Integrated Quality Inspection and Production Run Optimization for Imperfect Production Systems with Zero-Inflated Non-Homogeneous Poisson Deterioration

Abstract

1. Introduction

2. Literature Review

2.1. Imperfect Production and Inventory Models

2.2. Maintenance and Inspection Policies

2.3. Quality Inspection Planning

2.4. Reliability Analysis and Modeling

2.5. Research Gaps and Contributions

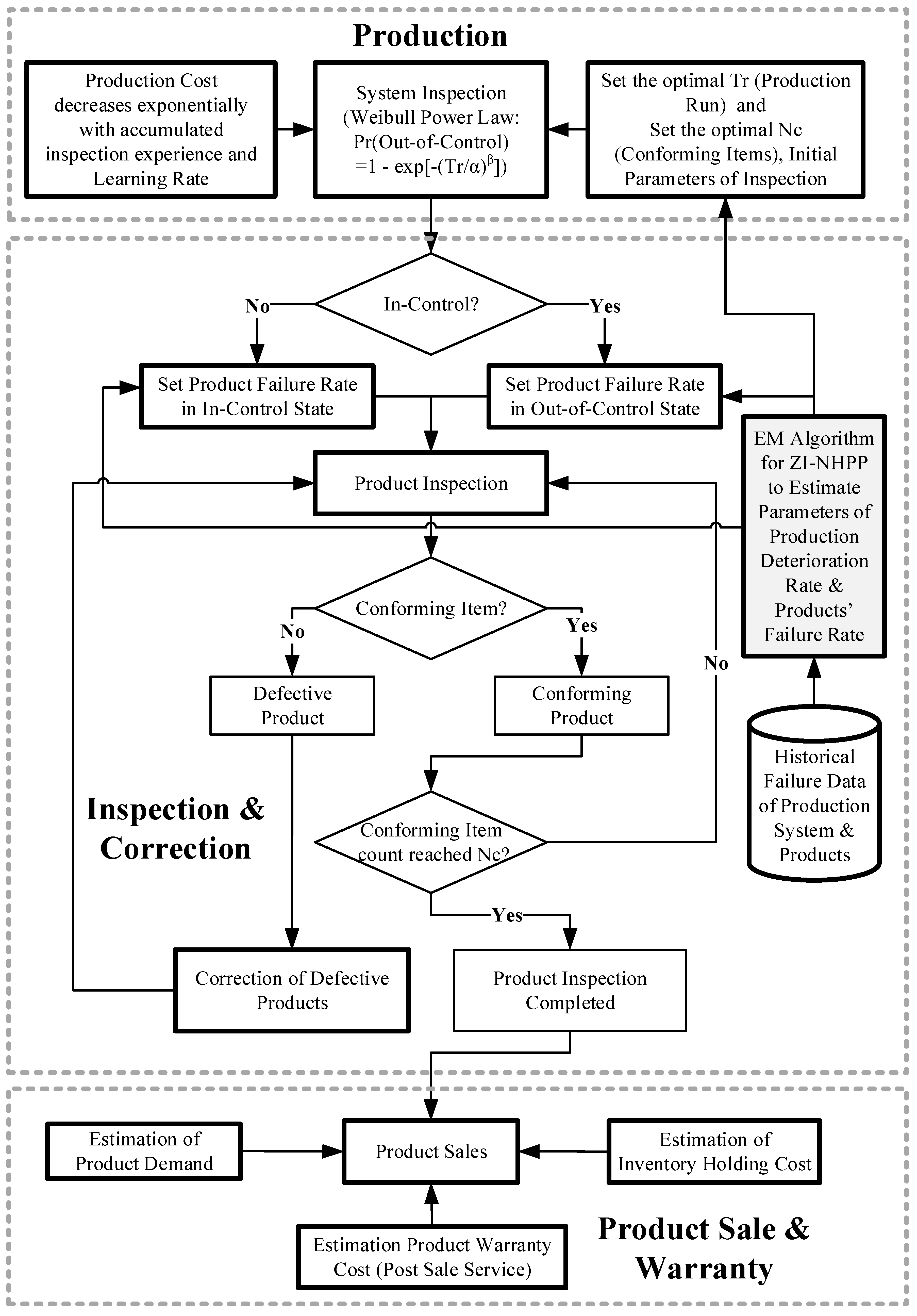

3. Problem Description and Model Development

3.1. Problem Description

3.2. Development of the Mathematical Model

- Statement: The production cost is strictly decreasing and convex in for , and . Furthermore, is strictly increasing and convex in .

- The parameter governs the rate at which the system transitions to reduced productivity due to deterioration. Higher accelerates performance degradation, driving costs upward, and its convexity implies that deterioration mitigation measures (e.g., preventive maintenance or higher sampling rates) become increasingly valuable when deterioration becomes severe. □

- Statement: The inspection and correction cost has expected number of inspections under negative binomial sampling, and is the valid probability of needing correction, bounded in .

- This result highlights that inventory cost is driven not merely by time or production scale individually, but by the extent to which production output matches demand over a cycle. The convex structure implies that deviations from the balance point become increasingly costly, so small mismatches are inexpensive while large overproduction accumulates inventory rapidly. When combined with deterioration effects, longer production runs may reduce setup frequency but push the system further from the demand-matching point, reinforcing the trade-off between holding cost and quality-related risks. □

- Statement: The warranty cost uses Weibull expected failures for states (in-control, low hazard) and (out-of-control, high hazard), weighted by system states, and is non-decreasing in . (: The out-of-control probability, : The in-control probability).

- The warranty cost increases as the system becomes more likely to be out-of-control during production, because items produced in that regime fail at a much higher hazard rate. Thus, even when defects are not immediately observable, inadequate inspection increases long-run failure liability, linking inspection decisions to post-sale cost exposure. □

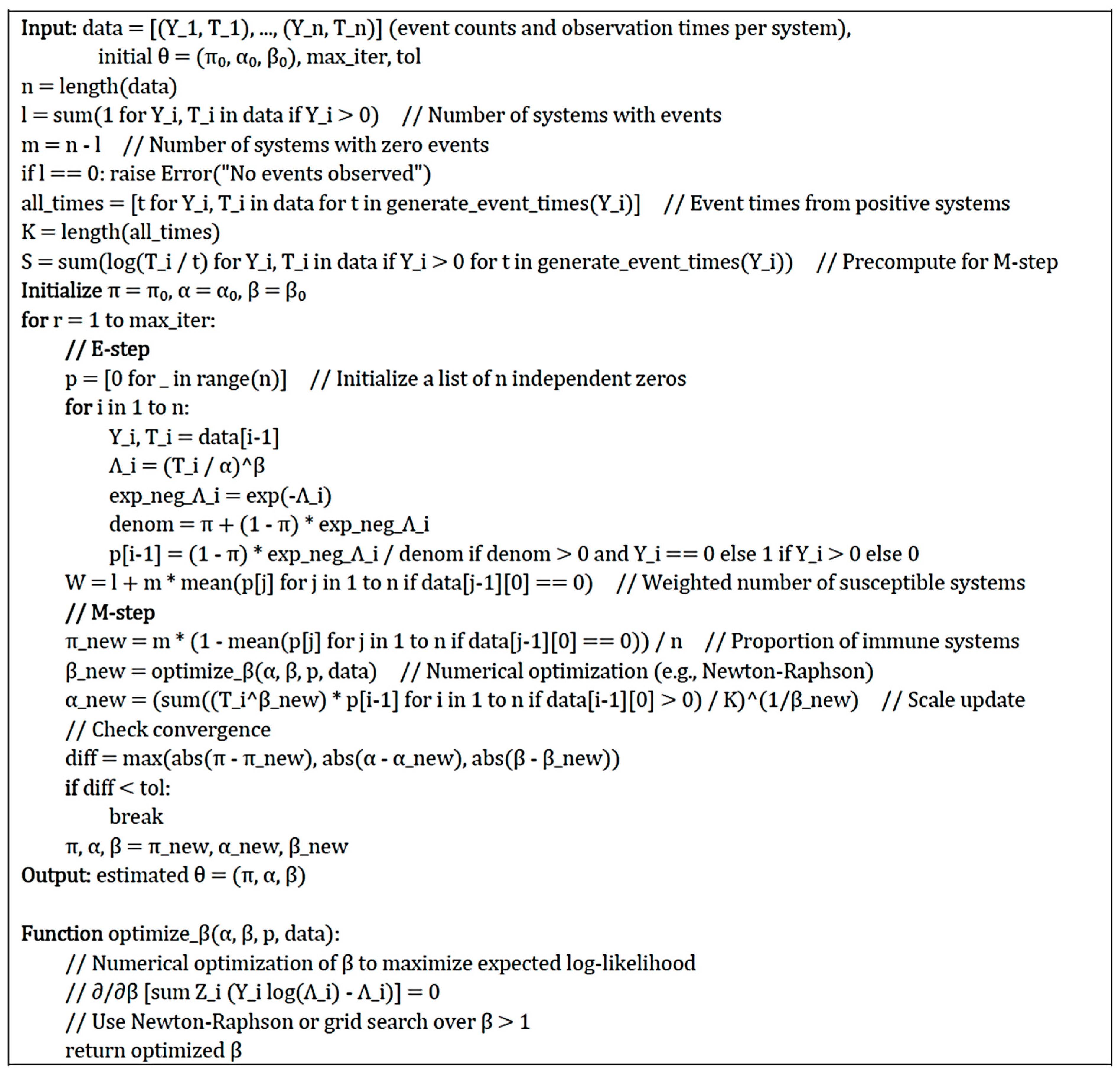

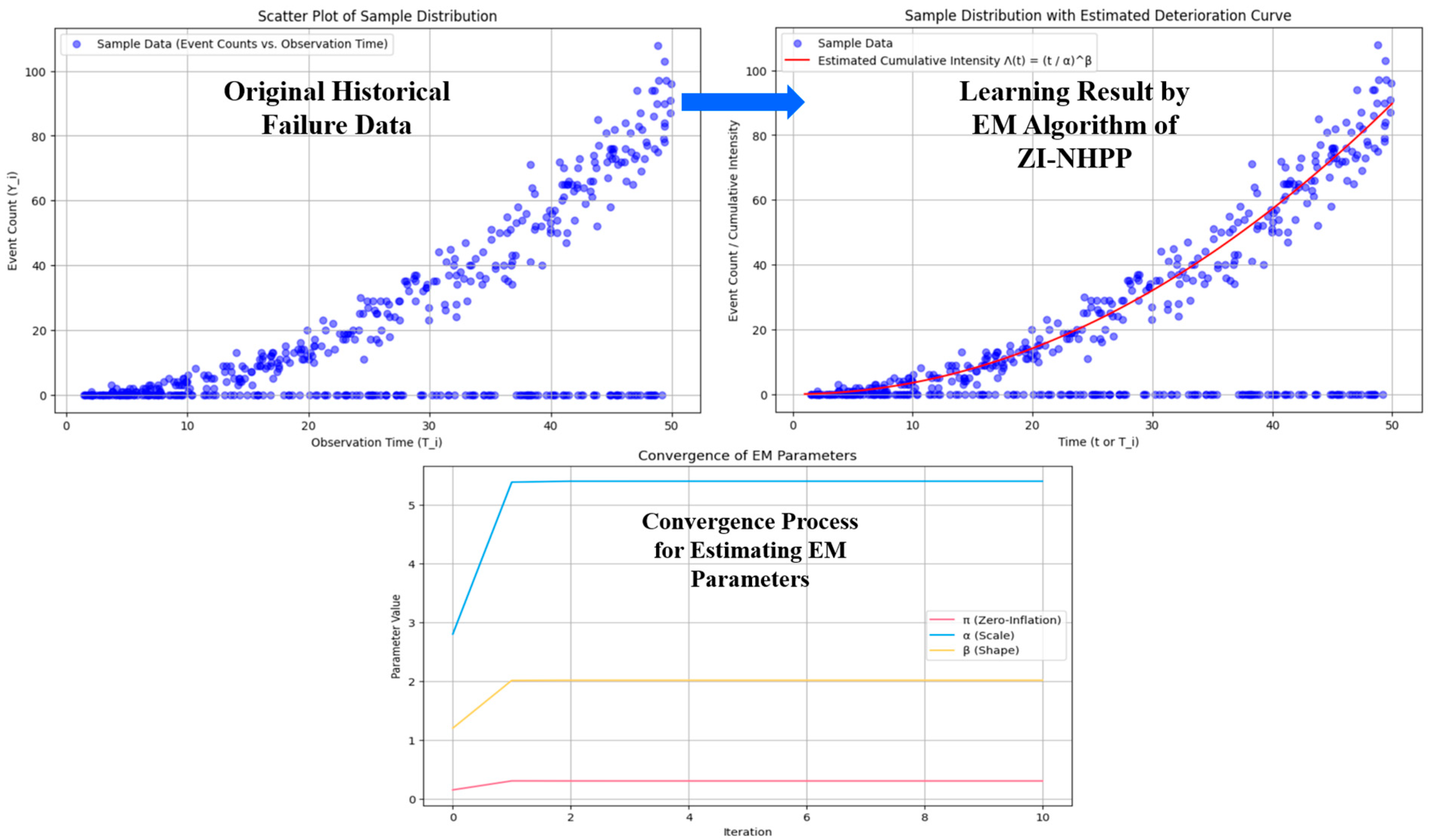

3.3. ZI-NHPP Framework for Estimating the Parameters of a Production System’s Deterioration

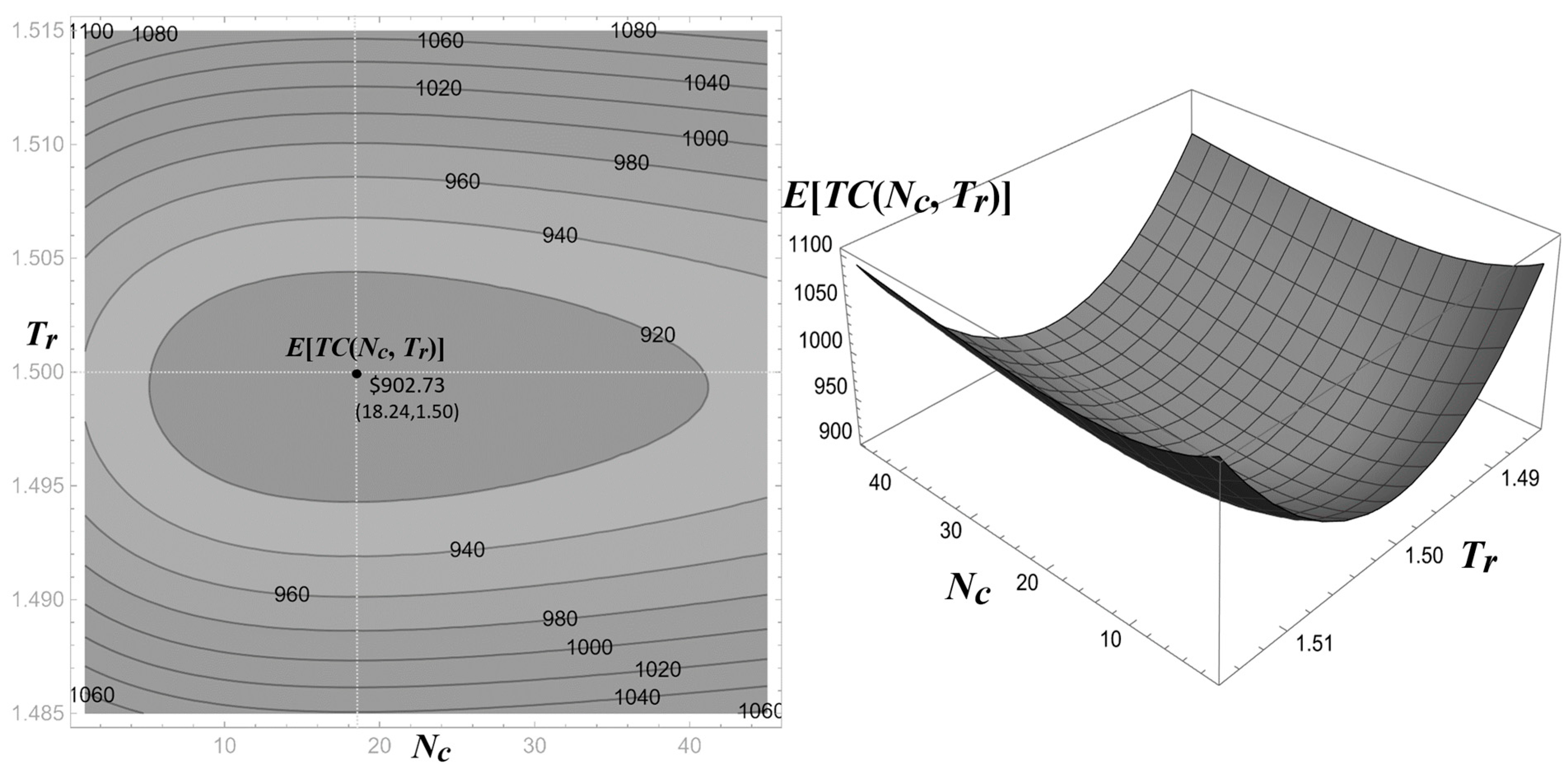

4. Application and Numerical Analysis

4.1. Numerical Example

4.2. Sensitivity Analysis

4.3. Managerial Insights

- (1)

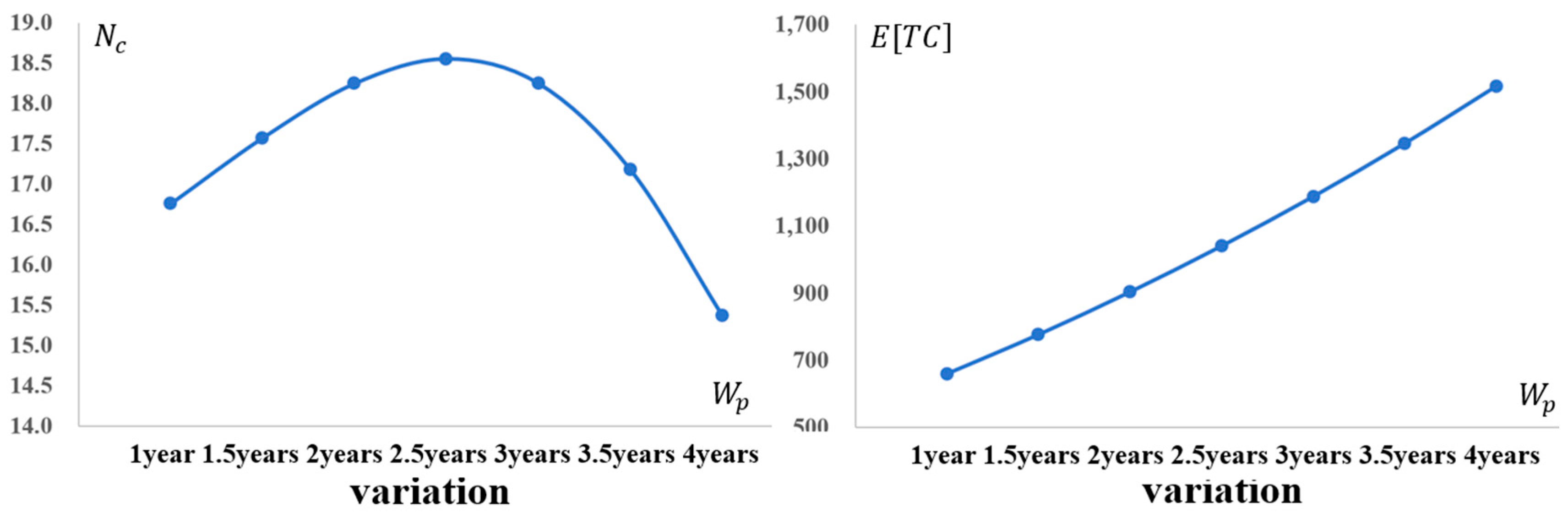

- Warranty Period ()

- (2)

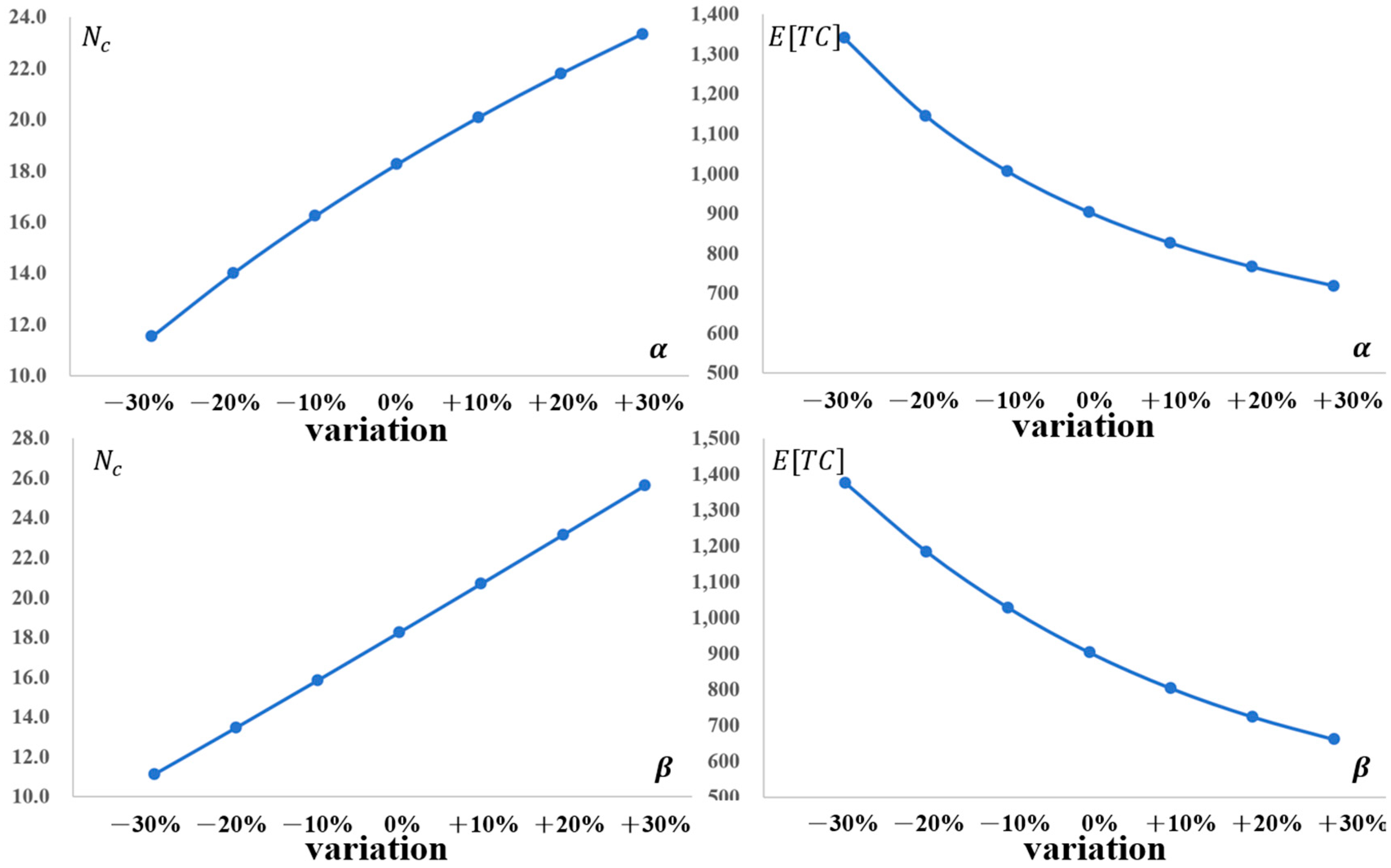

- Degradation Characteristics (,): When the production system deteriorates more gradually or follows a predictable pattern, the economic necessity of confirming the in-control state increases. A healthier system incentivizes higher sampling intensity because verifying quality provides greater marginal benefits. Conversely, when deterioration accelerates or becomes more erratic, simply increasing inspection frequency becomes less effective; the optimal strategy shifts toward more frequent production cycles or equipment improvements.

- (3)

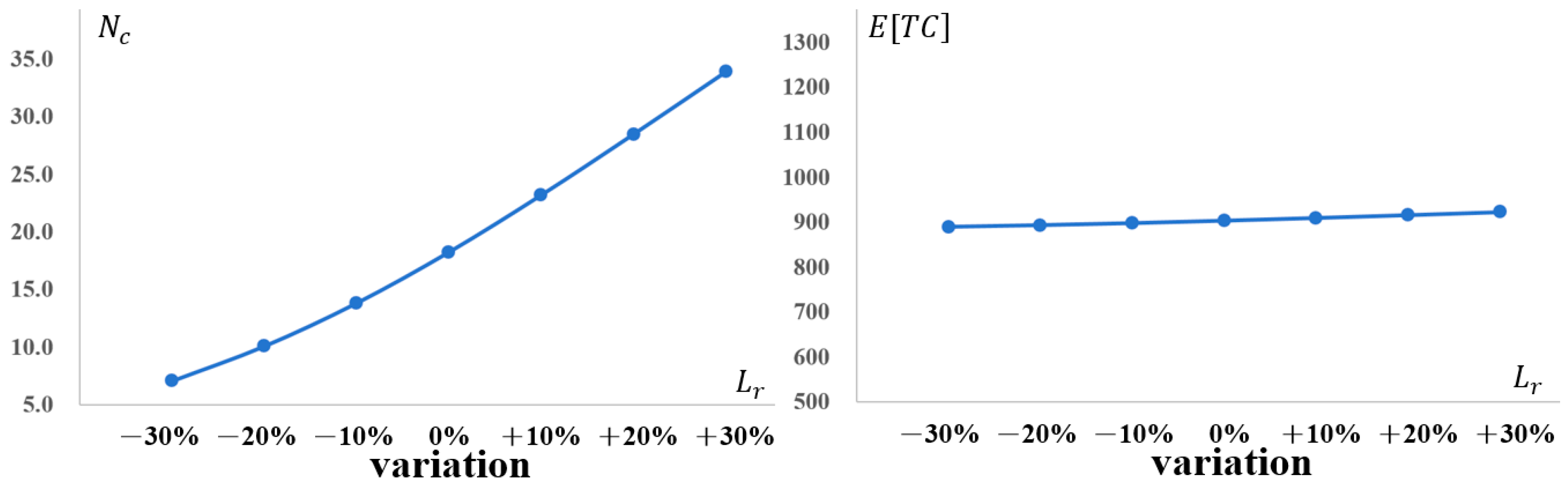

- Employee Learning Rate (): Improvements in learning rates enhance productivity and reduce production-related cost components; however, this does not directly lead to proportional reductions in total expected costs. This is because increased productivity typically necessitates higher sampling intensity to ensure that the greater output maintains the same level of quality assurance.

- (4)

- Production Rate (): Higher production capacity reduces per-unit operational costs and enhances the firm’s ability to implement shorter production cycles, thereby mitigating deterioration risks. With increased capacity, inspection intensity tends to rise because verifying a larger output becomes more valuable. Conversely, at lower production rates, longer production cycles may be necessary to meet demand, increasing exposure to deterioration and making inspection a secondary rather than a primary control mechanism.

- (5)

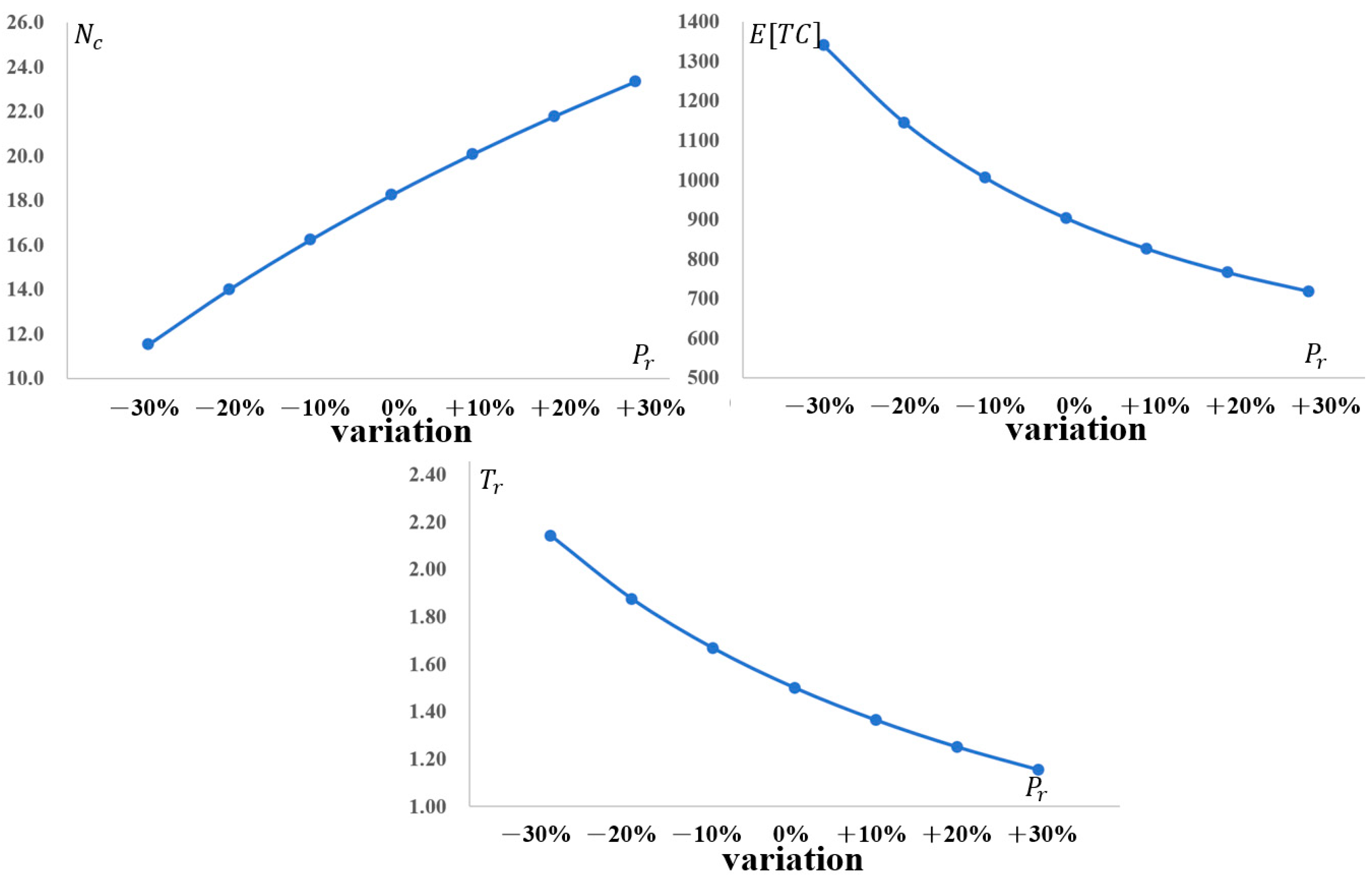

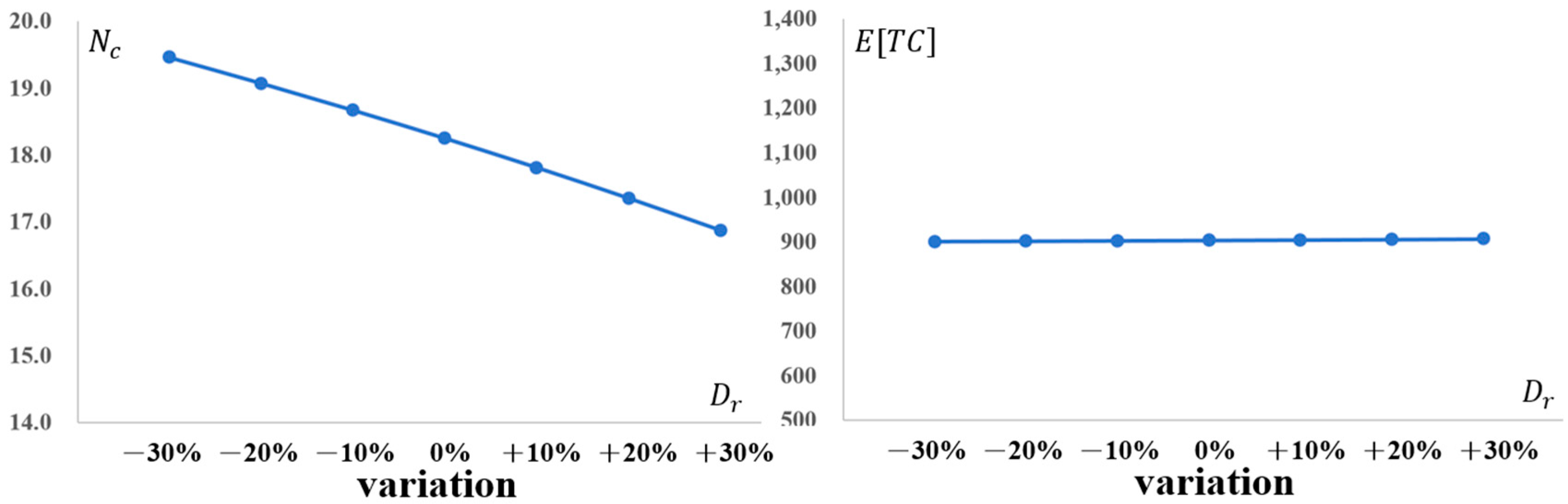

- Defect Rate (): Variations in defect probability have a limited impact on the total expected cost when the baseline defect rate is already moderate. However, they significantly influence inspection strategies: a higher likelihood of defects reduces the number of conforming samples required to infer the system state, as poor-quality signals become more apparent.

- (6)

- Integrated Managerial Implications: Across all parameter variations, a consistent pattern emerges. Production run length and inspection intensity are interconnected strategic levers rather than independent decisions. Policy shifts (e.g., warranty length, capacity, maintenance investment) alter the role of inspection—sometimes serving as the primary tool for verification, and other times acting as a secondary measure to prevention or production adjustments. Zero-inflation modeling prevents the overestimation of deterioration risks, thereby avoiding overly conservative inspection plans that traditional NHPP models might generate. The convex nature of the cost landscape indicates a stable region of near-optimal solutions, facilitating robust decision-making even when parameter estimates are imperfect.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

- In addition, holding fixed: , so increases as deterioration accelerates, consistent with the interpretation that higher leads to faster efficiency loss. Second derivative: , implying convexity in —the marginal cost of deterioration grows faster as deterioration intensifies. □

- Set to zero: , and second derivative proving convexity and global minimum at match point (zero cost). Integration with deterioration: Longer increases (from Lemma 2), creating a trade-off. □

- (1)

- In-control (): All items at low hazard.

- (2)

- (2) Out-of-control: Uninspected mix low high; inspected reworked to high.

- Thus, , linear in (increasing since ). Differentiating w.r.t. yields a net increase due to reworked items. □

References

- Ho, J.W. Quality Inspection Plan for Imperfect Production System with Assembly Configuration. Processes 2020, 8, 1545. [Google Scholar] [CrossRef]

- Cheng, G.Q.; Zhou, B.H.; Li, L. Integrated Production, Quality Control and Condition-Based Maintenance for Imperfect Production Systems. Reliab. Eng. Syst. Saf. 2018, 175, 251–264. [Google Scholar] [CrossRef]

- Mondal, S.K.; Khara, B. Imperfect Production Inventory System Considering Effects of Production Reliability. In Fuzzy Optimization, Decision-Making and Operations Research: Theory and Applications; Springer: Cham, Switzerland, 2023; pp. 587–617. [Google Scholar] [CrossRef]

- Sepehri, A.; Mishra, U.; Sarkar, B. A Sustainable Production–Inventory Model with Imperfect Quality under Preservation Technology and Quality Improvement Investment. J. Clean. Prod. 2021, 310, 127332. [Google Scholar] [CrossRef]

- Park, M. Combined Class of Distributions with an Exponentiated Weibull Family for Reliability Application. Qual. Technol. Quant. Manag. 2023, 20, 671–687. [Google Scholar] [CrossRef]

- Davies, J.; Truong-Ba, H.; Cholette, M.E.; Will, G. Optimal Inspections and Maintenance Planning for Anti-Corrosion Coating Failure on Ships Using Non-Homogeneous Poisson Processes. Ocean Eng. 2021, 238, 109695. [Google Scholar] [CrossRef]

- Fan, K.; Zhang, D.; Li, G.; Hu, X. Reliability Evaluation of Distribution System Based on Time-Varying Failure Rate Model and Non-Homogeneous Poisson Process. In Proceedings of the 2023 3rd International Conference on Energy Engineering and Power Systems (EEPS), Dali, China, 23–30 July 2023; pp. 593–597. [Google Scholar]

- Peng, J.; Liu, B.; Liu, Y.; Xu, X. Condition-Based Maintenance Policy for Systems with a Non-Homogeneous Degradation Process. IEEE Access 2020, 8, 81800–81811. [Google Scholar] [CrossRef]

- Seiß, S. An Ontology-Based Expert System for Quality Inspection Planning in the Construction Execution. In ECPPM 2022—eWork and eBusiness in Architecture, Engineering and Construction 2022; CRC Press: Boca Raton, FL, USA, 2023; pp. 599–606. [Google Scholar] [CrossRef]

- Sarkar, B.; Sett, B.K.; Sarkar, S. Optimal Production Run Time and Inspection Errors in an Imperfect Production System with Warranty. J. Ind. Manag. Optim. 2018, 14, 267–282. [Google Scholar] [CrossRef]

- Salas-Navarro, K.; Acevedo-Chedid, J.; Árquez, G.M.; Florez, W.F.; Ospina-Mateus, H.; Sana, S.S.; Cárdenas-Barrón, L.E. An EPQ Inventory Model Considering an Imperfect Production System with Probabilistic Demand and Collaborative Approach. J. Adv. Manag. Res. 2020, 17, 282–304. [Google Scholar] [CrossRef]

- Zhang, N.; Tian, S.; Xu, J.; Deng, Y.; Cai, K. Optimal Production Lot-Sizing and Condition-Based Maintenance Policy Considering Imperfect Manufacturing Process and Inspection Errors. Comput. Ind. Eng. 2023, 177, 108929. [Google Scholar] [CrossRef]

- Ghosh, D.; Rout, C.; Goswami, A. A Model of an Integrated Supply Chain with Imperfect Production, Product Deterioration, and Quality Inspection Errors. Sādhanā 2024, 49, 187. [Google Scholar] [CrossRef]

- Salmasnia, A.; Hajihosseini, Z.; Maleki, M.R. Joint Design of Control Chart, Production Cycle Length, and Maintenance Schedule for Imperfect Manufacturing Systems with Deteriorating Products under Stochastic Shift Size. J. Adv. Manuf. Syst. 2022, 21, 639–669. [Google Scholar] [CrossRef]

- Kovalyov, M.Y.; Lukashevich, M.N.; Pesch, E. Cost-Minimizing Planning of Container Inspection and Repair in Multiple Facilities. OR Spectr. 2023, 45, 181–204. [Google Scholar] [CrossRef] [PubMed]

- Hajej, Z.; Rezg, N.; Gharbi, A. Joint Production Preventive Maintenance and Dynamic Inspection for a Degrading Manufacturing System. Int. J. Adv. Manuf. Technol. 2021, 112, 221–239. [Google Scholar] [CrossRef]

- Fang, C.C.; Hsu, C.C.; Liu, J.H. Bayesian Statistical Method Enhances the Decision-Making for Imperfect Preventive Maintenance with a Hybrid Competing Failure Mode. Axioms 2022, 11, 734. [Google Scholar] [CrossRef]

- Fang, C.C.; Ma, L.; Kuo, W. Bayesian Analysis Enhances Sales and Warranty Strategies for Repairable Industrial Products by Considering Hybrid Deterioration Modes. IEEE Access 2025, 13, 72169–72188. [Google Scholar] [CrossRef]

- Rezaei-Malek, M.; Mohammadi, M.; Dantan, J.Y.; Siadat, A.; Tavakkoli-Moghaddam, R. A Review on Optimisation of Part Quality Inspection Planning in a Multi-Stage Manufacturing System. Int. J. Prod. Res. 2019, 57, 4880–4897. [Google Scholar] [CrossRef]

- Genta, G.; Galetto, M.; Franceschini, F. Inspection Procedures in Manufacturing Processes: Recent Studies and Research Perspectives. Int. J. Prod. Res. 2020, 58, 4767–4788. [Google Scholar] [CrossRef]

- Rezaei-Malek, M.; Tavakkoli-Moghaddam, R.; Siadat, A.; Dantan, J.Y. A Novel Model for the Integrated Planning of Part Quality Inspection and Preventive Maintenance in a Linear-Deteriorating Serial Multi-Stage Manufacturing System. Int. J. Adv. Manuf. Technol. 2018, 96, 3633–3650. [Google Scholar] [CrossRef]

- Lee, H.H.; Li, C. Supplier Quality Management: Investment, Inspection, and Incentives. Prod. Oper. Manag. 2018, 27, 304–322. [Google Scholar] [CrossRef]

- Afrinaldi, F.; Pratama, H.B. Selecting the Best Quality Inspection Alternative Based on the Quality, Economic and Environmental Considerations. Qual. Manag. J. 2020, 28, 2–16. [Google Scholar] [CrossRef]

- Abd Al Rahman, M.; Mousavi, A. A Review and Analysis of Automatic Optical Inspection and Quality Monitoring Methods in Electronics Industry. IEEE Access 2020, 8, 183192–183271. [Google Scholar] [CrossRef]

- Tripathi, H.; Al-Omari, A.I.; Saha, M.; Mali, A. Time Truncated Life Tests for New Attribute Sampling Inspection Plan and Its Applications. J. Ind. Prod. Eng. 2022, 39, 293–305. [Google Scholar] [CrossRef]

- Rachman, A.; Ratnayake, R.C. Machine Learning Approach for Risk-Based Inspection Screening Assessment. Reliab. Eng. Syst. Saf. 2019, 185, 518–532. [Google Scholar] [CrossRef]

- Kolus, A.; Duffuaa, S. Determining Optimal Process Means in a Multi-Stage Production System with Inspection Errors in 100% Inspection. Qual. Technol. Quant. Manag. 2025, 22, 105–130. [Google Scholar] [CrossRef]

- Xiao, T.; Park, C.; Lin, C.; Ouyang, L.; Ma, Y. Hybrid Reliability Analysis with Incomplete Interval Data Based on Adaptive Kriging. Reliab. Eng. Syst. Saf. 2023, 237, 109362. [Google Scholar] [CrossRef]

- Kong, X.; Yang, J.; Li, L. Reliability Analysis for Multi-Component Systems Considering Stochastic Dependency Based on Factor Analysis. Mech. Syst. Signal Process. 2022, 169, 108754. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, W.; Liu, B.; Li, Y.F. Reliability Assessment for Partially Monitored Systems Based on Degradation Hidden Markov Models with Time-Varying Parameters. IEEE Trans. Reliab. 2025, 74, 5272–5286. [Google Scholar] [CrossRef]

- Cai, B.; Fan, H.; Shao, X.; Liu, Y.; Liu, G.; Liu, Z.; Ji, R. Remaining Useful Life Re-Prediction Methodology Based on Wiener Process: Subsea Christmas Tree System as a Case Study. Comput. Ind. Eng. 2021, 151, 106983. [Google Scholar] [CrossRef]

- Elmahdy, E.E. Reliability Modelling of Heterogeneous Data by Using Different Competing Weibull Mixture Models. Adv. Appl. Stat. 2024, 91, 577–596. [Google Scholar] [CrossRef]

- Mahmood, T. Generalized linear model based monitoring methods for high-yield processes. Qual. Reliab. Eng. Int. 2020, 36, 1570–1591. [Google Scholar] [CrossRef]

| Symbol | Description |

|---|---|

| Total Expected Cost | |

| Expenditure on production equipment during production period | |

| Manufacturing cost of the first unit | |

| Employee learning rate | |

| Contraction constant | |

| Optimal number of conforming items for inspection | |

| Number of inspection items (used as for expected value) | |

| Inspection cost for the production system | |

| Correction cost | |

| Inspection cost for each item | |

| Defective rate under out-of-control state | |

| Inventory holding cost per unit time | |

| Demand rate per unit time | |

| Products generated per unit time | |

| Quantity demanded | |

| Per-item warranty cost | |

| Proportion of conforming items from the out-of-control production batch that remain conforming before warranty assessment. Not the complement of an in-control defective rate. | |

| Production run length | |

| The probability of no deterioration events in the system, capturing excess zeros in data due to robustness. | |

| Scale parameter of the Weibull distribution for the production system’s deterioration rate | |

| Shape parameter of the Weibull distribution, indicating the rate of increase in deterioration. | |

| Scale parameter of the Weibull distribution for the in-control state’s failure rate | |

| Shape parameter of the Weibull distribution for the in-control state’s failure rate | |

| Scale parameter of the Weibull distribution for the out-of-control state’s failure rate | |

| Shape parameter of the Weibull distribution for the out-of-control state’s failure rate | |

| Warranty term, the time frame for which warranty coverage is provided |

| Parameters | Value |

|---|---|

| Scale & Shape Parameters of the Production System Degradation | = 5.3; = 2.0 |

| The probability of no deterioration events in the system | = 0.3 |

| Defect Rate in Out-of-control State of the Production System | = 0.3 |

| System Inspection Cost | = 125 |

| System Correction Cost | = 100 |

| Inspection cost for each item | = 15 |

| Parameters of Product Failure Rate in In-control State | = 6.5; = 1.1 |

| Parameters of Product Failure Rate in Out-control State | = 4.7; = 3.6 |

| Production Rate | = 800 |

| Contraction constant | = 0.1 |

| Expenditure on production equipment during production period | = 300 |

| Manufacturing cost of the first unit | = 10 |

| Employee learning rate | = 0.5 |

| Quantity demanded | = 1200 |

| Demand rate per unit time | = 5 |

| Inventory holding cost per unit time | = 10.5 |

| Warranty cost for each item | = 20 |

| Proportion of conforming items from in-control state | = 0.95 |

| Product Warranty Term | = 2 years |

| 1 year | 16.8 | 1.5 | 659 | −30% | 11.5 | 1.5 | 1340 | −30% | 11.1 | 1.5 | 1376 |

| 1.5 years | 17.6 | 1.5 | 776 | −20% | 14 | 1.5 | 1144 | −20% | 13.5 | 1.5 | 1184 |

| 2 years | 18.2 | 1.5 | 903 | −10% | 16.2 | 1.5 | 1005 | −10% | 15.8 | 1.5 | 1028 |

| 2.5 years | 18.5 | 1.5 | 1039 | 0% | 18.2 | 1.5 | 903 | 0% | 18.2 | 1.5 | 903 |

| 3 years | 18.2 | 1.5 | 1187 | +10% | 20.1 | 1.5 | 825 | +10% | 20.7 | 1.5 | 803 |

| 3.5 years | 17.2 | 1.5 | 1345 | +20% | 21.8 | 1.5 | 765 | +20% | 23.1 | 1.5 | 724 |

| 4 years | 15.4 | 1.5 | 1515 | +30% | 23.3 | 1.5 | 718 | 30% | 25.6 | 1.5 | 661 |

| −30% | 7.1 | 1.5 | 889 | −30% | 11.4 | 2.14 | 1336 | −30% | 19.5 | 1.5 | 900 |

| −20% | 10.1 | 1.5 | 893 | −20% | 14.1 | 1.87 | 1147 | −20% | 19.1 | 1.5 | 901 |

| −10% | 13.8 | 1.5 | 897 | −10% | 16.1 | 1.67 | 1003 | −10% | 18.7 | 1.5 | 902 |

| 0% | 18.2 | 1.5 | 903 | 0% | 18.2 | 1.5 | 903 | 0% | 18.2 | 1.5 | 903 |

| 10% | 23.2 | 1.5 | 909 | 10% | 20.2 | 1.36 | 828 | +10% | 17.8 | 1.5 | 904 |

| 20% | 28.5 | 1.5 | 915 | 20% | 21.9 | 1.25 | 767 | +20% | 17.3 | 1.5 | 905 |

| 30% | 33.9 | 1.5 | 922 | 30% | 23.5 | 1.15 | 723 | +30% | 16.9 | 1.5 | 906 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, C.-C.; Chen, M.-N. Integrated Quality Inspection and Production Run Optimization for Imperfect Production Systems with Zero-Inflated Non-Homogeneous Poisson Deterioration. Mathematics 2025, 13, 3901. https://doi.org/10.3390/math13243901

Fang C-C, Chen M-N. Integrated Quality Inspection and Production Run Optimization for Imperfect Production Systems with Zero-Inflated Non-Homogeneous Poisson Deterioration. Mathematics. 2025; 13(24):3901. https://doi.org/10.3390/math13243901

Chicago/Turabian StyleFang, Chih-Chiang, and Ming-Nan Chen. 2025. "Integrated Quality Inspection and Production Run Optimization for Imperfect Production Systems with Zero-Inflated Non-Homogeneous Poisson Deterioration" Mathematics 13, no. 24: 3901. https://doi.org/10.3390/math13243901

APA StyleFang, C.-C., & Chen, M.-N. (2025). Integrated Quality Inspection and Production Run Optimization for Imperfect Production Systems with Zero-Inflated Non-Homogeneous Poisson Deterioration. Mathematics, 13(24), 3901. https://doi.org/10.3390/math13243901