Abstract

Electronic noses (e-noses) are devices based on combining different gas sensors’ responses to a given sample for identifying specific odor fingerprints. In recent years, this technology has been considered a promising novel tool in several fields of application, but several issues still hamper its widespread use. This review paper describes how some physical confounding factors, such as temperature, humidity, and gas flow, in terms of flow direction and flow rate, can drastically influence gas sensors’ responses and, consequently, e-nose results. Among the software and hardware approaches adopted to address such issues, different hardware compensation strategies proposed in the literature were critically analyzed. Solutions related to e-nose sensors’ modification, design and readout, sampling system and/or chamber geometry design were investigated. A trade-off between the loss of volatile compounds of interest, the decrease of sensors’ sensitivity, and the lack of fast responses need to be pointed out. The existing body of knowledge suggests that the e-nose design needs to be highly tailored to the target application to exploit the technology potentialities fully and highlights the need for further studies comparing the several solutions proposed as a starting point for the application-driven design of e-nose-based systems.

1. Introduction

Electronic noses (e-noses) are devices that mimic the olfactory system by combining nonspecific gas sensors’ responses to identify a specific odor or a smell-print [1]. This technology is based on interactions between gas sensors and volatile chemical compounds, both organic (VOCs) and inorganic, such as NH3, H2S, or greenhouse gases, generally representing a class of compounds with high vapor pressure at room temperature responsible for odor perception. As these volatile compounds usually result from chemical reactions, their detection can be used to monitor processes in different fields of application [2,3], including the food industry [4,5,6], for monitoring food quality and production; healthcare [7], for monitoring changes in metabolic processes; or environmental studies [8,9], for monitoring industrial emissions and their impact on citizens’ daily life. Comparing the structure of the mammalian olfactory system with a generic e-nose, four components can be identified: (1) the biological nose structure, which corresponds to the sampling block in e-noses to collect the target gas from its source; (2) the olfactory cells, which correspond to an array of specific and/or nonspecific gas sensors; (3) the olfactory bulb, in which acquisition of the signals is performed on the biological side, while in e-noses this role is played by standard analog signal acquisition systems; and (4) the central nervous system which, in biology, is where signals are processed, whereas in e-nose systems, machine learning techniques are implemented to reconstruct odor fingerprints [10]. With respect to standard analytical techniques (such as GC-MS), the e-nose does not pretend to identify specific volatile compounds in the target gas but to identify specific patterns of the whole gaseous mixture [11]. The advantages of the e-nose, especially over chemical analyses, include low cost, ease of use, and the ability to provide a fast response to complex mixtures, making it a powerful technology for volatile chemical compound analysis.

Despite e-nose technology being widely recognized as a potentially groundbreaking technology since its introduction, several challenges still limit the applications of gas sensing and e-noses in research activities; [12] real-life and industrial applications are still very rare, with some exceptions related to environmental odor monitoring, especially in Europe, where the use of e-noses is sometimes prescribed in plant permits [13,14,15,16]. The main issues with real-life application of e-noses are related to the poor stability of sensors’ responses due to the well-known effects of sensor drift, scarce reproducibility, and cross-sensitivity to several physical factors [12], which determine the kinetics and thermodynamics of the surface chemical reaction between the gas and the sensor active layer, and therefore significantly affect the sensor’s response [17]. Over the past several years, software strategies have been widely developed for addressing sensor drift compensation and scarce reproducibility by means of calibration transfer techniques, while for cross-sensitivity to physical factors, two approaches can be considered. First, the proper design of the system hardware, including the sampling system, the sensor chamber, and the sensors, can be optimized to reduce such interferences physically. Second, the effect of the interferences can be compensated for using software strategies, such as compensation algorithms based on empirical models [3,18]. Regarding software strategies [19], there are a wide range of studies specifically discussing the possibility of compensating for the effects of humidity variations by means of empirical models and machine learning algorithms, which entails the need to carry out specific training for the acquisition of sensors’ responses accounting for different humidity levels [20,21,22,23,24]. For example, Yan et al. [25] proposed a compensation model based on a power–law response. They used absolute humidity values to compensate for RH and temperature at the same time. The absolute humidity was fitted exponentially with the response of the sensor in order to compensate for humidity variations. On the other hand, Nenova et al. [24] implemented artificial neural networks (ANNs) to compensate for sensors’ responses to both temperature and RH variations. These correction approaches based on empirical models to be applied after data acquisition can provide an interesting perspective not only for humidity but also for other interfering factors such as temperature and flow. Nonetheless, since interferences can also negatively affect the quality of the signal, for instance by reducing sensors’ sensitivity to the target volatile chemical compounds, the implementation of hardware compensation strategies becomes fundamental when high sensor sensitivity is needed. Indeed, such strategies can generally include actions on the sampling system leading to pre-treatment of gaseous mixtures to mitigate their content of water [26], on the sensors’ chamber design properly tuning the flow rate and direction of the samples to be analyzed [27,28] and on the sensors in terms of sensors’ design or sensors’ readout to disfavor water molecules adsorption on sensors’ surface, promote the adsorption of the compounds of interest and improve the quality of sensors’ signals during the acquisition [29,30,31].

This review paper aims to provide an overview of the current limitations and proposed solutions when designing either an electronic nose system or a new study based on e-nose technology. Since the literature regarding gas sensing is extensive, this review focuses on the most relevant methods reported in the literature to overcome such criticalities for e-nose technology hardware development, including gas sensor selection and design, sample gas conditioning, and sensors’ chamber design and geometry.

In Section 3, an overview of the effects of the most relevant confounding factors is presented. Based on the literature and on the author’s direct experience, the following confounding factors, which are considered particularly critical in e-nose applications, have been selected [26]: target gas humidity (Section 3.1), temperature (Section 3.2), and flow (Section 3.3). Even if there are studies reporting possible effects of target gas pressure on sensors’ response [32,33], we decided to neglect this possible source of errors, as its effects appear to be small for relatively small target gas pressure variations [34,35], and most e-nose applications are usually designed to be operating at approximately ambient pressure. In Section 4, hardware compensation strategies aiming to improve the quality of e-nose sensors’ responses are reported in three different paragraphs: gas sensor choice and design (Section 4.1), sampling strategies to limit the effects of the confounding factors described in Section 3 (Section 4.2), and sensors’ chamber geometries (Section 4.3). Even if the confounding factors mentioned in Section 3 are, in some systems, compensated for by using data processing strategies, we consider these approaches out of the focus of the review and, therefore, they will not be described in this paper. Section 2 is an introductory paragraph to present the most used technology in gas sensors for e-nose applications, and Section 5 reports the analysis of the findings.

We selected 226 publications, including journal papers, book chapters, norms, and patents, ranging from 1982 (the year of the first publication describing the electronic nose) to June 2023. The papers were selected from Scopus, and works published in the last 20 years have been preferred with respect to works published before.

2. Sensor Technologies Used in E-Nose Systems

Various types of gas sensors are typically used in e-nose systems, differing in working principle, sensitivity, selectivity, response time, energy consumption, reversibility, and fabrication cost [36,37]

In this section, we provide a short description of the most common sensor technologies used in e-nose systems grouped by working principle:

- Chemo-resistant

- ο

- Conducting polymers (CPs): The first e-nose prototypes were realized with this kind of sensor. When exposed to target gases at ambient temperature, polymer conductivity is changed, with the transduction mechanisms being still unknown. CPs can be either used as they are, doped to enhance their response, or modified by adding other polymers, resulting in a composite polymer [38,39];

- ο

- Metal oxide semiconductor (MOSs): Changes in resistance are due to redox reactions involving the oxygen of the semiconducting metal oxide. The magnitude and the dynamic of the response are volatile compound-dependent. MOS sensors must be operated at temperatures between 197 °C and 397 °C, the temperature range in which oxygen is ion-sorbed as O−, enhancing the redox reactions [40]. MOS sensors are by far the most commonly used in e-nose systems because of their low cost, high sensitivity to several families of compounds (ppm and sub-ppm levels), and high level of customization. The most diffused metal oxide materials are semiconducting transition metals (e.g., TiO2, Fe2O3, NiO, and Cr2O3) and post-transition metals (e.g., SnO2 and ZnO) because of their facilitated ability to create electron-hole pairs [41]. MOS sensors can comprise n-type or p-type materials, referring to the capacity of the materials to interact with the target gases using free positive or negative charges due to the abundance of electrons in the valence band [40,42]; as a consequence of this different interaction mechanism, the direction of the sensor’s resistance to reducing and oxidizing gases will be different, as indicated in Table 1;

Table 1. MOS Sensors: Resistance changes for n-type and p-type sensors when exposed to gas [40].

Table 1. MOS Sensors: Resistance changes for n-type and p-type sensors when exposed to gas [40]. - ο

- Graphene and carbon nanotubes (CNTs): The interplay between gas molecules and carbon-based materials leads to the exchange of charges between the sensing layer and the gas molecules. This process alters the material’s conductivity, facilitating the identification of diverse gas concentrations. Additionally, they exhibit extended response and recovery times [43].

- Chemically sensitive field-effect transistors (ChemFETs): This sensor utilizes MOSFET technology and operates based on the principle that the MOSFET’s threshold voltage shifts upon interaction with specific gases. This interaction is facilitated via a catalytic metal, which leads to corresponding alterations in the work functions of both the metal and oxide layers. These work function changes are driven by the polarization of the surface and interface of the catalytic metal and oxide layer when exposed to the gas on the catalytically active surface. To allow for the sensor’s physical changes, the metal insulator interface must be accessible to the gas. Consequently, a porous gas-sensitive gate material is employed to facilitate gas diffusion into the material [44].

- Capacitive sensors: Capacitive sensors are composed of dual interdigitated electrode arrangements mirroring the configuration of the plates in a conventional capacitor. These sensors measure alterations in the dielectric coefficient of the polymer situated between the electrodes when the analyte is absorbed. Consequently, chemocapacitors (also known as di-electrometers) hinge on shifts in the dielectric attributes of the sensing material following the introduction of an analyte [45].

- Electrochemical (EC): Reduction or oxidation happens on catalytic electrode surfaces, given that this type of sensor is more selective than MOS and CP [2,46,47];

- Piezo-based chemical sensors:

- ο

- Quartz crystal microbalance (QCM): Quartz is used as an oscillator by applying a voltage difference to its ends. The surface is coated with various materials, and when target compounds are absorbed, the quartz oscillation frequency changes with the mass change [48,49];

- ο

- Surface acoustic wave (SAWs): These consist of coated piezoelectric material. The coating is done with sensing material, typically polymeric. Voltage deformations are induced, and a reaction between the target gas and the sensing material causes changes in deformations’ velocity and attenuation [48,50];

- Optical sensors: These belong to a family of sensors where the changes in optical properties (color, transmission, etc.) of a sensing element are used to detect volatile compounds or their patterns [37,44].

- Photoionization detector (PID): Target gases are ionized by ultraviolet light with high-energy photons. The ions produce a current that is the output of the detector; this type of sensor only provides an indication of the total amount of volatile chemical compounds in a gaseous mixture [51,52].

This list is provided as a reference to the reader for understanding the different sensor types mentioned in the next sections. Indeed, since MOS sensors are the most commonly used in e-nose systems, most of the approaches discussed in this review refer to this type of sensor. Other sensor types are also mentioned in some cases, although the relevant scientific studies are scarce.

3. Physical Factors Affecting E-Nose Sensor Responses

3.1. Humidity

Humidity is one of the main interferents often discussed in literature because it significantly affects sensors’ responses, altering their sensitivity to the target gases [53,54]. The moisture content of the air analyzed by e-noses is generally expressed in terms of relative humidity or, less frequently, absolute humidity. Relative humidity (RH) is the ratio between the vapor pressure of air and its saturation vapor pressure, usually expressed in terms of a percentage value indicating the amount of moisture stored in air under those conditions (i.e., temperature and pressure) with respect to the maximum capacity of air to contain water under the same conditions. On the other hand, absolute humidity represents the amount of water present in a volume of dry air, generally expressed in g/m3.

Several studies have dealt with e-nose applications in many different fields, such as healthcare and diagnostics, environmental odor monitoring, or industrial process control, discussing the effect of the moisture levels recorded by the humidity sensor installed in the e-nose chamber on the sensors’ responses.

As a general rule, the presence of humidity results in a shift of the whole baseline of the e-nose sensors, reducing the amplitude of sensors’ responses and, consequently, decreasing the sensors’ sensitivity.

The effect of humidity on MOS sensors is particularly studied since those sensor types are the most used in e-nose technology. Yan et al. reported ethanol analyses at different absolute humidity values (namely, 0.05, 0.25, and 0.35 g/m3) employing MOS sensors including commercial ones, such as TGS-2602 and MP135, and home-made ones based on WO3 and SnO2, resulting in a decrease of the sensors’ responses with the increase of water vapor content regardless of concentration [25]. A decline of gas sensors’ responses was also observed by High et al. when looking at the ratio between the resistance in air and the resistance of pure gases analyzed under laboratory conditions by means of In2O3 sensors [55] and by Yoon et al. with respect to the corresponding air-dry analysis [56]. By plotting sensors’ responses, temperature, and relative humidity onto a 3D surface plot, Abdullah et al. observed the lowest sensor responses when temperature and humidity were the highest, anticipating the effect of temperature on sensors that will be discussed in the next paragraph [57]. Similar trends can be observed in other types of sensors, such as SAW, optical, electrochemical, and QCM sensors, always showing a competitive mechanism of interaction between volatile chemical compounds and water molecules intervening in the working mechanism on which the outputs of sensors are based [53,58,59,60,61,62,63,64,65,66,67].

Clearly, the application of e-noses for environmental odor monitoring in the field is particularly critical in this regard because of the well-known variability of humidity in ambient air. Indeed, the variation of humidity levels could interfere with the working mechanisms of low-cost sensors usually employed in air quality measurements, such as MOS, electrochemical, and nondispersive infrared sensors [68,69]. As an example, Romain et al. observed a decrease in sensors’ responses with the increase of the relative humidity level during field experiments [70,71]. The influence of such parameters, such as seasonal meteorological effects typical of long-term applications, clearly emerged in an in-field e-nose application developed by De Vito et al. for the estimation of benzene by means of a device equipped with seven MOS sensors installed in an urban area [72]. With the purpose of developing a sensor array dedicated to environmental odor monitoring, the behavior of several types of MOS sensors according to different humidity rates was observed by Helli et al., underlining a decrease in sensitivity of some sensors (some of them showed responses independent from target gases’ water content), towards two environmental pollutants, i.e., H2S, NO2, analyzed at different humidity levels with dry atmosphere as reference air [73]. Sohn et al. demonstrated the humidity cross-sensitivity of conducting polymer sensors observing a shift in the plot of sensors’ response PCA on data regarding the monitoring of odor abatement performance of a biofilter [74].

It should be further highlighted that, besides the humidity content of the sample gas to be analyzed, the humidity level of the reference air should be considered. Suppose the reference air and the sample have different humidity contents. In that case, it will result in a variation in the sensor’s resistance when the input gas is changed from the reference air to the sample. This variation is not correlated with a different concentration of volatile chemical compounds. Thus, a proper setting of comparable water content between the reference air and the target gases is required. The two contributions to the sensor’s response would need to be separated [67,73,75].

3.2. Temperature

When speaking about the effect of temperature on e-nose sensors’ responses, two different types of temperatures should be considered: the sensor’s operating temperature and the gas sample’s temperature.

The sensor’s operating temperature, i.e., the temperature at which the active, sensitive layer is heated, is a crucial parameter, especially for MOS or graphene-based sensors, as the surface reactions highly depend on the sensing element temperature [40,76]. CP sensors work at ambient temperature, but it has been demonstrated that an increase in working temperature can increase sensitivity and decrease sensor poisoning up to approximately 70 °C, when the polymers start degrading [40,76].

The effect of the sensor’s temperature is widely studied in the scientific literature [77,78,79,80,81]; it affects sensor surface reactions, which can lead to different responses. In the literature, three different approaches for this effect are presented. On one hand, the temperature modulation approach results in operating sensors at different temperatures in the same array. This can lead to an increase of information that can be used for better classification [77,78]. Secondly, the operating temperature of the sensors can be optimized to increase mutual information [79], and finally, it has been proved that stabilization of the operating temperature with closed-loop control systems can increase sensors’ performance [80]. Even if the proposed approaches can now enhance the quality of the signal, some limitations to these solutions still need to be closely investigated, starting from the measurement of the actual operating temperature on the sensor surface in the most-used gas sensors or the effect of temperature variations on the sensor’s surface reaction. For this reason, this work will focus only on the effects of the gas temperature on the sensors’ responses [40,76].

Indeed, some studies have evaluated the impact of the gas temperature on MOS sensor responses: Romain et al. [70] observed that when e-noses based on MOS sensors are used in the field for environmental odor monitoring, a decrease in the ambient air temperature results in an increase in the sensor resistance, which in turn can alter the MOS sensor responses. A similar behavior was observed by Kashwan et al. [22], who applied an e-nose for the analysis of tea flavor, and Abidin et al. [81], who also reported a decrease in the sensors’ response to different levels of toluene in the range between 25 °C and 40 °C. Huerta et al. [81] came to the same conclusion in their work when they monitored the air quality in a toilet, as did Peterson et al. [82] in the measurement of nitrogen dioxide and ozone in urban environments. One work by Knobloch et al. [83] presents the dependence of target gas temperature on conductive polymer response. The authors conclude that the change in the response could be related to the fact that changes in temperature lead to a greater or lower concentration of volatiles in the headspace, which will generate different sensor responses, but further studies need to be carried out to evaluate the exact effects, as this temperature effect can mask sensors’ responses that can affect classification.

3.3. Flow

One of the main factors affecting gas sensors’ response is the sampled gas flow, as proven by several studies focusing their attention on the impact of this factor.

When speaking about the variations of gas flow over e-nose sensors, it should be considered that, in some applications, sampling and analysis are performed at different times. In contrast, in others, sampling and analysis occur at the same time. Considering the first kind of applications, the storage of the target gas via different techniques (e.g., Tedlar® bags [84], NalophanTM bags [85], adsorption materials [86], etc.) is required, and a later analysis is performed. In these cases, the central aspect that should be taken into account is the chamber geometry and the stability of the gas flow rate during the analysis phase. On the other hand, where there is no storage of the samples, the sensors’ response can be influenced by the flow regime of the target gas. Considering, for example, the biomedical field, e-noses are widely applied to exhaled breath analysis [87,88], which is intermittently generated and characterized by specific flow waveforms [89] that, if not adequately controlled, can result in artifacts in the sensors’ responses. Furthermore, in environmental monitoring applications where e-noses are typically installed outdoors in the open air, wind can cause alterations to the flow regime inside the sensor chamber. Gas flow variations can also occur in home or car air quality monitoring applications and home appliances, where internal fans typically affect the gas flow conditions.

However, to be more specific, the effect of gas flow should be considered by distinguishing three different flow-related aspects.

3.3.1. Flow Rate

The standard approach for e-noses requires that the target gas flows continuously in the sensor chamber, and the flow rate is the first flow-related aspect affecting sensor responses discussed in this work.

In a study by Madhavi et al. [28], the authors demonstrated the relationship between flow rate and sensors’ response. This study first presents a mathematical simulation of an MOS sensor’s (TGS2620, Figaro Engineering, Osaka, Japan) responses to changing flow rate and position of the sensor in the chamber. Then, measurements were performed in a setup identical to the simulated one. Five different flow rates (0.3, 0.6, 1.2, 1.8, and 2.4 L/min) and three different test gases (methanol, ethanol, and propanol) were considered. The authors conclude that response time decreases with flow increase while the amplitude of sensors’ response increases with increasing flow, thus demonstrating that increasing the gas flow rate improves the sensors’ responses in both terms of response rate and intensity. The authors also simulated the temperature on the sensor plate, which obviously decreases with the flow. As mentioned in the previous paragraph, up to now, it has not been possible to directly measure the working temperature in this kind of sensor, as they work in an open-loop control configuration, so the considerations of this effect are based only on the simulations, and no direct measurement is reported.

Despite no direct measurements of the relationship between gas flow rate and MOS sensor operating temperature being reported in the literature, this aspect is crucial because the sensor sensitivity is highly dependent on the operating temperature [40]. Similar considerations are presented by Sedlak et al. [90] regarding polymeric homemade sensors. This work tests the sensor with a concentration of 3ppm of NO2 with flow equal to 0.1, 0.5, 0.8, and 1 L/min. Sensitivity, response time, recovery time, limit of detection (LOD), and repeatability are considered important parameters to be evaluated. Experimental results showed an improvement of all the parameters with increasing flow, except repeatability.

Conversely, some works [91,92] propose another approach, called stop-flow operation, where the chamber is filled up with the target gas, and then the inlet and outlet ports of the chamber are closed, and the flow is stopped. In all the works considered, the authors show that the sensors’ response highly depends on the flow rate, which can be regarded as equal to zero in stop-and-wait mode. When flow is stopped, the sensors’ response changes due to the change in the flow rate, generating a transient reading before reaching a new plateau. Since the transient is related mainly to the flow rate change, this part of the signal does not give any information on the sample volatile chemical compound’s content and therefore has to be discarded from the analysis. This leads to a loss of data that can be extracted from the sensors’ response curve since in other works, it has been proven that the transient phase is also an important source of information [12,93]. Despite the abovementioned limitations of the stop-flow operation mode, this mode can be combined with the normal operation mode to increase measurement information [91]. Indeed, considering the different sensor responses when varying the flow rates during the analysis of one target gas, the quantity of information provided by each sensor is increased, thereby introducing the concept of “flow modulation” to the sensors’ response. This operation mode may, in principle, improve e-nose classification performance, but further studies are required to analyze the effects in more detail.

3.3.2. Flow Direction

The direction of the target gas flow concerning the sensors’ active surface layer also affects sensor response. Since the beginning of the century, this aspect has been widely investigated via simulations and experiments. Lezzi et al. [94] proposed a simulation model considering different orientations and sensor distances with respect to the chamber inlet. The authors concluded that having the sensor near the chamber input and perpendicular to the flow can reduce the time needed to have a constant concentration on the sensors’ surface, reducing rising time and increasing the sensors’ response. Shyla et al. [95] confirmed this result, simulating how orientation affects gas speed on the sensor’s surface. They concluded that the lower the gas speed on the sensor’s surface, obtained with the perpendicular configuration between the flow and the sensors, the larger the time window in which a single molecule in the sampled gas can react with the active layer, resulting in higher and more complete response rate. Moreover, in a work by Sedlack et al. [90], which was already cited in the previous paragraph, besides the flow rate, the authors studied the effect of the orientation of the gas sensor on its response. In this experiment, the flow was set equal to 1 L/min and the concentration equal to 3 ppm of NO2. Four different orientations were considered (0°, 45°, 90°, and 270°), with 0° identified as parallel to the flow direction. Sensitivity, response time, recovery time, limit of detection (LOD) repeatability, and signal-to-noise ratio were evaluated. All the parameters, excluding repeatability, improved by increasing the angle from 0° to 90°. Also, when the angle was set equal to 270°, repeatability had an opposite trend compared to the other parameters, i.e., improving when all the others worsened. Another work by Ryu et al. [96] came to the same conclusion by testing an MOS sensor, changing the gas impact angle and the distance between the gas inlet and the sensor active layer. Three different angles were tested (0°, 45° and 90°), considering 0° the condition when the flow direction was parallel to the active layer. NO2 was considered the target gas, and its concentration was 5 ppm. Sensitivity was considered the target parameter for evaluating best performance. Results show that the best configuration to enhance sensitivity was at 90°. Finally, there is another work by Scott et al. [97] on quartz crystal microbalance gas sensors (QCM), presenting results that seem to contrast those previously mentioned [97]. In this study, the performances of an array of three gas sensors are compared. Three different experimental setups were considered: (a) sensors parallel to the flow direction, (b) sensors perpendicular to the flow direction, and (c) sensors parallel to the flow direction, placing a baffle between the gas inlet and the sensors. Response time (i.e., the time to reach a stationary response) was considered the target parameter, given that configuration (c) showed a faster response than configuration (b), which in turn showed better results than configuration (a). These results can be interpreted in different ways. First, QCM sensors rely on a transduction mechanism based on mechanical oscillations of the active part, which can be more sensitive to flow impact as it can directly modify the QCM vibration. Furthermore, in this work, a new element is introduced with respect to all the works mentioned until now, which is the consideration of how the flow regime condition in the chamber affects the sensors’ response. This is indeed the third flow-related aspect affecting sensors’ behavior investigated in the next paragraph.

3.3.3. Chamber Fluid Dynamic

In 2004, Scott et al. [97] introduced the observation that e-nose chamber fluid dynamics affect sensors’ responses. In this study, the presence of a baffle increases the performance of the sensors in terms of response time, resulting in a faster response compared to the perpendicular configuration, which on the other hand was proven to perform best in other works [90,94,95,96].

All the authors [27,94,98,99,100,101,102,103,104,105,106,107] focusing on the sensors’ chamber design agree that, inside the chamber, stable and uniform conditions should be reached as soon as possible. To ensure stable and uniform conditions, laminar flow is required in the chamber, with no stagnant or recirculating zones, which may result in a different exposure of the sensors to the target gas. Moreover, to ensure a reproducible test, all the sensors should come into contact with the gas simultaneously. Finally, it is important to remember that in ideal conditions, the concentration in the e-nose chamber can be described as [108]:

where C(t) is the function of the concentration, Cin is the input concentration, fin is the input flow rate, and V is the volume. According to Equation (1), the time to reach the steady state increases with the chamber volume and decreases with the flow rate. A possible approach to ensure a fast response would be to reduce the chamber volume to a minimum, which typically depends on the number and size of sensors used.

4. Hardware Compensation Strategies

This section presents the hardware strategies that can be implemented in e-nose systems to compensate for the physical factors affecting sensors’ responses, as described in the previous section.

Such solutions include modifications and specific designs related to the following components: (a) the sensors, in terms of either fabrication methods or readout; (b) the design of the sampling system; and (c) the chamber geometry.

As shown in Table 2, depending on the hardware component under consideration, the effect of different physical factors can be compensated for: acting directly on the sensors may reduce the effects of both humidity and flow, whereas a suitable design of the sampling system may also help compensate for temperature variations. On the other hand, the optimization solely of the chamber geometry and sampling gas flow can provide a solution for gas flow variations only, without counteracting the effects of sample humidity and temperature.

Table 2.

E-nose hardware components and relevant physical factors whose effects on the sensors’ responses can be reduced via their optimization.

4.1. Gas Sensors

A key aspect for tuning the performance of gas sensors, especially in terms of sensitivity and selectivity, is represented by the physical and chemical microstructures of the active materials deposited on gas sensors’ surfaces, whose interactions with the gaseous mixtures result in sensors’ responses [109]. This strictly depends on the material deposition methods (e.g., thermal evaporation, electron beam evaporation, sputtering, ion cluster deposition, chemical vapor deposition, inkjet printing, etc.), which, for example, in the case of MOS sensors influence the porosity and the size of the grains of the active materials [110,111] and consequently their properties. A general rule relies on the need to increase surface-to-volume ratio as much as possible to improve the amount of exchange surface-promoting molecule interactions [111]. Thus, recent discoveries in recent years have boosted the study and development of novel low-dimensional structured materials for gas sensing applications, such as 2D material-based sensors [30,112]. Considering the promising results obtained, different strategies based on the development and design of the sensors themselves have been investigated to reduce the influence of external factors on their responses. In the literature, modifications to the system’s hardware, in terms of sensors design, formulation, and signal acquisition have been described, especially for addressing the unwanted effects related to humidity and flow variations.

4.1.1. Sensors’ Modifications to Reduce Humidity Dependence

Extensive research has been carried out to improve the performance of gas sensors in environments characterized by high variability of the humidity level [113]. Indeed, chemo-resistive sensors, which are the most commonly used in e-nose systems because of their low price and partial specificity towards volatile molecules, have as a main drawback a strong dependence to the humidity of the analyzed gas [114]. The huge number of studies dealing with the interference of humidity with chemo-resistive sensors’ responses, including sensors based on polymers, metal oxides, and two-dimensional layered nanomaterials as sensitive materials, has been recently summarized by Wang and Zhou [30]. For this reason, in this paragraph, we decided to limit our discussion on this specific topic to a general overview of the results reported in the above-mentioned review paper, together with some considerations. According to the authors [30], anti-humidity strategies based on sensor characterization can be categorized into:

- surface engineering;

- physical isolation;

- working parameter modulation;

- novel material development.

The performance of the sensors modified according to these anti-humidity strategies has been tested in laboratory conditions via exposure to pure gases (namely H2, acetone, benzene, NOx, CO, CO2, trimethylamine, ethanol, NH3, H2S, toluene, formaldehyde, and acetylene), generally at low concentrations with some exceptions [115,116,117,118], at different humidity levels ranging from dry conditions to 98% RH. The scope of such studies often increases the sensitivity of sensors, reducing interferences in order to make them able to detect very low concentration levels of some specific compounds, sometimes few ppm or ppb levels, in very high-humidity matrixes, such as human breath [114,119,120,121,122]. Consequently, a key point of investigation is the improvement of the independence of sensors’ responses from humidity without compromising their sensitivity to target gases.

Surface Engineering

Surface engineering for gas sensor modification includes the doping of the sensitive materials with noble metals (e.g., Au, Ag, Pd, Pt, Ru, or Rh) or other elements, such as lanthanide elements (e.g., Pr, Ce, or Tb), transition metals (eg.g., Ni or Co), aluminum or antimony; the addition to the formulation of hydrophobic or hydrophilic materials; and post-treatments for ready-to-use chemo-resistant sensors. Noble metals have advantages because water molecules preferentially adsorb on their surface, thanks to their strong affinity for water, protecting the chemisorbed oxygen of the sensitive materials and catalyzing gas-sensing reactions [115,123,124,125]. In the same way, other elements work as adsorbers of hydroxyl groups from water, facilitating the formation of ionized oxygen species [122,126]. Even if the doping of sensitive materials with other elements reported interesting results, the functionalization with noble metals should be preferred because the humidity tolerance is generally achieved with an increase of sensitivity of sensors with respect to the unmodified gas sensors [124,127,128,129].

A different strategy to limit the influence of water molecules on sensors’ responses without affecting sensors’ sensitivity is to coat the sensors with a hydrophobic layer, which acts on the water contact angle, decreasing the hydrophilicity of the sensors surface. The wettability properties of sensitive materials can be modified by adding organic components (e.g., polydimethylsiloxane (PDMS), polyaniline (PANI), 3-aminopropyltriethoxysilane (APTES), polyvinyldenefluoride (PDVF), black phosphorous (BP), octadecyltrichlorosilane (OTS), polysterene (PS)) or/and inorganic hydrophobic materials (e.g., graphite, carbon, multiwalled carbon nanotube (MWCNT), SnS2, ZrO2, Y2O3, CeO2) to the sensitive materials [130]. In the same way, hydrophilic materials (e.g., NiO, CuO, anhydrous calcium silicate (CS), SiO2) can be used as sensors coating, serving as water accumulators protecting the active sites of sensors from water molecules interference. In this case, the quantity of hydrophilic material must be properly tuned to avoid the opposite effect of enhancing the humidity dependence of sensors [131]. Apart from chemo-resistant sensors, the implementation of hydrophobic or hydrophilic coating on the sensors’ surface is an approach that is widely employed for preventing humidity interference on other macro-categories of sensors implemented in e-nose arrays, such as piezoelectric and optical sensors [132]. The layer-by-layer (LbL) alternate adsorption of oppositely charged polyions (i.e., polycations such as polyallylamine hydrochloride (PAH) or polydiallyldimethylammonium chloride (PDDA) and anionic compounds, such as tetrakis-4-sulfophenyl porphine (TSPP) or tetrakis-4-carboxyphenyl porphyrin (TCPP)) is widely employed to prevent humidity interference in piezoelectric sensors [133]. Therefore, hydrophobic substrates consisting of organic or inorganic materials, such as reverse-phase silica thin-layer chromatography plates, polyethylene terephthalate (PET) film, cellulose acetate membrane, silica gel plate, polypropylene membranes, PVDF membrane, acetate sheet, or TiO2 nanoporous film, can be incorporated into colorimetric sensors’ surfaces to immobilize sensing probes, mitigating the physical and chemical changes occurring in water molecule interaction in the detection system [59]. In the same way, coatings of hydrophobic materials, such as reduced graphene oxide (rGO) [134], MWCNT [135], or methyl trichlorosilane solution [136], or hydrophilic materials, such as sol-gel CuO film [137], as well as post-treatment, such as proton beam irradiation, plasma fluorination, or chemical etching, are highlighted as treatments that improve resistance to humidity without negatively affecting the sensitivity of sensors, unlike fluorocarbon plasma [138].

An interesting possibility for increasing the humidity tolerance of sensors is the high-humidity aging of sensors since, as reported in some studies, sensors have a sort of “memory” effect on water molecules [139,140]. Indeed, Itoh et al. [141] studied the effect of high-humidity aging on Pd, Pt, and Au-SnO2 sensors compared with room air-aged and dry air-aged sensors, investigating at the same time the superimposed effect of two different anti-humidity strategies, namely noble metal doping and humidity-aging. Sensors were placed in a quartz tube in which either humid air, with a relative humidity of up to 90%, or dry synthetic air flowed at a rate of 250 mL/min. In the case of room air-aging, sensors were positioned in the quartz tube with both ends opened to ambient air. The quartz tubes were heated to 400 °C for two weeks and then cooled to ambient temperature and installed in the gas sensing measurement system. The three batches of sensors were tested with a synthetic mixture of VOCs at three different humidity levels (namely 25%, 50%, and 75%), demonstrating the independence of the humidity-aged Pt, Pd, and Au/SnO2 sensors from humidity variations occurring in working conditions. However, even though dry air-aged sensors showed higher responses than high humidity-aged sensors and room air-aged sensors at low humidity levels, the high humidity-aged sensors showed a response that was almost constant under all the humidity conditions. Moreover, the authors evaluated the effect of the humidity-aging treatment on Pt, Pd, Au/SnO2, and Pt/SnO2 sensors, resulting in a poorer performance by Pt/SnO2 than the sensors loaded with Pd and Au. While in this case the presence of Pd had clearly a central role in protecting sensors from water molecule adsorption, other researchers tried to understand the effect of humid aging on the oxygen adsorption in SnO2 gas sensors. Suematsu et al. [142] evaluated the oxygen adsorption properties and hydrogen sensing properties of SnO2 sensors after aging them in humid air at 580 °C. The authors found that hydroxyl poisoning was suppressed via humid aging because this treatment produces an increase in the amount of oxygen adsorbed, thereby increasing the electrical resistance in air. Consequently, sensor responses to hydrogen, even in humid conditions, were improved. Nevertheless, further studies are needed to study the stability of such aging-treated sensors over time.

Physical Isolation

Physical isolation using waterproof and selective membranes coating the sensors’ surface is another strategy that can be applied to overcome the problem of humidity interference in the sensors’ responses. Such membranes, such as polylactic acid (PLA) membranes, polydimethylsiloxane (PDMS) membranes, PTFE membranes, or alumina (Al2O3) nanomembranes, block water molecules thanks to either their hydrophilicity or their hydrophobicity due to water contact angle modification and, simultaneously, allow for the diffusion of the target gas molecules [143]. Other barriers, such as molecular sieves MCM-48 or SBA-15, act as desiccants, creating bonds between silica and hydroxyl molecules, thereby ensuring the diffusion of the gas molecules through their pores. In this case, a decrease in sensor sensitivity is often observed because of a decrease in diffusion efficiency through the membranes or sieves of the target gas molecules regarding the sensitive material. Therefore, a proper characterization of semipermeable material thickness is fundamental.

Tuning of Working Conditions

Also, the tuning of the working conditions of chemo-resistant sensors may have an effect on their sensitivity to humidity. For instance, an increase in the sensors’ operating temperature could facilitate the desorption of water and thus prevent the interference of water with sensors’ responses. One of the drawbacks of this strategy is that the sensitivity of the sensors, which is strongly influenced by the operating temperature, could be negatively affected. Indeed, Gupta et al. tested the implementation of microheaters in chemical-sensitive field effect transistors (ChemFETs) to increase the operating temperature of sensors [144]. They obtained a negligible decline in sensors’ responses to relative humidity changes, but a decrease in detection of the target gas (i.e., H2) was observed. A possible alternative could be to implement a UV-light illumination system that provides more thermal energy without affecting the sensitivity to the target gases [144], thereby improving water molecules’ desorption from the sensitive materials.

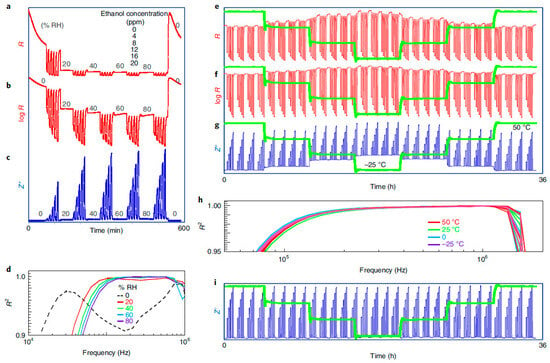

Besides strategies related to the sensors’ formulation and design to hamper humidity interference, another innovative approach could be based on signal acquisition. Potyrailo et al. [29] proposed an alternative readout method for MOS sensors (Figure 1). The authors performed dielectric excitation measurements on commercially available Figaro Sensors (TGS2611 and TGS2608). They carried out tests at RH between 0% and 80% and found that (1) the sensor baseline resulted less affected by humidity variations, (2) the sensor sensitivity increased with the increase in RH, and (3) the linearity of the response improved in the presence of water. Tests were also performed for gas temperatures ranging from −25 to 50 °C, and results showed that the sensors’ response is not affected by it when measured at specific excitation frequencies.

Figure 1.

In the work of Potyrailo [29], the impact of ambient humidity ranging from 0 to 80% RH on ethanol vapor exposure is examined in terms of resistance response, both on a linear scale (a) and logarithmic scale (b), as well as the dielectric response (Z″ at 0.17 MHz), which demonstrates a significant reduction in the influence of humidity (c). The frequency-dependent behavior of the R2 values, obtained via linear fitting at different RH levels, is also investigated (d). Furthermore, the effects of ambient temperature ranging from −25 to 50 °C on methane gas exposure are analyzed in relation to the resistance response, on both linear (e) and logarithmic (f) scales. The dielectric response (Z″ at 0.56 MHz) is also examined (g), along with the frequency dependence of the R2 values for varying ambient temperatures (h). Additionally, the temperature-insensitive dielectric response (Z′ at 2.7 MHz) is explored (i). Experimental details for the observations are provided as follows: For (a–d), the sensing element used is CCS801, with ethanol concentrations set at 0, 4, 8, 12, 16, and 20 ppm, while water vapor levels are set at 0, 20, 40, 60, and 80% RH. For (e–i), the sensing element utilized is TGS2611, with methane concentrations set at 0, 50, 100, 150, 200, and 250 ppm. The ambient temperatures employed are 50, 25, 0, and −25 °C, as indicated by the green lines in (e–g,i). Reprinted with permission from Ref. [29]. Copyright year 2020, copyright owner’s name Springer Nature.

Novel Materials Development

While some researchers have been focusing their efforts in improving the properties of sensitive materials employed in the production of chemo-resistant sensors, others have been developing novel materials accounting for novel structures, such as Ag2Te nanowires, nanoplates with Bi2Se3 film, 3D porous In2O3 microcubes, 3D reduced graphene oxide (rGO), ZnO needles, and PbTiO3 nanoplates, to produce novel sensors able to work under high moisture conditions [66,145]. Indeed, a promising possibility in gas sensing is represented by sensors based on 2D materials, such as graphene, transition metal dichalcogenides (TMDs), black phosphorous (BP), hexagonal boron nitride (h-BN), and MXenes [146]. Such 2D material-based sensors are generally characterized by very high sensitivity and low detection limits due to the increase of the contact surface area with the gaseous molecules [96,147], even at room temperature. In some cases, by tuning some physical parameters, a high conductivity level or high selectivity can be achieved [148,149]. Moreover, 2D material-based sensors could offer greater reproducibility in terms of sensor characteristics due to better control over the physical structure. This could help to control the humidity’s influence on sensors’ responses as reported, for example, by Donarelli et al., who demonstrated that the NO2 sensing signal of GO flake-based sensors is independent of RH changes [150].

Regarding MOS sensors specifically, although the most diffused n-type metal oxides have demonstrated their higher sensitivity to volatile molecules, p-type metal oxide-based sensors (e.g., CuO, NiO, and Co3O4) showed more stable response under humid conditions, having a limited shift in their baseline resistance at different RH levels. For example, Miao et al. produced a sensor for H2S detection independent from humidity, implementing an ultra-thin CuO nanosheet as the sensitive material, which proved to also be ultra-selective in the presence of other typical interfering compounds, such as toluene, ethanol, and acetone [151]. This pointed out the possibility of developing humidity-independent chemo-resistant gas sensors based on p-type metal oxides focused on improving their sensitivity and selectivity.

A further interesting perspective for obtaining humidity-independent gas sensors is the development of composite material-based sensors that can provide different morphological characteristics contributing to the different behavior of composite sensors’ responses concerning single metal oxide-based sensors [152,153]. Faia and Furtado investigated the responses of composite sensors based on a TiO2:ZnO pair, proving that the decrease of ZnO content in the sensor composition leads to a transition state from n- to p-type in the high humidity range, thus improving the stability of sensors’ responses when analyzing gases with a high moisture level [154].

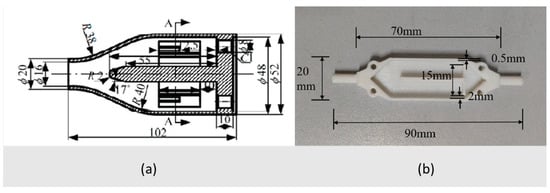

4.1.2. Sensors’ Modifications for Reducing the Effects of the Gas Flow

Strategies based on modifying the sensors were also proposed to address the issues related to the effects of flow variations inside the e-nose chamber. Indeed, an option to reduce the impact of the flow by modifying the sensors’ structure is presented by Dong et al. [155]. In this case, the authors presented the modification of a standard thermal conductivity gas sensor by placing an obstacle on the sensor case to protect the sensitive part. They added obstacles of different sizes (from 0.2 mm to 0.5 mm) and shapes (e.g., cylinder, quadrangular prism), and then they evaluated the effect of the introduction of such obstacles by means of simulations and experiments with carbon dioxide and nitrogen. Based on their experimental results, the authors concluded that adding properly sized obstacles can increase the gas sensor’s accuracy by reducing the flow’s impact on it.

This result leads to some interesting additional considerations of the possibility of designing a suitable housing for the sensors. However, further studies are needed to evaluate the impact related to the presence of a housing on the responses and develop such studies also for other kinds of sensors that are more commonly used in e-nose applications (such as MOS, QCM, polymer sensors, etc.).

4.2. Sampling

4.2.1. Sampling Strategies to Control Sample Gas Flow Variations

The e-nose sampling system is a crucial component to be considered for addressing the issues related to the effects of flow variations on the sensors’ responses. As mentioned, the main solution to avoid flow variations on the sensors is to perform so-called ‘indirect sampling’. Indeed, in most studies regarding e-noses, sampling is conducted in an indirect way, which means that the analysis is performed offline after collecting the target gas in bags, sorbent tubes, or other equivalent storage systems [12]. In such cases, flow can be regulated by using pumps or mass flow controllers, which guarantee a constant flow rate during analysis with the e-nose [156,157,158].

However, in some cases, e-nose analysis is performed without using a sample storage system and thus applying so-called ‘direct sampling’, which minimizes the loss of volatile target compounds that may occur during storage [159]. This is typically the case for all types of applications where a continuous analysis is required (for example, environmental monitoring, process control, biomedical applications, etc.). Direct sampling can become particularly challenging when applied to breath analysis because of the intrinsic high flowrate variability associated with breathing (from 0 to 2 L/s). Despite these difficulties, two commercially available e-noses (The eNose Company, Zutphen, the Netherlands, and Breathomix, Leiden, the Netherlands) are specifically designed to sample exhaled breath directly [160,161]. In these devices, the subject exhales directly on the sensors, and software compensations based on data from sensors’ response compensation and normalization are carried out to reduce its impact. On the other hand, Tiele et al. [162] present a method for exhaled breath sampling where the subject breathes into a sampling tube and automatically, with a pump, the target gas is directed into the e-nose chamber with a controlled flow. This indeed represents a sort of ‘intermediate’ condition between direct and indirect sampling.

4.2.2. Sampling Strategies to Control Humidity Variations

The design and development of specific sampling systems has also been discussed in several papers with the purpose of limiting the interference of humidity variations on sensor responses.

To maintain a stable humidity level across measurements, some authors have kept the same RH level between the sample gas and the reference air used to clean the sensors between each measurement and set the instrument baseline [163,164,165,166,167,168,169,170,171,172,173]. To regulate the humidity of reference air to the same level as the target gas, one possibility is to mix a dry air stream with a humid air stream to obtain the desired RH level [174,175,176].

In other studies, the control is carried on only one line, either on the reference air or sample gas [177,178,179,180,181,182,183,184,185,186,187]. To control the humidity of the reference air, it is possible to use either: (a) synthetic air [163]; or (b) ambient air opportunely treated using filters, such as charcoal filters [180], active carbon filters [177,185,188], silica gel filters [164,177,179,185], specific cartridges filled with other solid desiccant materials (e.g., anhydrous sodium carbonate [184], phosphoric anhydride [189], or calcium chloride grains [190]), electrical dehumidifiers [168] or solutions with Ca(NO3)2 [191]. Reference air pre-treatment eliminates volatile molecule interference in the sensor’s baseline and reduces relative humidity, discarding the water molecules that interfere in the interaction mechanism with the active layer of e-nose sensors. To this end, Wilson et al. [177] developed an experimental protocol for the rapid identification and discrimination of phytopathogenic microbes, analyzing the volatile compounds released by these microorganisms from woody samples of a variety of plant hosts. The Aromascan A32S, commercialized by Osmetech, is equipped with 32 conductive polymer sensors whose sensitivity has been previously tested with organic compounds potentially relevant to microbial identification and was employed for the analysis. The sensor chamber was maintained at 30 °C, the reference air was preconditioned by passing ambient air through several filters, such as carbon, silica gel, inline, and Hepa filters, to not only decrease moisture content but also to remove potential background odors. The same reference air was used to create a static headspace for the woody samples stored in the sampling chamber at 25 °C. Indeed, reference air was set in general at 4% RH and regulated within 2% below sample air at 25 °C. The authors underlined the importance of maintaining low relative humidity in the reference air because this ensured that any additional water content was related to the samples.

The pre-treatment of target samples is still an open issue because, besides being strictly related to the type of application, treating the sample to regulate humidity generally entails the risk of altering its composition, which in turn may negatively affect subsequent pattern recognition [192]. In general, the samples provided to e-noses can be (1) synthetic samples [193,194], obtained by mixing known quantities of pure compounds stored in bottled gases; (2) gaseous real samples directly collected and analyzed [16,23,195] or (3) solid- or liquid-based samples analyzed by creating and further collecting a static or dynamic headspace enriching synthetic air or nitrogen with controlled temperature and relative humidity [164,166,177,196]. One of the easiest and most intuitive methods to control the RH level of analyzed samples relies on the permeability of the materials where the gas is collected and stored before the analysis. For example, NalophanTM, which is the most common material used for the storage of samples to be analyzed via dynamic olfactometry (according to EN 13725:2022 [197]), is highly prone to diffusion of small hydrophilic molecules (e.g., water, ammonia, or hydrogen sulfide) [85,198]. Bax et al. [199] used its permeability to humidity to reduce the moisture content of exhaled breath samples analyzed for detecting respiratory failures in patients affected by SARS-CoV-2. In this study, the samples were collected and stored for 2 to 24 h in ambient air under the same working conditions of the e-nose, which enabled the achievement of good stability and reproducibility of sensors’ responses. Based on the same principle, Capelli et al. developed a protocol for e-nose analysis of urine headspaces for prostate cancer diagnosis [196]. To limit the interferences of compounds out of interest on sensors’ responses, the authors prepared urine headspace samples in controlled conditions (i.e., T = 60 °C and RH = 10%) using a climatic chamber taking advantage of the NalophanTM’s capability to diffuse water molecules.

Another possibility to control the sample humidity is to use sample preparation techniques for pre-treating the samples before e-nose analysis by filtering [164,167,184,190,200], adsorption on traps [166,178,200], or by elution in chromatographic columns [189]. Considering filter-based sampling systems, Mahdavi et al. [190] studied a suitable way to control the humidity level of the system by deeply investigating several types of filters filled with activated carbons, CaCl2 grains, or silica gel. Temperature-modulated gas sensors’ (i.e., TGS-2602, TGS-822, FIS SB-30, FIS SP-53B) responses were evaluated regarding acetone, ethanol, 1-propanol, and 1-butanol. For the purposes of the study, the authors concluded that activated carbons and silica gel were not fit-for-purpose because, besides water, they also adsorbed part of the target gas, thus making that gas detection impossible. Following the same approach, Shafiqul et al. [164] implemented a silica gel-based filter in the air reference line and in the gas generation line to characterize the odor fingerprint of Eurycoma longifolia extracts. Eight QCM sensors analyzed the dynamic headspace of the samples at the same relative humidity level as the reference air. The authors reported a decrease in the e-nose system’s variance and an increase in the sensors’ sensitivity to some volatiles present at very low concentrations in the headspace. In another study, Aishima [200] proposed a sensor array consisting of six MOS sensors to discriminate between liquor aromas (namely cognac and four different brands of whisky). A pre-concentration system was implemented by means of Tenax and a silica gel filter aiming to remove excess ethanol while simultaneously decreasing water content. Tenax is an absorbent material widely used for concentrating hydrophobic trace volatile compounds in headspaces because of its heat stability and reversible desorption via heating. Thus, it is generally used to eliminate the interference of hydrophilic molecules, such as ethanol. Due to the promising results obtained via clustering and stepwise LDA discrimination of the different liquor samples, the author suggested the implementation of sensors insensitive to ethanol (as for water in other cases) to make the system more user-friendly and portable.

Moreover, some studies have proposed a comparison between different sampling procedures and sample preparation techniques to understand and investigate the effective advantages of samples pre-treatments. Campagnoli et al. proposed two different approaches to prepare durum wheat samples for e-nose analysis to recognize grains contaminated with deoxynivalenol [178]. They used a PEN2 e-nose (Airesense Analytics) equipped with MOS sensors, with or without samples, during the pre-treatment step. For sample pre-treatment, a Tenax trap was used. Different protocols for the experiments were developed: one without any pre-treatment and the other four with adsorption on the Tenax trap at four different desorption temperatures (namely 180 °C, 200 °C, 220 °C, and 240 °C). Even though higher intensities of sensor signals have been recorded when increasing desorption temperature, the best PCA discrimination and CART classification performance between controls and contaminated samples was achieved via the sampling protocol without the pre-concentration phase. The simplicity of such an e-nose system suggested to the authors that this preliminary approach should be implemented to carry out analyses directly in the field. Comparison between different sampling preparation methods was also provided by Lozano et al. for developing a gas sensor-based device in order to discriminate between five different Spanish wines. Three sampling methods were proposed based on a: (a) static headspace (HS); (b) purge and trap (P&T) unit with a Tenax trap and (c) solid-phase micro-extraction (SPME), typically used in GC-MS analyses. The sensor array consisted of 16 home-made SnO2 sensors, some of them doped with chromium and indium. The radial plot of the average responses of the sensors to the five wines showed that HS was the sampling method providing the highest responses. This may be attributed to the removal of water and ethanol via the P&T and SPME methods. However, different contributions of the sensors were observed for each sampling technique. This was reflected in better clustering in the PCA score plot and higher success rate in ANN classification for the SPME and P&T methods, showing a considerable improvement in e-nose signal detection system performance. Following the same approach, Hong et al. [184] implemented a paper filter filled with 5 g of anhydrous sodium carbonate to identify a suitable protocol for recognition and quantitative analysis of four different cherry tomato juices (one unadulterated and three adulterated groups). Measurements were performed both with an e-nose (PEN 2 by Airesense Analytics, Schwerin, Germany) and an e-tongue (α-Astree Alpha Mos, Toulouse, France). Since the original sample matrix was rich in water, samples were analyzed directly during or after pre-treatment, using anhydrous sodium carbonate as a desiccant. The comparison of the e-nose signals obtained with the two approaches highlighted a slight decrease in signal intensity when the target gas was pre-treated. This change trend was explained by the authors by a reduced amount of headspace reaching the e-nose chamber for the analysis. As final result, PCA showed a better discrimination ability as a system, including ANOVA-selected variables from both pre-treated and non-pre-treated e-nose and e-tongue dataset in the data processing [184].

A similar approach was developed by Yang et al. [166]. In their work, the focus was the identification of coumarin-enriched Japanese green teas by analyzing their headspace with e-noses. The device used in the study was a custom-made e-nose (namely the FF-2A Fragrance and Flavour Analyzer) consisting of an array of 10 different MOS sensors. Two different measuring modes were implemented, pumping the headspace tea aroma directly into the e-nose chamber (1) or through a trap tube (2), whose material was not specified, to increase the VOC concentrations and remove humidity in the sample. The resulting sensor signals proved that the two measuring modes affected sensors’ responses. Indeed, the signal amplitude of some sensors seemed to be higher for the measurements carried out using the trap tube mode compared to the direct measurements, suggesting that humidity in the sample needs to be controlled because it can affect sensors in different ways. Features were extracted from sensors considering both measuring modes and achieving good clustering of different tea samples in the PCA space. The results reported in these studies highlighted that, on the one hand, sample preparation procedure surely affects sensors’ responses, limiting the interfering compounds’ action but, on the other hand, its effects are still not always clear. In this sense, a precise evaluation of sensor curves is required, sensor by sensor, and specific data processing procedures must be developed. It is also interesting to see that different types of information on the system variability may be provided from sensors’ signals acquired with and without sample pre-treatment.

Other suggestions on how to deal with unwanted cross-sensitivities by acting on the sampling system may come from research works in which the authors do not focus on the limitation of water’s effect on sensors’ responses but deal with other interfering compounds, such as ethanol in alcoholic beverages. For example, Pinheiro et al. tried to develop an instrument to monitor the fermentation stages of wine [167]. In this study, the relative humidity level of the air reference and gaseous samples was kept constant (namely at 50% RH) to limit its interference in CP sensors’ responses, which are highly affected by water and ethanol. Aiming to bypass ethanol interference, a hydrophobic pervaporation membrane, selective for organic molecules, especially for esters, was implemented. The aroma compounds were concentrated in the permeate and subsequently analyzed, demonstrating a great improvement of the e-nose capability of identifying fermentation stages based on wine odor fingerprint and not on ethanol content. Even though this approach was designed for ethanol, it suggests that similar membranes with different properties may be adopted with the purpose of protecting e-nose sensors from the water effect, too. Moreover, other techniques such as the GC column back-flush were introduced for the e-nose analysis of beverages with the purpose of removing ethanol and water [189].

As a last consideration of this aspect, it is worth mentioning that in field applications, controlling the RH level of the gas entering the e-nose chamber is quite challenging [70,201]. Specific e-noses for environmental applications [202] have been developed and designed with a specific system able to adjust the sample humidity level to a fixed value independently from the external ambient conditions. Although highly complex, these instruments have been widely employed for environmental monitoring of plant emissions [14,195,203,204], especially at receptors, thanks to their ability to reach a very high sensitivity, as well as in food or microbiological studies [205,206,207,208,209,210]. The need for simpler, faster, and cheaper monitoring tools is pushing towards the diffusion of e-noses without any type of humidity control, also in field applications. However, in order to avoid a significant worsening of e-nose performance, the water content in the reference air and in the sample gas needs to be continuously monitored [190]. For this reason, in some cases, specific calibration procedures which must be repeated periodically [211], thus resulting in high costs and time consumption, have been developed [64,76,77]. As a matter of fact, the most recent literature concerning the use of e-noses for environmental monitoring applications report the numerous advantages of developing specific algorithmic compensation methods to counteract the effects related to the variations in relative air humidity, temperature and sensors drift over time [22,23,24,25,212].

4.3. Sensors’ Chamber Geometries

Chamber geometry is a crucial aspect for enhancing sensors’ response in terms of response time and reliability. With respect to what was discussed in Section 3.3, the requirements for an e-nose sensor chamber to guarantee fast and reliable responses are: (a) small volume, (b) no recirculation or stagnant zones, and (c) laminar flow. Furthermore, most works point out that having the active layer of the sensor perpendicular to the flow direction can enhance its response.

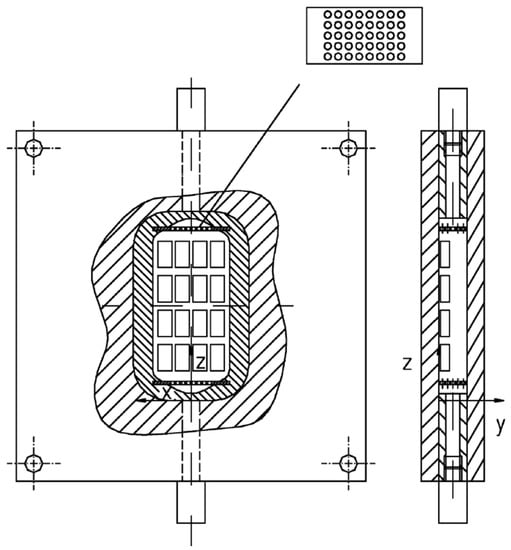

This paragraph presents and discusses a critical review of the possible chamber geometries proposed in the scientific literature to improve e-nose sensors’ responses. Falcitelli et al. [101] presented a work in which a commercial e-nose chamber and a modified version of the same were compared in a fluid dynamic simulation to demonstrate that some modification of the original geometry can enhance flow conditions (Figure 2). The original chamber is a parallelepiped with rounded corners and dimensions 33 × 54 × 8 mm. Sensors are arranged in four rows and four columns. In the modified geometry, the total volume is reduced by reducing the lateral spaces, and two diffusers have been added at the inlet and outlet to break up the jet, increasing uniformity and avoiding recirculation zones. Simulations were performed to evaluate the concentration distribution of a target gas within the chamber. Results show that the target concentration is reached in a shorter time and more homogeneously across the sensors in the modified geometry.

Figure 2.

Chamber presented by Falcitelli [101]. Lateral space is reduced, and a diffuser is placed at the input and output. Reprinted with permission from Ref. [101]. Copyright year 2002, copyright owner’s name Elsevier.

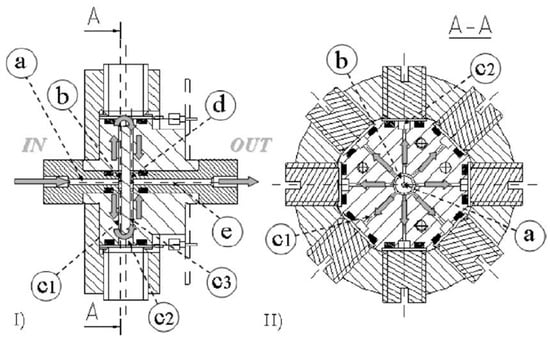

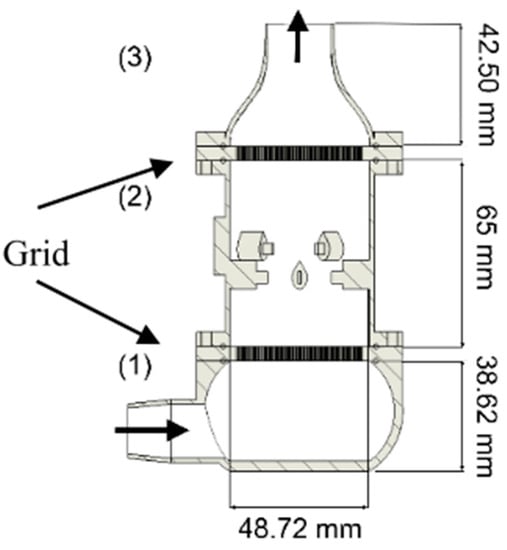

With the same purpose of optimizing the chamber geometry, Di Francesco et al. [100] proposed a radially symmetric chamber (Figure 3). This geometry can reduce stagnant or recirculating zones and ensure the same flow conditions over all the sensors. A PTFE flow splitter is used to deliver equal amounts of sample to all the sensors. Sensors are mounted on the lateral surface of the chamber, and for each sensor, two channels connect it to the splitter. Simulations were run, and the performance of the chamber was evaluated as follows: homogeneity of conditions in the chamber, the time needed for the concentration signal at the chamber outlet to reach 90% of the amplitude of the signal at the inlet (rise time), and the differences in the concentration profile at each sensor position (local rise times and signal amplitudes). Rise time was calculated as to equal 0.8 s, shorter than sensors’ response, inducing a negligible effect. Finally, according to their calculations, the authors state that deviations from the described geometry induced by work tolerances must be kept below a fixed limit to obtain the same concentration profiles at each sensor position.

Figure 3.

Schematic drawing of the measurement chamber proposed by Di Francesco [100]: (I) diametrical and (II) transversal cross-sections. Sample path is marked by arrows, while the tracts are indicated by circled letters: (a) input connection, (b) inlet collector, (c1) and (c3) radial channels, (c2) sensor cylindrical chambers, (d) outlet collector, (e) output connection. Reprinted with permission from Ref. [100]. Copyright year 2005, copyright owner’s name Elsevier.

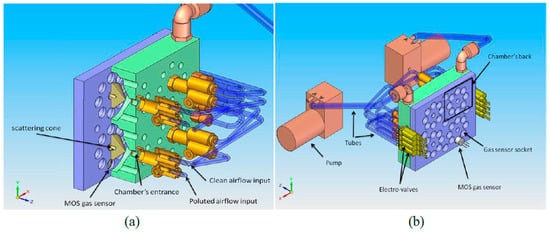

Gonzalez Jimenez et al. [213] proposed a chamber geometry with reduced inner volume for robot applications (Figure 4). The chamber is equipped with seven MOS sensors and the flow is directed to the sensors’ active layer by a central diffuser activated in sequence to minimize the measuring time in robotic applications. Steady state was reached after 60 s.

Figure 4.

Different views of the chamber proposed by Gonzalez Jimenez et al. [213]: (a) upper view, (b) bottom view of the pneumatic circuit and the main block containing four chambers which can accommodate up to 8 MOS sensors each. Reprinted with permission from Ref. [213]. Copyright year 2015, copyright owner’s name IOP Publishing.

Performances are compared with respect to a standard e-nose, and results show that rising time decreases using the proposed chamber with reduced inner volume. Viccione et al. [27,102] published two studies to develop a chamber geometry following the radially symmetric chamber principles proposed by Di Francesco [100]. In the two studies, the authors present the evaluation of different radial diffusers to ensure the same flow conditions for all the sensors. The chamber is a cylinder with 16 sensors arranged on two layers. Four different diffuser geometries were compared by evaluating concentration at each sensor, average contact time at the sensor, and time to reach the steady state, and results showed that one of the considered geometries performed better than the others. Differently from Di Francesco, no considerations were made to evaluate possible errors related to the effective geometry of the diffuser when it is realized. This aspect is crucial because small deviations from the original design may cause high and non-controlled variability in the results which, in turn, may induce errors in the e-nose operation. Furthermore, no rationale is proposed regarding the choice of the different geometries studied, as they are just a few of all possible combinations.

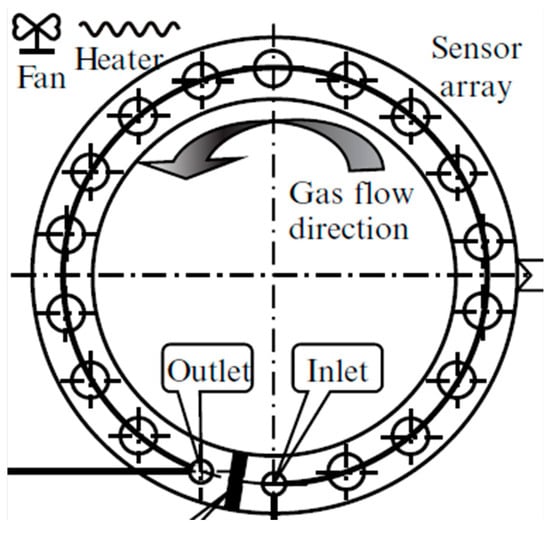

Wang et al. [214] presented a possible chamber geometry to minimize size and internal volume (Figure 5). The proposed geometry has a circumference with an internal section of 16 × 20 mm and a net volume of 140 mm3. A total of 16 sensors are placed on the circumference, where the airflow can be clockwise or anticlockwise at a rate set equal to 0.5 L/min. From a first analysis, assuming perfect mixing and no edge effects on the surfaces, surfaces are exposed to the same conditions. However, a time shift between the sensors’ responses should be considered according to their spatial distribution. Moreover, since the sensors are placed on the same line, local flow conditions may be affected by the presence of the previous sensors, thus locally producing a non-controlled flow rate and concentration variations due to the reactions of the target gas with the previously encountered sensors.

Figure 5.

Schematic diagram of the sensor chamber proposed by Wang et al. [214]. Adapted with permission from Ref. [213]. Copyright year 2015, copyright owner’s name IOP Publishing.