Nonlinear Stochastic Modeling with Heterogeneous Covariates for Degradation Analysis Applied to Wax Lubrication Layer

Abstract

1. Introduction

1.1. Background

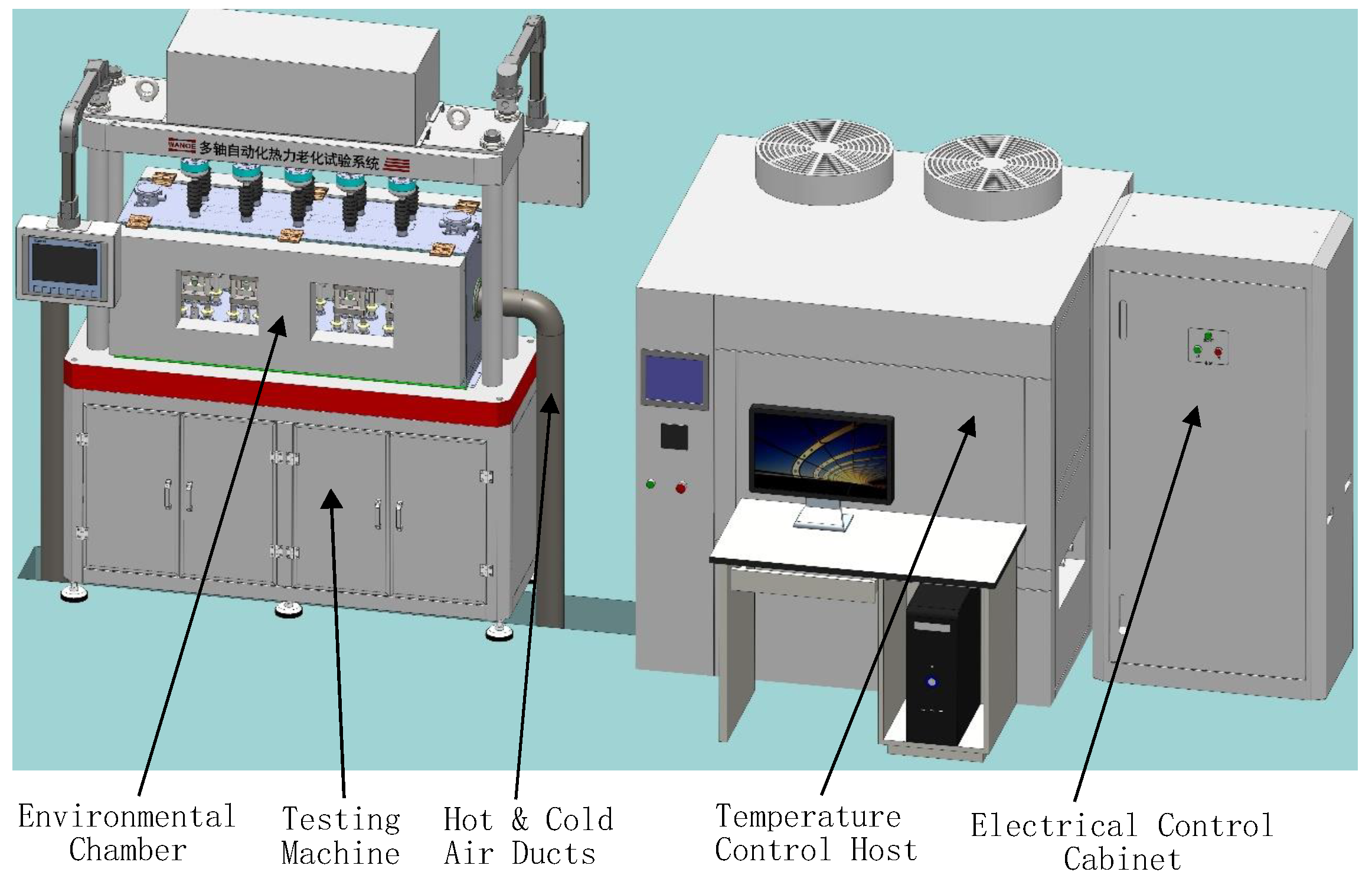

1.2. Motivating Example

1.3. Literature Review

1.4. Contribution and Outline

- (1)

- By addressing the challenge of modeling the unknown and nonlinear behavior of wax creep under the influence of temperature, we provide a comprehensive analysis of this complex phenomenon.

- (2)

- By utilizing a new degradation model based on the Wiener process, we describe the inherent relationships between creep and time without assuming a specific parametric form.

- (3)

- By considering that the working environment is different even if the covariates preset are the same, we view covariates as random variables to capture the heterogeneity among degradation data.

- (4)

- We propose a nonparametric estimator to estimate the nonlinear function concerning time and derive the corresponding asymptotic results.

2. Methodology

2.1. Nonlinear Wiener Process Models

2.2. Semiparametric Estimation via ML

2.3. The EM Algorithm for the MLE

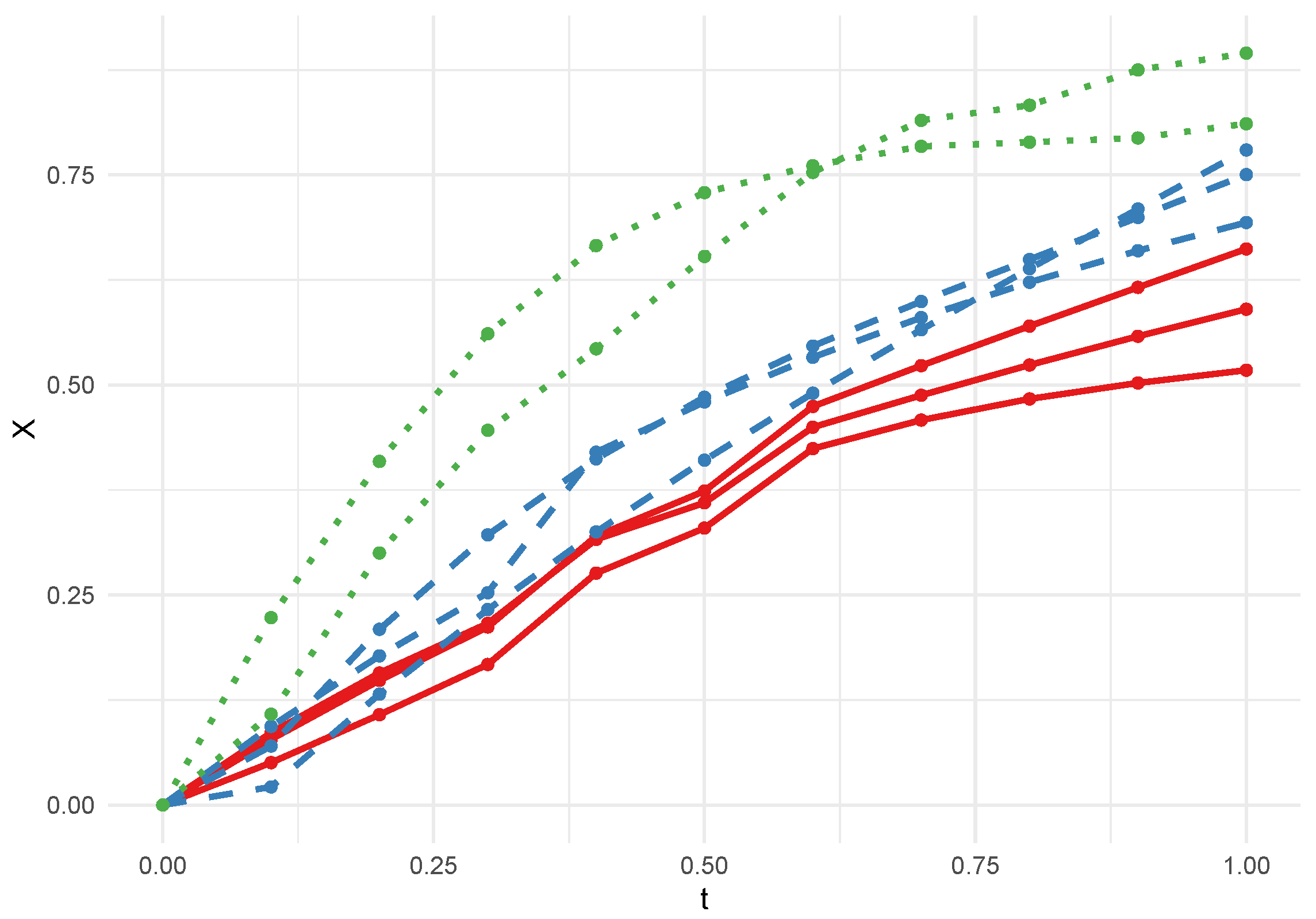

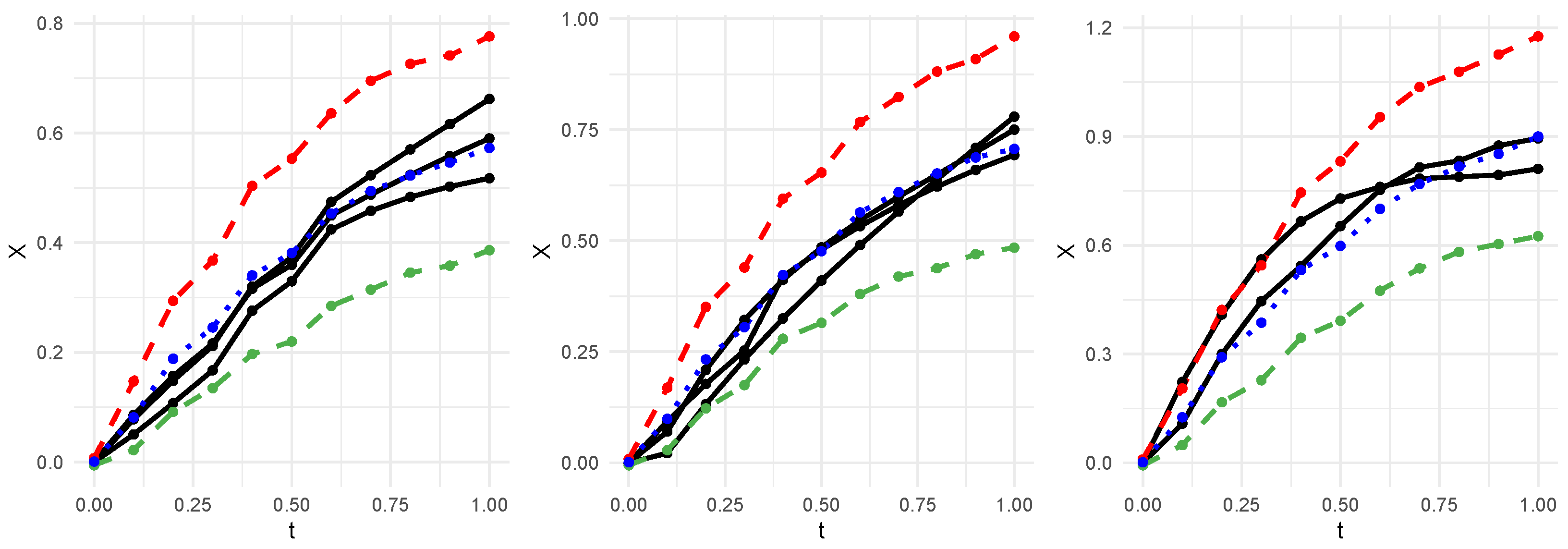

3. Numerical Experiments

4. Case Study

4.1. Data Overview

4.2. Estimation Results

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Doganaksoy, N. Reliability estimation following a field intervention. J. Qual. Technol. 2024, 56, 514–522. [Google Scholar] [CrossRef]

- Zhang, D.; Hao, Z.; Liang, Y.; Wang, F.; Liu, W.; Han, X. An efficient system reliability analysis method based on evidence theory with parameter correlations. IEEE Trans. Reliab. 2024, 74, 2200–2213. [Google Scholar] [CrossRef]

- Safaei, F.; Taghipour, S. Integrated degradation-based burn-in and maintenance model for heterogeneous and highly reliable items. Reliab. Eng. Syst. Saf. 2024, 244, 109942. [Google Scholar] [CrossRef]

- Choi, S.; Doksum, K.A. A new class of semiparametric transformation models based on first hitting times by latent degradation processes. Stat 2013, 2, 227–241. [Google Scholar] [CrossRef]

- Sinapour, H.; Damiri, S.; Pouretedal, H. The study of RDX impurity and wax effects on the thermal decomposition kinetics of HMX explosive using DSC/TG and accelerated aging methods. J. Therm. Anal. Calorim. 2017, 129, 271–279. [Google Scholar] [CrossRef]

- Lin, C.M.; Liu, S.J.; Wen, Y.S.; Liu, J.H.; He, G.S.; Zhao, X.; Yang, Z.J.; Ding, L.; Pan, L.P.; Li, J.; et al. Sandwich-like interfacial structured polydopamine (PDA)/Wax/PDA: A novel design for simultaneously improving the safety and mechanical properties of highly explosive-filled polymer composites. Energetic Mater. Front. 2022, 3, 189–198. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, X.; Xiang, B. Understanding the desensitizing mechanism of olefin in explosives: Shear slide of mixed HMX-olefin systems. J. Mol. Model. 2012, 18, 1503–1512. [Google Scholar] [CrossRef]

- Yang, L. Surface polarity of β-HMX crystal and the related adhesive forces with estane binder. Langmuir 2008, 24, 13477–13482. [Google Scholar] [CrossRef]

- Zhang, C. Understanding the desensitizing mechanism of olefin in explosives versus external mechanical stimuli. J. Phys. Chem. C 2010, 114, 5068–5072. [Google Scholar] [CrossRef]

- Wardhaugh, L.; Boger, D. The measurement and description of the yielding behavior of waxy crude oil. J. Rheol. 1991, 35, 1121–1156. [Google Scholar] [CrossRef]

- Kang, W.; Li, S.; Tian, Y.; Yin, Y.; Sui, H.; Wang, D. A functional data-driven method for modeling degradation of waxy lubrication layer. Qual. Reliab. Eng. Int. 2024, 40, 3751–3773. [Google Scholar] [CrossRef]

- Veloso, G.A.; Loschi, R.H. Dynamic linear degradation model: Dealing with heterogeneity in degradation paths. Reliab. Eng. Syst. Saf. 2021, 210, 107446. [Google Scholar] [CrossRef]

- Wang, D.; Wang, A.; Song, C. Flexible degradation modeling via the integration of local models and importance sampling. IEEE Trans. Instrum. Meas. 2024, 73, 1010012. [Google Scholar] [CrossRef]

- Ye, X.; Sun, Q.; Zhang, R.; Hu, Y.; Chen, C.; Xie, M.; Zhai, G. A path dependence identification method for power MOSFETs degradation due to bias temperature instability. IEEE Trans. Power Electron. 2024, 39, 12470–12477. [Google Scholar] [CrossRef]

- Lu, L.; Wang, B.; Hong, Y.; Ye, Z. General path models for degradation data with multiple characteristics and covariates. Technometrics 2021, 63, 354–369. [Google Scholar] [CrossRef]

- Ye, Z.S.; Chen, N.; Shen, Y. A new class of Wiener process models for degradation analysis. Reliab. Eng. Syst. Saf. 2015, 139, 58–67. [Google Scholar] [CrossRef]

- Li, N.; Lei, Y.; Yan, T.; Li, N.; Han, T. A Wiener-process-model-based method for remaining useful life prediction considering unit-to-unit variability. IEEE Trans. Ind. Electron. 2018, 66, 2092–2101. [Google Scholar] [CrossRef]

- Zhang, Z.; Si, X.; Hu, C.; Lei, Y. Degradation data analysis and remaining useful life estimation: A review on Wiener-process-based methods. Eur. J. Oper. Res. 2018, 271, 775–796. [Google Scholar] [CrossRef]

- Wang, H.; Liao, H.; Ma, X.; Bao, R. Remaining useful life prediction and optimal maintenance time determination for a single unit using isotonic regression and gamma process model. Reliab. Eng. Syst. Saf. 2021, 210, 107504. [Google Scholar] [CrossRef]

- Wang, X.; Wang, B.X.; Hong, Y.; Jiang, P.H. Degradation data analysis based on gamma process with random effects. Eur. J. Oper. Res. 2021, 292, 1200–1208. [Google Scholar] [CrossRef]

- Cheng, G.; Li, L.; Zhang, L.; Yang, N.; Jiang, B.; Shangguan, C.; Su, Y. Optimal joint inspection and mission abort policies for degenerative systems. IEEE Trans. Reliab. 2022, 72, 137–150. [Google Scholar] [CrossRef]

- Ye, Z.S.; Chen, N. The inverse Gaussian process as a degradation model. Technometrics 2014, 56, 302–311. [Google Scholar] [CrossRef]

- Jiang, P.; Wang, B.; Wang, X.; Zhou, Z. Inverse Gaussian process based reliability analysis for constant-stress accelerated degradation data. Appl. Math. Model. 2022, 105, 137–148. [Google Scholar] [CrossRef]

- Zhuang, L.; Xu, A.; Wang, Y.; Tang, Y. Remaining useful life prediction for two-phase degradation model based on reparameterized inverse Gaussian process. Eur. J. Oper. Res. 2024, 319, 877–890. [Google Scholar] [CrossRef]

- Ye, Z.S.; Xie, M. Stochastic modelling and analysis of degradation for highly reliable products. Appl. Stoch. Model. Bus. Ind. 2015, 31, 16–32. [Google Scholar] [CrossRef]

- Hajiha, M.; Liu, X.; Hong, Y. Degradation under dynamic operating conditions: Modeling, competing processes and applications. J. Qual. Technol. 2021, 53, 347–368. [Google Scholar] [CrossRef]

- Dai, L.; Guo, J.; Wan, J.L.; Wang, J.; Zan, X. A reliability evaluation model of rolling bearings based on WKN-BiGRU and Wiener process. Reliab. Eng. Syst. Saf. 2022, 225, 108646. [Google Scholar] [CrossRef]

- Zhang, S.; Zhai, Q.; Shi, X.; Liu, X. A Wiener process model with dynamic covariate for degradation modeling and remaining useful life prediction. IEEE Trans. Reliab. 2022, 72, 214–223. [Google Scholar] [CrossRef]

- Zhai, Q.; Ye, Z.S. A multivariate stochastic degradation model for dependent performance characteristics. Technometrics 2023, 65, 315–327. [Google Scholar] [CrossRef]

- Gebraeel, N.Z.; Lawley, M.A.; Li, R.; Ryan, J.K. Residual-life distributions from component degradation signals: A Bayesian approach. IiE Trans. 2005, 37, 543–557. [Google Scholar] [CrossRef]

- Si, X.S. An adaptive prognostic approach via nonlinear degradation modeling: Application to battery data. IEEE Trans. Ind. Electron. 2015, 62, 5082–5096. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Z.; Li, H.; Yang, Y.; Huang, C.G.; Yazdi, M.; Kang, H.S. A hybrid prognosis scheme for rolling bearings based on a novel health indicator and nonlinear Wiener process. Reliab. Eng. Syst. Saf. 2024, 245, 110014. [Google Scholar] [CrossRef]

- Sun, F.; Li, H.; Cheng, Y.; Liao, H. Reliability analysis for a system experiencing dependent degradation processes and random shocks based on a nonlinear Wiener process model. Reliab. Eng. Syst. Saf. 2021, 215, 107906. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, Z.; Bao, R.; Liu, C.; Wu, Q.; Cao, S. A novel failure time estimation method for degradation analysis based on general nonlinear Wiener processes. Reliab. Eng. Syst. Saf. 2023, 230, 108913. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Zhang, Y.; Liu, C.; Fu, H. A nonlinear Wiener process degradation model with autoregressive errors. Reliab. Eng. Syst. Saf. 2018, 173, 48–57. [Google Scholar] [CrossRef]

- Wang, X. Semiparametric inference on a class of Wiener processes. J. Time Ser. Anal. 2009, 30, 179–207. [Google Scholar] [CrossRef]

- Wang, X. Wiener processes with random effects for degradation data. J. Multivar. Anal. 2010, 101, 340–351. [Google Scholar] [CrossRef]

- Zhai, Q.; Ye, Z.S. Degradation in common dynamic environments. Technometrics 2018, 60, 461–471. [Google Scholar] [CrossRef]

- Duan, F.; Wang, G. Exponential-dispersion degradation process models with random effects and covariates. IEEE Trans. Reliab. 2018, 67, 1128–1142. [Google Scholar] [CrossRef]

- Gorjian, N.; Ma, L.; Mittinty, M.; Yarlagadda, P.; Sun, Y. A review on reliability models with covariates. In Engineering Asset Lifecycle Management, Proceedings of the 4th World Congress on Engineering Asset Management (WCEAM 2009), Athens, Greece, 28–30 September 2009; Springer: Berlin/Heidelberg, Germany, 2010; pp. 385–397. [Google Scholar] [CrossRef]

- Kim, M.; Song, C.; Liu, K. Individualized degradation modeling and prognostics in a heterogeneous group via incorporating intrinsic covariate information. IEEE Trans. Autom. Sci. Eng. 2021, 19, 2079–2094. [Google Scholar] [CrossRef]

- Van Der Vaart, A.W.; Wellner, J.A. Weak Convergence and Empirical Processes: With Applications to Statistics; Springer: New York, NY, USA, 1996. [Google Scholar] [CrossRef]

- Wellner, J.A.; Zhang, Y. Two estimators of the mean of a counting process with panel count data. Ann. Stat. 2000, 28, 779–814. [Google Scholar] [CrossRef]

- Wellner, J.A.; Zhang, Y. Two likelihood-based semiparametric estimation methods for panel count data with covariates. Ann. Stat. 2007, 35, 2106–2142. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2024. [Google Scholar]

| Estimate | 0.1080 | 0.4957 | 0.4601 | 0.0998 | 0.4984 | 0.5043 |

| SD | 0.0236 | 0.0322 | 0.0656 | 0.0028 | 0.0076 | 0.0263 |

| Estimate | 0.1010 | 0.4886 | 0.4840 | 0.0999 | 0.4960 | 0.4963 |

| SD | 0.0145 | 0.0274 | 0.0501 | 0.0032 | 0.0096 | 0.0230 |

| Estimate | 0.1235 | 0.4914 | 0.4751 | 0.1155 | 0.4981 | 0.4861 |

| SD | 0.0326 | 0.0288 | 0.0667 | 0.0247 | 0.0078 | 0.0427 |

| Estimate | 0.1099 | 0.4907 | 0.4720 | 0.0994 | 0.4974 | 0.4871 |

| SD | 0.0257 | 0.0286 | 0.0582 | 0.0113 | 0.0103 | 0.0388 |

| Estimate | 0.4886 | 0.4769 | 0.4923 | 0.5025 | 0.4974 | 0.4933 |

| SD | 0.0429 | 0.0350 | 0.1141 | 0.0125 | 0.0097 | 0.0313 |

| Estimate | 0.4885 | 0.4663 | 0.5202 | 0.4977 | 0.4989 | 0.4906 |

| SD | 0.0378 | 0.0419 | 0.1478 | 0.0129 | 0.0126 | 0.0285 |

| Estimate | 0.4851 | 0.4836 | 0.4751 | 0.5009 | 0.4975 | 0.4936 |

| SD | 0.0299 | 0.1217 | 0.0667 | 0.0128 | 0.0086 | 0.0285 |

| Estimate | 0.4789 | 0.5099 | 0.4720 | 0.4991 | 0.4979 | 0.4986 |

| SD | 0.0342 | 0.1360 | 0.0582 | 0.0119 | 0.0097 | 0.0284 |

| Estimate | 0.0209 | 0.0142 | 0.0101 | 0.0068 | 0.0494 | 0.0347 | 0.0242 | 0.0148 |

| SD | 0.0158 | 0.0103 | 0.0061 | 0.0037 | 0.0167 | 0.0118 | 0.0081 | 0.0050 |

| Estimate | 0.0054 | 0.0040 | 0.0027 | 0.0017 | 0.0175 | 0.0110 | 0.0077 | 0.0044 |

| SD | 0.0028 | 0.002 | 0.0014 | 0.0006 | 0.0082 | 0.0042 | 0.0028 | 0.0016 |

| Estimate | 0.0247 | 0.0193 | 0.0147 | 0.0097 | 0.0671 | 0.0403 | 0.0295 | 0.0172 |

| SD | 0.0183 | 0.0159 | 0.0134 | 0.0082 | 0.0390 | 0.0166 | 0.0113 | 0.0086 |

| Estimate | 0.0107 | 0.0068 | 0.0050 | 0.0032 | 0.0321 | 0.0195 | 0.0136 | 0.0085 |

| SD | 0.0055 | 0.0038 | 0.0034 | 0.0020 | 0.0134 | 0.0065 | 0.0033 | 0.0024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Tian, Y.; Wang, D. Nonlinear Stochastic Modeling with Heterogeneous Covariates for Degradation Analysis Applied to Wax Lubrication Layer. Mathematics 2025, 13, 872. https://doi.org/10.3390/math13050872

Li S, Tian Y, Wang D. Nonlinear Stochastic Modeling with Heterogeneous Covariates for Degradation Analysis Applied to Wax Lubrication Layer. Mathematics. 2025; 13(5):872. https://doi.org/10.3390/math13050872

Chicago/Turabian StyleLi, Shixiang, Yubin Tian, and Dianpeng Wang. 2025. "Nonlinear Stochastic Modeling with Heterogeneous Covariates for Degradation Analysis Applied to Wax Lubrication Layer" Mathematics 13, no. 5: 872. https://doi.org/10.3390/math13050872

APA StyleLi, S., Tian, Y., & Wang, D. (2025). Nonlinear Stochastic Modeling with Heterogeneous Covariates for Degradation Analysis Applied to Wax Lubrication Layer. Mathematics, 13(5), 872. https://doi.org/10.3390/math13050872