1. Introduction

In today’s diverse and fast-paced world, there are numerous ways for companies to achieve competitive advantages through the outsourcing of logistics and supply chain practices. Manufacturers, distribution firms, and those with supply chains have all been shown to benefit from outsourcing to third-party logistics (3PL) providers. 3PL refers to the process by which a manufacturer outsources logistics and distribution functions. Inventory management, cross-docking, door-to-door distribution, and product packaging are all facilities that a 3PL business provides [

1]. Globalization has aided in the establishment of a global network of industrial activities. The demand for 3PL services is expected to rise in order to keep it thriving. The reach of 3PL services is expected to expand over the forecast period, as supply chain efficiency improvements in terms of cost and reliability can be achieved with the aid of 3PL companies’ managerial and information technology expertise. Numerous critical factors have stimulated the growth of the 3PL market, such as the increase in trading activities due to globalization, fueled by dynamic business markets and global economic growth. Various trade-related practices are complex to tackle, but they are on the rise as a result of globalization. Thus, 3PL companies help companies to keep track of and control these activities. Another top impacting factor is the rise in focus of manufacturers and retailers on core competencies. Manufacturers or retailers find it challenging to deal with all affairs based on their abilities while maintaining core competencies in the industry [

2]. 3PLs essentially give them the ability to focus on their primary functions, core businesses, and sub-contracting activities, such as logistics, which they have less expertise at, therefore providing a steadfast platform for outsourcing all or parts of the supply chain functions. For instance, 3PL companies can make better use of transportation assets to foster respective specialization in production and distribution by balancing the needs of multiple client shippers through transportation and distribution functions, leading to economies of scale. Furthermore, if a company lacks the technological capability to achieve its objectives, it is pivotal to outsource to 3PLs.

The growth of the 3PL service market has been accelerated due to the resonance of the e-commerce boom and increased reverse logistics operations. Faster, more reliable delivery, high inventory turnover, and inventory staged in forwarding locations near customers are all part of the e-commerce trend. There has been a massive influx of third-party logistics (3PL) companies to help sustain this incredibly complicated supply chain, offering a wide variety of services. 3PLs are often contacted for assistance with omnichannel e-commerce fulfillment, warehouse, and delivery facilities, while 3PLs invest in technology both to serve their clients and for their own use. The role of e-commerce has been further amplified and accelerated due to the present global crisis: the COVID-19 pandemic [

3]. Since the outbreak of COVID-19, many shoppers are opting to buy online versus traveling to a physical store. The pandemic has also forced businesses to adapt to a fully digitalized business model to reach their consumer base. This boost in e-commerce creates challenges to supply chain operations, mainly last-mile delivery. Last-mile fulfillment is one of the most challenging and expensive aspects of a supply chain to manage [

4]. Consumers are becoming more accustomed to receiving services that are both fast and efficient. For shippers, the final-mile highlights key factors and complex challenges as part of the overall transportation space [

5]. On the pulse of adapting to growth in the logistics industry, e-commerce is seeing many of these market changes far before the consumer experiences them. In this respect, 3PLs have tailored to new distribution models, suitable warehouse locations, expansion of transportation modes, and increased visibility demand for shippers. As a matter of fact, a lot of companies are turning to 3PL providers for retooling their supply chain, with a significant minority (12.4%) of organizations plan to increase the use of 3PLs in the wake of COVID-19, according to a recent survey by the Business Continuity Institute [

6].

Based on the above discussions, choosing a third-party logistics provider (3PL) is a huge decision, thus a significant problem for any firm. Evaluation and selection of appropriate 3PL is an indispensable part of building sustainable supply chain partnerships. The noted fact is that supply chain management and logistics services done well are viable strategies in an e-commerce business or any business succeeding. The process of selecting 3PL providers begins with the development of decision criteria for defining and assessing potential candidates that can satisfy the firm’s service needs [

7]. Industry experts give the assessment information of the potential alternatives within this context considering the chosen criteria such as quality, cost, capacity, flexibility time, delivery capability, and benefits and risks of the outsourcing decision. Moreover, it is necessary to find 3PLs that have made significant investments in state-of-the-art technologies. For instance, the 3PL provider should have the technology solution to sync warehousing inventory with the ordering system and platform, providing real-time information on availability. That type of visibility can help with tracking, ordering, and forecasting. On top of developing core businesses that maintain competition in supply chains and meet global needs in the economic environment, large firms are focusing on creating sustainable supply chains. In respect of that, social and environmental factors have become significant for creating a more green and resilient supply chain. Global warming and recent economic disasters have necessitated a greater need for more sustainable logistics services [

8].

Owing to the characteristics of multifaceted decision-making problems, 3PL selection can be regarded as a complicated multi-criteria decision-making (MCDM) problem due to the availability of quantitative, qualitative, and multiple criteria in the natural decision-making process. Given the abovementioned importance of sustainable 3PL providers, there is sparse research to date that the 3PL selection problem developing countries, especially in Vietnam, according to our literature review. In Vietnam, logistics services’ growth rate reaches 16–20% per year [

9]. However, the logistics service industry’s competitiveness is still low, and logistics costs are still very high at a rate of 20–25% of Vietnam’s GDP. Within this context, the 3PL solution can help reduce costs, boost sales, and build brand identity given Vietnam’s size and diversity. According to Armstrong and Associates, the revenue of the 3PL market in Vietnam achieved a USD 4.1 billion in 2019 [

10], ranking the third in Southeast Asia, just behind Indonesia (18.6) and Thailand (6.0). The remarkable growth of the 3PL market has come from the development of the e-commerce industry. In fact, the demand for 3PL is expected to escalate, as manufacturers and retailers aim to focus on their core businesses. Hence, they tend to outsource logistics services. As a result, evaluating and selecting optimized 3PL providers is an indispensable part of any firm’s long-term strategies.

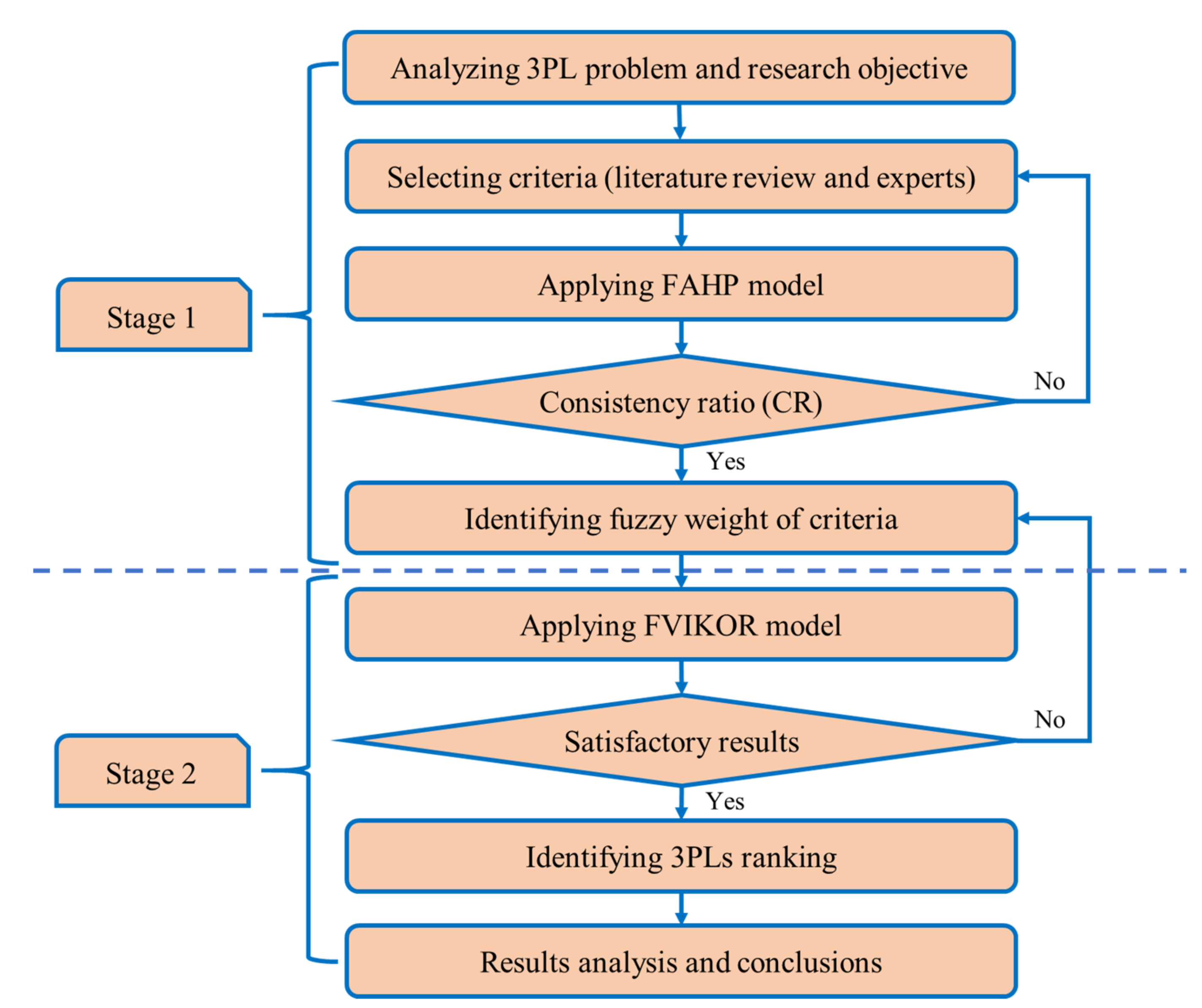

To this end, this article aims to provide a comprehensive and coherent evaluation model for assessing and ranking 3PL providers, more specifically, to solve the problem in Vietnam. A two-stage multi-criteria optimization model is presented for this purpose. Additionally, we consider the fuzziness in the decision data and group decision-making process to use linguistic variables in the AHP and VIKOR methods. Thus, in the first stage, FAHP is applied to evaluate and calculate each criterion’s relative significant fuzzy weight. The fuzzy numbers in triangular forms were used to convert the qualitative content and ambiguity of parameters in the real-world decision-making process, which are generally represented in linguistic terms. According to the well-developed 3PL evaluation and selection literature, the authors define the list of criteria including economic, service level, environmental, social, and risk are dominant decision-making factors in 3PL selection. In detail, the list of 15 criteria is categorized as follows: economic (logistics cost, financial stability, IT and R&D systems, network management), service level (quality of service, reliability and delivery time, flexibility and responsiveness), environmental (environmental pollution, ecological laws, green operation), social (health and safety, voice of customer, reputation), and risk (operational risk, financial risk). In the second stage, FVIKOR is developed to rank multiple alternatives based on the compromise solution approach that provides a maximum “group utility of the majority” and the minimum “individual regret of the opponent”. Eventually, the author considered an empirical case study of 10 Vietnamese 3PL companies into the evaluation and selection process by using the prescribed approach.

One of the innovations of this study is to determine the best 3PL providers in Vietnam while considering the most influential and conflicting criteria in recent times, which has almost been missed in the literature. Methodologically, a combination of FAHP and FVIKOR has been done for the first time to solve the problem. In terms of applications, the developed integrated model can assist management stakeholders to better understand the entire process of 3PL assessment and selection from the standpoint of sustainability. Uncertain and vague judgments during the evaluation process were also addressed with linguistics terms and fuzzy theory to enhance the robust results. As a result, the evolved approach offers a complete, accurate, and effective decision-making method for the 3PL evaluation and selection.

The remnant of this paper is outlined as follows. Conducted research on outsourcing for logistics are reviewed and the gaps addressed by the current study are examined in the next section.

Section 3 summarizes the materials and methods used in the research.

Section 4 presents the result analysis of a case study in Vietnam. The paper is concluded in

Section 5 by providing managerial insights and contributions of the research.

2. Literature Review

Recent literature review on the 3PL industry concerned sustainable development with approaches where the economic, environmental, and social dimensions of a business are harmonized. For example, Raut et al. [

11] emphasized that ecological, social, and economic dimensions must be considered to obtain well-rounded sustainable 3PLs. The authors proposed a hybrid MCDM model using the data envelopment analysis (DEA) and analytic network process (ANP) to help decision makers assess and obtain the optimized 3PLs from the environmental sustainability perspective. Findings showed that better transportation planning, inventory and warehouse management, lower inventory costs, and sustainable supply chain activities are all aided by eco-friendly transportation and 3PLs. In addition to investigating the economic effect (pricing policies) regarding the activities of 3 PLs, Jamali and Rasti-Barzoki [

12] simultaneously considered two significant sustainable indicators: green transport by lowering carbon emissions and consumer satisfaction by providing product time. In this research, the effects of the 3PLs in the sustainable supply chain were investigated using a game-theoretical approach. The term “green logistics outsourcing” is more than just a buzzword since today, organizations aim to minimize simultaneously the negative economic impacts of logistics policies and social factors such as pollution’s effects on the environment. In light of this, Vazifehdan and Darestani [

13] presented a combinational approach using the quality function deployment (QFD), fuzzy ANP, and superiority and inferiority ranking (SIR) methods to provide an assessing and ranking model for outsourcing green logistics. The proposed model was illustrated for a case study in the petrochemical industry, where the strategic outsourcing of green logistics is undoubtedly indispensable.

Approaches to logistics outsourcing are summarized in the latest review paper of Aguezzoul [

14], in which the author classified the methodologies into five groups: MCDM techniques, statistical approaches, artificial intelligence, mathematical programming, and hybrid methods. According to the current systematic review, MCDM techniques are the most widely cited, and most of them combined with techniques from the same category or with other methods. However, most of the studies conducted on 3PLs are empirical and focus majorly on the benefits and risks of the outsourcing decision. Raut et al. [

11] pointed out that there is limited literature that has used MCDM methods to analyze environment sustainability issues for 3PL assessment and selection, especially in developing countries context.

Table 1 presents a literature review on the 3PL sector in terms of problem characteristics, approaches, and applied areas in the past decade, as well as indicating the gap proposed by the current study. As can be seen, the main MCDM methods used in the case of logistics outsourcing problems, which are analytic hierarchy process (AHP) [

15,

16,

17,

18], analytic network process (ANP) [

11,

13,

19], VIKOR [

19], technique for order preference by similarity to ideal solution (TOPSIS) [

16,

17,

20,

21,

22], data envelopment analysis [

11,

22,

23,

24], and other MCDM methods [

25,

26].

It is noteworthy that when choosing MCDM methods, it is prudent to select methods of normalization and other parameters, as each method and combination brings different results [

27]. Among well-known weighting methods, AHP has been the most commonly used due to its popularity and applicability. For ranking methods, TOPSIS and VIKOR techniques, based on the distance from the ideal solution, have become very popular in the field [

28]. In the last few decades, fuzzy TOPSIS was used in a very broad spectrum of areas, with implementations in the defense industry [

29]. Group decision-making is a vital point of a fuzzy TOPSIS technique, where multiple experts influence the final decision. Meanwhile, the VIKOR method of compromise ranking determines a compromise solution, providing a maximum “group utility” for the “majority” and a minimum of an individual regret for the “opponent”. For VIKOR, rankings obtained using any normalization methods could be even reversed in comparison to rankings obtained using VIKOR without normalization, while the TOPSIS method’s normalized values by vector normalization may be dependent on the evaluation unit.

In this paper, the authors propose an integrated approach of fuzzy analytic hierarchy process (FAHP), and fuzzy vlsekriterijumska optimizacija i kompromisno resenje (FVIKOR) for the 3PL selection problem. The AHP method is a multicriteria method of analysis based on an additive weighting process, in which several relevant attributes are represented through their relative importance [

30,

31,

32]. The pairwise comparison method in the AHP is a powerful procedure to identify the importance of different factors to the objective. Its understandability in theory, simplicity in application, and robustness of its outcomes have been proven in practice and validated by a diverse range of decision-making problems. However, the shortcoming of the AHP method is that it does not take into account the uncertainty associated with the mapping of human judgment to a number by natural language. To solve this, the fuzzy AHP based on the fuzzy interval arithmetic with triangular fuzzy numbers has been integrated into many studies. For rankings, VIKOR method simultaneously ranks multiple alternatives based on the compromise solution approach that provides a maximum “group utility of the majority” as well as the minimum “individual regret of the opponent” [

33]. Owing to the fuzziness in the decision data and group decision-making process, linguistic variables are also utilized in the VIKOR model to assess the weights of all criteria and the ratings of each alternative with respect to each criterion.

Thus, the authors aim to fill the gap in the existing literature by solving a case study of evaluating and selecting 10 potential 3PL providers in Vietnam. The main contributions of this paper are as follows: (1) a combined model using the FAHP and FVIKOR methods is devoted to the emerging research topic of sustainability in the 3PL selection problem; (2) a case study of assessing 10 potential 3PL providers in Vietnam is used to test the quality of the model; (3) the results reflect that the gap of applying the proposed method in the field of the 3PL industry is successfully addressed, and the integrated framework can be a powerful decision support tool for the evaluation and selection problem in any area.

5. Discussion and Conclusions

Logistics outsourcing to 3PL is a critical component for today’s businesses to lead supply chains toward sustainability. As the world becomes increasingly globalized, and consumer demand for fast and free shipping keeps climbing, so does the demand for 3PL services. Efficient and momentous decisions on outsourcing are vital to the performance of businesses in today’s competitive market. A complete transformation in business operations and logistical procedures caused by the COVID-19 pandemic indicates that processes have become more dynamic than before so that companies are being placed in a position to choose between the most critical tasks. The pandemic also reveals for many organizations that they have a lack of visibility in the further reaches of their supply chain [

70]. Thus, one of the services that offers many potentials is outsourcing to 3PL providers, which must be placed at the forefront of any business with supply chain management. A 3PL having advanced technology along with an efficient and expert workforce will enhance businesses with their expertise and operational efficiency. In today’s context, it must be mentioned that green factors and policies have become increasingly important for businesses as public awareness of their environmental impact has grown. The environmental performance of a corporation is influenced by the environmental performance and image of its suppliers, in addition to the company’s internal environmental efforts.

Hence, this paper proposes a hybrid multi-criteria optimization model which can be employed for solving the logistics outsourcing problems to a third party in this era. The research procedure consists of two stages. First, FAHP is used to evaluate and calculate the relative significant fuzzy weight of each criterion. Knowing the well-developed status of 3PL evaluation and selection, the authors define the list of criteria including economic, service level, environmental, social, and risk as dominant decision-making factors in 3PL selection. Consequently, the list of 15 criteria is defined including economic (logistics cost, financial stability, IT and R&D systems, network management), service level (quality of service, reliability and delivery time, flexibility and responsiveness), environmental (environmental pollution, environmental laws, green operation), social (health and safety, voice of customer, reputation), and risk (operational risk, financial risk). In the second stage, FVIKOR is developed to rank the alternatives. The use of linguistic terms through the whole evaluation process can resolve the fuzzy and uncertain decision-making problem in nature [

71]. Results from the AHP indicate that reliability and delivery time, voice of customer, logistics cost, network management, and quality of service are the most impactful factors when choosing providers in the Vietnam 3PL market. From the final ranking by FVIKOR, 3PL01 was identified as the most efficient logistics provider with a score of 0.0375.

Therefore, the contributions of the papers can be summarized as follows. First, this paper proposed a hybrid MCDM model by combining FAHP and FVIKOR models for the evaluation and selection of logistics providers based on multiple factors in economic, environmental, and social aspects. Second, the results of a case study of 10 potential logistics companies in Vietnam provide managerial insights into the logistics industry in Vietnam. Third, the authors expect that the results of the paper will reflect the current picture of Vietnamese logistics, especially in the COVID-19 pandemic. Therefore, this paper can be used as a useful guideline for government, investors, and policymakers in selecting and investing in the logistics industry toward sustainability.

It is proven through many applications of MCDM methods in several types of industries. The capabilities of these methods to be tailor-fitted according to the requirements of certain industries make them more applicable if may not all, to many kinds of industries. Future studies should consider new assessment factors with respect to the post-COVID-19 pandemic that can impact the process of evaluation and selection of logistics providers to enhance the robust results. Besides, other MCDM models, such as DEA, TOPSIS, PROMETHEE II, COPRAS, SWARA, etc., should be combined for ranking alternatives [

72,

73], and the accuracy and reliability of these rankings should be measured using a reference for ranking similarity coefficients (i.e., weighted Spearman’s rank correlation coefficient, rank similarity coefficient) [

28,

74].