In Situ Growth of Dopamine on QCM for Humidity Detection

Abstract

1. Introduction

2. Experimental

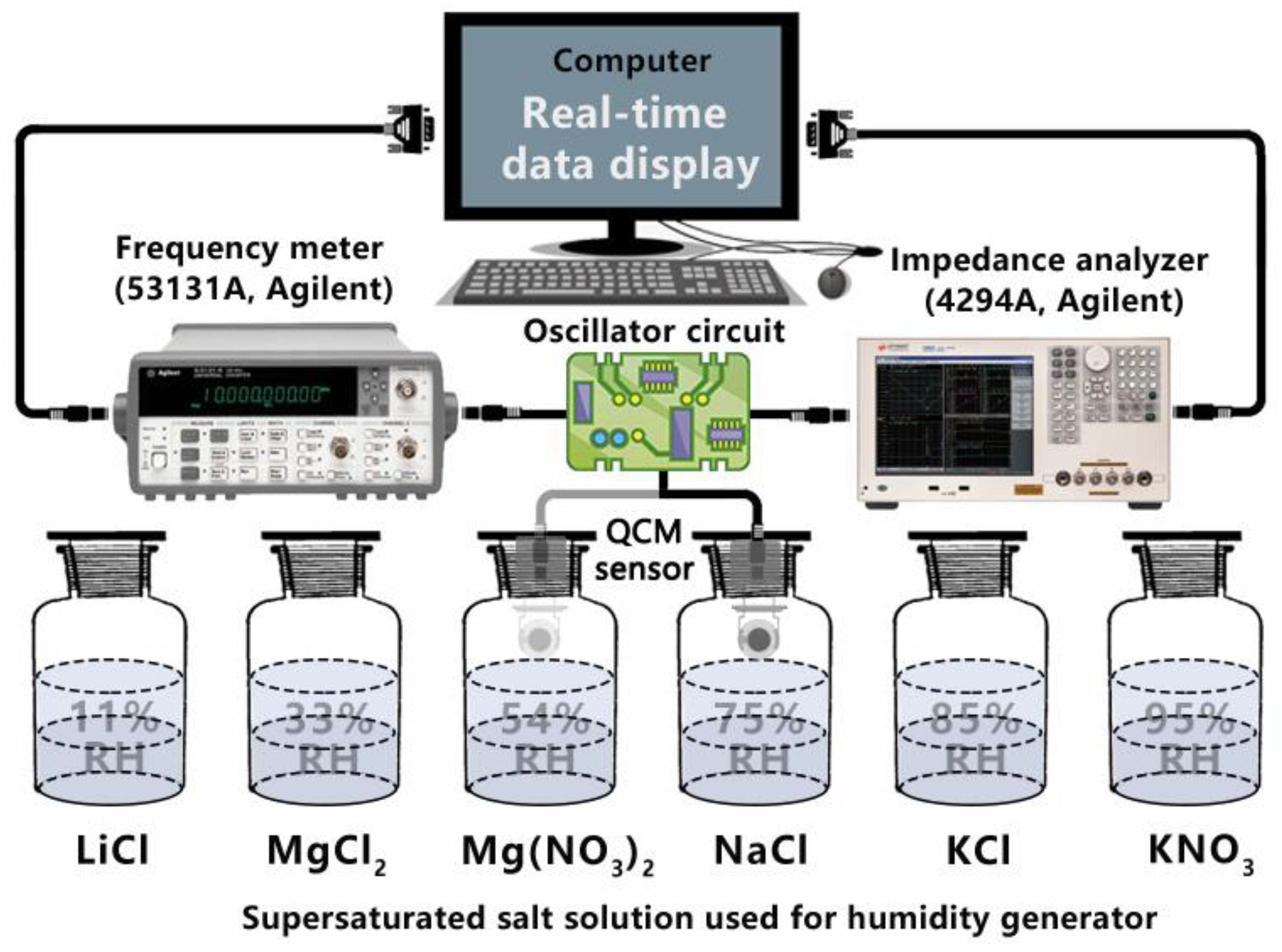

2.1. Materials and Detection System

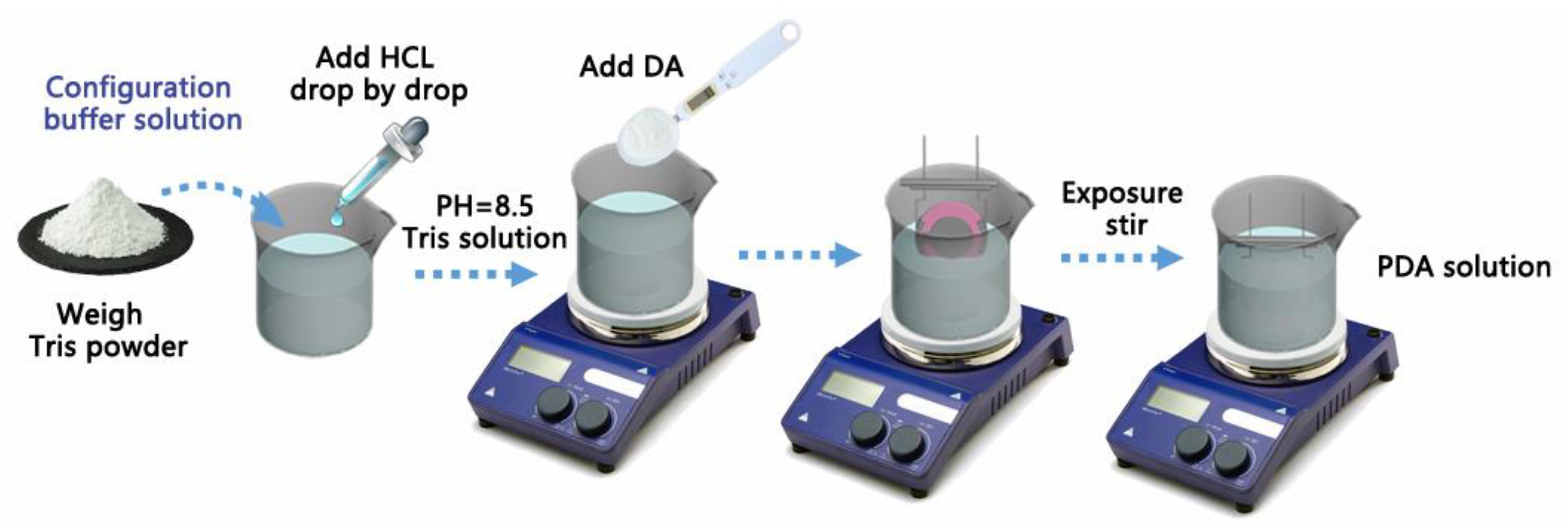

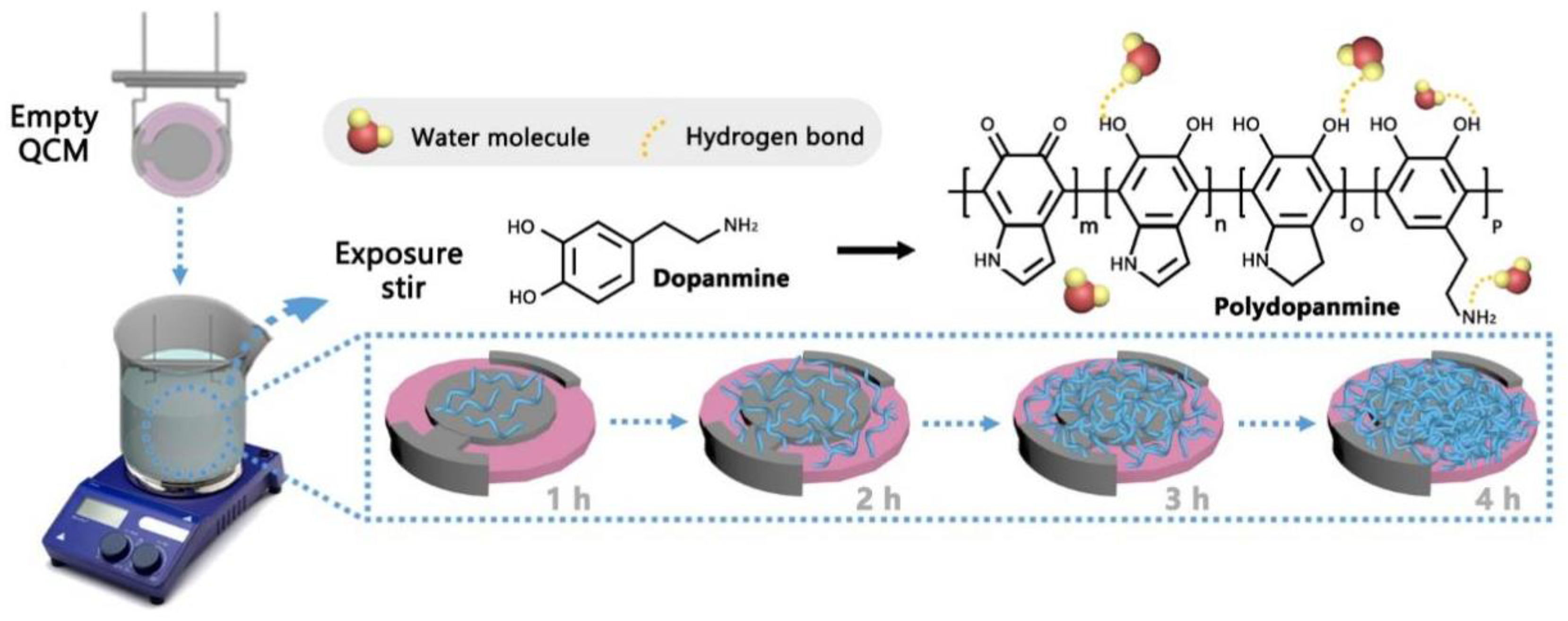

2.2. Material Synthesis and Sensor Preparation

2.3. Characterization

3. Results and Discussion

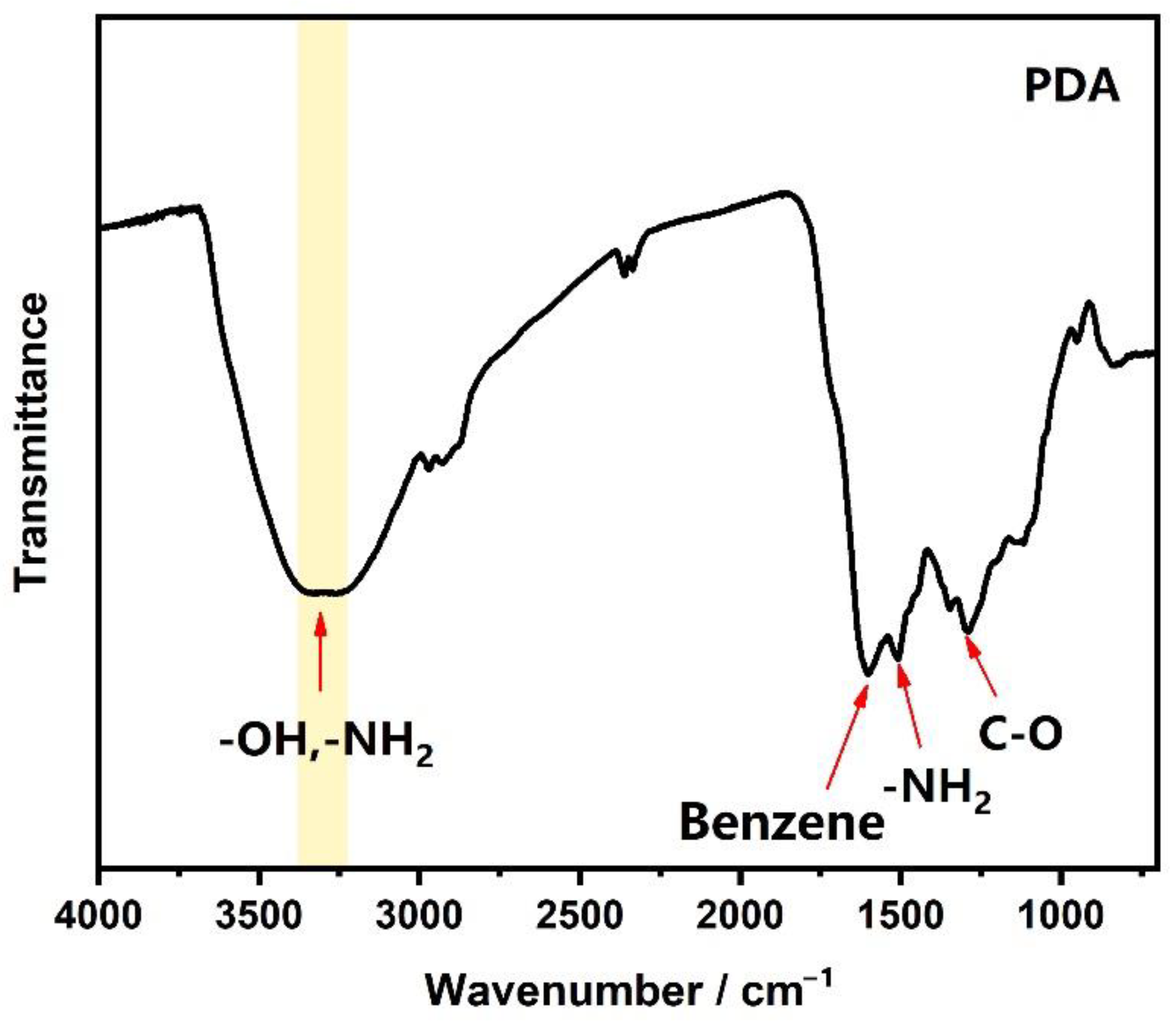

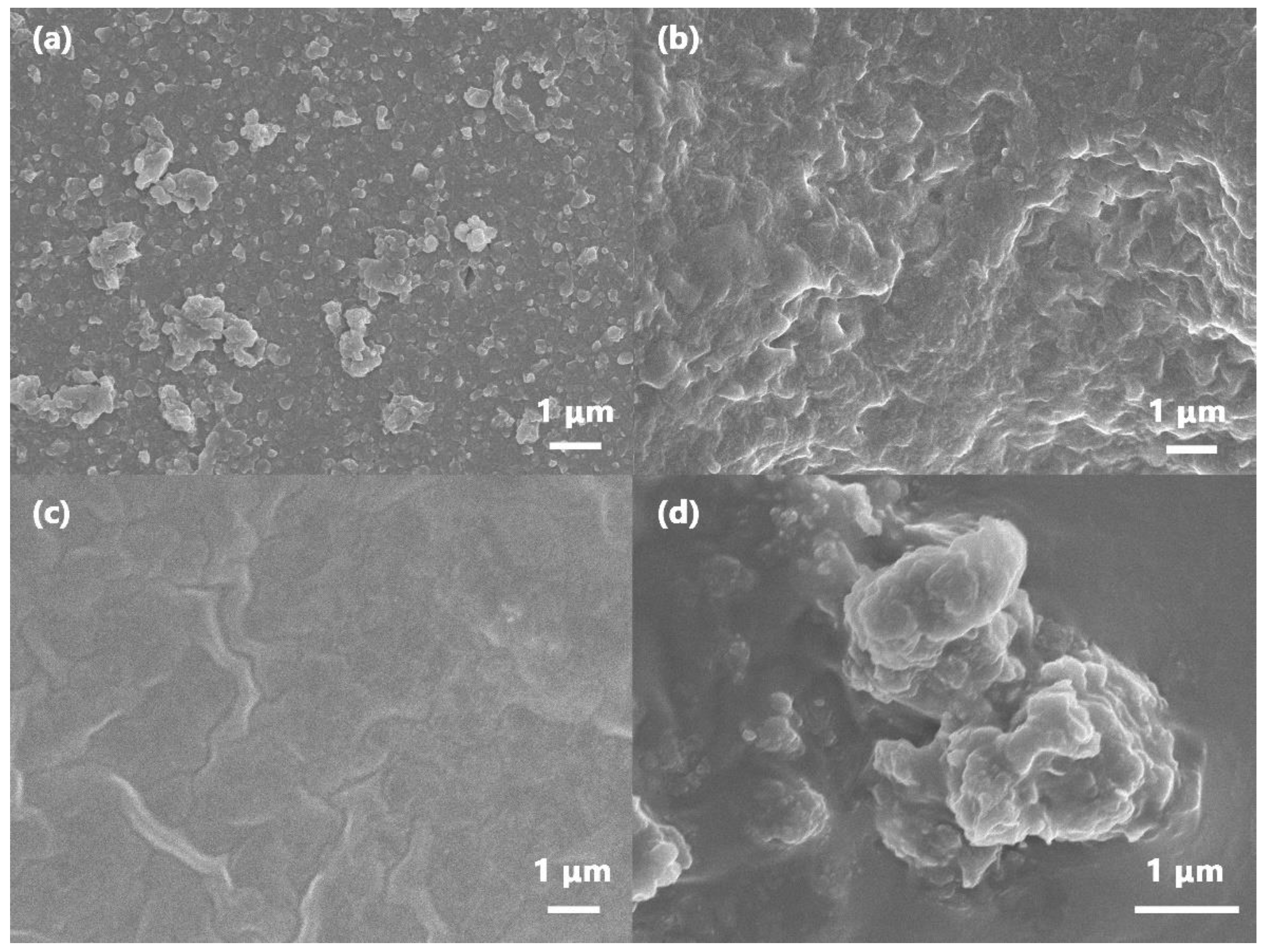

3.1. Structural and Morphological Characteristics

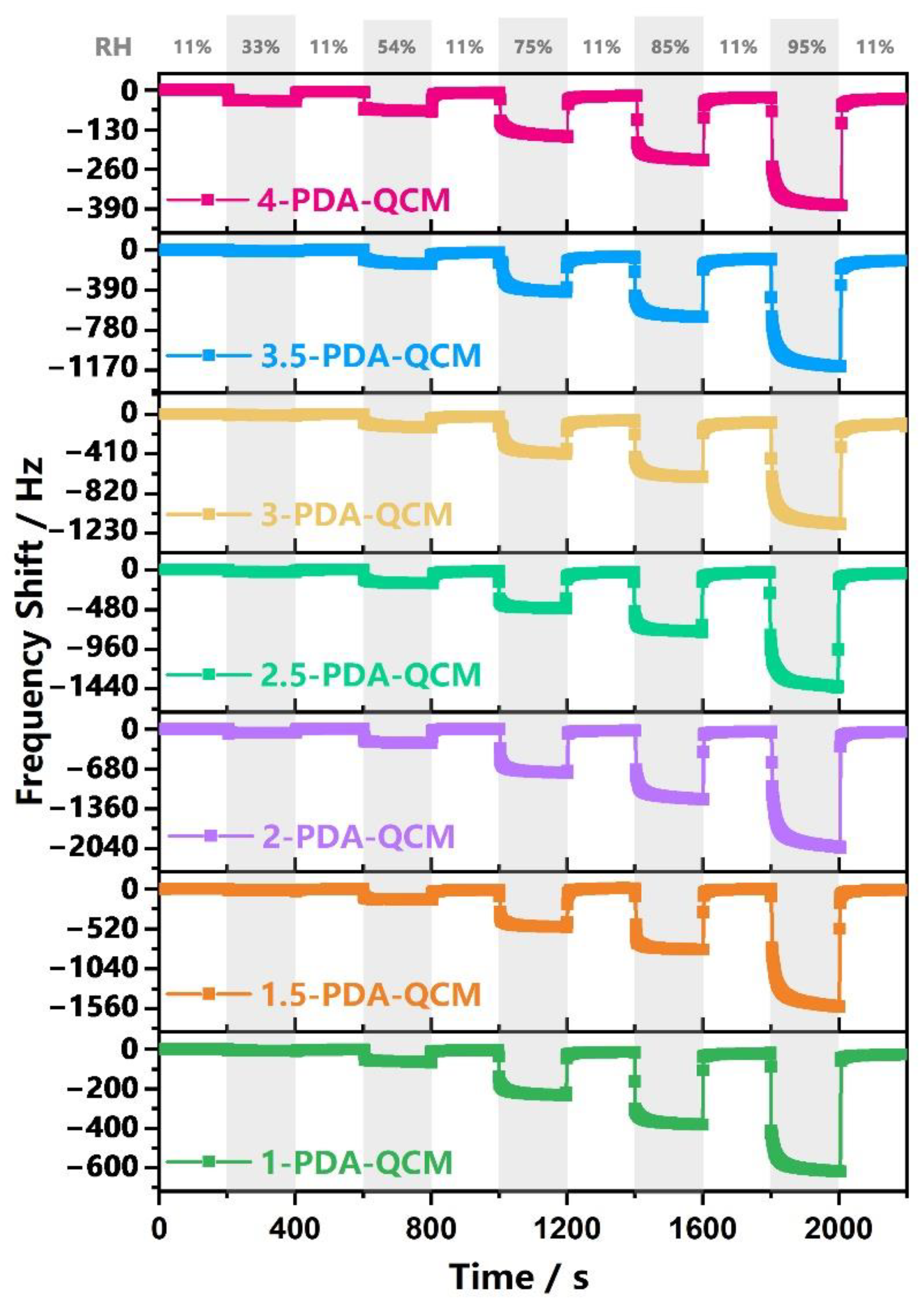

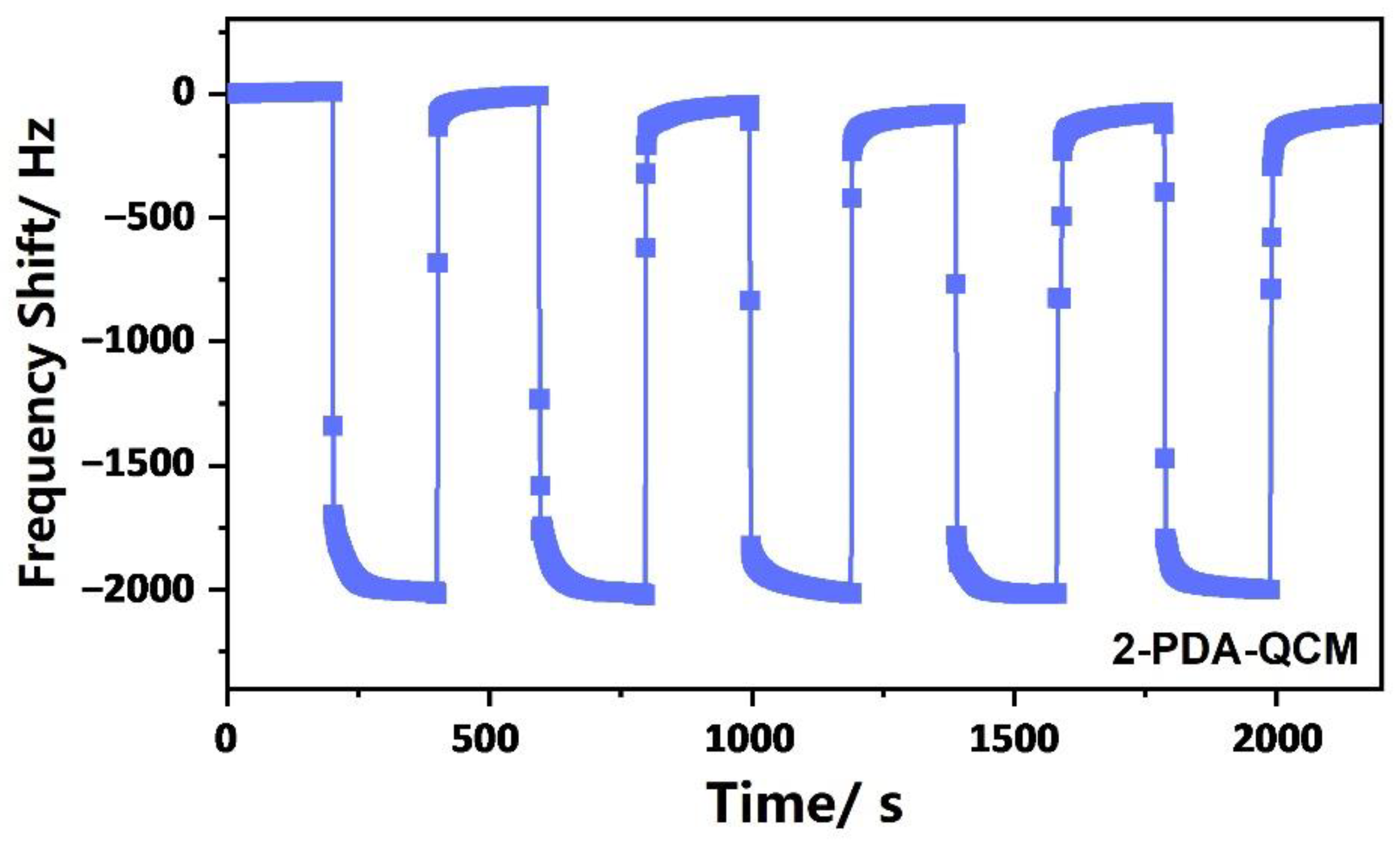

3.2. Humidity Sensing Properties of the QCM Humidity Sensors

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dessler, E.; Sherwood, S.C. A matter of humidity. Science 2009, 323, 1020–1021. [Google Scholar] [CrossRef] [PubMed]

- Alwis, L.; Sun, T.; Grattan, K.T.V. Optical fibre-based sensor technology for humidity and moisture measurement: Review of recent progress. Measurement 2013, 46, 4052–4074. [Google Scholar] [CrossRef]

- Kulwicki, B.M. Humidity sensors. J. Am. Ceram. Soc. 1991, 74, 697–708. [Google Scholar] [CrossRef]

- Duan, Z.; Jiang, Y.; Tai, H. Recent advances in humidity sensors for human body related humidity detection. J. Mater. Chem. C 2021, 9, 14963–14980. [Google Scholar] [CrossRef]

- Blank, T.A.; Eksperiandova, L.P.; Belikov, K.N. Recent trends of ceramic humidity sensors development: A review. Sens. Actuators B Chem. 2016, 228, 416–442. [Google Scholar] [CrossRef]

- Farahani, H.; Wagiran, R.; Hamidon, M.N. Humidity sensors principle, mechanism, and fabrication technologies: A comprehensive review. Sensors 2014, 14, 7881–7939. [Google Scholar] [CrossRef]

- Najjar, R.; Nematdoust, S. A resistive-type humidity sensor based on polypyrrole and ZnO nanoparticles: Hybrid polymers visa-vis nanocomposites. RSC Adv. 2016, 6, 112129–112139. [Google Scholar] [CrossRef]

- Yang, T.; Yu, Y.; Zhu, L.; Wu, X.; Wang, X.; Zhang, J. Fabrication of silver interdigitated electrodes on polyimide films via surface modification and ion-exchange technique and its flexible humidity sensor application. Sens. Actuators B Chem. 2014, 208, 327–333. [Google Scholar] [CrossRef]

- Duan, Z.H.; Zhao, Q.N.; Wang, S.; Huang, Q.; Yuan, Z.; Zhang, Y.J.; Jiang, Y.D.; Tai, H.L. Halloysite nanotubes: Natural, envi-ronmental-friendly and low-cost nanomaterials for high-performance humidity sensor. Sensor Actuators B Chem. 2020, 317, 128204. [Google Scholar] [CrossRef]

- Qi, P.J.; Xu, Z.W.; Zhou, T.T.; Zhang, T.; Zhao, H.R. Study on a quartz crystal microbalance sensor based on chitosan-functionalized mesoporous silica for humidity detection. J. Colloid Interf. Sci. 2021, 583, 340–350. [Google Scholar] [CrossRef]

- Wang, L.; Xu, J.; Wang, X.; Cheng, Z.; Xu, J. Facile preparation of N-rich functional polymer with porous framework as QCM sensing material for rapid humidity detection. Sens. Actuators B Chem. 2019, 288, 289–297. [Google Scholar] [CrossRef]

- Rianjanu, A.; Fauzi, F.; Triyana, K.; Wasisto, H.S. Electrospun Nanofibers for Quartz Crystal Microbalance Gas Sensors: A Review. ACS Appl. Nano Mater. 2021, 10, 9957–9975. [Google Scholar] [CrossRef]

- Ayankojo, A.G.; Reut, J.; Boroznjak, R.; Öpik, A.; Syritski, V. Molecularly imprinted poly(meta-phenylenediamine) based QCM sensor for detecting Amoxicillin. Sens. Actuators B Chem. 2018, 258, 766–774. [Google Scholar] [CrossRef]

- Li, Z.J.; Teng, M.Z.; Yang, R.H.; Lin, F.Y.; Fu, Y.; Lin, W.Q.; Zheng, J.D.; Zhong, X.P.; Chen, X.D.; Yang, B.; et al. Sb-doped WO3 based QCM humidity sensor with self-recovery ability for real-time monitoring of respiration and wound. Sensor Actuators B Chem. 2022, 361, 131691. [Google Scholar] [CrossRef]

- Addabbo, T.; Fort, A.; Mugnaini, M.; Vignoli, V.; Baldi, A.; Bruzzi, M. Quartz-Crystal Microbalance Gas Sensors Based on TiO2Nanoparticles. IEEE Trans. Instrum. Meas. 2018, 67, 722–730. [Google Scholar] [CrossRef]

- Fauzi, F.; Rianjanu, A.; Santoso, I.; Triyana, K. Gas and humidity sensing with quartz crystal microbalance (QCM) coated with graphene-based materials–A mini review. Sens. Actuators A Phys. 2021, 330, 112837. [Google Scholar] [CrossRef]

- Xie, J.; Wang, H.; Lin, Y.; Zhou, Y.; Wu, Y. Highly sensitive humidity sensor based on quartz crystal microbalance coated with ZnO colloid spheres. Sens. Actuators B Chem. 2012, 177, 1083–1088. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, J.; Li, H.; Zhu, Y.; Xu, J. Synthesis of mesoporous SnO2–SiO2 composites and their application as quartz crystal microbalance humidity sensor. Sens. Actuators B Chem. 2014, 193, 320–325. [Google Scholar] [CrossRef]

- Cha, X.; Yu, F.F.; Fan, Y.; Chen, J.F.; Wang, L.Y.; Xiang, Q.; Duan, Z.M.; Xu, J.Q. Superhydrophilic ZnO nanoneedle array: Controllable in situ growth on QCM Transducer and enhanced humidity sensing properties and mechanism. Sensor Actuators B Chem. 2018, 263, 436–444. [Google Scholar] [CrossRef]

- Wang, S.; Xie, G.; Su, Y.; Su, L.; Zhang, Q.; Du, H.; Tai, H.; Jiang, Y. Reduced graphene oxide-polyethylene oxide composite films for humidity sensing via quartz crystal microbalance. Sens. Actuators B Chem. 2018, 255, 2203–2210. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Yao, Y.; Li, N.; Chen, X.; Bi, X. Multi-Walled Carbon Nanotubes/Graphene Oxide Composites for Humidity Sensing. IEEE Sens. J. 2013, 13, 4749–4756. [Google Scholar] [CrossRef]

- Yao, Y.; Chen, X.; Li, X.; Chen, X.; Li, N. Investigation of the stability of QCM humidity sensor using graphene oxide as sensing films. Sens. Actuators B Chem. 2014, 191, 779–783. [Google Scholar] [CrossRef]

- Yuan, Z.; Tai, H.L.; Ye, Z.B.; Liu, C.H.; Xie, G.Z.; Du, X.S.; Jiang, Y.D. Novel highly sensitive QCM humidity sensor with low hysteresis based on graphene oxide (GO)/poly(ethyleneimine) layered film. Sens. Actuators B Chem. 2016, 234, 145–154. [Google Scholar] [CrossRef]

- Jaruwongrungsee, K.; Tuantranont, A.; Wanna, Y.; Wisitsoraat, A.; Lomas, T. Quartz Crystal Microbalance humidity sensor using electrospun PANI micro/nano dots. IEEE Int. Conf. Nanotechnol. 2007, 7, 316–319. [Google Scholar]

- Wang, L.; Gao, J.; Xu, J. QCM formaldehyde sensing materials: Design and sensing mechanism. Sens. Actuators B Chem. 2019, 293, 71–82. [Google Scholar] [CrossRef]

- Tang, L.; Chen, W.; Chen, B.; Lv, R.; Zheng, X.; Rong, C.; Lu, B.; Huang, B. Sensitive and renewable quartz crystal microbalance humidity sensor based on nitrocellulose nanocrystals. Sens. Actuators B Chem. 2020, 327, 128944. [Google Scholar] [CrossRef]

- Chen, W.X.; Chen, B.; Lv, R.X.; Wu, M.L.; Zhou, J.; Lu, B.L.; Huang, B.; Lu, Q.L.; Tang, L.R. Fabrication of quartz crystal microbalance humidity sensors based on super-hydrophilic cellulose nanocrystals. Cellulose 2021, 28, 3409–3421. [Google Scholar] [CrossRef]

- Yao, Y.; Huang, X.; Chen, Q.; Zhang, Z.; Ling, W. High Sensitivity and High Stability QCM Humidity Sensors Based on Polydopamine Coated Cellulose Nanocrystals/Graphene Oxide Nanocomposite. Nanomaterials 2020, 10, 2210. [Google Scholar] [CrossRef]

- Zhang, D.; Song, X.; Wang, Z.; Chen, H. Ultra-highly sensitive humidity sensing by polydopamine/graphene oxide nanostructure on quartz crystal microbalance. Appl. Surf. Sci. 2020, 538, 147816. [Google Scholar] [CrossRef]

- Jiang, H.; Tang, L. Uniformization of QCM’s mass sensitivity distribution by optimizing its metal electrode configurations. IEEE Sens. J. 2021, 21, 9008–9015. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, T.; Qi, R.; Dai, J.; Liu, S.; Fei, T.; Lu, G. Development of solution processible organic-inorganic hybrid materials with core-shell framework for humidity monitoring. Sens. Actuators B Chem. 2018, 255, 2878–2885. [Google Scholar] [CrossRef]

- Qi, P.; Zhao, C.; Wang, R.; Fei, T.; Zhang, T. High-Performance QCM Humidity Sensors Using Acidized-Multiwalled Carbon Nanotubes as Sensing Film. IEEE Sens. J. 2018, 18, 5278–5283. [Google Scholar] [CrossRef]

- Ho, C.C.; Ding, S.J. The pH-controlled nanoparticles size of polydopamine for anti-cancer drug delivery. J. Mater. Sci-Mater. M. 2013, 24, 2381–2390. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Dellatore, S.M.; Miller, W.M.; Messersmith, P.B. Mussel-Inspired Surface Chemistry for Multifunctional Coatings. Science 2007, 5849, 426–430. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Xing, Y.X.; Wang, Z.Q.; Zheng, X.Y.; Zhang, J.X.; Cai, K.Y. Nanoscale polydopamine (PDA) meets pi-pi interactions: An interface-directed coassembly approach for mesoporous nanoparticles. Langmuir 2016, 46, 12119–12128. [Google Scholar] [CrossRef]

- Sauerbrey, G. The use of quartz oscillators for weighing thin layers and for microweighing. Z. Phys. 1959, 155, 206–222. [Google Scholar] [CrossRef]

- Hlavay, J.; Guilbault, G.G. Applications of the piezoelectric crystal detector in analytical chemistry. Ion-Sel. Electrode Rev. 1977, 13, 3–16. [Google Scholar] [CrossRef]

- Buck, R.P.; Lindner, E.; Kutner, W. Piezoelectric chemical sensors. Pure Appl. Chem. 2004, 6, 1139–1160. [Google Scholar] [CrossRef]

- Farzaneh, A.; Mohammadzadeh, A.; Esrafili, M.D.; Mermer, O. Experimental and theoretical study of TiO2 based nanostructured semiconducting humidity sensor. Ceram. Int. 2019, 7, 8362–8369. [Google Scholar] [CrossRef]

- Li, R.; Fan, Y.; Ma, Z.; Zhang, D.; Liu, Y.; Xu, J. Controllable preparation of ultrathin MXene nanosheets and their excellent QCM humidity sensing properties enhanced by fluoride doping. Microchim. Acta 2021, 188, 81. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, K.; Xu, R.; Jiang, D.; Luo, L.; Zhu, Z. Quartz crystal microbalance coated with carbon nanotube films used as humidity sensor. Sens. Actuators A Phys. 2005, 120, 142–146. [Google Scholar] [CrossRef]

- Havar, A.K.; Okur, S. Humidity sensing properties of chitosan by using quartz crystal microbalance method. Sens. Lett. 2012, 10, 906–910. [Google Scholar] [CrossRef]

| QCM Sensor | Response Time (s) | Recover Time (s) | Film Mass (ng) |

|---|---|---|---|

| 1-PDA-QCM | 187 | 211 | 1016 |

| 2-PDA-QCM | 5 | 11 | 3278 |

| 3-PDA-QCM | 24 | 16 | 4299 |

| 4-PDA-QCM | 163 | 64 | 5155 |

| QCM Sensor | Relative Humidity | HBW | R0 | Q |

|---|---|---|---|---|

| 1-PDA-QCM | 11% RH | 197.08 | 10.02 | 50,712 |

| 33% RH | 199.13 | 10.28 | 50,190 | |

| 54% RH | 205.39 | 10.48 | 48,660 | |

| 75% RH | 211.05 | 10.73 | 47,355 | |

| 85% RH | 223.63 | 11.41 | 44,690 | |

| 95% RH | 286.67 | 14.97 | 34,842 | |

| 2-PDA-QCM | 11% RH | 194.06 | 9.80 | 51,489 |

| 33% RH | 206.29 | 10.00 | 48,433 | |

| 54% RH | 211.12 | 10.28 | 47,326 | |

| 75% RH | 223.15 | 10.95 | 44,775 | |

| 85% RH | 265.93 | 12.60 | 37,570 | |

| 95% RH | 384.85 | 20.43 | 25,960 | |

| 3-PDA-QCM | 11% RH | 261.92 | 12.45 | 38,144 |

| 33% RH | 262.03 | 12.63 | 38,128 | |

| 54% RH | 263.71 | 13.00 | 37,885 | |

| 75% RH | 274.80 | 13.70 | 36,355 | |

| 85% RH | 278.84 | 13.88 | 35,829 | |

| 95% RH | 282.55 | 14.16 | 35,357 | |

| 4-PDA-QCM | 11% RH | 199.78 | 10.04 | 50,026 |

| 33% RH | 203.30 | 10.12 | 49,160 | |

| 54% RH | 205.48 | 10.18 | 48,640 | |

| 75% RH | 209.26 | 10.46 | 47,761 | |

| 85% RH | 211.09 | 10.55 | 47,346 | |

| 95% RH | 232.27 | 11.29 | 43,026 |

| Relative Condition | Storage Day 1 | Storage Day 3 | Storage Day 7 | Storage Day 30 |

|---|---|---|---|---|

| Frequency Shift (Hz) | ||||

| 33% RH | 42.53 | 50.09 | 41.58 | 74.89 |

| 54% RH | 187.24 | 135.49 | 120.45 | 109.01 |

| 75% RH | 751.17 | 359.67 | 313.87 | 296.30 |

| 85% RH | 1081.28 | 639.81 | 566.40 | 496.12 |

| 95% RH | 1950.51 | 1433.73 | 948.26 | 883.25 |

| Materials | Fabrication Method | Range | Sensitivity | Res./Rec. Time | Ref. |

|---|---|---|---|---|---|

| TiO2 | Spin coating | 30%~70% RH | 2 Hz/% RH | ~/~ | [39] |

| S-Ti3C2 | Drop casting | 11%~97% RH | 12.8 Hz/% RH | 6 s/2 s | [40] |

| CNT | Spin coating | 5%~97% RH | 12.5 Hz/% RH | 60 s/70 s | [41] |

| Chitosan | Spin coating | 11%~94% RH | 7.5 Hz/% RH | ~/~ | [42] |

| PANI | Electrospinning | 20%~80% RH | 3.0 Hz/% RH | 5 s/20 s | [24] |

| PDA | In situ growth | 11%~95% RH | 20.77 Hz/% RH | 5 s/11 s | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, P.; Xu, Z.; Zhang, T. In Situ Growth of Dopamine on QCM for Humidity Detection. Chemosensors 2022, 10, 522. https://doi.org/10.3390/chemosensors10120522

Qi P, Xu Z, Zhang T. In Situ Growth of Dopamine on QCM for Humidity Detection. Chemosensors. 2022; 10(12):522. https://doi.org/10.3390/chemosensors10120522

Chicago/Turabian StyleQi, Pengjia, Ziwei Xu, and Tong Zhang. 2022. "In Situ Growth of Dopamine on QCM for Humidity Detection" Chemosensors 10, no. 12: 522. https://doi.org/10.3390/chemosensors10120522

APA StyleQi, P., Xu, Z., & Zhang, T. (2022). In Situ Growth of Dopamine on QCM for Humidity Detection. Chemosensors, 10(12), 522. https://doi.org/10.3390/chemosensors10120522