Simulation of MCDM Process—Stope and Fan Pattern Selection in an Underground Mine with Uncertainty

Abstract

1. Introduction

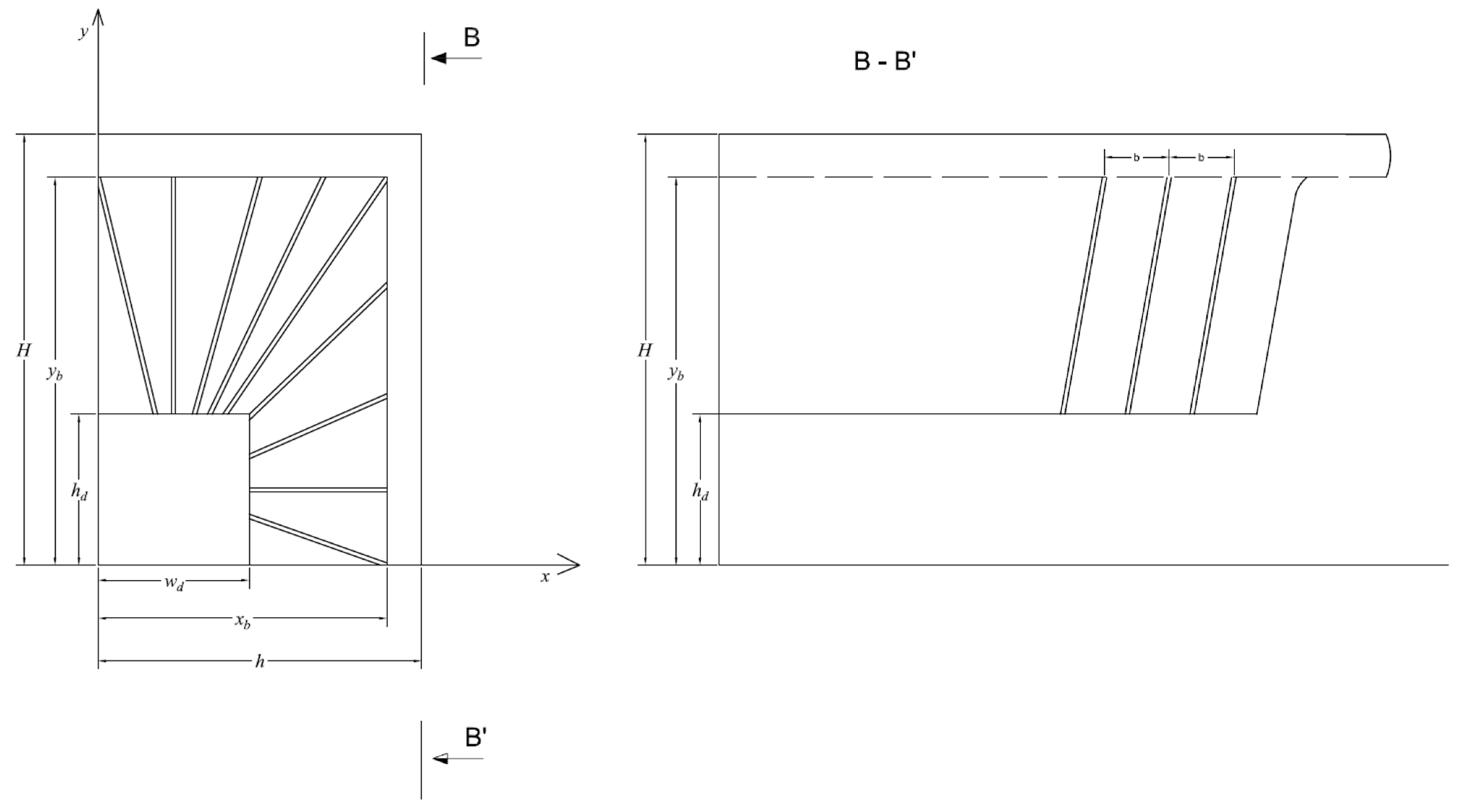

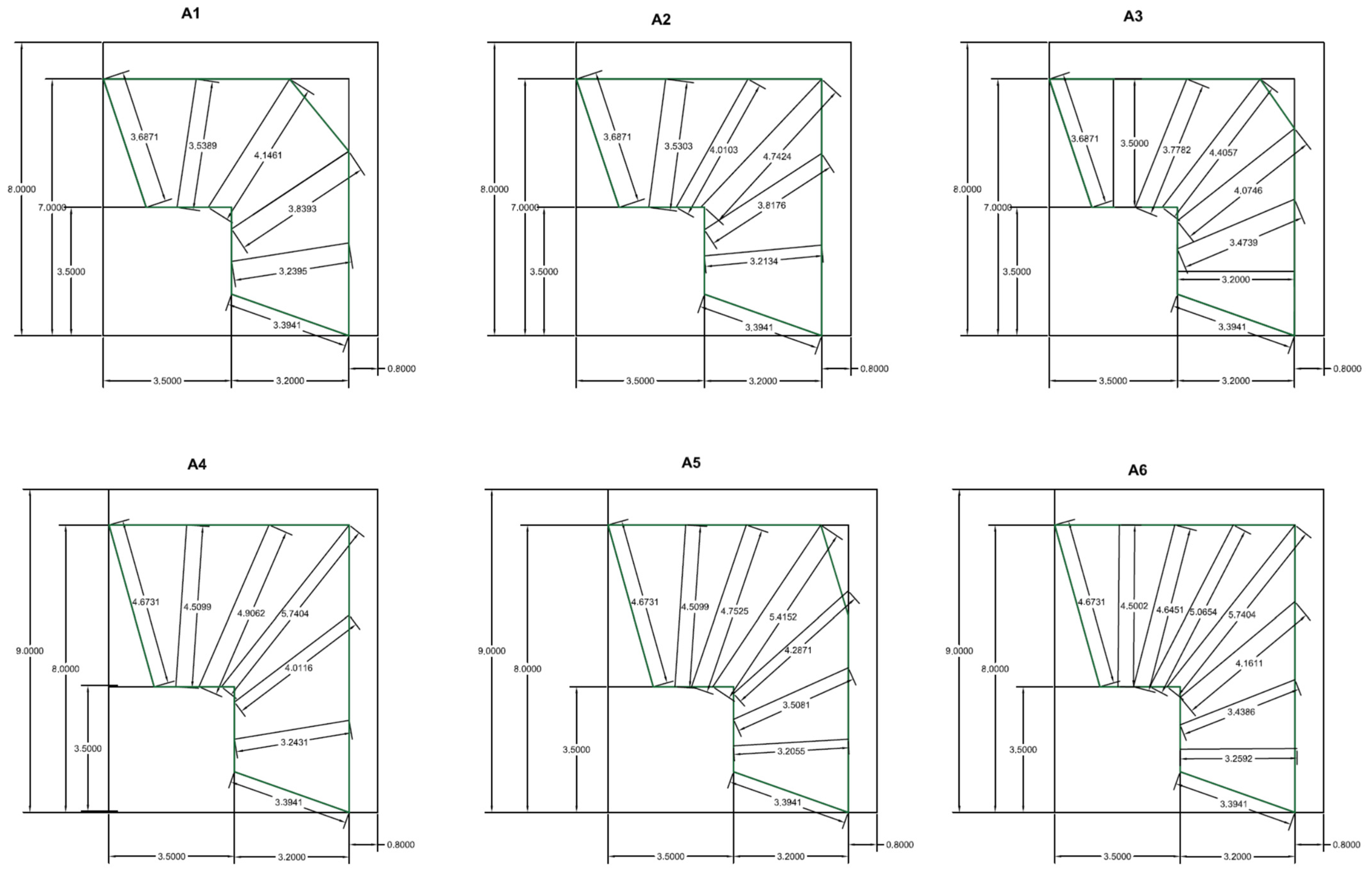

2. Model of Stope and Fan Pattern Selection

2.1. Methodology of Ranking Alternatives by Perimeter Similarity (RAPS)

- —a given set of alternatives, where m is the total number of alternatives,

- —a given set of criteria, where n is the total number of criteria,

- —an assessment of alternative Ai with respect to a set of criteria.

- Sbenefit—a set of benefit criteria,

- Scost—a set of cost criteria.

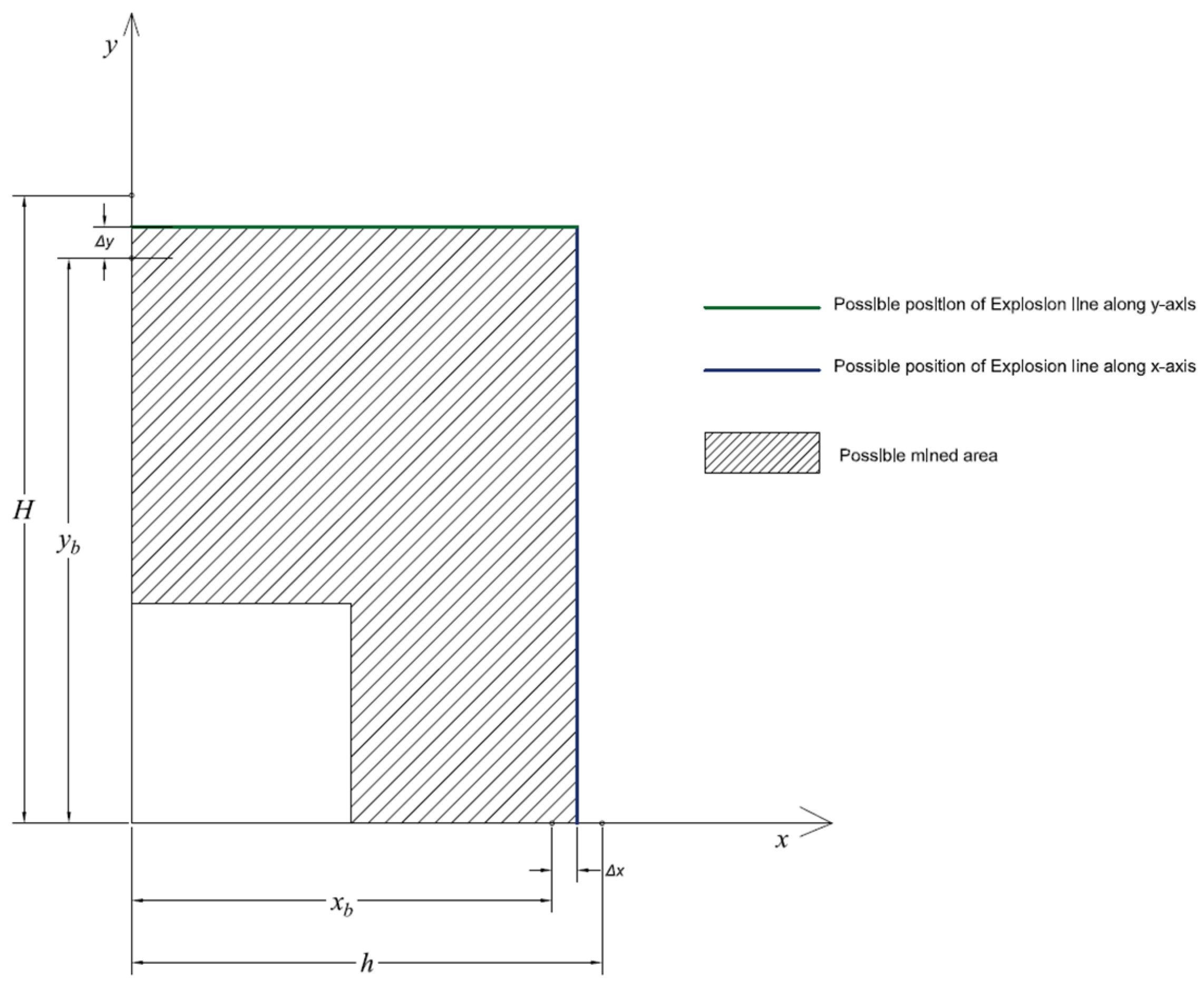

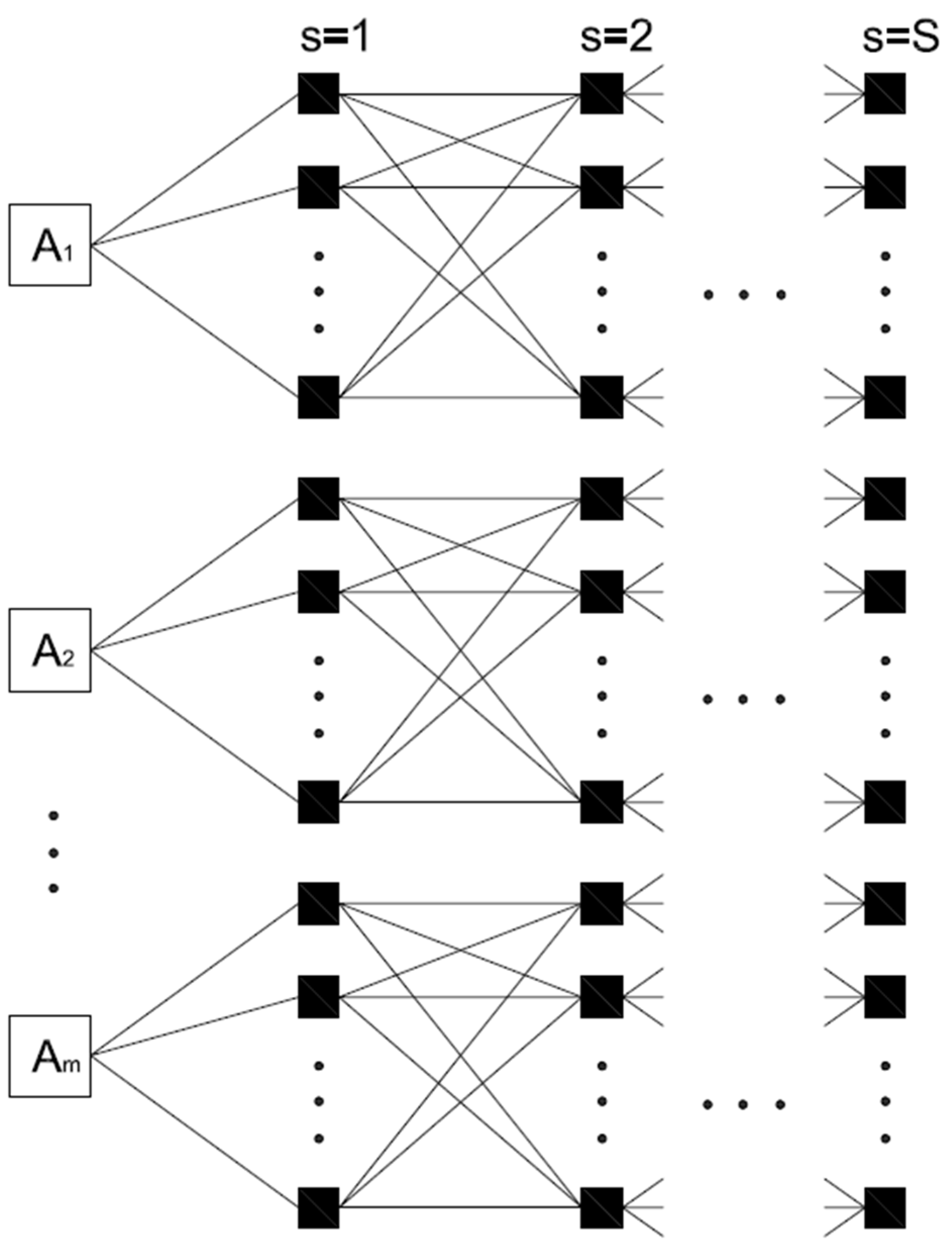

2.2. Simulation of the Selection Process

- H is the height of stope,

- h is width of the stope,

- and represents drilling limits for blastholes,

- and are dimensions of production drift, and

- is burden.

- C—compactness,

- S—surface of figure, which is defined by blastholes of fan pattern, m2,

- P—perimeter of figure, which is defined by blastholes of fan pattern, m.

- x—is width of explosion line, m,

- y—is height of the explosion line, m,

- —width of production drift, m,

- —height of production drift, m,

- b—burden, m,

- γ—bulk density of mined ore,

- —artificial value of time created by simulation, minutes,

- t—calculated value needed for drilling one fan pattern not burdened by uncertainty, minutes.

- μ—calculated value needed for drilling one fan pattern t,

- σ—the standard deviation of the distribution that can be defined by the following equation:

3. Numerical Example

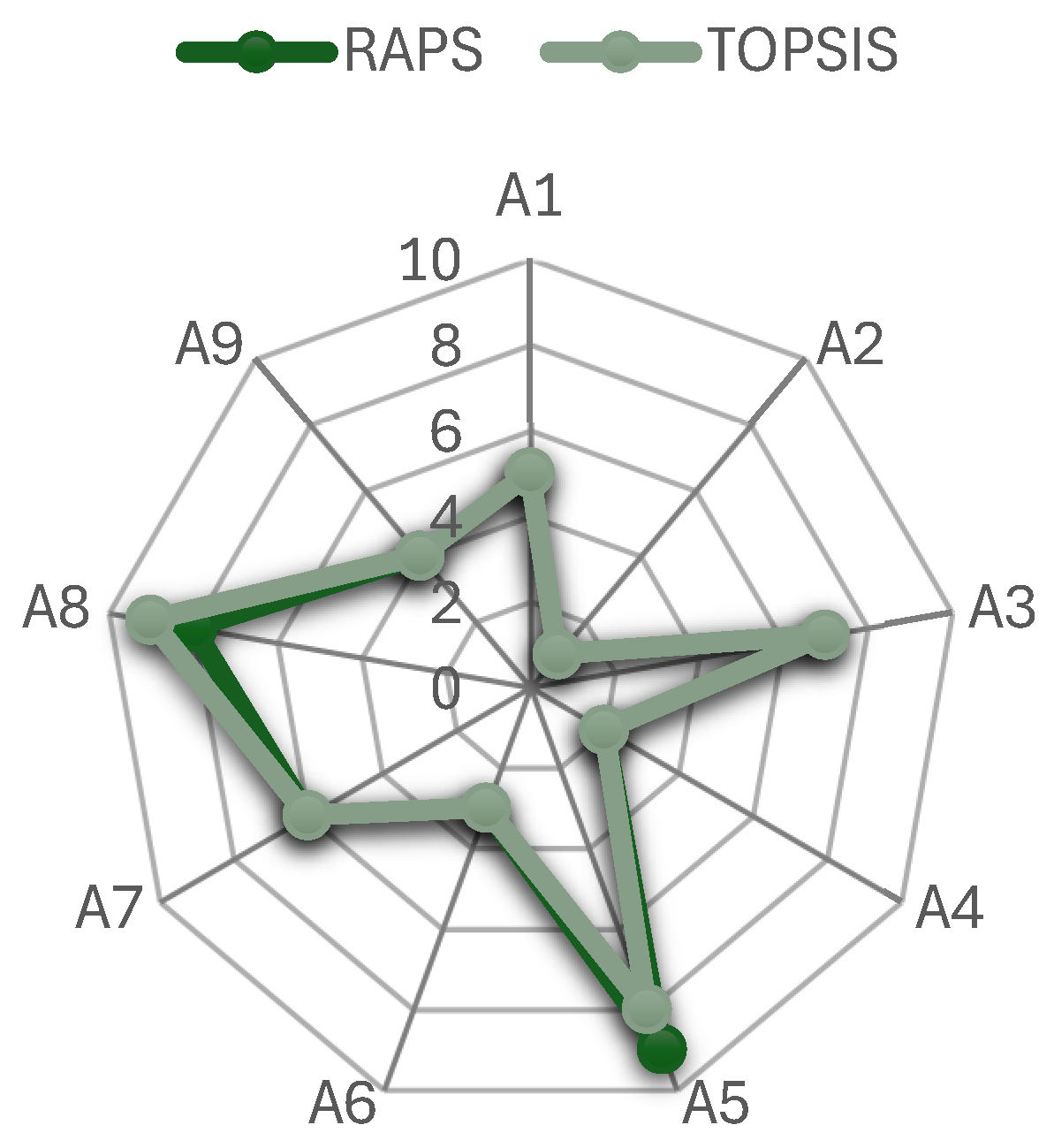

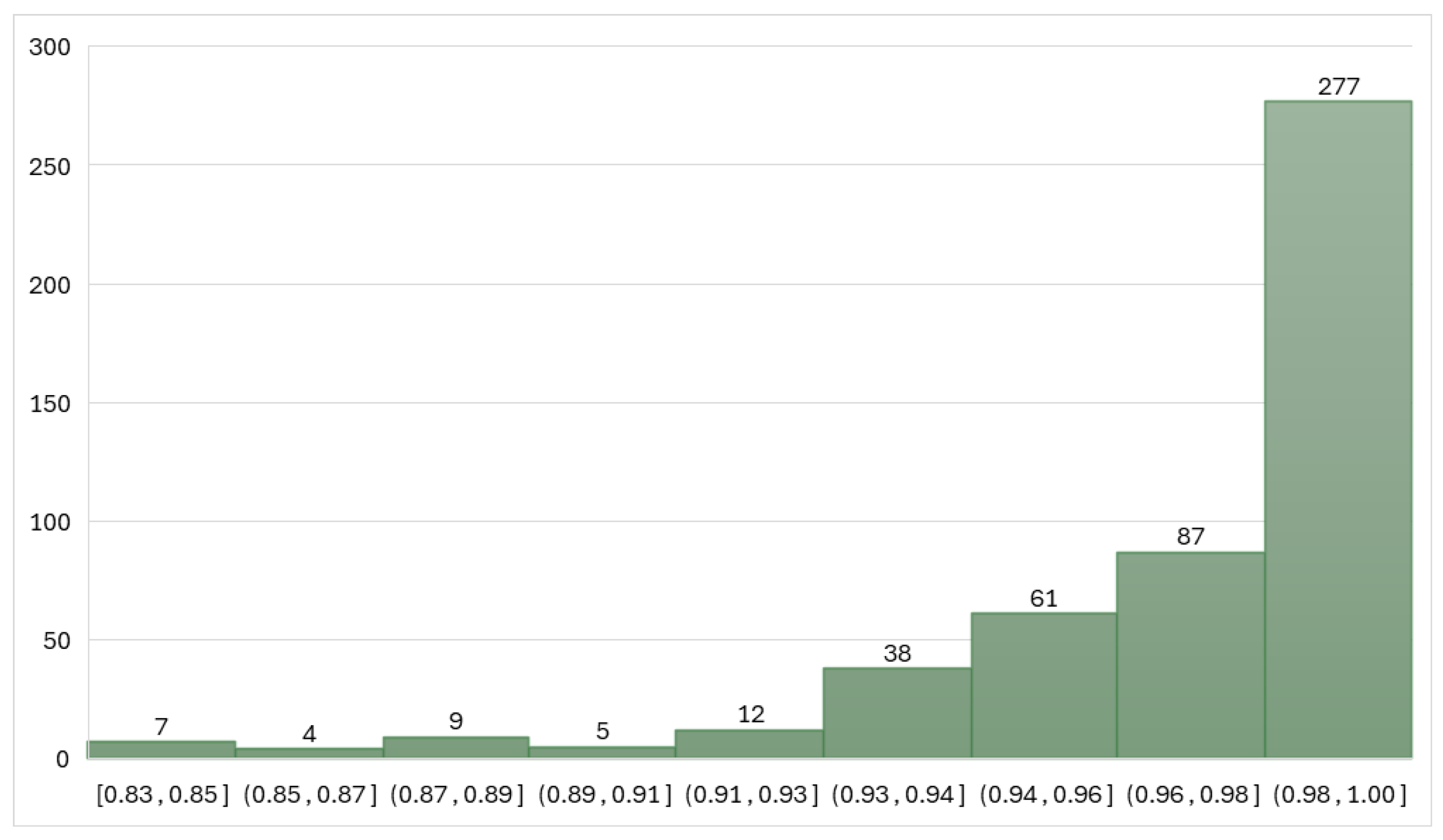

4. Validity Test of Simulation of the RAPS Method

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MCDM | Multiple Criteria Decision Making |

| RAPS | Ranking Alternatives by Perimeter Similarity |

| TOPSIS | Technique for Order of Preference by Similarity to Ideal Solution |

| AHP | Analytic Hierarchy Process |

| PROMETHEE | Preference Ranking Organization Method for Enrichment of Evaluations |

| ELECTRE | Elimination Et Choice Translating Reality |

| TAOV | Total Area Based on Orthogonal Vectors |

| ARAS | Additive Ratio Assessment |

| WASPAS | Weighted Aggregated Sum Product Assessment |

| COPRAS | Complex Proportional Assessment |

References

- Sitorus, F.; Cilliers, J.J.; Brito-Parada, P.R. Multi-criteria decision making for the choice problem in mining and mineral processing: Applications and trends. Expert Syst. Appl. 2019, 121, 393–417. [Google Scholar] [CrossRef]

- Brans, J.P.; Vincke, P.; Mareschal, B. How to select and how to rank projects: The PROMETHEE method. Eur. J. Oper. Res. 1986, 24, 228–238. [Google Scholar] [CrossRef]

- Roy, B. The outranking approach and the foundations of ELECTRE methods. In Readings in Multiple Criteria Decision Aid; Springer: Berlin/Heidelberg, Germany, 1990; pp. 155–183. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Tzeng, G.H.; Huang, J.J. Multiple Attribute Decision Making: Methods and Applications; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Pouresmaieli, M.; Ataei, M.; Nouri Qarahasanlou, A.; Barabadi, A. Multi-criteria Decision-making Methods for Sustainable Decision-making in the Mining Industry (A Comprehensive Study). J. Min. Environ. 2024, 15, 683–706. [Google Scholar]

- Himanshu, V.K.; Mishra, A.K.; Roy, M.P.; Singh, P.K. Underground Ring Blasting. In Blasting Technology for Underground Hard Rock Mining; Springer Nature: Singapore, 2023; pp. 75–91. [Google Scholar]

- Namin, F.S.; Ghadi, A.; Saki, F. A literature review of Multi Criteria Decision-Making (MCDM) towards mining method selection (MMS). Resour. Policy 2022, 77, 102676. [Google Scholar] [CrossRef]

- Bakhtavar, E.; Yousefi, S.; Jafarpour, A. Evaluation of shaft locations in underground mines: Fuzzy multi-objective optimization by ratio analysis with fuzzy cognitive map weights. J. South. Afr. Inst. Min. Metall. 2019, 119, 855–864. [Google Scholar] [CrossRef] [PubMed]

- Cardozo, F.A.; Campos, H.J.; Petter, C.O.; Ambrós, W.M. Application of Monte Carlo Analytic Hierarchy Process (MAHP) in Underground Mining Access Selection. Mining 2023, 3, 773–785. [Google Scholar] [CrossRef]

- Rahimdel, M.J.; Aryafar, A.; Tavakkoli, E. Selection of the most proper drilling and blasting pattern by using MADM methods (A case study: Sangan Iron Ore Mine, Iran). Rud.-Geološko-Naft. Zb. 2020, 35. [Google Scholar] [CrossRef]

- Sandanayake DS, S.; Topal, E.; Asad MW, A. Designing an optimal stope layout for underground mining based on a heuristic algorithm. Int. J. Min. Sci. Technol. 2015, 25, 767–772. [Google Scholar] [CrossRef]

- Li, C.; Liu, G.; Guo, L.; Zheng, D.; Yuan, X. A New CRITIC-GRA Model for Stope Dimension Optimization Considering Open Stoping Stability, Mining Capacity and Costs. Appl. Sci. 2024, 14, 5249. [Google Scholar] [CrossRef]

- Qiu, H.-Y.; Huang, M.-Q.; Weng, Y.-J. Stability Evaluation and Structural Parameters Optimization of Stope Based on Area Bearing Theory. Minerals 2022, 12, 808. [Google Scholar] [CrossRef]

- Onederra, I.; Chitombo, G. Design methodology for underground ring blasting. Min. Technol. 2007, 116, 180–195. [Google Scholar] [CrossRef]

- Wang, M.; Shi, X.; Zhou, J. Charge design scheme optimization for ring blasting based on the developed Scaled Heelan model. Int. J. Rock Mech. Min. Sci. 2018, 110, 199–209. [Google Scholar] [CrossRef]

- Blair, D.P.; Minchinton, A. Near-field blast vibration models. In Proceedings of the 8th International Symposium of Rock Fragmentation by Blasting, Santiago, Chile, 7–11 May 2006; pp. 152–159. [Google Scholar]

- Bai, X.; Marcotte, D.; Simon, R. Underground stope optimization with network flow method. Comput. Geosci. 2013, 52, 361–371. [Google Scholar] [CrossRef]

- Vishwakarma, A.K.; Dey, K.; Himanshu, V.K.; Singh, R.K.; Roy, M.P. Optimization of Blast Design Parameter for Ring Blasting in Underground Hard Rock Mine Using Numerical Simulation. Min. Metall. Explor. 2024, 41, 139–148. [Google Scholar] [CrossRef]

- Vishwakarma, A.K.; Himanshu, V.K.; Dey, K. Determination of Optimal Burden for Ringhole Blasting in Underground Hard Rock Mining Under Varying Geotechnical Properties. Rock Mech. Rock Eng. 2024, 57, 5727–5741. [Google Scholar] [CrossRef]

- Urošević, K.; Gligorić, Z.; Miljanović, I.; Beljić, Č.; Gligorić, M. Novel Methods in Multiple Criteria Decision-Making Process (MCRAT and RAPS)—Application in the Mining Industry. Mathematics 2021, 9, 1980. [Google Scholar] [CrossRef]

- Schwartzberg, J.E. Reapportionment, gerrymanders, and the notion of compactness. Minn. Law Rev. 1966, 50, 443–452. [Google Scholar]

- Baker, W.E.; Cox, P.A.; Kulesz, J.J.; Strehlow, R.A.; Westine, P.S. Explosion Hazards and Evaluation; Elsevier Scientific Pub. Co., Ltd.: Amsterdam, The Netherlands, 1983. [Google Scholar]

- Zhang, Z.-X.; Sanchidrián, J.A.; Ouchterlony, F.; Luukkanen, S. Reduction of fragment size from mining to mineral processing: A review. Rock Mech. Rock Eng. 2023, 56, 747–778. [Google Scholar] [CrossRef]

- Zardari, N.H.; Ahmed, K.; Shirazi, S.M.; Yusop, Z.B. Weighting Methods and Their Effects on Multi-Criteria Decision Making Model Outcomes in Water Resources Management; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Hajiagha, S.H.R.; Mahdiraji, H.A.; Hashemi, S.S. Total area based on orthogonal vectors (Taov) as a novel method of multi-criteria decision aid. Technol. Econ. Dev. Econ. 2018, 24, 1679–1694. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Turskis, Z. A new additive ratio assessment (ARAS) method in multicriteria decision-making. Technol. Econ. Dev. Econ. 2010, 16, 159–172. [Google Scholar] [CrossRef]

- Benesty, J.; Chen, J.; Huang, Y.; Cohen, I. Pearson Correlation Coefficient. In Noise Reduction in Speech Processing. Springer Topics in Signal Processing, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Selvanathan, M.; Jayabalan, N.; Saini, G.K.; Supramaniam, M.; Hussin, N. Employee productivity in Malaysian private higher educational institutions. PalArch’s J. Archaeol. Egypt/Egyptol. 2020, 17, 66–79. [Google Scholar]

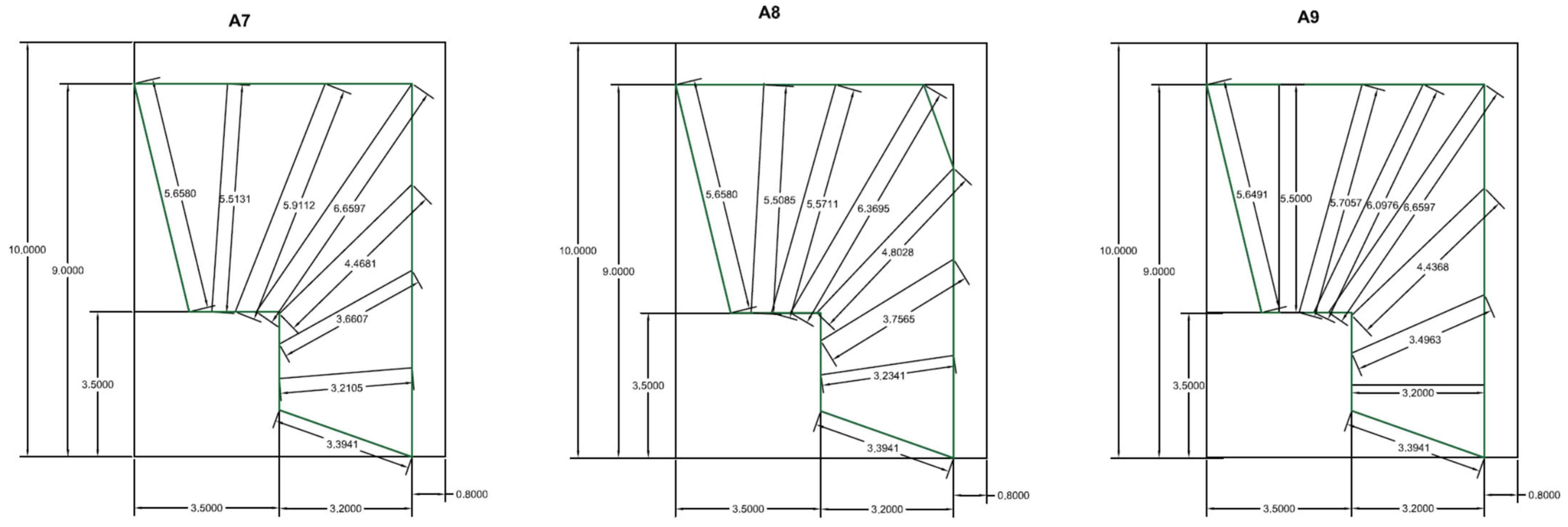

| Alternatives | Total Length of Blastholes, m | Burden, m | Total Height of Stope, m |

|---|---|---|---|

| A1 | 21.8 | 1.5 | 8 |

| A2 | 26.5 | 1.8 | 8 |

| A3 | 29.5 | 2.0 | 8 |

| A4 | 30.5 | 1.5 | 9 |

| A5 | 33.7 | 1.8 | 9 |

| A6 | 38.8 | 2.0 | 9 |

| A7 | 38.5 | 1.5 | 10 |

| A8 | 38.1 | 1.8 | 10 |

| A9 | 44.1 | 2.0 | 10 |

| Alternative | Compactness Index | Tonnage, t | Cost, €/fan Pattern | Drilling Time (Minutes) | Fragmentation 1—Bad, 2—Medium, 3—Good |

|---|---|---|---|---|---|

| A1 | 4.46 | 151.02 | 650.00 | 106.35 | 2.00 |

| A2 | 5.09 | 181.22 | 705.60 | 128.94 | 3.00 |

| A3 | 4.45 | 201.36 | 774.00 | 141.02 | 1.00 |

| A4 | 4.42 | 179.59 | 810.00 | 145.01 | 3.00 |

| A5 | 3.98 | 215.51 | 834.00 | 157.98 | 1.00 |

| A6 | 4.42 | 239.46 | 892.80 | 182.94 | 3.00 |

| A7 | 4.15 | 208.17 | 954.00 | 176.97 | 2.00 |

| A8 | 3.67 | 249.80 | 993.60 | 177.80 | 1.00 |

| A9 | 4.15 | 277.56 | 1068.00 | 204.33 | 3.00 |

| Criterion/ Alternative | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| min | max | min | min | max | |

| A1 | 4.4559 | 166.0871 | 650.0000 | 109.3835 | 2.0000 |

| A2 | 5.0858 | 205.7918 | 705.6000 | 136.2610 | 3.0000 |

| A3 | 4.4475 | 219.1037 | 774.0000 | 152.8601 | 1.0000 |

| A4 | 4.4155 | 193.1554 | 810.0000 | 164.3363 | 3.0000 |

| A5 | 3.9803 | 208.7047 | 834.0000 | 175.8313 | 1.0000 |

| A6 | 4.4180 | 231.1049 | 892.8000 | 172.7319 | 3.0000 |

| A7 | 4.1500 | 204.8728 | 954.0000 | 192.7527 | 2.0000 |

| A8 | 3.6724 | 238.9781 | 993.6000 | 177.7501 | 1.0000 |

| A9 | 4.1482 | 290.1105 | 1068.0000 | 229.7601 | 3.0000 |

| Criterion/ Alternative | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| min | max | min | min | max | |

| A1 | 0.8242 | 0.5725 | 1.0000 | 1.0000 | 0.6667 |

| A2 | 0.7221 | 0.7094 | 0.9212 | 0.8027 | 1.0000 |

| A3 | 0.8257 | 0.7552 | 0.8398 | 0.7156 | 0.3333 |

| A4 | 0.8317 | 0.6658 | 0.8025 | 0.6656 | 1.0000 |

| A5 | 0.9227 | 0.7194 | 0.7794 | 0.6221 | 0.3333 |

| A6 | 0.8312 | 0.7966 | 0.7280 | 0.6333 | 1.0000 |

| A7 | 0.8849 | 0.7062 | 0.6813 | 0.5675 | 0.6667 |

| A8 | 1.0000 | 0.8237 | 0.6542 | 0.6154 | 0.3333 |

| A9 | 0.8853 | 1.0000 | 0.6086 | 0.4761 | 1.0000 |

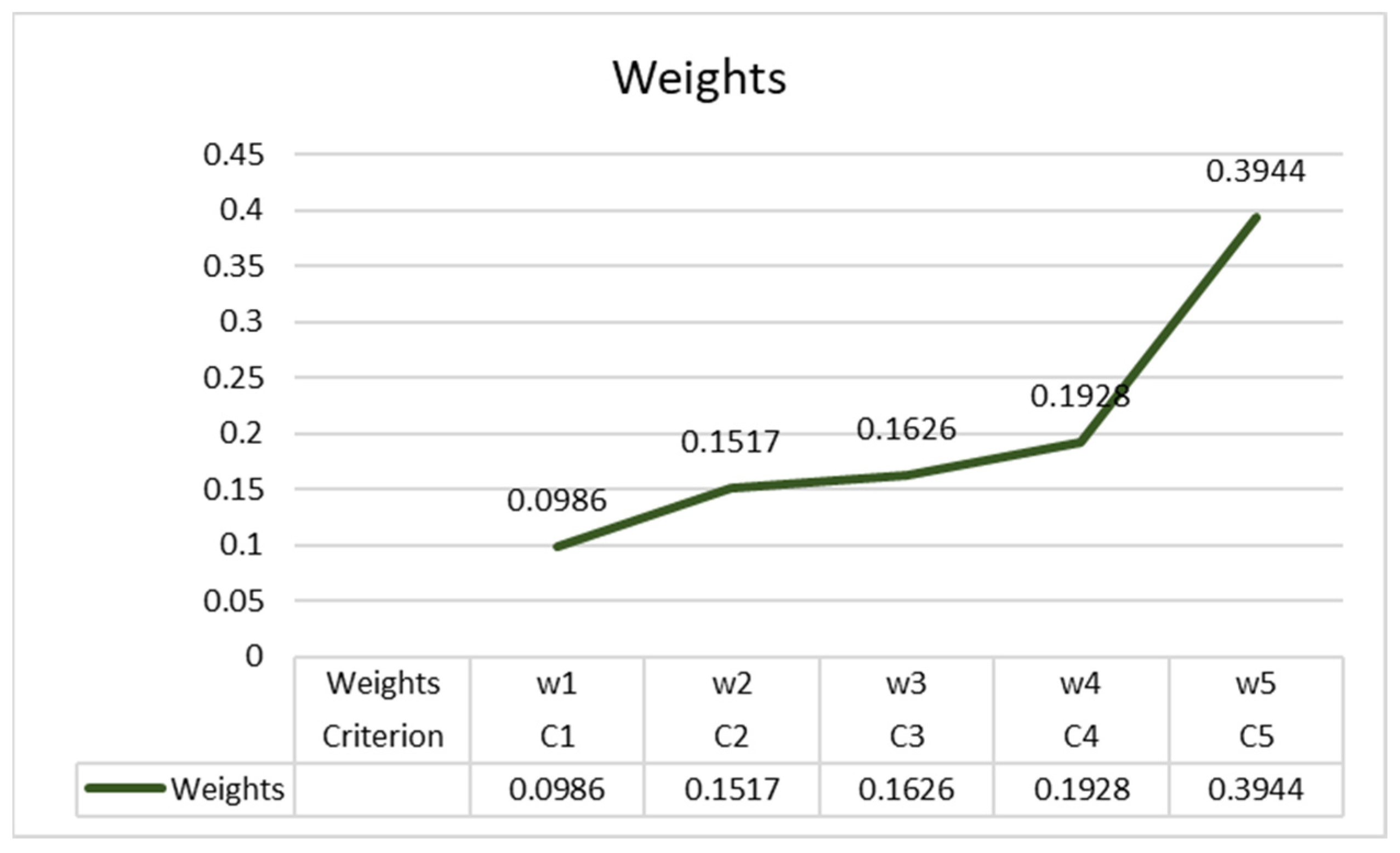

| Criterion/ Weight | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| W | 0.0986 | 0.1517 | 0.1626 | 0.1928 | 0.3944 |

| Criterion/ Alternative | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| min | max | min | min | max | |

| A1 | 0.0813 | 0.0868 | 0.1626 | 0.1626 | 0.2629 |

| A2 | 0.0712 | 0.1076 | 0.1497 | 0.1305 | 0.3944 |

| A3 | 0.0814 | 0.1146 | 0.1365 | 0.1163 | 0.1315 |

| A4 | 0.0820 | 0.1010 | 0.1304 | 0.1082 | 0.3944 |

| A5 | 0.0910 | 0.1091 | 0.1267 | 0.1011 | 0.1315 |

| A6 | 0.0820 | 0.1208 | 0.1183 | 0.1029 | 0.3944 |

| A7 | 0.0873 | 0.1071 | 0.1108 | 0.0922 | 0.2629 |

| A8 | 0.0986 | 0.1250 | 0.1063 | 0.1000 | 0.1315 |

| A9 | 0.0873 | 0.1517 | 0.0989 | 0.0774 | 0.3944 |

| Optimal Alternative/ Criterion | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| min | max | min | min | max | |

| Q | 0.0986 | 0.1517 | 0.1626 | 0.1626 | 0.3944 |

| Optimal Alternative/ Criterion | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| min | max | min | min | max | |

| Qmax | 0.1517 | 0.3944 | |||

| Qmin | 0.0986 | 0.1626 | 0.1626 |

| Criterion/ Alternative | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| min | max | min | min | max | |

| A1 Qmax | 0.0868 | 0.2629 | |||

| A1 Qmin | 0.0813 | 0.1626 | 0.1626 | ||

| A2 Qmax | 0.1076 | 0.3944 | |||

| A2 Qmin | 0.0712 | 0.1497 | 0.1305 | ||

| A3 Qmax | 0.1146 | 0.1315 | |||

| A3 Qmin | 0.0814 | 0.1365 | 0.1163 | ||

| A4 Qmax | 0.1010 | 0.3944 | |||

| A4 Qmin | 0.0820 | 0.1304 | 0.1082 | ||

| A5 Qmax | 0.1091 | 0.1315 | |||

| A5 Qmin | 0.0910 | 0.1267 | 0.1011 | ||

| A6 Qmax | 0.1208 | 0.3944 | |||

| A6 Qmin | 0.0820 | 0.1183 | 0.1029 | ||

| A7 Qmax | 0.1071 | 0.2629 | |||

| A7 Qmin | 0.0873 | 0.1108 | 0.0922 | ||

| A8 Qmax | 0.1250 | 0.1315 | |||

| A8 Qmin | 0.0986 | 0.1063 | 0.1000 | ||

| A9 Qmax | 0.1517 | 0.3944 | |||

| A9 Qmin | 0.0873 | 0.0989 | 0.0774 |

| Max | Min | |

|---|---|---|

| Optimal Alternative | 0.4225 | 0.2502 |

| A1 | 0.2769 | 0.2438 |

| A2 | 0.4088 | 0.2110 |

| A3 | 0.1744 | 0.1970 |

| A4 | 0.4071 | 0.1883 |

| A5 | 0.1708 | 0.1859 |

| A6 | 0.4125 | 0.1770 |

| A7 | 0.2839 | 0.1685 |

| A8 | 0.1814 | 0.1762 |

| A9 | 0.4225 | 0.1530 |

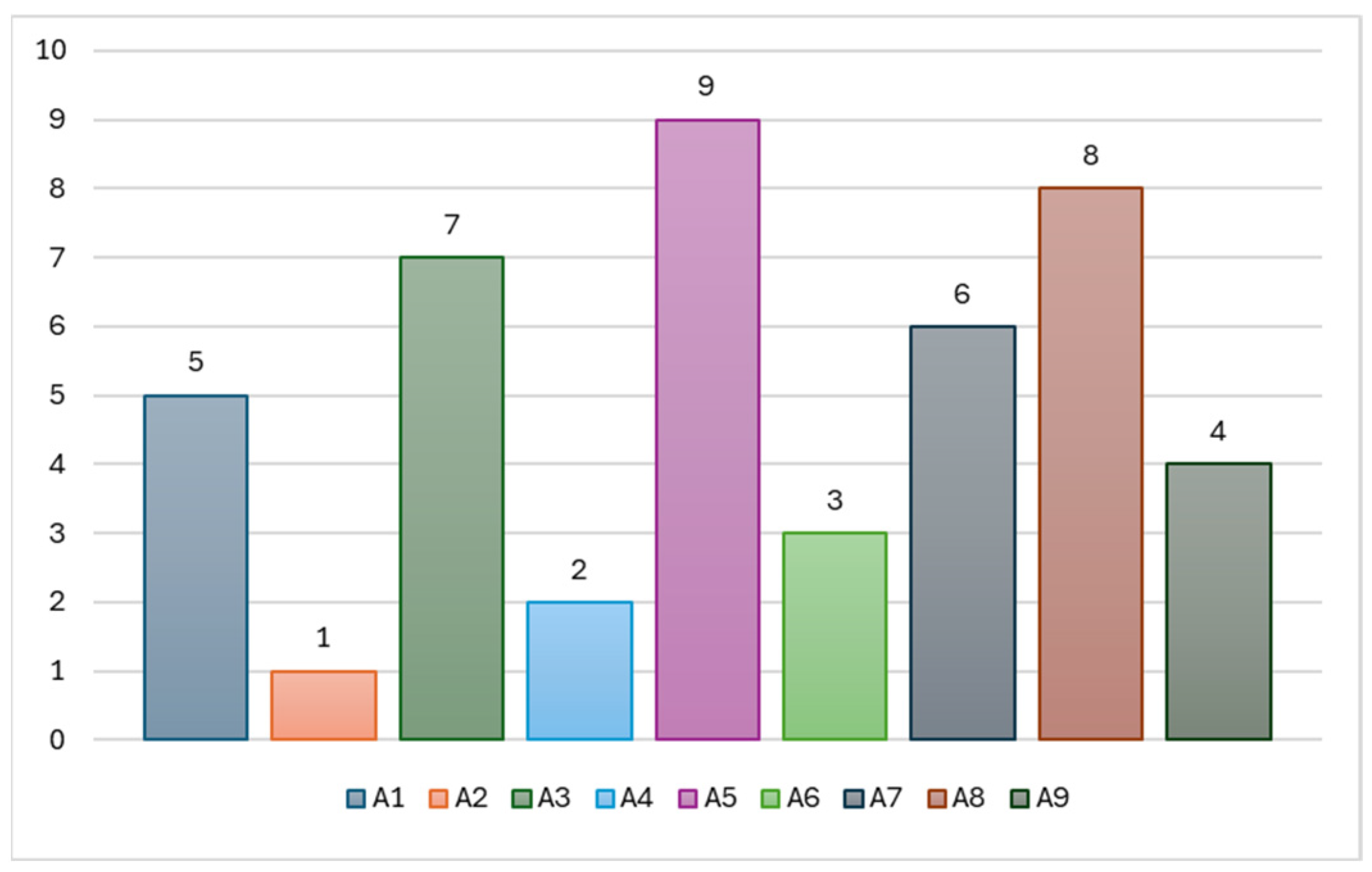

| Max | Min | Perimeter | Perimeter Similarity | |

|---|---|---|---|---|

| Qk Uik | Qh Uih | |||

| Q | 0.4225 | 0.2502 | 1.1637 | |

| A1 | 0.2769 | 0.2438 | 0.8897 | 0.7645 |

| A2 | 0.4088 | 0.2110 | 1.0798 | 0.9279 |

| A3 | 0.1744 | 0.1970 | 0.6344 | 0.5452 |

| A4 | 0.4071 | 0.1883 | 1.0439 | 0.8970 |

| A5 | 0.1708 | 0.1859 | 0.6092 | 0.5235 |

| A6 | 0.4125 | 0.1770 | 1.0383 | 0.8922 |

| A7 | 0.2839 | 0.1685 | 0.7825 | 0.6724 |

| A8 | 0.1814 | 0.1762 | 0.6104 | 0.5245 |

| A9 | 0.4225 | 0.1530 | 1.0249 | 0.8807 |

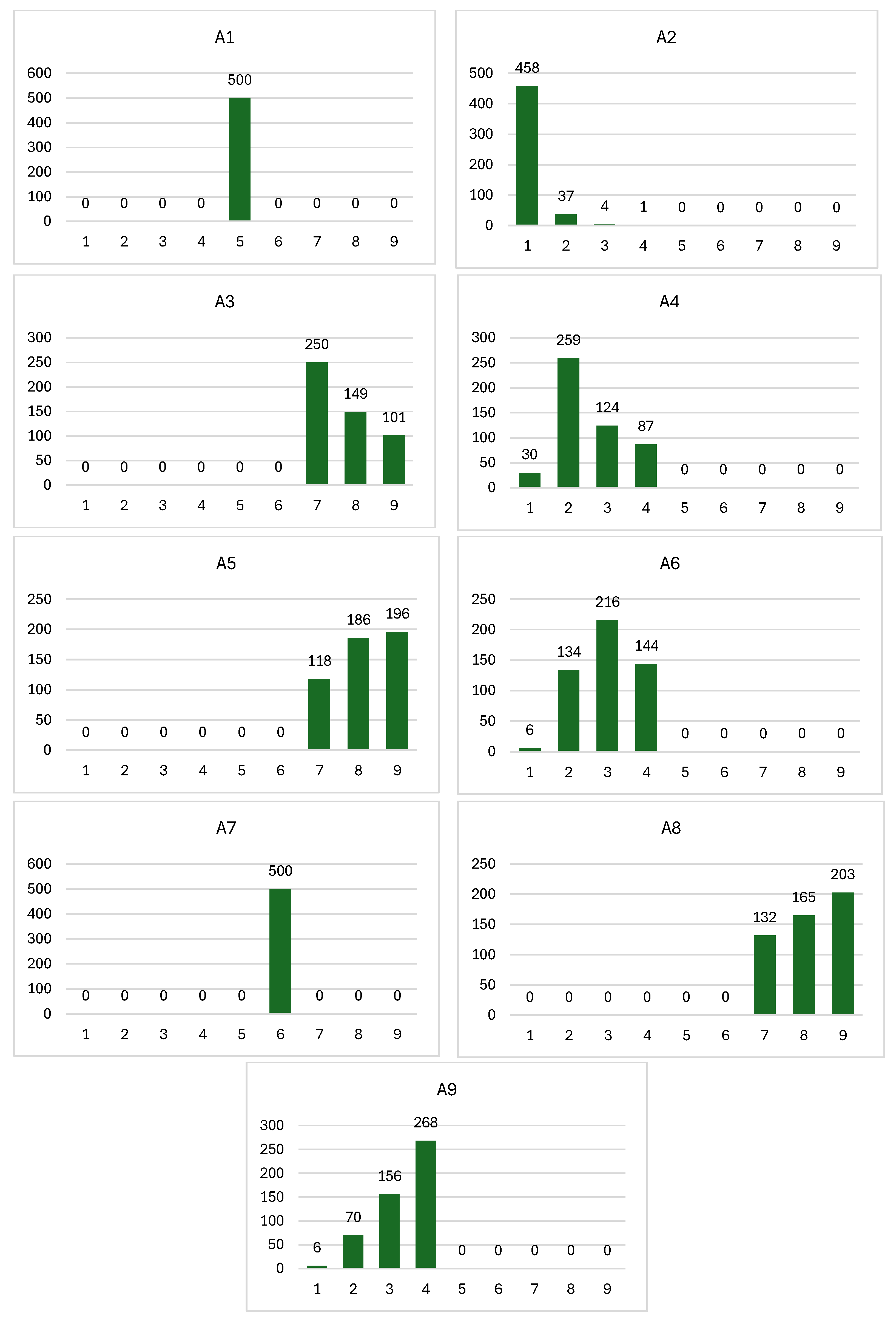

| 100 Simulations | 200 Simulations | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | |

| A1 | 0 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 200 | 0 | 0 | 0 | 0 |

| A2 | 95 | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 188 | 12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| A3 | 0 | 0 | 0 | 0 | 0 | 0 | 53 | 28 | 19 | 0 | 0 | 0 | 0 | 0 | 0 | 102 | 56 | 42 |

| A4 | 3 | 57 | 19 | 21 | 0 | 0 | 0 | 0 | 0 | 9 | 108 | 44 | 39 | 0 | 0 | 0 | 0 | 0 |

| A5 | 0 | 0 | 0 | 0 | 0 | 0 | 18 | 33 | 49 | 0 | 0 | 0 | 0 | 0 | 0 | 41 | 68 | 91 |

| A6 | 1 | 28 | 44 | 27 | 0 | 0 | 0 | 0 | 0 | 1 | 52 | 93 | 54 | 0 | 0 | 0 | 0 | 0 |

| A7 | 0 | 0 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 200 | 0 | 0 | 0 |

| A8 | 0 | 0 | 0 | 0 | 0 | 0 | 29 | 39 | 32 | 0 | 0 | 0 | 0 | 0 | 0 | 57 | 76 | 67 |

| A9 | 1 | 10 | 37 | 52 | 0 | 0 | 0 | 0 | 0 | 2 | 28 | 63 | 107 | 0 | 0 | 0 | 0 | 0 |

| 300 Simulations | 400 Simulations | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | |

| A1 | 0 | 0 | 0 | 0 | 300 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 400 | 0 | 0 | 0 | 0 |

| A2 | 280 | 20 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 372 | 26 | 2 | 0 | 0 | 0 | 0 | 0 | 0 |

| A3 | 0 | 0 | 0 | 0 | 0 | 0 | 154 | 88 | 58 | 0 | 0 | 0 | 0 | 0 | 0 | 204 | 115 | 81 |

| A4 | 15 | 163 | 66 | 56 | 0 | 0 | 0 | 0 | 0 | 21 | 211 | 95 | 73 | 0 | 0 | 0 | 0 | 0 |

| A5 | 0 | 0 | 0 | 0 | 0 | 0 | 65 | 114 | 121 | 0 | 0 | 0 | 0 | 0 | 0 | 87 | 157 | 156 |

| A6 | 3 | 77 | 138 | 82 | 0 | 0 | 0 | 0 | 0 | 4 | 107 | 176 | 113 | 0 | 0 | 0 | 0 | 0 |

| A7 | 0 | 0 | 0 | 0 | 0 | 300 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 400 | 0 | 0 | 0 |

| A8 | 0 | 0 | 0 | 0 | 0 | 0 | 81 | 98 | 121 | 0 | 0 | 0 | 0 | 0 | 0 | 109 | 128 | 163 |

| A9 | 2 | 40 | 96 | 162 | 0 | 0 | 0 | 0 | 0 | 3 | 56 | 127 | 214 | 0 | 0 | 0 | 0 | 0 |

| 500 Simulations | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | |

| A1 | 0 | 0 | 0 | 0 | 500 | 0 | 0 | 0 | 0 |

| A2 | 458 | 37 | 4 | 1 | 0 | 0 | 0 | 0 | 0 |

| A3 | 0 | 0 | 0 | 0 | 0 | 0 | 250 | 149 | 101 |

| A4 | 30 | 259 | 124 | 87 | 0 | 0 | 0 | 0 | 0 |

| A5 | 0 | 0 | 0 | 0 | 0 | 0 | 118 | 186 | 196 |

| A6 | 6 | 134 | 216 | 144 | 0 | 0 | 0 | 0 | 0 |

| A7 | 0 | 0 | 0 | 0 | 0 | 500 | 0 | 0 | 0 |

| A8 | 0 | 0 | 0 | 0 | 0 | 0 | 132 | 165 | 203 |

| A9 | 6 | 70 | 156 | 268 | 0 | 0 | 0 | 0 | 0 |

| Percentage Share | 100 Simulations | 200 Simulations | 300 Simulations | 400 Simulations | 500 Simulations |

|---|---|---|---|---|---|

| A1 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| A2 | 95.00 | 94.00 | 93.33 | 93.00 | 91.60 |

| A3 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| A4 | 3.00 | 4.50 | 5.00 | 5.25 | 6.00 |

| A5 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| A6 | 1.00 | 0.50 | 1.00 | 1.00 | 1.20 |

| A7 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| A8 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| A9 | 1.00 | 1.00 | 0.67 | 0.75 | 1.20 |

| Correlation | RAPS | TAOV | ARAS | SAW | TOPSIS | COPRAS | VIKOR | WASPAS | ELECTRE |

|---|---|---|---|---|---|---|---|---|---|

| RAPS | - | 0.89 | 0.95 | 0.88 | 0.96 | 0.96 | 0.80 | 0.95 | 0.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urošević, K.; Gligorić, Z.; Janković, I.; Gluščević, B.; Beljić, Č. Simulation of MCDM Process—Stope and Fan Pattern Selection in an Underground Mine with Uncertainty. Mathematics 2025, 13, 786. https://doi.org/10.3390/math13050786

Urošević K, Gligorić Z, Janković I, Gluščević B, Beljić Č. Simulation of MCDM Process—Stope and Fan Pattern Selection in an Underground Mine with Uncertainty. Mathematics. 2025; 13(5):786. https://doi.org/10.3390/math13050786

Chicago/Turabian StyleUrošević, Katarina, Zoran Gligorić, Ivan Janković, Branko Gluščević, and Čedomir Beljić. 2025. "Simulation of MCDM Process—Stope and Fan Pattern Selection in an Underground Mine with Uncertainty" Mathematics 13, no. 5: 786. https://doi.org/10.3390/math13050786

APA StyleUrošević, K., Gligorić, Z., Janković, I., Gluščević, B., & Beljić, Č. (2025). Simulation of MCDM Process—Stope and Fan Pattern Selection in an Underground Mine with Uncertainty. Mathematics, 13(5), 786. https://doi.org/10.3390/math13050786