Uncertain Interval Forecasting for Combined Electricity-Heat-Cooling-Gas Loads in the Integrated Energy System Based on Multi-Task Learning and Multi-Kernel Extreme Learning Machine

Abstract

:1. Introduction

1.1. Research Motivation

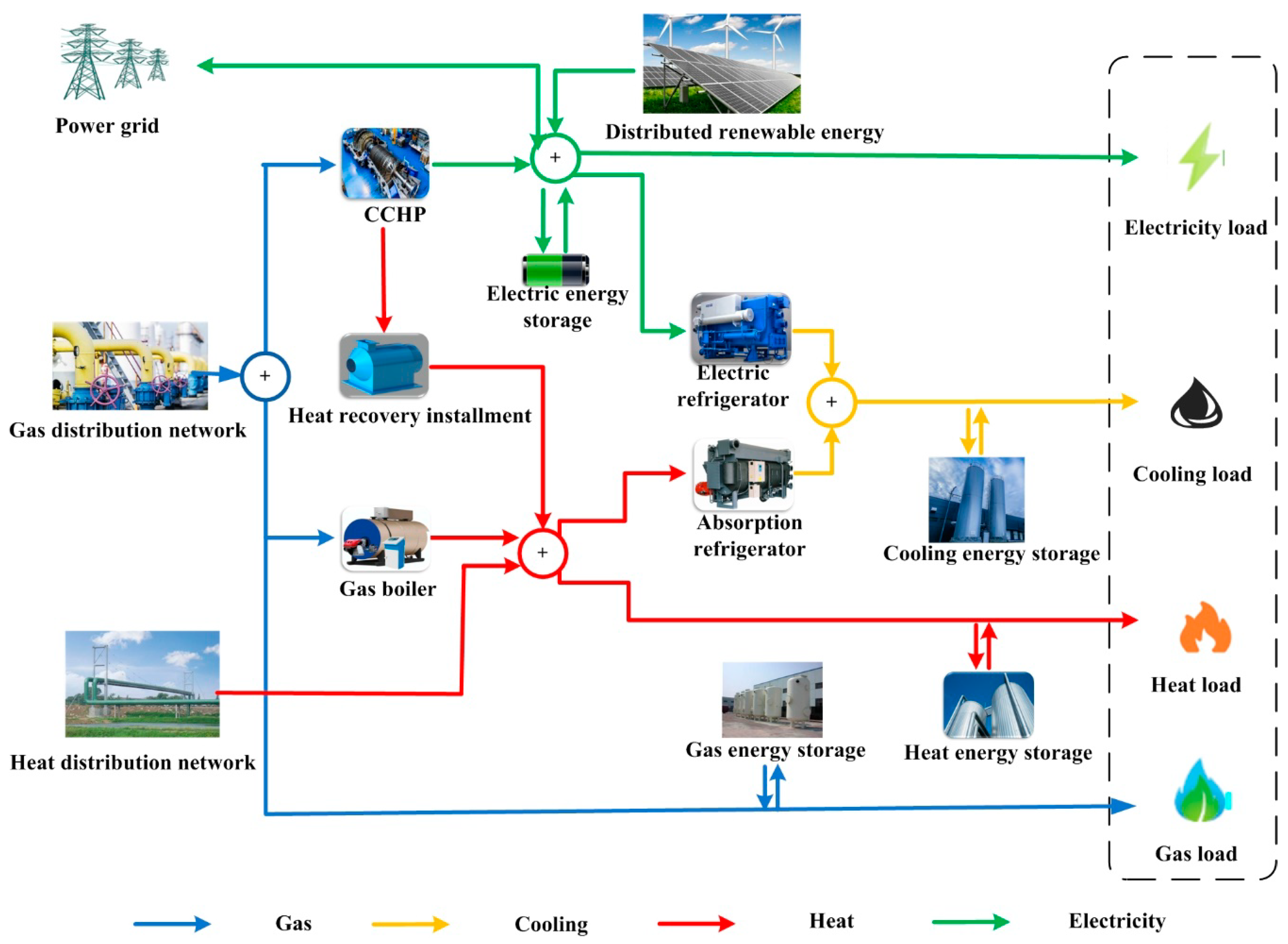

1.2. The Analysis of the Complicated Coupling Relations among the Various Energy Subsystems in the IES

1.3. Literature Review

1.4. Our Contributions

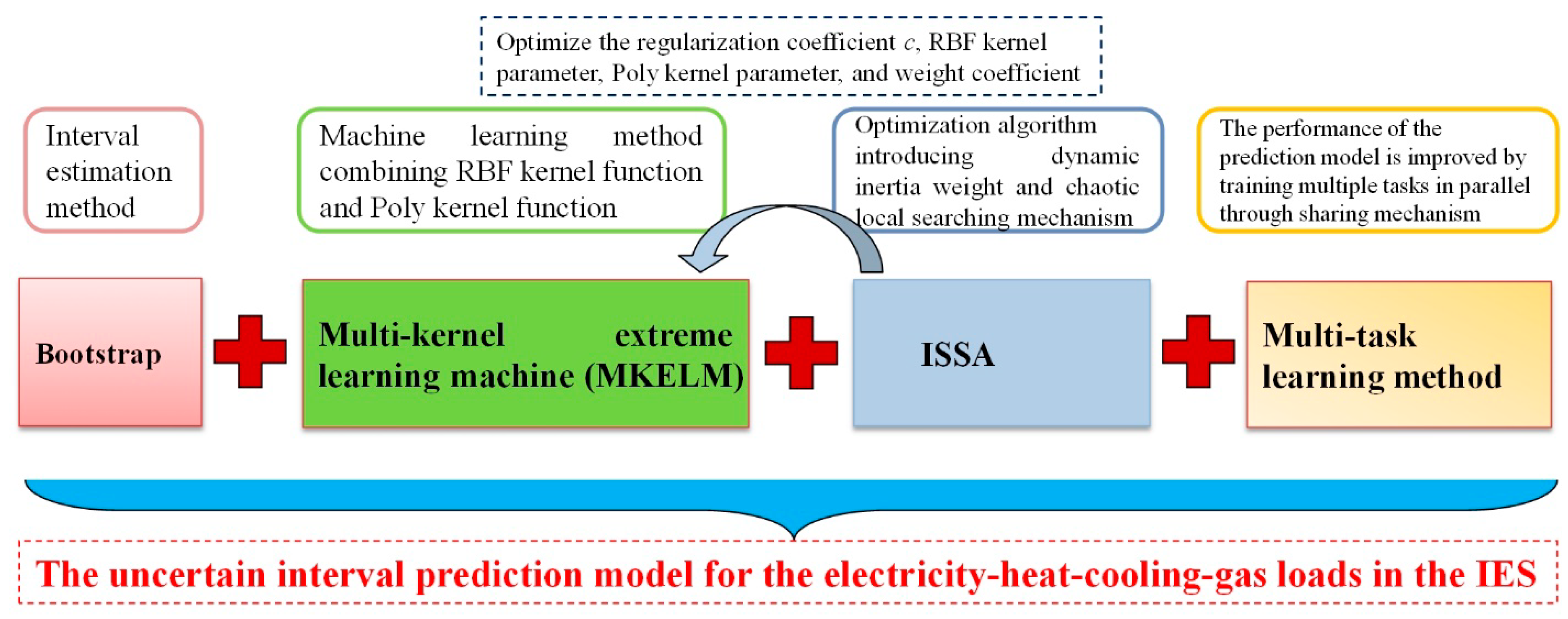

- (1)

- The complicated coupling relations among the various integrated energy subsystems are untangled systematically, and the significant input variables of the established hybrid load prediction model are determined.

- (2)

- The uncertain interval forecasting model of the combined electricity-heat-cooling-gas loads in the IES is established based on the MTL method, the Bootstrap method, the MKELM, and the ISSA.

- (3)

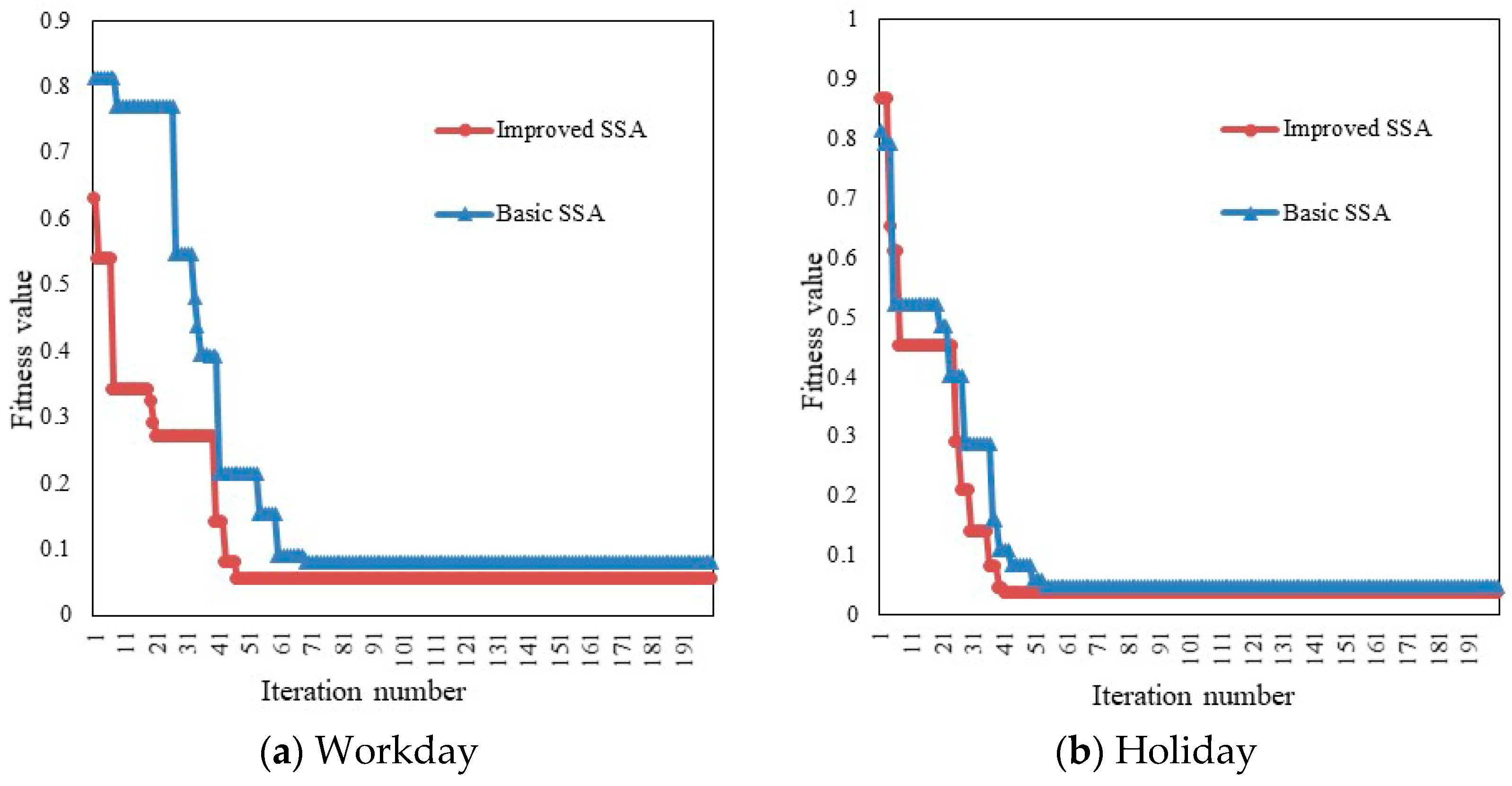

- Aiming at solving the problems of local optimum, low convergence speed, and low precision of the basic SSA, the improved SSA (ISSA) is proposed by introducing the inertia weight mechanism and chaotic local searching strategy into the basic SSA.

- (4)

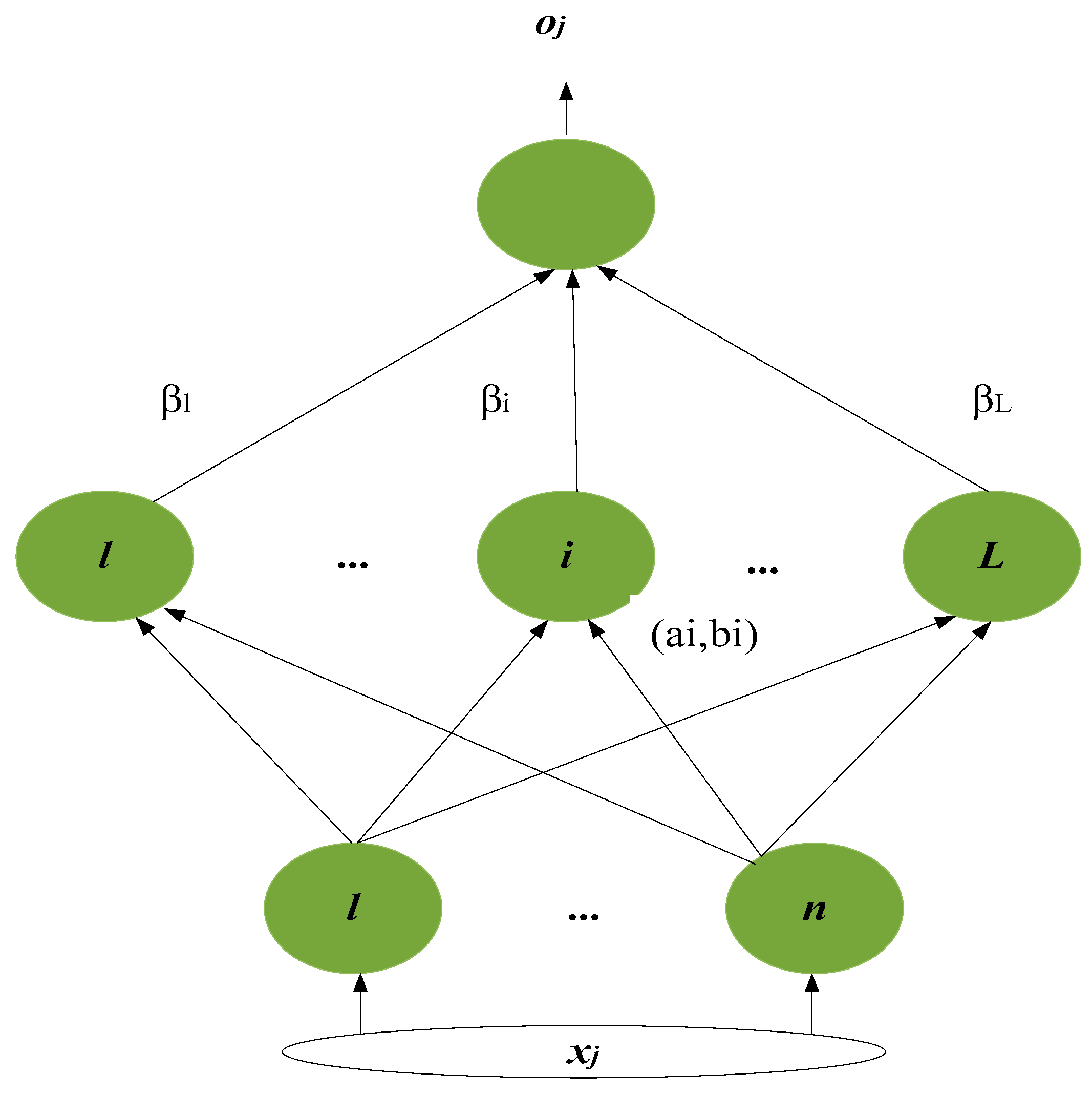

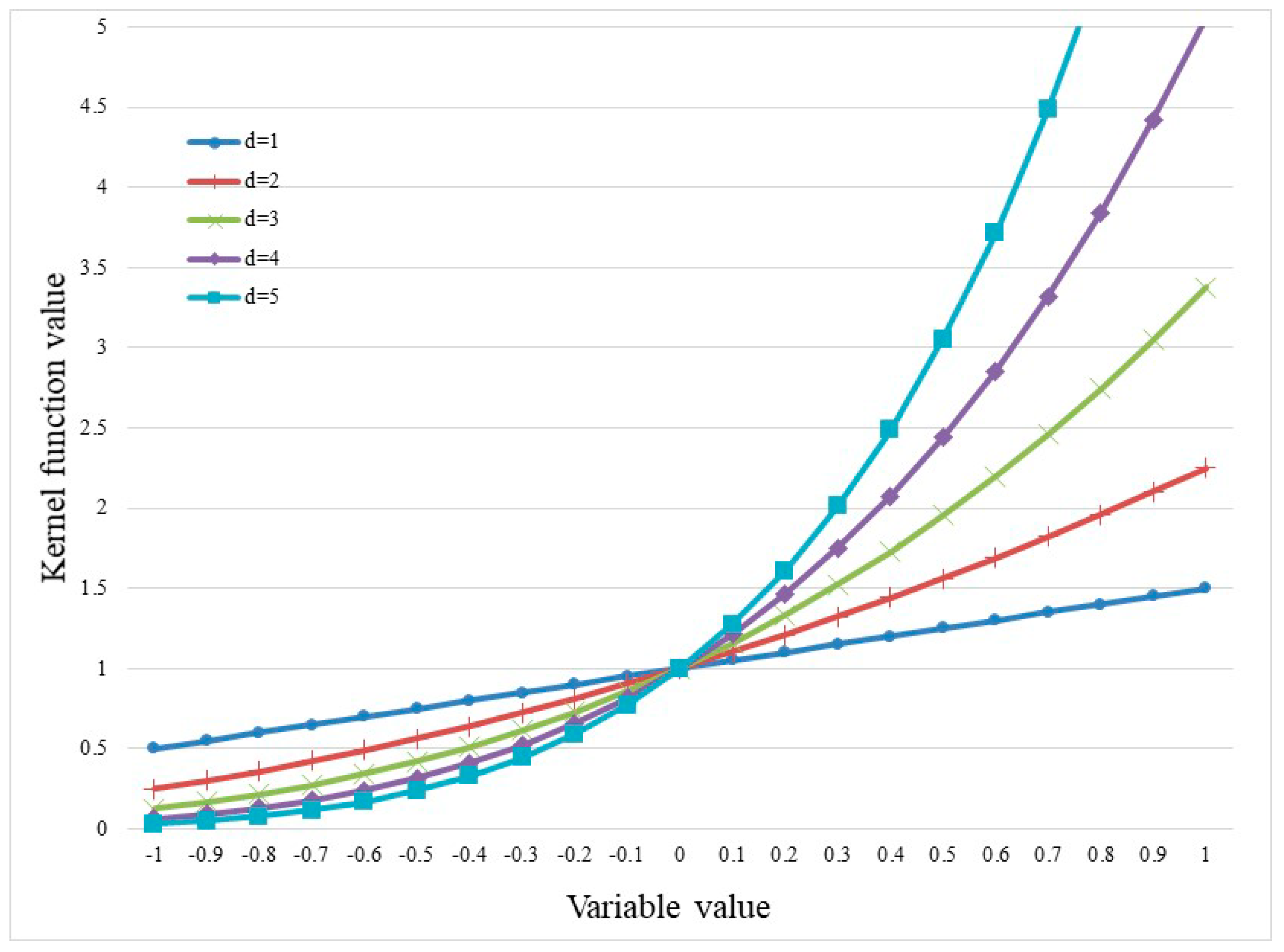

- The MKELM model is proposed by combining the RBF kernel function and the Poly kernel function, so as to integrate the superior learning ability and the generalization ability of the two kernel functions.

1.5. Organization of the Research

2. Materials and Methods

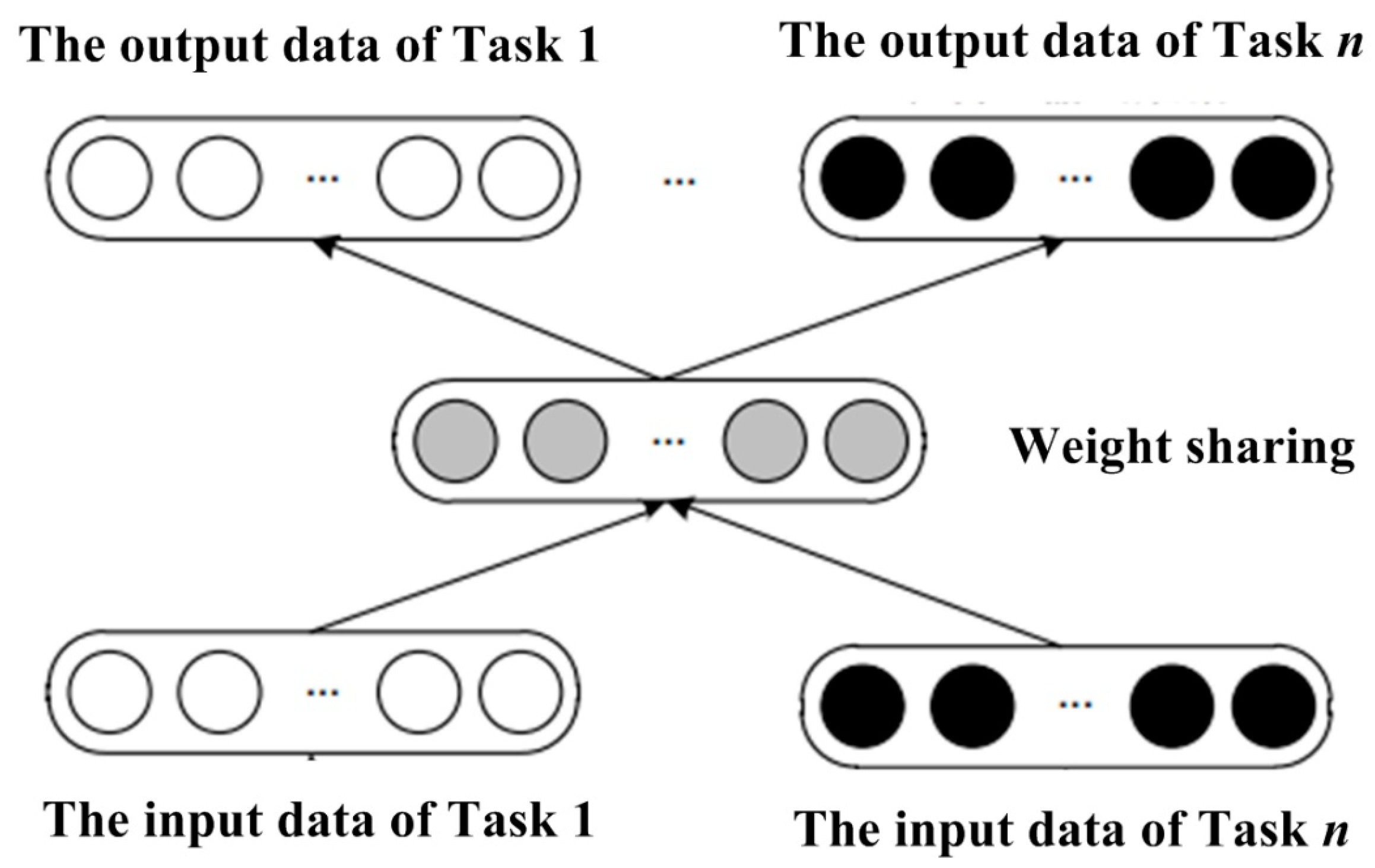

2.1. The Multi-Task Learning Method

2.2. The Bootstrap Method

2.3. The Multi-Kernel Extreme Learning Machine

2.4. The Improved SSA

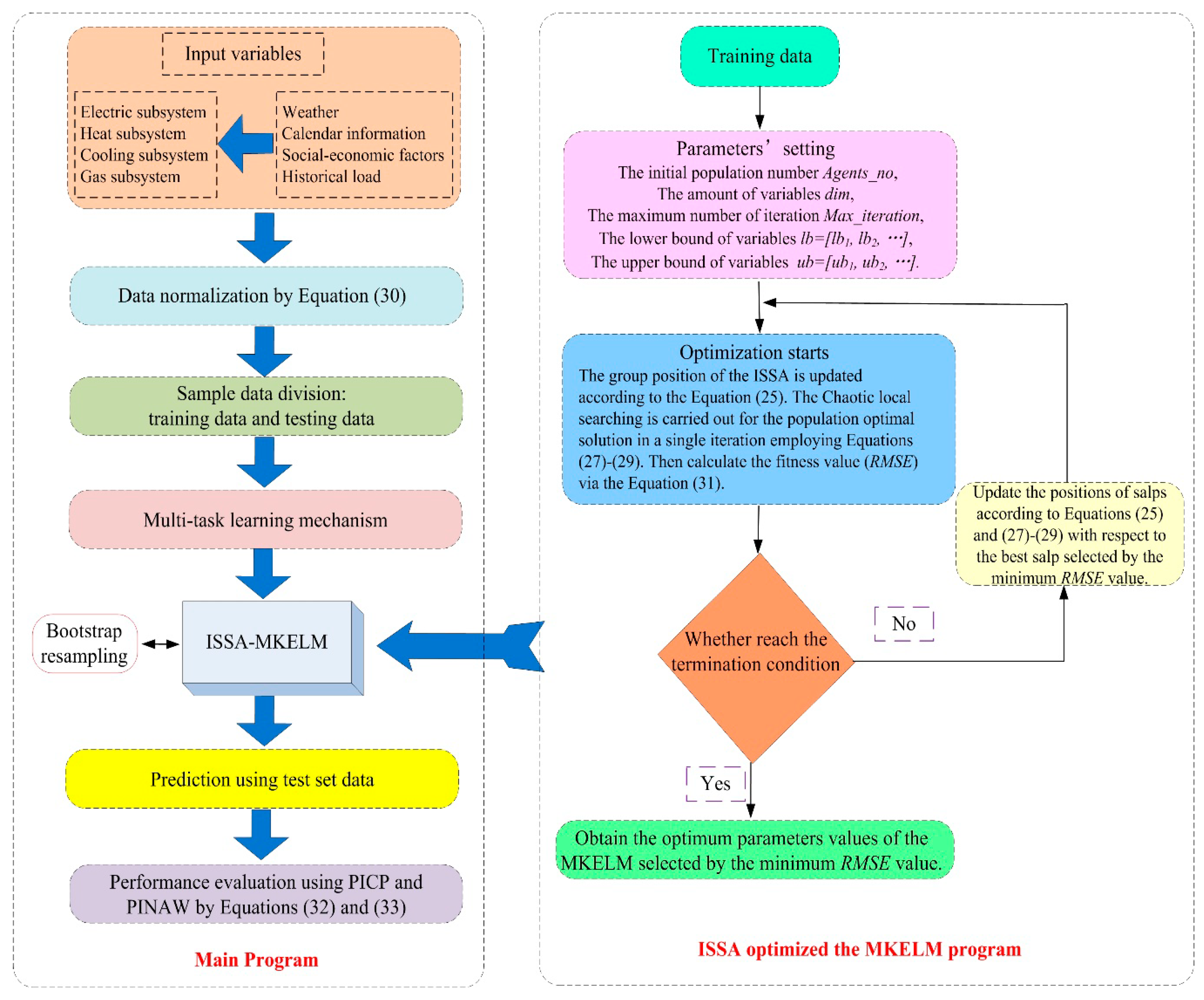

- (1)

- Parameters setting

- (2)

- Population initialization

- (3)

- Fitness function construction

- (4)

- Iteration

- (1)

- The individual is generated into chaotic variables aswhere is the chaotic variable, and are the minimum value and maximum value of the j-th variable.

- (2)

- Generating chaotic sequence by logic mapping as

- (3)

- The chaotic sequence is transformed into the searching space of the target solution to generate a new position, and compared with the group optimal individual. The better value is selected to update, so as to complete the local searching process. This procedure can be written as

2.5. The Established Uncertain Interval Forecasting Model for the Combined Electricity-Heat-Cooling-Gas Loads in the IES

- (1)

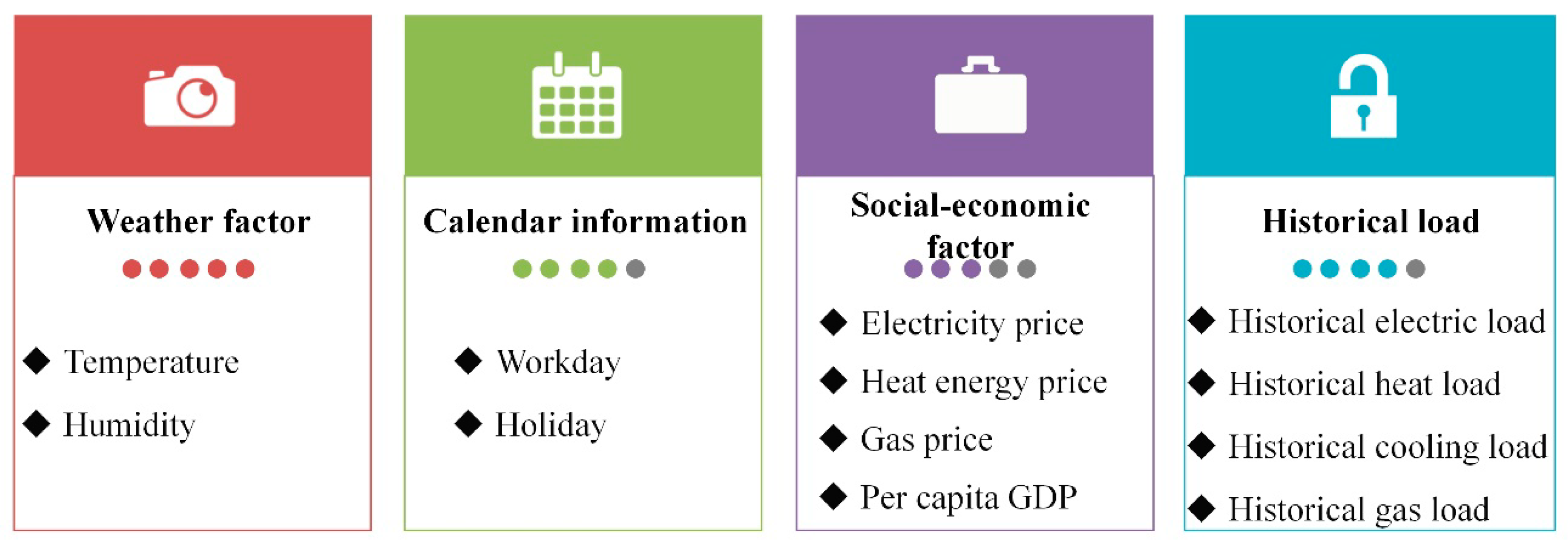

- The selection of model variables and the preprocessing of sample data

- (2)

- Sample division

- (3)

- Multi-tasks construction

- (4)

- Parameters setting of the ISSA and the optimal values for the parameters in the MKELM

- (5)

- Uncertain interval prediction

- (6)

- Forecasting performance evaluation

3. Results

3.1. Variables Selection and Data Preprocess

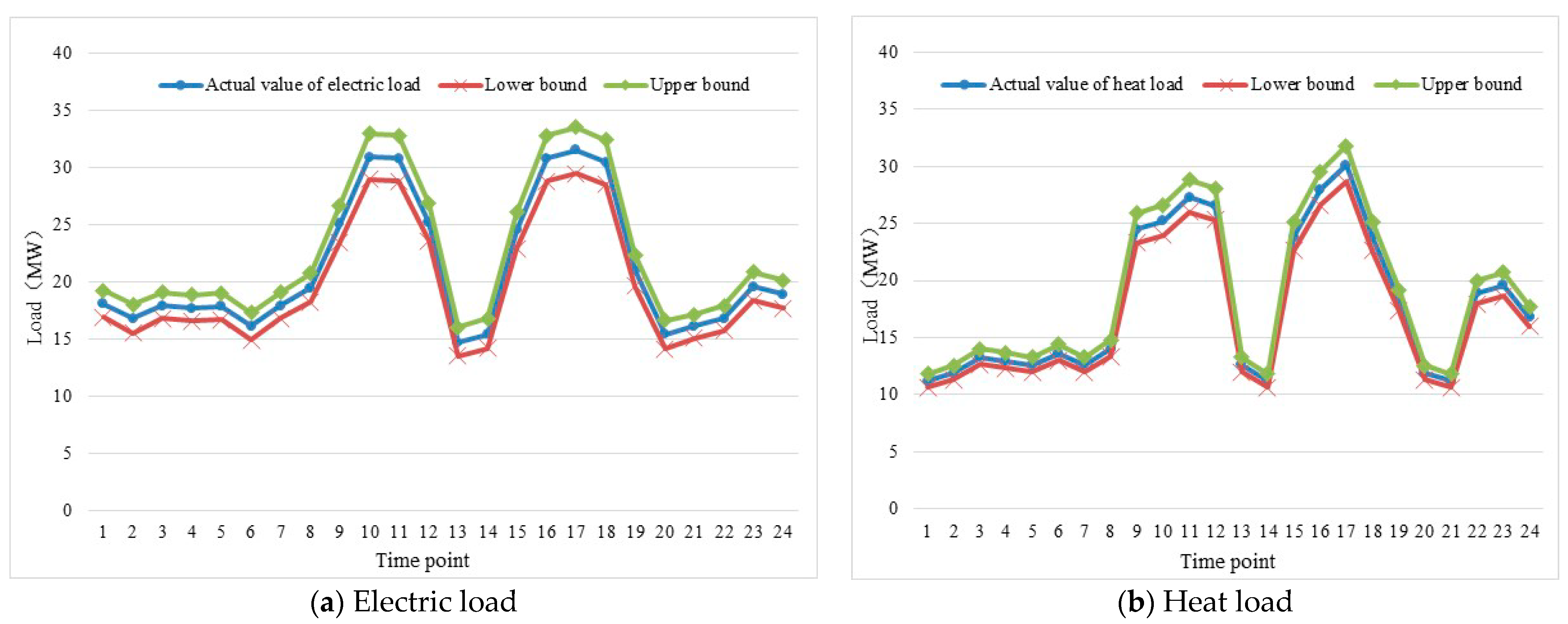

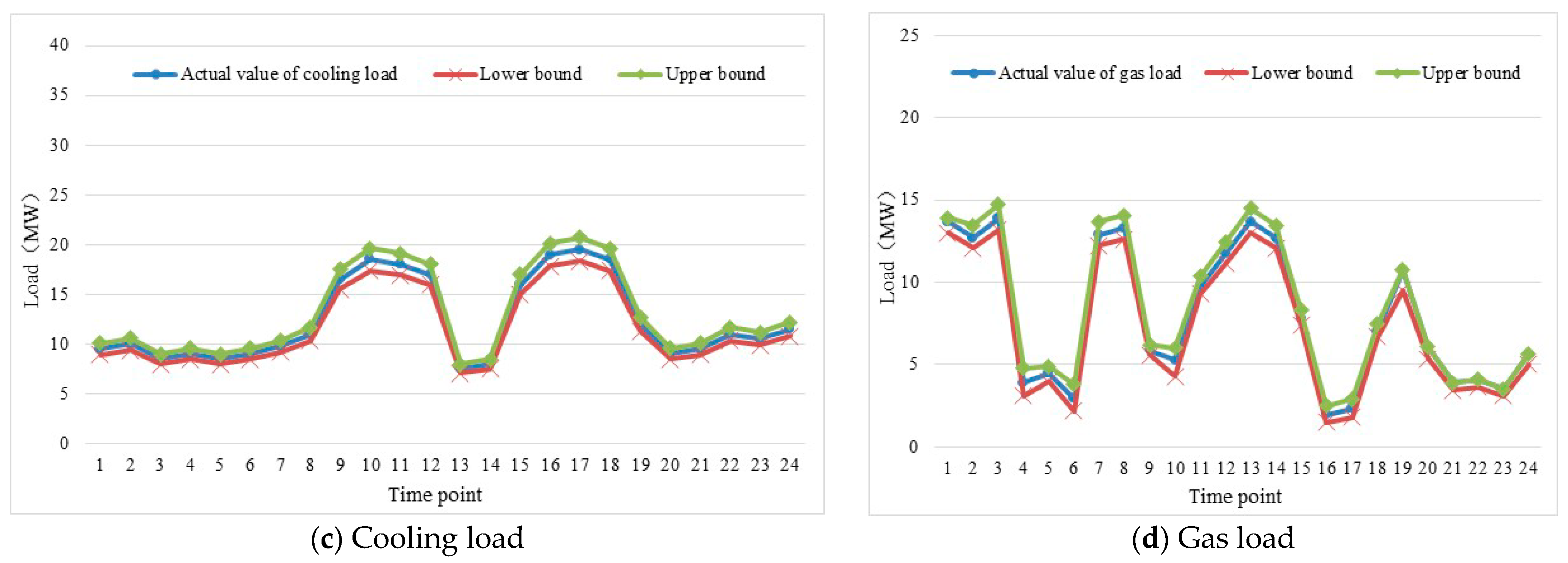

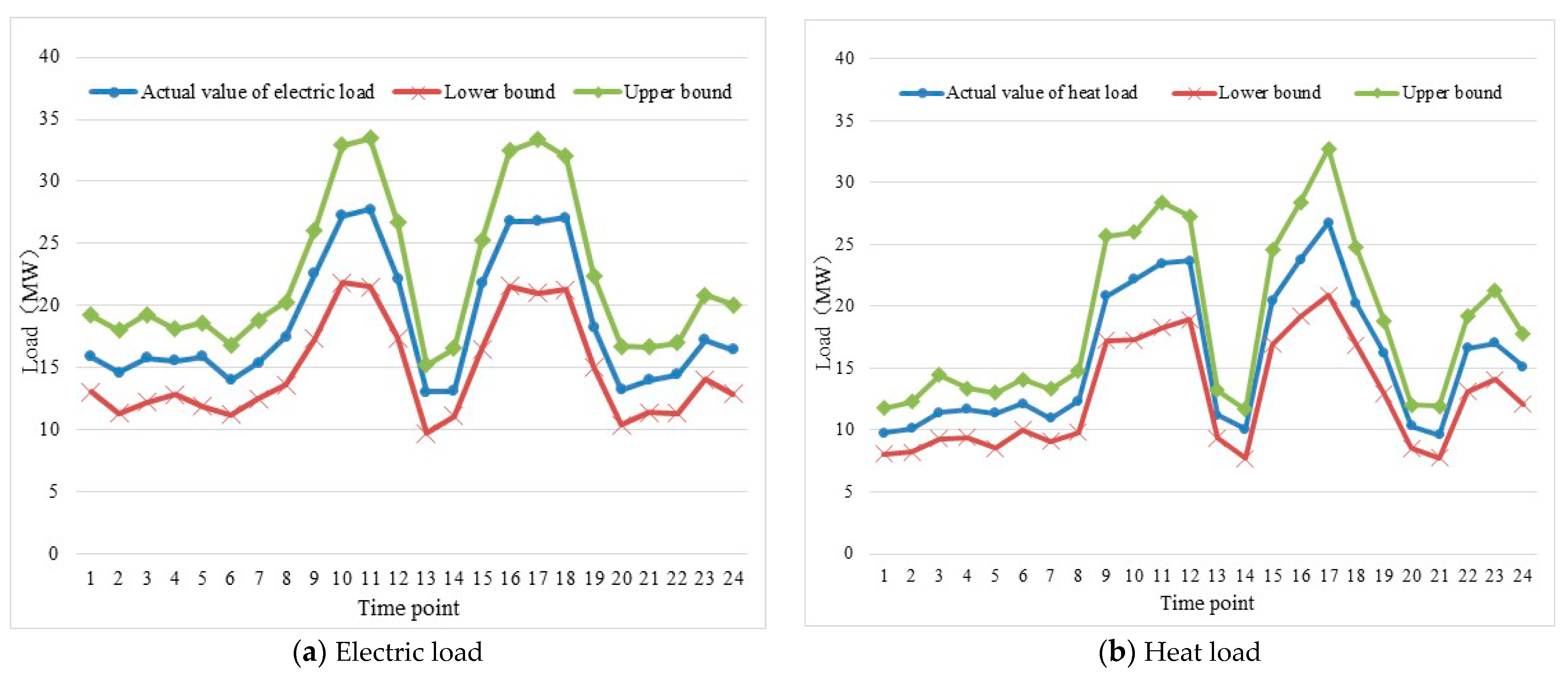

3.2. Forecasting Results Analysis

- (1)

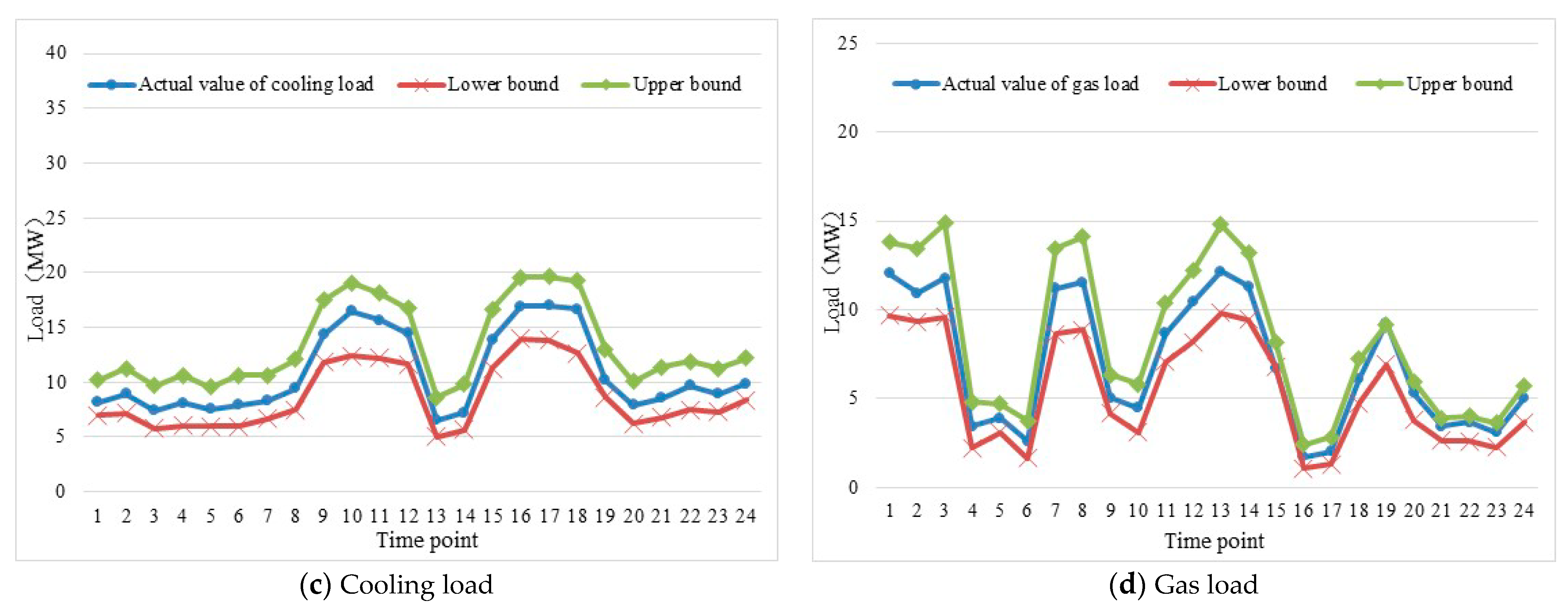

- Electric, heat, cooling, and gas loads have peak, flat, and valley periods, but the number of peak, flat, and valley is different. The prediction results of the uncertain interval forecasting model established in this paper can better reflect the fluctuation characteristics of various loads. However, generally, the prediction interval is relatively large in the peak and valley periods, which indicates that the load is often difficult to predict at the time point with large fluctuation.

- (2)

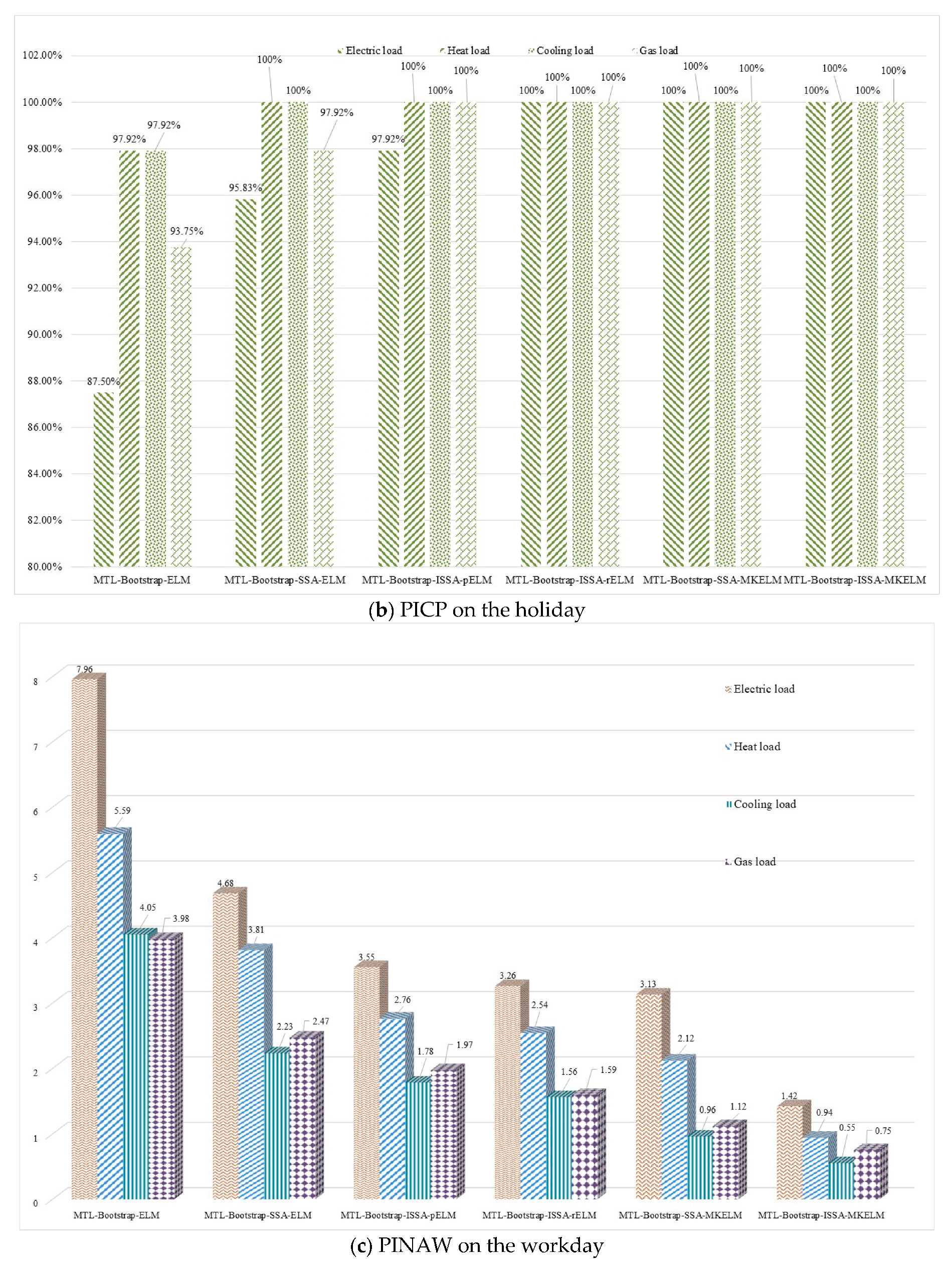

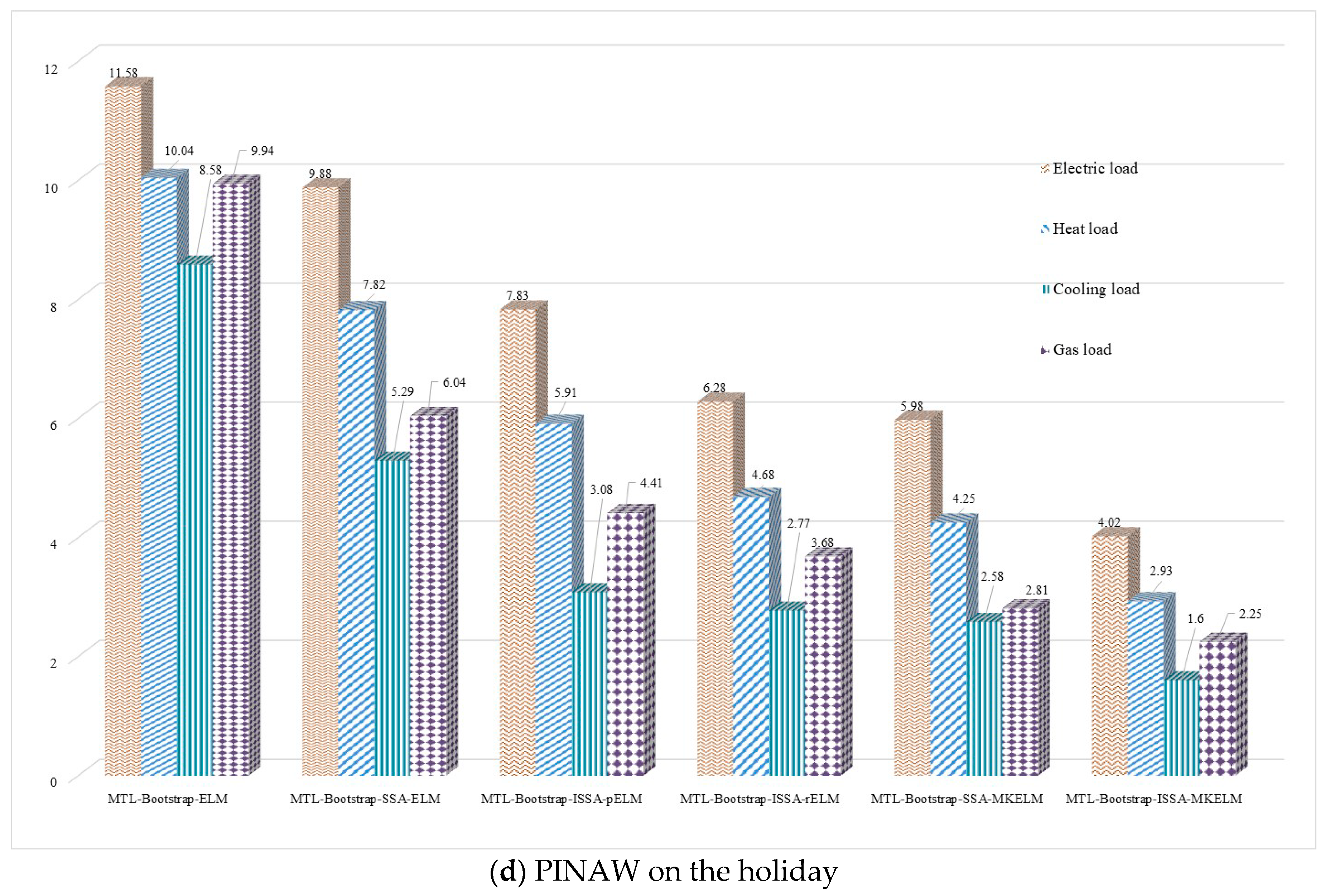

- The electric load, heat load, and gas load fluctuate greatly, but the prediction interval of electric load is large. The PINAW values of electric load prediction on a workday (July 12) and holiday (July 22) are 1.42 MW and 4.02 MW, respectively, while the PINAW values of heat load, gas load, and cooling load prediction on workday (July 12) and holiday (July 22) are 0.94 MW and 2.93 MW, 0.55 MW and 1.60 MW, as well as 0.75 MW and 2.25 MW, respectively. This is mainly because the inertia of heat load, gas load, and cooling load is stronger than that of electric load, and the characteristics of easy storage for heat load, cooling load, and gas load can provide more flexible backup for the IES of industrial park, which makes the prediction interval of heat load, cooling load, and gas load relatively small.

- (3)

- Although the fluctuation of electric, heat, cooling, and gas load is various on a workday (July 12) and holiday (July 22), the forecasting results of the workday are better than those of the holiday. The PICP values of electric, heat, cooling, and gas loads prediction are all 100% on the workday and holiday, while the PINAW values of electric, heat, cooling, and gas loads prediction on the workday are 1.42 MW, 0.94 MW, 0.75 MW, and 0.55 MW, respectively, which are 64.76%, 67.85%, 66.64%, and 65.75% lower than those on the holiday (the PINAW values of electric, heat, cooling, and gas load prediction on holiday are 4.02 MW, 2.93 MW, 2.25 MW, and 1.60 MW, respectively). The multi-energy loads demand on holiday has more uncertainties, therefore, it is much more difficult to carry out accurate load forecasting.

4. Discussion

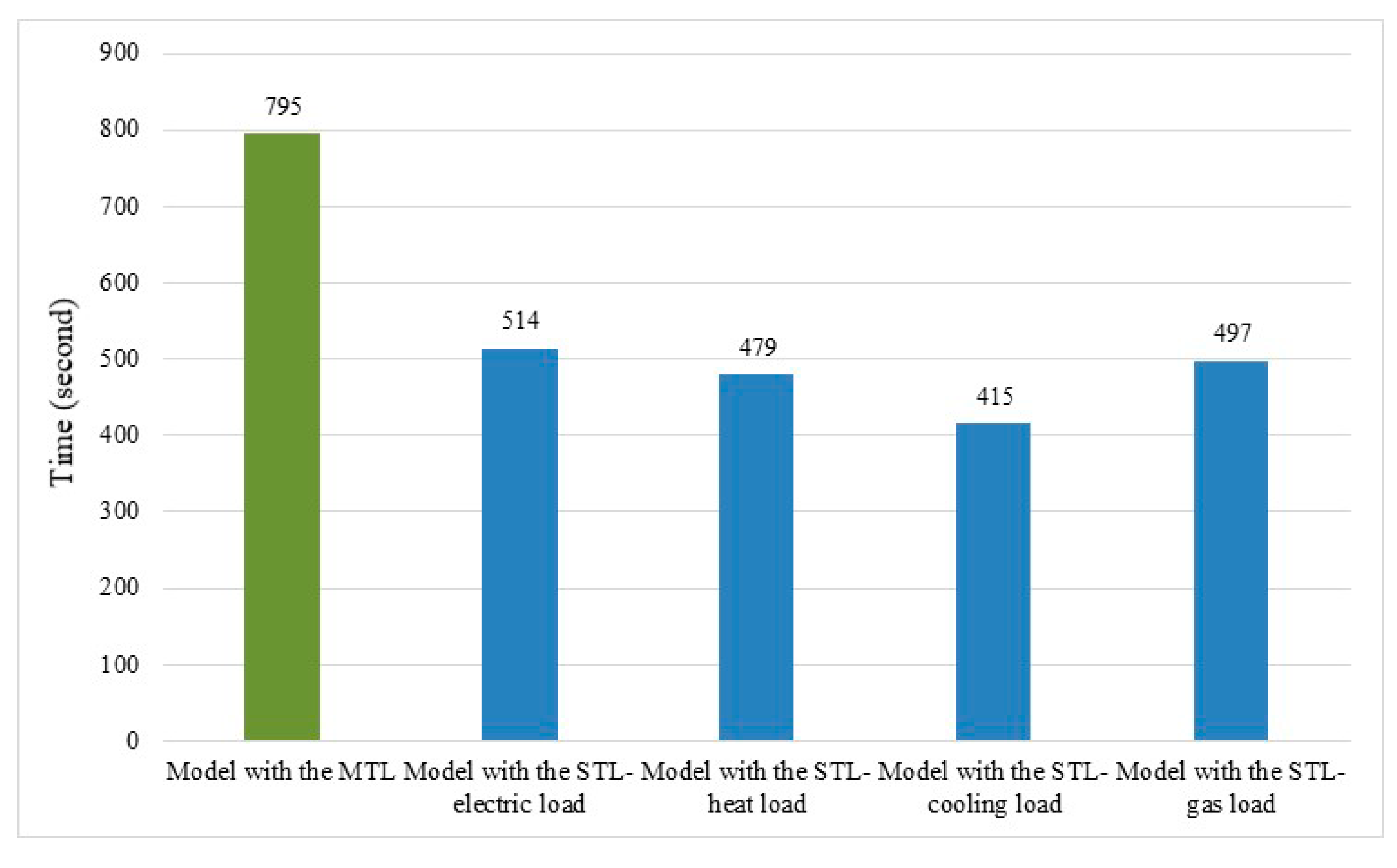

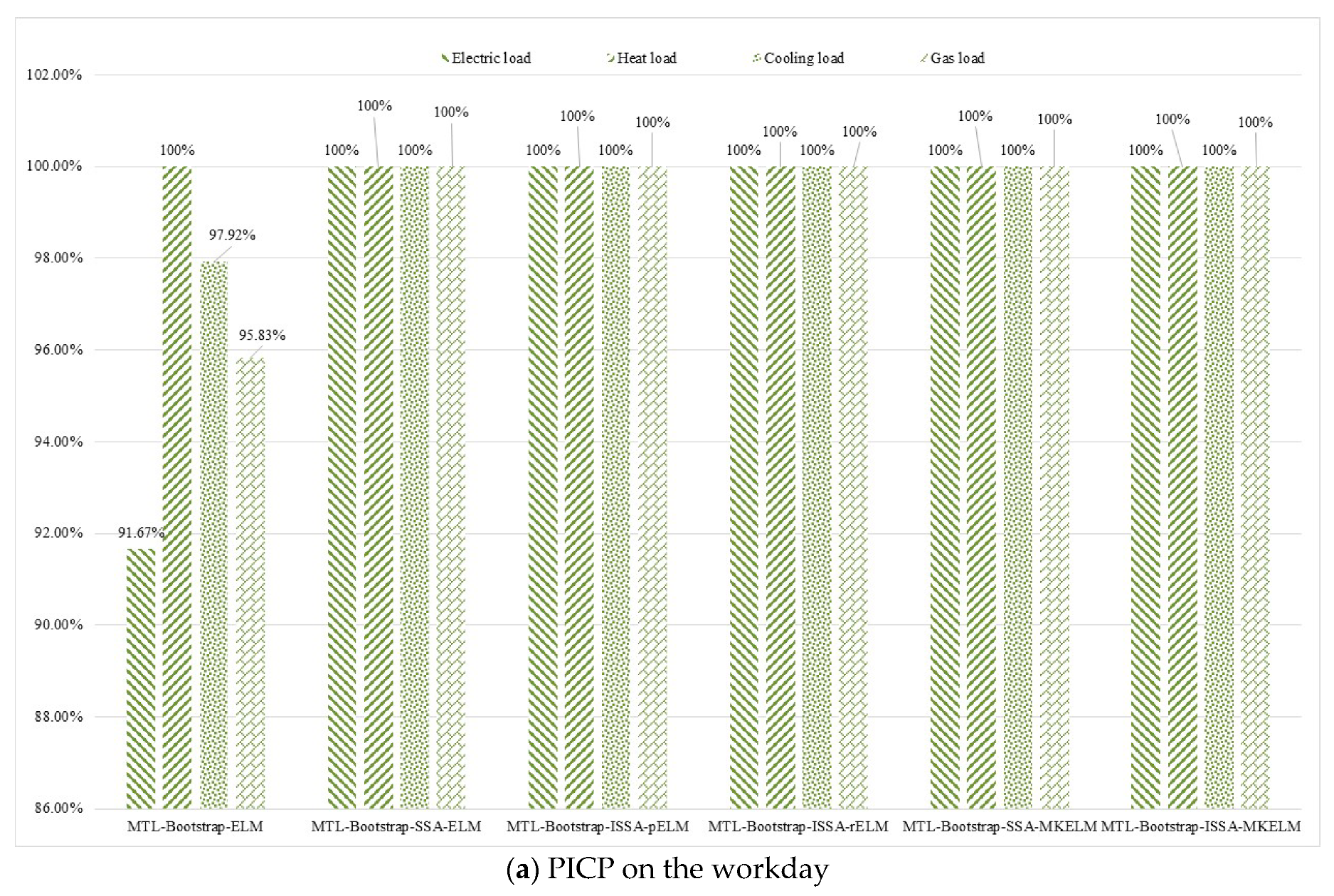

4.1. Comparison Discussion on the Forecasting Results Obtained by the MTL Method and STL Method

4.2. Comparison Discussion on the Forecasting Results Obtained by Other Optimization Algorithms and Kernel Functions of the ELM

5. Conclusions

- (1)

- The prediction results of the electricity-heat-cooling-gas loads of the IES on the workday and holiday forecasted by the established uncertain interval prediction model integrating the MTL method, the Bootstrap method, the ISSA, and the MKELM method are in good accordance with the actual loads. Additionally, the prediction results on the workday are better than those on the holiday, although the fluctuation of electric, heat, cooling, and gas loads are varied on the workday and holiday.

- (2)

- Through comparing the prediction accuracy of the Bootstrap-ISSA-MKELM based on the MTL method and the Bootstrap-ISSA-MKELM based on the STL method, it can be found that the Bootstrap-ISSA-MKELM based on the MTL method has superior performance than that based on the STL method. This is primarily because the MTL mechanism can comprehensively consider the complicated coupling relations among electric, heat, cooling, and gas loads in the IES, and make full use of the information of multi-energy loads. When one load is predicted, the information contained other related loads will be utilized, so that the prediction accuracy of electric, heat, cooling, and gas loads has been greatly improved. Additionally, the MTL mechanism can effectively shorten the calculation time. This is mainly because that the uncertain interval prediction results of the four kinds of loads can be obtained by one time via the model based on the MTL method as the multi-energy loads data can be input into the model at one time. However, the STL mechanism needs to train each energy load one by one, which makes the cumulative training time becomes longer.

- (3)

- Through comparing the results of the proposed model and five comparison models (including MTL-Bootstrap-ELM, MTL-Bootstrap-SSA-ELM, MTL-Bootstrap-ISSA -pELM, MTL-Bootstrap-ISSA-rELM, and MTL-Bootstrap-SSA-MKELM), it can be found that the proposed ISSA and the MKELM method in this paper is effective and feasible in uncertain interval prediction of the combined electricity-heat-cooling-gas loads in the IES. Additionally, the established uncertain interval prediction model MTL-Bootstrap-ISSA- MKELM in this paper has the superior performance in combined electricity-heat-cooling-gas loads uncertain interval prediction than other five selected models.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| IES | Integrated energy system |

| SSA | Salp swarm algorithm |

| ISSA | Improved salp swarm algorithm |

| MTL | Multi-task learning |

| ELM | Extreme learning machine |

| KELM | Kernel extreme learning machine |

| MKELM | Multi-kernel extreme learning machine |

| CCHP | Combined cooling-heat-power |

| P2G | Power to gas |

| CHP | Combined heat and power |

| AI | Artificial intelligent |

| ARIMA | Auto-regressive-integrated-moving-average |

| STL | Single task learning |

| ANN | Artificial neural network |

| rELM | RBF single kernel extreme learning machine |

| pELM | Poly single kernel extreme learning machine |

| RMSE | Root mean square error (Unit: MW) |

| PICP | Prediction interval coverage probability (Unit: %) |

| PINAW | Prediction interval normalized averaged width (Unit: MW) |

References

- Cai, W.; Liu, C.; Lai, K.-H.; Li, L.; Cunha, J.; Hu, L. Energy performance certification in mechanical manufacturing industry: A review and analysis. Energy Convers. Manag. 2019, 186, 415–432. [Google Scholar] [CrossRef]

- Zhou, X.; Feng, C. The impact of environmental regulation on fossil energy consumption in China: Direct and indirect effects. J. Clean. Prod. 2017, 142, 3174–3183. [Google Scholar] [CrossRef]

- Collins, S.; Deane, J.P.; Poncelet, K.; Panos, E.; Pietzcker, R.C.; Delarue, E.; Ó Gallachóir, B.P. Integrating short term variations of the power system into integrated energy system models: A methodological review. Renew. Sustain. Energy Rev. 2017, 76, 839–856. [Google Scholar] [CrossRef] [Green Version]

- Yuan, X.-C.; Sun, X.; Zhao, W.; Mi, Z.; Wang, B.; Wei, Y.-M. Forecasting China’s ronal energy demand by 2030: A Bayesian approach. Resour. Conserv. Recycl. 2017, 127, 85–95. [Google Scholar] [CrossRef]

- Ranaweera, D.K.; Karady, G.G.; Farmer, R.G. Economic impact analysis of load forecasting. IEEE Trans. Power Syst. 1997, 12, 1388–1392. [Google Scholar] [CrossRef]

- Xiao, L.; Wang, J.; Yang, X.; Xiao, L. A hybrid model based on data preprocessing for electrical power forecasting. Int. J. Electr. Power Energy Syst. 2015, 64, 311–327. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Huang, Y.; Li, F.; Zeng, M.; Li, J.; Wang, X.; Zhang, F. Planning and operation method of the ronal integrated energy system considering economy and environment. Energy 2019, 171, 731–750. [Google Scholar] [CrossRef]

- Yang, Y.; Li, S.; Li, W.; Qu, M. Power load probability density forecasting using Gaussian process quantile regression. Appl. Energy 2018, 213, 499–509. [Google Scholar] [CrossRef]

- Guo, Z.; Zhou, K.; Zhang, X.; Yang, S. A deep learning model for short-term power load and probability density forecasting. Energy 2018, 160, 1186–1200. [Google Scholar] [CrossRef]

- Kim, Y.; Son, H.; Kim, S. Short term electricity load forecasting for institutional buildings. Energy Rep. 2019, 5, 1270–1280. [Google Scholar] [CrossRef]

- Yang, A.; Li, W.; Yang, X. Short-term electricity load forecasting based on feature selection and Least Squares Support Vector Machines. Knowl. Based Syst. 2019, 163, 159–173. [Google Scholar] [CrossRef]

- Geysen, D.; De Somer, O.; Johansson, C.; Brage, J.; Vanhoudt, D. Operational thermal load forecasting in district heating networks using machine learning and expert advice. Energy Build. 2018, 162, 144–153. [Google Scholar] [CrossRef]

- Suryanarayana, G.; Lago, J.; Geysen, D.; Aleksiejuk, P.; Johansson, C. Thermal load forecasting in district heating networks using deep learning and advanced feature selection methods. Energy 2018, 157, 141–149. [Google Scholar] [CrossRef]

- Nigitz, T.; Gölles, M. A generally applicable, simple and adaptive forecasting method for the short-term heat load of consumers. Appl. Energy 2019, 241, 73–81. [Google Scholar] [CrossRef]

- Zhou, X.; Zi, X.; Liang, L.; Fan, Z.; Yan, J.; Pan, D. Forecasting performance comparison of two hybrid machine learning models for cooling load of a largescale commercial building. J. Build. Eng. 2019, 21, 64–73. [Google Scholar]

- Ahmad, T.; Chen, H.; Shair, J.; Xu, C. Deployment of data-mining short and medium-term horizon cooling load forecasting models for building energy optimization and management. Int. J. Refrig. 2019, 98, 399–409. [Google Scholar] [CrossRef]

- Beyca, O.F.; Ervural, B.C.; Tatoglu, E.; Ozuyar, P.G.; Zaim, S. Using machine learning tools for forecasting natural gas consumption in the province of Istanbul. Energy Econ. 2019, 80, 937–949. [Google Scholar] [CrossRef]

- Shi, J.; Tan, T.; Guo, J.; Liu, Y. Multi-task learning based on deep architecture for various types of load forecasting in regional energy system integration. Power Syst. Technol. China 2018, 42, 698–706. [Google Scholar]

- Tan, Z.; De, G.; Li, M.; Lin, H.; Yang, S.; Huang, L.; Tan, Q. Combined electricity-heat-cooling-gas load forecasting model for integrated energy system based on multi-task learning and least square support vector machine. J. Clean. Prod. 2020, 248, 119252. [Google Scholar] [CrossRef]

- Lazos, D.; Sproul, A.B.; Kay, M. Optimisation of energy management in commercial buildings with weather forecasting inputs: A review. Renew. Sustain. Energy Rev. 2014, 39, 587–603. [Google Scholar] [CrossRef]

- Nepal, B.; Yamaha, M.; Yokoe, A.; Yamaji, T. Electricity load forecasting using clustering and ARIMA model for energy management in buildings. Jpn. Archit. Rev. 2020, 3, 62–76. [Google Scholar] [CrossRef] [Green Version]

- Amini, M.H.; Kargarian, A.; Karabasoglu, O. ARIMA-based decoupled time series forecasting of electric vehicle charging demand for stochastic power system operation. Electr. Power Syst. Res. 2016, 140, 378–390. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Li, R.; Ma, M. Forecasting US shale gas monthly production using a hybrid ARIMA and metabolic nonlinear grey model. Energy 2018, 160, 378–387. [Google Scholar] [CrossRef]

- Li, W.Q.; Chang, L. A combination model with variable weight optimization for short-term electrical load forecasting. Energy 2018, 164, 575–593. [Google Scholar] [CrossRef]

- Amber, K.P.; Aslam, M.W.; Hussain, S.K. Electricity consumption forecasting models for administration buildings of the UK higher education sector. Energy Build. 2015, 90, 127–136. [Google Scholar] [CrossRef]

- Capozzoli, A.; Grassi, D.; Causone, F. Estimation models of heating energy consumption in schools for local authorities planning. Energy Build. 2015, 105, 302–313. [Google Scholar] [CrossRef] [Green Version]

- Fan, G.-F.; Peng, L.-L.; Hong, W.-C. Short term load forecasting based on phase space reconstruction algorithm and bi-square kernel regression model. Appl. Energy 2018, 224, 13–33. [Google Scholar] [CrossRef]

- Lei, J.; Jin, T.; Hao, J.; Li, F. Short-term load forecasting with clustering–regression model in distributed cluster. Clust. Comp. 2019, 22, 10163–10173. [Google Scholar] [CrossRef]

- Pereira, C.M.; de Almeida, N.N.; Velloso, M.L.F. Fuzzy modeling to forecast an electric load time series. Procedia Comput. Sci. 2015, 55, 395–404. [Google Scholar] [CrossRef] [Green Version]

- Černe, G.; Dovžan, D.; Škrjanc, I. Short-term load forecasting by separating daily profiles and using a single fuzzy model across the entire domain. IEEE Trans. Ind. Electr. 2018, 65, 7406–7415. [Google Scholar] [CrossRef]

- Coelho, V.N.; Coelho, I.M.; Coelho, B.N.; Reis, A.J.R. A self-adaptive evolutionary fuzzy model for load forecasting problems on smart grid environment. Appl. Energy 2016, 169, 567–584. [Google Scholar] [CrossRef]

- Malekizadeh, M.; Karami, H.; Karimi, M.; Moshari, A.; Sanjari, M.J. Short-term load forecast using ensemble neuro-fuzzy model. Energy 2020, 196, 117–127. [Google Scholar] [CrossRef]

- Xu, N.; Dang, Y.; Gong, Y. Novel grey prediction model with nonlinear optimized time response method for forecasting of electricity consumption in China. Energy 2017, 118, 473–480. [Google Scholar] [CrossRef]

- Zhao, H.; Guo, S. An optimized grey model for annual power load forecasting. Energy 2016, 107, 272–286. [Google Scholar] [CrossRef]

- Mi, J.; Fan, L.; Duan, X.; Qiu, Y. Short-term power load forecasting method based on improved exponential smoothing grey model. Math. Prob. Eng. 2018, 2018, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Özcan, T. Application of Seasonal and Multivariable Grey Prediction Models for Short-Term Load Forecasting. Alphanumeric J. 2017, 5, 329–338. [Google Scholar]

- Kim, J.; Moon, J.; Hwang, E.; Kang, P. Recurrent inception convolution neural network for multi short-term load forecasting. Energy Build. 2019, 194, 328–341. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, B.; Xu, Y.; Xu, T.; Liu, C.; Zhu, Z. Multi-scale convolutional neural network with time-cognition for multi-step short-term load forecasting. IEEE Access 2019, 7, 88058–88071. [Google Scholar]

- Zahid, M.; Ahmed, F.; Javaid, N.; Abbasi, R.A.; Kazmi, H.S.Z.; Javaid, A.; Bilal, M.; Akbar, M.; Ilahi, M. Electricity price and load forecasting using enhanced convolutional neural network and enhanced support vector regression in smart grids. Electronics 2019, 8, 122. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Wang, S.; Wang, S.; Li, Y. Day-ahead aggregated load forecasting based on two-terminal sparse coding and deep neural network fusion. Electr. Power Syst. Res. 2019, 177, 105987. [Google Scholar] [CrossRef]

- Ge, Q.; Guo, C.; Jiang, H.; Lu, Z.; Yao, G.; Zhang, J.; Hua, Q. Industrial Power Load Forecasting Method Based on Reinforcement Learning and PSO-LSSVM. IEEE Trans. Cybern. 2020, 1–13. [Google Scholar]

- Xiong, J.; Wang, T.; Li, R. Research on a hybrid LSSVM intelligent algorithm in short term load forecasting. Clust. Comp. 2019, 22, 8271–8278. [Google Scholar] [CrossRef]

- Ma, H.; Tang, J.M. Short-Term Load Forecasting of Microgrid Based on Chaotic Particle Swarm Optimization. Procedia Comp. Sci. 2020, 166, 546–550. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Zhang, Y.; He, Z.; Yuan, W.; Yang, Y.; Qiu, W.; Li, L. A combined model based on SSA, neural networks, and LSSVM for short-term electric load and price forecasting. Neural Comp. Appl. 2020, 33, 1–16. [Google Scholar] [CrossRef]

- Li, S.; Goel, L.; Wang, P. An ensemble approach for short-term load forecasting by extreme learning machine. Appl. Energy 2016, 170, 22–29. [Google Scholar] [CrossRef]

- Chen, Y.; Kloft, M.; Yang, Y.; Li, C.; Li, L. Mixed kernel based extreme learning machine for electric load forecasting. Neurocomputing 2018, 312, 90–106. [Google Scholar] [CrossRef]

- Li, C.; Lin, S.; Xu, F.; Liu, D.; Liu, J. Short-term wind power prediction based on data mining technology and improved support vector machine method: A case study in Northwest China. J. Clean. Prod. 2018, 205, 909–922. [Google Scholar] [CrossRef]

- Li, C.; Georgiopoulos, M.; Anagnostopoulos, G.C. Multitask classification hypothesis space with improved generalization bounds. IEEE Trans. Neural Netw. Learn. Syst. 2015, 26, 1468–1479. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Tian, X.; Liu, T.; Tao, D. On better exploring and exploiting task relationships in multitask learning: Joint model and feature learning. IEEE Trans. Neural Netw. Learn. Syst. 2014, 29, 1975–1985. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chandra, R.; Ong, Y.-S.; Goh, C.-K. Co-evolutionary multi-task learning with predictive recurrence for multi-step chaotic time series prediction. Neurocomputing 2017, 243, 21–34. [Google Scholar] [CrossRef]

- Chandra, R.; Ong, Y.-S.; Goh, C.-K. Co-evolutionary multi-task learning for dynamic time series prediction. Appl. Soft Comput. 2018, 70, 576–589. [Google Scholar] [CrossRef] [Green Version]

- Nunes, M.; Gerding, E.; McGroarty, F.; Niranjan, M. A comparison of multitask and single task learning with artificial neural networks for yield curve forecasting. Expert Syst. Appl. 2019, 119, 362–375. [Google Scholar] [CrossRef] [Green Version]

- Shireen, T.; Shao, C.; Wang, H.; Li, J.; Zhang, X.; Li, M. Iterative multi-task learning for time-series modeling of solar panel PV outputs. Appl. Energy 2018, 212, 654–662. [Google Scholar] [CrossRef]

- Xu, L.; Wang, S.; Tang, R. Probabilistic load forecasting for buildings considering weather forecasting uncertainty and uncertain peak load. Appl. Energy 2019, 237, 180–195. [Google Scholar] [CrossRef]

- Zhu, X.; Zeng, B.; Dong, H.; Liu, J. An interval-prediction based robust optimization approach for energy-hub operation scheduling considering flexible ramping products. Energy 2020, 194, 116821. [Google Scholar] [CrossRef]

- Khosravi, A.; Nahavandi, S.; Creighton, D.; Atiya, A.F. Lower upper bound estimation method for construction of neural network-based prediction intervals. IEEE Trans. Neural Netw. 2010, 22, 337–346. [Google Scholar] [CrossRef] [PubMed]

- Lauret, P.; Fock, E.; Randrianarivony, R.N.; Manicom-Ramsamy, J.-F. Bayesian neural network approach to short time load forecasting. Energy Convers. Manag. 2008, 49, 1156–1166. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, T.; Wang, Y.; Strbac, G.; Kang, C. Using Bayesian deep learning to capture uncertainty for residential net load forecasting. IEEE Trans. Power Syst. 2019, 35, 188–201. [Google Scholar] [CrossRef] [Green Version]

- He, F.; Zhou, J.; Feng, Z.-K.; Liu, G.; Yang, Y. A hybrid short-term load forecasting model based on variational mode decomposition and long short-term memory networks considering relevant factors with Bayesian optimization algorithm. Appl. Energy 2019, 237, 103–116. [Google Scholar] [CrossRef]

- Yang, Y.; Li, W.; Gulliver, T.A.; Li, S. Bayesian Deep Learning-Based Probabilistic Load Forecasting in Smart Grids. IEEE Trans. Ind. Inf. 2019, 16, 4703–4713. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Sun, M.; Zhang, N. Two-Stage Bootstrap Sampling for Probabilistic Load Forecasting. IEEE Trans. Eng. Manag. 2020, 1–9. [Google Scholar] [CrossRef]

- Xu, Y.; Mi, C.; Zhu, Q.-X.; Gao, J.-Y.; He, Y.-L. An effective high-quality prediction intervals construction method based on parallel bootstrapped RVM for complex chemical processes. Chemom. Int. Lab. Syst. 2017, 171, 161–169. [Google Scholar] [CrossRef]

- Liu, Z.F.; Li, L.L.; Tseng, M.L.; Lim, M.K. Prediction short-term photovoltaic power using improved chicken swarm optimizer-Extreme learning machine model. J. Clean. Prod. 2020, 248, 119272. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Q.; Luo, J.; Xu, Y.; Zhang, X. An enhanced Bacterial Foraging Optimization and its application for training kernel extreme learning machine. Appl. Soft Comp. 2020, 86, 105884. [Google Scholar] [CrossRef]

- Liu, X.; Wang, L.; Huang, G.-B.; Zhang, J.; Yin, J. Multiple kernel extreme learning machine. Neurocomputing 2015, 149, 253–264. [Google Scholar] [CrossRef]

- Wang, M.; Chen, H.; Li, H.; Cai, Z.; Zhao, X.; Tong, C.; Li, J.; Xu, X. Grey wolf optimization evolving kernel extreme learning machine: Application to bankruptcy prediction. Eng. Appl. Art. Int. 2017, 63, 54–68. [Google Scholar] [CrossRef]

- Evgeniou, T.; Charles, A.M.; Massimiliano, P. Learning multiple tasks with kernel methods. J. Mach. Learn. Res. 2005, 6, 615–637. [Google Scholar]

- Xu, S.; An, X.; Qiao, X.; Zhu, L.; Li, L. Multi-output least-squares support vector regression machines. Pattern Recognit. Lett. 2013, 34, 1078–1084. [Google Scholar] [CrossRef]

- Bădin, L.; Cinzia, D.; Léopold, S. A bootstrap approach for bandwidth selection in estimating conditional efficiency measures. Eur. J. Oper. Res. 2019, 277, 784–797. [Google Scholar] [CrossRef]

- Flores-Agreda, D.; Cantoni, E. Bootstrap estimation of uncertainty in prediction for generalized linear mixed models. Comp. Stat. Data Anal. 2019, 130, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Wang, R.; Lei, H.; Zhang, T.; Liu, Y.; Zheng, X. Interval prediction of solar power using an Improved Bootstrap method. Sol. Energy 2018, 159, 97–112. [Google Scholar] [CrossRef]

- Huang, G.B.; Zhou, H.; Ding, X.; Zhang, R. Extreme learning machine for regression and multiclass classification. IEEE Trans. Syst. Man Cybern. Part B (Cybern.) 2011, 42, 513–529. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Wang, Y.; Zhou, G.; Jin, J.; Wang, B.; Wang, X.; Cichocki, A. Multi-kernel extreme learning machine for EEG classification in brain-computer interfaces. Expert Syst. Appl. 2018, 96, 302–310. [Google Scholar] [CrossRef]

- Liu, Z.; Loo, C.K.; Pasupa, K. A novel error-output recurrent two-layer extreme learning machine for multi-step time series prediction. Sustain. Cities Soc. 2021, 66, 102613. [Google Scholar] [CrossRef]

- Sin, M.C.; Gan, S.N.; Annuar, M.S.M.; Tan, I.K.P. Chain cleavage mechanism of palm kernel oil derived medium-chain-length poly(3-hydroxyalkanoates) during high temperature decomposition. Polym. Degrad. Stab. 2011, 96, 1705–1710. [Google Scholar]

- Li, Q.; Xiong, Q.; Ji, S.; Yu, Y.; Wu, C.; Yi, H. A method for mixed data classification base on RBF-ELM network. Neurocomputing 2021, 431, 7–22. [Google Scholar] [CrossRef]

- Mirjalili, S.; Gandomi, A.H.; Mirjalili, S.Z.; Saremi, S.; Faris, H.; Mirjalili, S.M. Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar] [CrossRef]

| Parameters | C | |||

| Workday (2018.07.12) | 1.58 | 0.34 | 0.77 | 2.89 |

| Holiday (2018.07.22) | 1.94 | 0.51 | 0.43 | 2.14 |

| Method | Workday (July 12) Electric Load | Holiday (July 22) Electric Load | Workday (July 9–13) Electric Load | Holiday (July 21–22) Electric Load | ||||

| PICP | PINAW | PICP | PINAW | PICP | PINAW | PICP | PINAW | |

| Model with the STL | 100% | 2.99 | 100% | 7.66 | 100% | 3.02 | 100% | 7.68 |

| Model with the MTL | 100% | 1.42 | 100% | 4.02 | 100% | 1.39 | 100% | 3.99 |

| Method | Workday (July 12) Heat load | Holiday (July 22) Heat load | Workday (July 9–13) Heat load | Holiday (July 21–22) Heat load | ||||

| PICP | PINAW | PICP | PINAW | PICP | PINAW | PICP | PINAW | |

| Model with the STL | 100% | 2.36 | 100% | 6.13 | 100% | 2.33 | 100% | 6.21 |

| Model with the MTL | 100% | 0.94 | 100% | 2.93 | 100% | 0.91 | 100% | 2.89 |

| Method | Workday (July 12) Cooling load | Holiday (July 22) Cooling load | Workday (July 9–13) Cooling load | Holiday (July 21–22) Cooling load | ||||

| PICP | PINAW | PICP | PINAW | PICP | PINAW | PICP | PINAW | |

| Model with the STL | 100% | 1.68 | 100% | 4.68 | 100% | 1.70 | 100% | 4.83 |

| Model with the MTL | 100% | 0.55 | 100% | 1.60 | 100% | 0.54 | 100% | 1.56 |

| Method | Workday (July 12) Gas load | Holiday (July 22) Gas load | Workday (July 9–13) Gas load | Holiday (July 21–22) Gas load | ||||

| PICP | PINAW | PICP | PINAW | PICP | PINAW | PICP | PINAW | |

| Model with the STL | 95.83% | 1.12 | 93.75% | 2.84 | 96.13% | 1.23 | 94.02% | 2.88 |

| Model with the MTL | 100% | 0.75 | 100% | 2.25 | 100% | 0.78 | 100% | 2.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Guo, S. Uncertain Interval Forecasting for Combined Electricity-Heat-Cooling-Gas Loads in the Integrated Energy System Based on Multi-Task Learning and Multi-Kernel Extreme Learning Machine. Mathematics 2021, 9, 1645. https://doi.org/10.3390/math9141645

Zhao H, Guo S. Uncertain Interval Forecasting for Combined Electricity-Heat-Cooling-Gas Loads in the Integrated Energy System Based on Multi-Task Learning and Multi-Kernel Extreme Learning Machine. Mathematics. 2021; 9(14):1645. https://doi.org/10.3390/math9141645

Chicago/Turabian StyleZhao, Haoran, and Sen Guo. 2021. "Uncertain Interval Forecasting for Combined Electricity-Heat-Cooling-Gas Loads in the Integrated Energy System Based on Multi-Task Learning and Multi-Kernel Extreme Learning Machine" Mathematics 9, no. 14: 1645. https://doi.org/10.3390/math9141645

APA StyleZhao, H., & Guo, S. (2021). Uncertain Interval Forecasting for Combined Electricity-Heat-Cooling-Gas Loads in the Integrated Energy System Based on Multi-Task Learning and Multi-Kernel Extreme Learning Machine. Mathematics, 9(14), 1645. https://doi.org/10.3390/math9141645