1. Introduction

One of the significant problems in structural engineering is the initiation and propagation of cracks, which affects durability, service life, and human safety. Established methods like Griffith’s theory [

1] and linear elastic fracture mechanics (LEFM) [

2] provide the basic concepts for crack initiation and propagation. Still, they fail when dealing with intricate processes such as crack initiation, nucleation, and branching [

3]. To address the limitations of conventional methods, the phase-field method (PFM) emerged approximately two decades ago and has gained considerable popularity in modeling crack initiation and propagation. In the PFM, instead of a discrete discontinuity, the cracks are represented diffusely by a scalar phase-field (PF) parameter

[

4,

5,

6]. This PF parameter transitions from a completely intact (

) to a completely fractured material (

), thereby eliminating the necessity for explicit tracing of the crack propagation.

The PFM is used for simulating fracture phenomena in research and practical applications [

7], enabling the prediction of various phenomena, such as crack coalescence [

8] and branching [

6] under diverse loading conditions. This method was first introduced by Bourdin et al. [

9] in the late 1990s by considering the variational form of Griffith’s theory, which was numerically implemented in 2000 [

5]. The method was then further extended by Miehe et al. [

10,

11] in 2010, considering a thermodynamically consistent crack field. This extension of the PFM has opened numerous applications for tackling fracture analysis in brittle and ductile materials subjected to pure mechanical [

12,

13,

14,

15] or thermomechanical [

8,

16] loading conditions. Although the PFM is still in the development phase, it has been applied to simulate intricate crack phenomena, including fatigue [

17,

18], dynamic [

6,

19], and anisotropic [

20,

21,

22] crack propagation, as well as hydrogen-assisted [

7,

18] cracking. Despite its significant success, the PFM still suffers from its high computational cost. It requires a fine mesh density and small loading increments for accurate crack propagation [

23,

24].

The finite element method (FEM) is widely used because of its well-established and commercially available software for crack propagation using PFM. FEM has the advantage of utilizing adaptive meshing strategies efficiently, which can significantly reduce computational cost [

25,

26]. Still, creating and refining the best possible mesh in certain areas can pose a significant challenge in scenarios involving three-dimensional problems, irregular geometries, and multiple cracks evolving simultaneously. Meshless methods have gained increasing popularity due to their capability to handle complex geometries and evolving discontinuities without dependence on element connectivity [

27,

28,

29]. The complex variable element-free Galerkin method [

29] and the complex variable moving least-squares approximation [

30] offer a potential alternative for modeling complex problems, such as 3D elastoplastic and fracture analysis. Specifically, in fracture problems, the complex least-squares approximation mitigates ill-conditioning, providing high accuracy and efficient computation. The local radial basis function collocation method (LRBFCM) offers high accuracy and is particularly suitable for strong-form discretizations of partial differential equations, as demonstrated by recent studies [

8,

31,

32,

33]. The LRBFCM has been successful in solving heat diffusion [

32], thermoelasticity [

34], PF formulated dendritic growth [

31], and elasto-plastic [

35] problems. Additionally, the authors have developed and validated a meshless PFM for brittle fracture under various loading conditions [

8,

24,

36], thereby demonstrating its potential as a robust alternative to FEM in fracture analysis.

While meshless methods help to mitigate certain geometric limitations of FEM, they are still computationally demanding because a fine spatial resolution is required for both displacement and PF variables. To reduce this cost, various adaptive strategies have been proposed, including adaptive mesh refinement [

37,

38], adaptive time-stepping [

39], and error-driven spatial adaptivity [

40]. Although adaptive mesh-refinement is well-established in FEM, creating efficient adaptive schemes for meshless methods remains an active area of research. Notably, there is a lack of systematic studies on integrating adaptive loading step sizes with variable node densities in meshless PF simulations. The adaptive time-stepping introduced in [

39] works by using an error indicator that is based on both the PF and the history field variables. These methods have proven effective, but they require the simultaneous evaluation and monitoring of multiple variables. This study introduces a simpler, more efficient process, where the loading step size is adaptively controlled solely based on the PF variable.

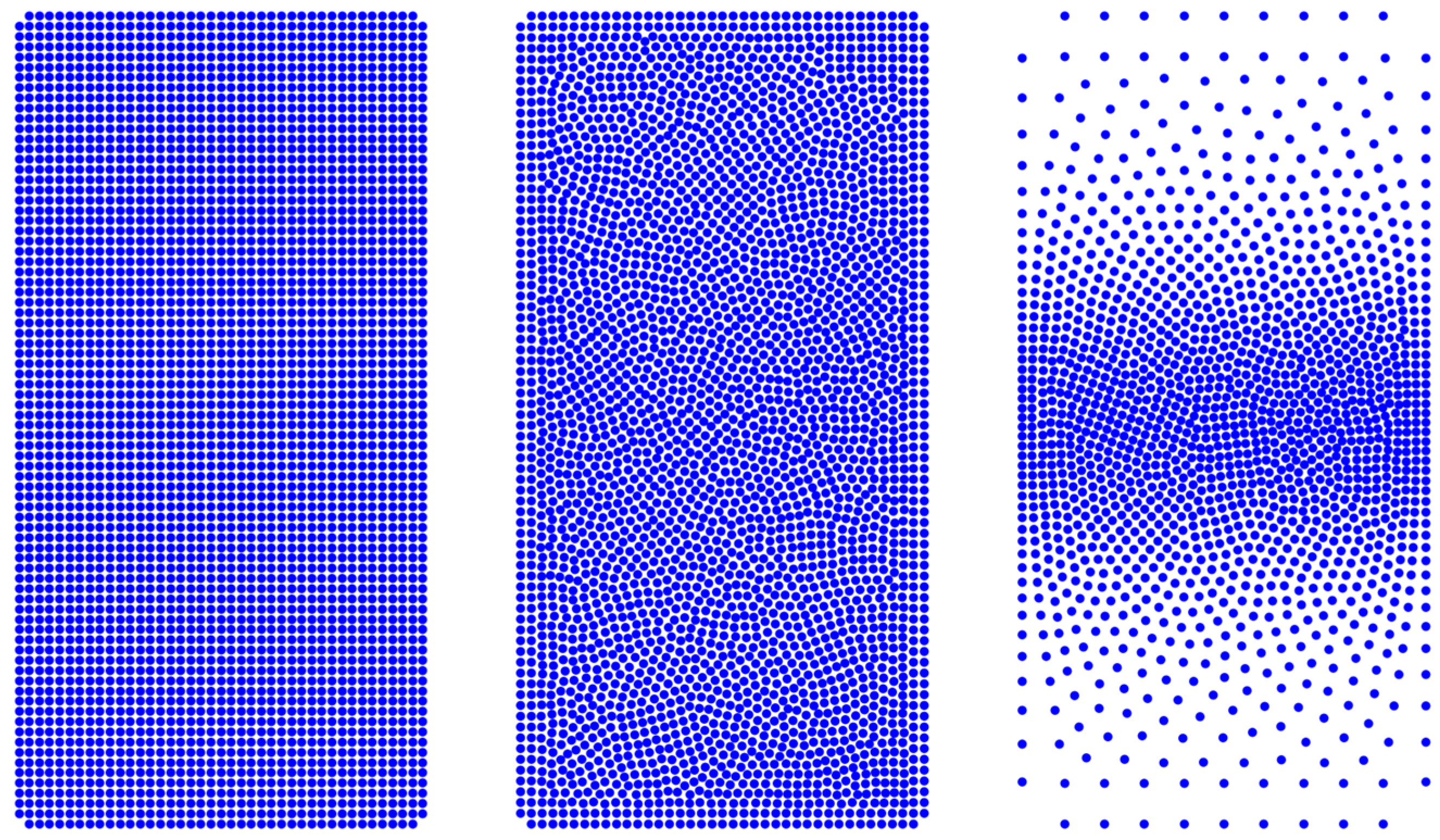

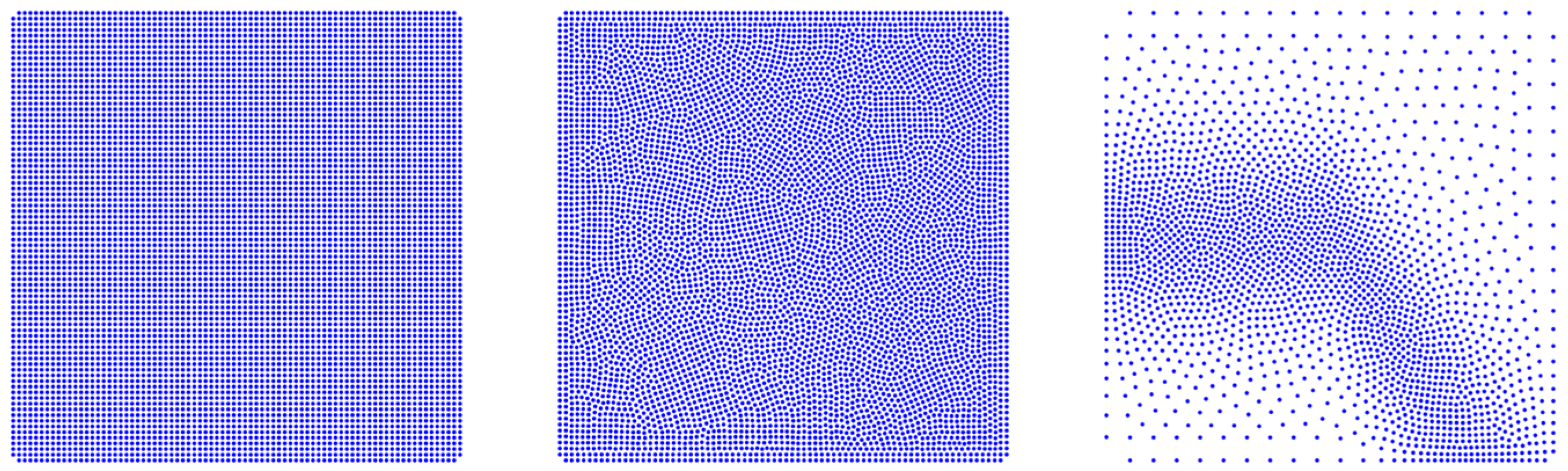

The concept of variable node density offers an attractive approach to strike a balance between accuracy and efficiency. Refining discretization solely along the expected crack path while using coarser nodes elsewhere can significantly decrease computational effort without compromising accuracy. Several FEM studies have examined similar ideas using adaptive meshing and enrichment techniques [

37,

41,

42,

43,

44,

45]. However, in meshless methodologies, the application of predetermined variable node densities, where refinement is prescribed in advance based on anticipated crack trajectories, has not been thoroughly investigated in relation to traditional fracture benchmarks. Furthermore, the interaction between variable node density and adaptive load stepping, which modulates the incremental load step size according to crack progression, remains largely unexamined.

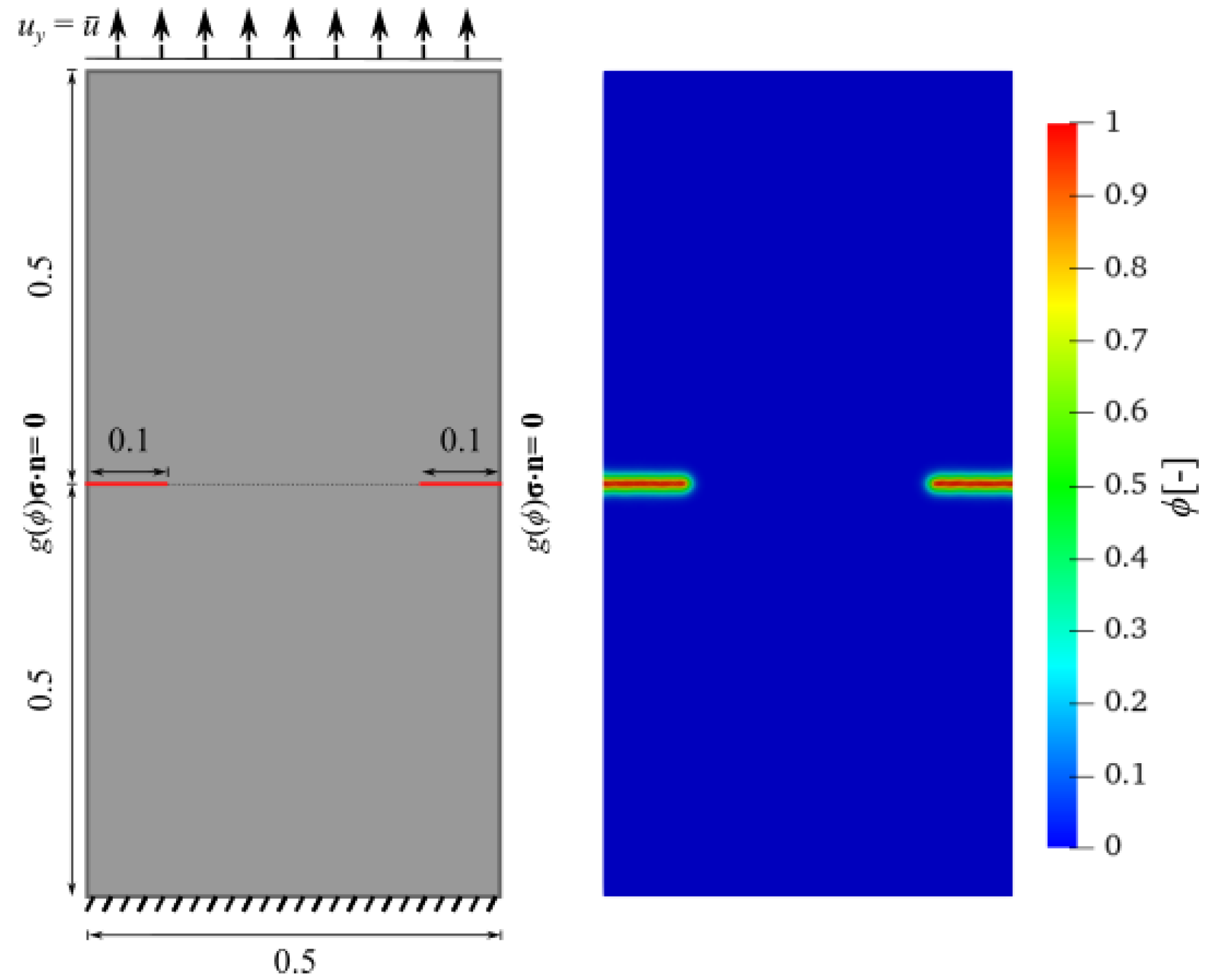

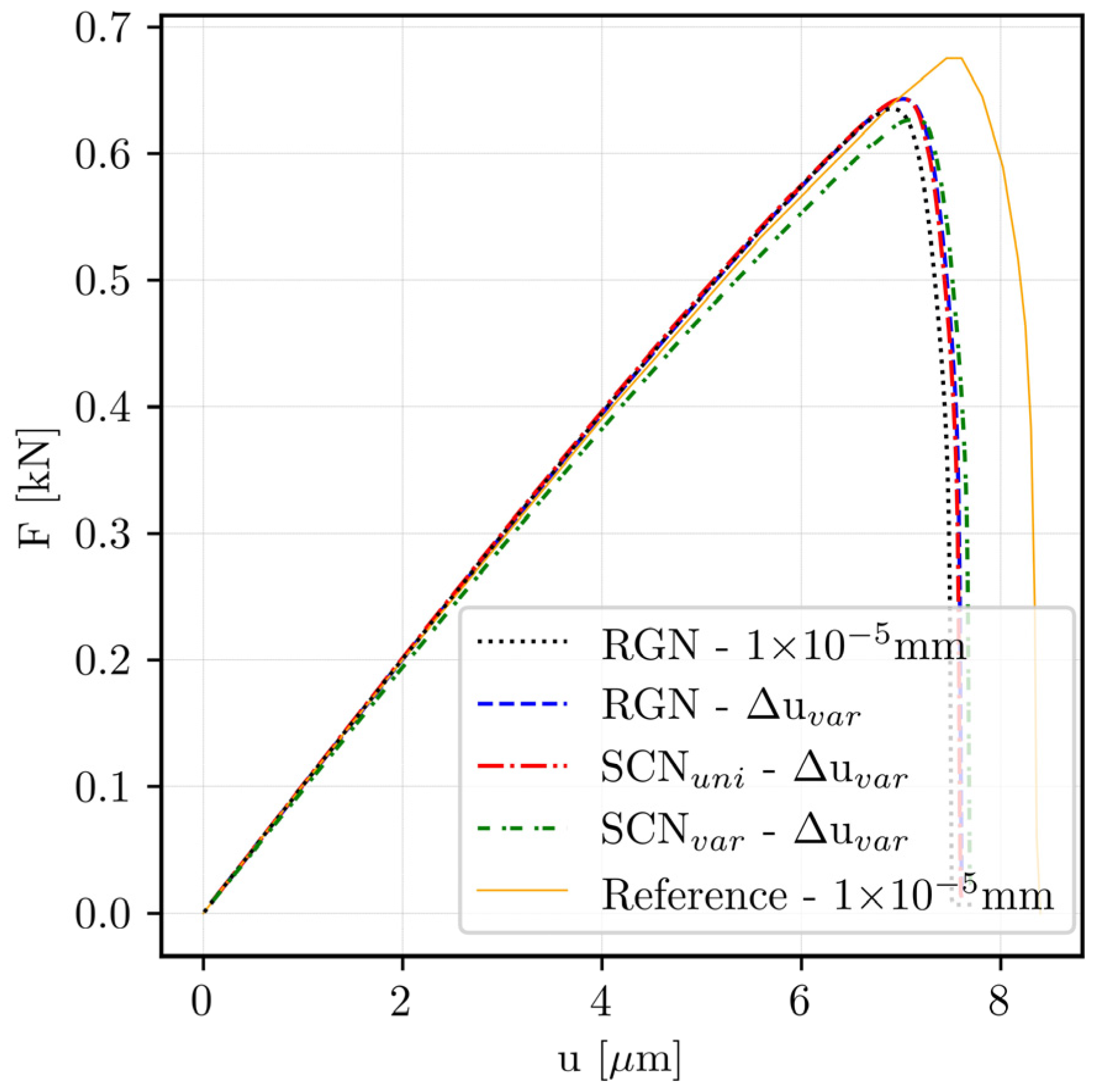

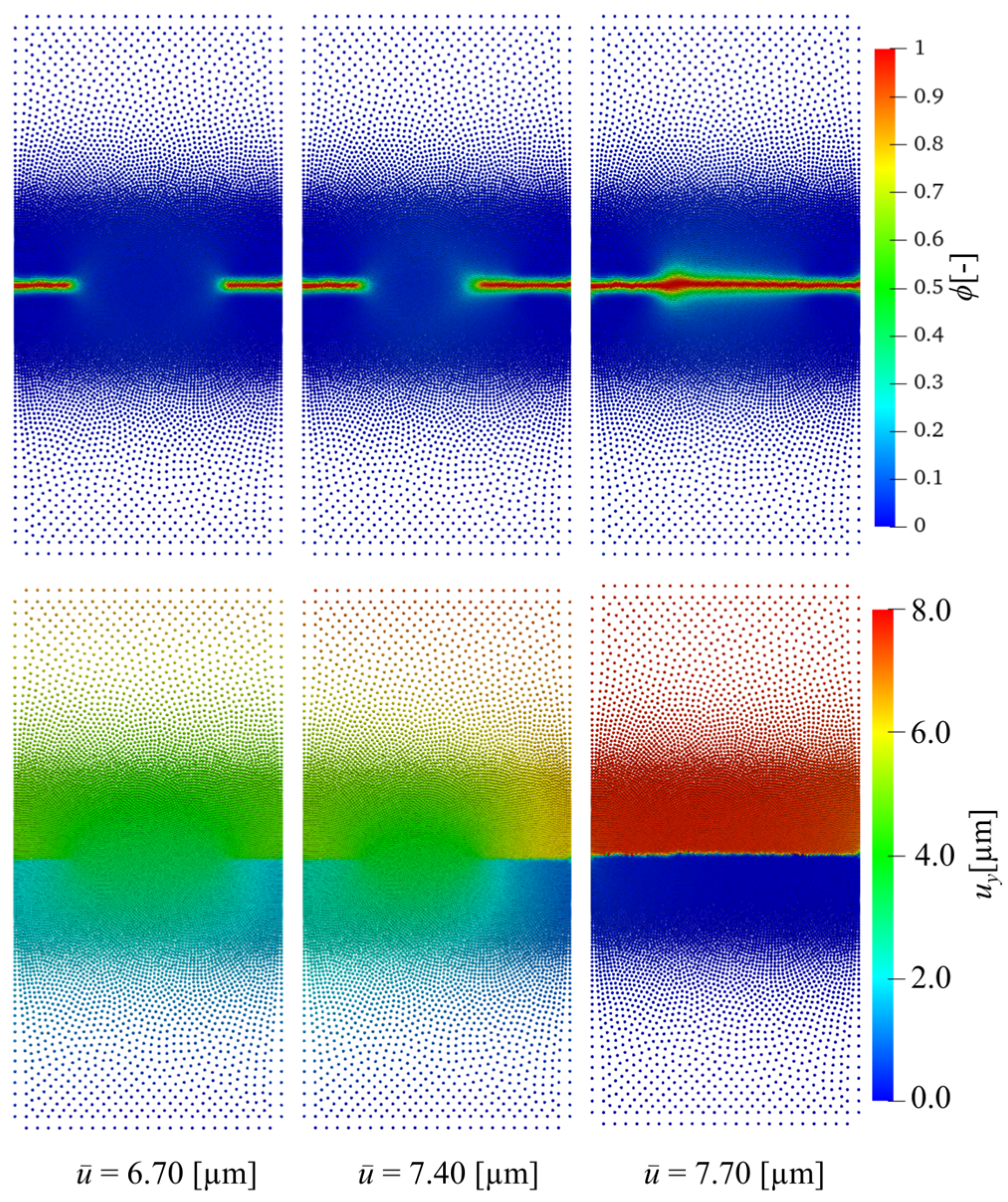

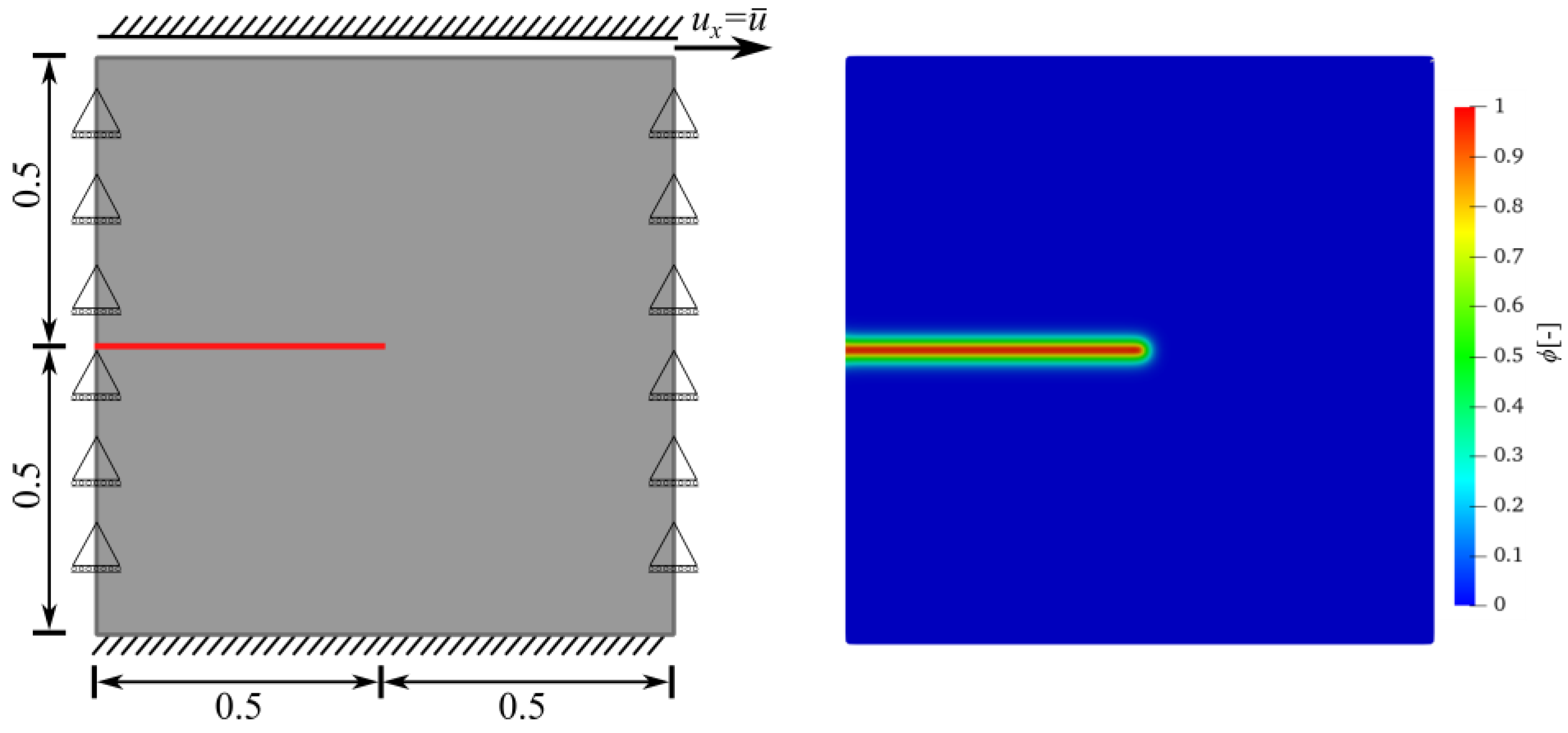

This paper comprehensively addresses these gaps through a systematic analysis of meshless PF fracture simulations, employing two well-established benchmark tests: the Single-Edge Notch Shear (SENS) test and the Symmetric Double-Notch Tension (SDNT) test. These benchmark problems are frequently used in scholarly literature to validate fracture models, as their crack propagation and load–displacement behavior are well-documented [

12,

46]. Three approaches are examined: (i) uniform node density with non-adaptive load stepping, (ii) uniform node density with adaptive load stepping, and (iii) variable node density with adaptive load stepping. The results are evaluated based on the prediction of crack propagation, force–displacement behavior, and computational efficiency. Particular emphasis is placed on minimizing computation time by integrating adaptive stepping and variable node density.

The paper is divided into different sections.

Section 2 explains the governing equations of the fourth-order PF formulation, the strong-form meshless method, and its application in the solution procedure. It also describes the adaptive loading increment size and the approach for creating variable node density distributions.

Section 3 presents the benchmark test cases and offers an overview of the numerical results. Finally,

Section 4 highlights the main findings and proposes future research directions.

2. Governing Equations and Numerical Method

The governing equations for the PF and mechanical models are derived from the minimization of the total energy functional [

36] with respect to displacement

and PF parameter

, which can be presented in the strong-form as follows

where

is the degradation function,

is the stress tensor,

is the body force,

is the strain history field,

is the tensile strain energy density (SED) and

is the length scale parameter. The elastic strain

tensor is defined

.

The strain energy density (SED) serves as the principal driving force for crack propagation. Therefore, if the total SED is considered as the crack driving force, it may lead to physically inaccurate predictions of crack propagation [

10,

42,

47] under mixed-mode loading conditions. For physically correct crack propagation, this study employs the spectral-split method [

10] to decompose the SED into tensile and compressive parts, which is given as

where

denotes the trace of the strain tensor, the positive (

) and negative (

) strain tensors are calculated by computing the eigenvalues

(principal strains) and their corresponding eigenvectors

(normal directions) as

. The Macauli brackets

are operated as

. In this study, the hybrid PFM formulation is utilized with the exception of the condition mentioned in [

12]

.

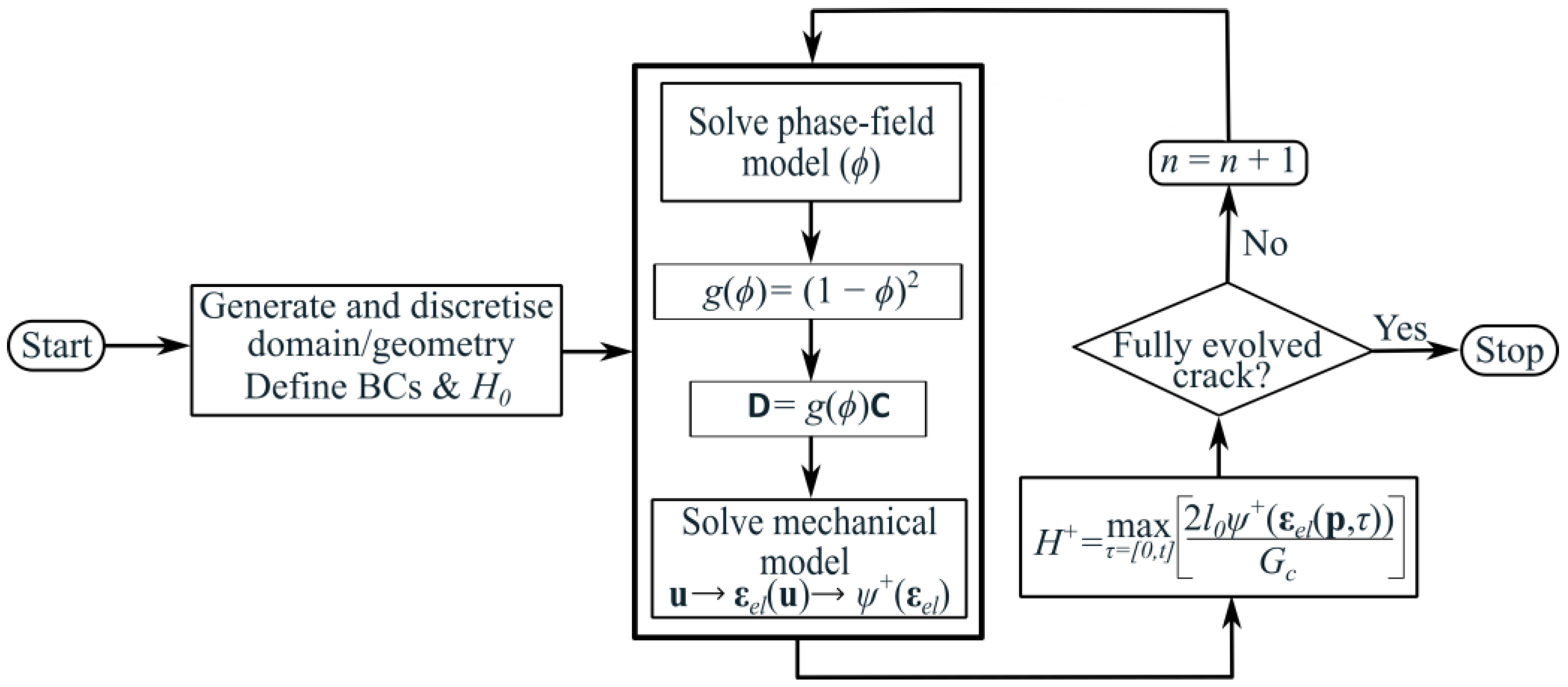

The governing equations for mechanical (1) and PF (2) models are solved in a staggered manner, as shown in

Figure 1, with the following boundary conditions.

where

are the Dirichlet and traction boundary conditions, respectively. The prescribed traction vector is denoted by

and

shows the unit normal vector.

The pre-existing crack in a geometry can be initiated in three different ways: it can be initiated by inserting a geometric discontinuity [

48] by putting double nodes in the element mesh. The second way is to apply an initial condition for the PF parameter by putting

over the nodes where the initial crack exists [

38,

48] and

elsewhere. This study uses the third way to introduce the pre-existing cracks, which is with the help of the initial history field [

19]. The history field is used because it introduces a smooth pre-existing crack that aligns naturally with the diffusive crack representation of the PFM. The history field-based crack is generated by defining a function for the shortest distance

from the nodes over the crack length

to any position vector

in the domain as

The scalar is used, which is obtained by selecting in all the simulations of this study.

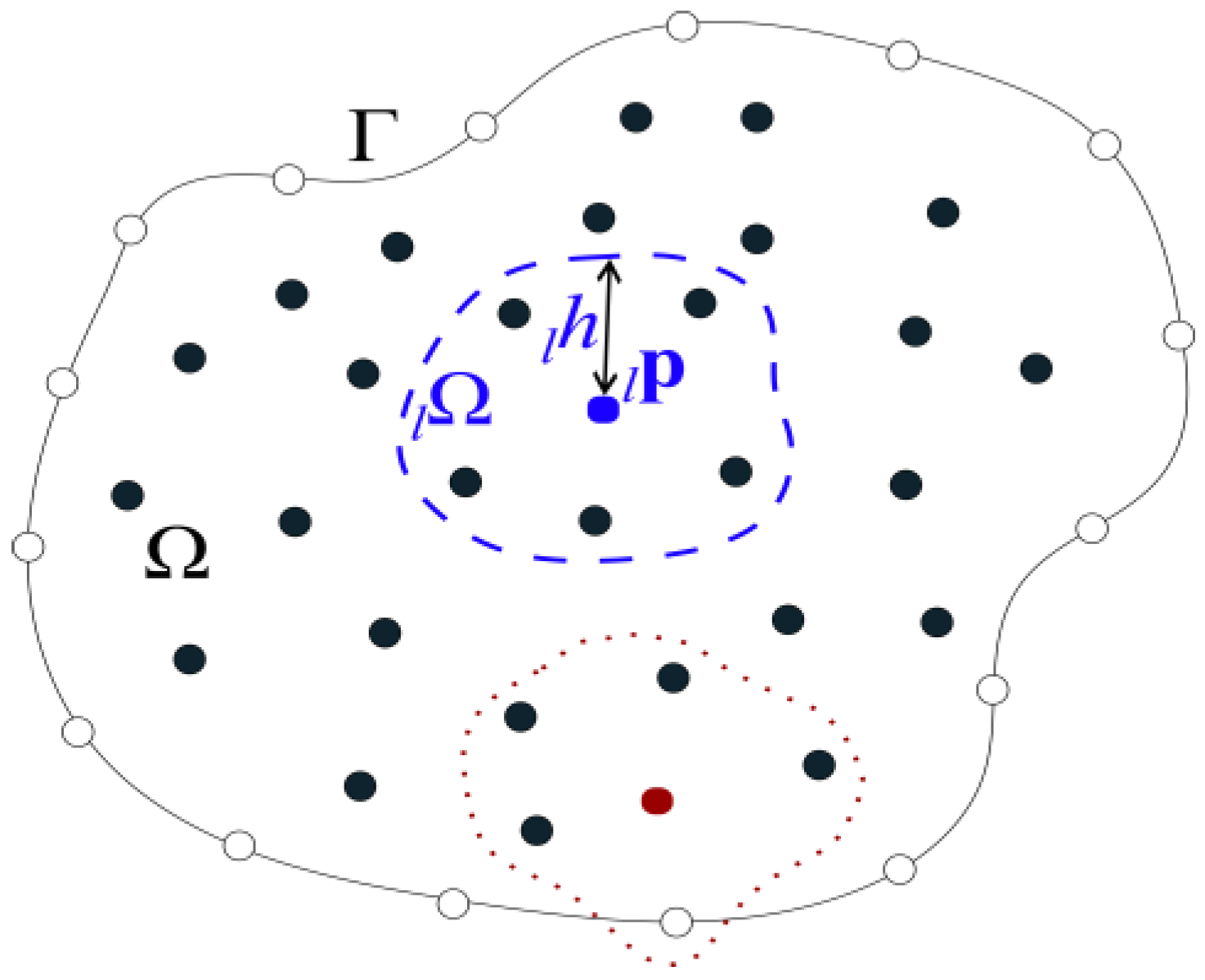

The governing equations of the PF and mechanical models are discretized using the LRBFCM [

49], as shown schematically in

Figure 2 with scattered node (SCN) arrangements and two local sub-domains

. The working principle of the LRBFCM is based on approximating an arbitrary function

with augmented monomials

in each sub-domain as

where

is the number of nodes in the local sub-domain,

are the unknown coefficients,

denotes the radial basis function (RBF), and the central node is denoted by

.

represents the number of augmented polynomials and

denotes the respective polynomials, that is,

. The arbitrary function

in Equation (8) can be further written as

where

is the combination of RBFs and augmented monomials, and the terms in Equation (9) can be written in a linear system of equations as

The

is the local interpolation matrix, which consists of the augmented monomials and RBFs as

is the vector comprising the known values and is defined as

The

can be calculated by inverting Equation (10) as

Any linear differential operator

can be applied to Equation (9) as

by putting the values of the unknown coefficients from Equations (13) to (14) can reach to

The operator weights in Equation (15), in a compact form, can be written as

and thus the final equation becomes

The solution process is illustrated schematically in

Figure 1, starting with the creation and discretization of the domain and geometry. In the presence of a pre-existing crack, the history field is initialized with the help of Equation (7). After the history field is initialized, the PF and mechanical models are solved sequentially. This involves solving the PF model for the PF parameter

, followed by the calculation of the degradation function

. Subsequently, the material properties are degraded using

, and together with the degraded properties, the mechanical model is solved for displacements. Displacements are then utilized to compute the strain tensor, and the tensile SED is determined using Equation (3), which is then compared with the history field. The history field is updated for nodes with higher SED values than the initial history field, and an additional loading increment is applied. This process continues until the material fails completely.

The PF model is solved by splitting the fourth-order differential Equation (2) of the PF into two second-order equations by assuming an auxiliary variable

as

The two Equations (17) and (18) are solved in a monolithic manner for the unknown PF parameter using the differential operators obtained with the augmented PHSs in the meshless LRBFCM.

The mechanical model presented in Equation (1) is solved using the plane strain condition with the composed approach by directly applying the divergence operator to the stress tensor

, explained in [

35], as

where

is the tensor of elasticity with degraded material properties. The symmetric gradient is denoted by

.

The incremental loading step sizes are adjusted adaptively using the technique introduced in [

36], by calculating the relative error of the current PF

with the initial PF

using

and the incremental load step size is then adjusted according to the change in PF

as

In all the simulations of this study, the step size () is adjusted adaptively using Equation (20).

This approach is implemented numerically in Julia (version 1.8.0). A custom Fortran library generates matrix coefficients, which are crucial for accurate calculations. All simulations are run on an AMD Ryzen 9 7950X 16-core processor at 4.50 GHz.

4. Conclusions

This study presents an adaptive step size strategy integrated with variable node density to reduce the computation cost. Two benchmark tests, the symmetric double-notch tension test and a SENS test, were used to analyze the proposed framework. Identical numerical tests were performed for both benchmarks, ensuring consistent assessment of the proposed methodology’s efficiency and accuracy.

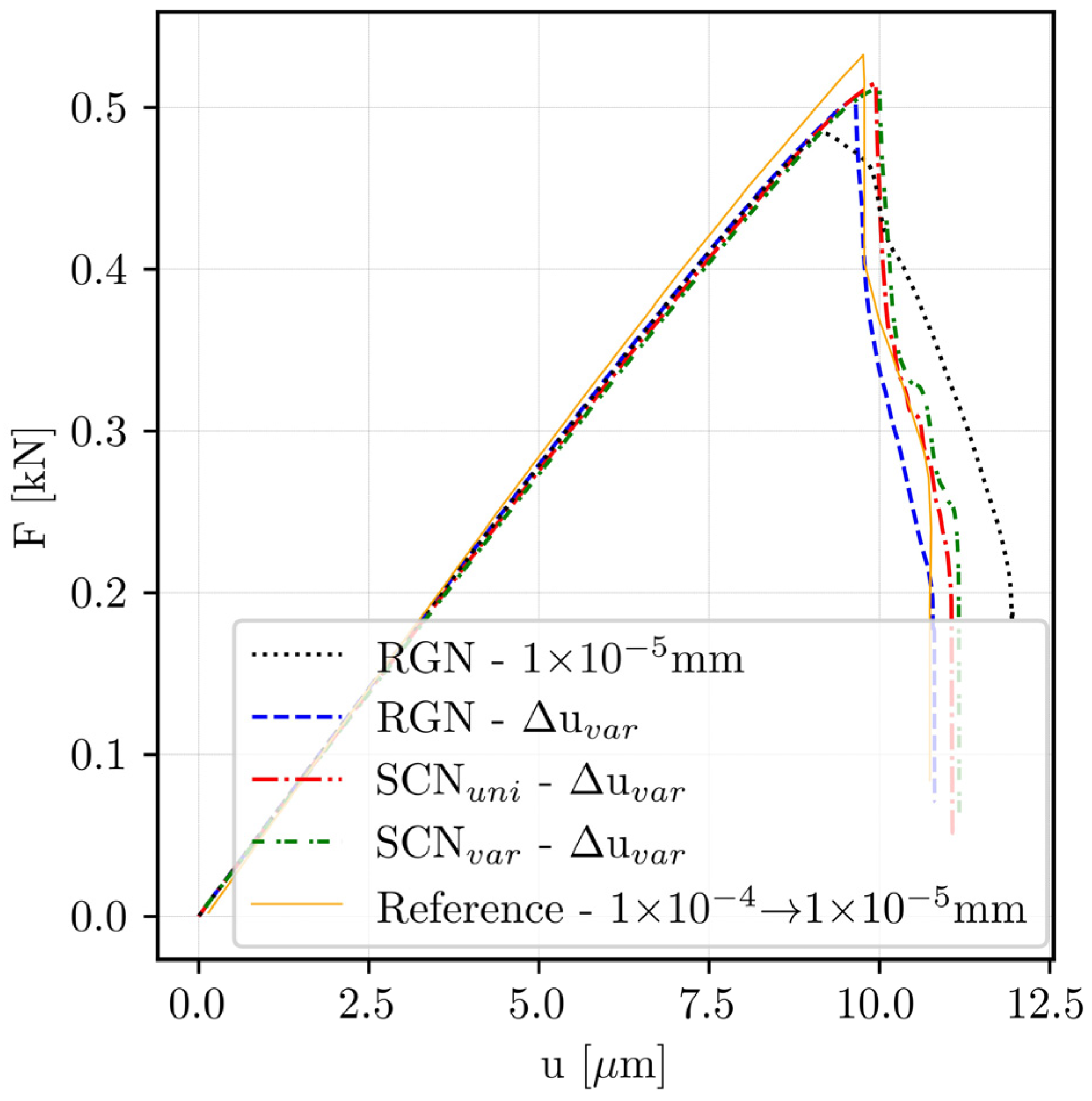

All configurations accurately reproduced the force–displacement graphs for symmetric crack propagation in the first benchmark. Although the RGN with uniform node distributions and a constant loading increment () produced consistent and stable results, it required significantly more time to compute due to the uniform node spacing maintained throughout the entire domain. The adaptive loading step size strategy () allows the solver to automatically decrease the time step near the peak load, where nonlinearities are more pronounced. Consequently, computational time was reduced for RGN and SCNuni without losing accuracy.

The enhancement in computational efficiency became more pronounced when the SCN

var was utilized, while maintaining high accuracy and substantially reducing the computational time. As shown in

Table 4, the SCN

var configurations reduce the total CPU time by about 30 times, in the computational environment used in this study, relative to RGN, while maintaining identical peak-load and crack propagation patterns. This enhancement is achieved by concentrating computational resources in critical regions by increasing node density along the anticipated crack propagation path, while preserving a coarser node density in other areas.

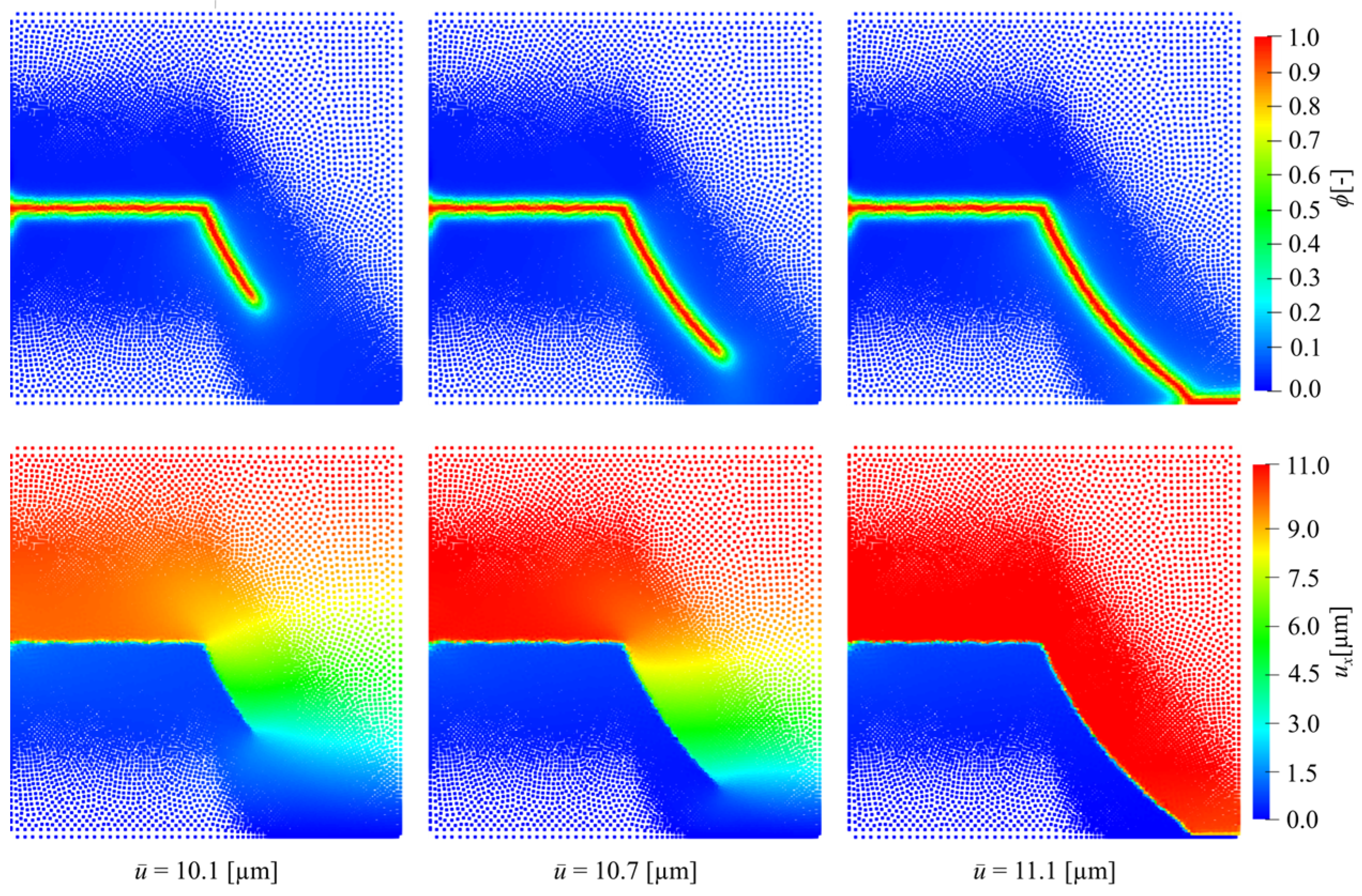

The SENS showed a similar trend; all node configurations precisely captured the crack propagation, and the force–displacement curves aligned well with the reference solution. The SCN

var arrangements reduced the total CPU time by approximately three times in comparison to RGN, as shown in

Table 7. These findings demonstrate that both the SCN

var and the adaptive loading step size strategy can significantly reduce computational time in these benchmark tests without compromising accuracy. However, the extent of these computational efficiency improvements can differ based on the crack configuration, solver implementation, and hardware configuration.

The current study demonstrates that increasing node density exclusively in regions of interest offers a good balance between computational efficiency and predictive accuracy, thereby facilitating future research on the implementation of adaptive node redistribution. This advancement will support large-scale industrial fracture simulations employing strong-form meshless methods.

The proposed adaptive stepping strategy is versatile and relies solely on the evolution of the PF variable, without assuming any specific geometry or crack pattern. However, the current study does not address complex or multiple interacting cracks. The application of this method to handle complicated crack networks and geometries would require further investigation, particularly the extension to three dimensions, and thus represents a key future research direction. Therefore, these limitations should be taken into account when addressing complex fracture problems using this approach.