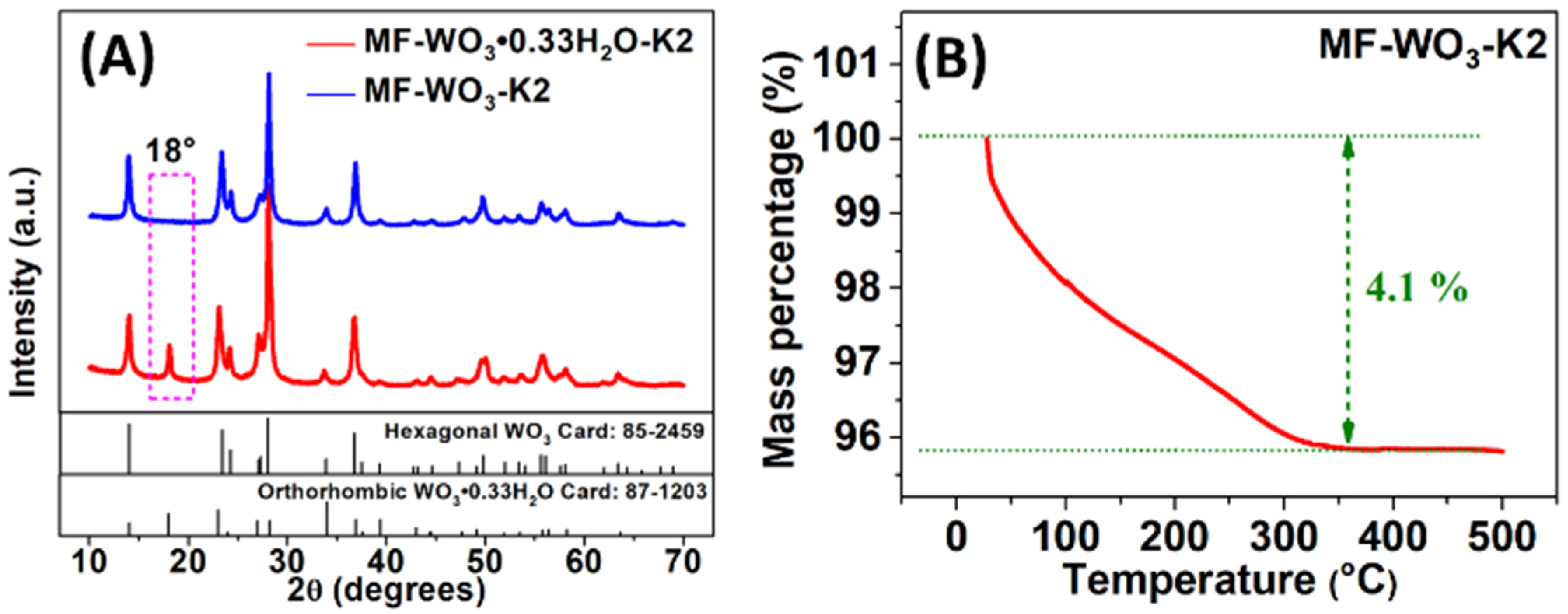

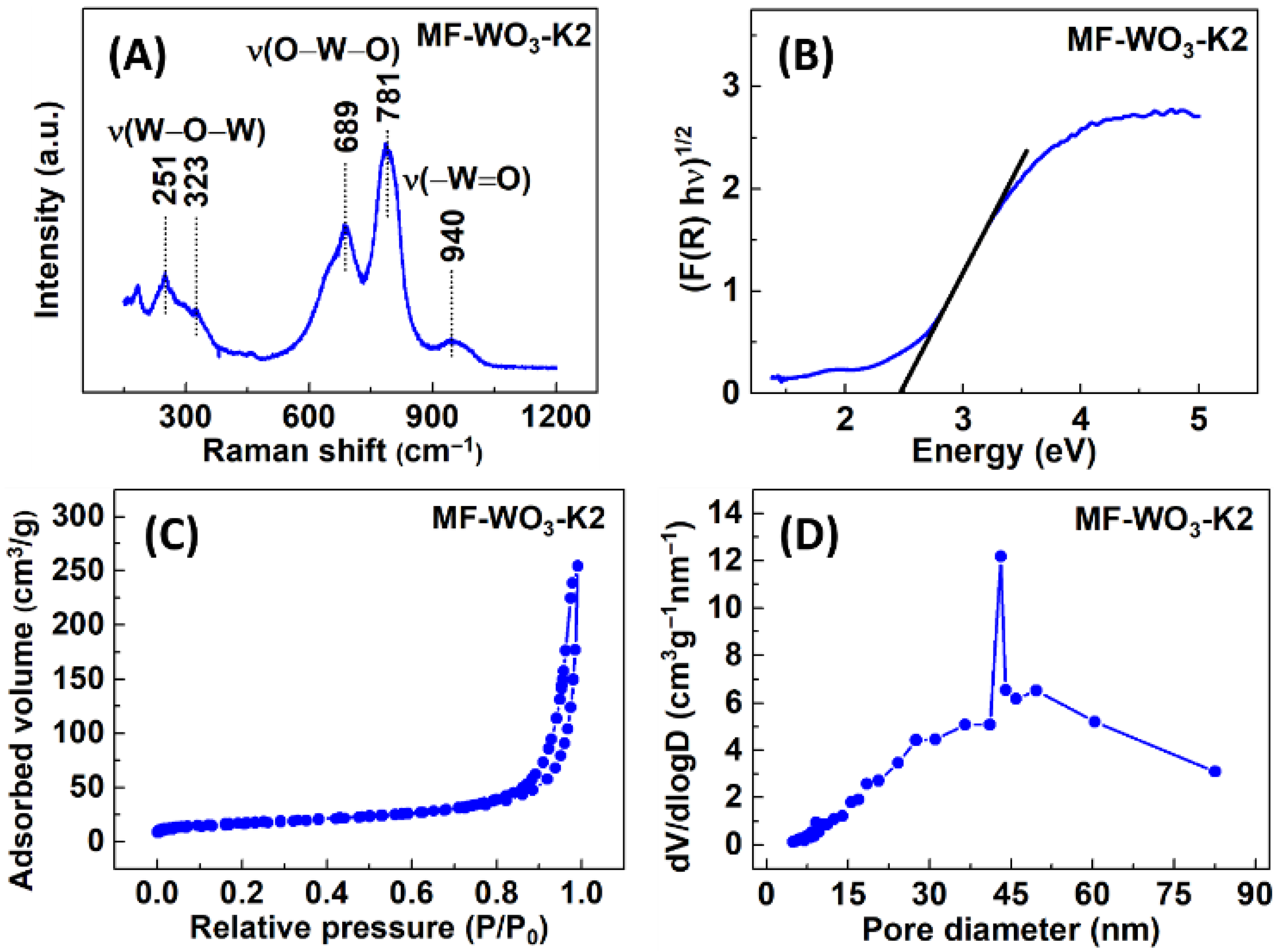

3.1. Structural, Morphological, Chemical, and Thermal Characterization of the WO3 Microflowers

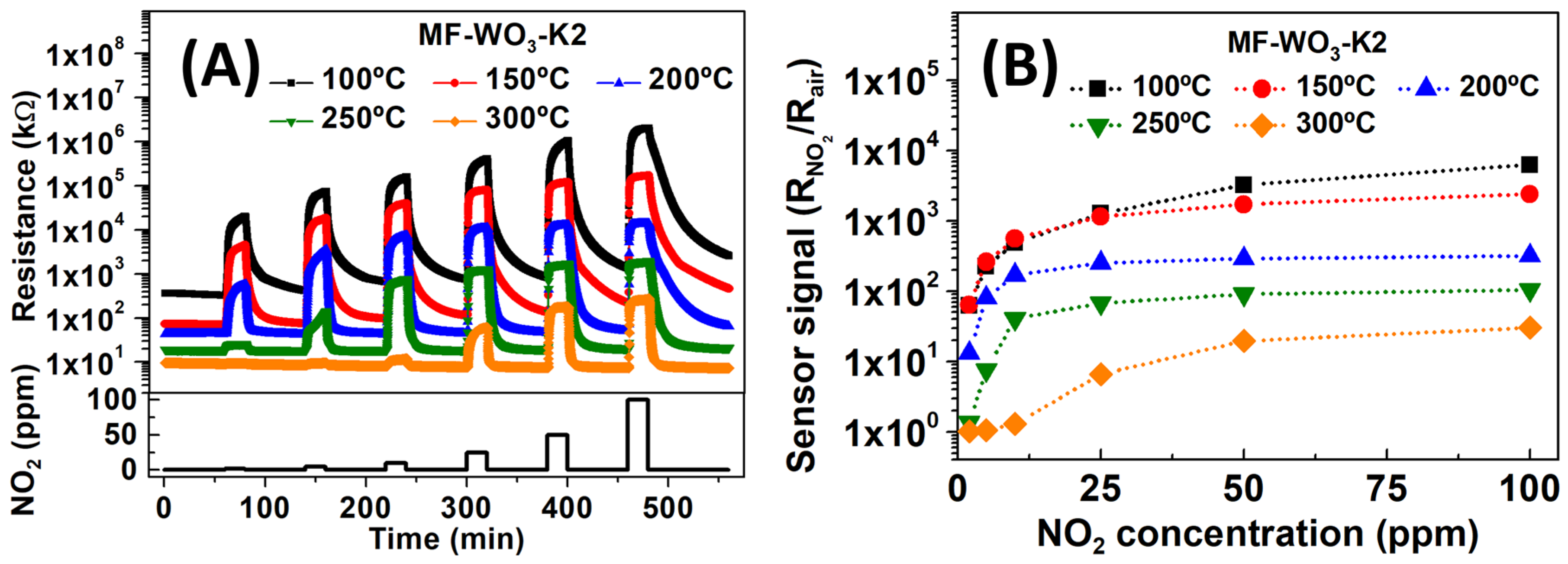

3.2. Gas Sensing Measurements

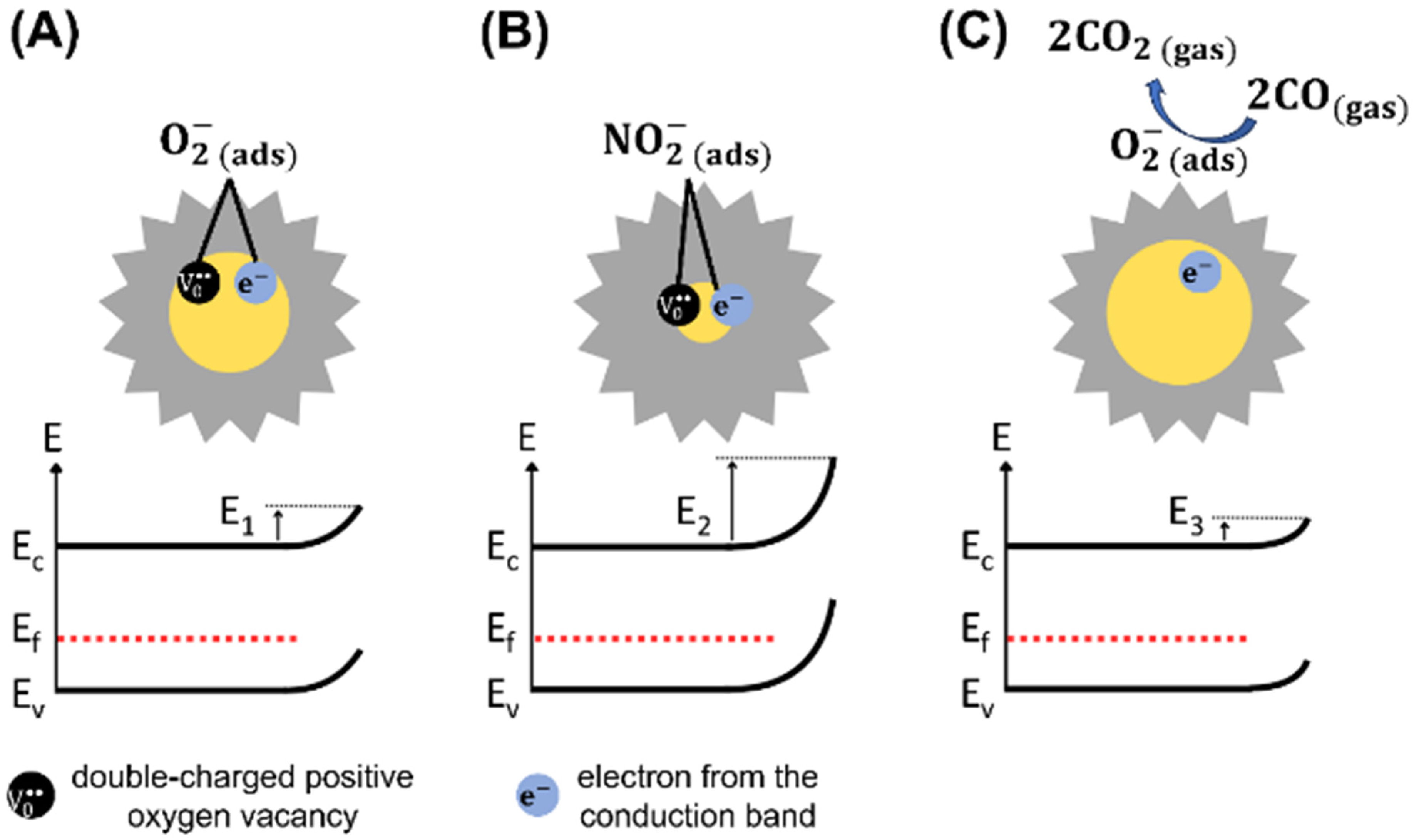

3.3. Gas Sensing Mechanisms

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duan, X.; Xu, D.; Jia, W.; Li, R.; Sun, B.; Yan, R.; Zhao, W. WO3/WS2 Nanoflowers Fabricated by Low-Temperature in-Situ Oxidation for Rapid Detection of Nitrogen Dioxide. Sens. Actuators A Phys. 2024, 365, 114854. [Google Scholar] [CrossRef]

- World Health Organization. Health Aspects of Air Pollution with Particulate Matter, Ozone and Nitrogen Dioxide: Report on a WHO Working Group, Bonn, Germany, 13–15 January 2003; World Health Organization: Geneva, Switzerland, 2003. [Google Scholar]

- Long, H.; Zeng, W.; Zhang, H. Synthesis of WO3 and Its Gas Sensing: A Review. J. Mater. Sci. Mater. Electron. 2015, 26, 4698–4707. [Google Scholar] [CrossRef]

- Urasinska-Wojcik, B.; Vincent, T.A.; Chowdhury, M.F.; Gardner, J.W. Ultrasensitive WO3 Gas Sensors for NO2 Detection in Air and Low Oxygen Environment. Sens. Actuators B Chem. 2017, 239, 1051–1059. [Google Scholar] [CrossRef]

- Righettoni, M.; Amann, A.; Pratsinis, S.E. Breath Analysis by Nanostructured Metal Oxides as Chemo-Resistive Gas Sensors. Mater. Today 2015, 18, 163–171. [Google Scholar] [CrossRef]

- Bai, X.; Ji, H.; Gao, P.; Zhang, Y.; Sun, X. Morphology, Phase Structure and Acetone Sensitive Properties of Copper-Doped Tungsten Oxide Sensors. Sens. Actuators B Chem. 2014, 193, 100–106. [Google Scholar] [CrossRef]

- Tyagi, S.; Chaudhary, M.; Ambedkar, A.K.; Sharma, K.; Gautam, Y.K.; Singh, B.P. Metal Oxide Nanomaterial-Based Sensors for Monitoring Environmental NO2 and Its Impact on the Plant Ecosystem: A Review. Sens. Diagn. 2022, 1, 106–129. [Google Scholar] [CrossRef]

- Song, W.; Zhang, R.; Bai, X.; Jia, Q.; Ji, H. Exposed Crystal Facets of WO3 Nanosheets by Phase Control on NO2-Sensing Performance. J. Mater. Sci. Mater. Electron. 2020, 31, 610–620. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.; Li, X.; Ge, C.; Hussain, S.; Liu, G.; Qiao, G. WO3 Porous Nanosheet Arrays with Enhanced Low Temperature NO2 Gas Sensing Performance. Sens. Actuators B Chem. 2020, 316, 128050. [Google Scholar] [CrossRef]

- Morais, P.V.; Suman, P.H.; Silva, R.A.; Orlandi, M.O. High Gas Sensor Performance of WO3 Nanofibers Prepared by Electrospinning. J. Alloys Compd. 2021, 864, 158745. [Google Scholar] [CrossRef]

- Perfecto, T.M.; Zito, C.A.; Volanti, D.P. Room-Temperature Volatile Organic Compounds Sensing Based on WO3·0.33H2O, Hexagonal-WO3, and Their Reduced Graphene Oxide Composites. RSC Adv. 2016, 6, 105171–105179. [Google Scholar] [CrossRef]

- Phanichphant, S. Semiconductor Metal Oxides as Hydrogen Gas Sensors. Procedia Eng. 2014, 87, 795–802. [Google Scholar] [CrossRef]

- Hoa, N.D.; El-Safty, S.A. Gas Nanosensor Design Packages Based on Tungsten Oxide: Mesocages, Hollow Spheres, and Nanowires. Nanotechnology 2011, 22, 485503. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.-Y.; Kim, S.-J.; Hwang, I.-S.; Lee, J.-H. Glucose-Mediated Hydrothermal Synthesis and Gas Sensing Characteristics of WO3 Hollow Microspheres. Sens. Actuators B Chem. 2009, 142, 236–242. [Google Scholar] [CrossRef]

- Li, X.-L.; Lou, T.-J.; Sun, X.-M.; Li, Y.-D. Highly Sensitive WO3 Hollow-Sphere Gas Sensors. Inorg. Chem. 2004, 43, 5442–5449. [Google Scholar] [CrossRef]

- Van Dang, T.; Duc Hoa, N.; Van Duy, N.; Van Hieu, N. Chlorine Gas Sensing Performance of On-Chip Grown ZnO, WO3, and SnO2 Nanowire Sensors. ACS Appl. Mater. Interfaces 2016, 8, 4828–4837. [Google Scholar] [CrossRef]

- Behera, B.; Chandra, S. Synthesis of WO3 Nanorods by Thermal Oxidation Technique for NO2 Gas Sensing Application. Mater. Sci. Semicond. Process 2018, 86, 79–84. [Google Scholar] [CrossRef]

- Shendage, S.S.; Patil, V.L.; Vanalakar, S.A.; Patil, S.P.; Harale, N.S.; Bhosale, J.L.; Kim, J.H.; Patil, P.S. Sensitive and Selective NO2 Gas Sensor Based on WO3 Nanoplates. Sens. Actuators B Chem. 2017, 240, 426–433. [Google Scholar] [CrossRef]

- Xia, H.; Wang, Y.; Kong, F.; Wang, S.; Zhu, B.; Guo, X.; Zhang, J.; Wang, Y.; Wu, S. Au-Doped WO3-Based Sensor for NO2 Detection at Low Operating Temperature. Sens. Actuators B Chem. 2008, 134, 133–139. [Google Scholar] [CrossRef]

- Li, G.; Li, J.; Wang, Y.; Du, Y.; Xu, H.; Wang, Y. In-Situ Growth WO3@ZIF-8 Core-Shell Nanorod Arrays for Highly Responsive and Selective NO2 Detection. Microchem. J. 2025, 216, 114735. [Google Scholar] [CrossRef]

- Do, D.T.; Nguyen, D.Y.N.; Tran, T.T.H.; Phan, H.P.; Luu, T.L.A.; Dang, T.T.; Pham, T.H.; Nguyen, H.L.; Nguyen, V.H.; Nguyen, C.T. Engineering Hierarchical Cubic WO3 Nanostructures for Sub-Ppb-Level NO2 Gas Sensor. Sens. Actuators A Phys. 2025, 393, 116847. [Google Scholar] [CrossRef]

- Do, D.T.; Nguyen, D.Y.N.; Pham, T.A.; Nguyen, C.T.; Nguyen, V.H. Comparative Study of Monoclinic and Cubic WO3 Nanoplates on NO2 Gas-Sensing Properties. RSC Adv. 2025, 15, 22930–22940. [Google Scholar] [CrossRef] [PubMed]

- Roopa; Pradhan, B.K.; Tyagi, D.; Salma; Mauraya, A.K.; Kushvaha, S.S.; Muthusamy, S.K. NO2 Gas Sensing Characteristics of WO3 Thin Films Synthesised by the Thermal Oxidation of DC Sputtered W Films: Effect of Oxidation Temperature. J. Alloys Compd. 2025, 1036, 181706. [Google Scholar] [CrossRef]

- Ganesan, M.; Harish, S.; Shanmugasundaram, K.; Mohan, M.K.; Archana, J.; Navaneethan, M. Highly Sensitive and Selective Au-Loaded WO3 Nanoplates for NO2 Gas Detection. Sens. Actuators B Chem. 2025, 440, 137900. [Google Scholar] [CrossRef]

- Jiang, H.-Y.; Chen, G.-L.; Xin, Y.-Y.; Shen, S.-K.; Deng, Z.-P.; Xu, Y.-M.; Huo, L.-H.; Gao, S. Honeycomb-like WO3 Architecture Derived from Grapevine Boosts Efficient Detection of Trace NO2 Gas at near Room Temperature. Sens. Actuators B Chem. 2025, 436, 137686. [Google Scholar] [CrossRef]

- Li, G.; Wang, Y.; Du, Y.; Xu, H.; Wang, Y. WO3-SnO2 Nanocomposites with Isotype Heterojunctions for Sensitive Detection of NO2. Mater. Lett. 2025, 396, 138743. [Google Scholar] [CrossRef]

- Qiu, Y.; Wang, Y. Synthesis, Growth Kinetics and Ultra-Sensitive Performance of Electrospun WO3 Nanofibers for NO2 Detection. Appl. Surf. Sci. 2023, 608, 155112. [Google Scholar] [CrossRef]

- Liaqat, M.J.; Hussain, S.; Shahid, A.; Amu-Darko, J.N.O.; Ibrahim, T.K.; Ibrahim, S.M.; Manavalan, R.K.; Zhang, X.; Qiao, G.; Liu, G. Hydrothermally Grown WO3-SnO2 Nanocomposites for Efficient NO2 Detection at Low Concentration. Sens. Actuators B Chem. 2025, 436, 137711. [Google Scholar] [CrossRef]

- Rani, S.; Dahiya, R.; Kumar, V.; Berwal, P.; Sihag, S. Hydrothermally Engineered WO3 Nanosheets as Potential NO2 Gas Sensor. Ionics 2025, 31, 993–1002. [Google Scholar] [CrossRef]

- Li, R.; Wang, Q.; Wang, Y.; An, B.; Yang, Y.; Wu, Z.; Wang, P.; Zhang, T.; Han, R.; Xie, E. Unraveling the Effect of Oxygen Vacancy on WO3 Surface for Efficient NO2 Detection at Low Temperature. ACS Appl. Mater. Interfaces 2024, 16, 51738–51747. [Google Scholar] [CrossRef]

- Singh, J.P.; Sharma, A.; Tomar, M.; Chowdhuri, A. WO3 and WO3-SnO2 Composite-Based Sensors for Low-Temperature Detection of NO2 Gas. J. Electron. Mater. 2024, 53, 6688–6699. [Google Scholar] [CrossRef]

- Kaur, H.; Bhatti, H.S.; Singh, K. Pr Doped SnO2 Nanostructures: Morphology Evolution, Efficient Photocatalysts and Fluorescent Sensors for the Detection of Cd2+ Ions in Water. J. Photochem. Photobiol. A Chem. 2020, 388, 112144. [Google Scholar] [CrossRef]

- Wang, C.; Ding, M.; Kou, X.; Guo, L.; Feng, C.; Li, X.; Zhang, H.; Sun, P.; Sun, Y.; Lu, G. Detection of Nitrogen Dioxide down to Ppb Levels Using Flower-like Tungsten Oxide Nanostructures under Different Annealing Temperatures. J. Colloid Interface Sci. 2016, 483, 314–320. [Google Scholar] [CrossRef]

- Wang, M.; Li, X.; Wang, Y.; Han, S.; Song, R.; Xu, Z.; Bai, L.; Hussain, S.; Liu, G.; Qiao, G.; et al. In-Situ Grown Hydrated Tungsten Oxide Nanosheets for Low Temperature Ppb-Level NO2 Detection with Alleviated Humidity Interference. Sens. Actuators B Chem. 2023, 396, 134623. [Google Scholar] [CrossRef]

- Wilken, M.; Ciftyürek, E.; Cwik, S.; Mai, L.; Mallick, B.; Rogalla, D.; Schierbaum, K.; Devi, A. CVD Grown Tungsten Oxide for Low Temperature Hydrogen Sensing: Tuning Surface Characteristics via Materials Processing for Sensing Applications. Small 2023, 19, 2204636. [Google Scholar] [CrossRef]

- Yadav, A.; Sharma, A.; Baloria, V.; Singh, P.; Gupta, G. Ultrahigh Sensitive NO Sensor Based on WO3 Film with Ppb-Level Sensitivity. Ceram. Int. 2023, 49, 7853–7860. [Google Scholar] [CrossRef]

- Bai, S.; Ma, Y.; Luo, R.; Chen, A.; Li, D. Room Temperature Triethylamine Sensing Properties of Polyaniline–WO3 Nanocomposites with p–n Heterojunctions. RSC Adv. 2016, 6, 2687–2694. [Google Scholar] [CrossRef]

- Bose, A.K.; Manhas, M.S.; Ganguly, S.N.; Sharma, A.H.; Banik, B.K. Carbide, Nitride and Boride Materials Synthesis and Processing; Weimer, A.W., Ed.; Springer Netherlands: London, UK, 1997; ISBN 978-94-010-6521-4. [Google Scholar]

- Nüchter, M.; Ondruschka, B.; Bonrath, W.; Gum, A. Microwave Assisted Synthesis — A Critical Technology Overview. Green. Chem. 2004, 6, 128–141. [Google Scholar] [CrossRef]

- Schütz, M.B.; Xiao, L.; Lehnen, T.; Fischer, T.; Mathur, S. Microwave-Assisted Synthesis of Nanocrystalline Binary and Ternary Metal Oxides. Int. Mater. Rev. 2018, 63, 341–374. [Google Scholar] [CrossRef]

- Modak, M.; Rane, S.; Jagtap, S. WO3: A Review of Synthesis Techniques, Nanocomposite Materials and Their Morphological Effects for Gas Sensing Application. Bull. Mater. Sci. 2023, 46, 28. [Google Scholar] [CrossRef]

- Yu, Y.; Zeng, W.; Xu, M.; Peng, X. Hydrothermal Synthesis of WO3·H2O with Different Nanostructures from 0D to 3D and Their Gas Sensing Properties. Phys. E Low-Dimens. Syst. Nanostruct. 2016, 79, 127–132. [Google Scholar] [CrossRef]

- Gui, Y.; Liu, Z.; Fang, S.; Tian, J.; Gong, F. Synthesis of Flower-like WO3/Graphene Nanocomposite by Microwave-Assisted Hydrothermal Method and the Enhanced Gas-Sensing Properties to Aniline. J. Mater. Sci. Mater. Electron. 2016, 27, 2890–2895. [Google Scholar] [CrossRef]

- Li, S.; Lin, P.; Zhao, L.; Wang, C.; Liu, D.; Liu, F.; Sun, P.; Liang, X.; Liu, F.; Yan, X.; et al. The Room Temperature Gas Sensor Based on Polyaniline@flower-like WO3 Nanocomposites and Flexible PET Substrate for NH3 Detection. Sens. Actuators B Chem. 2018, 259, 505–513. [Google Scholar] [CrossRef]

- He, M.; Xie, L.; Zhao, X.; Hu, X.; Li, S.; Zhu, Z.-G. Highly Sensitive and Selective H2S Gas Sensors Based on Flower-like WO3/CuO Composites Operating at Low/Room Temperature. J. Alloys Compd. 2019, 788, 36–43. [Google Scholar] [CrossRef]

- Hu, J.; Sun, Y.; Wang, X.; Chen, L.; Zhang, W.; Chen, Y. Synthesis and Gas Sensing Properties of Molybdenum Oxide Modified Tungsten Oxide Microstructures for Ppb-Level Hydrogen Sulphide Detection. RSC Adv. 2017, 7, 28542–28547. [Google Scholar] [CrossRef]

- Gurlo, A.; Bârsan, N.; Weimar, U. Metal Oxides. In Metal Oxides: Chemistry and Applications; Fierro, J.L.G., Ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 683–729. ISBN 9780367392222. [Google Scholar]

- Bai, S.; Zhang, K.; Shu, X.; Chen, S.; Luo, R.; Li, D.; Chen, A. Carboxyl-Directed Hydrothermal Synthesis of WO3 Nanostructures and Their Morphology-Dependent Gas-Sensing Properties. CrystEngComm 2014, 16, 10210–10217. [Google Scholar] [CrossRef]

- Di Natale, F.; Lancia, A. Recovery of Tungstate from Aqueous Solutions by Ion Exchange. Ind. Eng. Chem. Res. 2007, 46, 6777–6782. [Google Scholar] [CrossRef]

- Shirke, Y.M.; Porel Mukherjee, S. Selective Synthesis of WO3 and W18O49 Nanostructures: Ligand-Free PH-Dependent Morphology-Controlled Self-Assembly of Hierarchical Architectures from 1D Nanostructure and Sunlight-Driven Photocatalytic Degradation. CrystEngComm 2017, 19, 2096–2105. [Google Scholar] [CrossRef]

- Shi, J.; Hu, G.; Cong, R.; Bu, H.; Dai, N. Controllable Synthesis of WO3·nH2O Microcrystals with Various Morphologies by a Facile Inorganic Route and Their Photocatalytic Activities. New J. Chem. 2013, 37, 1538–1544. [Google Scholar] [CrossRef]

- Liang, S.; Zhu, S.; Chen, Y.; Wu, W.; Wang, X.; Wu, L. Rapid Template-Free Synthesis and Photocatalytic Performance of Visible Light-Activated SnNb2O6 Nanosheets. J. Mater. Chem. 2012, 22, 2670–2678. [Google Scholar] [CrossRef]

- Djaoued, Y.; Balaji, S.; Brüning, R. Electrochromic Devices Based on Porous Tungsten Oxide Thin Films. J. Nanomater. 2012, 2012, 674168. [Google Scholar] [CrossRef]

- Daniel, M.F.; Desbat, B.; Lassegues, J.C.; Gerand, B.; Figlarz, M. Infrared and Raman Study of WO3 Tungsten Trioxides and WO3, XH2O Tungsten Trioxide Tydrates. J. Solid State Chem. 1987, 67, 235–247. [Google Scholar] [CrossRef]

- Díaz–Reyes, J.; Dorantes–García, V.; Pérez–Benítez, A.; Balderas–López, J.A. Obtaining of Films of Tungsten Trioxide (WO3) by Resistive Heating of a Tungsten Filament. Superficies y vacío 2008, 21, 12–17. [Google Scholar]

- Mukherjee, R.; Sahay, P.P. Effect of Precursors on the Microstructural, Optical, Electrical and Electrochromic Properties of WO3 Nanocrystalline Thin Films. J. Mater. Sci. Mater. Electron. 2015, 26, 6293–6305. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, P.; Yang, T.; Gao, Y.; Li, X.; Lu, G.; Du, Y. Flower-like WO3 Architectures Synthesized via a Microwave-Assisted Method and Their Gas Sensing Properties. Sens. Actuators B Chem. 2013, 186, 734–740. [Google Scholar] [CrossRef]

- Wang, C.; Li, X.; Feng, C.; Sun, Y.; Lu, G. Nanosheets Assembled Hierarchical Flower-like WO3 Nanostructures: Synthesis, Characterization, and Their Gas Sensing Properties. Sens. Actuators B Chem. 2015, 210, 75–81. [Google Scholar] [CrossRef]

- Mirabella, D.A.; Aldao, C.M. Dependence of N-Type Metal-Oxide Gas Sensor Response on the Pressure of Oxygen and Reducing Gases. ACS Sens. 2024, 9, 1938–1944. [Google Scholar] [CrossRef]

- Staerz, A.; Russ, T.; Weimar, U.; Barsan, N. Understanding the Sensing Mechanism of WO3 Based Gas Sensors. In Proceedings of the 2019 IEEE International Symposium on Olfaction and Electronic Nose (ISOEN), Fukuoka, Japan, 26–29 May 2019; IEEE: Fukuoka, Japan, 2019. [Google Scholar]

- Staerz, A.; Somacescu, S.; Epifani, M.; Kida, T.; Weimar, U.; Barsan, N. WO3-Based Gas Sensors: Identifying Inherent Qualities and Understanding the Sensing Mechanism. ACS Sens. 2020, 5, 1624–1633. [Google Scholar] [CrossRef]

- Hua, Z.; Li, Y.; Zeng, Y.; Wu, Y. A Theoretical Investigation of the Power-Law Response of Metal Oxide Semiconductor Gas Sensors Ι: Schottky Barrier Control. Sens. Actuators B Chem. 2018, 255, 1911–1919. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Go, S.; Sexton, D.; Li, X.; Alkadi, N.; Kolmakov, A.; Amm, B.; St-Pierre, R.; Scherer, B.; Nayeri, M.; et al. Extraordinary Performance of Semiconducting Metal Oxide Gas Sensors Using Dielectric Excitation. Nat. Electron. 2020, 3, 280–289. [Google Scholar] [CrossRef]

- Beknalkar, S.A.; Patil, V.L.; Harale, N.S.; Suryawanshi, M.P.; Patil, A.P.; Patil, V.B.; Kim, J.H.; Patil, P.S. 2-D to 3-D Conversion of WO3 Nanostructures Using Structure Directing Agent for Enhanced NO2 Gas Sensing Performance. Sens. Actuators A Phys. 2020, 304, 111882. [Google Scholar] [CrossRef]

- Wang, X.; Ansari, D. Superior Sensitivity and Low Detection Limit of NO2 Sensor Based on Layered Tungsten Oxide. J. Environ. Chem. Eng. 2022, 10, 107786. [Google Scholar] [CrossRef]

- Gao, M.; Zhang, W.; Guo, J.; Liu, L. Gas Sensor Based on Two-Dimensional GaSe for Sensitive NO2 Detection. Sens. Actuators B Chem. 2025, 444, 138447. [Google Scholar] [CrossRef]

- Ambi, R.R.; Mali, R.A.; Pawar, A.B.; Mulla, M.G. Temperature Controllable Synthesis of NiO Microflower-like Architecture for Selective Detection of NO2. Ceram. Int. 2025, 51, 31407–31416. [Google Scholar] [CrossRef]

- Du, H.; Li, X.; Zhang, Z.; Li, Q.; Zhao, L.; Wang, J. Ultrasensitive NO2 Sensor Based on In2O3 Nanocubes/SnS2 Nanoflowers Hetero Composites. Sens. Actuators B Chem. 2025, 444, 138277. [Google Scholar] [CrossRef]

- Rakshit, S.; Mondal, S.; Jana, P.C.; Datta, R. CuO Nanoparticles: Structural, Optical and Electronic Properties with Gas Sensing Performance for Efficient Detection of NO2 Gas. J. Mater. Sci. Mater. Electron. 2025, 36, 1260. [Google Scholar] [CrossRef]

- Zhang, S.; Xing, M.; Zhang, B.; Zhang, B.; Luo, N.; Wang, Y. NiMoO4/NiO Heterojunction Based Low Detection Limit High Sensitivity NO2 Gas Sensor. Microchem. J. 2025, 215, 114290. [Google Scholar] [CrossRef]

- Park, J.-C.; Kim, S.; Yuk, Y.; Lee, D.; Oh, I.; Scott, M.C.; Oh, M.H.; Lee, S. Non−noble Metal Catalyst Embedded WO3 Microspheres for Enhancement of NO2 Gas Sensing. Sens. Actuators B Chem. 2026, 447, 138825. [Google Scholar] [CrossRef]

- Biswas, S.; Ranwa, S. Morphology Tunability to Large-Scale Cross-Linked Vertically Grown MoS2 Nanopetals Using Ambient Pressure Chemical Vapor Deposition for NO2 Sensing. J. Electron. Mater. 2025. [Google Scholar] [CrossRef]

- Chen, Q.; Shi, Y.; Zhao, K.; Niu, H.; Liu, J. Highly Sensitive Flexible NO2 Resistive Gas Sensor Based on Polythiophene/Multi-Walled Carbon Nanotubes/SnO2 Ternary Composite. J. Appl. Polym. Sci. 2025, e58105. [Google Scholar] [CrossRef]

- Hambir, S.; Chowdhari, U.; Pattanshetti, S.; Pujari, B.; Jagtap, S. Experimental and Theoretical Investigations of Flowerlike WO3-RGO Heterostructure for NO2 Gas Sensing at Low Operating Temperature. J. Alloys Compd. 2025, 1039, 183137. [Google Scholar] [CrossRef]

- Guo, J.; Chang, X.; Zheng, W.; Zhang, J.; Liu, X. Synergistic Enhancement of NO2 Sensing via Pd-Sensitized Oxygen Vacancy Engineering in WO3 Nanoplates. ACS Sens. 2025, 10, 7661–7669. [Google Scholar] [CrossRef]

- Srivastava, I.; Dwivedi, C.; Srivastava, S.; Dhanda, A.; Husale, S.; Gupta, G.; Singh, P. Oxygen Vacancy Enriched ZnO Nanorods for Highly Sensitive NOx Gas Sensor. Mater. Lett. 2026, 402, 139317. [Google Scholar] [CrossRef]

- Sopiha, K.V.; Malyi, O.I.; Persson, C.; Wu, P. Chemistry of Oxygen Ionosorption on SnO2 Surfaces. ACS Appl. Mater. Interfaces 2021, 13, 33664–33676. [Google Scholar] [CrossRef]

- Gurlo, A. Interplay between O2 and SnO2: Oxygen Ionosorption and Spectroscopic Evidence for Adsorbed Oxygen. ChemPhysChem 2006, 7, 2041–2052. [Google Scholar] [CrossRef]

- Yamazoe, N.; Fuchigami, J.; Kishikawa, M.; Seiyama, T. Interactions of Tin Oxide Surface with O2, H2O AND H2. Surf. Sci. 1979, 86, 335–344. [Google Scholar] [CrossRef]

- Ciftyurek, E.; Li, Z.; Schierbaum, K. Adsorbed Oxygen Ions and Oxygen Vacancies: Their Concentration and Distribution in Metal Oxide Chemical Sensors and Influencing Role in Sensitivity and Sensing Mechanisms. Sensors 2023, 23, 29. [Google Scholar] [CrossRef] [PubMed]

- Giancaterini, L.; Emamjomeh, S.M.; De Marcellis, A.; Palange, E.; Resmini, A.; Anselmi-Tamburini, U.; Cantalini, C. The Influence of Thermal and Visible Light Activation Modes on the NO2 Response of WO3 Nanofibers Prepared by Electrospinning. Sens. Actuators B Chem. 2016, 229, 387–395. [Google Scholar] [CrossRef]

- Epifani, M.; Prades, J.D.; Comini, E.; Pellicer, E.; Avella, M.; Siciliano, P.; Faglia, G.; Cirera, A.; Scotti, R.; Morazzoni, F.; et al. The Role of Surface Oxygen Vacancies in the NO2 Sensing Properties of SnO2 Nanocrystals. J. Phys. Chem. C 2008, 112, 19540–19546. [Google Scholar] [CrossRef]

- Han, X.; Yin, X. Density Functional Theory Study of the NO2-Sensing Mechanism on a WO3 (0 0 1) Surface: The Role of Surface Oxygen Vacancies in the Formation of NO and NO3. Mol. Phys. 2016, 114, 3546–3555. [Google Scholar] [CrossRef]

- Kucharski, S.; Vorochta, M.; Piliai, L.; Beale, A.M.; Blackman, C. Interplay between CO and Surface Lattice Oxygen Ions in the Vacancy-Mediated Response Mechanism of SnO2-Based Gas Sensors. ACS Sens. 2025, 10, 1898–1908. [Google Scholar] [CrossRef]

- Suman, P.H.; Junker-Reiss, B.; Weimar, U.; Orlandi, M.O.; Barsan, N. Unraveling the Gas Sensing Mechanism of Single-Crystalline Sn3O4 Nanobelts Using Operando DRIFT Spectroscopy and Isotopically Labeled Gases. Sens. Actuators B Chem. 2026, 447, 138909. [Google Scholar] [CrossRef]

- Wang, C.; Yin, L.; Zhang, L.; Xiang, D.; Gao, R. Metal Oxide Gas Sensors: Sensitivity and Influencing Factors. Sensors 2010, 10, 2088–2106. [Google Scholar] [CrossRef]

- Staerz, A.; Weimar, U.; Barsan, N. Understanding the Potential of WO3 Based Sensors for Breath Analysis. Sensors 2016, 16, 1815. [Google Scholar] [CrossRef]

- Yang, L.; Marikutsa, A.; Rumyantseva, M.; Konstantinova, E.; Khmelevsky, N.; Gaskov, A. Quasi Similar Routes of NO2 and NO Sensing by Nanocrystalline WO3: Evidence by In Situ DRIFT Spectroscopy. Sensors 2019, 19, 3405. [Google Scholar] [CrossRef]

- Wei, Z.; Zhou, Q.; Lu, Z.; Xu, L.; Gui, Y.; Tang, C. Morphology Controllable Synthesis of Hierarchical WO3 Nanostructures and C2H2 Sensing Properties. Phys. E Low-Dimens. Syst. Nanostruct. 2019, 109, 253–260. [Google Scholar] [CrossRef]

- Toldra-Reig, F.; Serra, J.M. Development of Potentiometric Sensors for C2H4 Detection. Sensors 2018, 18, 2992. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.-H.; Chou, T.-C.; Chen, W.-C.; Niu, J.-S.; Lin, K.-W.; Cheng, S.-Y.; Tsai, J.-H.; Liu, W.-C. Study of a WO3 Thin Film Based Hydrogen Gas Sensor Decorated with Platinum Nanoparticles. Sens. Actuators B Chem. 2020, 317, 128145. [Google Scholar] [CrossRef]

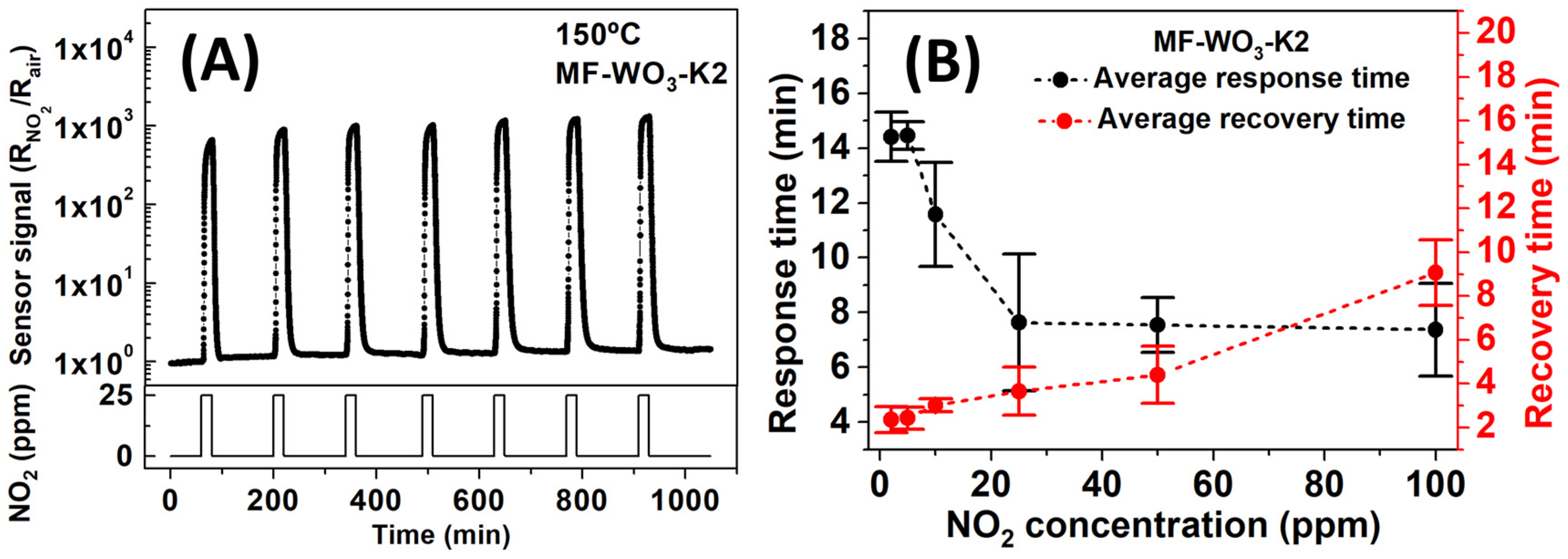

| NO2 Concentration (ppm) | Sensor Signal () (SD) |

|---|---|

| 2 | 59 (7) |

| 5 | 225 (44) |

| 10 | 464 (117) |

| 25 | 927 (231) |

| 50 | 1560 (117) |

| 100 | 2372 (97) |

| NO2 Concentration (ppm) | Average Response Time (min) (SD) | Average Recovery Time (min) (SD) |

|---|---|---|

| 2 | 14.4 (0.9) | 2.3 (0.6) |

| 5 | 14.5 (0.5) | 2.4 (0.5) |

| 10 | 11.6 (1.9) | 3.0 (0.3) |

| 25 | 7.6 (2.5) | 3.7 (1.1) |

| 50 | 7.5 (1) | 4.4 (1.3) |

| 100 | 7.4 (1.7) | 9.1 (1.5) |

| Constants | ||||

|---|---|---|---|---|

| Values |

| WO3 Material | Operating Temperature (°C) | NO2 Concentration (ppm) | Sensor Signal | Response/ Recovery Times (s) | LOD | Reference |

|---|---|---|---|---|---|---|

|

MF-WO3-K2 sensor | 150 | 5 | 225 * 226 ** 22,578% *** | 870/144 | 65 ppb | This work |

| WO3 Nanofibers | 150 | 10 | 220 * | - | 0.5 ppm | [10] |

| WO3 Microflowers | 150 | 100 | 55.5 * | 9/225 | 1 ppm | [64] |

| WO3 nanosheets | 100 | 10 | 460 * | 54/63 | - | [9] |

| WO3 Layer-like | 160 | 5 | 106 ** | 32/13 | - | [65] |

| GaSe | 150 | 2 | 83% *** | 80 ppb | [66] | |

| NiO | 200 | 5 | 4.2% *** | 6/78 | [67] | |

| In2O3/SnS2 | 180 | 5 | 15.61 * | 34/65 | 25 ppb | [68] |

| CuO | 200 | 10 | 30% *** | 1 ppm | [69] | |

| NiMoO4/NiO | 160 | 1 | 16.18 * | 32/717 | 4.7 ppb | [70] |

|

WO3 S: WO3 | 150 | 5 | 5.6 * 578 * | 186/>3000 185/130 | - 54 | [71] |

| MoS2 nanopetal | 100 | 100 | 61.78% *** | 22/225 | 1 ppm | [72] |

| PTh/MWCNT/SnO2 | 150 | 100 | 76.8% *** | 23/75 | - | [73] |

|

WO3-rGO heterostructure | 100 | 5 | 77 ** | 24/457 | - | [74] |

| Pd-WO3-Ov | 160 | 10 | 106.44 * | 37.2/28.5 | 51 ppb | [75] |

| ZnO nanorods | 250 | 50 | 8.8 * | 28/20 | - | [76] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morais, P.V.; Suman, P.H.; Orlandi, M.O. NO2 Detection Using Hierarchical WO3 Microflower-Based Gas Sensors: Comprehensive Study of Sensor Performance. Chemosensors 2025, 13, 390. https://doi.org/10.3390/chemosensors13110390

Morais PV, Suman PH, Orlandi MO. NO2 Detection Using Hierarchical WO3 Microflower-Based Gas Sensors: Comprehensive Study of Sensor Performance. Chemosensors. 2025; 13(11):390. https://doi.org/10.3390/chemosensors13110390

Chicago/Turabian StyleMorais, Paulo V., Pedro H. Suman, and Marcelo O. Orlandi. 2025. "NO2 Detection Using Hierarchical WO3 Microflower-Based Gas Sensors: Comprehensive Study of Sensor Performance" Chemosensors 13, no. 11: 390. https://doi.org/10.3390/chemosensors13110390

APA StyleMorais, P. V., Suman, P. H., & Orlandi, M. O. (2025). NO2 Detection Using Hierarchical WO3 Microflower-Based Gas Sensors: Comprehensive Study of Sensor Performance. Chemosensors, 13(11), 390. https://doi.org/10.3390/chemosensors13110390