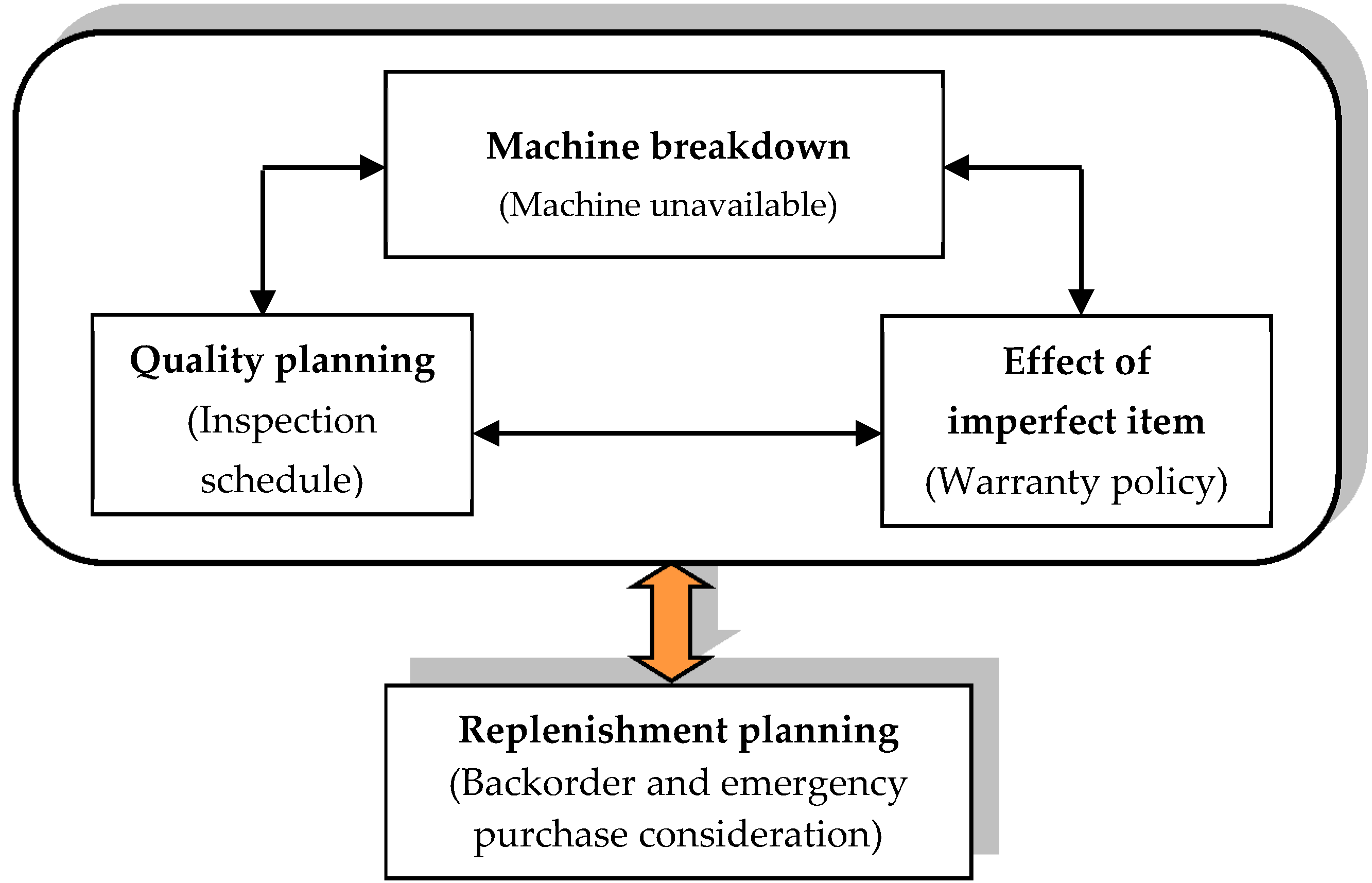

Production-Inventory System for Deteriorating Items with Machine Breakdown, Inspection, and Partial Backordering

Abstract

:1. Introduction

2. Literature Review

2.1. Economic Production Quantity with Machine Unavailability and Maintenance

2.2. Economic Production Quantity with Defective Item and Warranty

2.3. Deterioration Factor

3. Notation and Assumptions

3.1. Notation

3.2. Assumption

- A single item with a constant rate of production, demand, and deteriorating is considered.

- Production rate is greater than the demand rate.

- The deteriorated items are not replaced.

- Machine repair time is not dependent on the machine breakdown.

4. Model Development

4.1. Relevant Cost Functions for Deteriorating Production-Inventory System

4.1.1. Holding Cost Function

4.1.2. Deterioration Cost

4.1.3. Inspection Cost, Risk Cost and Corrective Cost of the Machine

4.1.4. Rework Cost

4.1.5. Post-sale Warranty Cost

4.1.6. Emergency Purchasing Cost for Partial Backorder and Lost Sale Cost

4.1.7. Expected Deteriorating Economic Production Quantity Total Cost

4.2. Expected Replenishment Time for the Proposed Model Considering Random Machine Unavailability

4.2.1. Machine Breakdown with an Exponentially Distributed Repair Time

Scenario A: Without repair timeReplenishment time considering machine breakdown with a negligible repair time

Scenario B: With repair timeGeneral form: Replenishment time considering machine breakdown and repair time

4.3. Optimization of the Deteriorating Economic Production Quantity Model

- ,

- ,

- ,

4.3.1. Optimal Conditions for Deriving the Optimal Solution of the Proposed Model

4.3.2. Derivation of Iterative Solutions to the Deteriorating Economic Production Quantity Model

4.4. Solution Procedure

- Step 1:

- If input parameteris λ not in the range of Equation (39c), the solution is infeasible.

- Step 2:

- Initiate an integer value of n. Let n = 1, sn-1 = 0 and T1, n-1 = 0 at n = 1.

- Step 3:

- Compute the parameter values of a1, a2, k1, k2, k3, k4, and Ck, n-1 using Equations (38a) and (38b).

- Step 4:

- Derive in Equation (40c).

- Step (4-1):

- From Equation (40c), calculate using sn-1, and T1, n-1.

- Step (4-2):

- Determine if sn = sn-1, let s* = sn; then, go to step 5. Otherwise, let n = n + 1 and compute Ck, n-1 and T1, n-1 using Equations (38b) and (40a); then return to Step 4.

- Step 5:

- Calculate and using Equations (38b) and (40a) and the optimal elapsed time of inspection plan, s*. Finally, determine using Equation (7), then solve Q* using pT1* and derive the optimal total system cost per unit time, E[TEC].

5. Case Example and Sensitivity Analysis

| θ= 0.01 P = 14,000 units d = 8500 units CS = $120 HS =$1.5 Cm = $10 | Rrsk = $4500 Vsk = $20 Sd = $30 CR = $19 h1 = 0.003 h2 = 0.0025 | θ1 = 0.0025 θ2 = 0.002 µ = 0.006 Cw = 35 AEp =120 λ = 0.009 |

- (a)

- (b)

- For decreasing {θ1} and increasing {θ2}, the total sum of the production the up-time period and down-time period tends to decrease. That investment on the defective rate reduction will influence the production and delivery policies. In practice, when the defective rate decreases, a frequent delivery policy should be implemented (Table 3 and Table 4 or Figure 4 and Figure 5).

- (c)

- (d)

- The total cost is positively sensitive to {d}, {θ} and {Hs} (Table 2, Table 8, Table 13, and Figure 6). When the unit holding cost increases, the production up-time period and down-time period tend to decrease. That is, a manager may use a frequent and small lot-size policy when the unit holding cost increases (Figure 4 and Figure 5). The results are similar to the parameter of the deterioration rate {θ}.

- (e)

- (f)

- (g)

- The production lot size, Q, is positively sensitive to {p}, the arrival rate of machine breakdown {μ} and variable risk cost {Vsk}, and it is negatively sensitive to {d}, {Hs} and the deterioration rate {θ}. In practice, when {d} increases and {p} decreases, the total sum of the production up-time period and down-time period should be shortened (Table 2, Table 7, Table 8, Table 9, Table 10, and Table 13, and Figure 7).

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Wild, T. Best Practice in Inventory Management, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2002. [Google Scholar]

- Wee, H.M.; Widyadana, G.A. Economic production quantity models for deteriorating items with rework and stochastic preventive maintenance time. Int. J. Prod. Res. 2012, 50, 2940–2952. [Google Scholar] [CrossRef]

- Wee, H.M.; Widyadana, G.A. A production model for deteriorating items with stochastic preventive maintenance time and rework process with FIFO rule. Omega 2013, 41, 941–954. [Google Scholar] [CrossRef]

- Yeh, R.H.; Ho, W.-T.; Tseng, S.-T. Optimal production run length for products sold with warranty. Eur. J. Oper. Res. 2000, 120, 575–582. [Google Scholar] [CrossRef]

- Wang, C.-H.; Sheu, S.-H. Optimal lot sizing for products sold under free-repair warranty. Eur. J. Oper. Res. 2003, 149, 131–141. [Google Scholar] [CrossRef]

- Peymankar, M.; Dehghanian, F.; Ghiami, Y.; Abolbashari, M.H. The effects of contractual agreements on the economic production quantity model with machine breakdown. Int. J. Prod. Econ. 2018, 201, 203–215. [Google Scholar] [CrossRef]

- Wee, H.-M. Economic production lot size model for deteriorating items with partial back-ordering. Comput. Ind. Eng. 1993, 24, 449–458. [Google Scholar] [CrossRef]

- Yan, H.; Cheng, T.C.E. Optimal Production Stopping and Restarting Times for an EOQ Model with Deteriorating Items. J. Oper. Res. Soc. 1998, 49, 1288. [Google Scholar] [CrossRef]

- Groenevelt, H.; Pintelon, L.; Seidmann, A. Production Lot Sizing with Machine Breakdowns. Manag. Sci. 1992, 38, 104–123. [Google Scholar] [CrossRef]

- Moinzadeh, K.; Aggarwal, P. Analysis of a Production/Inventory System Subject to Random Disruptions. Manag. Sci. 1997, 43, 1577–1588. [Google Scholar] [CrossRef]

- Giri, B.; Yun, W.; Dohi, T. Optimal design of unreliable production–inventory systems with variable production rate. Eur. J. Oper. Res. 2005, 162, 372–386. [Google Scholar] [CrossRef]

- Abboud, N.; Jaber, M.Y.; Noueihed, N. Economic lot sizing with the consideration of random machine unavailability time. Comput. Oper. Res. 2000, 27, 335–351. [Google Scholar] [CrossRef]

- Lin, G.C.; Gong, D.-C. On a production-inventory system of deteriorating items subject to random machine breakdowns with a fixed repair time. Math. Comput. Model. 2006, 43, 920–932. [Google Scholar] [CrossRef]

- Aghezzaf, E.-H.; Jamali, M.; Ait-Kadi, D. An integrated production and preventive maintenance planning model. Eur. J. Oper. Res. 2007, 181, 679–685. [Google Scholar] [CrossRef]

- Chakraborty, T.; Giri, B.; Chaudhuri, K. Production lot sizing with process deterioration and machine breakdown. Eur. J. Oper. Res. 2008, 185, 606–618. [Google Scholar] [CrossRef]

- Chakraborty, T.; Giri, B.; Chaudhuri, K. Production lot sizing with process deterioration and machine breakdown under inspection schedule. Omega 2009, 37, 257–271. [Google Scholar] [CrossRef]

- Liao, G.-L.; Chen, Y.H.; Sheu, S.-H. Optimal economic production quantity policy for imperfect process with imperfect repair and maintenance. Eur. J. Oper. Res. 2009, 195, 348–357. [Google Scholar] [CrossRef]

- Chung, C.-J.; Widyadana, G.A.; Wee, H.M. Economic production quantity model for deteriorating inventory with random machine unavailability and shortage. Int. J. Prod. Res. 2011, 49, 883–902. [Google Scholar] [CrossRef]

- Widyadana, G.A.; Wee, H.M. Optimal deteriorating items production inventory models with random machine breakdown and stochastic repair time. Appl. Math. Model. 2011, 35, 3495–3508. [Google Scholar] [CrossRef]

- Cheng, G.Q.; Zhou, B.H.; Li, L. Integrated production, quality control and condition-based maintenance for imperfect production systems. Reliab. Eng. Syst. Saf. 2018, 175, 251–264. [Google Scholar] [CrossRef]

- Al-Salamah, M. Economic production quantity with the presence of imperfect quality and random machine breakdown and repair based on the artificial bee colony heuristic. Appl. Math. Model. 2018, 63, 68–83. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Jaber, M. Economic production quantity model with learning in production, quality, reliability and energy efficiency. Comput. Ind. Eng. 2019, 129, 502–511. [Google Scholar] [CrossRef]

- Chiu, Y.-S.P.; Chen, Y.-R.; Chiu, V.; Chiu, S.W. Joint effects of stochastic machine failure, backorder of permissible shortage, rework, and scrap on stock replenishing decision. Int. J. Ind. Eng. Comput. 2019, 10, 263–280. [Google Scholar] [CrossRef]

- Chiu, S.W.; Chen, H.-Y.; Wu, H.Y.; Chiu, Y.-S.P. Mathematical modelling for a fabrication–inventory problem with scrap, an acceptable stock-out level, stochastic failures and a multi-shipment policy. Arab. J. Basic Appl. Sci. 2019, 26, 58–71. [Google Scholar] [CrossRef]

- Tsao, Y.-C.; Lee, P.-L.; Liao, L.-W.; Zhang, Q.; Vu, T.-L.; Tsai, J. Imperfect economic production quantity models under predictive maintenance and reworking. Int. J. Syst. Sci. Oper. Logist. 2019, 1–14. [Google Scholar] [CrossRef]

- Lee, H.L.; Rosenblatt, M.J. Simultaneous Determination of Production Cycle and Inspection Schedules in a Production System. Manag. Sci. 1987, 33, 1125–1136. [Google Scholar] [CrossRef]

- Hayek, P.A.; Salameh, M.K. Production lot sizing with the reworking of imperfect quality items produced. Prod. Plan. Control. 2001, 12, 584–590. [Google Scholar] [CrossRef]

- Huang, C.-K. An integrated vendor-buyer cooperative inventory model for items with imperfect quality. Prod. Plan. Control. 2002, 13, 355–361. [Google Scholar] [CrossRef]

- Goyal, S.K.; Huang, C.-K.; Chen, K.-C. A simple integrated production policy of an imperfect item for vendor and buyer. Prod. Plan. Control. 2003, 14, 596–602. [Google Scholar] [CrossRef]

- Wang, C.-H. The impact of a free-repair warranty policy on EMQ model for imperfect production systems. Comput. Oper. Res. 2004, 31, 2021–2035. [Google Scholar] [CrossRef]

- Chen, X.; Li, L.; Zhou, M. Manufacturer’s pricing strategy for supply chain with warranty period-dependent demand. Omega 2012, 40, 807–816. [Google Scholar] [CrossRef]

- Sana, S.S. Preventive maintenance and optimal buffer inventory for products sold with warranty in an imperfect production system. Int. J. Prod. Res. 2012, 50, 6763–6774. [Google Scholar] [CrossRef]

- Chiu, S.W.; Chou, C.-L.; Wu, W.-K. Optimizing replenishment policy in an EPQ-based inventory model with nonconforming items and breakdown. Econ. Model. 2013, 35, 330–337. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Wee, H.M. Manufacturing system with immediate rework and partial backordering. Int. J. Adv. Oper. Manag. 2015, 7, 41. [Google Scholar] [CrossRef]

- Sarkar, B.; Saren, S.; Sarkar, D.B. Product inspection policy for an imperfect production system with inspection errors and warranty cost. Eur. J. Oper. Res. 2016, 248, 263–271. [Google Scholar] [CrossRef]

- Sett, B.K.; Sarkar, S.; Sarkar, B. Optimal buffer inventory and inspection errors in an imperfect production system with preventive maintenance. Int. J. Adv. Manuf. Technol. 2017, 90, 545–560. [Google Scholar] [CrossRef]

- Cunha, L.R.A.; Delfino, A.P.S.; Dos Reis, K.A.; Leiras, A. Economic production quantity (EPQ) model with partial backordering and a discount for imperfect quality batches. Int. J. Prod. Res. 2018, 56, 1–15. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Sarkar, B.; Hasani, M. Delayed payment policy in multi-product single-machine economic production quantity model with repair failure and partial backordering. J. Ind. Manag. Optim. 2019. [Google Scholar] [CrossRef]

- Nobil, A.H.; Sedigh, A.H.A.; Tiwari, S.; Wee, H.M. An imperfect multi-item single-machine production system with shortage, rework, and scrap considering inspection, dissimilar deficiency levels, and non-zero setup times. Sci. Iran. E 2019, 26, 557–570. [Google Scholar]

- Taheri-Tolgari, J.; Mohammadi, M.; Naderi, B.; Arshadi-Khamseh, A.; Mirzazadeh, A. An inventory model with imperfect item, inspection errors, preventive maintenance and partial backlogging in uncertainty environment. J. Ind. Manag. Optim. 2019, 15, 1317–1344. [Google Scholar] [CrossRef]

- Misra, R.B. Optimum production lot size model for a system with deteriorating inventory. Int. J. Prod. Res. 1975, 13, 495–505. [Google Scholar] [CrossRef]

- Goyal, S.; Gunasekaran, A. An integrated production-inventory-marketing model for deteriorating items. Comput. Ind. Eng. 1995, 28, 755–762. [Google Scholar] [CrossRef]

- Skouri, K.; Papachristos, S. Optimal stopping and restarting production times for an EOQ model with deteriorating items and time-dependent partial backlogging. Int. J. Prod. Econ. 2003, 81, 525–531. [Google Scholar] [CrossRef]

- Teng, J.-T.; Chang, C.-T. Economic production quantity models for deteriorating items with price-and stock-dependent demand. Comput. Oper. Res. 2005, 32, 297–308. [Google Scholar] [CrossRef]

- Law, S.-T.; Wee, H.-M. An integrated production-inventory model for ameliorating and deteriorating items taking account of time discounting. Math. Comput. Model. 2006, 43, 673–685. [Google Scholar] [CrossRef]

- Palanivel, M.; Uthayakumar, R. An EPQ model for deteriorating items with variable production cost, time dependent holding cost and partial backlogging under inflation. OPSEARCH 2015, 52, 1–17. [Google Scholar] [CrossRef]

- Chen, T.-H. Optimizing pricing, replenishment and rework decision for imperfect and deteriorating items in a manufacturer-retailer channel. Int. J. Prod. Econ. 2017, 183, 539–550. [Google Scholar] [CrossRef]

- Daryanto, Y.; Wee, H.M.; Widyadana, G.A. Low Carbon Supply Chain Coordination for Imperfect Quality Deteriorating Items. Mathematics 2019, 7, 234. [Google Scholar] [CrossRef]

- Chung, C.-J.; Wee, H.-M. Economic Replenishment Plan with Imperfect Production Process and Business-Return Dependent Demand. Asia Pac. J. Oper. Res. 2012, 29, 1250036. [Google Scholar] [CrossRef]

| Author(s) | EPQ | Machine Breakdown | Preventive Maintenance | Rework | Warranty | Emergency Purchase | Partial Backorder | Deteriorating Items |

|---|---|---|---|---|---|---|---|---|

| Misra (1975) | √ | √ | ||||||

| Groenevelt et al. (1992) | √ | √ | ||||||

| Wee (1993) | √ | √ | √ | |||||

| Yan & Cheng (1998) | √ | √ | √ | |||||

| Abboud et al. (2000) | √ | √ | √ | |||||

| Yeh et al. (2000) | √ | √ | ||||||

| Wang & Sheu (2003) | √ | √ | √ | |||||

| Skouri & Papachristos (2003) | √ | √ | √ | |||||

| Giri et al. (2005) | √ | √ | ||||||

| Lin & Gong (2006) | √ | √ | √ | |||||

| Aghezzaf et al. (2007) | √ | √ | √ | |||||

| Chakraborty et al. (2008) | √ | √ | √ | |||||

| Chakraborty et al. (2009) | √ | √ | √ | |||||

| Liao et al. (2009) | √ | √ | √ | √ | ||||

| Chung et al. (2011) | √ | √ | √ | |||||

| Widyadana & Wee (2011) | √ | √ | √ | |||||

| Wee & Widyadana (2012) | √ | √ | √ | √ | ||||

| Sana (2012) | √ | √ | √ | √ | ||||

| Wee & Widyadana (2013) | √ | √ | √ | √ | ||||

| Chiu et al. (2013) | √ | √ | ||||||

| Palanivel & Uthayakumar (2015) | √ | √ | √ | |||||

| Taleizadeh & Wee (2015) | √ | √ | √ | |||||

| Sarkar & Saren (2016) | √ | √ | ||||||

| Sett et al. (2017) | √ | √ | √ | |||||

| Peymankar et al. (2018) | √ | √ | √ | |||||

| Cheng et al. (2018) | √ | √ | √ | |||||

| Al-Salamah (2018) | √ | √ | √ | |||||

| Cunha et al. (2018) | √ | √ | ||||||

| Marchi et al. (2019) | √ | √ | √ | |||||

| Chiu et al. (2019a) | √ | √ | √ | |||||

| Chiu et al. (2019b) | √ | √ | ||||||

| Tsao et al. (2019) | √ | √ | √ | √ | ||||

| Taleizadeh et al. (2019) | √ | √ | √ | |||||

| Nobil et al. (2019) | √ | √ | ||||||

| Taheri-Tolgari et al. (2019) | √ | √ | √ | √ | ||||

| This paper | √ | √ | √ | √ | √ | √ | √ | √ |

| {θ} | 0.008 | 0.009 | {0.01} | 0.011 | 0.012 |

| T1 | 0.09177 | 0.086523 | 0.082084 | 0.078265 | 0.074934 |

| s | 0.065694 | 0.065694 | 0.065694 | 0.065694 | 0.065694 |

| Q | 505 | 476 | 451 | 430 | 412 |

| T2 | 0.05936 | 0.055964 | 0.053091 | 0.05062 | 0.04846 |

| ETC | 9933.06 | 10,515.81 | 11,066.99 | 11,591.23 | 12,092.13 |

| PTCD(%) | −10.25% | −4.98% | 0.00% | 4.74% | 9.26% |

| {θ1} | 0.002 | 0.00225 | {0.0025} | 0.00275 | 0.003 |

| T1 | 0.08158 | 0.08184 | 0.082084 | 0.08233 | 0.08257 |

| s | 0.066663 | 0.066173 | 0.065694 | 0.065225 | 0.064766 |

| Q | 449 | 450 | 451 | 453 | 454 |

| T2 | 0.05277 | 0.05293 | 0.053091 | 0.05325 | 0.05341 |

| ETC | 11,001.57 | 11,034.45 | 11,066.99 | 11,099.20 | 11,131.09 |

| PTCD(%) | −0.59% | −0.29% | 0.00% | 0.29% | 0.58% |

| {θ2} | 0.0016 | 0.0018 | {0.002} | 0.0022 | 0.0024 |

| T1 | 0.08248 | 0.08228 | 0.082084 | 0.08189 | 0.08169 |

| s | 0.064949 | 0.065319 | 0.065694 | 0.066076 | 0.066465 |

| Q | 453 | 452 | 451 | 450 | 449 |

| T2 | 0.05334 | 0.05322 | 0.053091 | 0.05296 | 0.05283 |

| ETC | 11,053.66 | 11,060.43 | 11,066.99 | 11,073.34 | 11,079.47 |

| PTCD(%) | −0.12% | −0.06% | 0.00% | 0.06% | 0.11% |

| {h1} | 0.0024 | 0.0027 | {0.003} | 0.0033 | 0.0036 |

| T1 | 0.082081 | 0.082082 | 0.082084 | 0.082085 | 0.082086 |

| s | 0.065699 | 0.065697 | 0.065694 | 0.065691 | 0.065689 |

| Q | 451 | 451 | 451 | 451 | 451 |

| T2 | 0.05309 | 0.053090 | 0.053091 | 0.053092 | 0.053093 |

| ETC | 11,066.63 | 11,0066.81 | 11,066.99 | 11,067.17 | 11,067.35 |

| PTCD(%) | 0.00% | −0.54% | 0.00% | 0.00% | 0.00% |

| {h2} | 0.002 | 0.00225 | {0.0025} | 0.00275 | 0.003 |

| T1 | 0.082086 | 0.082085 | 0.082084 | 0.082083 | 0.082082 |

| s | 0.065691 | 0.065692 | 0.065694 | 0.065695 | 0.065697 |

| Q | 451 | 451 | 451 | 451 | 451 |

| T2 | 0.053092 | 0.053092 | 0.053091 | 0.053091 | 0.053090 |

| ETC | 11,066.93 | 11,066.96 | 11,066.99 | 11,067.02 | 11,067.05 |

| PTCD(%) | 0.00% | 0.00% | 0.00% | 0.00% | 0.00% |

| {μ} | 0.0048 | 0.0054 | {0.006} | 0.0066 | 0.0072 |

| T1 | 0.073423 | 0.077874 | 0.082084 | 0.086087 | 0.089911 |

| s | 0.065694 | 0.065694 | 0.065694 | 0.065694 | 0.065694 |

| Q | 404 | 428 | 451 | 473 | 494 |

| T2 | 0.047492 | 0.05037 | 0.053091 | 0.055679 | 0.058152 |

| ETC | 12,343.16 | 11,651.93 | 11,066.99 | 10,563.59 | 10,124.38 |

| PTCD(%) | 11.53% | 5.29% | 0.00% | −4.55% | −8.52% |

| {d} | 6800 | 7650 | {8500} | 9350 | 10200 |

| T1 | 0.079767 | 0.08090 | 0.082084 | 0.083321 | 0.084616 |

| s | 0.065694 | 0.065694 | 0.065694 | 0.065694 | 0.065694 |

| Q | 574 | 514 | 451 | 387 | 321 |

| T2 | 0.08443 | 0.067125 | 0.053091 | 0.04142 | 0.03151 |

| ETC | 9109.88 | 10,105.41 | 11,066.99 | 11,993.88 | 12,885.30 |

| PTCD(%) | −17.68% | −8.69% | 0.00% | 8.38% | 16.43% |

| {P} | 11,200 | 12,600 | {14,000} | 15,400 | 16,800 |

| T1 | 0.095234 | 0.087922 | 0.082084 | 0.077284 | 0.073247 |

| s | 0.065885 | 0.065789 | 0.065694 | 0.065599 | 0.065506 |

| Q | 275 | 360 | 451 | 533 | 608 |

| T2 | 0.030236 | 0.04239 | 0.053091 | 0.062712 | 0.071497 |

| ETC | 11,859.74 | 11,449.98 | 11,066.99 | 10,713.00 | 10,387.06 |

| PTCD(%) | 7.16% | 3.46% | 0.00% | −3.20% | −6.14% |

| {Rrsk} | 3600 | 4050 | {4500} | 4950 | 5400 |

| T1 | 0.078498 | 0.080359 | 0.082084 | 0.083694 | 0.085205 |

| s | 0.073184 | 0.069136 | 0.065694 | 0.062719 | 0.0601157 |

| Q | 432 | 442 | 451 | 460 | 468 |

| T2 | 0.050773 | 0.051976 | 0.053091 | 0.054132 | 0.055109 |

| ETC | 10,597.38 | 10,841.13 | 11,066.99 | 11,277.80 | 11,475.74 |

| PTCD(%) | −4.24% | −2.04% | 0.00% | 1.90% | 3.69% |

| {Vsk} | 16 | 18 | {20} | 22 | 24 |

| T1 | 0.078382 | 0.080306 | 0.082084 | 0.083740 | 0.085296 |

| s | 0.058758 | 0.062323 | 0.065694 | 0.068900 | 0.071964 |

| Q | 431 | 442 | 451 | 460 | 496 |

| T2 | 0.0506977 | 0.051942 | 0.053091 | 0.04142 | 0.03151 |

| ETC | 10,582.21 | 10,834.14 | 11,066.99 | 11,283.88 | 11,487.18 |

| PTCD(%) | −4.38% | −2.10% | 0.00% | 1.96% | 3.80% |

| {CR} | 15.2 | 17.1 | {19} | 20.9 | 22.8 |

| T1 | 0.081985 | 0.082035 | 0.082084 | 0.082133 | 0.082133 |

| s | 0.065883 | 0.065788 | 0.065694 | 0.065600 | 0.065506 |

| Q | 451 | 451 | 451 | 452 | 452 |

| T2 | 0.053028 | 0.053059 | 0.053091 | 0.053123 | 0.053155 |

| ETC | 10,989.72 | 11,028.36 | 11,066.99 | 11,105.61 | 11,144.22 |

| PTCD(%) | −0.70% | −0.35% | 0.00% | 0.35% | 0.70% |

| {HS} | 1.2 | 1.35 | {1.5} | 1.65 | 1.8 |

| T1 | 0.091799 | 0.08655 | 0.082084 | 0.078289 | 0.074957 |

| S | 0.065643 | 0.065644 | 0.065694 | 0.065695 | 0.065696 |

| Q | 505 | 476 | 451 | 430 | 412 |

| T2 | 0.059372 | 0.055979 | 0.053091 | 0.050638 | 0.048484 |

| ETC | 9953.03 | 10,535.96 | 11,066.99 | 11,611.72 | 12,112.79 |

| PTCD(%) | −10.07% | −4.80% | 0.00% | 4.92% | 9.45% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kung, K.Y.; Huang, Y.D.; Wee, H.M.; Daryanto, Y. Production-Inventory System for Deteriorating Items with Machine Breakdown, Inspection, and Partial Backordering. Mathematics 2019, 7, 616. https://doi.org/10.3390/math7070616

Kung KY, Huang YD, Wee HM, Daryanto Y. Production-Inventory System for Deteriorating Items with Machine Breakdown, Inspection, and Partial Backordering. Mathematics. 2019; 7(7):616. https://doi.org/10.3390/math7070616

Chicago/Turabian StyleKung, K.Y., Y.D. Huang, H.M. Wee, and Y. Daryanto. 2019. "Production-Inventory System for Deteriorating Items with Machine Breakdown, Inspection, and Partial Backordering" Mathematics 7, no. 7: 616. https://doi.org/10.3390/math7070616

APA StyleKung, K. Y., Huang, Y. D., Wee, H. M., & Daryanto, Y. (2019). Production-Inventory System for Deteriorating Items with Machine Breakdown, Inspection, and Partial Backordering. Mathematics, 7(7), 616. https://doi.org/10.3390/math7070616